Advantageous Strain Sensing Performances of FBG Strain Sensors Equipped with Planar UV-Curable Resin

Abstract

:1. Introduction

2. Principle and Fabrication of the FBG Strain Sensor

2.1. Principle of the Uncoated FBG and Coated FBG

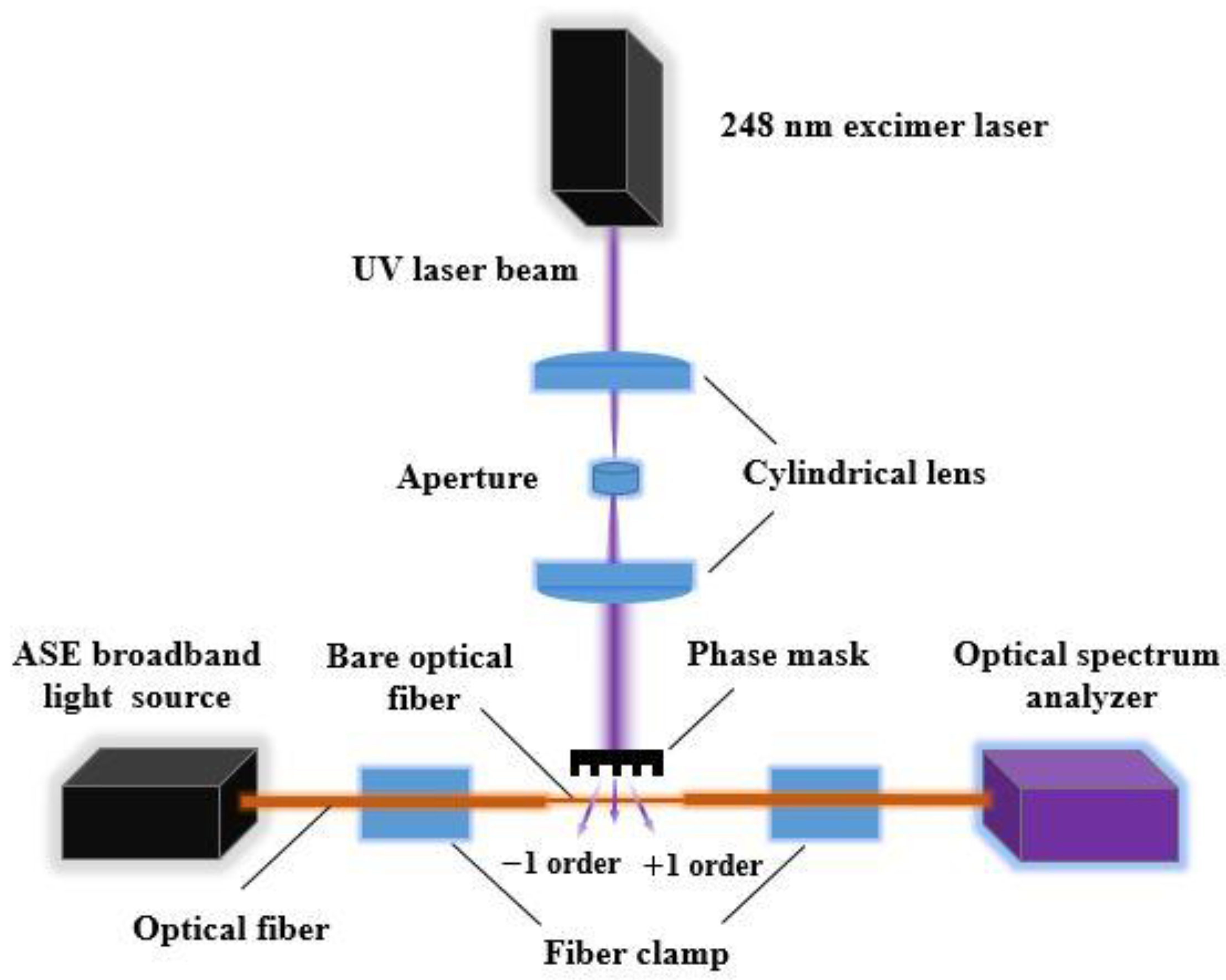

2.2. Fabrication of Uncoated FBG Strain Sensors

2.3. Fabrication of the FBG Strain Sensors

3. Results and Discussion

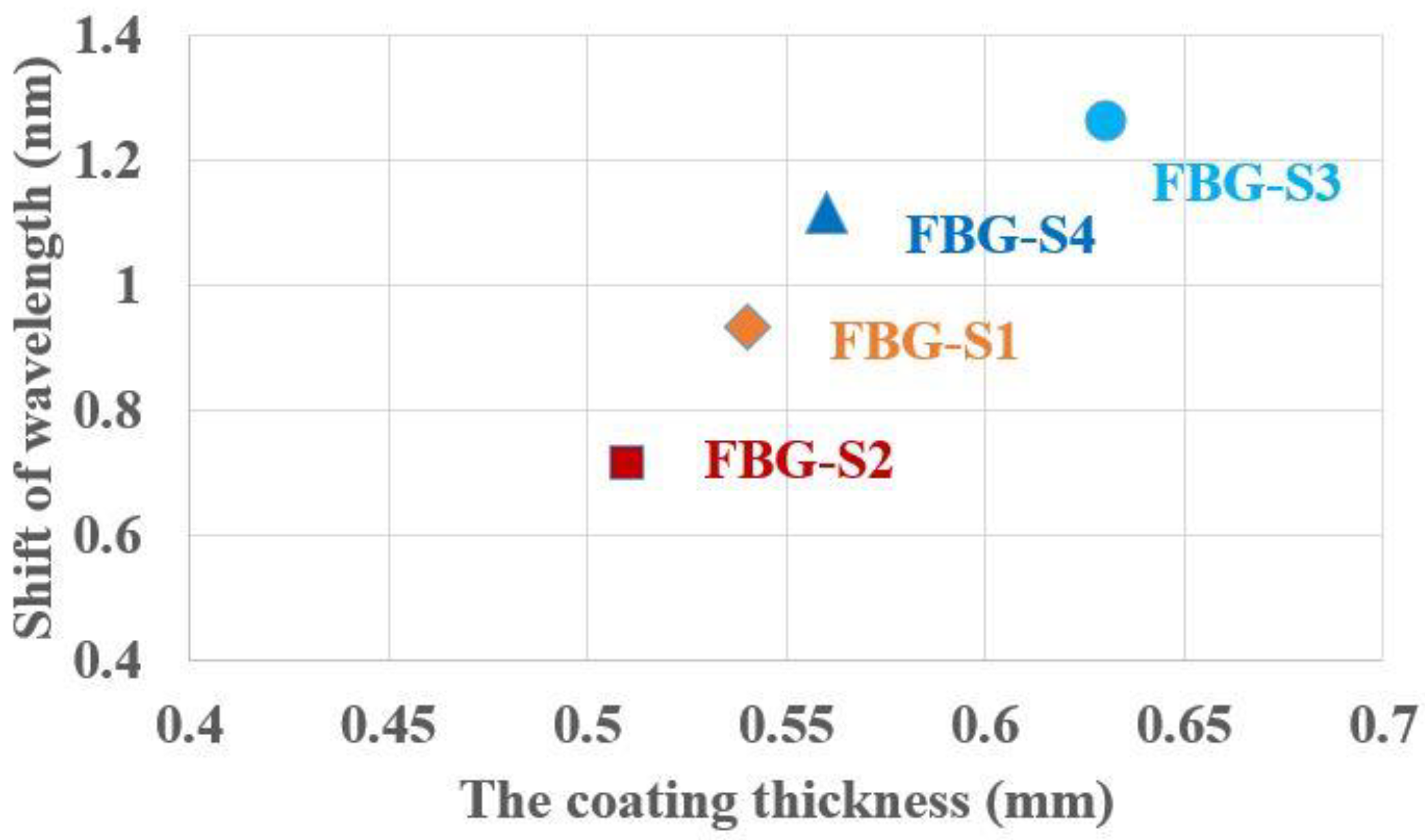

3.1. Optical Properties of the FBG Strain Sensors

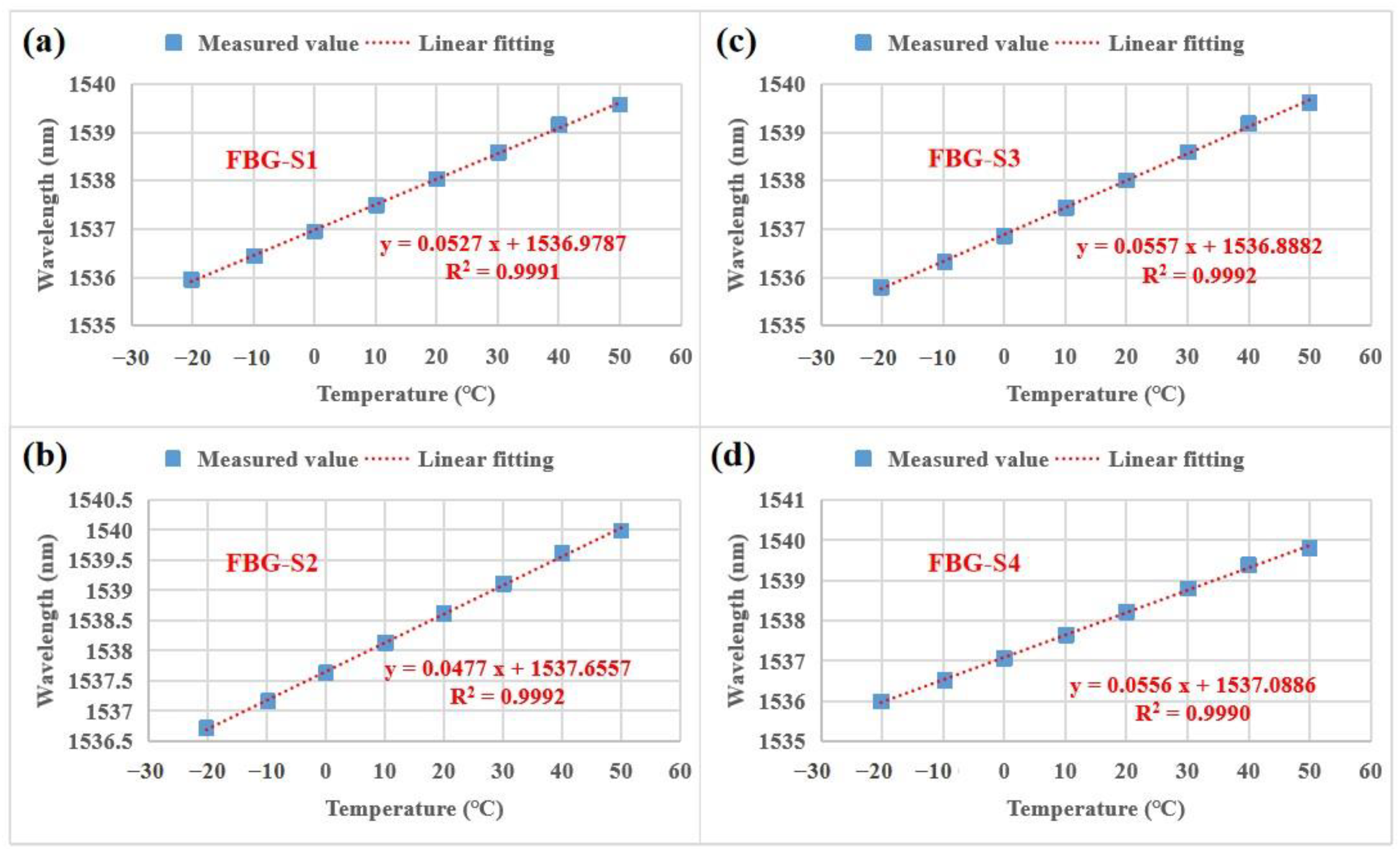

3.2. Temperature Sensing Properties of the FBG Strain Sensors

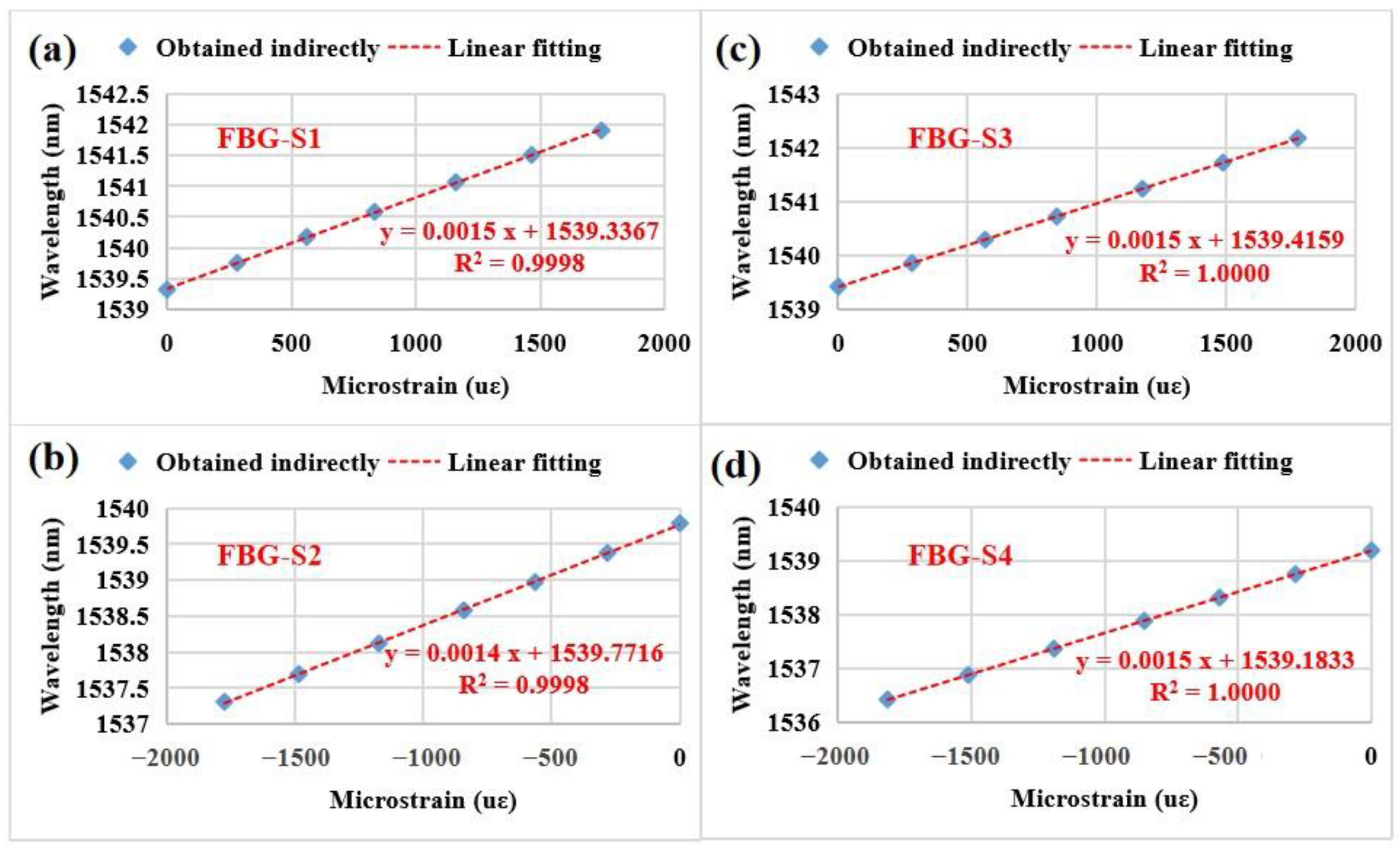

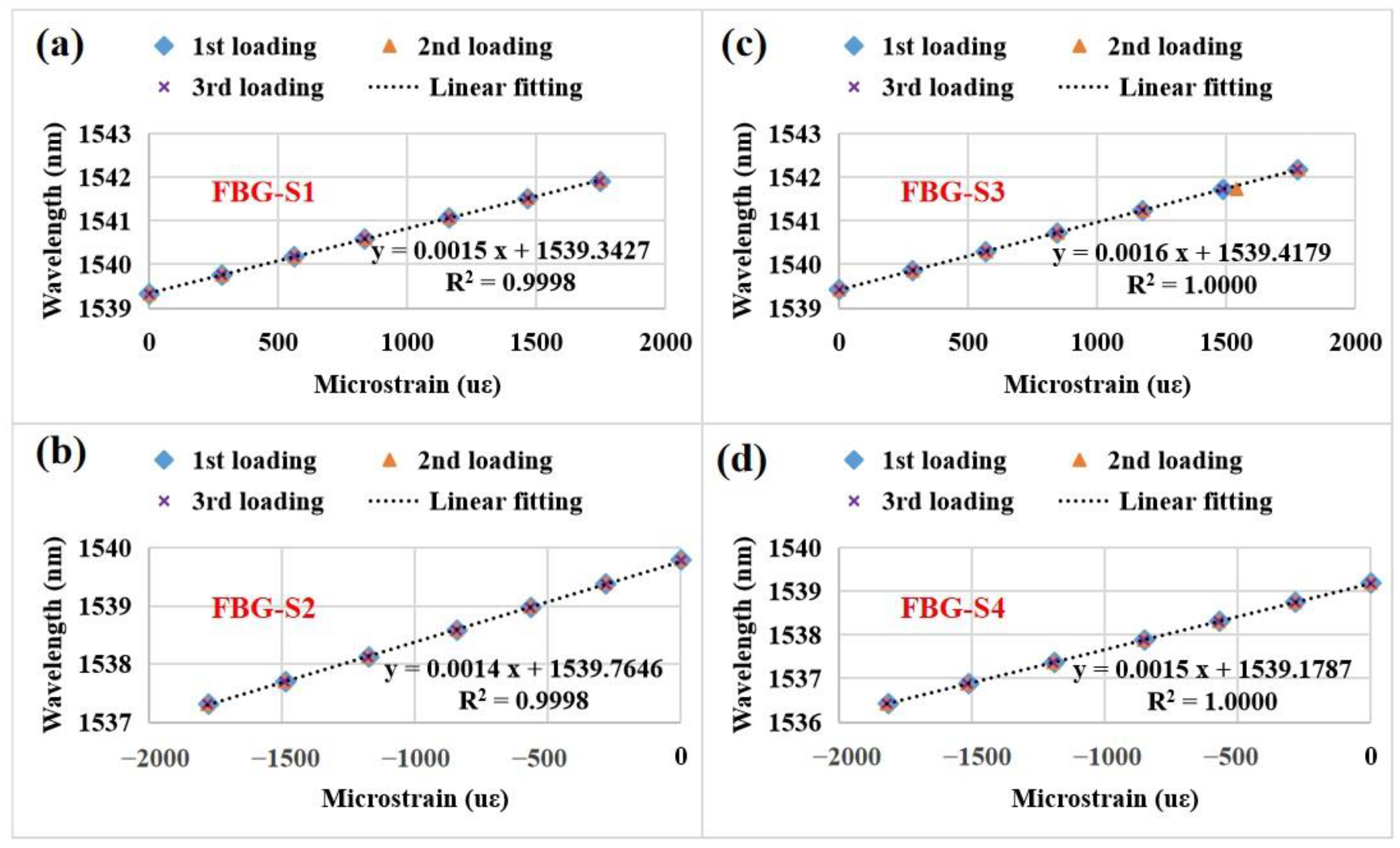

3.3. Strain Sensing Properties of the FBG Strain Sensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farrar, C.R.; Worden, K. An introduction to structural health monitoring. Philos. Trans. R. Soc. A 2007, 365, 303–315. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Tan, Y.; Chen, Y.; Hong, Y.; Zhou, Z. Investigation of sensitivity enhancing and temperature compensation for fiber Bragg grating (FBG)-based strain sensor. Opt. Fiber Technol. 2019, 48, 199–206. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, X.; Chen, Y.; Zhang, X. A method of strain measurement based on fiber Bragg grating sensors. Vibroeng. Procedia 2015, 5, 140–144. [Google Scholar]

- Hsu, C.Y.; Chiang, C.C.; Hsieh, T.S.; Chen, T.H.; Chen, Y.H. A study of strain measurement in cylindrical shells subjected to underwater shock loading using FBG sensors. Optik 2020, 217, 164701. [Google Scholar] [CrossRef]

- Mihailov, S.J. Fiber Bragg grating sensors for harsh environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Zhang, Q.; Li, E.; Sun, Y.; Zhang, Z.; Pu, S.; Cheng, X.; Rong, F. Strain monitoring of combustible gas implosion test based on fiber Bragg grating. Shock Vib. 2019, 2019, 9858125. [Google Scholar] [CrossRef]

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Martinez-Luengo, M.; Kolios, A.; Wang, L. Structural health monitoring of offshore wind turbines: A review through the Statistical Pattern Recognition Paradigm. Renew. Sustain. Energy Rev. 2016, 64, 91–105. [Google Scholar] [CrossRef] [Green Version]

- Hirayama, N.; Sano, Y. Fiber Bragg grating temperature sensor for practical use. ISA Trans. 2000, 39, 169–173. [Google Scholar] [CrossRef]

- Raju, S.J.; Haque, S.M.; Goud, B.K.; De, R.; Misal, J.S.; Rao, K.D. Fiber Bragg grating sensor for in situ substrate temperature measurement in a magnetron sputtering system. Phys. Scr. 2022, 97, 095505. [Google Scholar] [CrossRef]

- Al Handawi, K.; Vahdati, N.; Rostron, P.; Lawand, L.; Shiryayev, O. Strain based FBG sensor for real-time corrosion rate monitoring in pre-stressed structures. Sens. Actuators 2016, 236, 276–285. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, W.; Zhang, H.; Liu, B.; Zhao, J.; Tu, Q.; Kai, G.; Dong, X. An embedded FBG sensor for simultaneous measurement of stress and temperature. IEEE Photonics Technol. Lett. 2005, 18, 154–156. [Google Scholar] [CrossRef]

- James, S.W.; Dockney, M.L.; Tatam, R.P. Simultaneous independent temperature and strain measurement using in-fibre Bragg grating sensors. Electron. Lett. 1996, 32, 1133–1134. [Google Scholar] [CrossRef]

- Nascimento, M.; Ferreira, M.S.; Pinto, J.L. Simultaneous sensing of temperature and Bi-directional strain in a prismatic Li-ion battery. Batteries 2018, 4, 23. [Google Scholar] [CrossRef] [Green Version]

- Mokhtar, M.R.; Sun, T.; Grattan, K.T.V. Bragg grating packages with nonuniform dimensions for strain and temperature sensing. IEEE Sens. J. 2011, 12, 139–144. [Google Scholar] [CrossRef]

- Nascimento, M.; Novais, S.; Ding, M.S.; Ferreira, M.S.; Koch, S.; Passerini, S.; Pinto, J.L. Internal strain and temperature discrimination with optical fiber hybrid sensors in Li-ion batteries. J. Power Sources 2019, 410, 1–9. [Google Scholar] [CrossRef]

- Huang, J.; Albero Blanquer, L.; Bonefacino, J.; Logan, E.R.; Alves Dalla Corte, D.; Delacourt, C.; Gallant, B.M.; Boles, S.T.; Dahn, J.R.; Tam, H.; et al. Operando decoding of chemical and thermal events in commercial Na (Li)-ion cells via optical sensors. Nat. Energy 2020, 5, 674–683. [Google Scholar] [CrossRef]

- Campanella, C.E.; Cuccovillo, A.; Campanella, C.; Yurt, A.; Passaro, V.M. Fibre Bragg grating based strain sensors: Review of technology and applications. Sensors 2018, 18, 3115. [Google Scholar] [CrossRef] [Green Version]

- Moyo, P.; Brownjohn, J.M.W.; Suresh, R.; Tjin, S.C. Development of fiber Bragg grating sensors for monitoring civil infrastructure. Eng. Struct. 2005, 27, 1828–1834. [Google Scholar] [CrossRef]

- Li, R.; Chen, Y.; Tan, Y.; Zhou, Z.; Li, T.; Mao, J. Sensitivity enhancement of FBG-based strain sensor. Sensors 2018, 18, 1607. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Wang, W.; Song, H.; Zhou, S.; Zhou, W. A high sensitivity FBG strain sensor based on flexible hinge. Sensors 2019, 19, 1931. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.W.; Jeong, M.S.; Lee, I.; Kwon, I.B. Static mechanical characteristics of tin-coated fiber Bragg grating sensors. Sens. Actuators A 2014, 214, 156–162. [Google Scholar] [CrossRef]

- Li, X.; Shen, Z.; Zheng, M.; Hou, D.; Wen, Q. Great increase of the tensile strength in the lamellar PI-coated FBG sensors. Opt. Contin. 2023, 2, 110–118. [Google Scholar] [CrossRef]

- Oliveira, R.; Bilro, L.; Nogueira, R. Fabry-Pérot cavities based on photopolymerizable resins for sensing applications. Opt. Mater. Express 2018, 8, 2208–2221. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Diaz, C.R.; Marques, C.; Frizera, A.; Pontes, M.J. Analysis of viscoelastic properties influence on strain and temperature responses of Fabry-Perot cavities based on UV-curable resins. Opt. Laser Technol. 2019, 120, 105743. [Google Scholar] [CrossRef]

- Leal-Junior, A.; Frizera, A.; Marques, C. Development and characterization of UV-resin coated fiber bragg gratings. Sensors 2020, 20, 3026. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Lesiak, P.; Domanski, A.; Wolinski, T.; Boczkowska, A.; Farrell, G. The influence of thermal expansion of a composite material on embedded polarimetric sensors. Smart Mater. Struct. 2011, 20, 125002. [Google Scholar] [CrossRef] [Green Version]

- Lesiak, P.; Szeląg, M.; Budaszewski, D.; Plaga, R.; Mileńko, K.; Rajan, G.; Semenova, Y.; Farrell, G.; Boczkowska, A.; Domański, A.; et al. Influence of lamination process on optical fiber sensors embedded in composite material. Measurement 2012, 45, 2275–2280. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, M.; Wang, X.; Zhao, Y.; Jin, B.; Dai, W. The analysis of FBG central wavelength variation with crack propagation based on a self-adaptive multi-peak detection algorithm. Sensors 2019, 19, 1056. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Yuan, S.; Chen, J. On crack propagation monitoring by using reflection spectra of AFBG and UFBG sensors. Sens. Actuators A 2019, 285, 491–500. [Google Scholar] [CrossRef]

- Mansoursamaei, M.; Malakzadeh, A. Simultaneous measurement of temperature and strain using a single fiber bragg grating on a tilted cantilever beam. Opt. Rev. 2021, 28, 289–294. [Google Scholar] [CrossRef]

- Park, C.S.; Joo, K.I.; Kang, S.W.; Kim, H.R. A PDMS-coated optical fiber Bragg grating sensor for enhancing temperature sensitivity. J. Opt. Soc. Korea 2011, 15, 329–334. [Google Scholar] [CrossRef] [Green Version]

- Bhaskar, C.V.N.; Pal, S.; Pattnaik, P.K. Recent advancements in fiber Bragg gratings based temperature and strain measurement. Results Opt. 2021, 5, 100130. [Google Scholar] [CrossRef]

- Mizunami, T.; Tatehata, H.; Kawashima, H. High-sensitivity cryogenic fibre-Bragg-grating temperature sensors using Teflon substrates. Meas. Sci. Technol. 2001, 12, 914. [Google Scholar]

- Shen, Y.; He, J.; Sun, T.; Grattan, K.T. High-temperature sustainability of strong fiber Bragg gratings written into Sb-Ge-codoped photosensitive fiber: Decay mechanisms involved during annealing. Opt. Lett. 2004, 29, 554–556. [Google Scholar] [CrossRef]

- Rajini-Kumar, R.; Suesser, M.; Narayankhedkar, K.G.; Krieg, G.; Atrey, M.D. Performance evaluation of metal-coated fiber Bragg grating sensors for sensing cryogenic temperature. Cryogenics 2008, 48, 142–147. [Google Scholar] [CrossRef]

- Parne, S.; Sai Prasad, R.L.N.; Dipankar, S.G.; Sai Shankar, M.; Kamineni, S. Polymer-coated fiber Bragg grating sensor for cryogenic temperature measurements. Microw. Opt. Technol. Let. 2011, 53, 1154–1157. [Google Scholar] [CrossRef]

- Mahakud, R.; Kumar, J.; Prakash, O.; Dixit, S.K. Study of the nonuniform behavior of temperature sensitivity in bare and embedded fiber Bragg gratings: Experimental results and analysis. Appl. Opt. 2013, 52, 7570–7579. [Google Scholar] [CrossRef] [PubMed]

- Hsiao, T.C.; Hsieh, T.S.; Chen, Y.C.; Huang, S.C.; Chiang, C.C. Metal-coated fiber Bragg grating for dynamic temperature sensor. Optik 2016, 127, 10740–10745. [Google Scholar] [CrossRef]

- Sampath, U.; Kim, D.; Kim, H.; Song, M. Polymer-coated FBG sensor for simultaneous temperature and strain monitoring in composite materials under cryogenic conditions. Appl. Opt. 2018, 57, 492–497. [Google Scholar] [CrossRef]

- Huang, F.; Chen, T.; Si, J.; Pham, X.; Hou, X. Fiber laser based on a fiber Bragg grating and its application in high-temperature sensing. Opt. Commun. 2019, 452, 233–237. [Google Scholar] [CrossRef]

- Fu, H.; Wang, S.; Chang, H.; You, Y. A high resolution and large range fiber Bragg grating temperature sensor with vortex beams. Opt. Fiber Technol. 2020, 60, 102369. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Frizera, A.; Marques, C. Thermal and mechanical analyses of fiber Bragg gratings-embedded polymer diaphragms. IEEE Photonics Technol. Lett. 2020, 32, 623–626. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Chiang, C.C.; Hsieh, T.S.; Hsu, H.C.; Tsai, L.; Hou, C.H. Study of fiber Bragg gratings with TiN-coated for cryogenic temperature measurement. Opt. Laser Technol. 2021, 136, 106768. [Google Scholar] [CrossRef]

- dos Santos, R.A.; Leal-Junior, A.G.; Ribeiro, M.R.; Benincá, E.A.; Marques, C.A.; Pereira, L.; Antunes, P.; Corrêa, J.H.; Pontes, M.J.; Neto, A.F.; et al. Datacenter thermal monitoring without blind spots: FBG-based quasi-distributed sensing. IEEE Sens. J. 2021, 21, 9869–9876. [Google Scholar] [CrossRef]

- Esposito, F.; Campopiano, S.; Iadicicco, A. Miniaturized strain-free fiber Bragg grating temperature sensors. IEEE Sens. J. 2022, 22, 16898–16903. [Google Scholar] [CrossRef]

- Dey, K.; Vangety, N.; Roy, S. Machine learning approach for simultaneous measurement of strain and temperature using FBG sensor. Sens. Actuators A 2022, 333, 113254. [Google Scholar] [CrossRef]

- Zhang, Z.; Shen, C.; Li, L. Temperature-independent fiber-Bragg-grating-based atmospheric pressure sensor. Opt. Commun. 2018, 411, 108–113. [Google Scholar] [CrossRef]

- Zhang, M.; Xing, Y.; Zhang, Z.; Chen, Q. Design and experiment of FBG-based icing monitoring on overhead transmission lines with an improvement trial for windy weather. Sensors 2014, 14, 23954–23969. [Google Scholar] [CrossRef] [Green Version]

| FBG-S1 | FBG-S2 | FBG-S3 | FBG-S4 | |||||

|---|---|---|---|---|---|---|---|---|

| State | Initial State | Coated State | Initial State | Coated State | Initial State | Coated State | Initial State | Coated State |

| Wavelength/nm | 1539.299 | 1538.367 | 1539.636 | 1538.920 | 1539.623 | 1538.359 | 1539.675 | 1538.559 |

| −3 dB bandwidth/nm | 0.512 | 0.517 | 0.632 | 0.630 | 0.634 | 0.632 | 0.618 | 0.612 |

| SMSR/dB | −20.50 | −15.25 | −19.50 | −23.75 | −18.87 | −20.75 | −17.12 | −17.25 |

| Year | Materials/Design | Reference | |||

|---|---|---|---|---|---|

| Minimum | Maximum | ||||

| 2001 | FBG fixed on Teflon substrate | −196 | 27 | 150 | [34] |

| 2004 | Strong FBG | 25 | 950 | 15.14 | [35] |

| 2008 | Metal coated FBG | −269 | 27 | 33.5 | [36] |

| 2011 | Teflon coated FBG | −196 | 25 | 12.85 | [37] |

| 2013 | An embedded FBG | 30 | 90 | 30.9 | [38] |

| 2016 | Chromium nitride coated FBG | 100 | 650 | 14 | [39] |

| 2018 | Polymer coated FBG | −180 | 25 | 48 | [40] |

| 2019 | Fs-FBG | 300 | 1000 | 15.9 | [41] |

| 2020 | FBG based on vortex light | 27 | 427 | 14.42 | [42] |

| 2020 | FBG embedded diaphragm | 20 | 35 | 49.8 | [43] |

| 2021 | Titanium nitride coated FBG | −195 | 20 | 10.71 | [44] |

| 2021 | Normal FBG | 26 | 50 | 8.75 | [45] |

| 2022 | Metallic packaged FBG | 5 | 50 | 28.9 | [46] |

| 2022 | Integrated FBG | 0 | 250 | 40 | [47] |

| 2023 | Planar UV-curable resin coated FBG | −20 | 50 | 55.7 | Present work |

| ESG-S1/ESG-S2 | FBG-S3/FBG-S4 | ESG-S3/ESG-S4 | FBG-S1/FBG-S2 | |

|---|---|---|---|---|

| (mm) | 307.0 | 257.0 | 228.0 | 164.0 |

| (mm) | 31.0 | 25.9 | 22.9 | 16.6 |

| Ratio () | 9.903 | 9.923 | 9.956 | 9.879 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Zheng, M.; Hou, D.; Wen, Q. Advantageous Strain Sensing Performances of FBG Strain Sensors Equipped with Planar UV-Curable Resin. Sensors 2023, 23, 2811. https://doi.org/10.3390/s23052811

Li X, Zheng M, Hou D, Wen Q. Advantageous Strain Sensing Performances of FBG Strain Sensors Equipped with Planar UV-Curable Resin. Sensors. 2023; 23(5):2811. https://doi.org/10.3390/s23052811

Chicago/Turabian StyleLi, Xiaojin, Min Zheng, Dan Hou, and Qiao Wen. 2023. "Advantageous Strain Sensing Performances of FBG Strain Sensors Equipped with Planar UV-Curable Resin" Sensors 23, no. 5: 2811. https://doi.org/10.3390/s23052811

APA StyleLi, X., Zheng, M., Hou, D., & Wen, Q. (2023). Advantageous Strain Sensing Performances of FBG Strain Sensors Equipped with Planar UV-Curable Resin. Sensors, 23(5), 2811. https://doi.org/10.3390/s23052811