Sequential Dual Coating with Thermosensitive Polymers for Advanced Fiber Optic Temperature Sensors

Abstract

1. Introduction

2. Materials and Methods

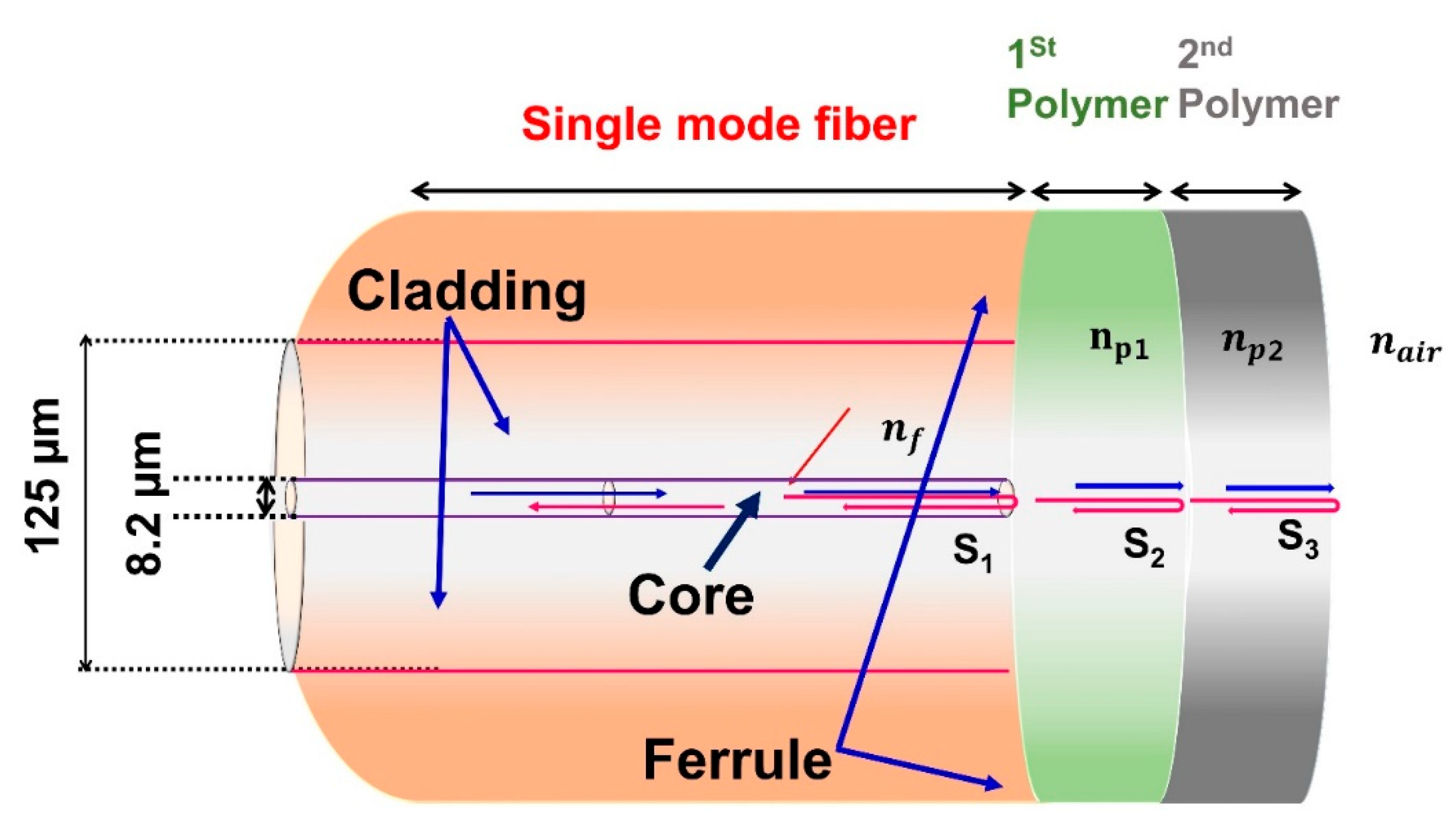

2.1. Sensing Operation Principle

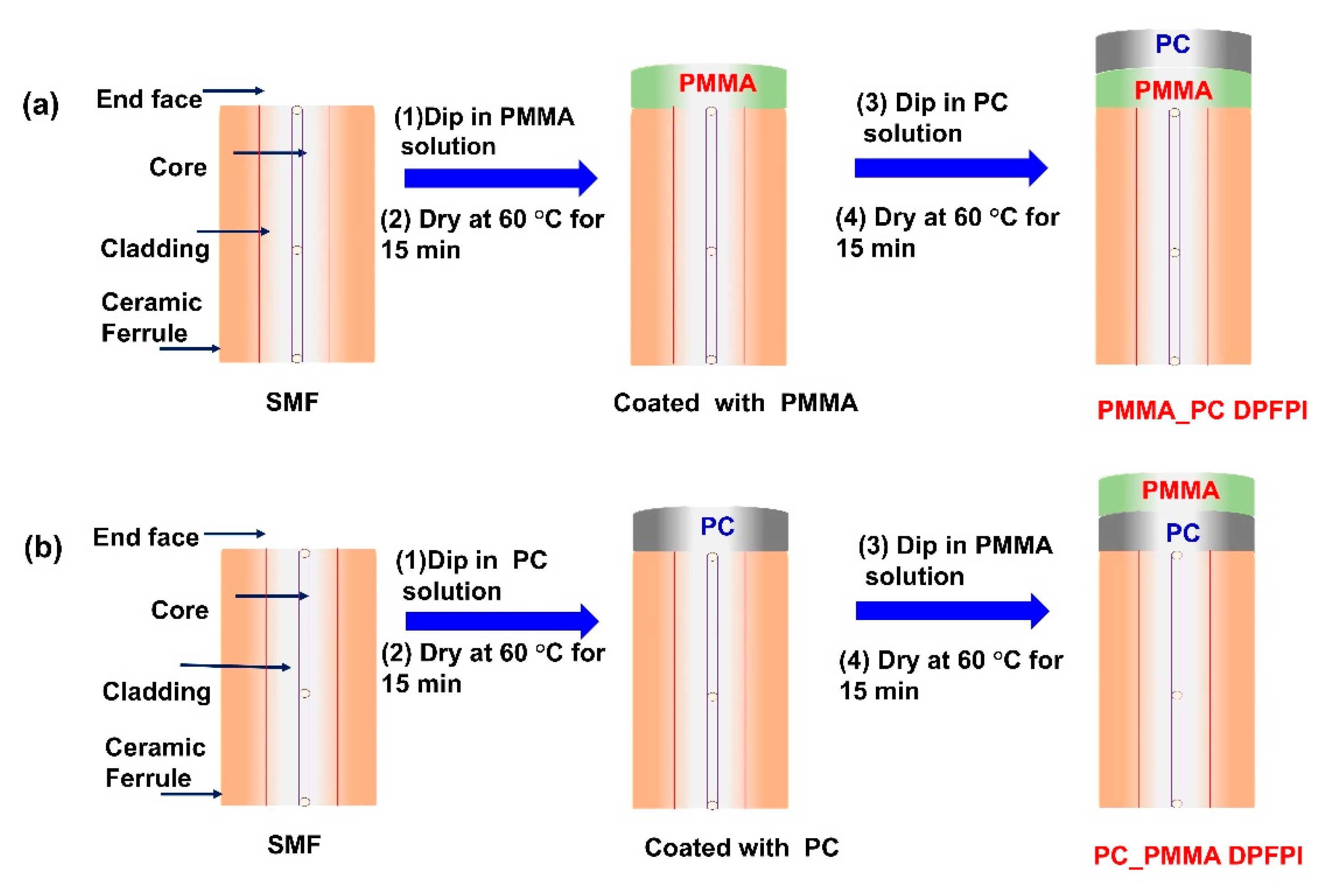

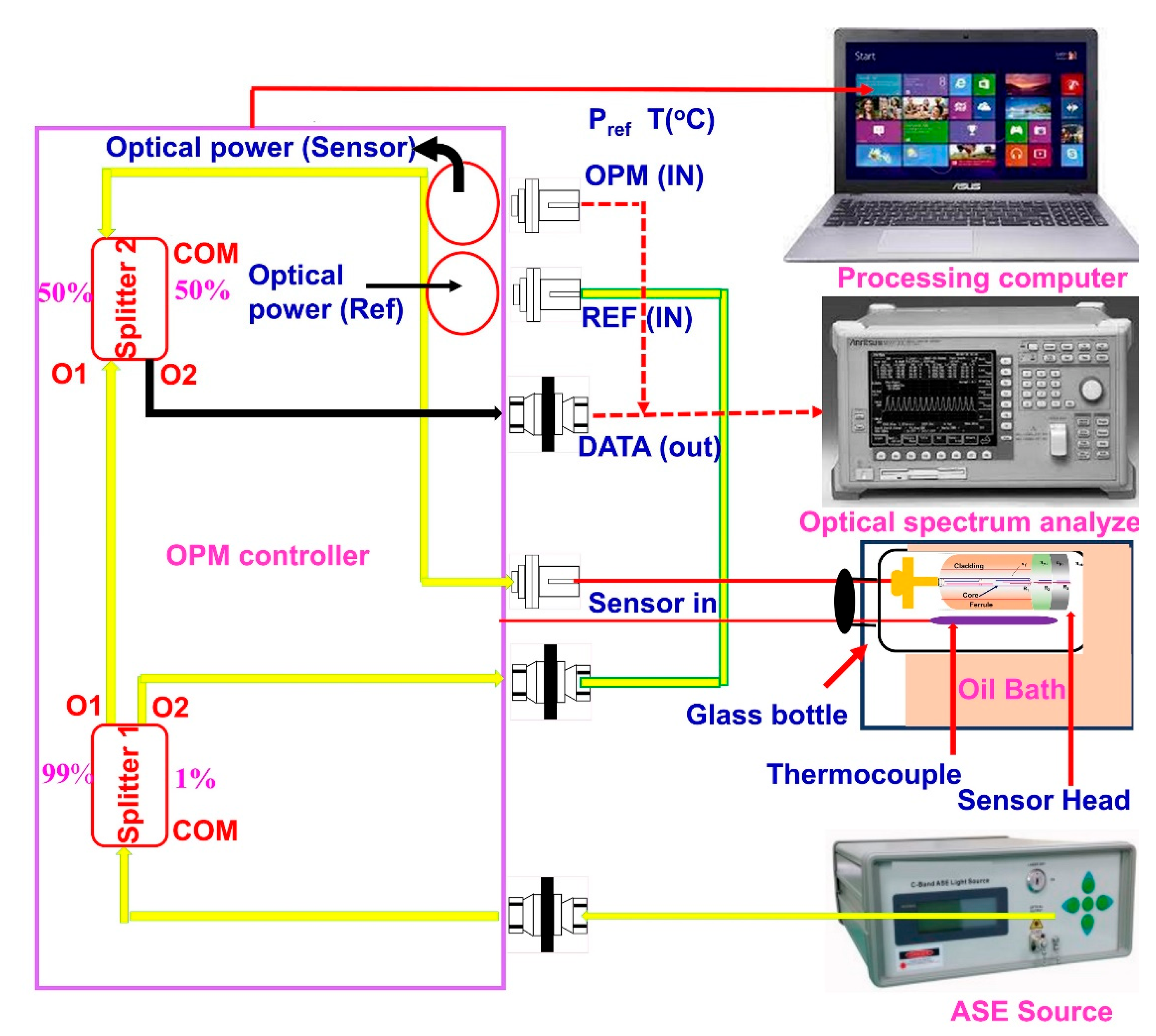

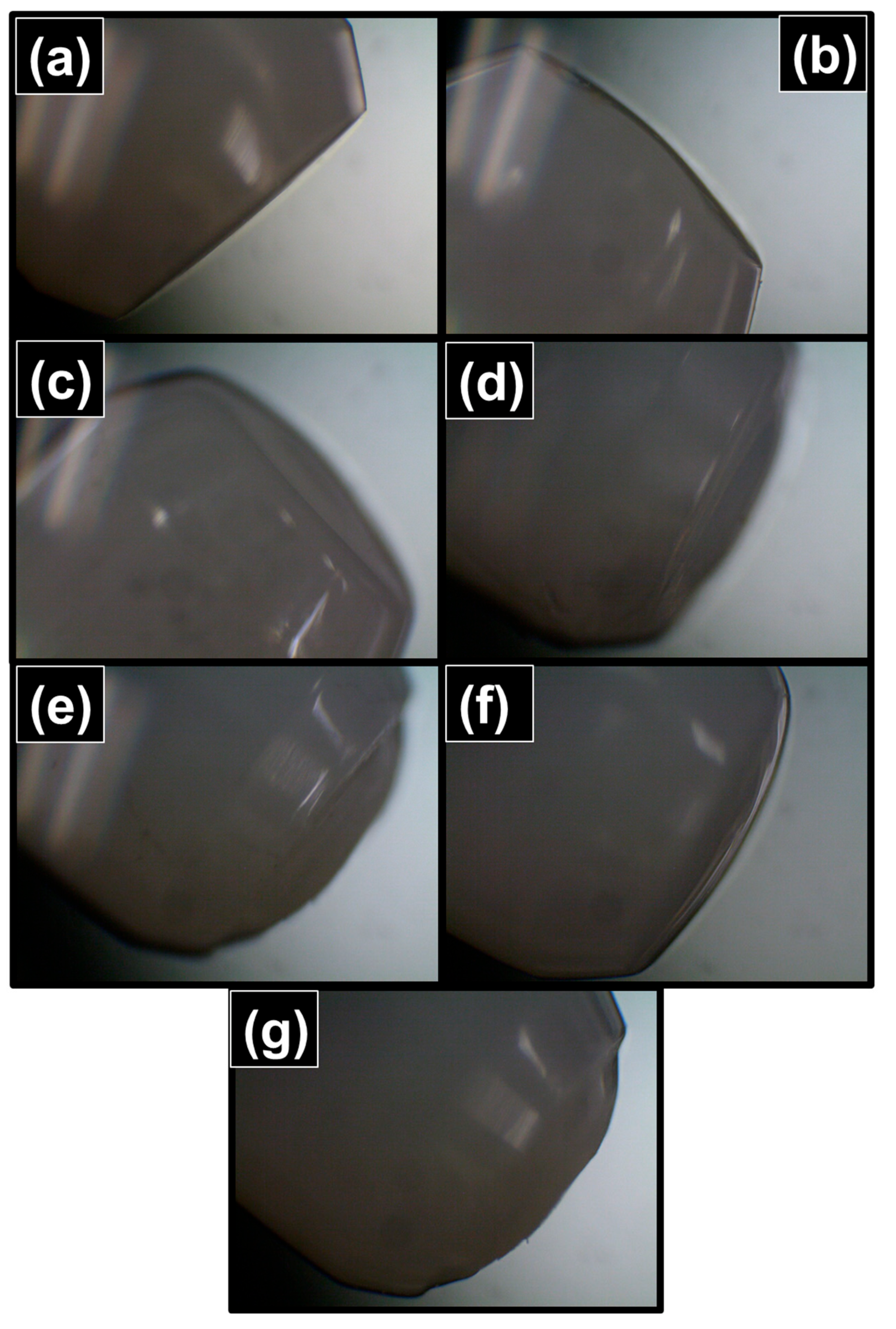

2.2. DPFPI Sensor Fabrication and Experimental Set-Up

2.3. Temperature Response Test

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, W.; Li, C.; Wang, M.; Yu, X.; Fan, J.; Xiong, Y.; Yang, Y.; Li, L. The Polydimethylsiloxane Coated Fiber Optic for All Fiber Temperature Sensing Based on the Multithin–Multifiber Structure. IEEE Sens. J. 2020, 21, 51–56. [Google Scholar] [CrossRef]

- Saha, N.; Kumar, A. Highly sensitive temperature sensor based on a long period grating inscribed metal clad ridge waveguide with PDMS surrounding. OSA Contin. 2019, 2, 946–956. [Google Scholar] [CrossRef]

- Pevec, S.; Kunavar, J.; Budinski, V.; Njegovec, M.; Donlagic, D. An All-Fiber Fabry–Pérot Sensor for Emulsion Concentration Measurements. Sensors 2023, 23, 1905. [Google Scholar] [CrossRef] [PubMed]

- Sekine, M.; Furuya, M. Development of Measurement Method for Temperature and Velocity Field with Optical Fiber Sensor. Sensors 2023, 23, 1627. [Google Scholar] [CrossRef]

- Ma, S.; Pang, Y.; Ji, Q.; Zhao, X.; Li, Y.; Qin, Z.; Liu, Z.; Xu, Y. High-Temperature Sensing Based on GAWBS In Silica Single-Mode Fiber. Sensors 2023, 23, 1277. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, F.; Han, Z.; Cheng, P.; Ding, Z. Research Advances on Fiber-Optic SPR Sensors with Temperature Self-Compensation. Sensors 2023, 23, 644. [Google Scholar] [CrossRef]

- Chen, M.-Q.; Zhao, Y.; Xia, F.; Peng, Y.; Tong, R.-J. High sensitivity temperature sensor based on fiber air-microbubble Fabry-Perot interferometer with PDMS-filled hollow-core fiber. Sens. Actuators A Phys. 2018, 275, 60–66. [Google Scholar] [CrossRef]

- Yu, Z.; Yan, B.; Li, Z.; Ruan, X.; Zhang, Y.; Dai, Y. Graphene induced sensitivity enhancement of thin-film coated long period fiber grating. J. Appl. Phys. 2018, 124, 184503. [Google Scholar] [CrossRef]

- Pereira, L.; Min, R.; Woyessa, G.; Bang, O.; Marques, C.; Varum, H.; Antunes, P. Interrogation Method with Temperature Compensation Using Ultra-Short Fiber Bragg Gratings in Silica and Polymer Optical Fibers as Edge Filters. Sensors 2022, 23, 23. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Li, Y.; Zong, X.; Zhao, L.; Li, P.; Yu, K.; Liu, Y. Wedged Fiber Optic Surface Plasmon Resonance Sensor for High-Sensitivity Refractive Index and Temperature Measurements. Sensors 2022, 22, 9099. [Google Scholar] [CrossRef]

- Wang, Q.; Du, C.; Zhang, J.; Lv, R.; Zhao, Y. Sensitivity-enhanced temperature sensor based on PDMS-coated long period fiber grating. Opt. Commun. 2016, 377, 89–93. [Google Scholar] [CrossRef]

- Zhao, J.-R.; Huang, X.-G.; He, W.-X.; Chen, J.-H. High-Resolution and Temperature-Insensitive Fiber Optic Refractive Index Sensor Based on Fresnel Reflection Modulated by Fabry–Perot Interference. J. Light. Technol. 2010, 28, 2799–2803. [Google Scholar] [CrossRef]

- Liu, Y.; Yuan, L.B. Ultrasensitive temperature sensor based on a urethane acrylate-coated off-axis spiral long period fiber grating. Optik 2020, 223, 165557. [Google Scholar] [CrossRef]

- Chah, K.; Yüksel, K.; Kinet, D.; Yazd, N.S.; Mégret, P.; Caucheteur, C. Fiber Bragg grating regeneration at 450°C for improved high temperature sensing. Opt. Lett. 2019, 44, 4036–4039. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, S.; Gao, S.; Zhang, H.; Wan, L.; Huang, X.; Huang, B.; Feng, Y.; Liu, W.; Li, Z. High-Temperature Sensor Based on Fabry-Perot Interferometer in Microfiber Tip. Sensors 2018, 18, 202. [Google Scholar] [CrossRef]

- Salunkhe, T.T.; Lee, H.K.; Choi, H.W.; Park, S.J.; Kim, I.T. Simply Fabricated Inexpensive Dual-Polymer-Coated Fabry-Perot Interferometer-Based Temperature Sensors with High Sensitivity. Sensors 2021, 21, 7632. [Google Scholar] [CrossRef]

- Han, Y.; Liu, B.; Wu, Y.; Mao, Y.; Wu, J.; Zhao, L.; Nan, T.; Wang, J.; Tang, R.; Zhang, Y.; et al. Ultra-compact silicon-microcap based improved Michelson interferometer high-temperature sensor. Opt. Express 2021, 29, 6703–6713. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, Q.; He, C.; Tian, J.; Sun, Y.; Yao, Y. Fiber Optic Sensor for Simultaneous Measurement of Refractive Index and Temperature Based on Internal-and- External-Cavity Fabry–Pérot Interferometer Configuration. IEEE Sensors J. 2021, 21, 9877–9884. [Google Scholar] [CrossRef]

- Lei, X.; Dong, X. High-Sensitivity Fabry–Perot Interferometer High-Temperature Fiber Sensor Based on Vernier Effect. IEEE Sensors J. 2020, 20, 5292–5297. [Google Scholar] [CrossRef]

- Salunkhe, T.T.; Lee, D.J.; Lee, H.K.; Choi, H.W.; Park, S.J.; Kim, I.T. Enhancing Temperature Sensitivity of the Fabry–Perot Interferometer Sensor with Optimization of the Coating Thickness of Polystyrene. Sensors 2020, 20, 794. [Google Scholar] [CrossRef] [PubMed]

- Salunkhe, T.T.; Choi, H.W.; Park, S.J.; Kim, J.H.; Kim, I.T. High sensitivity temperature sensor based on Fresnel reflection with thermosensitive polymer: Control of morphology and coating thickness. Jpn. J. Appl. Phys. 2020, 59, SGGG06. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, F.; Liu, Z.; Duan, Z.; Cui, W.; Han, J.; Gu, Y.; Wu, Z.; Jing, Z.; Sun, C. Fiber-optic anemometer based on single-walled carbon nanotube coated tilted fiber Bragg grating. Opt. Express 2017, 25, 24521–24530. [Google Scholar] [CrossRef] [PubMed]

- Mathew, J.; Semenova, Y.; Farrell, G. Relative Humidity Sensor Based on an Agarose-Infiltrated Photonic Crystal Fiber Interferometer. IEEE J. Sel. Top. Quantum Electron. 2011, 18, 1553–1559. [Google Scholar] [CrossRef]

- Estella, J.; de Vicente, P.; Echeverría, J.C.; Garrido, J.J. A fibre-optic humidity sensor based on a porous silica xerogel film as the sensing element. Sensors Actuators B Chem. 2010, 149, 122–128. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Díaz, C.R.; Marques, C.; Frizera, A.; Pontes, M.J. Analysis of viscoelastic properties influence on strain and temperature responses of Fabry-Perot cavities based on UV-curable resins. Opt. Laser Technol. 2019, 120, 105743. [Google Scholar] [CrossRef]

- Sun, H.; Luo, H.; Wu, X.; Liang, L.; Wang, Y.; Ma, X.; Zhang, J.; Hu, M.; Qiao, X. Spectrum ameliorative optical fiber temperature sensor based on hollow-core fiber and inner zinc oxide film. Sensors Actuators B Chem. 2017, 245, 423–427. [Google Scholar] [CrossRef]

- Ge, M.; Li, Y.; Han, Y.; Xia, Z.; Guo, Z.; Gao, J.; Qu, S. High-sensitivity double-parameter sensor based on the fibre-tip Fabry–Pérot interferometer. J. Mod. Opt. 2017, 64, 596–600. [Google Scholar] [CrossRef]

- Lee, C.-L.; You, Y.-W.; Dai, J.-H.; Hsu, J.-M.; Horng, J.-S. Hygroscopic polymer microcavity fiber Fizeau interferometer incorporating a fiber Bragg grating for simultaneously sensing humidity and temperature. Sensors Actuators B Chem. 2016, 222, 339–346. [Google Scholar] [CrossRef]

- Zhao, X.; Zuo, C.; Wu, X.; Cheng, J.; Shi, J.; Zhang, W.; Yu, B. High-Sensitivity Temperature Sensor Based on Vernier-Effect and Cascaded Polarization Mode Interferometers. In Proceedings of the 6th Optoelectronics Global Conference (OGC), Shenzhen, China, 15–18 September 2021; pp. 153–156. [Google Scholar]

- Fu, X.; Ran, R.; Li, Q.; Zhang, R.; Li, D.; Fu, G.; Jin, W.; Bi, W.; Qi, Y.; Hu, Q. A sensitivity-enhanced temperature sensor with end-coated PDMS in few mode fiber based on vernier effect. Opt. Commun. 2021, 497, 127173. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, L.; Liu, C.; Wang, H.; Sun, S.; Yang, D. Sensitivity-Enhanced Fiber Temperature Sensor Based on Vernier Effect and Dual In-Line Mach–Zehnder Interferometers. IEEE Sensors J. 2019, 19, 7983–7987. [Google Scholar] [CrossRef]

- Sampath, U.; Kim, D.-G.; Kim, H.; Song, M. Cryogenic Temperature Sensor Based on Fresnel Reflection From a Polymer-Coated Facet of Optical Fiber. IEEE Sensors J. 2018, 18, 3640–3644. [Google Scholar] [CrossRef]

- Hernandez-Romano, I.; Monzon-Hernandez, D.; Moreno-Hernandez, C.; Villatoro, J. Highly Sensitive Temperature Sensor Based on a Polymer-Coated Microfiber Interferometer. IEEE Photon- Technol. Lett. 2015, 27, 2591–2594. [Google Scholar] [CrossRef]

- Ayupova, T.; Shaimerdenova, M.; Tosi, D. Shallow-Tapered Chirped Fiber Bragg Grating Sensors for Dual Refractive Index and Temperature Sensing. Sensors 2021, 21, 3635. [Google Scholar] [CrossRef] [PubMed]

- Niu, H.; Chen, W.; Liu, Y.; Jin, X.; Li, X.; Peng, F.; Geng, T.; Zhang, S.; Sun, W. Strain, bending, refractive index independent temperature sensor based on a graded index multimode fiber embedded long period fiber grating. Opt. Express 2021, 29, 22922. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, L.; Zeng, L.; Hu, Y.; Duan, J.-A. Micro-bending sensing based on single-mode fiber spliced multimode fiber Bragg grating structure. Opt. Commun. 2021, 505, 127513. [Google Scholar] [CrossRef]

- Zhang, Z.; Liao, C.; Tang, J.; Bai, Z.; Guo, K.; Hou, M.; He, J.; Wang, Y.; Liu, S.; Zhang, F. High-Sensitivity Gas-Pressure Sensor Based on Fiber-Tip PVC Diaphragm Fabry–Pérot Interferometer. J. Light. Technol. 2017, 35, 4067–4071. [Google Scholar] [CrossRef]

- Rong, Q.; Sun, H.; Qiao, X.; Zhang, J.; Hu, M.; Feng, Z. A miniature fiber-optic temperature sensor based on a Fabry–Perot interferometer. J. Opt. 2012, 14. [Google Scholar] [CrossRef]

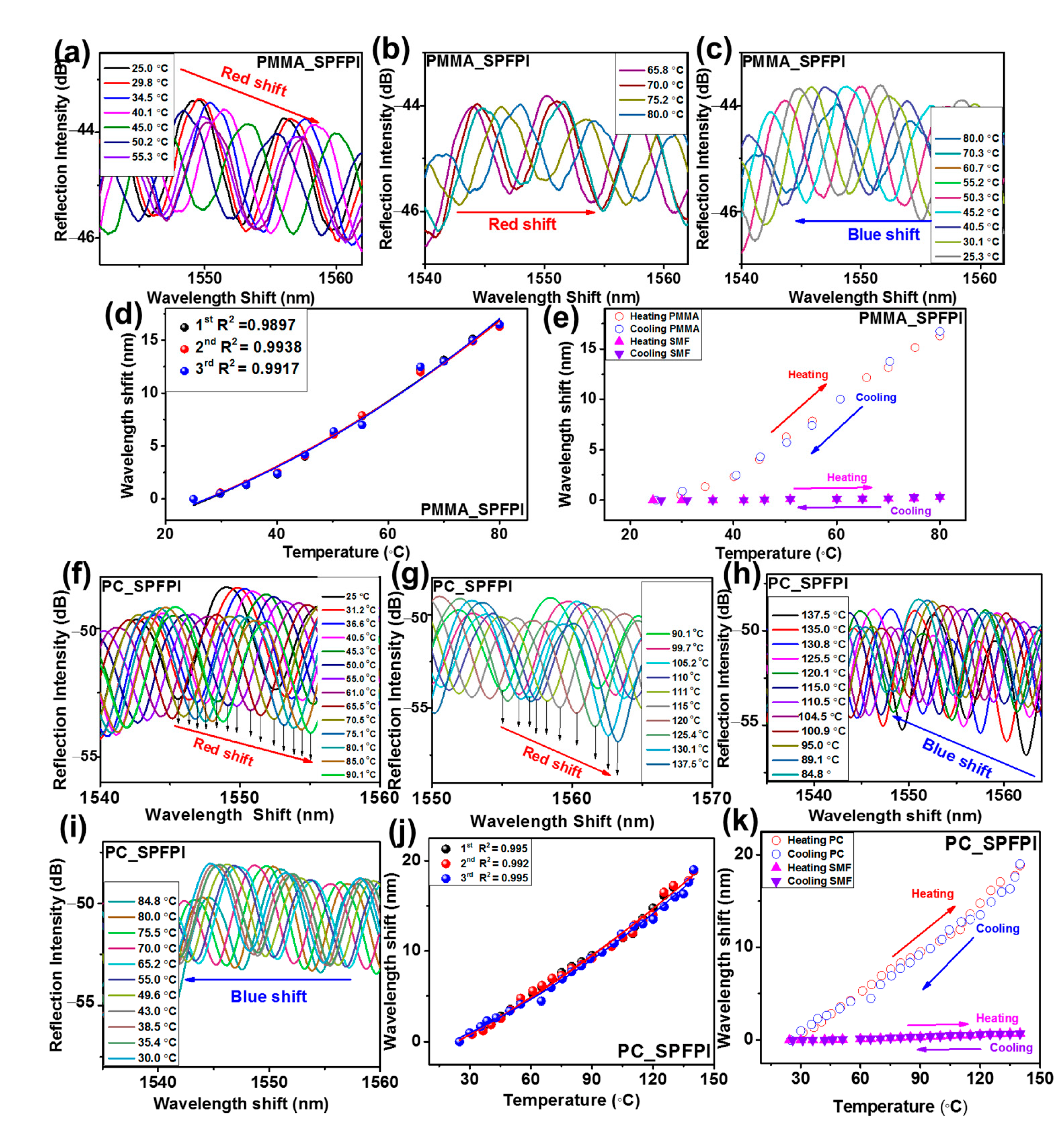

| Sensor | FSR (nm) | Average Temperature Sensitivity (pm °C−1) | Temperature Sensitivity (pm °C−1) (~70–80 °C) | Goodness of Fittine Factor (R2) | Standard Deviation for Temperature (°C) | Standard Deviation for Wavelength (nm) |

|---|---|---|---|---|---|---|

| PMMA-SPFPI | 7.1 | 282.5 | 294.5 | 0.994 | 0.0297 | 0.727 |

| PC_SPFPI | 6.8 | 205.7 (~25–137 °C) | 193.7 (~127–137 °C) | 0.995 | 0.0226 | 0.0098 |

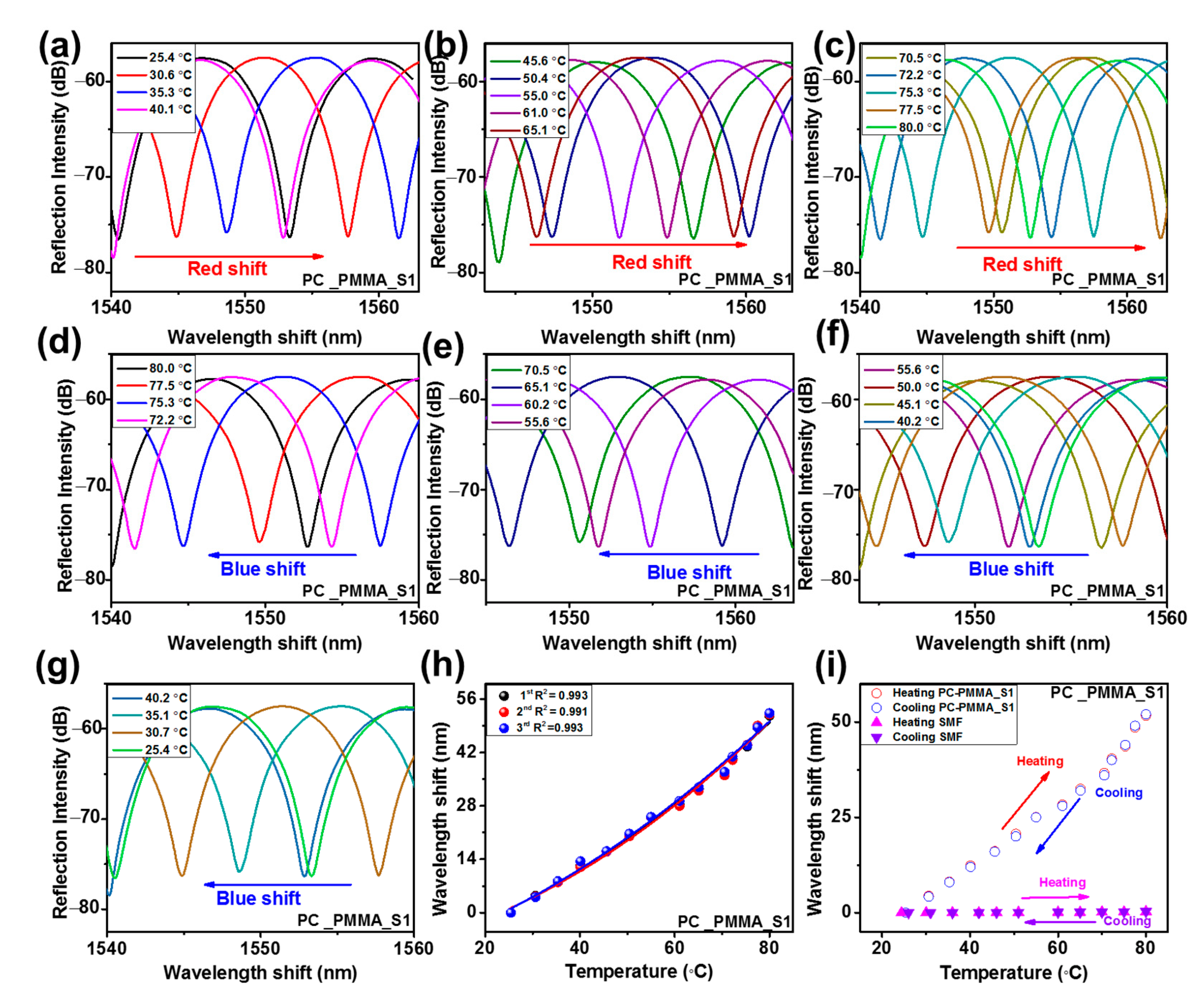

| PMMA_PC_S1 | 9.6 | 916.7 | 1558.9 | 0.998 | 0.279 | 0.029 |

| PMMA_PC_S2 | 4.5 | 654.9 | 902.4 | 1 | 0.263 | 0.0565 |

| PC_PMMA_S1 | 12.8 | 1238.7 | 1820.4 | 0.993 | 0.0756 | 0.042 |

| PC_PMMA_S2 | 3.7 | 751.7 | 1262.6 | 0.996 | 0.0785 | 0.0554 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salunkhe, T.T.; Kim, I.T. Sequential Dual Coating with Thermosensitive Polymers for Advanced Fiber Optic Temperature Sensors. Sensors 2023, 23, 2898. https://doi.org/10.3390/s23062898

Salunkhe TT, Kim IT. Sequential Dual Coating with Thermosensitive Polymers for Advanced Fiber Optic Temperature Sensors. Sensors. 2023; 23(6):2898. https://doi.org/10.3390/s23062898

Chicago/Turabian StyleSalunkhe, Tejaswi Tanaji, and Il Tae Kim. 2023. "Sequential Dual Coating with Thermosensitive Polymers for Advanced Fiber Optic Temperature Sensors" Sensors 23, no. 6: 2898. https://doi.org/10.3390/s23062898

APA StyleSalunkhe, T. T., & Kim, I. T. (2023). Sequential Dual Coating with Thermosensitive Polymers for Advanced Fiber Optic Temperature Sensors. Sensors, 23(6), 2898. https://doi.org/10.3390/s23062898