Virtual Commissioning of Distributed Systems in the Industrial Internet of Things

Abstract

:1. Introduction

- Advance of verification in early stages of implementation;

- Safety: no risks if systems, i.e., automation technology infrastructure, fail;

- Security: test setup for cybersecurity testing (e.g., penetration tests);

- Cost and time savings during development and commissioning;

- Improvement in quality;

- Enabling machine learning applications;

- Test setup for both the logic and middleware layer at the same time;

- Test setup for both hardware and software.

- Perspective on the evolution and next generation of DSPSs;

- Description of the usage of simulation from an OT perspective for IT applications in IIoT and the possibility for VICO in distributed systems;

- Comprehensive overview of possible use cases using physical simulation in IIoT;

- VICO of a distributed system or industrial application in an experimental setup;

- Evaluation of feasibility and quality of statements.

2. Background

2.1. Industrial Internet of Things Network and Industry 4.0

- The network participants are predominantly industrial devices, e.g., PLCs, iPCs, and higher-functionality field sensors;

- The type of applications that are run on the devices;

- The stricter requirements with regard to safety, security, latency, and location awareness [14].

- Real-time behavior: non, soft, hard or isochronous real-time;

- Distribution: higher distributed networks due to wide-area networks (WAN) in addition to existing local-area networks (LAN);

- Heterogeneity: heterogeneous infrastructure that can also include homogeneous or standardized components;

- Installation: wired or wireless (e.g., battery-operated devices).

2.2. Edge Computing

2.3. Evolution of Distributed Stream Processing Systems

2.4. Simulation

- Static vs. dynamic simulation (with regard to the occurrence of time-dependent changes);

- Physical vs. mathematical simulation;

- Manual vs. computer simulation;

- Deterministic vs. stochastic simulation;

- Continuous vs. discrete simulation;

- Terminated vs. nonterminated simulation;

- Stationary vs. nonstationary simulation (reaching a stationary phase after a finite time);

- Real-time vs. non-real-time simulation.

- Time-orientated simulation with fixed time cycle for updating the model;

- Process-orientated simulation, where simulation time can pass between the call of a method of an object and the return from the call (wait function);

- Event-orientated simulation based on event sequences (events are not time-consuming).

2.5. V-Model for System Development and Virtual Commissioning

3. State of the Art

3.1. HiL and SiL for Edge Computing in the IIoT

3.2. Simulation for DSPSs of the Fourth and Fifth Generation

3.3. Novelty and Objectives

- Physical simulation of the industrial plant instead of network simulation;

- Focus on deployment in IIoT and I4.0;

- Direct interaction (exchange of data streams) between simulation and application—no two-step procedure;

- Usage of simulation is not limited to verification and validation but considered during the whole software development process;

- This article provides a holistic overview of the wide range of use cases for this approach. It is not limited to a single implementation;

- Application of HiL and SiL is not limited to a single device; it is for entire systems;

- Higher degree of realism.

| • Link realism | • Topology flexibility |

| • Traffic realism | • Scalability |

| • Resource realism | • Easy replication |

| • OS realism | • Low cost |

| • Functional realism |

| Related Work | Application Field | Pros | Cons |

|---|---|---|---|

| HiL and SiL for Edge Computing in the IIoT | |||

| [47] | machine learning | + use of simulation for data generation |

- no streaming data, collection of data sets - no direct interaction, no feedback loop - simulation and training are decoupled in time |

| [53] | vehicle dynamics |

+ test environment for edge-based CPSs + HiL + model-based simulation |

- only used for test and validation purposes - not used during software development process - no focus on industrial use cases or DSPSs |

| [55] | communication, robotics |

+ evaluation of robot controller communication + HiL |

- limited to communication testing - hardware resources are not considered - focus on robot platforms operated in cloud - no focus on edge computing, DSPSs or AI |

| [30] | digital twins |

+ confirms the relevance of simulation for I4.0 + confirms the relevance of classic VICO and HiL + simulation for development of digital twins | - limited to discrete event simulation |

| [56] | supplier selection, risk management | + simulation combined with machine learning |

- no focus on edge computing or DSPSs - limited to discrete event simulation |

| [57] | robot system |

+ verification of functional constraints and latency + physical simulation + machine learning application + deployment in cloud and edge |

- no feedback loop - no consideration of edge device resources - simulation is only used for verification purpose - simulation is not used for software development |

| [58] | autonomousvehicles |

+ machine learning on control units + SiL and HiL + prototyping in cloud and edge |

- only one device is in the loop - no focus on industrial use cases or DSPSs |

| Simulation for DSPSs of the fourth and fifth generation | |||

| [10] | DSPSs |

+ criticizes the lack of realism in performance evaluation in state-of-the-art approaches + criticizes the low suitability for IoT | - no solution provided (review article ) |

| [62] | stream processing |

+ real-world values are recorded + realism regarding the input data |

- discrete event simulator - two-step procedure; thus, no feedback loop - decoupled in time - evaluation in a real-world setup not possible |

| [63] | IoT |

+ evaluation of end-to-end latency + distributed edge computing application + edge computing simulator | - based on network simulator |

| [65] | Edge computing |

+ identifies a lack of realism in the state of the art + container-based and virtual machine emulation + interfaces for simulation and physical devices |

- only network simulation interface - no consideration of target system - is limited to the network |

4. Method

- Transfer of the standard procedure of VICO for control loop applications to edge computing applications.

- VICO for systems in the IIoT that are not limited to a single algorithm on a single edge device but complex interaction in a system running in an industrial environment.

- Usage of traditional OT methods for realistic and cost-efficient VICO, as well as validation and verification of IT applications in the IIoT.

- Generation of realistic data streams. The simulated streams should resemble the real data and data streams at the manufacturing sites;

- Dynamic, time-dependent simulation, often time-orientated simulation, i.e., with hard cycle times, is required for realistic validation;

- Physical simulation of the whole target system, e.g., components, plants, etc., in contrast to network simulation limited to nodes and edges;

- Applicability for HiL and SiL;

- Real-time capability for time-critical applications.

- SiL is limited to software tests, as it has no relation to hardware. SiL requires the applications to evaluate, e.g., the edge computing algorithms of the logic and middleware layer of the data stream system, to be in the same programming language as in the (real) target system but independent from the later executing device. This piece of code can be run on the same computer or, depending on the capabilities of the simulation tool, directly in the simulation.

- HiL is suited for both software tests and hardware-dependent tests. The algorithms are running on the target device, in the correct programming language, and installed and deployed as in the future target system. Thus, the discrepancies to operation in the real (target) system are minimized. We also explicitly assign virtualized hardware in the sense of virtual machines or docker container to HiL.

- Real-time or non-real-time simulation;

- Testing a single device or several networked devices;

- Testing a single algorithm deployed on one device or on a whole system;

- Communication in the loop or unidirectional;

- Communication to device (HiL) or software (SiL);

- Realism of the transmission medium.

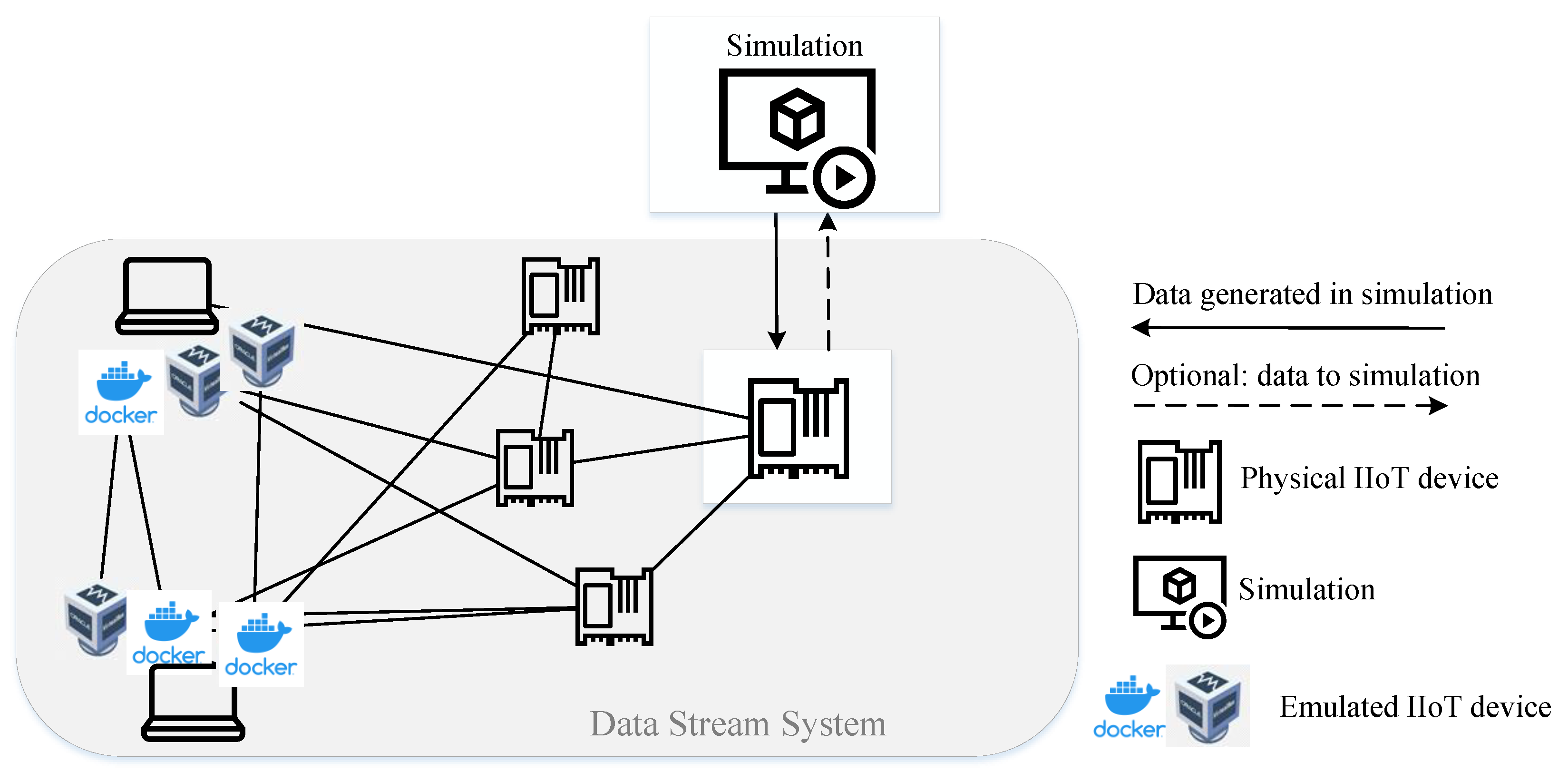

4.1. Architecture 1

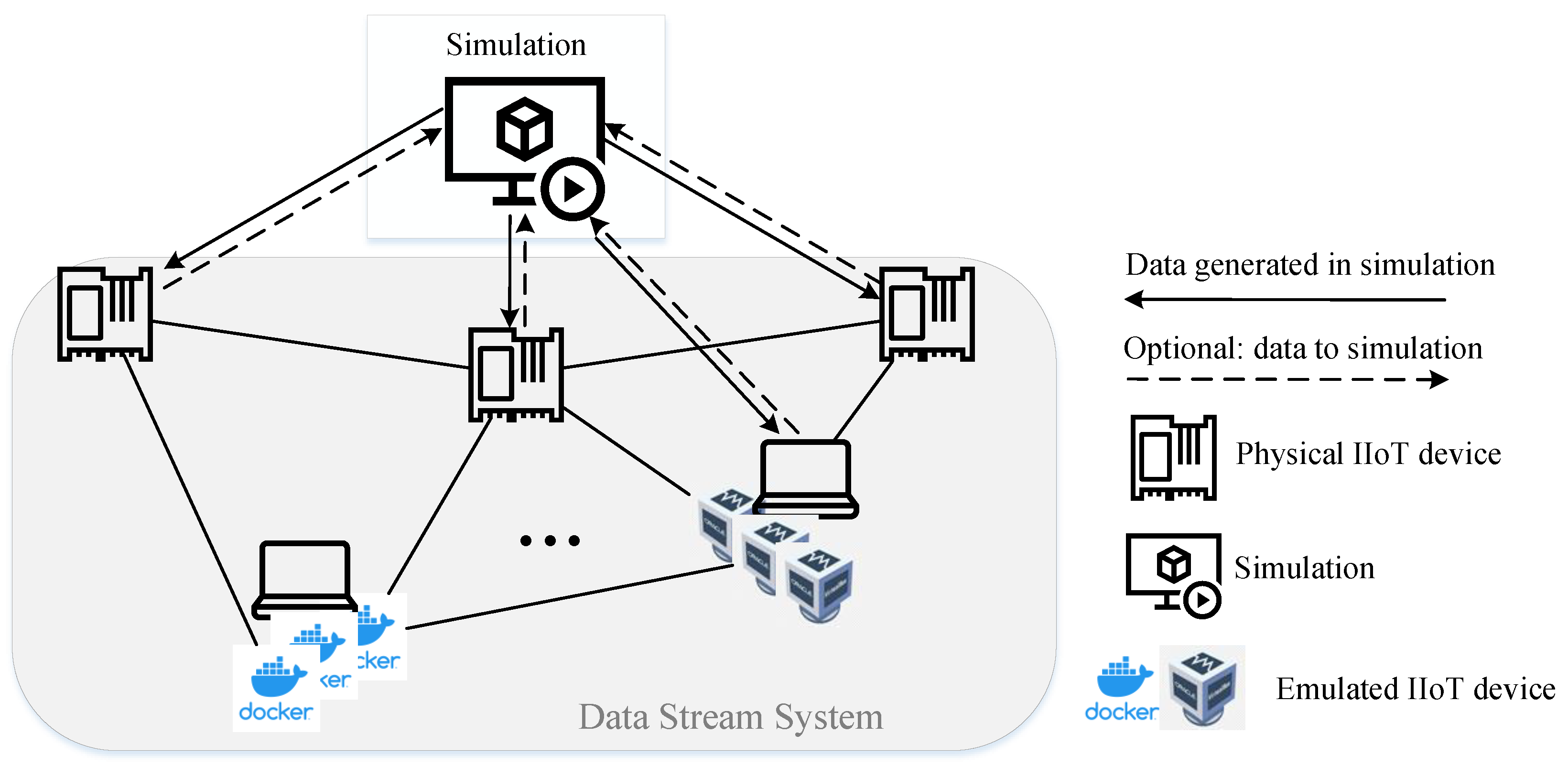

4.2. Architecture 2

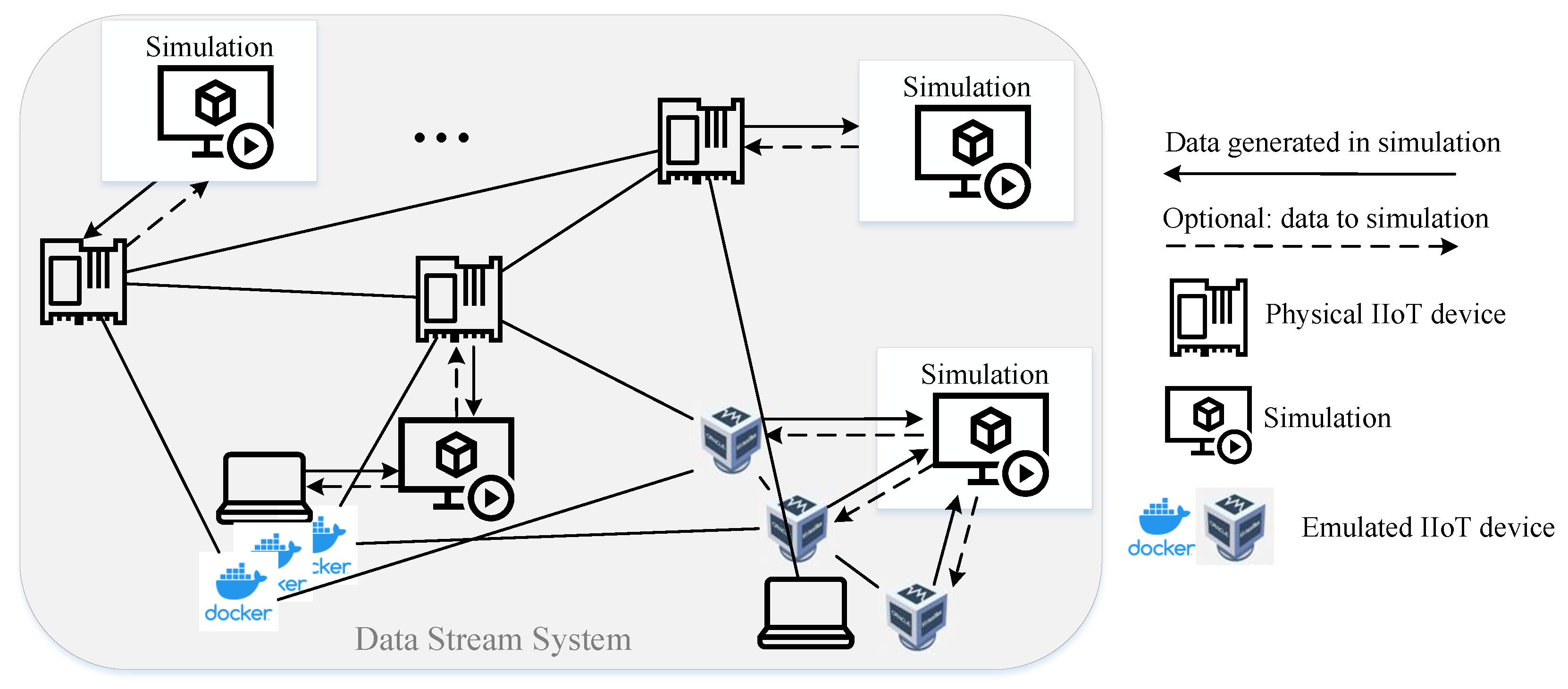

4.3. Architecture 3

5. Comprehensive Overview over Possible Use Cases

5.1. Simulation for System Applications

- SiL:

- System test for validation of the software functionality;

- Dynamic adoption of the system when adding further network nodes;

- System behavior in case of removal of network nodes or agents.

- HiL (additional to SiL):

- Sizing of the hardware;

- Behavior in case of overload;

- Behavior in case of hardware errors or defects.

5.1.1. Distributed Ledger Technology and Smart Contracts

- Immutable, long-term storage of selected relevant IIoT dataFor various scenarios, e.g., legal requirement of proof, the long-term storage and verifiable immutability of selected data are necessary. Different to traditional manual paper-based records, DLT enables a digital and automated record. Data streams and event data can be generated by the simulation, and the verification of the functionality—in the case of IOTA the distributed data base SkyllaDB and the permanode functionality—can be run. This can clarify how much additional load is put on the devices, which devices are suited for running the distributed data base and DLT nodes, which scope of data (data rate and amount of data) is realistic to be stored, and so on.

- SC-based access right managementSCs are digital contracts characterized by more determinism and automation. Digital services, pay-per-use business models and access right management, e.g., for reading and writing IIoT data and analysis results, are only some of the possible use case of SCs. In the aforementioned case, a customer pays for a digital service and receives access to the respective data or information for a certain period of time, e.g., results of an anomaly detection, condition monitoring or predictive maintenance. With simulative analysis, the correct execution of the SC and the verification of the created SC can be tested, respectively. In addition, the latency between fulfilled condition and execution of SCs can be measured and experiments with regard to the optimization of quorum and choice of nodes, e.g., depending on their reputation, that decide about the SC.

5.1.2. Multiagent Systems

- The performance in environment;

- The interaction between the agents;

- The behavior of agents in error states;

- The behavior when devices or agents are added or removed in the system.

5.1.3. DSPS of the Fourth and Fifth Generation

5.2. Simulation for Edge Computing Algorithms in General

5.2.1. Prototyping and Choice of Algorithms and Software

5.2.2. Choice and Sizing of Hardware for Edge Computing

5.2.3. Generation of Optimal Data for Training Machine Learning Algorithms

- Qualitative aspects: The quality of machine learning models is highly linked to data quality. From a quality point of view, simulation enables machine learning in industry as follows:

- –

- Not for each possible scenario that can happen in real production processes—data are recorded and available. In simulation, the full spectrum of scenarios, including destructive or dangerous events, can be manually generated and data recorded or streamed;

- –

- Exclusively good data and correct labeled data: strange effects due to unknown influencing factors do not appear accidentally in simulation; Training with abnormal data or wrongly labeled data leads to models of worse quality;

- –

- Data generated in simulation allows reproducibility.

- Quantitative aspects: For data-based learning, a certain amount of data needs to be available for training, validation, and testing during model development and evaluation. There are different reasons that lead to a lack of available data in industry. As edge computing is, among others, motivated by data security aspects that are at the same time one of the biggest disadvantages in cloud computing, processed data streams in industry are often only available locally in the plant, and thus not accessible to data science engineers during development. Another scenario occurs in the early stages of the engineering process of a new component or plant itself, i.e., the component or plant does not (yet) exist. Furthermore, the value of data was not recognized for a long time, and historic data were not saved at all or without the required metadata. Moreover, in brown-field applications (retrofit), sometimes the plant exists already, but the required sensors are installed along with the commissioning of the processing algorithms.

5.2.4. Planning of Sensors and Development of Virtual Sensors

5.2.5. Hyperparameter Optimization

5.2.6. Providing a Ground Truth

- Anomaly detection: Anomalies can be detected by comparison between the behavior of a simulation model and the real world. Differences that are above average indicate anomalies. Different kinds of anomalies can be detected this way, e.g., drifts, i.e., slowly emerging anomalies, which are characterized by an increasing difference over time or point anomalies that are single outlier values.

- Data compression: In delta compression, only the difference between predicted value and real data is transmitted. For lossy compression, the efficiency can even be increased by reducing the transmission to differences above a certain threshold.

5.2.7. Testing Faulty States

5.2.8. Dealing with Dynamic Changes

- Changes in topology:

- –

- Are the algorithms robust to deal with a dynamic number of network participants (addition or removal of faulty devices)?

- –

- Are the algorithms robust to deal with changing linkages between the devices?

- –

- Can data loss be avoided and processing tasks be transferred to other network participants?

- Changes in data streams:

- –

- Can the processing algorithms handle changes in sampling rates or additional or removed streams?

- –

- Can data loss be avoided?

- Changes in algorithms:

- –

- Can software be updated during operation mode?

- –

- Is a continuous execution of the algorithms granted?

- –

- Is consistency of software revisions guaranteed throughout the DSPS?

5.2.9. Prototyping and Validation of In-the-Loop Applications

5.2.10. Training of Operators and Maintenance Staff

- Performing updates to the distributed system;

- Adding or replacing models or algorithms for edge computing in the distributed system (possibly even during run time);

- Reacting in case of software errors;

- (Re)starting the distributed system;

- Starting a new training phase after parameter changes;

- Evaluation of the results of the data processing, e.g., detected anomalies (is it an indication of a defect and must it be investigated, or are explainable external circumstances responsible for the deviating behavior?);

- labeling data, i.e., data streams are stored and the operator adds meta-information during the operation, e.g., about currently occurring changes, defects, replacements, etc.

5.2.11. Marketing and Sales

6. Simulation Experiments

6.1. Experimental Setup

6.1.1. Description of the Network Layer

6.1.2. Description of Middleware-Layer Application

6.1.3. Description of the Logic-Layer Applications

- Anomaly detection:The anomaly detection is based on unsupervised learning, i.e., the nonparametric statistic method kernel density estimation. The efficient one-pass algorithm is suited for the detection of different kinds of anomalies in streaming data (for details, see [4]).

- DLT and SCs:In a previous work ([22]), we presented two use cases for DLT in the IIoT. The first use case describes the immutable long-term storage of relevant data using the DLT IOTA. The second use case describes a possible access right management based on IOTA in combination with SCs. For both use cases, an IOTA network has to be established on the IIoT devices.

- Data stream compression:

6.2. Conducting Experiments and Results

- The choice between two different implementations for streaming the data from simulation to edge devices that are available for selection. The choice has to be made between a client subscription, i.e., the logic-layer applications subscribe to the respective data streams, or function blocks in the PLC application that forward the data streams to the respective addresses for processing. In this work, it was decided to implement the client subscription. For the sake of completeness, an evaluation and comparison of the second approach would be useful. In the described setup, this is possible to conduct under very similar boundary conditions, thanks to the simulation setup.

- The second question that was not considered yet is the instantiability of the snaps for edge computing. As several incoming data streams can occur on one device for the same processing tasks, in this use case, several instances of snaps (one snap per stream to be processed) have to run in parallel.

- Another fact that was not clear before is the demand for normalization of the representation of the CPU utilization of the control units. As one of four kernels is reserved for the PLC applications, the utilization for edge computing can only achieve a maximum of 75%, which is below the threshold of 80% specified in the training.

- No errors occurred when changing the number of network participants;

- When adding devices in the network, the new devices started to process tasks within the scope of their capabilities;

- When overload of one device occurred, the currently executed computing tasks were returned for new assignment to the further existing devices. However, there is an interruption in the execution of the task until it is assigned to another device. This shows that the agent control leads to a more stable execution of tasks, as they are repeatedly assigned in the case of the failure of a device;

- Starting or stopping the simulation, and thus changes in the data streams for simulating, e.g., network defects, did not interrupt the correct execution of the MAS.

6.3. Limitations

- A comprehensive overview over various applications of simulation is given in Section 5. The evaluation is limited to the use cases presented in the Section 5.1.1, Section 5.1.2, Section 5.2.1, Section 5.2.2, Section 5.2.3, Section 5.2.7 and Section 5.2.8;

- Since the edge computing algorithms themselves have been independently evaluated in our previous works, measurements and evaluation metrics of the experiments conducted are limited to evaluate system character and adaptability to dynamic changes;

- To evaluate the effectiveness and quality of training machine learning algorithms with a simulation, a comparison with inference with real machine data is required;

- The simulation is based on iPhysics, i.e., a tool that requires a CAD data import. Other types of simulations and tools may also be appropriate but have not yet been evaluated;

- The experiments were not yet performed in hard real time, since the simulation was run on a Windows notebook and Python was used as the main programming language;

- The experiments so far are based on the coupling between ctrlX CORE control units and the simulation environments iPhysics. Additional experiments with other edge devices, simulation tools, and programming languages are necessary for better assessability of the approaches.

7. Discussion

- The presented approach focuses on the industrial use, as it is to be expected that suitable simulation models are available or can easily be created with the existing tools. Additional application might be possible in the context of vehicles and vehicle fleets. A transfer to the IoT in general might be reasonable and possible but has to be examined for the respective use case, since physical simulation is not available for all use cases;

- The success of the simulation coupling highly depends on the quality of the simulation model, the suitability of the tool, and the infrastructure;

- The available functions of the simulation tools can be a limiting factor. Since the use case of HiL and SiL originates from the VICO of control applications on control units, some simulation tools are partly not yet able to run other programming languages than IEC 61131-3 code or to connect to other devices than PLCs.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| CPS | Cyberphysical System |

| DLT | Distributed Ledger Technology |

| DSPS | Distributed Stream Processing System |

| HiL | Hardware-in-the-Loop |

| HPO | Hyperparameter Optimization |

| I4.0 | Industry 4.0 |

| IEC | International Electrotechnical Commission |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| IT | Information Technology |

| MiL | Model-in-the-Loop |

| MAS | Multiagent System |

| OT | Operational Technology |

| PLC | Programmable Logic Controller |

| QoS | Quality of Service |

| RAMI 4.0 | Reference Architecture Model 4.0 |

| RL | Reinforcement Learning |

| SiL | Software-in-the-Loop |

| VICO | Virtual Commissioning |

References

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar] [CrossRef] [Green Version]

- Qiu, T.; Chi, J.; Zhou, X.; Ning, Z.; Atiquzzaman, M.; Wu, D.O. Edge Computing in Industrial Internet of Things: Architecture, Advances and Challenges. IEEE Commun. Surv. Tutor. 2020, 22, 2462–2488. [Google Scholar] [CrossRef]

- Rosenberger, J.; Schramm, D.; Bühren, M. Perspective on Efficiency Enhancements in Processing Streaming Data in Industrial IoT Networks. In Proceedings of the 2021 IEEE Global Conference on Artificial Intelligence and Internet of Things (GCAIoT) (2021 IEEE GCAIoT), Dubai, United Arab Emirates, 12–16 December 2021. [Google Scholar]

- Rosenberger, J.; Müller, K.; Selig, A.; Bühren, M.; Schramm, D. Extended kernel density estimation for anomaly detection in streaming data. Procedia CIRP 2022, 112, 156–161. [Google Scholar] [CrossRef]

- Rosenberger, J.; Schramm, D.; Urlaub, M. Multi-Agent Reinforcement Learning for Intelligent Resource Allocation in IIoT Networks. In Proceedings of the 2021 IEEE Global Conference on Artificial Intelligence and Internet of Things (GCAIoT) (2021 IEEE GCAIoT), Dubai, United Arab Emirates, 12–16 December 2021. [Google Scholar]

- Michalák, P.; Watson, P. PATH2iot: A Holistic, Distributed Stream Processing System. In Proceedings of the 2017 IEEE International Conference on Cloud Computing Technology and Science (CloudCom), Hong Kong, China, 11–14 December 2017; pp. 25–32. [Google Scholar] [CrossRef] [Green Version]

- The Apache Software Foundation. Apache Edgent Incubator. Available online: https://incubator.apache.org/projects/edgent.html (accessed on 11 August 2021).

- Bosch Rexroth, A.G. ctrlX Automation Website. Available online: https://apps.boschrexroth.com/microsites/ctrlx-automation/en/ (accessed on 30 September 2022).

- De Blasi, S.; Engels, E. Next generation control units simplifying industrial machine learning. In Proceedings of the IEEE 29th International Symposium on Industrial Electronics (ISIE), Delft, The Netherlands, 17–19 June 2020. [Google Scholar]

- Liu, X.; Buyya, R. Resource Management and Scheduling in Distributed Stream Processing Systems: A Taxonomy, Review, and Future Directions. ACM Comput. Surv. 2020, 53, 1–41. [Google Scholar] [CrossRef] [Green Version]

- Blatt. VDI 3693 Part 1: Virtual Commissioning—Model Types and Glossary; VDI: Düsseldorf, Germany, 2016. [Google Scholar]

- Barth, M. Automatisch Generierte Simulationsmodelle Verfahrenstechnischer Anlagen für den Steuerungstest. Ph.D. Thesis, Helmut-Schmidt-Universität Hamburg, Hamburg, Germany, 2012. [Google Scholar]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Pereira, C.E.; Neumann, P. Industrial Communication Protocols. In Springer Handbook of Automation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 981–999. [Google Scholar] [CrossRef]

- Becerril, J.A.V.; Prasanna, H.K. Migration of 3D Simulation Software in a Real Digital Twin Framework. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2021. [Google Scholar]

- DIN EN 62264; Enterprise-Control System Integration. Beuth Verlag GmbH: Berlin, Germany, 2014. [CrossRef]

- DIN SPEC 91345; Reference Architecture Model Industrie 4.0 (RAMI4.0). Beuth Verlag GmbH: Berlin, Germany, 2016. Available online: https://www.beuth.de/en/technical-rule/din-spec-91345/250940128 (accessed on 27 February 2023).

- DIN EN 62890; Life-Cycle-Management von Systemen und Produkten der Mess-, Steuer-und Regelungstechnik der Industrie. Beuth Verlag GmbH: Berlin, Germany, 2017.

- Plattform Industrie 4.0: Downloads & News. Available online: https://www.plattform-i40.de/SiteGlobals/IP/Forms/Listen/Downloads/EN/Downloads_Formular.html?cl2Categories_Typ_name=infographik (accessed on 27 January 2022).

- Yu, W.; Liang, F.; He, X.; Hatcher, W.G.; Lu, C.; Lin, J.; Yang, X. A Survey on the Edge Computing for the Internet of Things. IEEE Access 2018, 6, 6900–6919. [Google Scholar] [CrossRef]

- Xue, H.; Huang, B.; Qin, M.; Zhou, H.; Yang, H. Edge Computing for Internet of Things: A Survey. In Proceedings of the 2020 International Conferences on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData) and IEEE Congress on Cybermatics (Cybermatics), Rhodes, Greece, 2–6 November 2020; pp. 755–760. [Google Scholar] [CrossRef]

- Rosenberger, J.; Rauterberg, F.; Schramm, D. Performance study on IOTA Chrysalis and Coordicide in the Industrial Internet of Things. In Proceedings of the 2021 IEEE Global Conference on Artificial Intelligence and Internet of Things (GCAIoT), Dubai, United Arab Emirates, 12–16 December 2021. [Google Scholar]

- Cruz, T.; Simões, P.; Monteiro, E. Virtualizing Programmable Logic Controllers: Toward a Convergent Approach. IEEE Embed. Syst. Lett. 2016, 8, 69–72. [Google Scholar] [CrossRef] [Green Version]

- Azarmipour, M.; Elfaham, H.; Gries, C.; Epple, U. PLC 4.0: A Control System for Industry 4.0. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 5513–5518. [Google Scholar] [CrossRef]

- Scordino, C.; Savino, I.M.; Cuomo, L.; Miccio, L.; Tagliavini, A.; Bertogna, M.; Solieri, M. Real-Time Virtualization For Industrial Automation. In Proceedings of the 2020 25th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Vienna, Austria, 8–11 September 2020; Volume 1, pp. 353–360. [Google Scholar] [CrossRef]

- Cinque, M.; Cotroneo, D.; De Simone, L.; Rosiello, S. Virtualizing mixed-criticality systems: A survey on industrial trends and issues. Future Gener. Comput. Syst. 2022, 129, 315–330. [Google Scholar] [CrossRef]

- Dias de Assunção, M.; da Silva Veith, A.; Buyya, R. Distributed data stream processing and edge computing: A survey on resource elasticity and future directions. J. Netw. Comput. Appl. 2018, 103, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Fragkoulis, M.; Carbone, P.; Kalavri, V.; Katsifodimos, A. A Survey on the Evolution of Stream Processing Systems. arXiv 2020, arXiv:2008.00842. [Google Scholar]

- Flemming, V. Simulation in der Arbeitsvorbereitung. Available online: https://tu-dresden.de/ing/maschinenwesen/if/fue/ressourcen/dateien/studium/lehrunterlagen/simav/skript?lang=en (accessed on 27 February 2023).

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Sauerbier, T. Theorie und Praxis von Simulationssystemen; Vieweg & Sohn Verlaggesellschaft: Wiesbaden, Germany, 1999; p. 5. [Google Scholar]

- VDI Guideline 3633; Part 1: Simulation of Systems in Materials Handling, Logistics and Production—Fundamentals. Beuth: Berlin, Germany, 2014.

- Gutenschwager, K.; Rabe, M.; Spieckermann, S.; Wenzel, S. Simulation in Produktion und Logistik; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Glöckler, M. Simulation Mechatronischer Systeme; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Gräßler, I. Competitive engineering in the age of Industry 4.0 and beyond. In Proceedings of the TMCE. Las Palmas de Gran Canaria, Las Palmas de Gran Canaria, Spain, 7–11 May 2018. [Google Scholar]

- Boehm, B.W. Verifying and validating software requirements and design specifications. IEEE Softw. 1984, 1, 75. [Google Scholar] [CrossRef]

- VDI Guideline 2206; Development of Mechatronic and Cyber-Physical Systems. VDI-Verlag: Düsseldorf, Germany, 2021.

- Eickhoff, J.; Eickhoff, J. System Simulation in System Engineering. In Simulating Spacecraft Systems; Springer: Berlin/Heidelberg, Germany, 2009; pp. 11–21. [Google Scholar]

- Breiner, S.; Subrahmanian, E.; Jones, A. Categorical foundations for system engineering. In Disciplinary Convergence in Systems Engineering Research; Springer: Berlin/Heidelberg, Germany, 2018; pp. 449–463. [Google Scholar]

- Menager, N. Effizienzsteigerung bei Auslegung und Inbetriebnahme Mechatronischer Systeme Durch Verwendung Modellbasierter Entwicklungsmethoden auf Basis Offener Standards. Ph.D. Thesis, University Duisburg-Essen, Duisburg, Germany, 2017. [Google Scholar]

- Allmacher, C.; Dudczig, M.; Knopp, S.; Klimant, P. Virtual reality for virtual commissioning of automated guided vehicles. In Proceedings of the 2019 IEEE Conference on Virtual Reality and 3D User Interfaces (VR), IEEE, Osaka, Japan, 23 March 2019; pp. 838–839. [Google Scholar]

- IEC 61131-3:2013; Programmable Controllers—Part 3: Programming Languages. International Electrotechnical Commission: Geneva, Switzerland, 2003.

- Liu, Z.; Ali, A.; Kenesei, P.; Miceli, A.; Sharma, H.; Schwarz, N.; Trujillo, D.; Yoo, H.; Coffee, R.; Layad, N.; et al. Bridging Data Center AI Systems with Edge Computing for Actionable Information Retrieval. In Proceedings of the 2021 3rd Annual Workshop on Extreme-scale Experiment-in-the-Loop Computing (XLOOP), St. Louis, MO, USA, 19 November 2021; pp. 15–23. [Google Scholar] [CrossRef]

- Li, G.; Dong, Y.; Li, J.; Song, X. Strategy for dynamic blockchain construction and transmission in novel edge computing networks. Future Gener. Comput. Syst. 2022, 130, 19–32. [Google Scholar] [CrossRef]

- Fernández, F.; Zverev, M.; Garrido, P.; Juárez, J.R.; Bilbao, J.; Agüero, R. Even Lower Latency in IIoT: Evaluation of QUIC in Industrial IoT Scenarios. Sensors 2021, 21, 5737. [Google Scholar] [CrossRef]

- Rafiq, A.; Ali Muthanna, M.S.; Muthanna, A.; Alkanhel, R.; Abdullah, W.A.M.; Abd El-Latif, A.A. Intelligent edge computing enabled reliable emergency data transmission and energy efficient offloading in 6TiSCH-based IIoT networks. Sustain. Energy Technol. Assess. 2022, 53, 102492. [Google Scholar] [CrossRef]

- Golmie, N.T. Machine Learning in Network Modeling and Simulation. Available online: https://www.nist.gov/programs-projects/machine-learning-network-modeling-and-simulation (accessed on 15 September 2022).

- De Vita, F.; Bruneo, D.; Puliafito, A.; Nardini, G.; Virdis, A.; Stea, G. A Deep Reinforcement Learning Approach for Data Migration in Multi-Access Edge Computing. In Proceedings of the 2018 ITU Kaleidoscope: Machine Learning for a 5G Future (ITU K), Santa Fe, Argentina, 26–28 November 2018; pp. 1–8. [Google Scholar] [CrossRef]

- De Vita, F.; Nardini, G.; Virdis, A.; Bruneo, D.; Puliafito, A.; Stea, G. Using Deep Reinforcement Learning for Application Relocation in Multi-Access Edge Computing. IEEE Commun. Stand. Mag. 2019, 3, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Schettler, M.; Buse, D.S.; Zubow, A.; Dressler, F. How to Train your ITS? Integrating Machine Learning with Vehicular Network Simulation. In Proceedings of the 2020 IEEE Vehicular Networking Conference (VNC), New York, NY, USA, 16–18 December 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Brockman, G.; Cheung, V.; Pettersson, L.; Schneider, J.; Schulman, J.; Tang, J.; Zaremba, W. OpenAI Gym. arXiv 2016, arXiv:1606.01540. [Google Scholar]

- Stable-Baselines3. Stable-Baselines3 Docs—Reliable Reinforcement Learning Implementations. 2020. Available online: https://stable-baselines3.readthedocs.io/en/master/ (accessed on 8 December 2021).

- Nagy, S.J.; Szabó, R.; Vajda, M.L.; Vörös, A. Demonstrator for dependable edge-based cyber-physical systems. In Proceedings of the 2021 10th Latin-American Symposium on Dependable Computing (LADC), Florianópolis, Brazil, 22–26 November 2021; pp. 1–8. [Google Scholar] [CrossRef]

- Eclipse. Simulation of Urban MObility. Available online: https://www.eclipse.org/sumo/ (accessed on 23 January 2023).

- Lv, H.; Pang, Z.; Xiao, M.; Yang, G. Hardware-in-the-Loop Simulation for Evaluating Communication Impacts on the Wireless-Network-Controlled Robots. In Proceedings of the IECON 2022—48th Annual Conference of the IEEE Industrial Electronics Society, Brussels, Belgium, 17–20 October 2022. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Aldegheri, S.; Bombieri, N.; Fummi, F.; Girardi, S.; Muradore, R.; Piccinelli, N. Late Breaking Results: Enabling Containerized Computing and Orchestration of ROS-based Robotic SW Applications on Cloud-Server-Edge Architectures. In Proceedings of the 2020 57th ACM/IEEE Design Automation Conference (DAC), San Francisco, CA, USA, 20–24 July 2020; pp. 1–2. [Google Scholar] [CrossRef]

- Grigorescu, S.; Cocias, T.; Trasnea, B.; Margheri, A.; Lombardi, F.; Aniello, L. Cloud2Edge Elastic AI Framework for Prototyping and Deployment of AI Inference Engines in Autonomous Vehicles. Sensors 2020, 20, 5450. [Google Scholar] [CrossRef]

- Korala, H.; Georgakopoulos, D.; Jayaraman, P.P.; Yavari, A. A Survey of Techniques for Fulfilling the Time-Bound Requirements of Time-Sensitive IoT Applications. ACM Comput. Surv. 2022, 54, 1–36. [Google Scholar] [CrossRef]

- Chintapalli, S.; Dagit, D.; Evans, B.; Farivar, R.; Graves, T.; Holderbaugh, M.; Liu, Z.; Nusbaum, K.; Patil, K.; Peng, B.J.; et al. Benchmarking Streaming Computation Engines: Storm, Flink and Spark Streaming. In Proceedings of the 2016 IEEE International Parallel and Distributed Processing Symposium Workshops (IPDPSW), Chicago, IL, USA, 23–27 May 2016; pp. 1789–1792. [Google Scholar] [CrossRef]

- Karimov, J.; Rabl, T.; Katsifodimos, A.; Samarev, R.; Heiskanen, H.; Markl, V. Benchmarking Distributed Stream Data Processing Systems. In Proceedings of the 2018 IEEE 34th International Conference on Data Engineering (ICDE), Paris, France, 16–19 April 2018; pp. 1507–1518. [Google Scholar] [CrossRef] [Green Version]

- Hidalgo, N.; Rosas, E.; Saavedra, T.; Morales, J. SLedge: Scheduling and Load Balancing for a Stream Processing EDGE Architecture. Appl. Sci. 2022, 12, 6474. [Google Scholar] [CrossRef]

- Mudassar, M.; Zhai, Y.; Lejian, L. Adaptive Fault-Tolerant Strategy for Latency-Aware IoT Application Executing in Edge Computing Environment. IEEE Internet Things J. 2022, 9, 13250–13262. [Google Scholar] [CrossRef]

- iFogSim. Available online: https://github.com/Cloudslab/iFogSim (accessed on 11 October 2022).

- Zeng, Y.; Chao, M.; Stoleru, R. EmuEdge: A Hybrid Emulator for Reproducible and Realistic Edge Computing Experiments. In Proceedings of the 2019 IEEE International Conference on Fog Computing (ICFC), Prague, Czech Republic, 24–26 June 2019; pp. 153–164. [Google Scholar] [CrossRef]

- IEC 63278-1; ED1—Asset Administration Shell (AAS) for Industrial Applications—Part 1: Asset Administration Shell Structure. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- The MathWorks, Inc. Simulink. Available online: https://www.mathworks.com/products/simulink.html (accessed on 22 October 2022).

- Virtual Commissioning VIBN with iPhysics. Available online: https://www.machineering.com/en/ (accessed on 20 October 2022).

- Functional Mock-Up Interface—The Leading Standard to Exchange Dynamic Simulation Models. Available online: https://fmi-standard.org/ (accessed on 20 October 2022).

- DYMOLA Systems Engineering. Available online: https://www.3ds.com/products-services/catia/products/dymola/ (accessed on 20 October 2022).

- Carelli, A.; Palmieri, A.; Vilei, A.; Castanier, F.; Vesco, A. Enabling Secure Data Exchange through the IOTA Tangle for IoT Constrained Devices. Sensors 2022, 22, 1384. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, J.; Sun, S.; Kiritsis, D. Decentralized Industrial IoT Data Management Based on Blockchain and IPFS. In Advances in Production Management Systems. Towards Smart and Digital Manufacturing, Proceedings of the IFIP WG 5.7 International Conference, APMS 2020, Novi Sad, Serbia, 30 August–3 September 2020; Lalic, B., Majstorovic, V., Marjanovic, U., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2020; pp. 222–229. [Google Scholar]

- Schweizer, A.; Knoll, P.; Urbach, N.; von der Gracht, H.A.; Hardjono, T. To What Extent Will Blockchain Drive the Machine Economy? Perspectives from a Prospective Study. IEEE Trans. Eng. Manag. 2020, 67, 1169–1183. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Seitz, M.; Salazar, L.A.C.; Gehlhoff, F.; Dogan, A.; Fay, A. Multi-agent systems to enable Industry 4.0. Automatisierungstechnik 2020, 68, 445–458. [Google Scholar] [CrossRef]

- Wan, J.; Chen, B.; Wang, S.; Xia, M.; Li, D.; Liu, C. Fog Computing for Energy-Aware Load Balancing and Scheduling in Smart Factory. IEEE Trans. Ind. Inform. 2018, 14, 4548–4556. [Google Scholar] [CrossRef]

- Wang, R.; Cao, Y.; Noor, A.; Alamoudi, T.A.; Nour, R. Agent-enabled task offloading in UAV-aided mobile edge computing. Comput. Commun. 2020, 149, 324–331. [Google Scholar] [CrossRef]

- Leusin, M.E.; Frazzon, E.M.; Uriona Maldonado, M.; Kück, M.; Freitag, M. Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era. Technologies 2018, 6, 107. [Google Scholar] [CrossRef] [Green Version]

- Turker, A.K.; Aktepe, A.; Inal, A.F.; Ersoz, O.O.; Das, G.S.; Birgoren, B. A Decision Support System for Dynamic Job-Shop Scheduling Using Real-Time Data with Simulation. Mathematics 2019, 7, 278. [Google Scholar] [CrossRef] [Green Version]

- Farahvash, P.; Boucher, T.O. A multi-agent architecture for control of AGV systems. Robot. Comput. Integr. Manuf. 2004, 20, 473–483. [Google Scholar] [CrossRef]

- Guo, K.; Zhu, J.; Shen, L. An Improved Acceleration Method Based on Multi-Agent System for AGVs Conflict-Free Path Planning in Automated Terminals. IEEE Access 2021, 9, 3326–3338. [Google Scholar] [CrossRef]

- Feng, F.; Pang, Y.; Lodewijks, G.; Li, W. Collaborative framework of an intelligent agent system for efficient logistics transport planning. Comput. Ind. Eng. 2017, 112, 551–567. [Google Scholar] [CrossRef]

- Kuhnle, A.; Jakubik, J.; Lanza, G. Reinforcement learning for opportunistic maintenance optimization. Prod. Eng. 2019, 13, 33–41. [Google Scholar] [CrossRef]

- Rosenberger, J.; Urlaub, M.; Rauterberg, F.; Lutz, T.; Selig, A.; Bühren, M.; Schramm, D. Deep Reinforcement Learning Multi-Agent System for Resource Allocation in Industrial Internet of Things. Sensors 2022, 22, 4099. [Google Scholar] [CrossRef]

- Martin, D.; Kühl, N.; Satzger, G. Virtual sensors. Bus. Inf. Syst. Eng. 2021, 63, 315–323. [Google Scholar] [CrossRef]

- Šabanovič, E.; Kojis, P.; Šukevičius, Š.; Shyrokau, B.; Ivanov, V.; Dhaens, M.; Skrickij, V. Feasibility of a neural network-based virtual sensor for vehicle unsprung mass relative velocity estimation. Sensors 2021, 21, 7139. [Google Scholar] [CrossRef]

- Wong, E.; Schneider, T.; Schmitt, J.; Schmidt, F.R.; Kolter, J.Z. Neural network virtual sensors for fuel injection quantities with provable performance specifications. In Proceedings of the 2020 IEEE Intelligent Vehicles Symposium (IV), IEEE, Las Vegas, NV, USA, 13 November 2020; pp. 1753–1758. [Google Scholar]

- von Rueden, L.; Mayer, S.; Sifa, R.; Bauckhage, C.; Garcke, J. Combining Machine Learning and Simulation to a Hybrid Modelling Approach: Current and Future Directions. In Advances in Intelligent Data Analysis XVIII, Proceedings of the 18th International Symposium on Intelligent Data Analysis, IDA 2020, Konstanz, Germany, 27–29 April 2020; Berthold, M.R., Feelders, A., Krempl, G., Eds.; Springer: Cham, Switzerland, 2020; pp. 548–560. [Google Scholar]

- Rosenberger, J.; Kübel, A.; Rothfuß, F. Comparison and extension of autoencoder models for uni- and multivariate signal compression in IIoT. In Proceedings of the 2022 Data Compression Conference (DCC), Snowbird, UT, USA, 22–25 March 2022; p. 481. [Google Scholar] [CrossRef]

- Snaps in Ubuntu Core. Available online: https://ubuntu.com/core/docs/snaps-in-ubuntu-core (accessed on 29 September 2022).

- Die Fieldbox-Familie wächst. Available online: https://www.machineering.com/en/blog/wissen/article/die-fieldbox-familie-waechst/ (accessed on 12 February 2023).

- Rauterberg, F. Performancevergleich von Datenkompressionsalgorithmen auf Industriellen Edge-Devices; Student Research Paper; Technische Hochschule Mittelhessen: Friedberg, Germany, 2022; in press. [Google Scholar]

- Lindstrom, P.; Isenburg, M. Fast and Efficient Compression of Floating-Point Data. IEEE Trans. Vis. Comput. Graph. 2006, 12, 1245–1250. [Google Scholar] [CrossRef]

| Results | Search Query |

|---|---|

| 105 | “edge computing” AND “simulation” AND “hardware-in-the-loop” AND IIoT |

| 47 | “edge computing” AND “virtual commissioning” AND “machine learning” AND “IIoT” |

| 177 | “distributed stream processing system” AND edge AND simulation AND IoT |

| 6 | “distributed stream processing system” AND edge AND simulation AND IIoT |

| 48 | “distributed stream processing system” AND “edge computing” AND simulation AND IoT |

| 4 | “distributed stream processing system” AND “edge computing” AND simulation AND IIoT |

| 2 | “distributed stream processing system” AND edge AND “process simulation” |

| 0 | “distributed stream processing system” AND edge AND “dynamic simulation” |

| 0 | “distributed stream processing system” AND edge AND “physical simulation” |

| Stream Variable | Description | Data Type | Range |

|---|---|---|---|

| Selected streams of physical control unit 1 (192.168.8.102) | |||

| Pusher_AXIS | Position of the pusher | float32 | 0 to 0.25 |

| Selected streams of physical control unit 2 (192.168.8.103) | |||

| Gleitschiene_Links_Axis | Position of the sliding rail (left) | float32 | 0 to 0.025 |

| EndOfLaufwagen_ACT_SPD | Current speed of the carriage | float32 | −0.8 to 0.8 |

| EndOfLaufwagen_Axis | Position of the carriage | float32 | 0 to 1.5 |

| EndOfLaufwagen_DLT_POS | Delta actual value–reference value of carriage position | float32 | 0 to 1.5 |

| Selected streams of physical control unit 3 (192.168.8.104) | |||

| Drehschieber_Achse_101_AXIS | Position of rotary vane | float32 | 0 to 0.13 |

| Selected streams of virtual control unit 4 (192.168.8.83) | |||

| EndoflHubgeruest01_ACT_SPD | Current speed of the portal | float32 | max. 1.4 |

| EndoflHubgeruest01_AXIS | Position of the portal | float32 | −2 to 0 |

| EndoflHubgeruest01_DLT_POS | Delta actual value–reference value portal position | float32 | −2 to 0 |

| EndoflGreifarm01_ACT_SPD | Current speed of the gripper arm | float32 | max. 0.6 |

| EndoflGreifarm01_AXIS | Position of the gripper arm | float32 | −0.3 to 5 |

| EndoflGreifarm01_DLT_POS | Delta actual value–reference value of gripper arm position | float32 | −0.3 to 5 |

| Experiment | Description | Success |

|---|---|---|

| Overall system | ||

| Evaluation of overall system | All algorithms run together and the system interacts with a simulated plant | √ |

| • Run PLC application | Controlling simulation model via real and virtualized PLCs | √ |

| • Run MAS | Agent, watchdog, and resource monitoring as snaps on control unit | √ |

| • Run IOTA | Faucet, masterpeer, and replica nodes as snaps on control unit | √ |

| • Run anomaly detection | Anomaly detection algorithm EEM-KDE as snap on control unit | √ |

| • Run data compression | Autoencoder and fpzip as snaps on control unit | √ |

| Middleware-layer | ||

| Resource allocation | Agents trigger task execution or forwarding depending on available resources | √ |

| Load test | Watchdog frees resources and sends task back to task queue for reassignment | √ |

| Adaptivity to dynamic changes | Adding/removing agents or data streams during runtime | √ |

| Logic-layer | ||

| Anomaly detection | Detection of manually forced anomalies | √ |

| Data compression | Both autoencoder and fpzip compress and decompress data | √ |

| IOTA | √ | |

| • Adaptivity to dynamic changes | Adding/removing nodes during runtime | √ |

| • Tangle | Tangle is built and synchronized | √ |

| • Smart Contracts | Execute SCs that interact with simulation | planned |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosenberger, J.; Selig, A.; Ristic, M.; Bühren, M.; Schramm, D. Virtual Commissioning of Distributed Systems in the Industrial Internet of Things. Sensors 2023, 23, 3545. https://doi.org/10.3390/s23073545

Rosenberger J, Selig A, Ristic M, Bühren M, Schramm D. Virtual Commissioning of Distributed Systems in the Industrial Internet of Things. Sensors. 2023; 23(7):3545. https://doi.org/10.3390/s23073545

Chicago/Turabian StyleRosenberger, Julia, Andreas Selig, Mirjana Ristic, Michael Bühren, and Dieter Schramm. 2023. "Virtual Commissioning of Distributed Systems in the Industrial Internet of Things" Sensors 23, no. 7: 3545. https://doi.org/10.3390/s23073545

APA StyleRosenberger, J., Selig, A., Ristic, M., Bühren, M., & Schramm, D. (2023). Virtual Commissioning of Distributed Systems in the Industrial Internet of Things. Sensors, 23(7), 3545. https://doi.org/10.3390/s23073545