Application of Multi-Channel Synchronized Dynamic Strain Gauges in Monitoring the Neutral Axis Position and Prestress Loss of Box Girder Bridges

Abstract

:1. Introduction

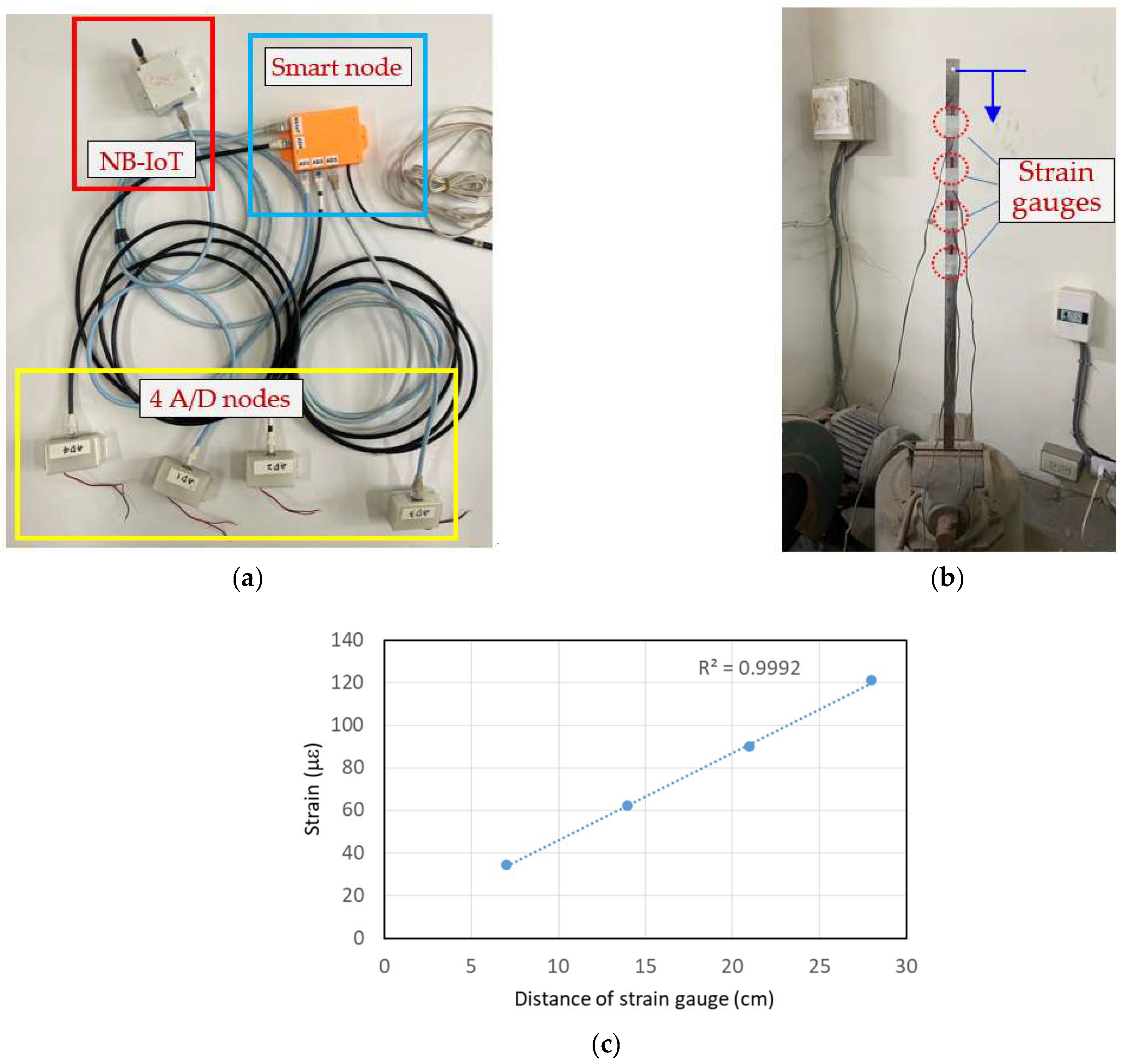

2. Laboratory Test

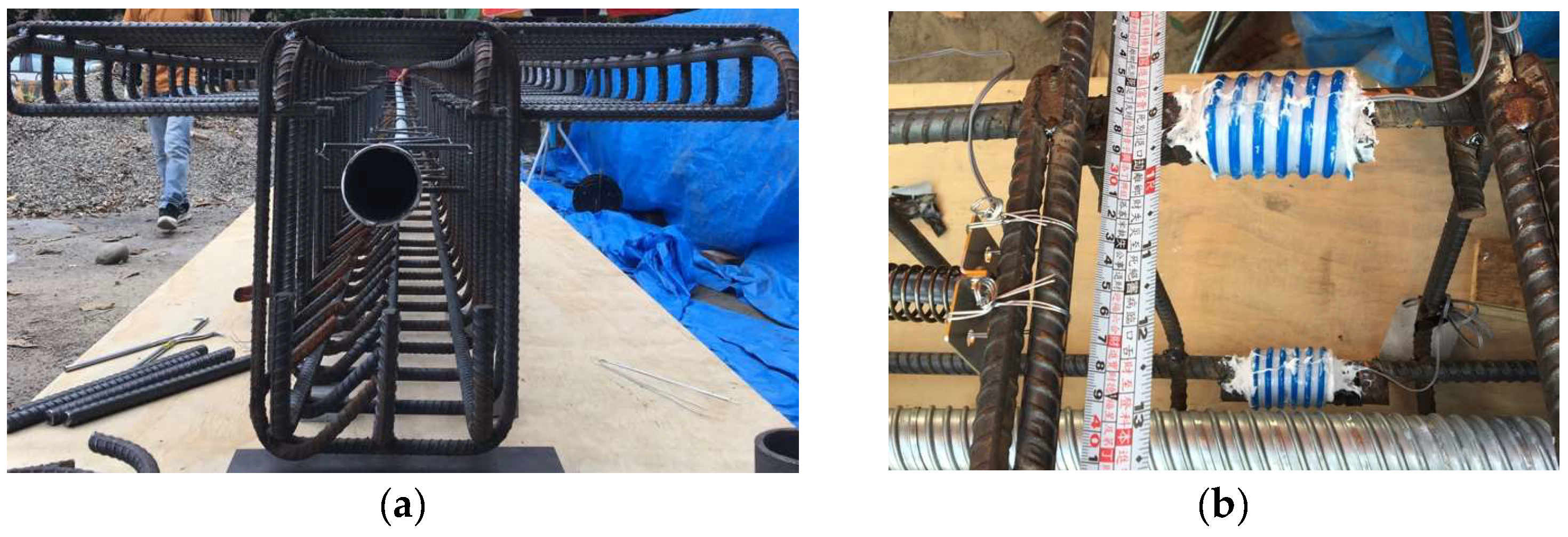

2.1. Description of the Specimen

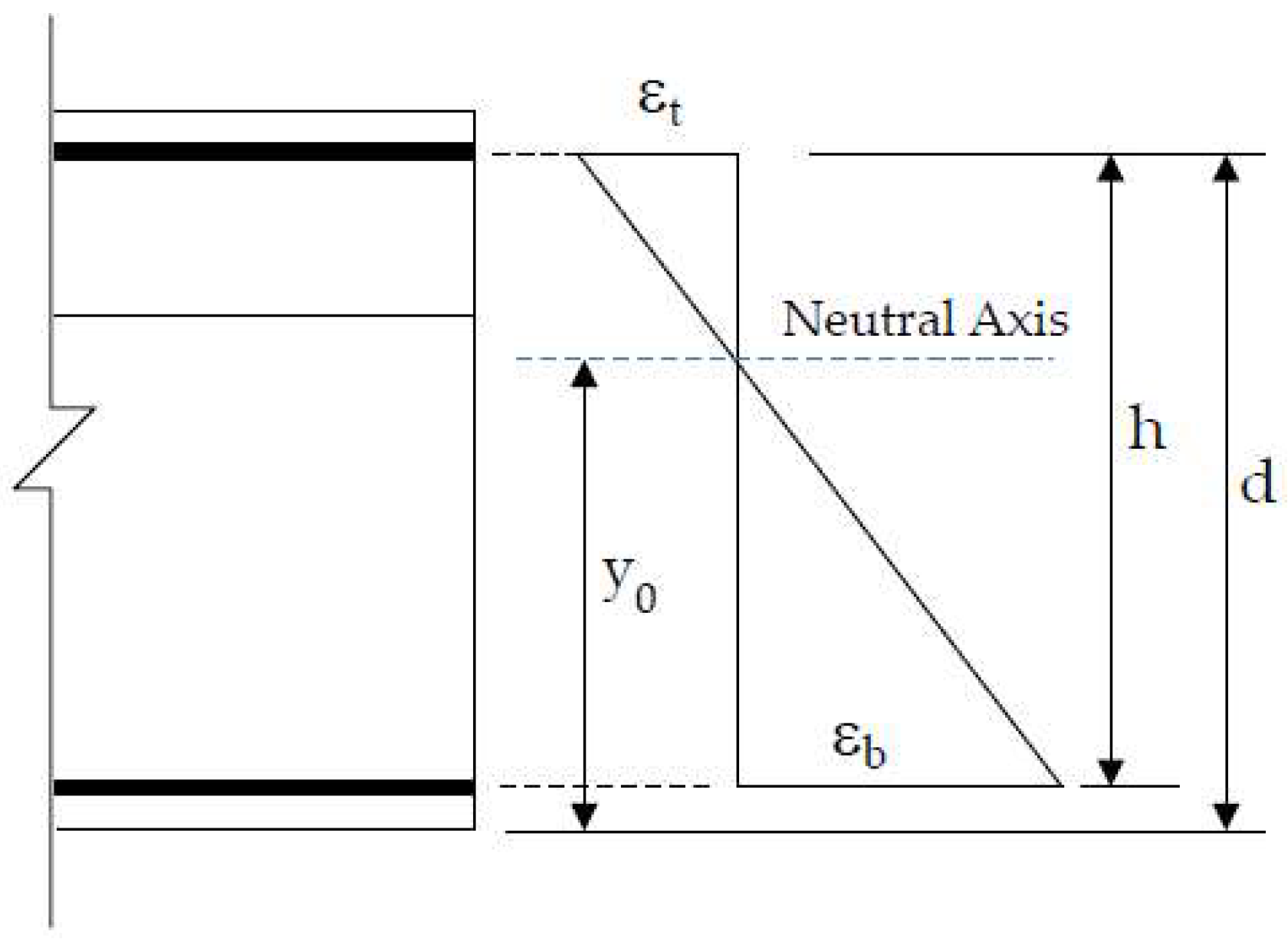

2.2. Effect of Prestress on N.A. Position

- : the distance from the bottom of the beam to the N.A.

- : the strains of the top and bottom layers of the reinforcement, respectively.

- h: the distance between the two strain gauges.

- d: the distance from the strain gauge on the top layer of the reinforcement to the bottom of the beam.

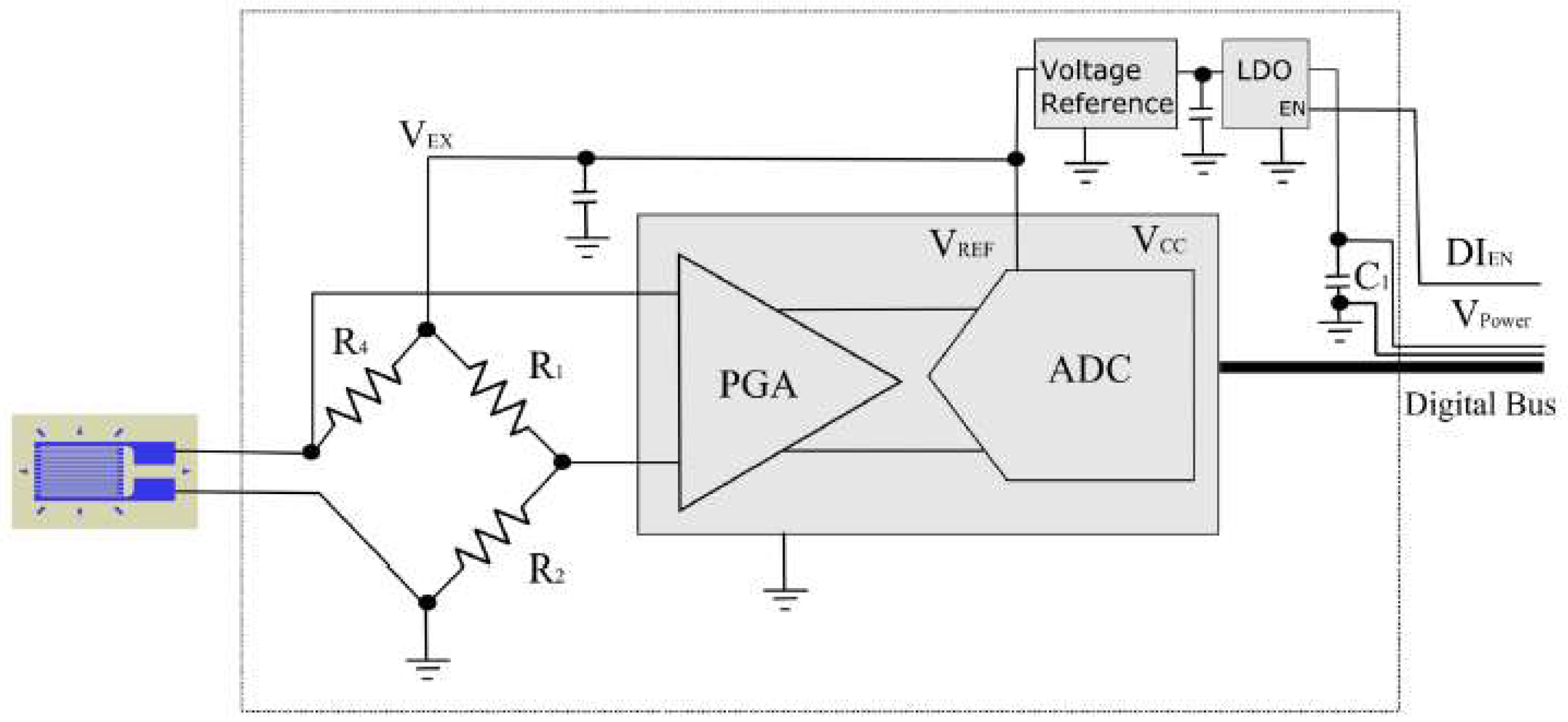

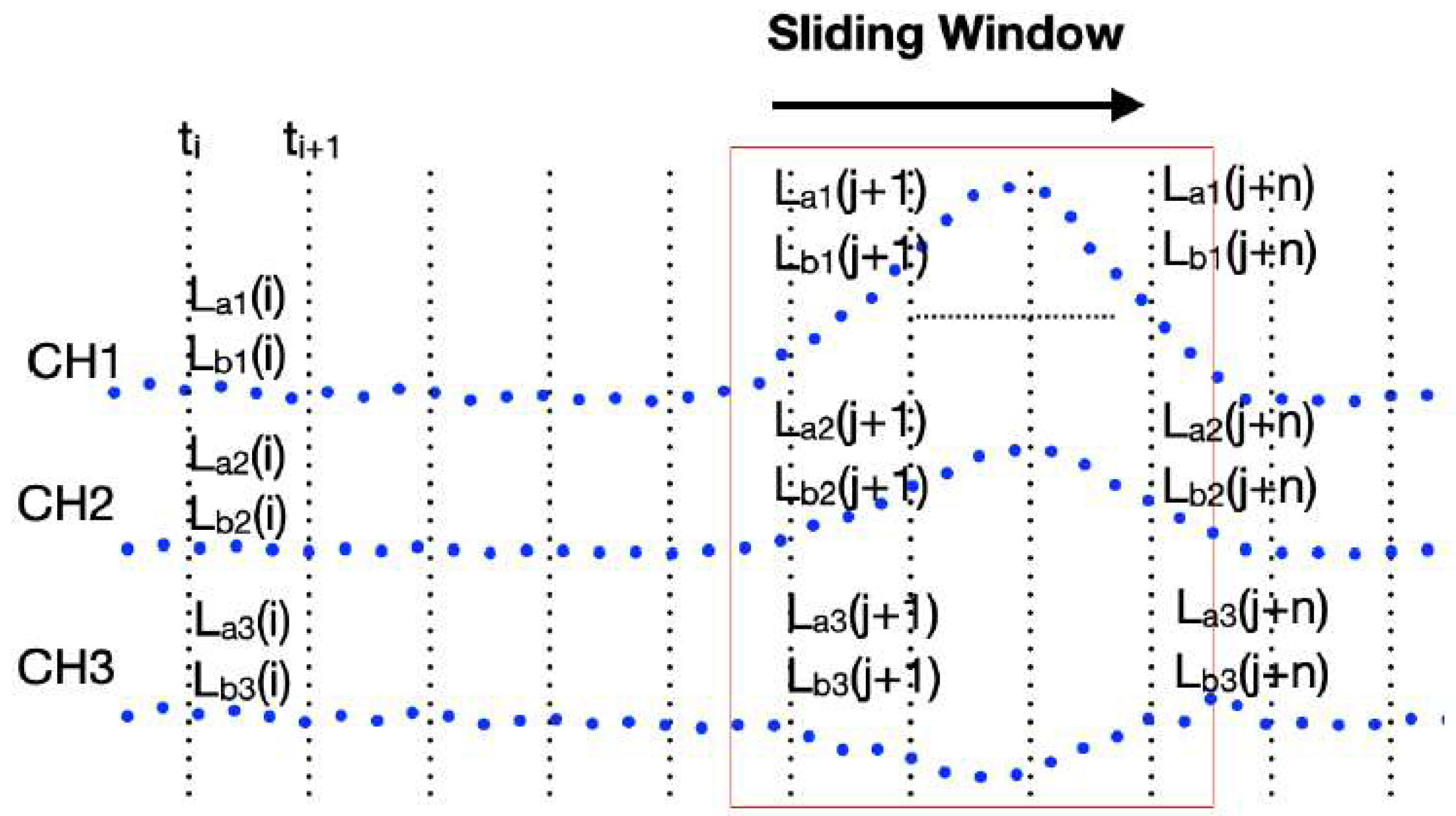

3. Edge Computing and Multi-Channel Synchronized Dynamic Strain Gauges

3.1. Edge Computing

3.2. Multi-Channel Synchronized Dynamic Strain Gauge

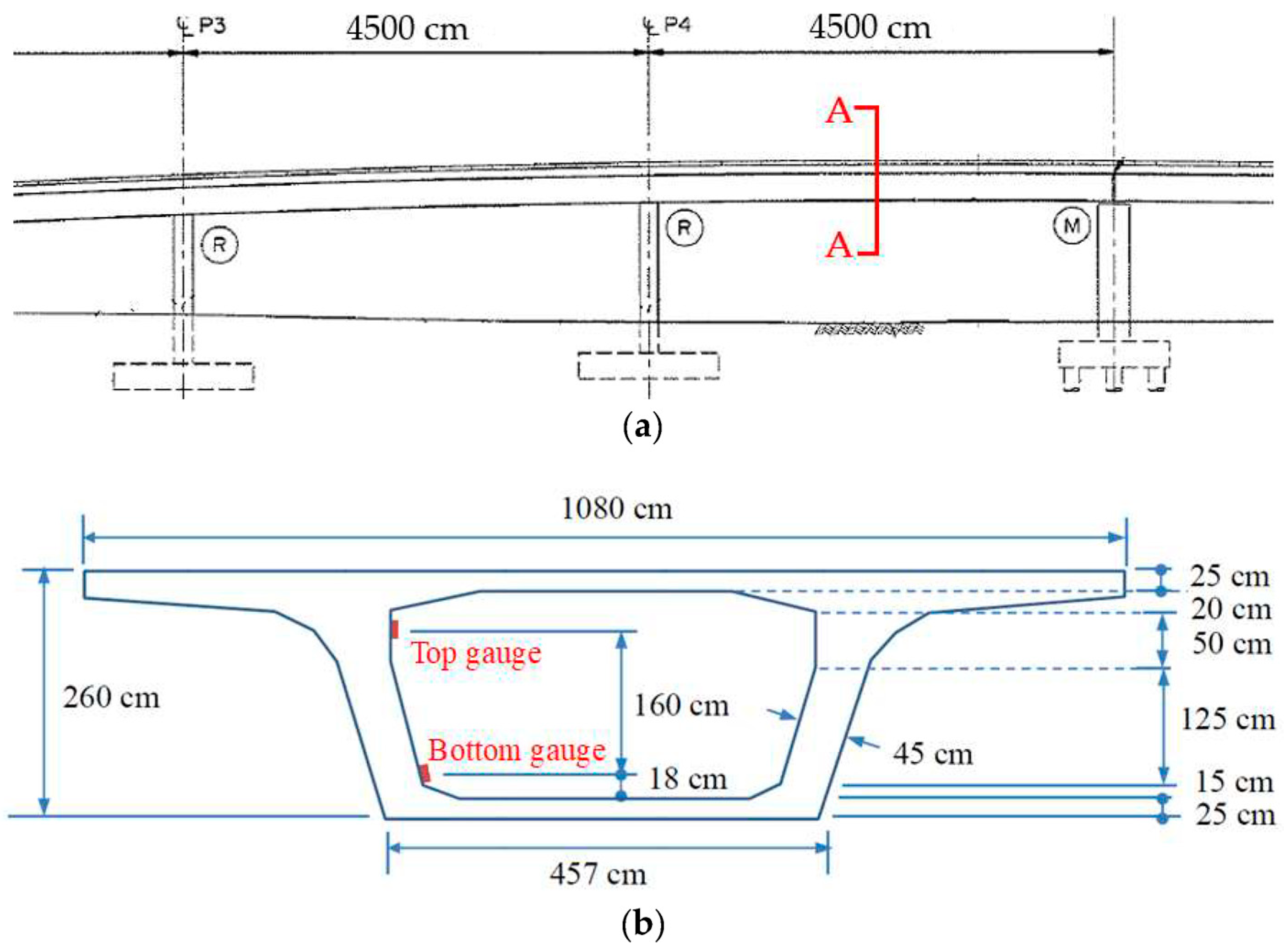

4. On-Site Application of Multi-Channel Synchronized Dynamic Strain Gauges

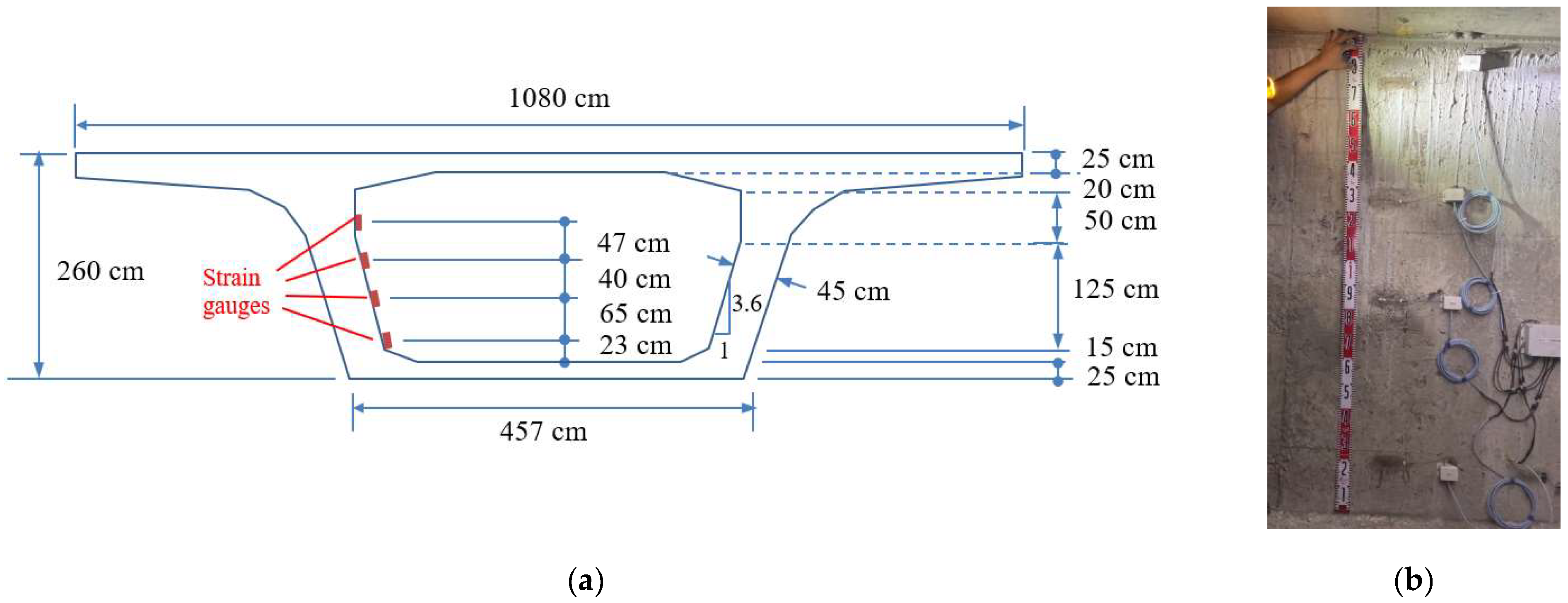

Description of the Prestressed Box-Girder Bridge

5. Conclusions

- The results of the laboratory test showed that the N.A. position tends to decrease with an increasing prestress force. In other words, if prestress loss occurs in the beam, an upward movement of the N.A. position should be observed.

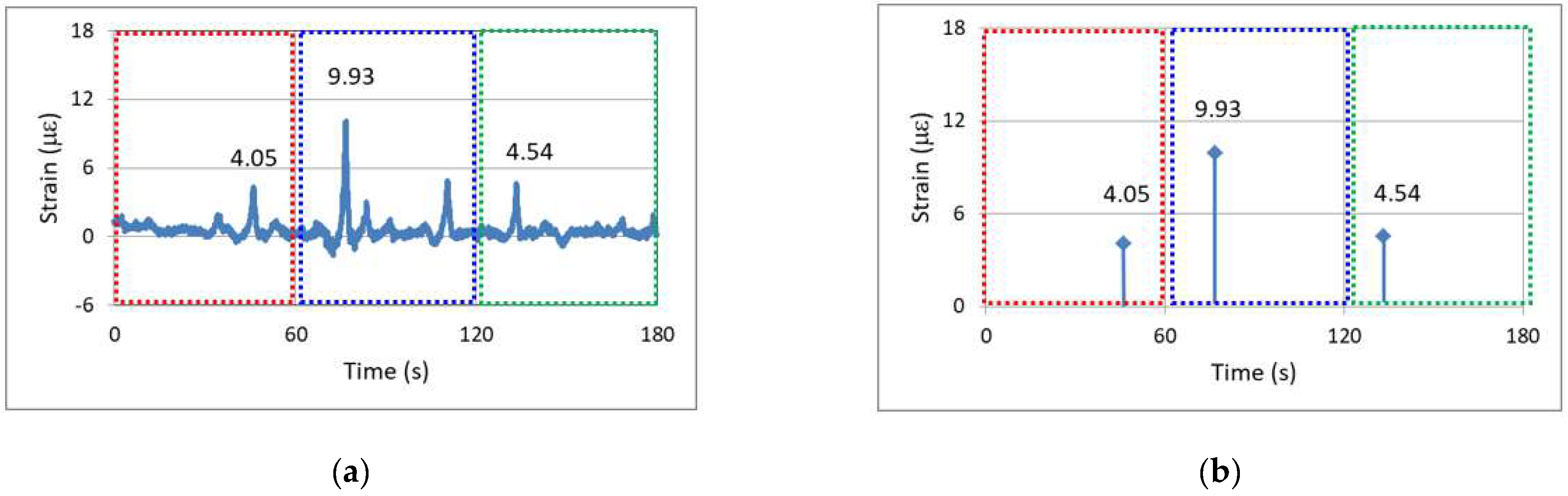

- The developed multi-channel synchronized dynamic strain gauges with edge computing can transmit only the key data every minute. These key data represent the maximum dynamic strain induced by the heaviest vehicle within that minute. This approach significantly enhances the monitoring efficiency and stability, allowing for the replacement of traditional computer-based monitoring systems with microcontroller systems in the field.

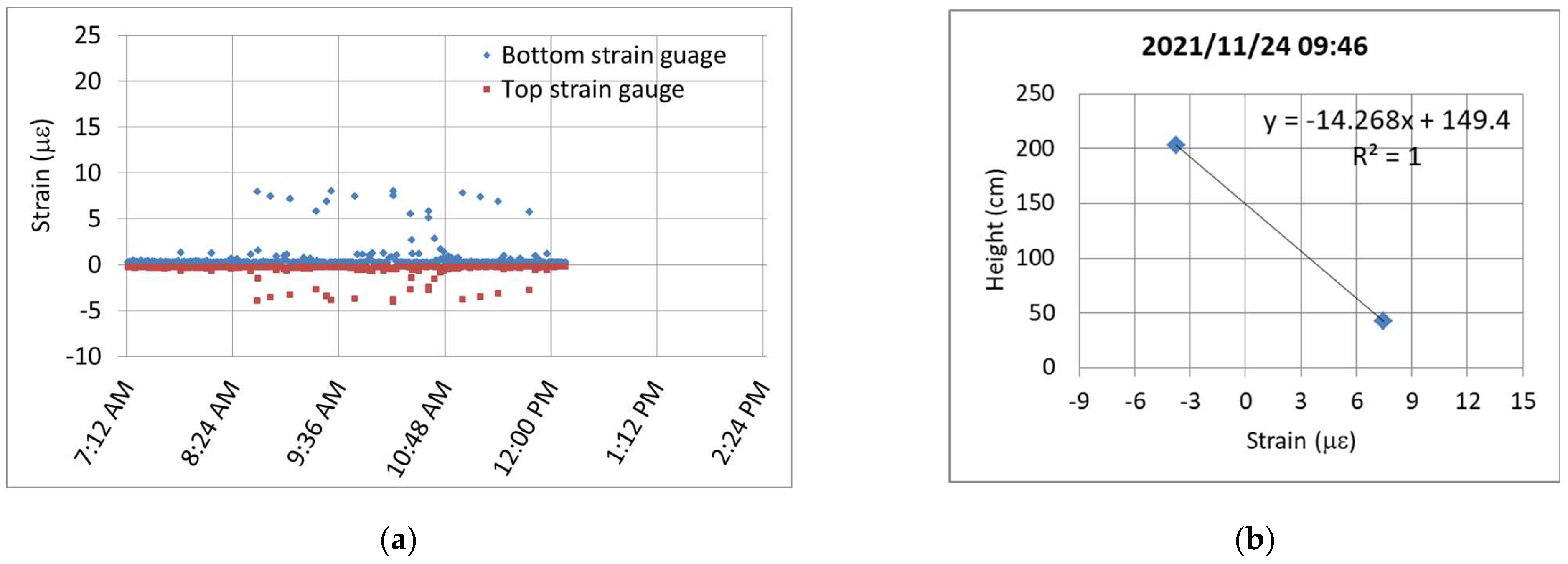

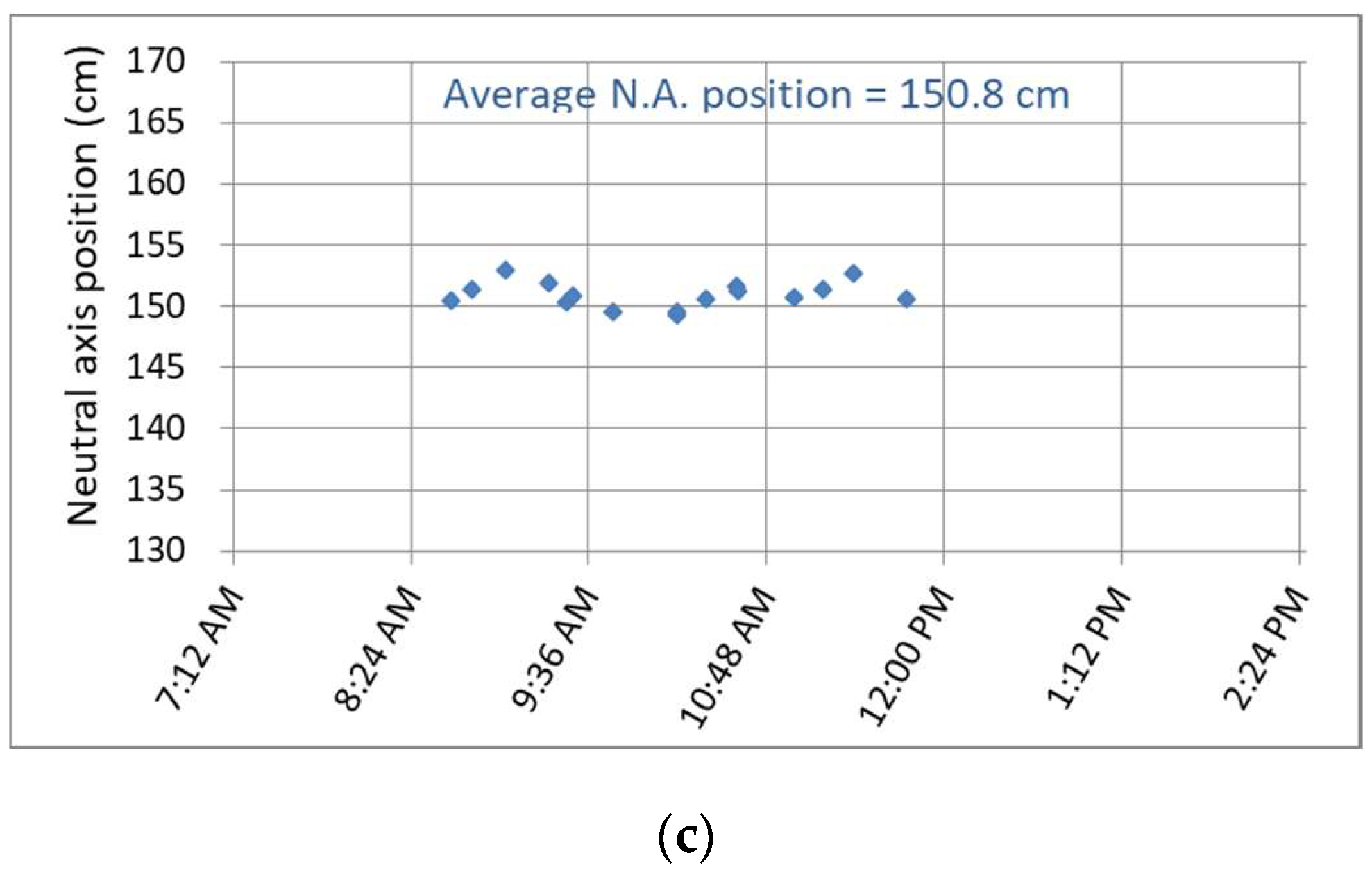

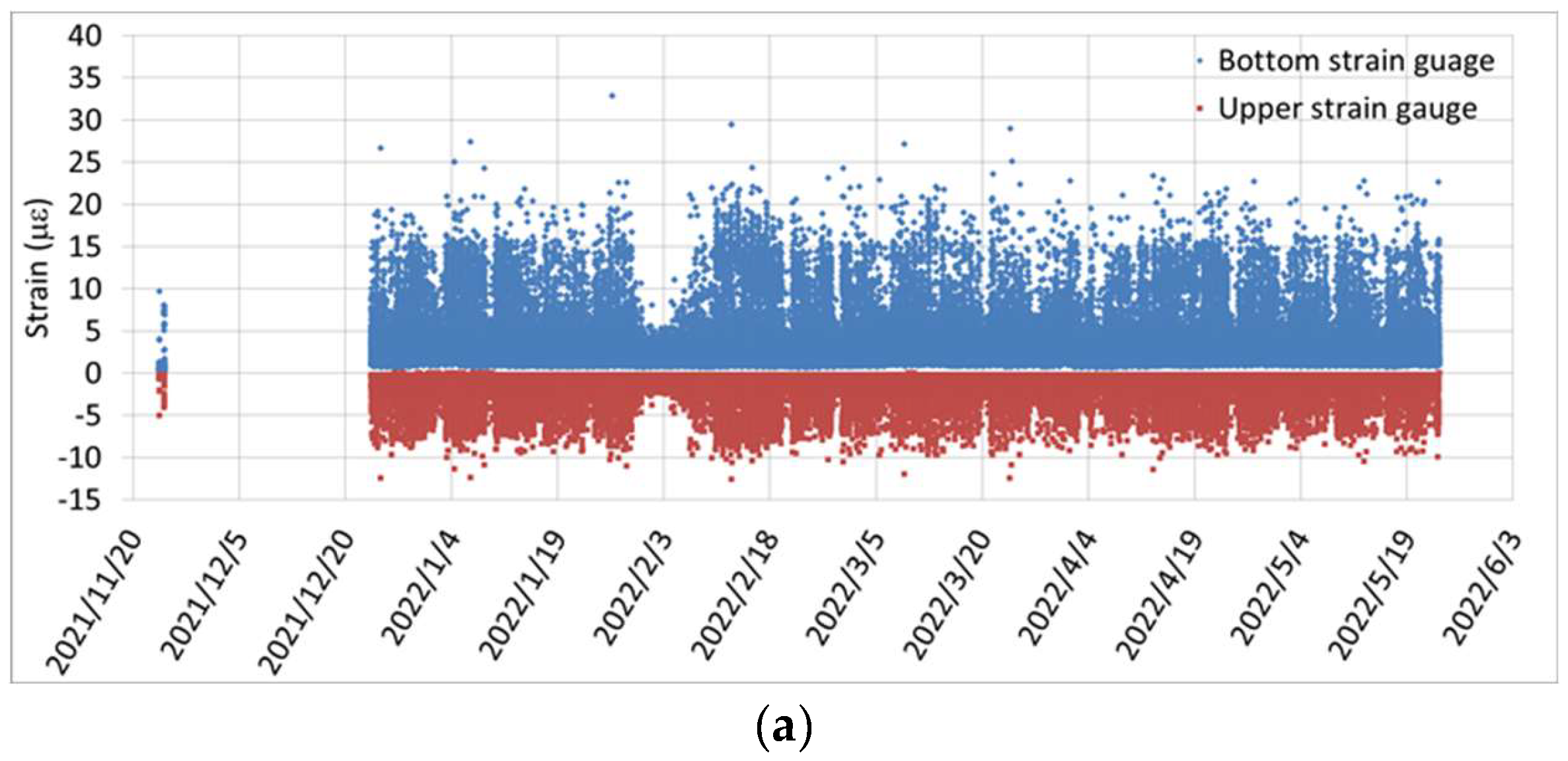

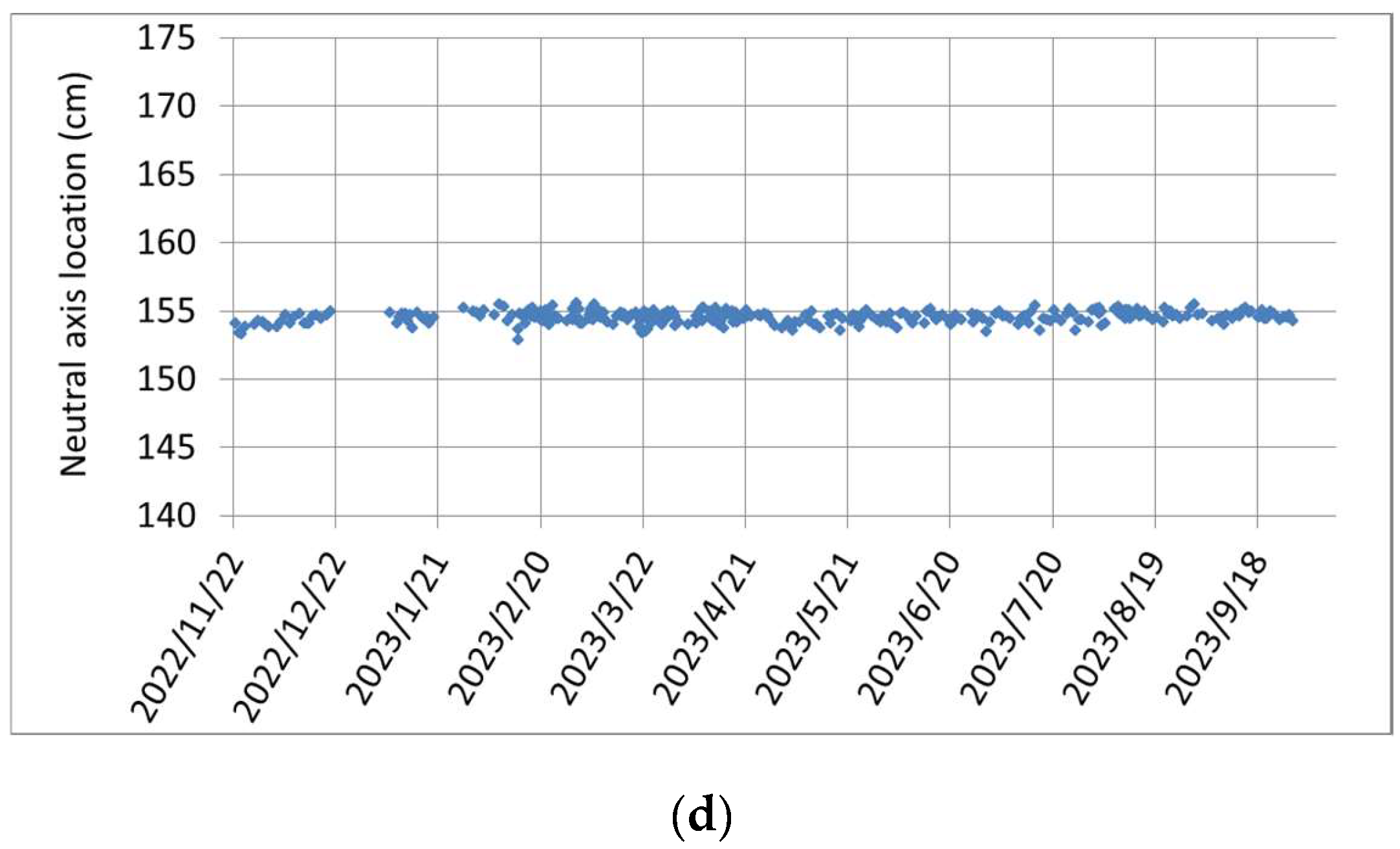

- Continuous monitoring data concerning the dual-channel synchronized dynamic strains depicts the tensile strains and compressive strains at the bottom and top strain gauges, respectively, when subjected to the loading of vehicles. The N.A. position can be obtained from the measured strain responses of the top and bottom strain gauges. The N.A. position fluctuates within a certain range over time. This phenomenon is attributed to the temperature gradient changes within the box girder.

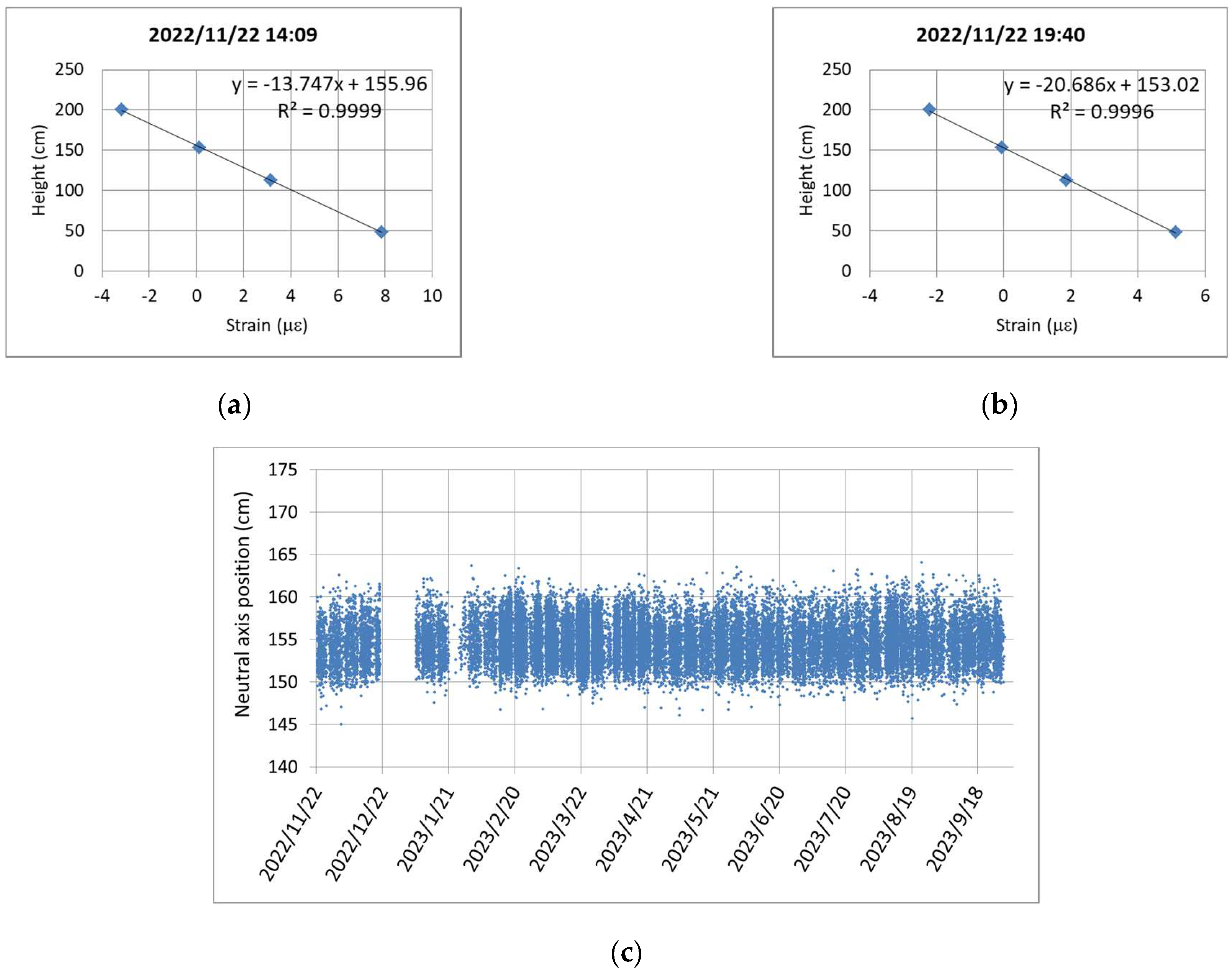

- Based on the on-site monitoring data, the measured N.A. position of the box girder is lower than the theoretical N.A. position, indicating a downward shift in the N.A. position due to the prestressing effect. Additionally, it is observed that the N.A. position is slowly moving upwards. This phenomenon confirms that shortly after the completion of the girder, there is a slow sustained loss of prestress due to significant concrete shrinkage and creep effects. This result aligns with that obtained from the laboratory experiment, which indicates that the N.A. position tends to move upward as the prestress decreases.

- This study utilized a newly developed four-channel synchronized dynamic strain gauges for on-site applications. The coefficient of determination (R-squared) for the linear regression equations of the four-channel strain data must be greater than 0.995 to be included in the calculation of the N.A. position. It is believed that the N.A. positions obtained from the four-channel strain gauge data are more reliable than those obtained from the two-channel strain gauge data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xia, Y.; Chen, B.; Weng, S.; Ni, Y.Q.; Xu, Y.L. Temperature effect on vibration properties of civil structures: A literature review and case studies. J. Civ. Struct. Heal. Monit. 2012, 2, 29–46. [Google Scholar] [CrossRef]

- Hu, W.H.; Said, S.; Rohrmann, R.G.; Cunha, A.; Teng, J. Continuous dynamic monitoring of a prestressed concrete bridge based on strain, inclination and crack measurements over a 14-year span. Struct. Health Monit. 2018, 17, 1073–1094. [Google Scholar] [CrossRef]

- Nandan, H.; Singh, M.P. Effects of thermal environment on structural frequencies: Part II—A system identification model. Eng. Struct. 2014, 81, 491–498. [Google Scholar] [CrossRef]

- Chen, C.; Kaloop, M.R.; Gao, Q.; Wang, Z. Environmental effects and output-only model identification of continuous bridge response. KSCE J. Civ. Eng. 2015, 19, 2198–2207. [Google Scholar] [CrossRef]

- Ge, Y.; Elshafie, M.Z.E.B.; Dirar, S.; Middleton, C.R. The response of embedded strain sensors in concrete beams subjected to thermal loading. Constr. Build. Mater. 2014, 70, 279–290. [Google Scholar] [CrossRef]

- Yang, K.; Ding, Y.; Sun, P.; Zhao, H.; Geng, F. Modeling of temperature time-lag effect for concrete box-girder bridges. Appl. Sci. 2019, 9, 3255. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, Y.T.; Chang, Y.W. An investigation of the temperature-drift effect on strain measurement of concrete beams. Appl. Sci. 2019, 9, 1662. [Google Scholar] [CrossRef]

- Newell, S.; Goggins, J. Investigation of thermal behaviour of a hybrid precasted concrete floor using embedded sensors. Int. J. Concr. Struct. 2018, 12, 66. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, Y.; Li, A.; Ren, Z.; Yang, K. Live-load strain evaluation of the prestressed concrete box-girder bridge using deep learning and clustering. Struct. Health Monit. 2020, 19, 1051–1063. [Google Scholar] [CrossRef]

- Ni, Y.; Chen, R. Strain monitoring based bridge reliability assessment using parametric Bayesian mixture model. Eng. Struct. 2021, 226, 111406. [Google Scholar] [CrossRef]

- Li, S.; Xu, H.; Zhang, X.; Cao, M.; Sumarac, D.; Novák, D. Automatic uncoupling of massive dynamic strains induced by vehicle- and temperature-loads for monitoring of operating bridges. Mech. Syst. Signal Process. 2022, 166, 108332. [Google Scholar] [CrossRef]

- Sigurdardottir, D.H.; Glisic, B. Neutral axis as damage sensitive feature. Smart Mater. Struct. 2013, 22, 075030. [Google Scholar] [CrossRef]

- Sigurdardottir, D.H.; Glisic, B. Detecting minute damage in beam-like structures using the neutral axis location. Smart Mater. Struct. 2014, 23, 125042. [Google Scholar] [CrossRef]

- Tang, Y.S.; Ren, Z.D. Dynamic method of neutral axis position determination and damage identification with distributed long-gauge fbg sensors. Sensors 2017, 17, 411. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Shen, Y.; Zou, Y.; Li, T.; Feng, X. Stiffness Degradation Characteristics Destructive Testing and Finite-Element Analysis of Prestressed Concrete T-beam. CMES-Comput. Model. Eng. Sci. 2018, 114, 75–93. [Google Scholar] [CrossRef]

- Parka, J.W.; Moonb, D.S.; Simc, S.H.; Spencer, B.F. Equivalent neutral axis for structural condition assessment using multisensory fusion. Eng. Struct. 2019, 197, 109350. [Google Scholar] [CrossRef]

- Suparp, S.; Sirisonthi, A.; Ali, N.; Saad, N.; Chaiyasarn, K.; Azab, M.; Joyklad, P.; Hussain, Q. Load versus Strain Relationships of Single and Continuous Span Full-Scale Pre-cast Prestressed Concrete Girders for Monorail Systems. Buildings 2022, 12, 1164. [Google Scholar] [CrossRef]

- Li, H.; Li, J.; Xin, Y.; Hao, H.; Le, T.D.; Pham, T.M. Prestress Force Monitoring and Quantification of Precast Segmental Beams through Neutral Axis Location Identification. Appl. Sci. 2022, 12, 2756. [Google Scholar] [CrossRef]

- Lin, Y.C.; Hsiao, C.Y.; Tong, J.H.; Liao, C.P.; Song, S.T.; Tsai, H.C.; Wang, J.-L. Application of Edge Computing in Structural Health Monitoring of Simply Supported PCI Girder Bridges. Sensors 2022, 22, 8711. [Google Scholar] [CrossRef]

- Wu, G.M.; Li, S.L.; Yi, T.H.; Mei, X.D.; Wang, Y.F. Theoretically thermal-varying models of the neutral axis position for local damage detection of bridge girders. Eng. Struct. 2023, 279, 11563. [Google Scholar] [CrossRef]

- Anastasopoulos, D.; Roeck, G.D.; Reynders, P.B. Influence of damage versus temperature on modal strains and neutral axis positions of girder-like structures. Mech. Syst. Signal Process. 2019, 134, 106311. [Google Scholar] [CrossRef]

| εt (με) | εb (με) | N.A. Position (cm) | |

|---|---|---|---|

| Loading 500 kgf | −12.32 | 23.16 | 28.37 |

| Loading 500 kgf | −11.89 | 24.34 | 29.04 |

| Unloading 500 kgf | 12.60 | −22.92 | 28.11 |

| Unloading 500 kgf | 13.52 | −24.35 | 28.03 |

| Average | 28.39 | ||

| Prestress Force (tf) | Loading Case | εt (με) | εb (με) | N.A. Position (cm) |

|---|---|---|---|---|

| 8.13 | Loading 500 kgf | −13.15 | 27.11 | 29.07 |

| Unloading 500 kgf | 12.59 | −24.33 | 28.58 | |

| 12.23 | Loading 500 kgf | −12.84 | 25.11 | 28.67 |

| Unloading 500 kgf | 12.75 | −23.79 | 28.31 | |

| 23.87 | Loading 500 kgf | −11.53 | 20.49 | 27.93 |

| Unloading 500 kgf | 11.55 | −20.51 | 27.92 | |

| 27.57 | Loading 500 kgf | −11.39 | 21.73 | 28.48 |

| Unloading 500 kgf | 11.19 | −20.10 | 28.01 | |

| 33.33 | Loading 500 kgf | −11.06 | 18.64 | 27.49 |

| Unloading 500 kgf | 10.77 | −18.44 | 27.62 | |

| 44.52 | Loading 500 kgf | −10.09 | 16.58 | 27.29 |

| Unloading 500 kgf | 10.16 | −16.22 | 27.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.-K.; Lin, Y.-C.; Tong, J.-H.; Cheng, H.-T.; Tsai, H.-C.; Wang, J.-L. Application of Multi-Channel Synchronized Dynamic Strain Gauges in Monitoring the Neutral Axis Position and Prestress Loss of Box Girder Bridges. Sensors 2024, 24, 3489. https://doi.org/10.3390/s24113489

Lin S-K, Lin Y-C, Tong J-H, Cheng H-T, Tsai H-C, Wang J-L. Application of Multi-Channel Synchronized Dynamic Strain Gauges in Monitoring the Neutral Axis Position and Prestress Loss of Box Girder Bridges. Sensors. 2024; 24(11):3489. https://doi.org/10.3390/s24113489

Chicago/Turabian StyleLin, Shu-Ken, Yi-Ching Lin, Jian-Hua Tong, Han-Ting Cheng, Hsin-Chu Tsai, and Jui-Lin Wang. 2024. "Application of Multi-Channel Synchronized Dynamic Strain Gauges in Monitoring the Neutral Axis Position and Prestress Loss of Box Girder Bridges" Sensors 24, no. 11: 3489. https://doi.org/10.3390/s24113489