A Method for Sensing Dielectric Properties of Thin and Flexible Conductive Biocomposites

Abstract

:1. Introduction

2. Foundations and Materials

2.1. Microwave Reflectometry and Dielectric Properties

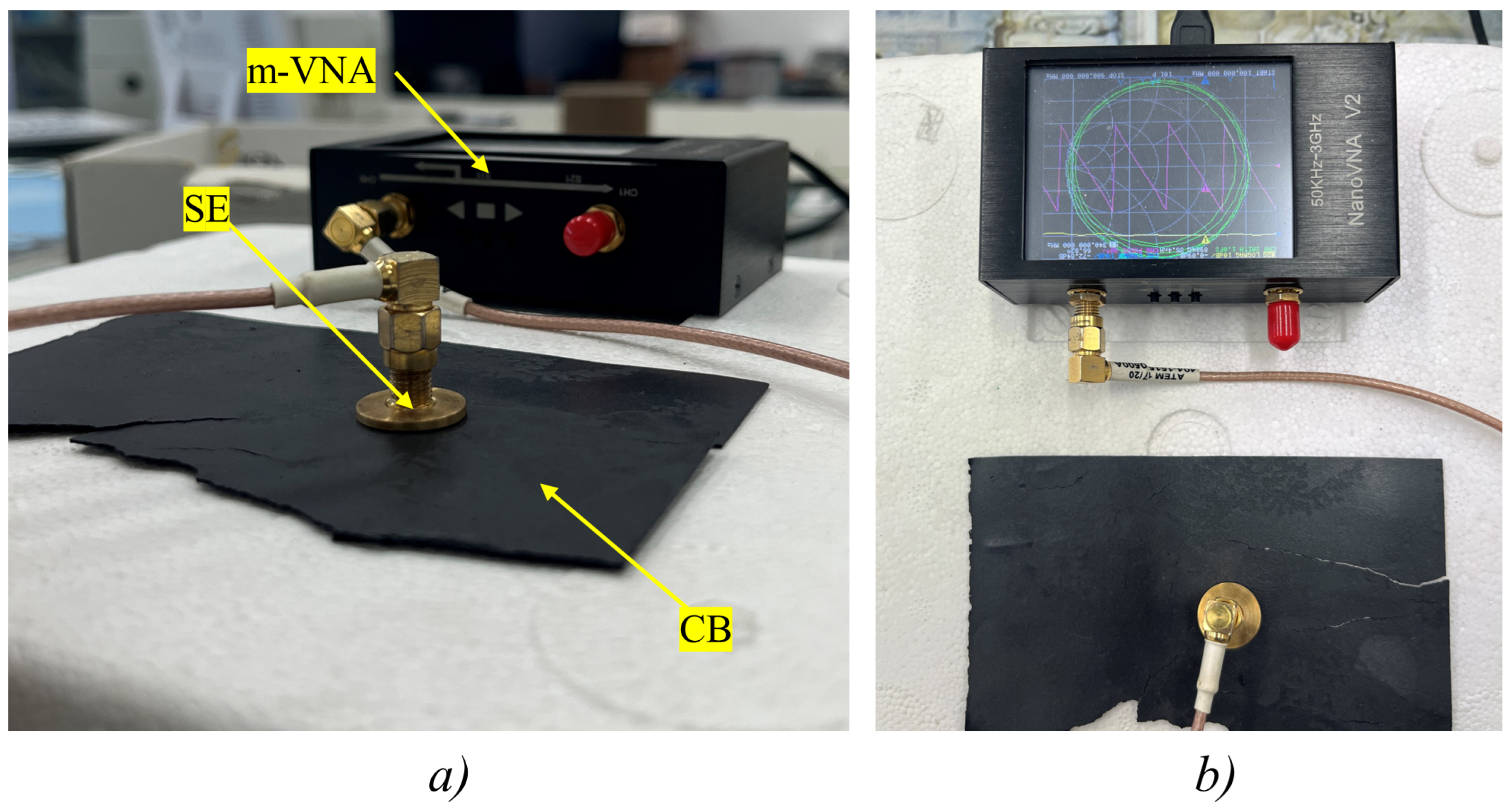

2.2. Experimental Setup

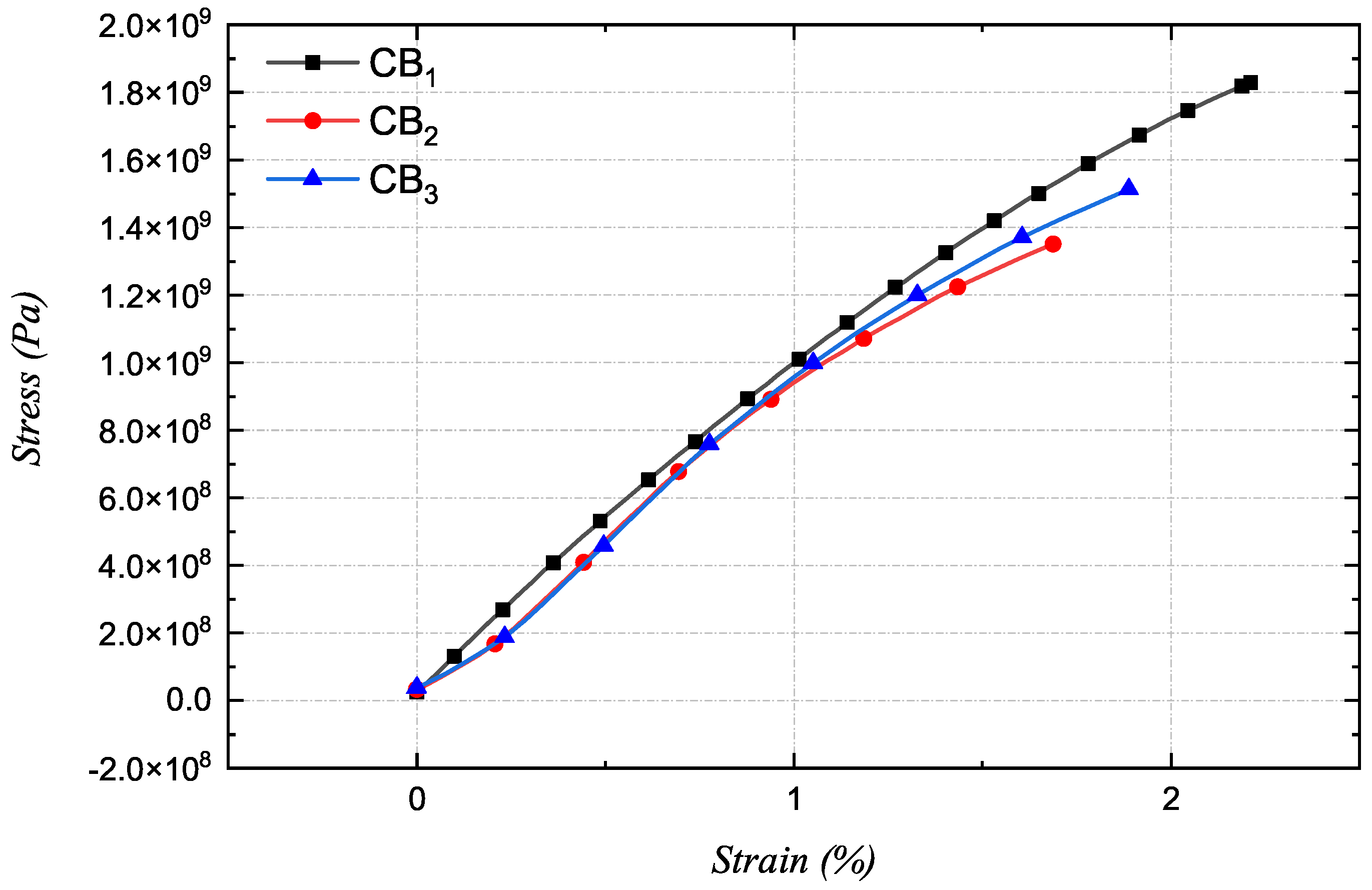

2.3. Conductive Biocomposites

3. Proposed Method

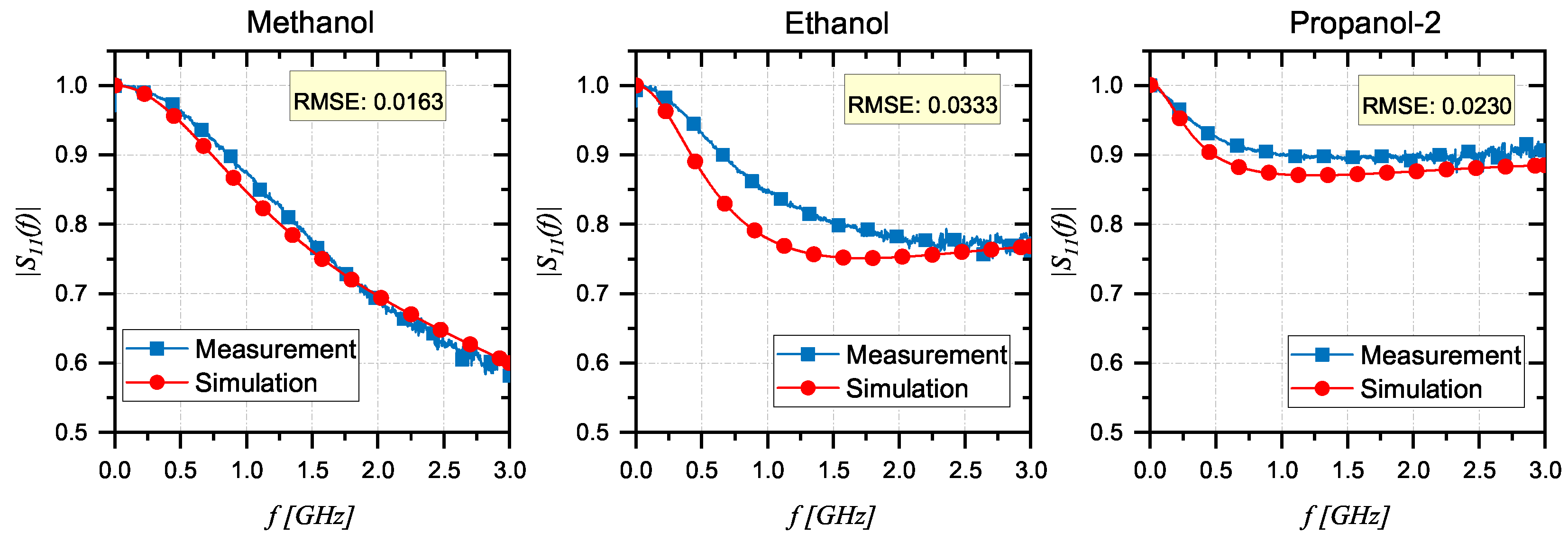

3.1. Preliminary Optimization on Reference Dielectric Samples

3.2. Final Dielectric Permittivity Estimation

- (a)

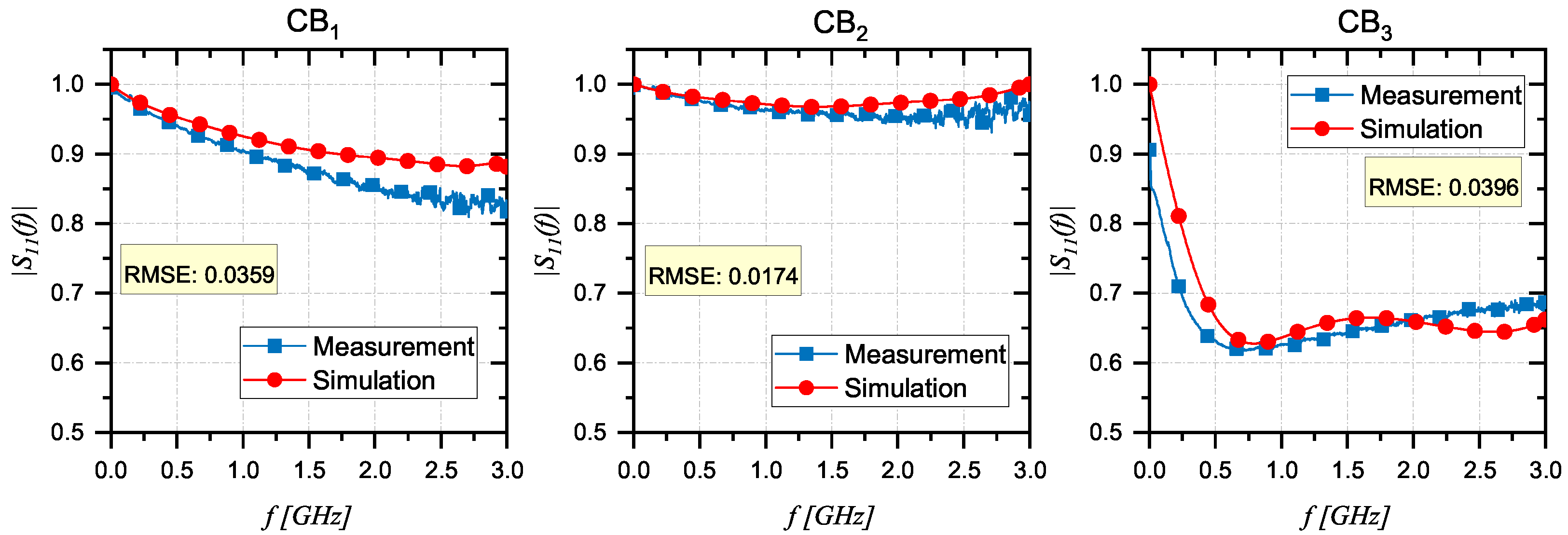

- Reflectometric measurement: the procedure initiates by conducting a reflectometric measurement on the CB under test. This involves using the developed experimental setup to measure how much of an EM signal is reflected by the CB in terms of .

- (b)

- Minimization procedure: the empirical data collected from the reflectometric measurement are then input into the EM simulator and serve as a target point for the simulation. The main goal here is to reduce the discrepancy between the simulated reflection scattering parameter, denoted as and the actual measured value, . To accomplish this, the procedure lies in fine-tuning the dielectric parameters within the EM simulator until a satisfactory match between the simulation and measurement is obtained. Specifically, discrete points of and were carefully selected to minimize computational resources without risking loss of information. Subsequently, these values were parameterized and subjected to an iterative process that continued until the difference between the simulation and measurement fell within an acceptable range.

- (c)

- Extrapolation of dielectric properties: after the simulation results closely mirror the empirical measurements, the adjusted dielectric properties within the simulation are considered to reflect the real properties of the CB under test. After achieving a good match, the next step involved interpolating the values of and . This interpolation is used to reconstruct the frequency-dependent trend of both the real and imaginary parts of the permittivity.

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of open access journals |

| CBs | Conductive biocomposites |

| MR | Microwave Reflectometry |

| m-VNA | Miniaturized Vector Network Analyzer |

| SE | Sensing element |

| MUT | Material under test |

| EM | Electromagnetic |

| EC | Ethyl cellulose |

| CF | Carbon fiber |

| EG | Expanded graphite |

| EIS | Electrical impedance spectroscopy |

| spm | Scanning probe microscopy (SPM) |

| AFM | Atomic force microscopy (AFM) |

| DSC | Differential Scanning Calorimetry |

| TGA | Thermogravimetric Analysis |

References

- Yaashikaa, P.; Senthil Kumar, P.; Karishma, S. Review on biopolymers and composites—Evolving material as adsorbents in removal of environmental pollutants. Environ. Res. 2022, 212, 113114. [Google Scholar] [CrossRef] [PubMed]

- Nagalakshmaiah, M.; Afrin, S.; Malladi, R.P.; Elkoun, S.; Robert, M.; Ansari, M.A.; Svedberg, A.; Karim, Z. Chapter 9—Biocomposites: Present trends and challenges for the future. In Green Composites for Automotive Applications; Koronis, G., Silva, A., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2019; pp. 197–215. [Google Scholar] [CrossRef]

- Mekonnen, T.; Misra, M.; Mohanty, A. Processing, performance, and applications of plant and animal protein-based blends and their biocomposites. In Biocomposites; Misra, M., Pandey, J.K., Mohanty, A.K., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2015; pp. 201–235. [Google Scholar] [CrossRef]

- Kundu, A.; Nandi, S.; Nandi, A.K. Nucleic acid based polymer and nanoparticle conjugates: Synthesis, properties and applications. Prog. Mater. Sci. 2017, 88, 136–185. [Google Scholar] [CrossRef]

- Chivrac, F.; Pollet, E.; Avérous, L. Progress in nano-biocomposites based on polysaccharides and nanoclays. Mater. Sci. Eng. R. Rep. 2009, 67, 1–17. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Avérous, L. Cellulose-based biocomposites: Comparison of different multiphasic systems. Compos. Interfaces 2007, 14, 787–805. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Vilaplana, F.; Strömberg, E.; Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010, 95, 2147–2161. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Al Mahmud, M.Z. Exploring the versatile applications of biocomposites in the medical field. Bioprinting 2023, 36, e00319. [Google Scholar] [CrossRef]

- Xie, H.; Cao, T.; Rodríguez-Lozano, F.J.; Luong-Van, E.K.; Rosa, V. Graphene for the development of the next-generation of biocomposites for dental and medical applications. Dent. Mater. 2017, 33, 765–774. [Google Scholar] [CrossRef]

- Gupta, I.; Cherwoo, L.; Bhatia, R.; Setia, H. Biopolymers: Implications and application in the food industry. Biocatal. Agric. Biotechnol. 2022, 46, 102534. [Google Scholar] [CrossRef]

- Rebelo, R.; Fernandes, M.; Fangueiro, R. Biopolymers in Medical Implants: A Brief Review. Procedia Eng. 2017, 200, 236–243. [Google Scholar] [CrossRef]

- Opriș, O.; Mormile, C.; Lung, I.; Stegarescu, A.; Soran, M.L.; Soran, A. An Overview of Biopolymers for Drug Delivery Applications. Appl. Sci. 2024, 14, 1383. [Google Scholar] [CrossRef]

- Li, X.; Yang, Y.; Fan, Y.; Feng, Q.; Cui, F.z.; Watari, F. Biocomposites reinforced by fibers or tubes as scaffolds for tissue engineering or regenerative medicine. J. Biomed. Mater. Res. Part A 2014, 102, 1580–1594. [Google Scholar] [CrossRef] [PubMed]

- Zarrintaj, P.; Seidi, F.; Youssefi Azarfam, M.; Khodadadi Yazdi, M.; Erfani, A.; Barani, M.; Chauhan, N.P.S.; Rabiee, N.; Kuang, T.; Kucinska-Lipka, J.; et al. Biopolymer-based composites for tissue engineering applications: A basis for future opportunities. Compos. Part B Eng. 2023, 258, 110701. [Google Scholar] [CrossRef]

- Dumont, V.C.; Mansur, H.S.; Mansur, A.A.; Carvalho, S.M.; Capanema, N.S.; Barrioni, B.R. Glycol chitosan/nanohydroxyapatite biocomposites for potential bone tissue engineering and regenerative medicine. Int. J. Biol. Macromol. 2016, 93, 1465–1478. [Google Scholar] [CrossRef] [PubMed]

- Fabra, M.; López-Rubio, A.; Lagaron, J. Biopolymers for food packaging applications. In Smart Polymers and Their Applications; Aguilar, M.R., San Román, J., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 476–509. [Google Scholar] [CrossRef]

- Unterweger, C.; Ranzinger, M.; Duchoslav, J.; Piana, F.; Pasti, I.; Zeppetzauer, F.; Breitenbach, S.; Stifter, D.; Fürst, C. Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers. J. Compos. Sci. 2022, 6, 228. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.J.; Dhakal, H. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Kamble, M.; Kulsange, B.; Salame, P.H. Bio-based Materials in Bioelectronics. In Biobased Materials: Recent Developments and Industrial Applications; Mishra, A.K., Hussain, C.M., Eds.; Springer Nature: Singapore, 2023; pp. 55–119. [Google Scholar] [CrossRef]

- Banitaba, S.N.; Khademolqorani, S.; Jadhav, V.V.; Chamanehpour, E.; Mishra, Y.K.; Mostafavi, E.; Kaushik, A. Recent progress of bio-based smart wearable sensors for healthcare applications. Mater. Today Electron. 2023, 5, 100055. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Wu, Q.; Rabu, J.; Goulin, K.; Sainlaud, C.; Chen, F.; Johansson, E.; Olsson, R.; Hedenqvist, M. Flexible strength-improved and crack-resistant biocomposites based on plasticised wheat gluten reinforced with a flax-fibre-weave. Compos. Part A Appl. Sci. Manuf. 2017, 94, 61–69. [Google Scholar] [CrossRef]

- Awuzie, C. Conducting Polymers. Mater. Today Proc. 2017, 4, 5721–5726. [Google Scholar] [CrossRef]

- Le, T.-H.; Kim, Y.; Yoon, H. Electrical and Electrochemical Properties of Conducting Polymers. Polymers 2017, 9, 150. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, A.; Friuli, M.; Sannino, A.; Demitri, C.; Lamanna, L. Green synthesis of stretchable ethyl cellulose film plasticized with transesterified sunflower oil. Carbohydr. Polym. Technol. Appl. 2023, 6, 100378. [Google Scholar] [CrossRef]

- Ates, M. Review study of electrochemical impedance spectroscopy and equivalent electrical circuits of conducting polymers on carbon surfaces. Prog. Org. Coatings 2011, 71, 1–10. [Google Scholar] [CrossRef]

- Marti, O.; Stifter, T.; Waschipky, H.; Quintus, M.; Hild, S. Scanning probe microscopy of heterogeneous polymers. Colloids Surfaces A Physicochem. Eng. Asp. 1999, 154, 65–73. [Google Scholar] [CrossRef]

- Marinello, F.; Pezzuolo, A.; Passeri, D.; Storia, A.L.; Mauriello, G. Scanning Probe Microscopy for polymer film characterization in food packaging. IOP Conf. Ser. Earth Environ. Sci. 2019, 275, 012009. [Google Scholar] [CrossRef]

- Joshi, J.; Homburg, S.V.; Ehrmann, A. Atomic Force Microscopy (AFM) on Biopolymers and Hydrogels for Biotechnological Applications—Possibilities and Limits. Polymers 2022, 14, 1267. [Google Scholar] [CrossRef] [PubMed]

- Trinh, B.M.; Ogunsona, E.O.; Mekonnen, T.H. Thin-structured and compostable wood fiber-polymer biocomposites: Fabrication and performance evaluation. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106150. [Google Scholar] [CrossRef]

- Macchioni, N.; Mannucci, M.; Olmi, R.; Palanti, S.; Riminesi, C. Microwave Reflectometric Tool for Non-Destructive Assessment of Decay on Timber Structures. Adv. Mater. Res. 2013, 778, 281–288. [Google Scholar] [CrossRef]

- Fang, Y.; Yang, X.; Chen, H.; Chen, Z.; Wang, R.; Li, Y.; Xie, S. Non-destructive quantitative evaluation of delamination depth and thickness in GFRP using microwave reflectometry. NDT E Int. 2024, 144, 103065. [Google Scholar] [CrossRef]

- Mehta, P.; Chand, K.; Narayanswamy, D.; Beetner, D.; Zoughi, R.; Stoecker, W. Microwave reflectometry as a novel diagnostic tool for detection of skin cancers. IEEE Trans. Instrum. Meas. 2006, 55, 1309–1316. [Google Scholar] [CrossRef]

- Schiavoni, R.; Maietta, G.; Filieri, E.; Masciullo, A.; Cataldo, A. Microwave Reflectometry Sensing System for Low-Cost in-vivo Skin Cancer Diagnostics. IEEE Access 2023, 11, 13918–13928. [Google Scholar] [CrossRef]

- Gao, Y.; Zoughi, R. Millimeter reflectometry as an effective diagnosis tool for skin burn injuries. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Taipei, Taiwan, 23–26 May 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Cataldo, A.; Farhat, I.; Farrugia, L.; Persico, R.; Schiavoni, R. A Method for Extracting Debye Parameters as a Tool for Monitoring Watered and Contaminated Soils. Sensors 2022, 22, 7805. [Google Scholar] [CrossRef]

- Sadeghi, A.M.; Hancock, G.D.; Waite, W.P.; Scott, H.D.; Rand, J.A. Microwave Measurements of Moisture Distributions in the Upper Soil Profile. Water Resour. Res. 1984, 20, 927–934. [Google Scholar] [CrossRef]

- Cataldo, A.; de Benedetto, E.; Schiavoni, R.; Tedesco, A.; Masciullo, A.; Cannazza, G. Microwave reflectometric systems and monitoring apparatus for diffused-sensing applications. Acta IMEKO 2021, 10, 202–208. [Google Scholar] [CrossRef]

- Clarke, R.N.; Gregory, A.P.; Cannell, D.; Patrick, M.; Wylie, S.; Youngs, I.; Hill, G. A Guide to the Characterisation of Dielectric Materials at RF and Microwave Frequencies; Institute of Measurement and Control/National Physical Laboratory: Teddington, UK, 2003.

- David, M.; Feldman, Y.; Ishai, P.B. Dielectric spectroscopy and techniques. In Non-Destructive Material Characterization Methods; Elsevier: Amsterdam, The Netherlands, 2024; pp. 587–619. [Google Scholar]

- Lamanna, L.; Pace, G.; Ilic, I.K.; Cataldi, P.; Viola, F.; Friuli, M.; Galli, V.; Demitri, C.; Caironi, M. Edible cellulose-based conductive composites for triboelectric nanogenerators and supercapacitors. Nano Energy 2023, 108, 108168. [Google Scholar] [CrossRef]

- Gregory, A.P.; Clarke, R.N. Tables of the Complex Permittivity of Dielectric Reference Liquids at Frequencies up to 5 GHz; Revised January 2012, Technical Report MAT 23; National Physical Laboratory: Teddington, UK, 2012.

- Hadi, J.M.; Aziz, S.B.; Abdulwahid, R.T.; Brza, M.A.; Tahir, H.B.; Hamad, S.M.; Shamsuri, N.A.; Woo, H.J.; Alias, Y.; Hamsan, M.H.; et al. Characterizing sodium-conducting biopolymer blend electrolytes with glycerol plasticizer for EDLC application. Ionics 2024, 30, 2409–2423. [Google Scholar] [CrossRef]

- Joshi, J.S.; Langwald, S.V.; Ehrmann, A.; Sabantina, L. Algae-Based Biopolymers for Batteries and Biofuel Applications in Comparison with Bacterial Biopolymers—A Review. Polymers 2024, 16, 610. [Google Scholar] [CrossRef]

- Ghozali, M.; Triwulandari, E.; Restu, W.K. Biopolymers in Electronics. In Biopolymers: Recent Updates, Challenges and Opportunities; Nadda, A.K., Sharma, S., Bhat, R., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 289–321. [Google Scholar] [CrossRef]

- Talaniuk, V.; Godzierz, M.; Iurhenko, M.; Sikorska, W.; Adamus, G.; Kobyliukh, A.; Szeluga, U. Conductive polymer biocomposites based on poly(3-hydroxybutyrate) and poly(butylene adipate-co-terephthalate) with various graphene fillers for thermistor applications. J. Therm. Anal. Calorim. 2024, 149, 2593–2607. [Google Scholar] [CrossRef]

- Tekoglu, S.; Wielend, D.; Scharber, M.C.; Sariciftci, N.S.; Yumusak, C. Conducting Polymer-Based Biocomposites Using Deoxyribonucleic Acid (DNA) as Counterion. Adv. Mater. Technol. 2020, 5, 1900699. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 31, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Tamjid, E.; Najafi, P.; Khalili, M.A. Shokouhnejad, N.; karimi, M.; Sepahdoost, N. Review of sustainable, eco-friendly, and conductive polymer nanocomposites for electronic and thermal applications: Current status and future prospects. Discov. Nano 2024, 19, 29. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cataldo, A.; Demitri, C.; Lamanna, L.; Masciullo, A.; Schiavoni, R. A Method for Sensing Dielectric Properties of Thin and Flexible Conductive Biocomposites. Sensors 2024, 24, 3508. https://doi.org/10.3390/s24113508

Cataldo A, Demitri C, Lamanna L, Masciullo A, Schiavoni R. A Method for Sensing Dielectric Properties of Thin and Flexible Conductive Biocomposites. Sensors. 2024; 24(11):3508. https://doi.org/10.3390/s24113508

Chicago/Turabian StyleCataldo, Andrea, Christian Demitri, Leonardo Lamanna, Antonio Masciullo, and Raissa Schiavoni. 2024. "A Method for Sensing Dielectric Properties of Thin and Flexible Conductive Biocomposites" Sensors 24, no. 11: 3508. https://doi.org/10.3390/s24113508