A Miniaturized Ultrawideband V-Shaped Tip E-Probe for Near-Field Measurements

Abstract

:1. Introduction

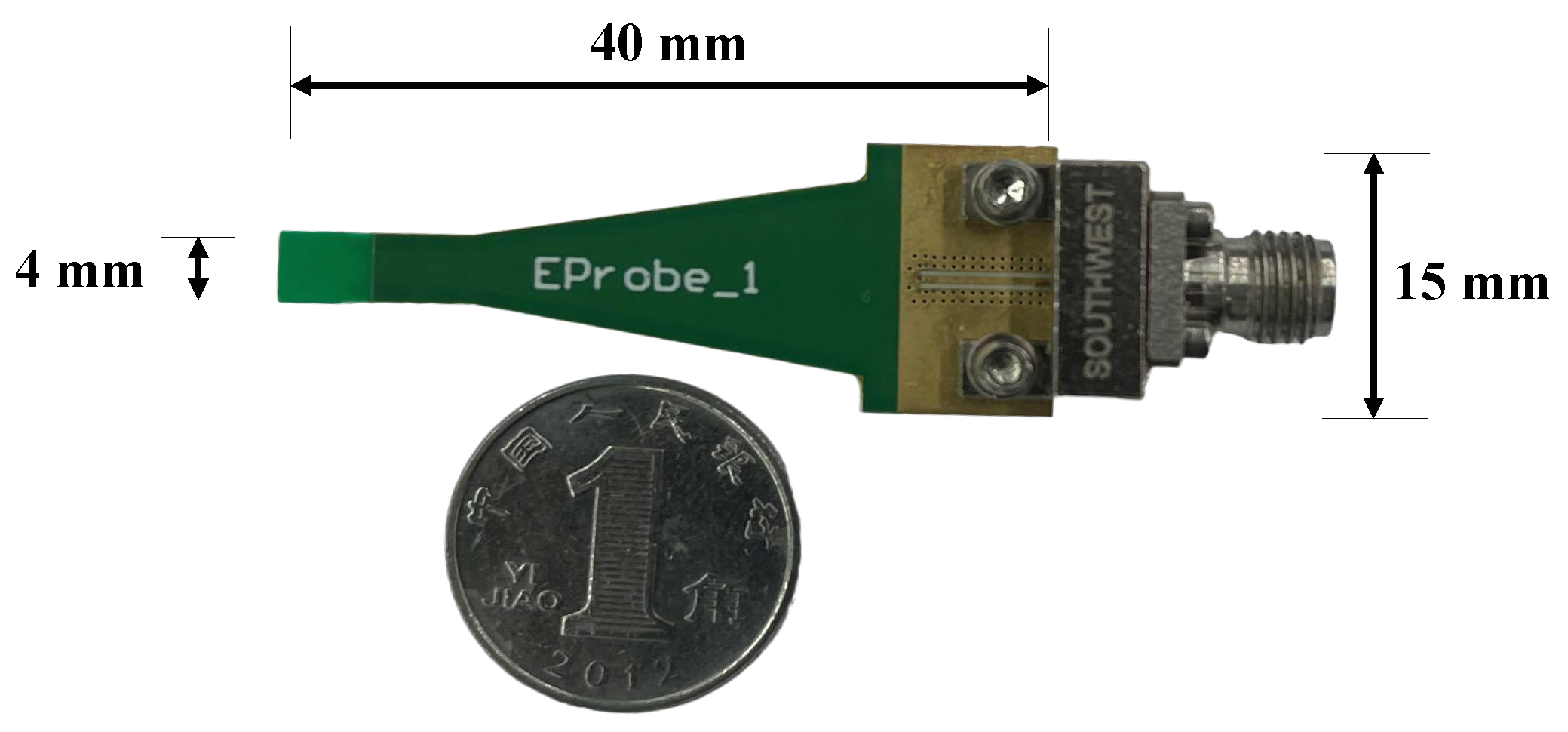

2. Proposed E-Probe Design

2.1. Probe Design Overview

2.2. Probe Analysis and Equivalent Circuit

2.3. Proposed V-Shaped Tip Structure

2.4. Body Gradient and Edge Structure

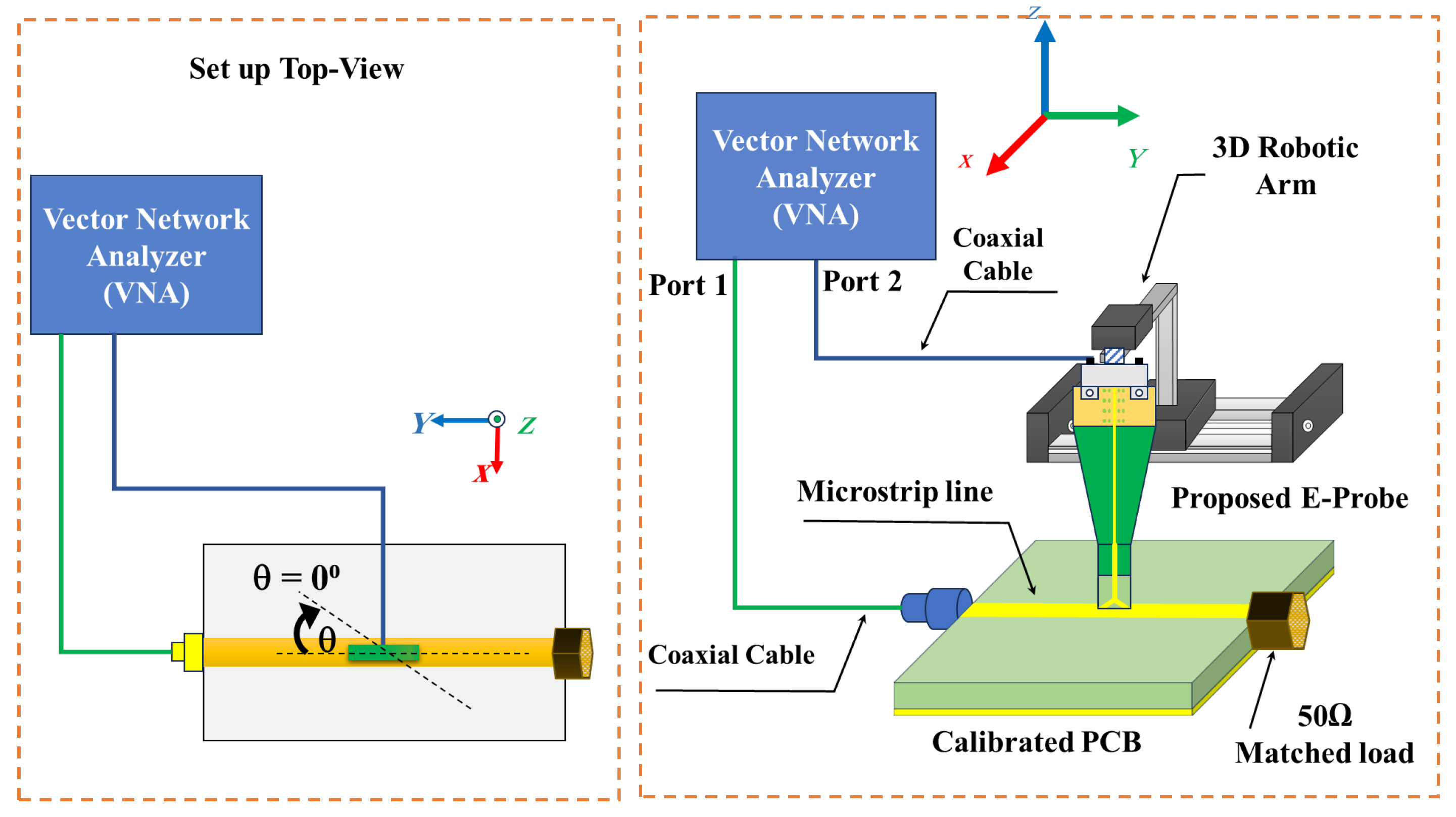

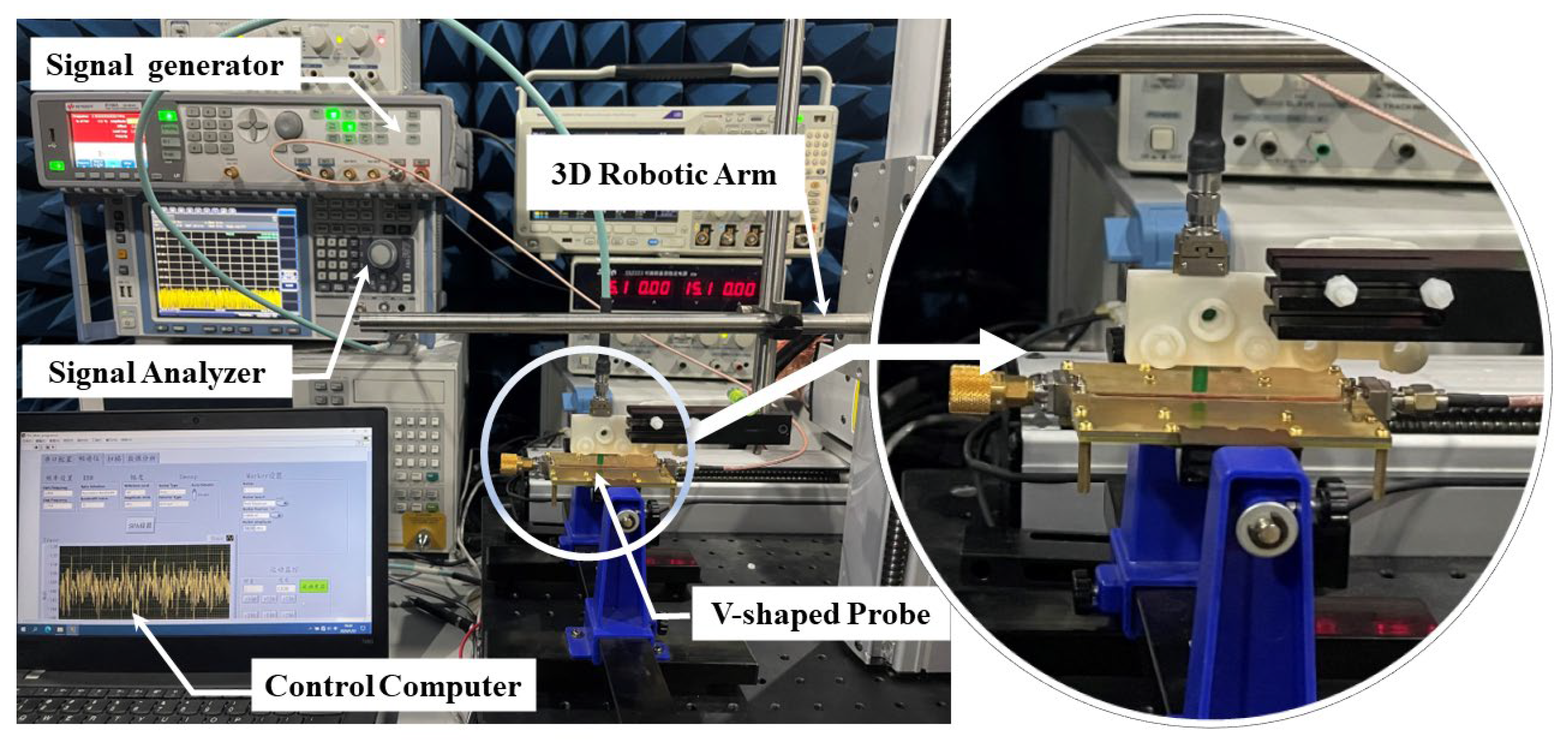

3. Validation and Measurement

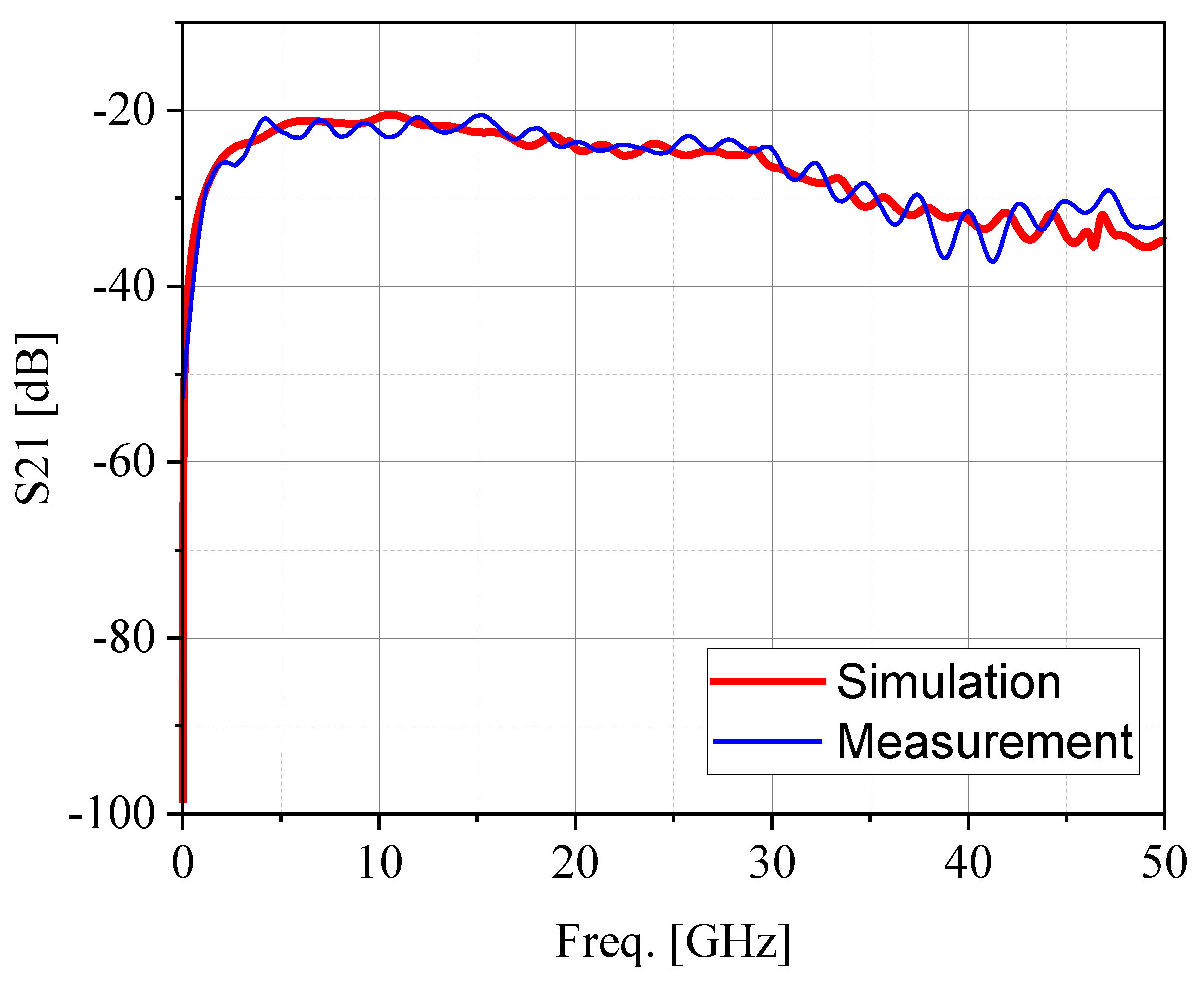

3.1. Frequency Bandwidth Measurement

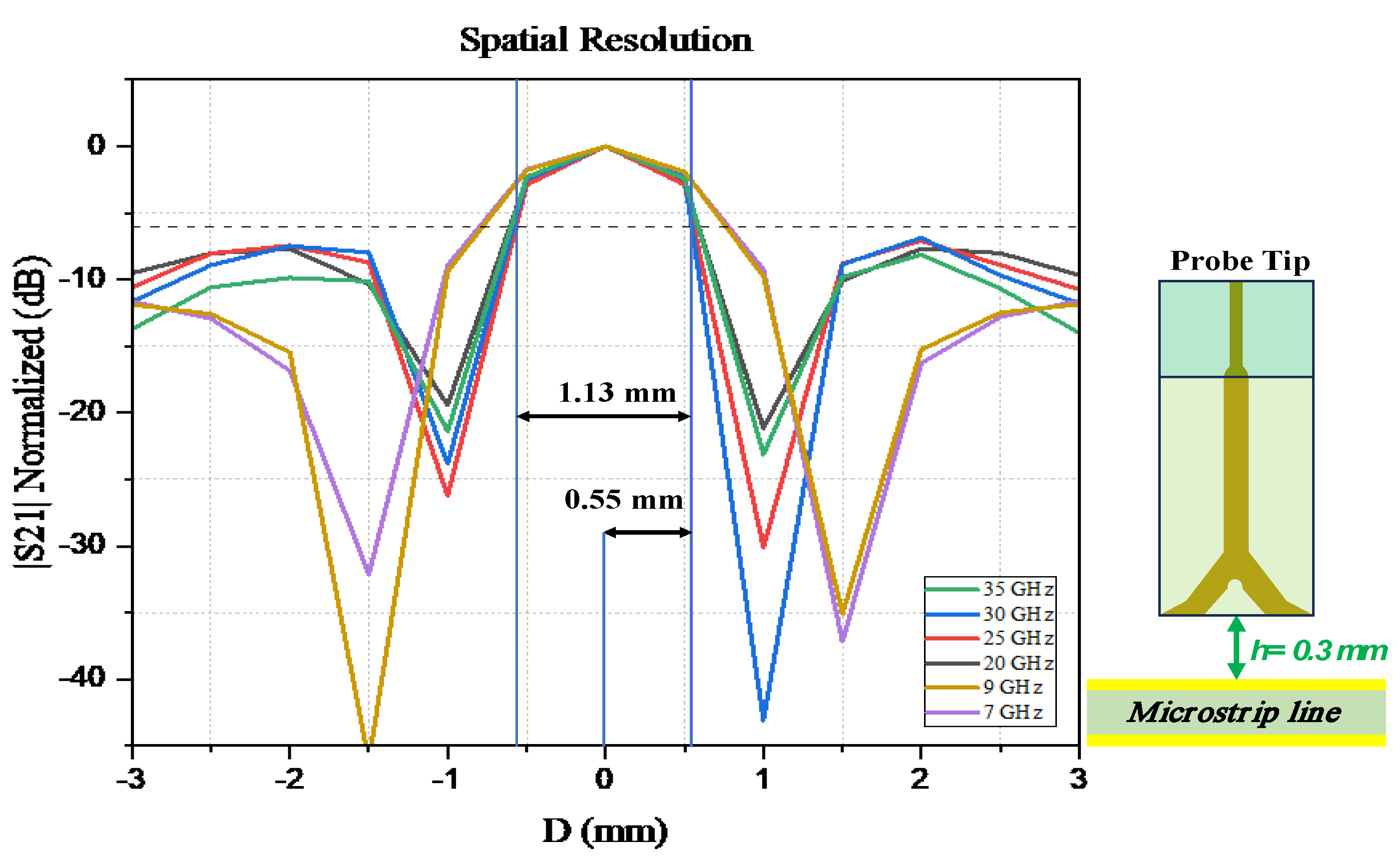

3.2. Spatial Resolution

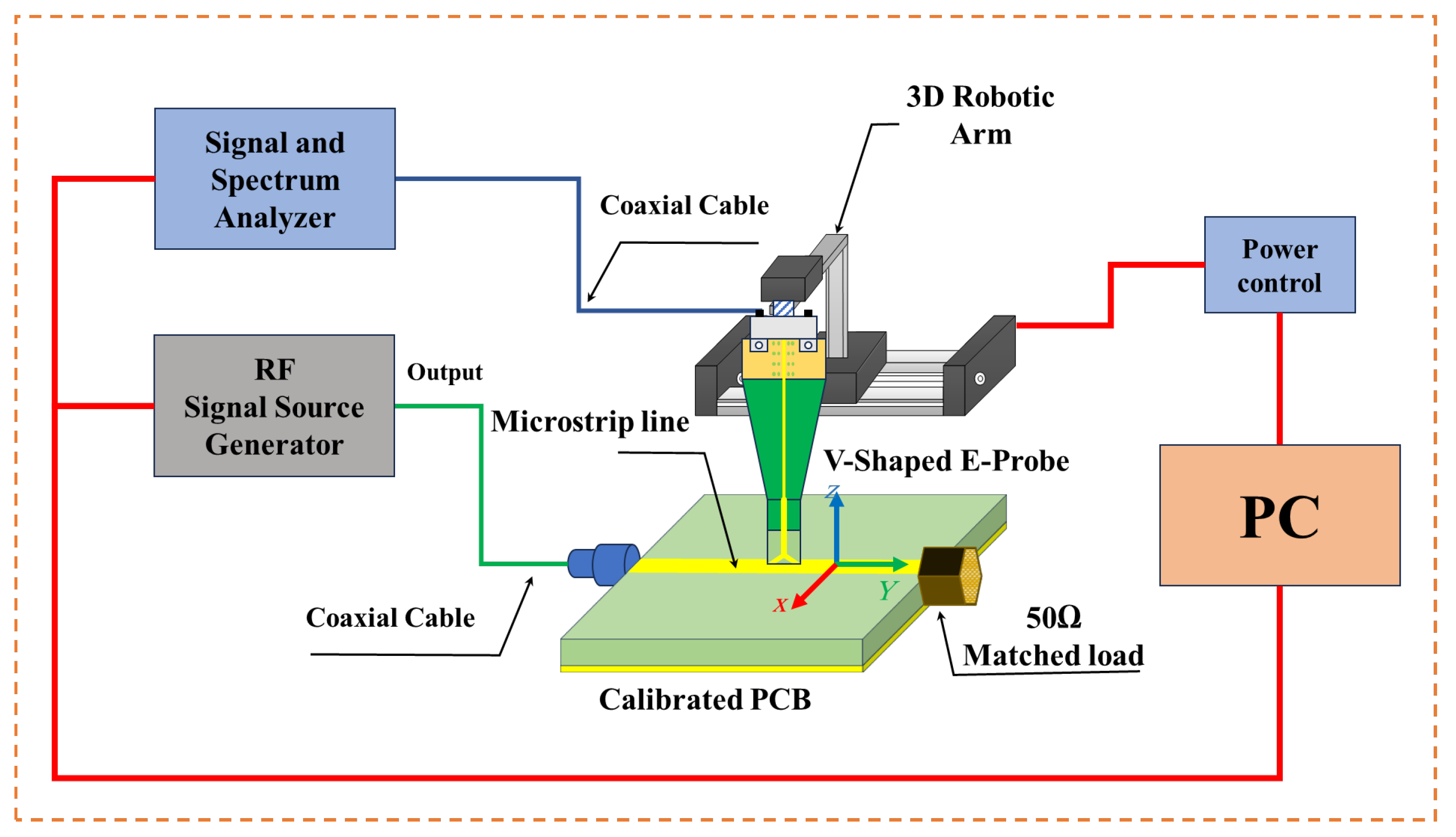

3.3. Sensitivity

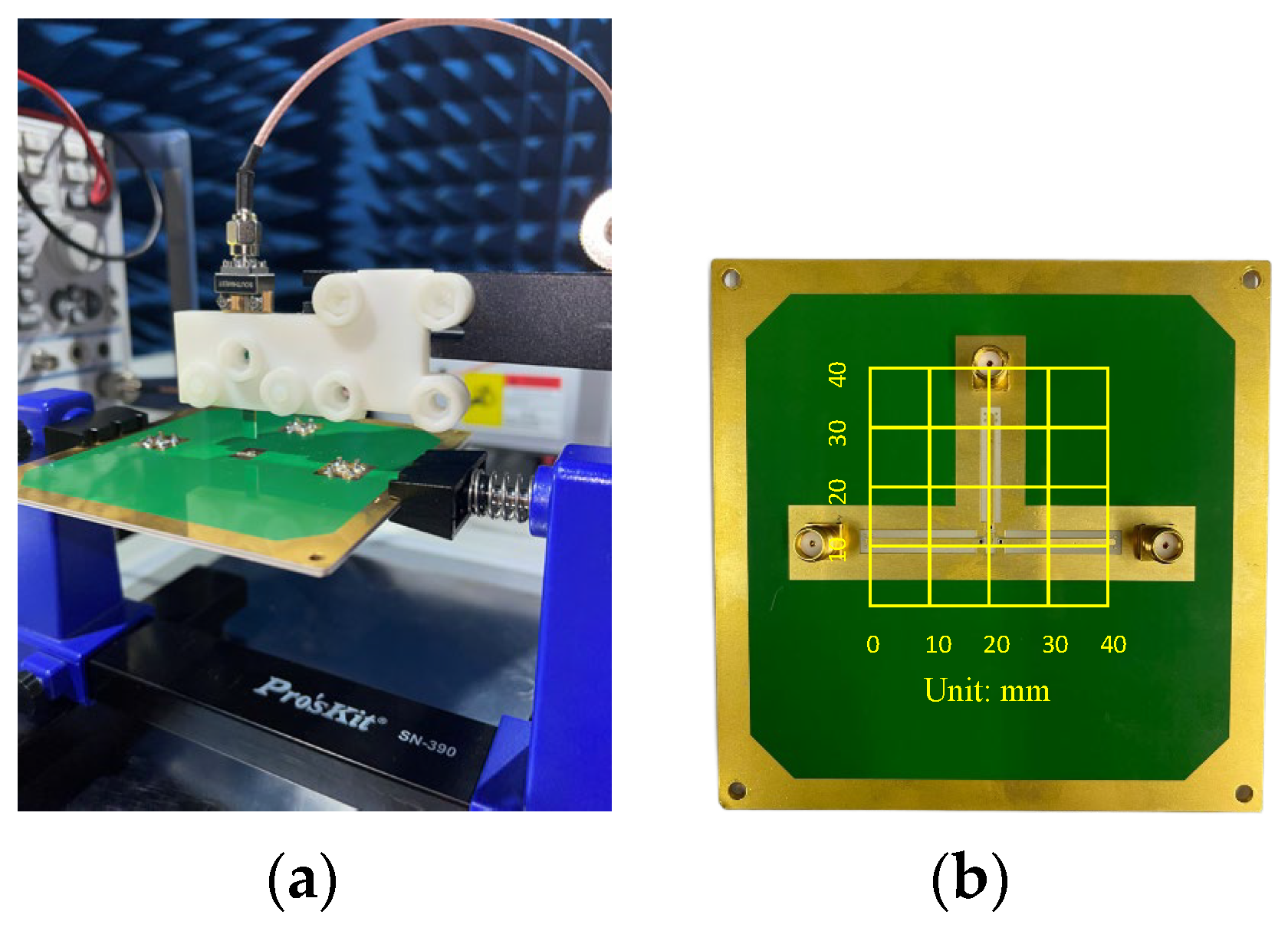

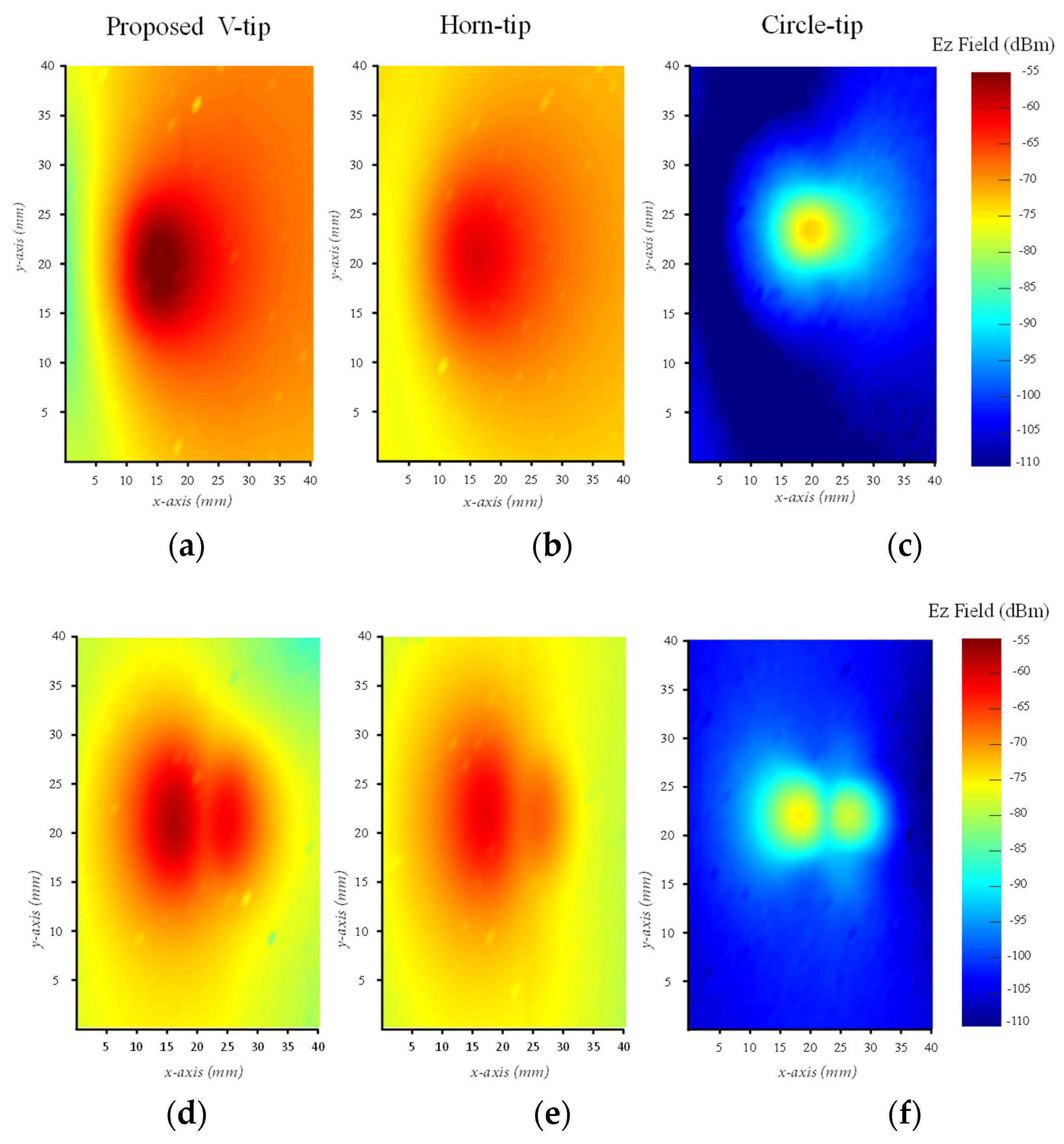

4. Application and Performance Comparison

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Paul, C.R. Introduction to Electromagnetic Compatibility; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Adamczyk, B. Foundations of Electromagnetic Compatibility: With Practical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Ott, H.W. Electromagnetic Compatibility Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- IEEE Electromagnetic Compatibility Society (IEEE EMC Society). Available online: https://www.emcs.org/ (accessed on 1 March 2024).

- International Electrotechnical Commission (IEC) Standards Related to EMC. Available online: https://www.iec.ch/emc/ (accessed on 1 March 2024).

- Cecelja, F.; Balachandran, W. Electrooptic sensor for near-field measurement. IEEE Trans. Instrum. Meas. 1999, 48, 650–653. [Google Scholar] [CrossRef]

- Thiele, L.; Geise, R.; Spieker, H.; Schüür, J.; Enders, A. Electro-optical-sensor for near-field measurements of large antennas. In Proceedings of the Fourth European Conference on Antennas and Propagation, Barcelona, Spain, 12–16 April 2010; pp. 1–5. [Google Scholar]

- Togo, H. Fiber-mounted Electro-optic Probe for Microwave Electric-field Measurement in Plasma Environment. IEICE Tech. Rep. IEICE Tech. Rep. 2013, 114, 39–44. [Google Scholar] [CrossRef]

- Shi, H.; Ma, J.; Li, X.; Liu, J.; Li, C.; Zhang, S. A quantum-based microwave magnetic field sensor. Sensors 2018, 18, 3288. [Google Scholar] [CrossRef] [PubMed]

- Yang, B.; Dong, Y.; Hu, Z.-Z.; Liu, G.-Q.; Wang, Y.-J.; Du, G.-X. Noninvasive Imaging Method of Microwave Near Field Based on Solid-State Quantum Sensing. IEEE Trans. Microw. Theory Tech. 2018, 66, 2276–2283. [Google Scholar] [CrossRef]

- IEC TS 61967-3:2005; Integrated Circuits—Measurement of Electromagnetic Emissions, 150 KHz to 1 GHz—Part 3: Measurement of Radiated Emissions—Surface Scan Method. IEC: Geneva, Switzerland, 2005.

- Ostermann, T.; Deutschmann, B. Characterization of the EME of integrated circuits with the help of the IEC standard 61967 [electromagnetic emission]. In Proceedings of the Eighth IEEE European Test Workshop, Maastricht, The Netherlands, 25–28 May 25 2003; pp. 132–137. [Google Scholar]

- Li, G.; Pommerenke, D.; Min, J. A low frequency electric field probe for near-field measurement in EMC applications. In Proceedings of the 2017 IEEE International Symposium on Electromagnetic Compatibility & Signal/Power Integrity (EMCSI), Washington, DC, USA, 7–11 August 2017; pp. 498–503. [Google Scholar]

- Song, E.; Park, H.H. A high-sensitivity electric probe based on board-level edge plating and LC resonance. IEEE Microw. Wirel. Compon. Lett. 2014, 24, 908–910. [Google Scholar] [CrossRef]

- Liu, W.; Yan, Z.; Wang, J.; Yan, X.; Fan, J. An Ultrawideband Electric Probe Based on U-Shaped Structure for Near-Field Measurement From 9 kHz to 40 GHz. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1283–1287. [Google Scholar] [CrossRef]

- Gao, Y.; Lauer, A.; Ren, Q.; Wolff, I. Calibration of electric coaxial near-field probes and applications. IEEE Trans. Microw. Theory Tech. 1998, 46, 1694–1703. [Google Scholar] [CrossRef]

- Fano, W.G.; Alonso, R.; Carducci, L.M. Near field magnetic probe applied to switching power supply. In Proceedings of the 2016 IEEE Global Electromagnetic Compatibility Conference (GEMCCON), Mar del Plata, Argentina, 7–9 November 2016; pp. 1–4. [Google Scholar]

- Chou, Y.-T.; Lu, H.-C. Space difference magnetic near-field probe with spatial resolution improvement. IEEE Trans. Microw. Theory Tech. 2013, 61, 4233–4244. [Google Scholar] [CrossRef]

- Yang, R.; Wei, X.-C.; Shu, Y.-F.; Yang, Y.-B. A High-Frequency and High Spatial Resolution Probe Design for EMI Prediction. IEEE Trans. Instrum. Meas. 2019, 68, 3012–3019. [Google Scholar] [CrossRef]

- Gao, Y.; Wolff, I. A New Miniature Magnetic Field Probe for Measuring Three-Dimensional Fields in Planar High-Frequency Circuits. IEEE Trans. Microw. Theory Tech. 1996, 44, 911–918. [Google Scholar] [CrossRef]

- Gao, Y.; Wolff, I. Miniature Electric Near-Field Probes for Measuring 3-D Fields in Planar Microwave Circuits. IEEE Trans. Microw. Theory Tech. 1998, 46, 907–913. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, J.; Zhang, W.; Wang, Y.; Fan, J. A Miniature Ultrawideband Electric Field Probe Based on Coax-Thru-Hole via Array for Near-Field Measurement. IEEE Trans. Instrum. Meas. 2017, 66, 2762–2770. [Google Scholar] [CrossRef]

- Zhou, Y.; Yan, Z.; Wang, J.; Hu, K.; Zhao, D.; Chen, Y.; Zhao, Y. A Miniaturized Ultrawideband Active Electric Probe With High Sensitivity for Near-Field Measurement. IEEE Trans. Instrum. Meas. 2022, 71, 1–8. [Google Scholar] [CrossRef]

- Min, Z.; Yan, Z.; Liu, W.; Wang, J.; Su, D.; Yan, X. A Miniature High-Sensitivity Active Electric Field Probe for Near-Field Measurement. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 2552–2556. [Google Scholar] [CrossRef]

- Liu, Y.-X.; Li, X.-C.; He, X.; Peng, Z.-H.; Mao, J.-F. An Ultra-Wideband Electric Field Probe With High Sensitivity for Near-Field Measurement. IEEE Trans. Instrum. Meas. 2023, 72, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Liu, W.; Yan, X.; Fan, J. Improved-Sensitivity Resonant Electric-Field Probes Based on Planar Spiral Stripline and Rectangular Plate Structure. IEEE Trans. Instrum. Meas. 2019, 68, 882–894. [Google Scholar] [CrossRef]

- Park, Y.; Bang, J.; Jung, K.; Choi, J. Design of a broadband electric near-field probe with improved sensitivity using additional tips. In Proceedings of the 2018 International Symposium on Antennas and Propagation (ISAP), Busan, Republic of Korea, 23–26 October 2018; pp. 1–2. [Google Scholar]

| Parameter | Value (mm) | Parameter | Value (mm) |

|---|---|---|---|

| l1 | 20.3 | w1 | 0.32 |

| l2 | 5 | w2 | 0.6 |

| l3 | 5 | w3 | 0.37 |

| lo | 2.4 | wp | 4 |

| lm | 1.4 | r1 | 0.72 |

| d1 | 0.55 | r2 | 0.59 |

| ts1 | 0.2032 | ts3 | 0.3048 |

| ts2 | 0.17 |

| Freq. | Proposed | [15] | [23] | [24] |

|---|---|---|---|---|

| 9 kHz | −15 dBm | 13 dBm | 10 dBm | 16 dBm |

| 1 MHz | −54 dBm | −20 dBm | −24 dBm | −15 dBm |

| 100 MHz | −94 dBm | -- | -- | −50 dBm |

| 500 MHz | −100 dBm | −40 dBm | −48 dBm | −64 dBm |

| 1 GHz | −105 dBm | −82 dBm | −69 dBm | −69 dBm |

| 5 GHz | −101 dBm | −82 dBm | −74 dBm | -- |

| 10 GHz | −100 dBm | −84 dBm | −75 dBm | -- |

| 20 GHz | −90 dBm | −82 dBm | -- | -- |

| 30 GHz | −91 dBm | -- | -- | -- |

| 40 GHz | −87 dBm | -- | -- | -- |

| Probe | Proposed | [15] | [25] | [26] | [27] | [22] |

|---|---|---|---|---|---|---|

| Tip | V-shaped | U-shaped | L-shaped | T-shaped | Rectangular | Monopole |

| B.W | 10 kHz- 50 GHz | 9 kHz- 40 GHz | 10 MHz- 60 GHz | Narrow Band | 6 GHz | 9 kHz- 20 GHz |

| S21 | −16 dB | −21 dB | −24 dB | −24 dB | −26.9 dB | −28 dB |

| Spatial Resolution | 0.55 mm | 1 mm | 0.7 mm | 2.5 mm | 1.97 mm | 2–3 mm |

| Detecting Field | Ez | Ez | Ez | Ez | Ez | Ez |

| Process | PCB | PCB | PCB | PCB | PCB | PCB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khodeir, M.M.; Yan, Z.; Zhao, F. A Miniaturized Ultrawideband V-Shaped Tip E-Probe for Near-Field Measurements. Sensors 2024, 24, 4295. https://doi.org/10.3390/s24134295

Khodeir MM, Yan Z, Zhao F. A Miniaturized Ultrawideband V-Shaped Tip E-Probe for Near-Field Measurements. Sensors. 2024; 24(13):4295. https://doi.org/10.3390/s24134295

Chicago/Turabian StyleKhodeir, Mahmoud Mohammed, Zhaowen Yan, and Fuyu Zhao. 2024. "A Miniaturized Ultrawideband V-Shaped Tip E-Probe for Near-Field Measurements" Sensors 24, no. 13: 4295. https://doi.org/10.3390/s24134295