A Rotating Machinery Fault Diagnosis Method Based on Dynamic Graph Convolution Network and Hard Threshold Denoising

Abstract

1. Introduction

- (1)

- A dynamic denoising graph neural network (DDGCN) is proposed for gearbox fault diagnosis. Dynamic graphs are constructed and applied to capture the temporal dependencies, allowing the DDGCN to consider changes in data over time and predicting the gearbox’s operating status.

- (2)

- A learnable hard threshold denoising layer is proposed and embedded within the dynamic graph neural network. This allows the proposed method to adaptively learn thresholds to filter out noise from dynamic graph structured data, thereby improving the reliability of the graph-structured data and subsequently enhancing the accuracy of fault diagnosis.

2. Preliminaries

3. Proposed Approach

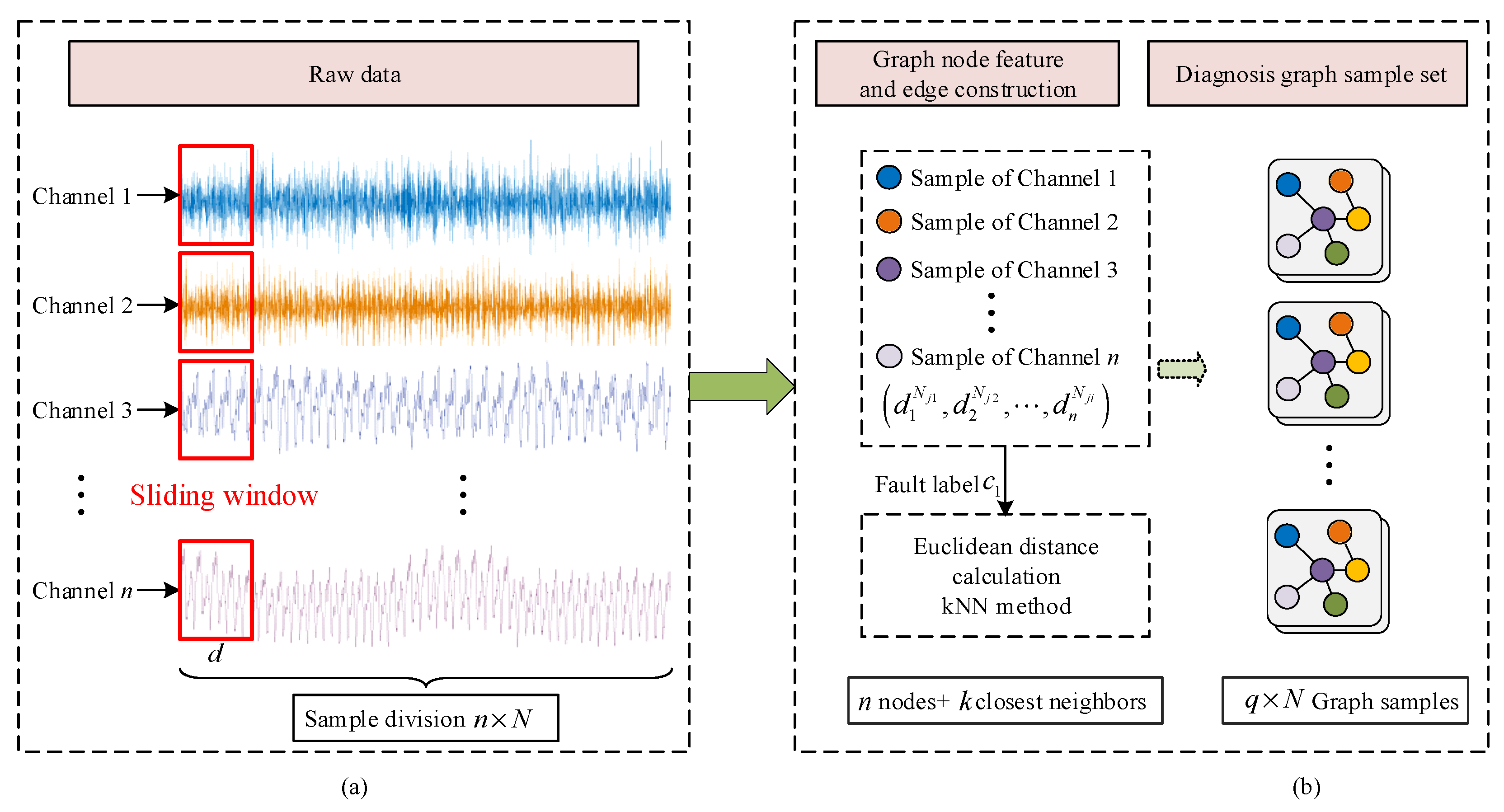

3.1. Dynamic GCN Network

3.2. Hard Threshold Denoising

3.3. Overall Fault Diagnosis Framework

| Algorithm 1: Dynamic denoising graph convolutional neural networks. |

| # Training process Dataset collection: Multi-sensor dataset. Input: Dynamic graphs . |

| For n in epoch do: |

| 1. The training data are generated by randomly drawing samples from dataset . |

| 2. Graph representation learning with GCN. |

| 3. Obtaining the final classification output according to Equation (12). |

| 4. Forward propagation according to Equation (13). |

| 5. Back propagation based on the loss function to update the model. |

| End for |

| Output: Optimal parameters for diagnostic models. |

4. Experimental Verifications on Gearbox Fault Diagnosis

4.1. Case Study 1: NPU Dataset

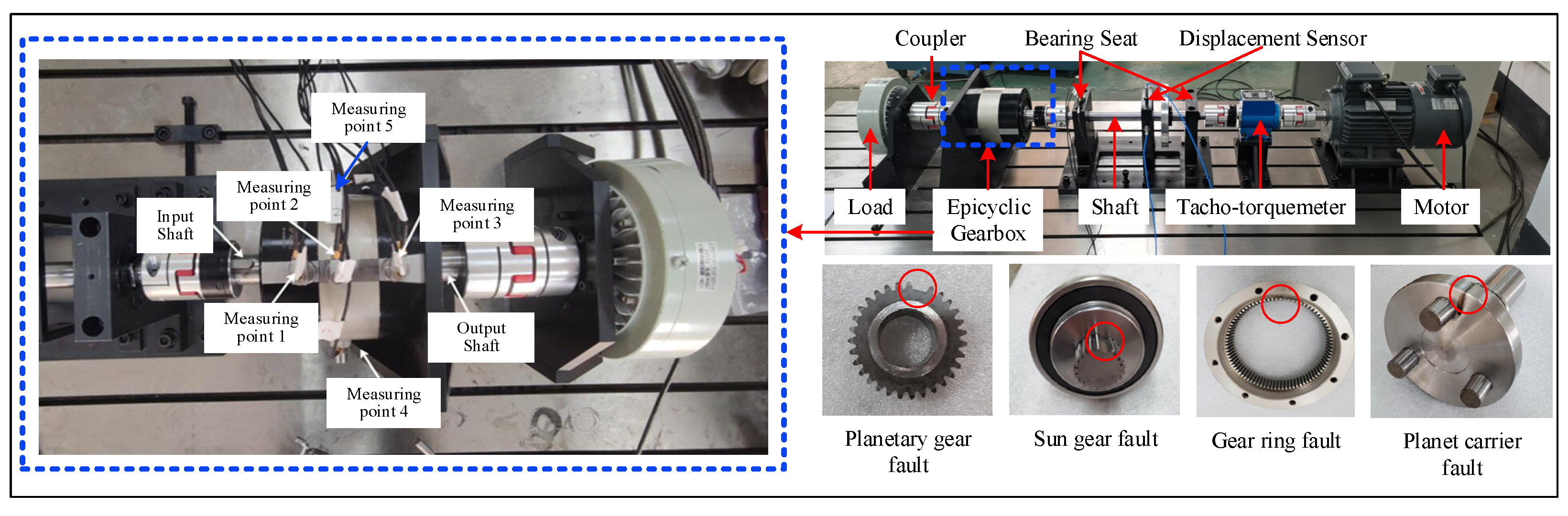

4.1.1. Experimental Setup and Data Description

4.1.2. Implementation Details

4.1.3. Diagnosis Result and Discussion

4.1.4. Feature Visualization Analysis

4.1.5. Noise Resistance Analysis

4.2. Case Study 2: XJTU Dataset

4.2.1. Experimental Setup and Data Description

4.2.2. Diagnosis Result and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, S.; Li, Y.; Wang, X.; Sun, D.; Deng, Z. Deep causal factorization network: A novel domain generalization method for cross-machine bearing fault diagnosis. Mech. Syst. Signal Process. 2023, 192, 110228. [Google Scholar] [CrossRef]

- Mian, T.; Choudhary, A.; Fatima, S. Multi-sensor fault diagnosis for misalignment and unbalance detection using machine learning. IEEE Trans. Ind. Appl. 2023, 59, 5749–5759. [Google Scholar] [CrossRef]

- Jia, S.; Li, Y.; Mao, G.; Noman, K. Multi-representation symbolic convolutional neural network: A novel multisource cross-domain fault diagnosis method for rotating system. Struct. Health Monit. 2023, 22, 3940–3955. [Google Scholar] [CrossRef]

- Kong, L.; Peng, X.; Chen, Y.; Wang, P.; Xu, M. Multi-sensor measurement and data fusion technology for manufacturing process monitoring: A literature review. Int. J. Extrem. Manuf. 2020, 2, 022001. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Li, S.; Han, B.; Jiang, X. Fast nonlinear blind deconvolution for rotating machinery fault diagnosis. Mech. Syst. Signal Process. 2023, 187, 109918. [Google Scholar] [CrossRef]

- Guan, Y.; Meng, Z.; Sun, D.; Liu, J.; Fan, F. 2MNet: Multi-sensor and multi-scale model toward accurate fault diagnosis of rolling bearing. Reliab. Eng. Syst. Saf. 2021, 216, 108017. [Google Scholar] [CrossRef]

- Sun, D.; Li, Y.; Jia, S.; Feng, K.; Liu, Z. Non-contact diagnosis for gearbox based on the fusion of multi-sensor heterogeneous data. Inf. Fusion 2023, 94, 112–125. [Google Scholar] [CrossRef]

- Wang, Z.; Xuan, J.; Shi, T. Multi-source information fusion deep self-attention reinforcement learning framework for multi-label compound fault recognition. Mech. Mach. Theory 2023, 179, 105090. [Google Scholar] [CrossRef]

- Yan, H.; Liu, Z.; Chen, J.; Feng, Y.; Wang, J. Memory-augmented skip-connected autoencoder for unsupervised anomaly detection of rocket engines with multi-source fusion. ISA Trans. 2023, 133, 53–65. [Google Scholar] [CrossRef]

- Zhao, X.; Zhu, X.; Liu, J.; Hu, Y.; Gao, T.; Zhao, L.; Yao, J.; Liu, Z. Model-assisted multi-source fusion hypergraph convolutional neural networks for intelligent few-shot fault diagnosis to electro-hydrostatic actuator. Inf. Fusion 2024, 104, 102186. [Google Scholar] [CrossRef]

- Sun, K.; Yin, A. Multi-Sensor Graph Adaptive Federated Generalization for Helicopter Transmission System Fault Diagnosis. IEEE Trans. Instrum. Meas. 2024, 73, 3524511. [Google Scholar] [CrossRef]

- Zhao, D.; Cui, L.; Liu, D. Bearing weak fault feature extraction under time-varying speed conditions based on frequency matching demodulation transform. IEEE/ASME Trans. Mechatron. 2022, 28, 1627–1637. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, H.; Cui, L. Frequency-chirprate synchrosqueezing-based scaling chirplet transform for wind turbine nonstationary fault feature time–frequency representation. Mech. Syst. Signal Process. 2024, 209, 111112. [Google Scholar] [CrossRef]

- Xia, J.; Wang, S.; Wang, X.; Xia, M.; Xie, K.; Cao, J. Multi-view Bayesian spatio-temporal graph neural networks for reliable traffic flow prediction. Int. J. Mach. Learn. Cybern. 2024, 15, 65–78. [Google Scholar] [CrossRef]

- Tian, C.; Chan, W.K. Spatial-temporal attention wavenet: A deep learning framework for traffic prediction considering spatial-temporal dependencies. IET Intell. Transp. Syst. 2021, 15, 549–561. [Google Scholar] [CrossRef]

- Guo, S.; Lin, Y.; Wan, H.; Li, X.; Cong, G. Learning dynamics and heterogeneity of spatial-temporal graph data for traffic forecasting. IEEE Trans. Knowl. Data Eng. 2021, 34, 5415–5428. [Google Scholar] [CrossRef]

- Li, Y.; Yu, R.; Shahabi, C.; Liu, Y. Diffusion convolutional recurrent neural network: Data-driven traffic forecasting. arXiv 2017, arXiv:1707.01926. [Google Scholar]

- Luo, G.; Zhang, H.; Yuan, Q.; Li, J.; Wang, F.-Y. ESTNet: Embedded spatial-temporal network for modeling traffic flow dynamics. IEEE Trans. Intell. Transp. Syst. 2022, 23, 19201–19212. [Google Scholar] [CrossRef]

- Chen, S.; Varma, R.; Sandryhaila, A.; Kovacevic, J. Discrete Signal Processing on Graphs: Sampling Theory. IEEE Trans. Signal Process. 2015, 63, 6510–6523. [Google Scholar] [CrossRef]

- Bruna, J.; Zaremba, W.; Szlam, A.; LeCun, Y. Spectral networks and locally connected networks on graphs. arXiv 2013, arXiv:1312.6203. [Google Scholar]

- Defferrard, M.; Bresson, X.; Vandergheynst, P. Convolutional neural networks on graphs with fast localized spectral filtering. In Proceedings of the Neural Information Processing Systems Foundation, Barcelona, Spain, 5–10 December 2016; pp. 3844–3852. [Google Scholar]

- Ding, Y.; Zhao, X.; Zhang, Z.; Cai, W.; Yang, N. Graph Sample and Aggregate-Attention Network for Hyperspectral Image Classification. IEEE Geosci. Remote Sens. Lett. 2022, 19, 1–5. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Noman, K.; Wang, D.; Feng, K.; Liu, Z.; Deng, Z. Cumulative spectrum distribution entropy for rotating machinery fault diagnosis. Mech. Syst. Signal Process. 2024, 206, 110905. [Google Scholar] [CrossRef]

- Kim, B.H.; Ye, J.C. Understanding graph isomorphism network for rs-fMRI functional connectivity analysis. Front. Neurosci. 2020, 14, 545464. [Google Scholar] [CrossRef] [PubMed]

- Velickovic, P.; Cucurull, G.; Casanova, A.; Romero, A.; Lio, P.; Bengio, Y. Graph attention networks. Stat 2017, 1050, 10–48550. [Google Scholar]

- Wang, H.; Xu, J.; Sun, C.; Yan, R.; Chen, X. Intelligent fault diagnosis for planetary gearbox using time-frequency representation and deep reinforcement learning. IEEE/ASME Trans. Mechatron. 2021, 27, 985–998. [Google Scholar] [CrossRef]

| Measuring Point Number | Location | Direction | Channel Number | Data Type |

|---|---|---|---|---|

| 1 | Near the input shaft | Radial | Y1 | Vibration signal |

| Tangential | X1 | |||

| Axial | Z1 | |||

| 2 | Inner gear ring | Radial | Y2 | |

| Tangential | X2 | |||

| Axial | Z2 | |||

| 3 | Near the output shaft | Radial | Y3 | |

| Tangential | X3 | |||

| Axial | Z3 | |||

| 4 | Inner gear ring position, −90° distribution from measurement point 2 | Axial | Y4 | |

| 5 | Inner gear ring position, +90° distribution from measurement point 2 | Axial | Y5 |

| Tasks | 2D-RECNN | GIN | GAT | DGCN | DDGCN |

|---|---|---|---|---|---|

| 7 sensors | 72.1% | 90.1% | 95.6% | 85.2% | 99.1% |

| 9 sensors | 81.2% | 90.3% | 97.5% | 91.2% | 99.4% |

| 11 sensors | 83.0% | 92.4% | 98.6% | 93.2% | 99.6% |

| Average accuracy | 78.76% | 90.26% | 97.23% | 89.86% | 99.36% |

| Standard deviation | 4.2% | 3.6% | 2.1% | 0.3% | 0.2% |

| SNR | Method | ||||

|---|---|---|---|---|---|

| 2D-RECNN | GIN | GAT | DGCN | DDGCN | |

| 4 dB | 81.2% | 90.3% | 97.5% | 91.2% | 99.4% |

| 3 dB | 78.2% | 86.4% | 90.5% | 86.2% | 95.4% |

| 2 dB | 71.2% | 82.3% | 88.5% | 85.2% | 93.4% |

| 1 dB | 63.3% | 76.3% | 86.5% | 82.2% | 90.6% |

| −1 dB | 54.7% | 75.3% | 79.7% | 77.2% | 87.9% |

| −2 dB | 51.6% | 71.3% | 75.5% | 70.2% | 81.4% |

| −3 dB | 41.5% | 65.2% | 71.6% | 68.2% | 78.7% |

| Tasks | 2D-RECNN | GIN | GAT | DGCN | DDGCN |

|---|---|---|---|---|---|

| 80% of training samples | 85.1% | 95.1% | 98.5% | 94.0% | 99.5% |

| 60% of training samples | 78.2% | 86.4% | 91.5% | 85.2% | 95.4% |

| 40% of training samples | 61.5% | 70.3% | 85.6% | 84.2% | 93.1% |

| 20% of training samples | 42.4% | 53.5% | 61.4% | 75.6% | 90.2% |

| Average accuracy | 66.8% | 76.3% | 84.3% | 84.8% | 94.6% |

| Standard deviation | 3.8% | 2.9% | 1.5% | 0.9% | 0.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Q.; Xue, L.; He, J.; Jia, S.; Li, Y. A Rotating Machinery Fault Diagnosis Method Based on Dynamic Graph Convolution Network and Hard Threshold Denoising. Sensors 2024, 24, 4887. https://doi.org/10.3390/s24154887

Zhou Q, Xue L, He J, Jia S, Li Y. A Rotating Machinery Fault Diagnosis Method Based on Dynamic Graph Convolution Network and Hard Threshold Denoising. Sensors. 2024; 24(15):4887. https://doi.org/10.3390/s24154887

Chicago/Turabian StyleZhou, Qiting, Longxian Xue, Jie He, Sixiang Jia, and Yongbo Li. 2024. "A Rotating Machinery Fault Diagnosis Method Based on Dynamic Graph Convolution Network and Hard Threshold Denoising" Sensors 24, no. 15: 4887. https://doi.org/10.3390/s24154887

APA StyleZhou, Q., Xue, L., He, J., Jia, S., & Li, Y. (2024). A Rotating Machinery Fault Diagnosis Method Based on Dynamic Graph Convolution Network and Hard Threshold Denoising. Sensors, 24(15), 4887. https://doi.org/10.3390/s24154887