Miniaturized Antenna Design for Wireless and Powerless Surface Acoustic Wave Temperature Sensors

Abstract

1. Introduction

2. Antenna Design

2.1. Non-Uniform-Pitch Cylindrical Helical Antenna (CHA) Design

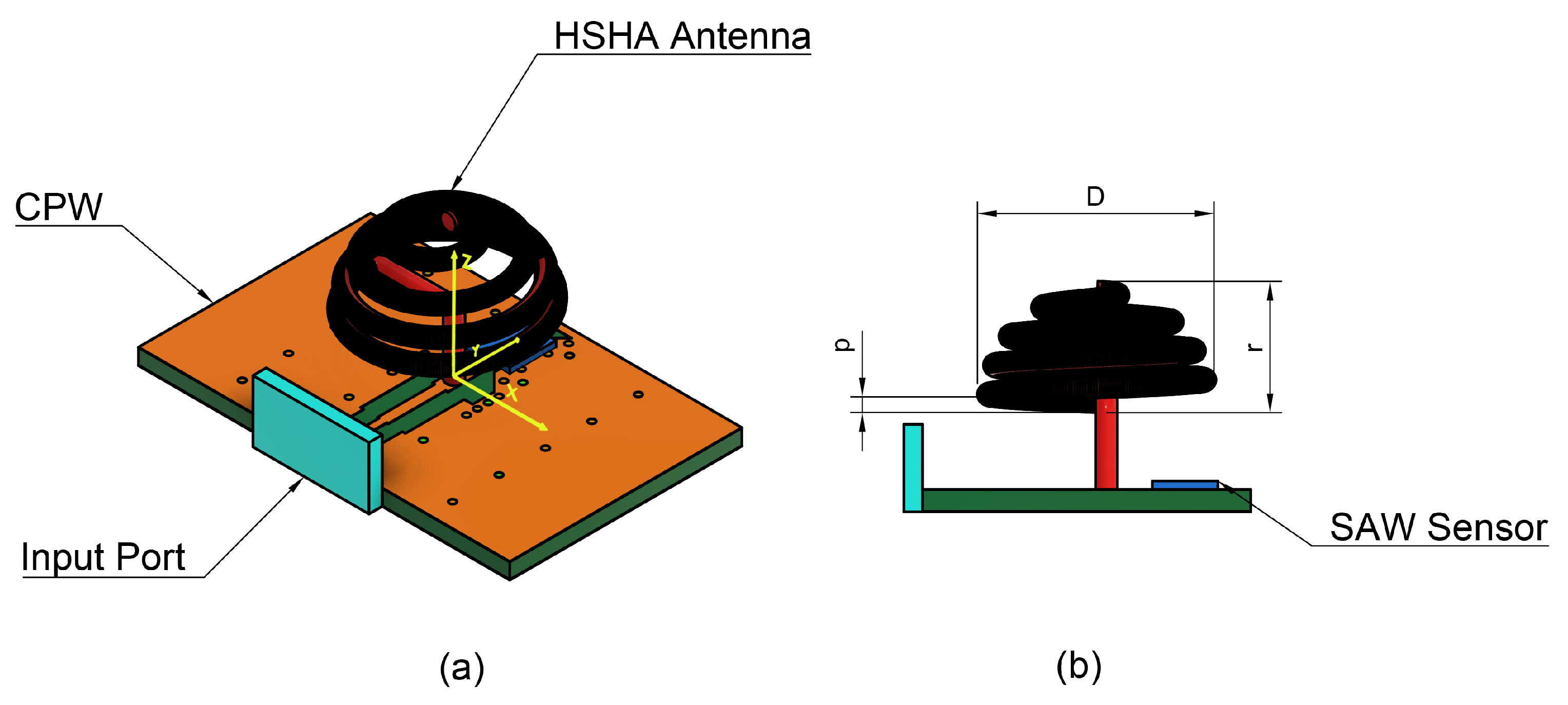

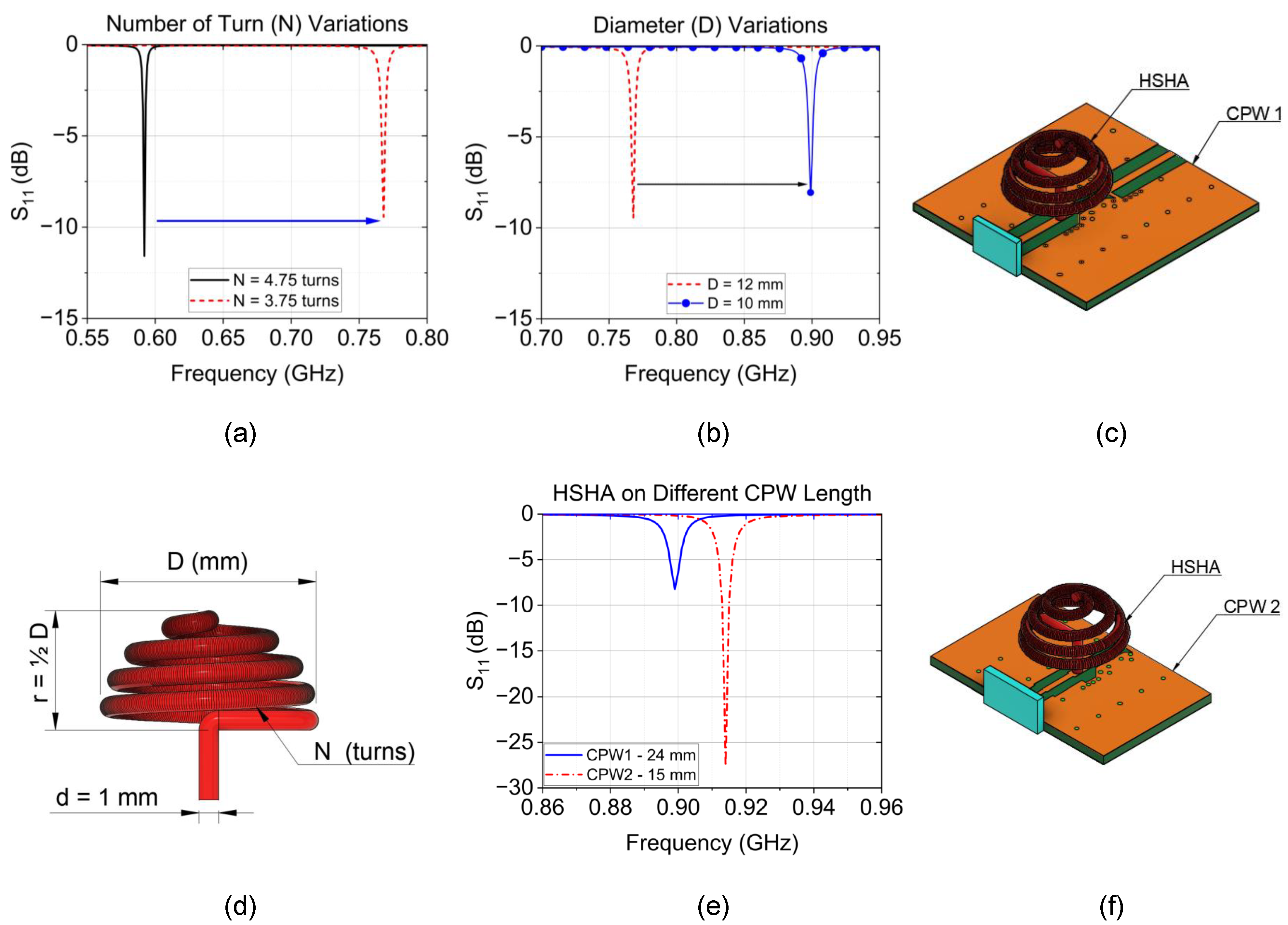

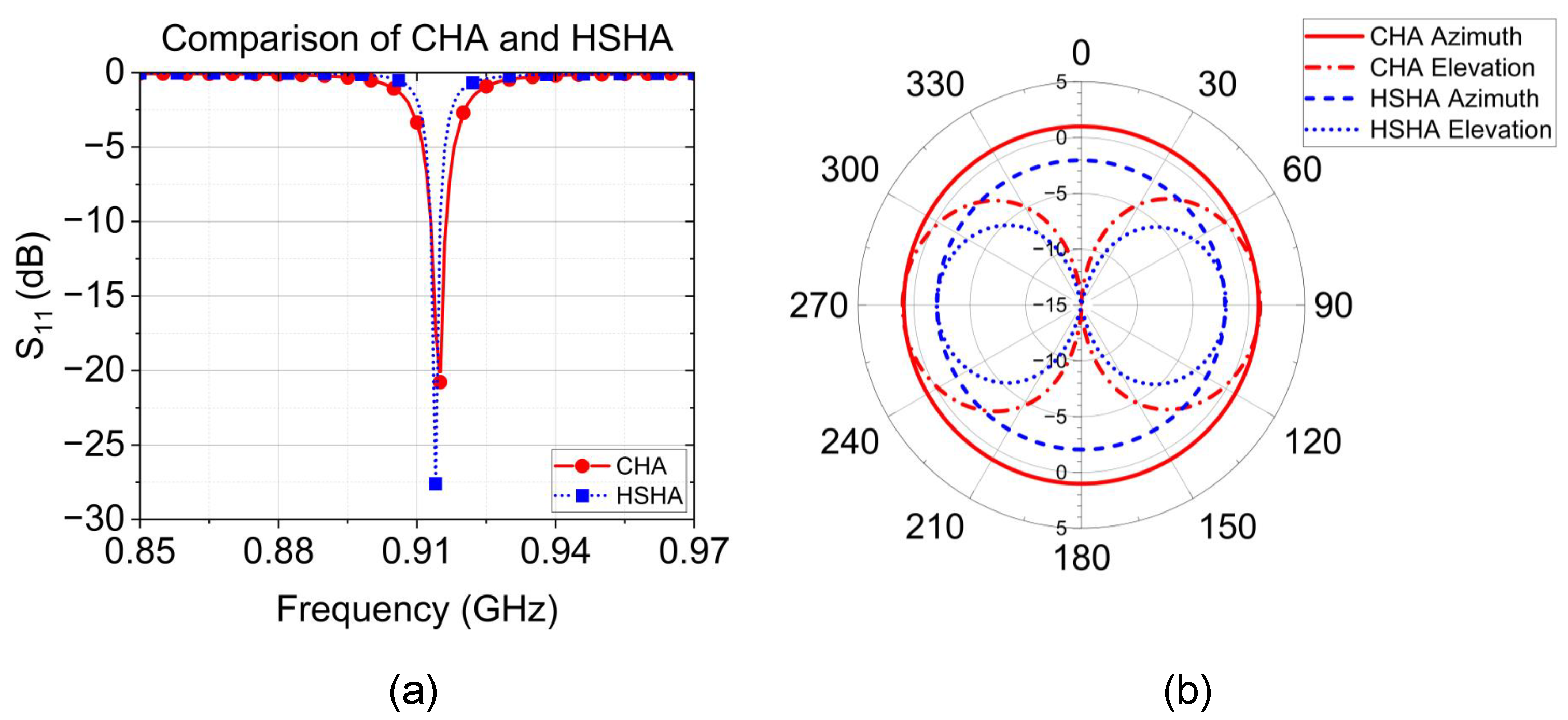

2.2. Hemispherical Helical Antenna (HSHA) Design

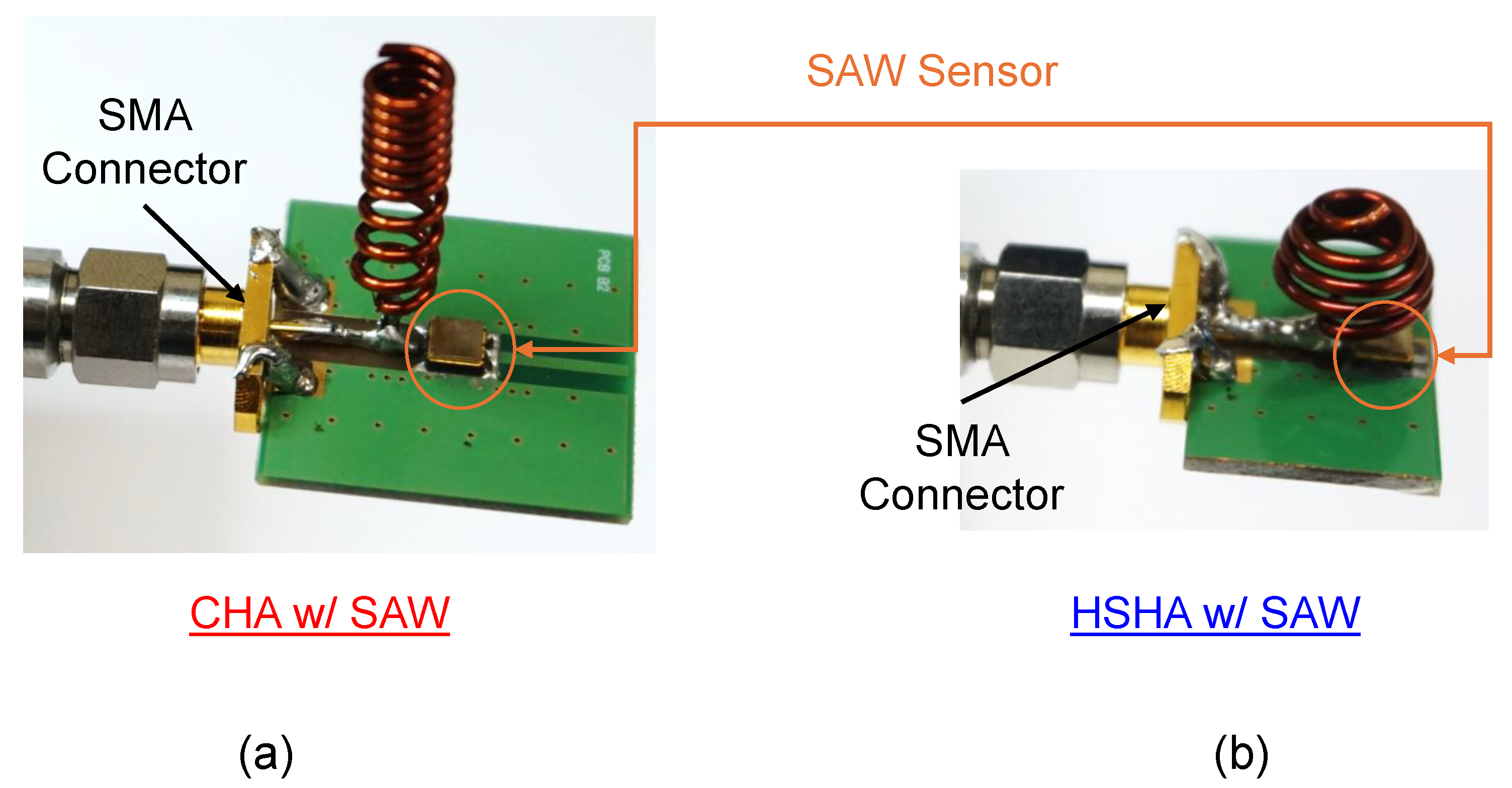

3. Antenna Fabrication and Measurement

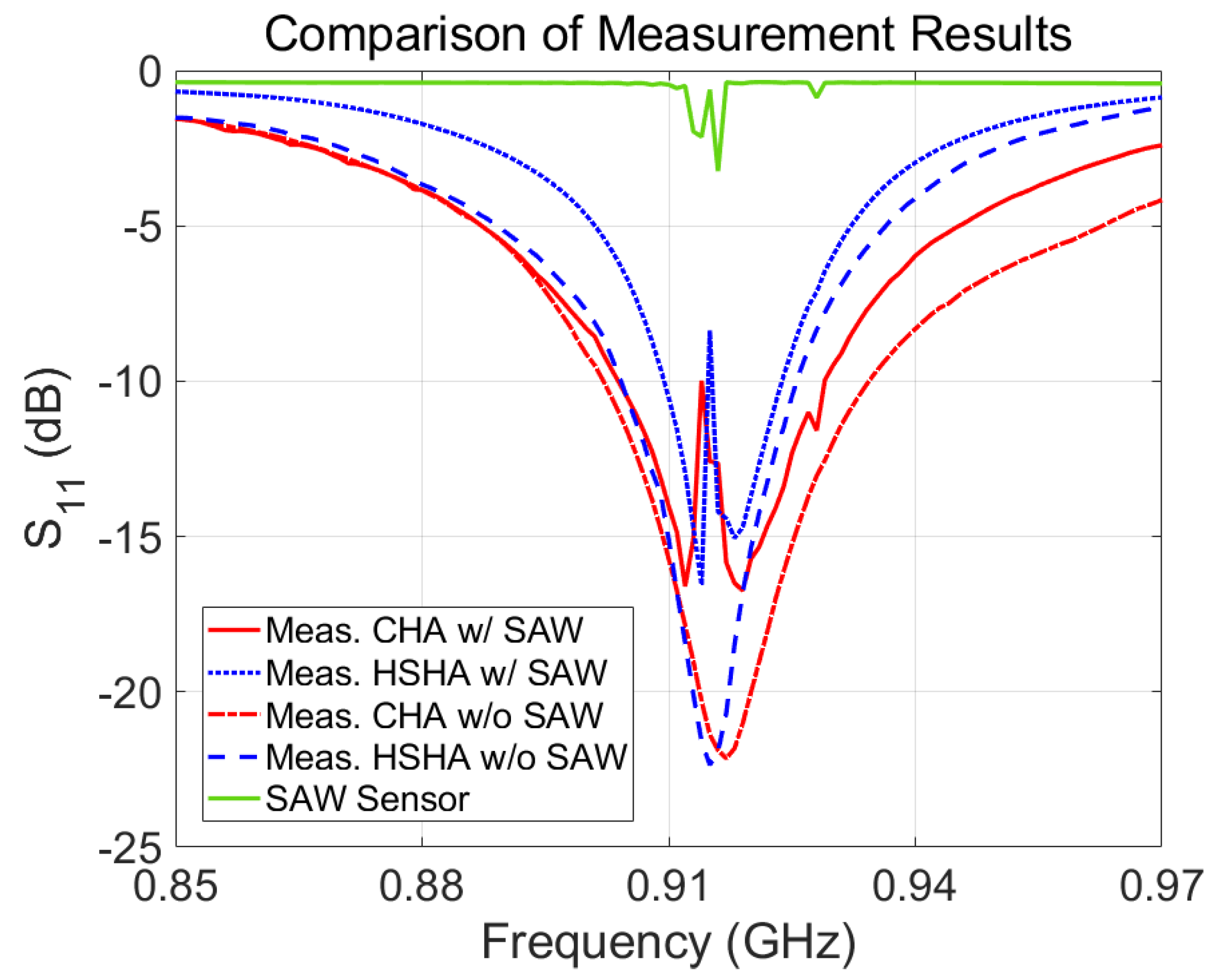

3.1. Return Loss

3.2. Received Power Test

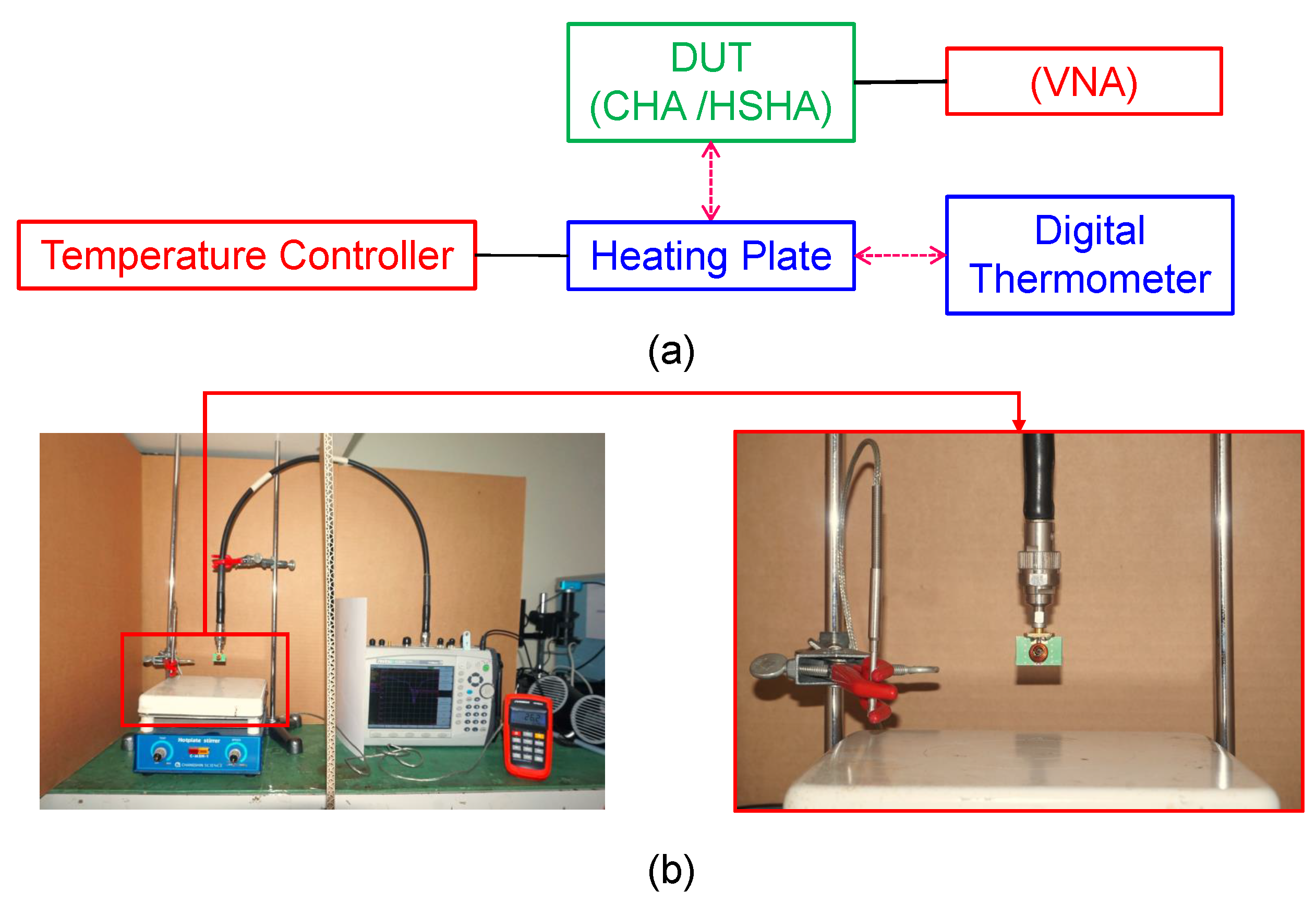

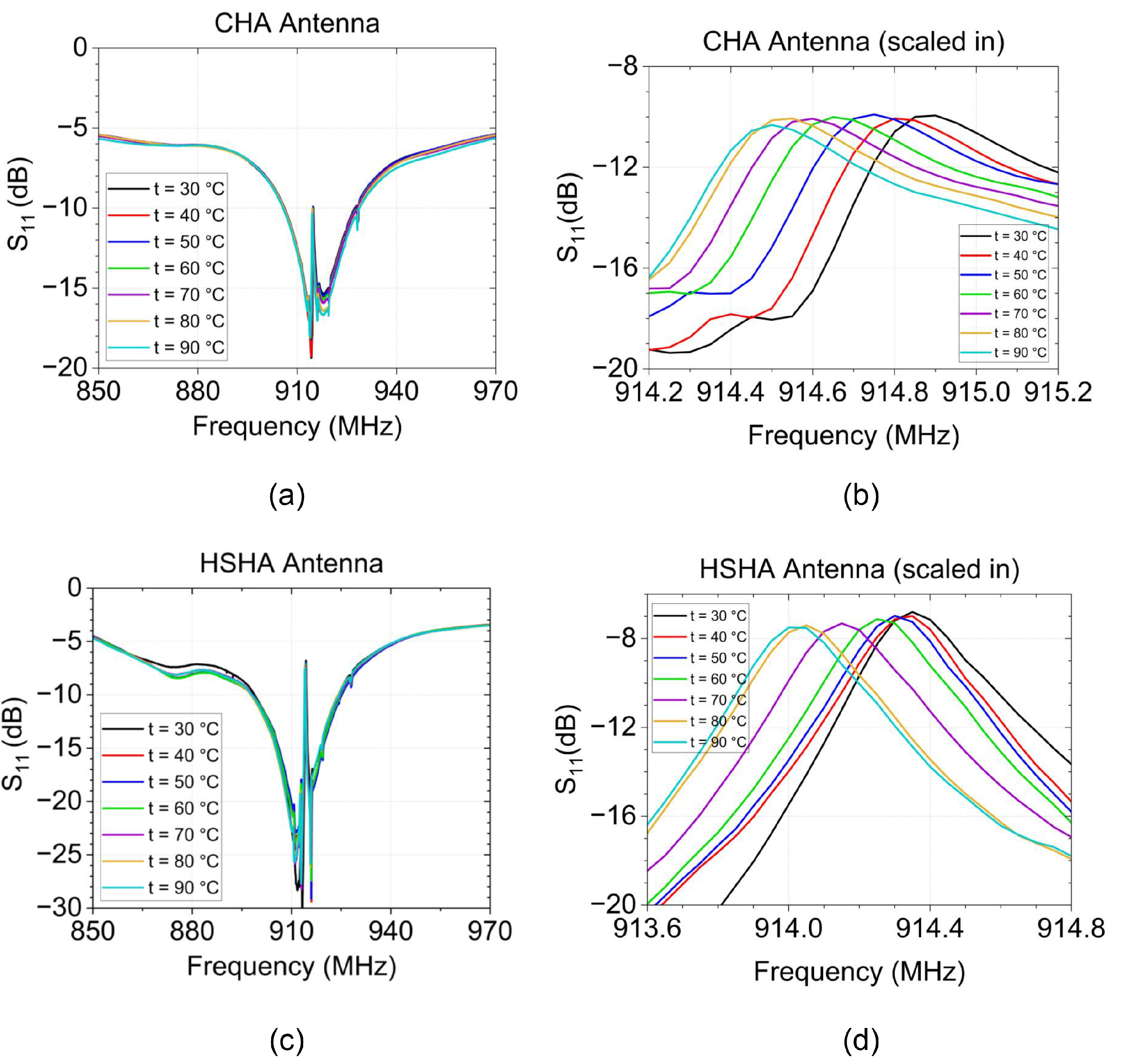

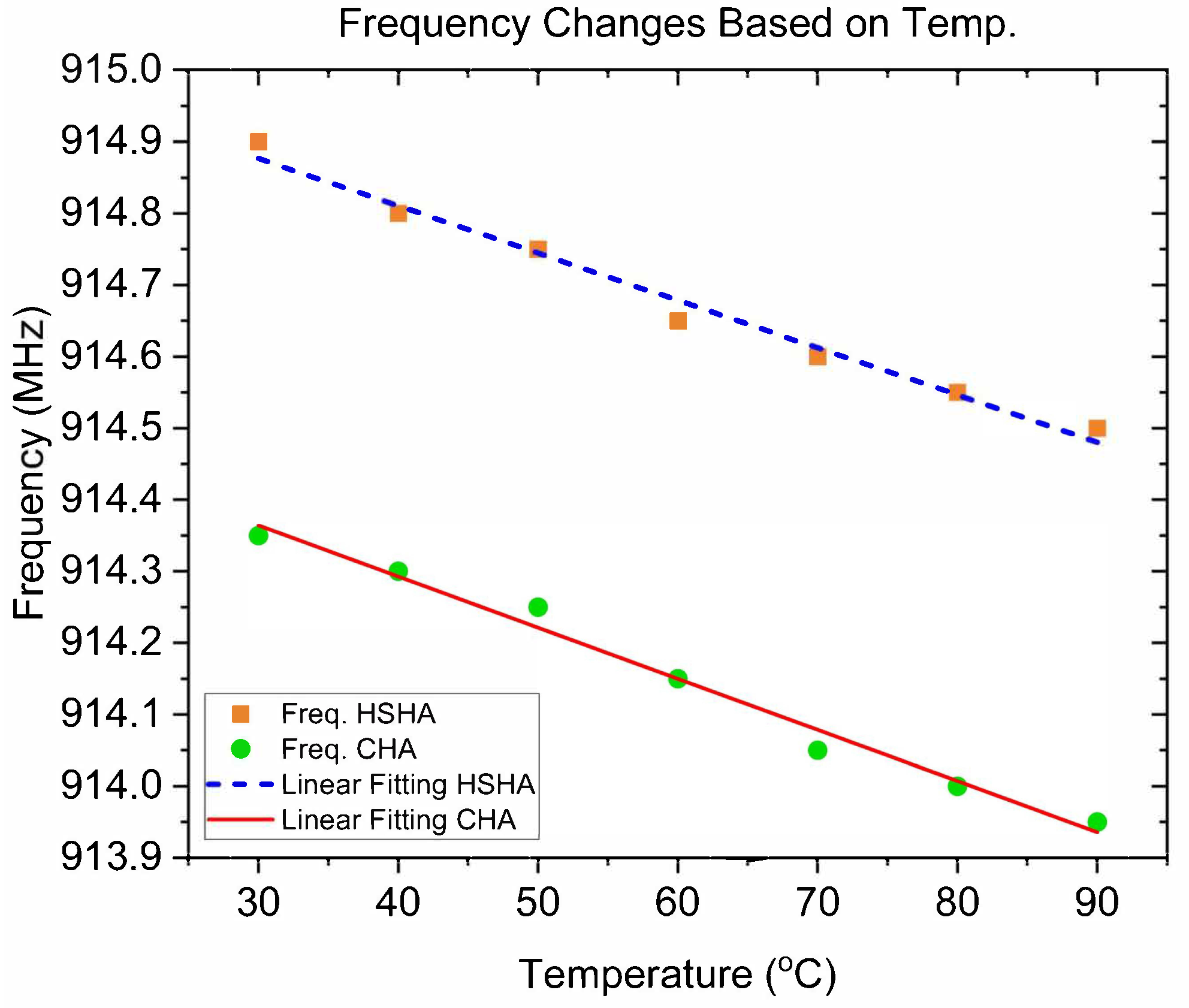

3.3. Temperature Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SAW | Surface Acoustic Wave |

| CHA | Cylindrical Helical Antenna |

| HSHA | Hemispherical Helical Antenna |

| RTDs | Resistance Temperature Detectors |

| RFID | Radio Frequency Identification |

| CPW | Coplanar Waveguide |

| Tx | Transmitter |

| Rx | Receiver |

| DUT | Device Under Test |

| VNA | Vector Network Analyzer |

| PCB | Printed Circuit Board |

| FSPL | Free Space Path Loss |

References

- Singh, R.; Singh, S.P. Development of a Low Cost Wireless Temperature Monitoring System for Industrial & Research Application. Int. J. Curr. Eng. Technol. 2015, 5, 355–361. [Google Scholar]

- Park, D.; Jung, H.-S.; Cho, H.-J.; Sul, S.-K. Design of wireless temperature monitoring system for measurement of magnet temperature of IPMSM. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 656–661. [Google Scholar]

- Khairi, N.A.; Jambek, A.B.; Boon, T.W.; Hashim, U. Design and analysis of a wireless temperature monitoring system. In Proceedings of the RSM 2013 IEEE Regional Symposium on Micro and Nanoelectronics, Langkawi, Malaysia, 25–27 September 2013; pp. 105–108. [Google Scholar]

- Wei, Q.; Park, H.-J.; Lee, J.H. Development of a wireless health monitoring system for measuring core body temperature from the back of the body. J. Healthc. Eng. 2019, 2019, 8936121. [Google Scholar] [CrossRef]

- Mansor, H.; Shukor, M.H.A.; Meskam, S.S.; Rusli, N.Q.A.M.; Zamery, N.S. Body temperature measurement for remote health monitoring system. In Proceedings of the 2013 IEEE International Conference on Smart Instrumentation, Measurement and Applications (ICSIMA), Kuala Lumpur, Malaysia, 25–27 November 2013; pp. 1–5. [Google Scholar]

- Mahan, J.R.; Conaty, W.; Neilsen, J.; Payton, P.; Cox, S.B. Field performance in agricultural settings of a wireless temperature monitoring system based on a low-cost infrared sensor. Comput. Electron. Agric. 2010, 71, 176–181. [Google Scholar] [CrossRef]

- Raghunathan, N.; Jiang, X.; Peroulis, D.; Ganguly, A. Wireless low-power temperature probes for food/pharmaceutical process monitoring. In Proceedings of the 2015 IEEE SENSORS, Busan, Republic of Korea, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Saha, S.; Majumdar, A. Data centre temperature monitoring with ESP8266 based Wireless Sensor Network and cloud based dashboard with real time alert system. In Proceedings of the 2017 Devices for Integrated Circuit (DevIC), Kalyani, India, 23–24 March 2017; pp. 307–310. [Google Scholar]

- Monteleone, S.; Sampaio, M.; Maia, R.F. A novel deployment of smart Cold Chain system using 2G-RFID-Sys temperature monitoring in medicine Cold Chain based on Internet of Things. In Proceedings of the 2017 IEEE International Conference on Service Operations and Logistics, and Informatics (SOLI), Bari, Italy, 18–20 September 2017; pp. 205–210. [Google Scholar]

- Li, C.; Feng, Q.; Jia, M.; Gao, L.; Jia, P.; Fang, Z.; Lu, H.; Xiong, J. Accurate real-time temperature measurement method in ultra-high temperature rotational environments for aero engines/turbines. IEEE Sens. J. 2022, 22, 6482–6490. [Google Scholar] [CrossRef]

- Bhar, I.; Mandal, N. A review on advanced wireless passive temperature sensors. Measurement 2022, 187, 110255. [Google Scholar] [CrossRef]

- Idhaiam, K.S.V.; Pozo, P.D.; Sabolsky, K.; Sabolsky, E.M.; Sierros, K.A.; Reynolds, D.S. All-ceramic LC resonator for chipless temperature sensing within high temperature systems. IEEE Sens. J. 2021, 21, 19771–19779. [Google Scholar] [CrossRef]

- Ji, Y.; Tan, Q.; Lu, X.; Zhang, G.; Zhang, W.; Xiong, J. Wireless passive separated LC temperature sensor based on high-temperature co-fired ceramic operating up to 1500 °C. J. Micromech. Microeng. 2019, 29, 035015. [Google Scholar] [CrossRef]

- Qian, Y.; Luo, Z.; Liu, Z.; Zhao, H.; Li, C.; Song, Y.; Nan, D.; Wei, J. Application of RTD sensor in the real-time measurement and wireless transmission. In Proceedings of the 2014 Fourth International Conference on Instrumentation and Measurement, Computer, Communication and Control, Harbin, China, 18–20 September 2014; pp. 658–662. [Google Scholar]

- Gao, X.; Cheng, L.; Xue, X.; Zhai, S.; Liang, Y.; Wang, W.; Liu, M.; Zhu, J.; Li, Z. Development of wireless and passive SAW temperature sensor with very high accuracy. Appl. Sci. 2021, 11, 7422. [Google Scholar] [CrossRef]

- Stevens, D.S.; Andle, J.C.; Sabah, S.; Jumani, S.J.; Wall, B.W.A.; Baier, M.; Martens, T.; Gruenwald, R. Applications of wireless temperature measurement using SAW resonators. In Proceedings of the Fourth International Symposium on Acoustic Wave Devices for Future Mobile Communication Systems, Chiba, Japan, 3–5 March 2010. [Google Scholar]

- Reindl, L.; Shrena, I.; Kenshil, S.; Peter, R. Wireless measurement of temperature using surface acoustic waves sensors. In Proceedings of the IEEE International Frequency Control Symposium and PDA Exhibition Jointly with the 17th European Frequency and Time Forum, Tampa, FL, USA, 4–8 May 2003; pp. 935–941. [Google Scholar]

- Lee, K.; Wang, W.; Kim, T.; Yang, S. A novel 440 MHz wireless SAW microsensor integrated with pressure–temperature sensors and ID tag. J. Micromech. Microeng. 2007, 17, 515. [Google Scholar] [CrossRef]

- Gallagher, M.W.; Santos, B.C.; Malocha, D.C. Wireless wideband SAW sensor-antenna design. In Proceedings of the 2010 IEEE International Frequency Control Symposium, Newport Beach, CA, USA, 1–4 June 2010; pp. 291–296. [Google Scholar]

- Sandoval, R.M.; Garcia-Sanchez, A.-J.; Garcia-Sanchez, F.; Garcia-Haro, J. Evaluating the more suitable ISM frequency band for IoT-based smart grids: A quantitative study of 915 MHz vs. 2400 MHz. Sensors 2016, 17, 76. [Google Scholar] [CrossRef]

- Malocha, D.C.; Humphries, J.; Figueroa, J.A.; Lamothe, M.; Weeks, A. 915 MHz SAW wireless passive sensor system performance. In Proceedings of the 2016 IEEE International Ultrasonics Symposium (IUS), Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Han, Y.; Qi, B.; Tan, J. Antenna design of passive wireless temperature sensor based on surface acoustic wave. In Proceedings of the 2017 IEEE 9th International Conference on Communication Software and Networks (ICCSN), Guangzhou, China, 6–8 May 2017; pp. 713–717. [Google Scholar]

- Balanis, C.A. Antenna Theory: Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 549–555. [Google Scholar]

- Stutzman, W.L.; Thiele, G.A. Antenna Theory and Design; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Zhao, S.; Fumeaux, C.; Coleman, C. Miniaturised high-frequency and very-high-frequency antennas based on optimised non-uniform helical structures. IET Microw. Antennas Propag. 2012, 6, 603–610. [Google Scholar] [CrossRef]

- Hui, H.T.; Chan, K.Y.; Yung, E.K.N. The low-profile hemispherical helical antenna with circular polarization radiation over a wide angular range. IEEE Trans. Antennas Propag. 2003, 51, 1415–1418. [Google Scholar] [CrossRef]

- Rayhana, A.I.; Alaaudeen, K.M. A conformable design of hemispherical helical antenna for ocean monitoring. In SSRG International Journal of Electronics and Communication Engineering (SSRG-IJECE); Seventh Sense Research Group: Tiruchirappalli, India, 2019; pp. 49–53. ISSN 2348-8549. [Google Scholar]

- Alsawaha, H.W.; Safaai-Jazi, A. Ultrawideband hemispherical helical antennas. IEEE Trans. Antennas Propag. 2010, 58, 3175–3181. [Google Scholar] [CrossRef]

- Zhang, Y.; Hui, H.T. A printed hemispherical helical antenna for GPS receivers. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 10–12. [Google Scholar] [CrossRef]

- Hui, H.T.; Yung, E.K.N.; Law, C.L.; Koh, Y.S.; Koh, W.L. Design of a small and low-profile 2 × 2 hemispherical helical antenna array for mobile satellite communications. IEEE Trans. Antennas Propag. 2004, 52, 346–348. [Google Scholar] [CrossRef]

- Görlür, A.; Karpuz, C. Influence of narrow transverse slit in CPW resonator on its resonance characteristics. Electron. Lett. 2000, 36, 49–50. [Google Scholar] [CrossRef]

- Rappaport, T.S. Wireless Communications: Principles and Practice; Cambridge University Press: Cambridge, UK, 2024; pp. 70–77. [Google Scholar]

| Helix Stage | S (mm) | N (turns) |

|---|---|---|

| First Stage | ||

| Second Stage | ||

| Third Stage |

| Stage | S (mm) | N (turns) |

|---|---|---|

| First Stage | ||

| Second Stage | ||

| Third Stage |

| Antenna Type | PCB Size () | Antenna Height (mm) | Diameter (mm) |

|---|---|---|---|

| CHA | 16.8 | 5 | |

| HSHA | 5 | 10 |

| Tx. Power (dBm) | Measured Rx. Power (dBm) CHA | Measured Rx. Power (dBm) HSHA | Calculated Rx. Power (dBm) CHA | Calculated Rx. Power (dBm) HSHA |

|---|---|---|---|---|

| 0 | −31.88 | −38.63 | −22.36 | −24.7 |

| 10 | −22.88 | −27.52 | −12.36 | −14.7 |

| 20 | −13.5 | −20.06 | −2.36 | −4.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sreang, N.; Chung, J.-Y. Miniaturized Antenna Design for Wireless and Powerless Surface Acoustic Wave Temperature Sensors. Sensors 2024, 24, 5490. https://doi.org/10.3390/s24175490

Sreang N, Chung J-Y. Miniaturized Antenna Design for Wireless and Powerless Surface Acoustic Wave Temperature Sensors. Sensors. 2024; 24(17):5490. https://doi.org/10.3390/s24175490

Chicago/Turabian StyleSreang, Naranut, and Jae-Young Chung. 2024. "Miniaturized Antenna Design for Wireless and Powerless Surface Acoustic Wave Temperature Sensors" Sensors 24, no. 17: 5490. https://doi.org/10.3390/s24175490

APA StyleSreang, N., & Chung, J.-Y. (2024). Miniaturized Antenna Design for Wireless and Powerless Surface Acoustic Wave Temperature Sensors. Sensors, 24(17), 5490. https://doi.org/10.3390/s24175490