Evaluating the Performance of Joint Angle Estimation Algorithms on an Exoskeleton Mock-Up via a Modular Testing Approach

Abstract

1. Introduction

2. Materials and Methods

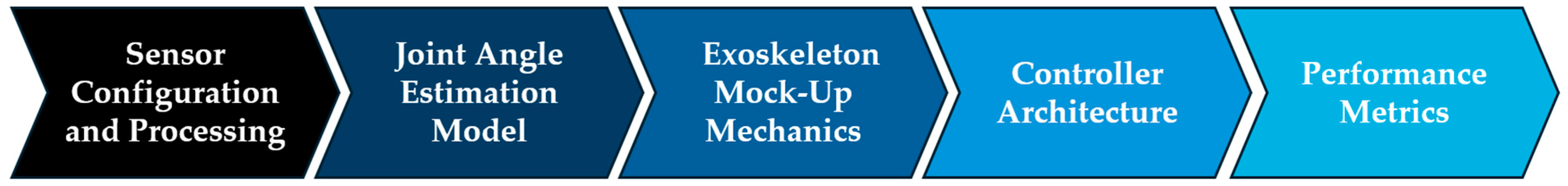

2.1. Testing Modules

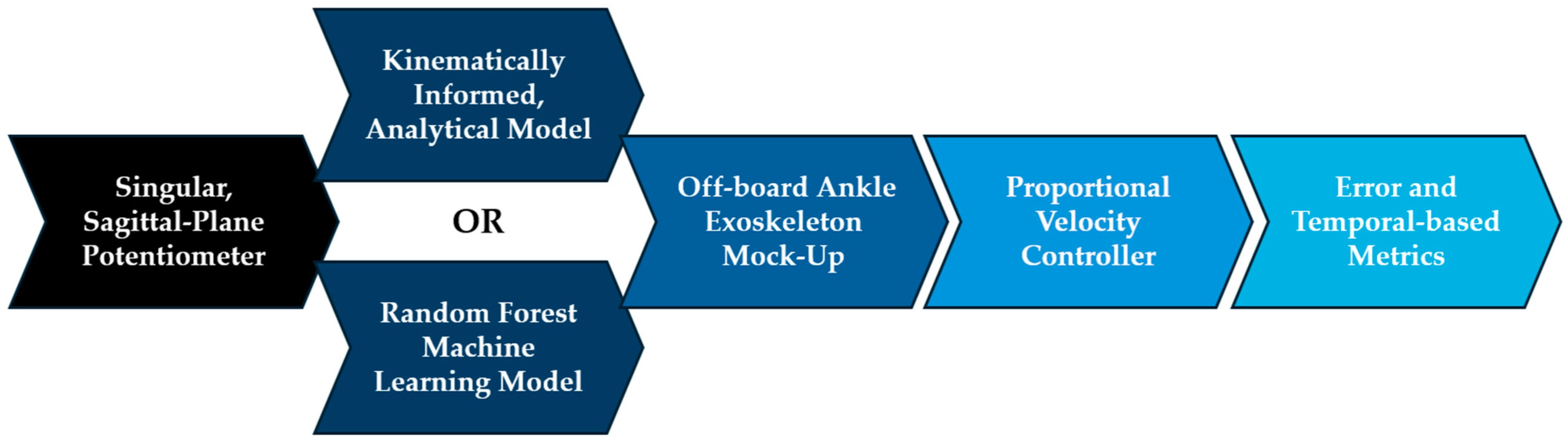

- The sensor configuration and processing module refers to all aspects of sensor selection, count, placement, and filtering. This module describes both the sensor array onboard the exoskeleton mock-up and the sensors used to collect human kinematic and/or kinetic data (which will serve as an input to the joint angle estimation module). This human subject data can either be pre-recorded or collected in real time as the exoskeleton mock-up is being tested (as seen in Figure 2). Both configurations mitigate the complexities of deploying the mechanical prototype on a human subject.

- The joint angle estimation model module encompasses all processes of converting filtered sensor data into an estimated joint angle, regardless of the approach taken (i.e., statistical, analytical, machine learning, model-based simulation, etc.). A predictive joint angle estimation model seeks to estimate a joint’s future position, rather than estimating the joint’s current position, so that an exoskeleton has sufficient time to actuate alongside the operator (rather than lagging behind the operator’s intended motion).

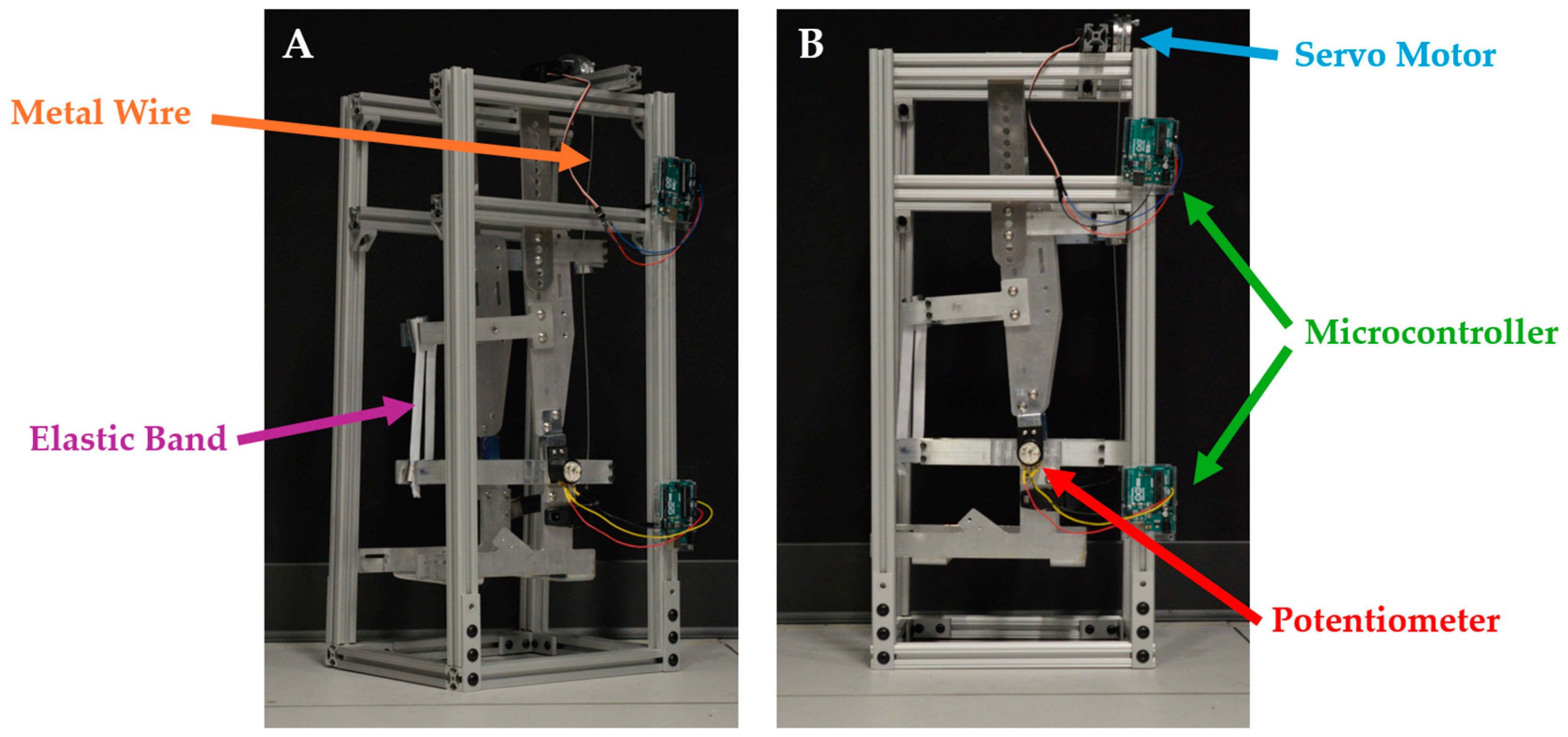

- The exoskeleton mock-up mechanics module refers to both the structural design and the actuation method of the physical mock-up.

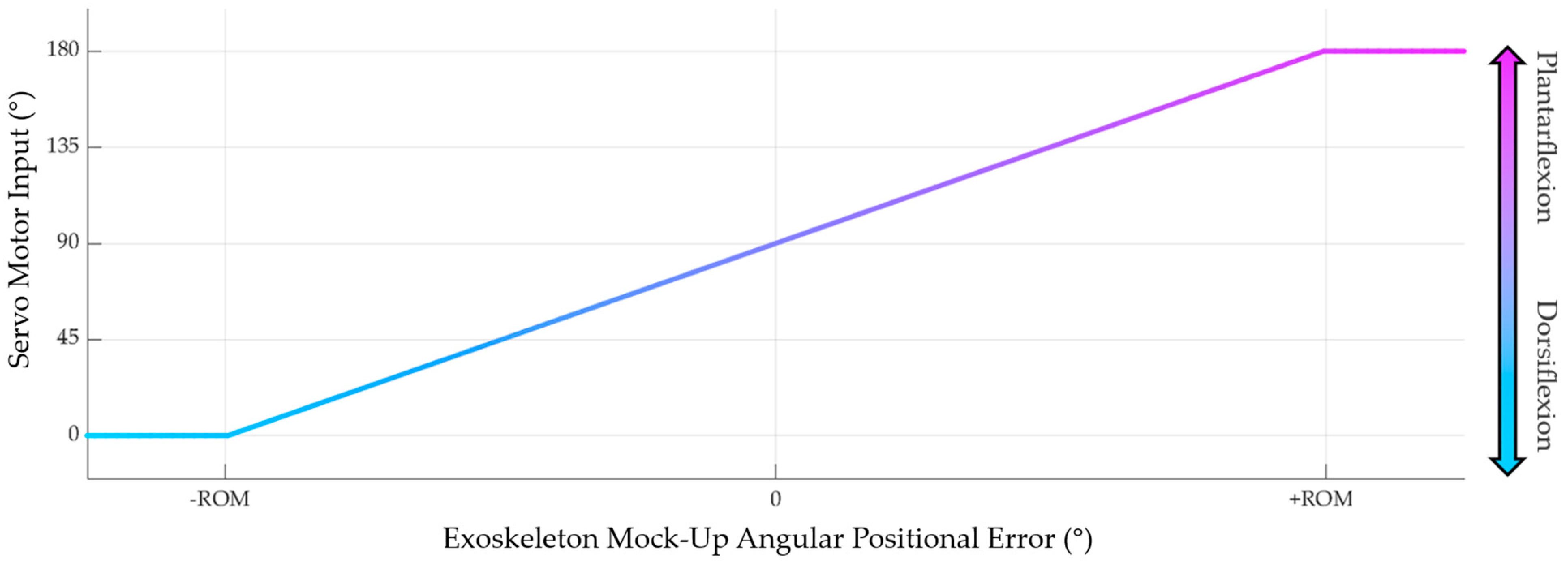

- The controller architecture module describes the process by which the exoskeleton mock-up is controlled to actuate to a desired, estimated joint angle.

- The performance metrics module is the broadest category and does not have a direct impact on the behavior of the test setup. However, this module has been included to provide further clarity when comparing different systems. Just within a single review on kinematic estimation and prediction models [31], at least five unique metrics were used to characterize the performance of the reviewed models (including mean absolute error, mean squared error, mean relative error, root-mean-squared error, and normalized root-mean-squared error), causing comparisons between model types to become more convoluted than simply comparing two numbers. Additionally, deploying joint angle estimation models on a physical system may require additional metrics to fully characterize the performance, such as computational delays and the model’s tendencies to lead or lag behind the desired joint angle estimations.

2.2. Participants

2.3. Sensor Configuration and Processing

2.4. Joint Angle Estimation Models

2.4.1. Kinematically Governed Extrapolation Model

2.4.2. Random Forest Machine Learning Model

2.5. Exoskeleton Mock-Up Mechanics

2.6. Controller Architecture

2.7. Deploying the Joint Angle Estimation Models on the Mock-Up Testbed

2.8. Performance Metrics

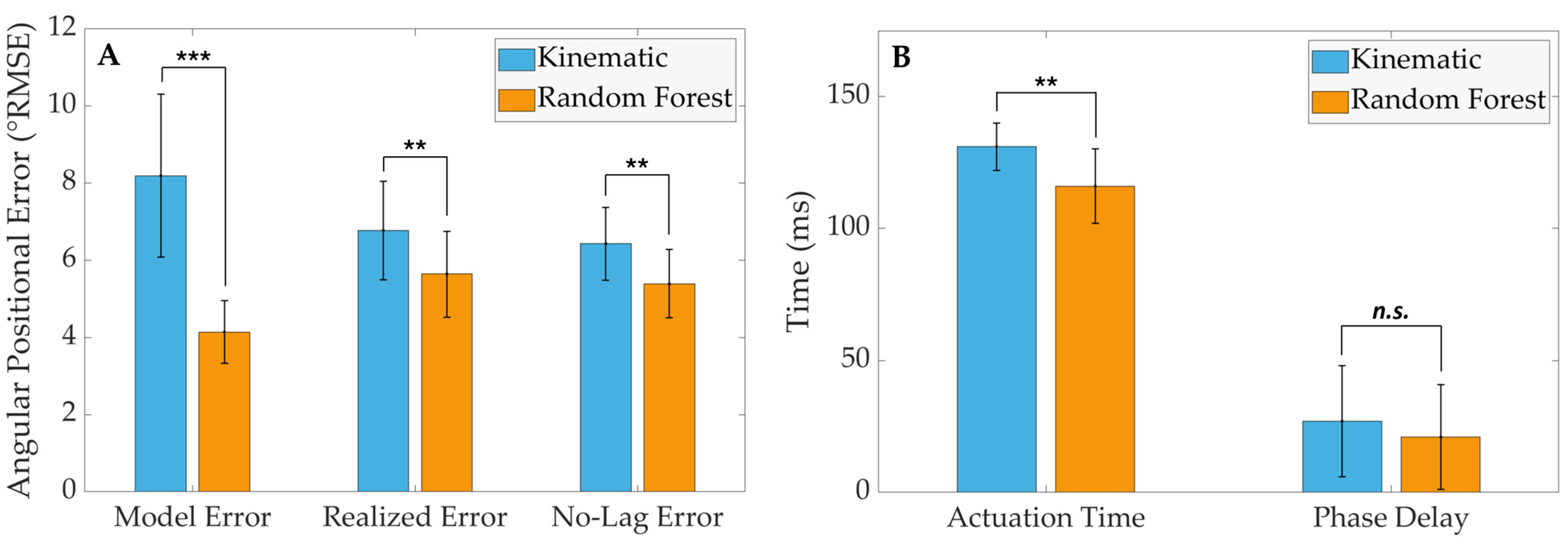

2.8.1. Model Error

2.8.2. Realized Error

2.8.3. Actuation Time

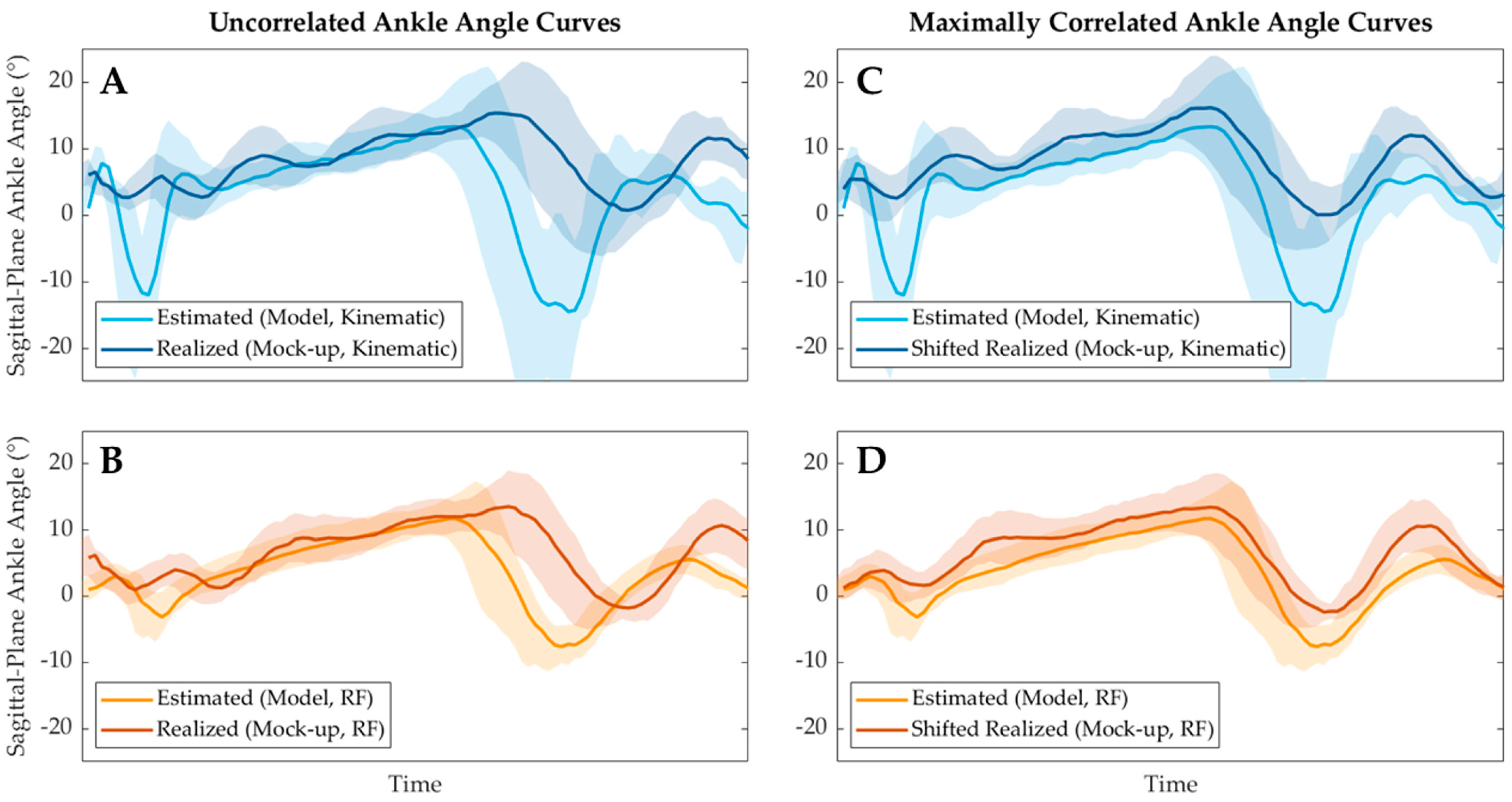

2.8.4. Phase Delay

2.8.5. No-Lag Error

2.8.6. Statistical Analysis

- One-tailed paired t-tests were performed to test for directional differences between joint angle estimation model types in terms of model errors, realized errors, and actuation times.

- Two-tailed paired t-tests were performed to test for bidirectional differences between joint angle estimation model types in terms of phase delays and no-lag errors.

3. Results

3.1. Performance Metric Evaluation

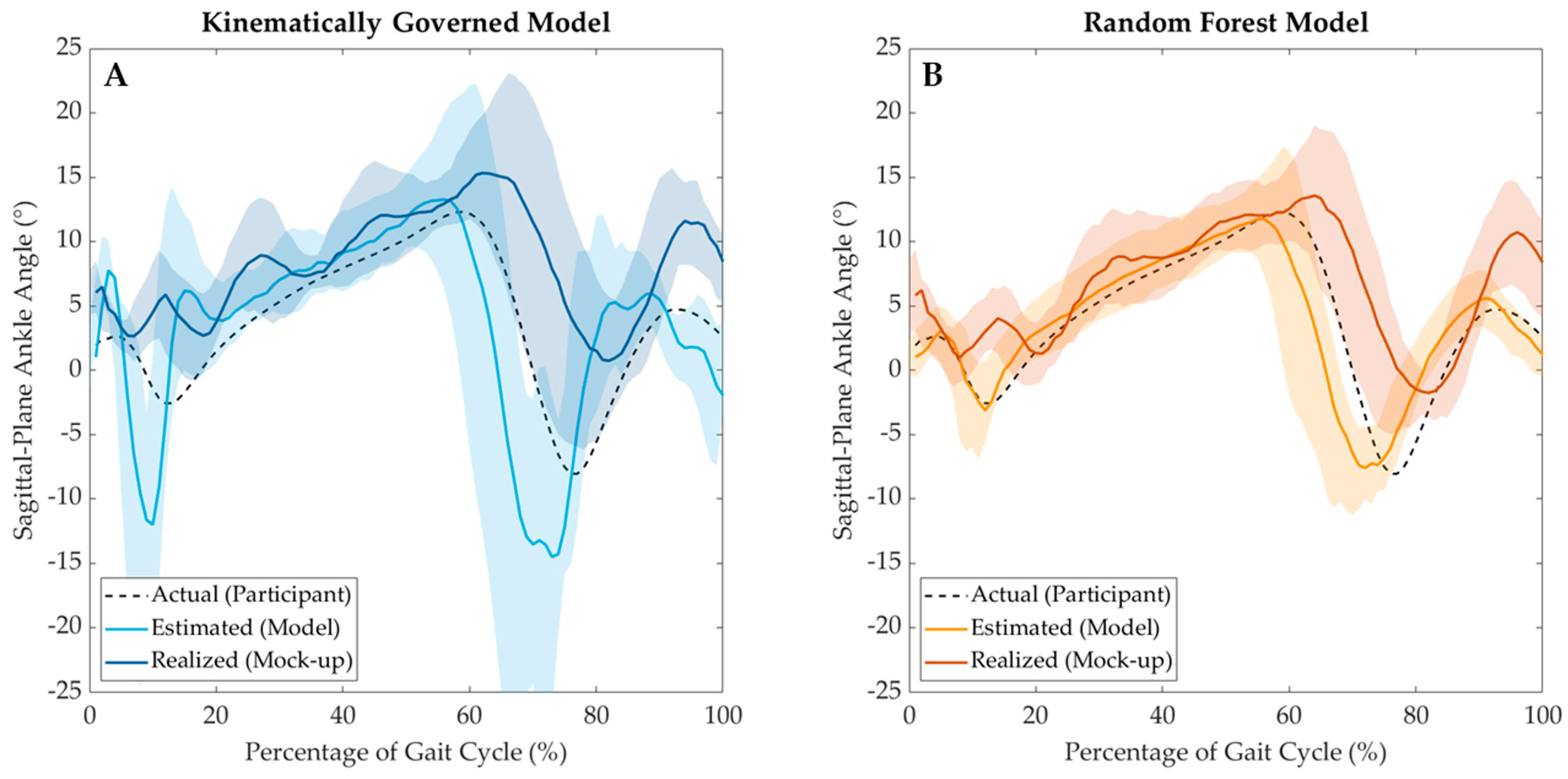

3.2. Visual Inspection of Exoskeleton Mock-Up Testbed Performance

4. Discussion

4.1. Results and Hypotheses Discussion

4.2. Limitations and Future Work

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Pinto-Fernandez, D.; Torricelli, D.; Sanchez-Villamanan MD, C.; Aller, F.; Mombaur, K.; Conti, R.; Vitiello, N.; Moreno, J.C.; Pons, J.L. Performance Evaluation of Lower Limb Exoskeletons: A Systematic Review. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1573–1583. [Google Scholar] [CrossRef]

- Kirkwood, G.L.; Otmar, C.D.; Hansia, M. Who’s Leading This Dance?: Theorizing Automatic and Strategic Synchrony in Human-Exoskeleton Interactions. Front. Psychol. 2021, 12, 624108. [Google Scholar] [CrossRef] [PubMed]

- Sawicki, G.S.; Ferris, D.P. Mechanics and energetics of level walking with powered ankle exoskeletons. J. Exp. Biol. 2008, 211, 1402–1413. [Google Scholar] [CrossRef]

- Ding, Y.; Panizzolo, F.A.; Siviy, C.; Malcolm, P.; Galiana, I.; Holt, K.G.; Walsh, C.J. Effect of timing of hip extension assistance during loaded walking with a soft exosuit. J. NeuroEng. Rehabil. 2016, 13, 87. [Google Scholar] [CrossRef]

- Galle, S.; Malcolm, P.; Collins, S.H.; De Clercq, D. Reducing the metabolic cost of walking with an ankle exoskeleton: Interaction between actuation timing and power. J. NeuroEng. Rehabil. 2017, 14, 35. [Google Scholar] [CrossRef]

- Young, A.J.; Foss, J.; Gannon, H.; Ferris, D.P. Influence of Power Delivery Timing on the Energetics and Biomechanics of Humans Wearing a Hip Exoskeleton. Front. Bioeng. Biotechnol. 2017, 5, 4. [Google Scholar] [CrossRef] [PubMed]

- Ingraham, K.A.; Remy, C.D.; Rouse, E.J. The role of user preference in the customized control of robotic exoskeletons. Sci. Robot. 2022, 7, eabj3487. [Google Scholar] [CrossRef] [PubMed]

- Young, A.J.; Ferris, D.P. State of the Art and Future Directions for Lower Limb Robotic Exoskeletons. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 171–182. [Google Scholar] [CrossRef]

- Liang, C.; Hsiao, T. Admittance Control of Powered Exoskeletons Based on Joint Torque Estimation. IEEE Access 2020, 8, 94404–94414. [Google Scholar] [CrossRef]

- Zhang, H.; Ahmad, S.; Liu, G. Torque Estimation for Robotic Joint With Harmonic Drive Transmission Based on Position Measurements. IEEE Trans. Robot. 2015, 31, 322–330. [Google Scholar] [CrossRef]

- Dinovitzer, H.; Shushtari, M.; Arami, A. Accurate Real-Time Joint Torque Estimation for Dynamic Prediction of Human Locomotion. IEEE Trans. Biomed. Eng. 2023, 70, 2289–2297. [Google Scholar] [CrossRef]

- Liang, W.; Wang, F.; Fan, A.; Zhao, W.; Yao, W.; Yang, P. Extended Application of Inertial Measurement Units in Biomechanics: From Activity Recognition to Force Estimation. Sensors 2023, 23, 4229. [Google Scholar] [CrossRef]

- Liu, Y.; Shih, S.-M.; Tian, S.-L.; Zhong, Y.-J.; Li, L. Lower extremity joint torque predicted by using artificial neural network during vertical jump. J. Biomech. 2009, 42, 906–911. [Google Scholar] [CrossRef]

- Fang, Z.; Woodford, S.; Senanayake, D.; Ackland, D. Conversion of Upper-Limb Inertial Measurement Unit Data to Joint Angles: A Systematic Review. Sensors 2023, 23, 6535. [Google Scholar] [CrossRef]

- Coker, J.; Chen, H.; Schall, M.C.; Gallagher, S.; Zabala, M. EMG and Joint Angle-Based Machine Learning to Predict Future Joint Angles at the Knee. Sensors 2021, 21, 3622. [Google Scholar] [CrossRef]

- Bi, L.; Feleke, A.G.; Guan, C. A review on EMG-based motor intention prediction of continuous human upper limb motion for human-robot collaboration. Biomed. Signal Process. Control 2019, 51, 113–127. [Google Scholar] [CrossRef]

- Xiong, D.; Zhang, D.; Zhao, X.; Zhao, Y. Deep Learning for EMG-based Human-Machine Interaction: A Review. IEEE/CAA J. Autom. Sin. 2021, 8, 512–533. [Google Scholar] [CrossRef]

- Huang, Y.; He, Z.; Liu, Y.; Yang, R.; Zhang, X.; Cheng, G.; Yi, J.; Ferreira, J.P.; Liu, T. Real-Time Intended Knee Joint Motion Prediction by Deep-Recurrent Neural Networks. IEEE Sens. J. 2019, 19, 11503–11509. [Google Scholar] [CrossRef]

- Sharma, A.; Rombokas, E. Improving IMU-Based Prediction of Lower Limb Kinematics in Natural Environments Using Egocentric Optical Flow. IEEE Trans. Neural Syst. Rehabil. Eng. 2022, 30, 699–708. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cheng, X.; Jabban, L.; Sui, X.; Zhang, D. Motion Intention Prediction and Joint Trajectories Generation Toward Lower Limb Prostheses Using EMG and IMU Signals. IEEE Sens. J. 2022, 22, 10719–10729. [Google Scholar] [CrossRef]

- Hollinger, D.; Schall, M.C.; Chen, H.; Zabala, M. The Effect of Sensor Feature Inputs on Joint Angle Prediction across Simple Movements. Sensors 2024, 24, 3657. [Google Scholar] [CrossRef] [PubMed]

- Lee, T.; Kim, I.; Lee, S.-H. Estimation of the Continuous Walking Angle of Knee and Ankle (Talocrural Joint, Subtalar Joint) of a Lower-Limb Exoskeleton Robot Using a Neural Network. Sensors 2021, 21, 2807. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, P.; Yun, Y.; Fox, J.; Madden, K.; Deshpande, A.D. Design, control, and testing of a thumb exoskeleton with series elastic actuation. Int. J. Robot. Res. 2017, 36, 355–375. [Google Scholar] [CrossRef]

- Sy, L.; Raitor, M.; Del Rosario, M.; Khamis, H.; Kark, L.; Lovell, N.H.; Redmond, S.J. Estimating Lower Limb Kinematics using a Reduced Wearable Sensor Count. arXiv 2020, arXiv:1910.00910. http://arxiv.org/abs/1910.00910. [Google Scholar] [CrossRef]

- Sy, L.W.; Lovell, N.H.; Redmond, S.J. Estimating Lower Body Kinematics using a Lie Group Constrained Extended Kalman Filter and Reduced IMU Count. arXiv 2021, arXiv:2103.11393. http://arxiv.org/abs/2103.11393. [Google Scholar] [CrossRef]

- Hossain, M.S.B.; Choi, H.; Guo, Z. Estimating lower extremity joint angles during gait using reduced number of sensors count via deep learning. In Fourteenth International Conference on Digital Image Processing (ICDIP 2022); Xie, Y., Jiang, X., Tao, W., Zeng, D., Eds.; SPIE: Bellingham, WA, USA, 2022; p. 59. [Google Scholar] [CrossRef]

- Argent, R.; Drummond, S.; Remus, A.; O’Reilly, M.; Caulfield, B. Evaluating the use of machine learning in the assessment of joint angle using a single inertial sensor. J. Rehabil. Assist. Technol. Eng. 2019, 6, 205566831986854. [Google Scholar] [CrossRef]

- Bonnet, V.; Joukov, V.; Kulic, D.; Fraisse, P.; Ramdani, N.; Venture, G. Monitoring of Hip and Knee Joint Angles Using a Single Inertial Measurement Unit During Lower Limb Rehabilitation. IEEE Sens. J. 2016, 16, 1557–1564. [Google Scholar] [CrossRef]

- Alemayoh, T.T.; Lee, J.H.; Okamoto, S. Leg-Joint Angle Estimation from a Single Inertial Sensor Attached to Various Lower-Body Links during Walking Motion. Appl. Sci. 2023, 13, 4794. [Google Scholar] [CrossRef]

- Pollard, R.S.; Hollinger, D.S.; Nail-Ulloa, I.E.; Zabala, M.E. A Kinematically-Informed Approach to Near Future Joint Angle Estimation at the Ankle. IEEE Trans. Med. Robot. Bionics 2024, 6, 1125–1134. [Google Scholar] [CrossRef]

- Belal, M.; Alsheikh, N.; Aljarah, A.; Hussain, I. Deep Learning Approaches for Enhanced Lower-Limb Exoskeleton Control: A Review. IEEE Access 2024, 99, 1. [Google Scholar] [CrossRef]

- Andriacchi, T.P.; Alexander, E.J.; Toney, M.K.; Dyrby, C.; Sum, J. A Point Cluster Method for In Vivo Motion Analysis: Applied to a Study of Knee Kinematics. J. Biomech. Eng. 1998, 120, 743–749. [Google Scholar] [CrossRef] [PubMed]

- Charlton, W.; Tate, P.; Smyth, P.; Roren, L. Repeatability of an optimized lower body model. Gait Posture 2004, 20, 213–221. [Google Scholar] [CrossRef]

- Bryan, G.M.; Franks, P.W.; Klein, S.C.; Peuchen, R.J.; Collins, S.H. A hip–knee–ankle exoskeleton emulator for studying gait assistance. Int. J. Robot. Res. 2021, 40, 722–746. [Google Scholar] [CrossRef]

- Sun, N.; Cao, M.; Chen, Y.; Chen, Y.; Wang, J.; Wang, Q.; Chen, X.; Liu, T. Continuous Estimation of Human Knee Joint Angles by Fusing Kinematic and Myoelectric Signals. IEEE Trans. Neural Syst. Rehabil. Eng. 2022, 30, 2446–2455. [Google Scholar] [CrossRef]

- Nester, C.J.; Hutchins, S.; Bowker, P.P. Shank Rotation: A Measure of Rearfoot Motion During Normal Walking. Foot Ankle Int. 2000, 21, 578–583. [Google Scholar] [CrossRef]

- Stoica, P.; Moses, R.L. Spectral Analysis of Signals; Prentice Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- Fournier Belley, A.; Bouffard, J.; Brochu, K.; Mercier, C.; Roy, J.S.; Bouyer, L. Development and reliability of a measure evaluating dynamic proprioception during walking with a robotized ankle-foot orthosis, and its relation to dynamic postural control. Gait Posture 2016, 49, 213–218. [Google Scholar] [CrossRef]

- Hussain, F.; Goecke, R.; Mohammadian, M. Exoskeleton robots for lower limb assistance: A review of materials, actuation, and manufacturing methods. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 1375–1385. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pollard, R.S.; Bass, S.M.; Schall, M.C., Jr.; Zabala, M.E. Evaluating the Performance of Joint Angle Estimation Algorithms on an Exoskeleton Mock-Up via a Modular Testing Approach. Sensors 2024, 24, 5673. https://doi.org/10.3390/s24175673

Pollard RS, Bass SM, Schall MC Jr., Zabala ME. Evaluating the Performance of Joint Angle Estimation Algorithms on an Exoskeleton Mock-Up via a Modular Testing Approach. Sensors. 2024; 24(17):5673. https://doi.org/10.3390/s24175673

Chicago/Turabian StylePollard, Ryan S., Sarah M. Bass, Mark C. Schall, Jr., and Michael E. Zabala. 2024. "Evaluating the Performance of Joint Angle Estimation Algorithms on an Exoskeleton Mock-Up via a Modular Testing Approach" Sensors 24, no. 17: 5673. https://doi.org/10.3390/s24175673

APA StylePollard, R. S., Bass, S. M., Schall, M. C., Jr., & Zabala, M. E. (2024). Evaluating the Performance of Joint Angle Estimation Algorithms on an Exoskeleton Mock-Up via a Modular Testing Approach. Sensors, 24(17), 5673. https://doi.org/10.3390/s24175673