Sequential Injection Analysis Method for the Determination of Glutathione in Pharmaceuticals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solution Preparation

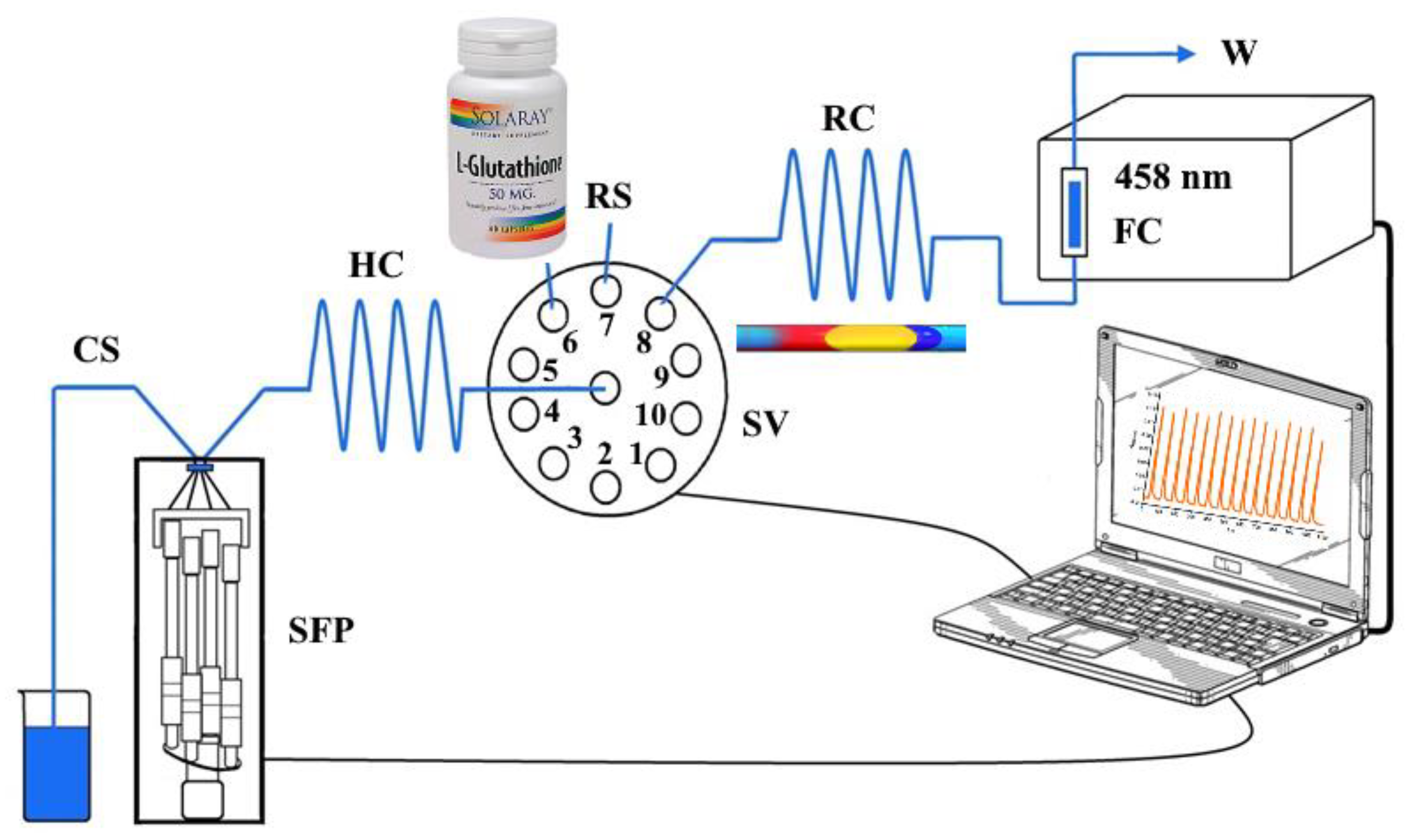

2.2. Apparatus and Analytical Procedure

3. Results and Discussion

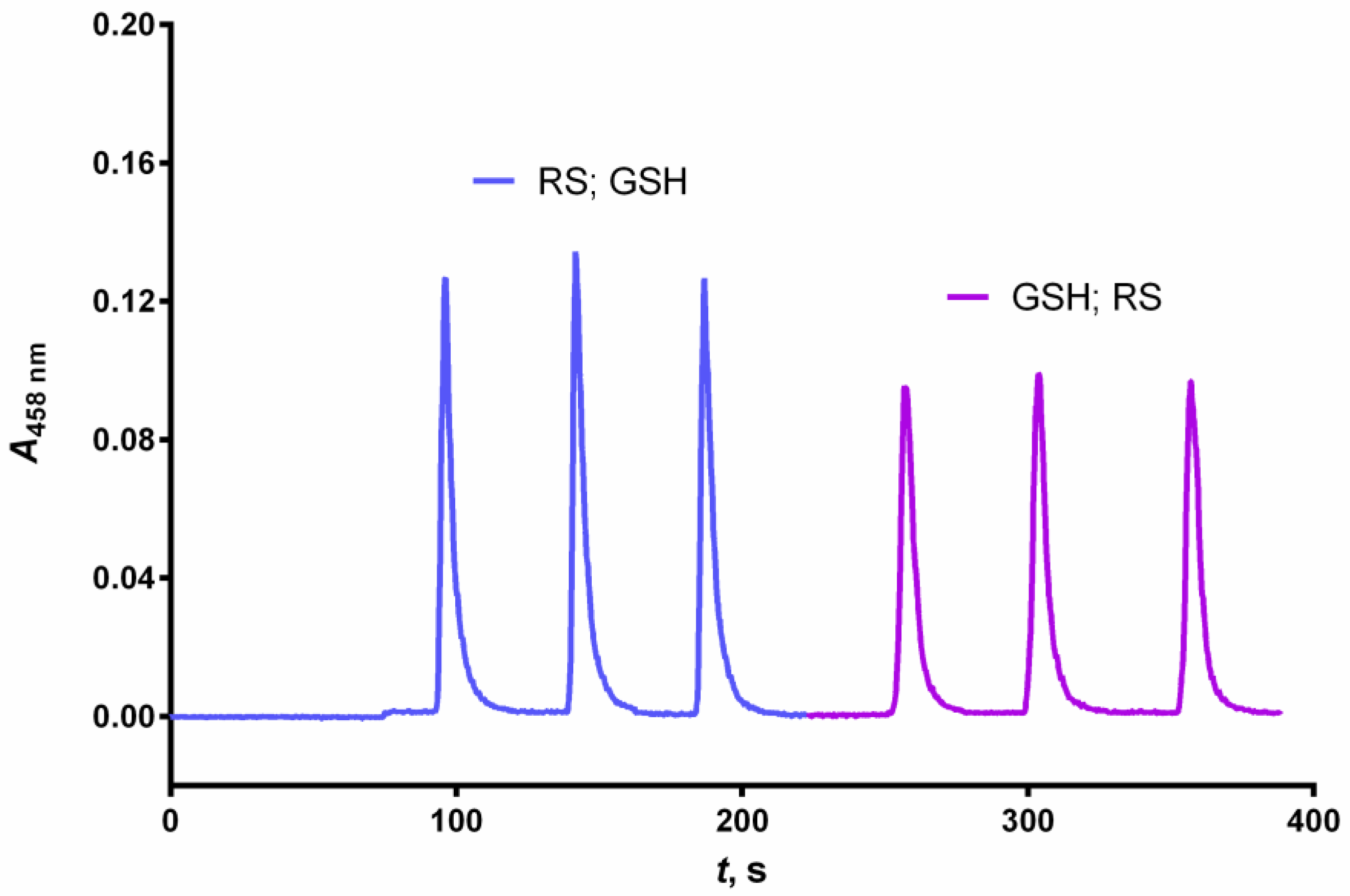

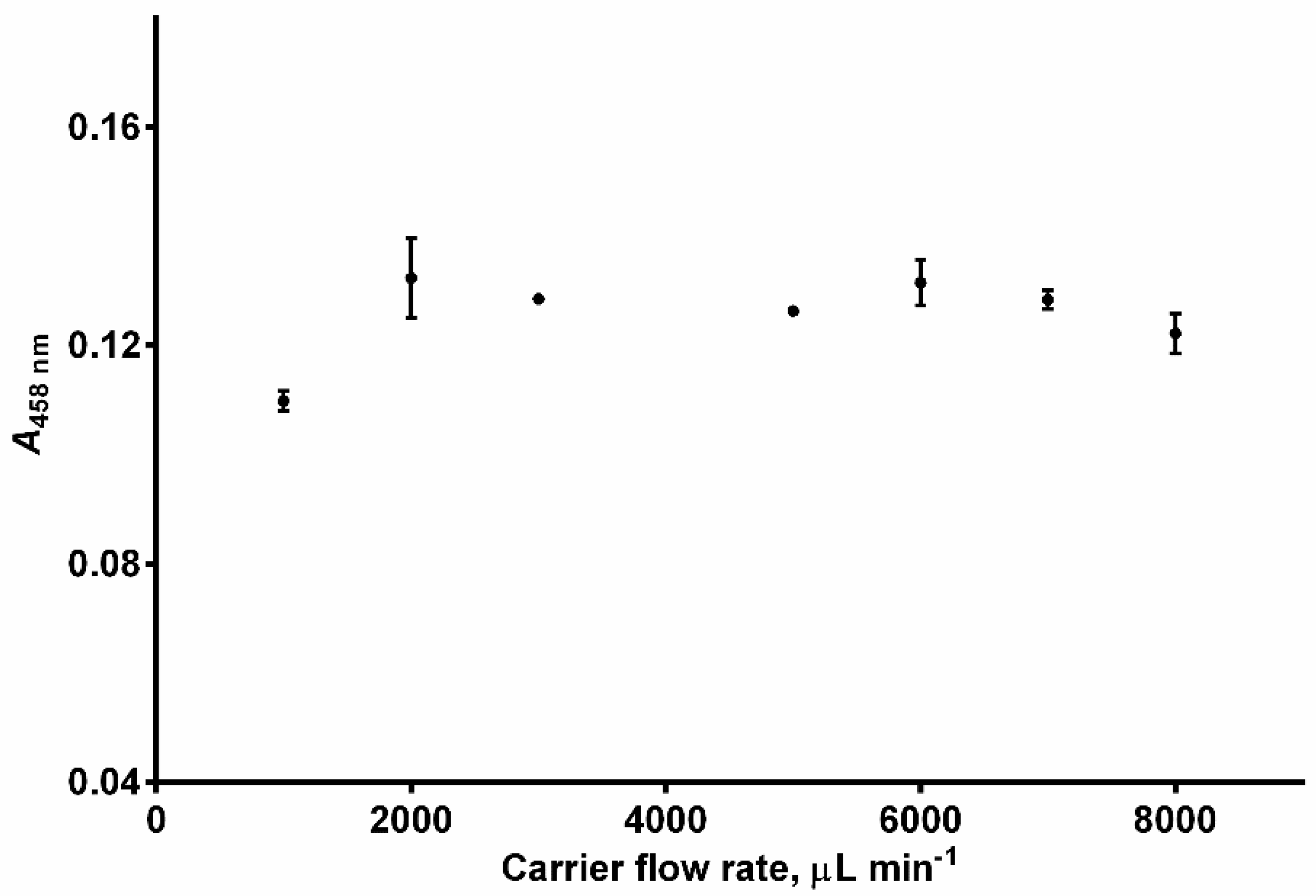

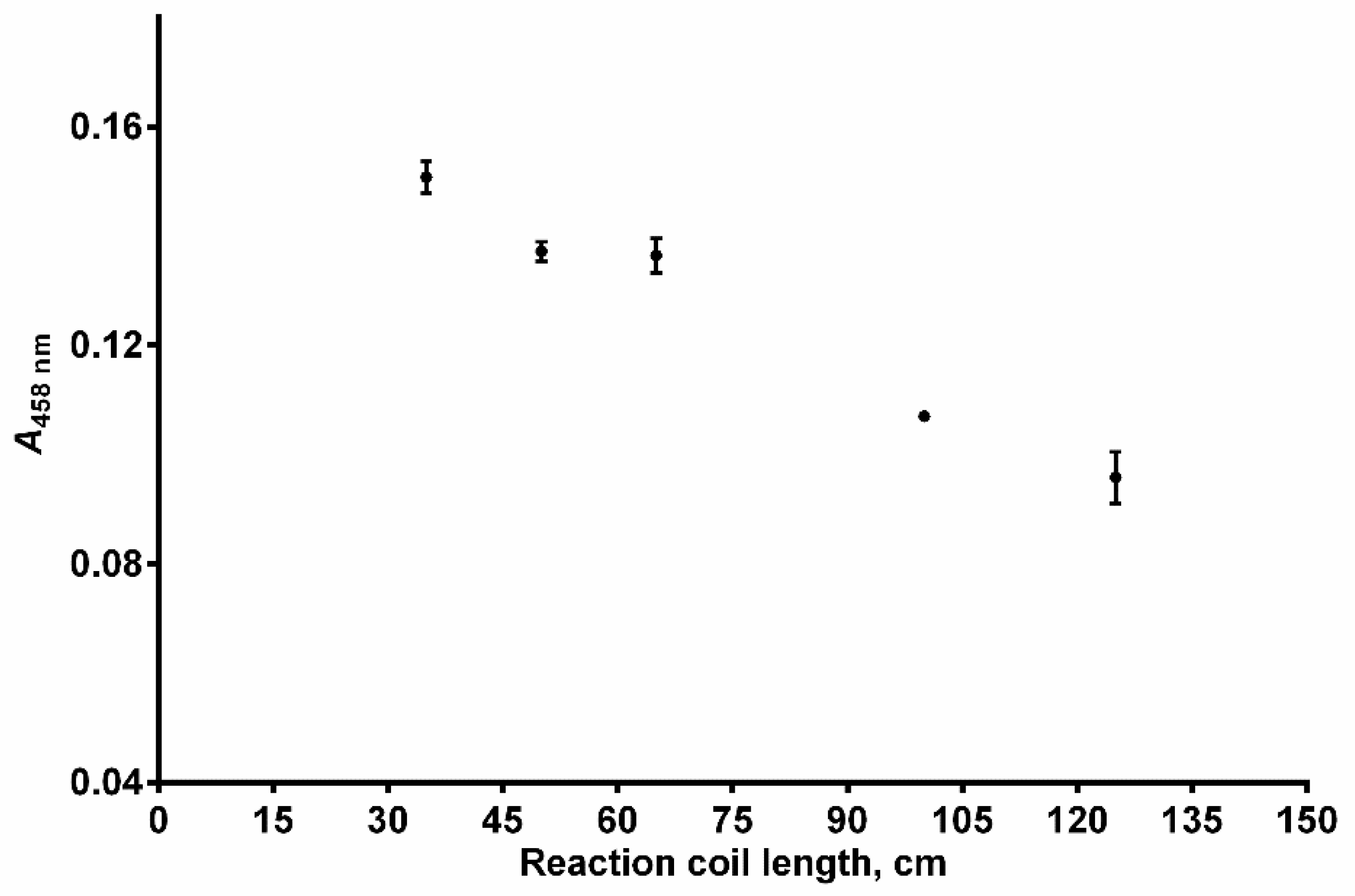

3.1. Optimization of the SIA System Parameters

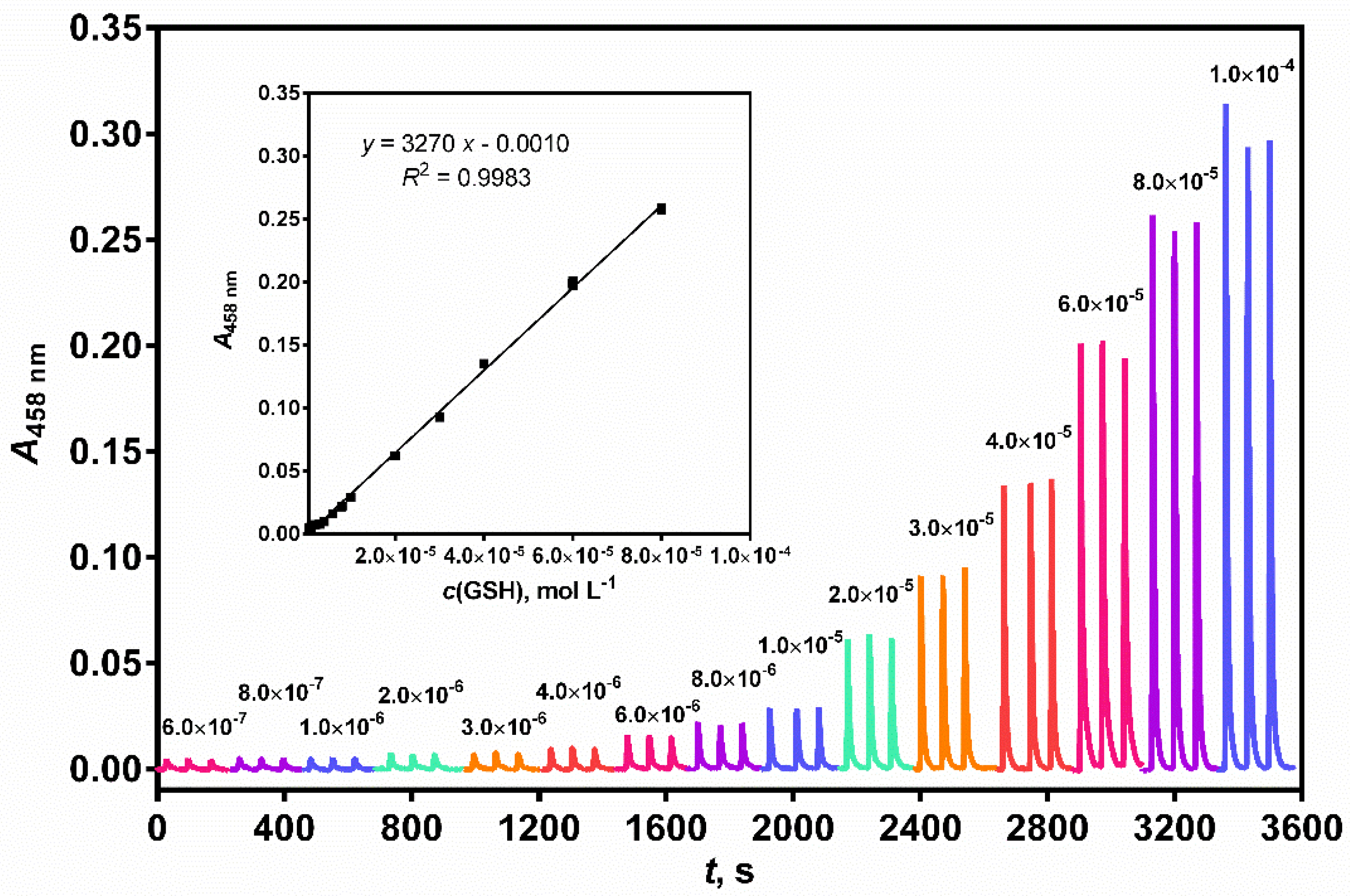

3.2. Analytical Figures of Merit

3.3. Effect of Interferences

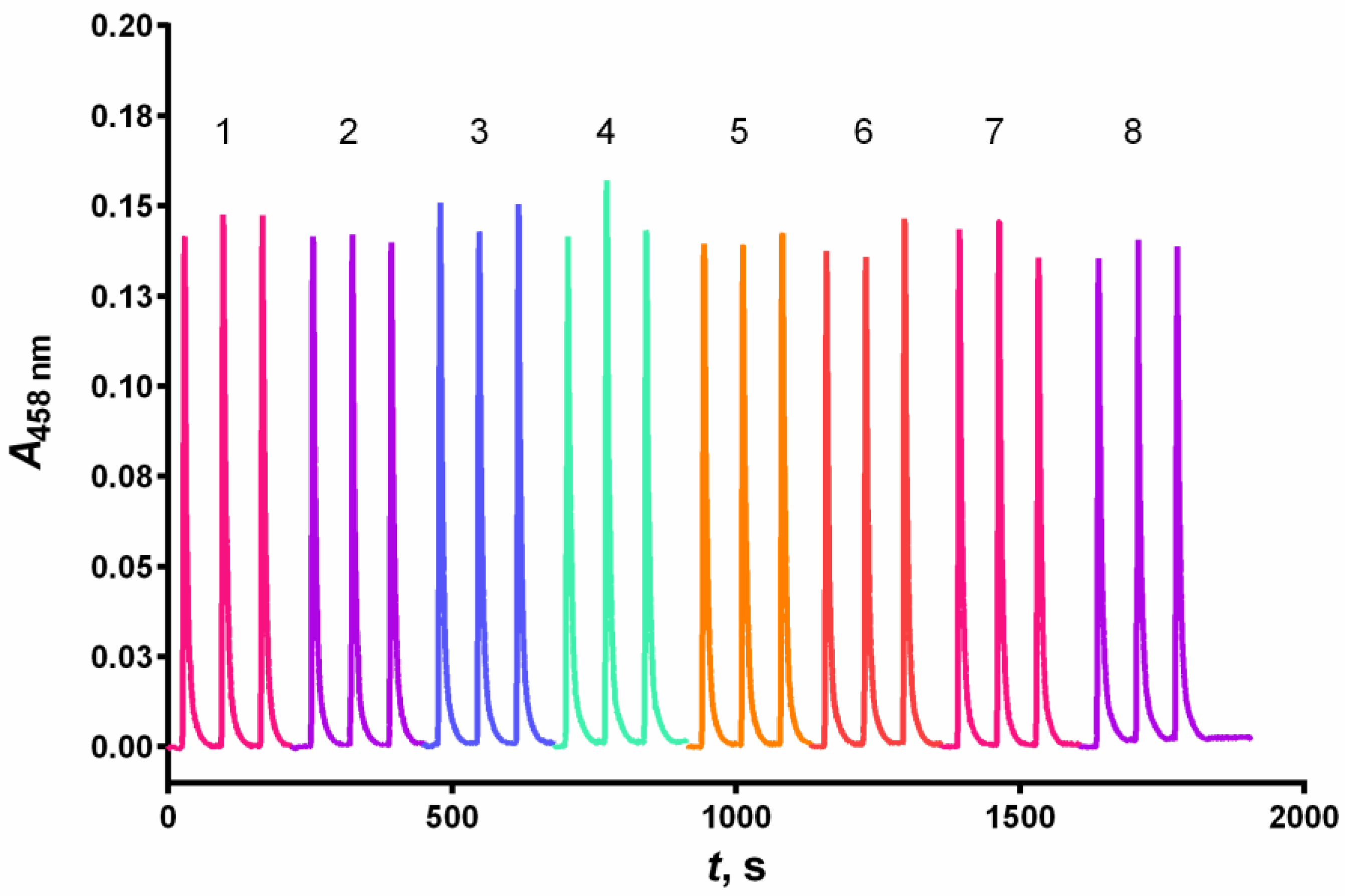

3.4. Method Validation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aquilano, K.; Baldelli, S.; Ciriolo, M.R. Glutathione: New roles in redox signaling for an old antioxidant. Front. Pharmacol. 2014, 5, 196. [Google Scholar] [CrossRef]

- Weschawalit, S.; Thongthip, S.; Phutrakool, P.; Asawanonda, P. Glutathione and its antiaging and antimelanogenic effects. Clin. Cosmet. Investig. Dermatol. 2017, 10, 147–153. [Google Scholar] [CrossRef]

- Berg, J.M.; Tymoczko, J.L.; Stryer, L. Biochemistry, 5th ed.; W.H. Freeman Publishing: New York, NY, USA, 2002; pp. 1018–1029. [Google Scholar]

- Ballatori, N.; Krance, S.M.; Notenboom, S.; Shi, S.; Tieu, K.; Hammond, C.L. Glutathione dysregulation and the etiology and progression of human diseases. Biol. Chem. 2009, 390, 191–214. [Google Scholar] [CrossRef]

- Hao, Y.; Xiong, D.; Wang, L.; Chen, W.; Zhou, B.; Liu, Y.-N. A reversible competition colorimetric assay for the detection of biothiols based on ruthenium-containing complex. Talanta 2013, 115, 253–257. [Google Scholar] [CrossRef]

- Detsri, E.; Seeharaj, P. Colorimetric detection of glutathione based on phthalic acid assisted synthesis of silver nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2017, 533, 125–132. [Google Scholar] [CrossRef]

- Turkey, M.E.; Mashkoor, S.M.; Taha, N.D. Spectrophotometric Determination of Glutathione by Iodate/Iodide. J. Phys. Conf. Ser. 2019, 1294, 052063. [Google Scholar] [CrossRef]

- Zhang, W.A.; Chen, B.J.; Wang, R.K.; Liu, J.; Wang, B. Peroxidase-like Nanozyme Composite-based Colorimetric Determination of Glutathione and Cysteine. Anal. Lett. 2024, 57, 1271–1281. [Google Scholar] [CrossRef]

- Abou El-Nour, K.M.; El-Sherbiny, I.M.; Abbas, A.M.; Salem, E.H.; Khairy, G.M. Applying smartphone camera, spectrophotometry, or ocular analysis-based dipsticks for the detection of glutathione level as a cancer biomarker. Talanta Open 2023, 7, 100211. [Google Scholar] [CrossRef]

- Tsiasioti, A.; Tzanavaras, P.D. Determination of glutathione and glutathione disulfide using zone fluidics and fluorimetric detection. Talanta 2021, 222, 121559. [Google Scholar] [CrossRef]

- Toyo’oka, T.; Imai, K. Fluorescence analysis of thiols with ammonium 7-fluorobenzo-2-oxa-1,3-diazole-4-sulphonate. Analyst 1984, 109, 1003–1007. [Google Scholar] [CrossRef]

- Shcherbatykh, A.A.; Chernov’yants, M.S.; Voloshin, N.A.; Chernyshev, A.V. Spiropyran 5,6′-dichloro-1,3,3-trimethylspiro indoline-2,2′-2H-pyrano 3,2-h quinoli ne application as a spectorphotometric and fluorescent probe for glutathione and cysteine sensing. Chem. Pap. 2022, 76, 5541–5550. [Google Scholar] [CrossRef]

- Swathy, S.; Sam, S.; Kumar, K.G. Polyethyleneimine capped silver nanoclusters based turn-off-on fluorescence sensor for the determination of glutathione. Talanta 2024, 278, 126541. [Google Scholar]

- Francioso, A.; Fanelli, S.; Cavallaro, R.A.; Fontana, M.; Mattioli, R.; D’Erme, M.; Mosca, L. Fluorometric Optimized Determination of Total Glutathione in Erythrocytes. Separations 2021, 8, 83. [Google Scholar] [CrossRef]

- Nozal, M.J.; Bernal, J.L.; Toribio, L.; Marinero, P.; Moral, O.; Manzanas, L.; Rodriguez, E. Determination of glutathione, cysteine and N-acetylcysteine in rabbit eye tissues using high-performance liquid chromatography and post-column derivatization with 5,5′-dithiobis(2-nitrobenzoic acid). J. Chromatogr. A 1997, 778, 347–353. [Google Scholar] [CrossRef] [PubMed]

- Głowacki, R.; Bald, E. Fully automated method for simultaneous determination of total cysteine, cysteinylglycine, glutathione and homocysteine in plasma by HPLC with UV absorbance detection. J. Chromatogr. B 2009, 877, 3400–3404. [Google Scholar] [CrossRef] [PubMed]

- Hou, W.; Wang, E. Liquid chromatography with electrocatalytic detection of cysteine, N-acetylcysteine and glutathione by a prussian blue film-modified electrode. J. Electroanal. Chem. Interfacial Electrochem. 1991, 316, 155–163. [Google Scholar] [CrossRef]

- Habib, A.; Mabrouk, M.M.; Fekry, M.; Mansour, F.R. Glycerol as a new mobile phase modifier for green liquid chromatographic determination of ascorbic acid and glutathione in pharmaceutical tablets. J. Pharm. Biomed. Anal. 2022, 219, 114870. [Google Scholar] [CrossRef]

- Tsiasioti, A.; Tzanavaras, P.D. Determination of glutathione and glutathione disulfide using liquid chromatography: A review on recent applications. Microchem. J. 2023, 193, 109157. [Google Scholar] [CrossRef]

- Pavlidis, A.; Tsiasioti, A.; Tzanavaras, P.D. Extraction and determination of free glutathione and its disulfide in various flour samples using liquid chromatography and on-line post column derivatization. Microchem. J. 2023, 193, 109145. [Google Scholar] [CrossRef]

- Bramanti, E.; Cavallaro, R.; Onor, M.; Zamboni, R.; D’Ulivo, A. Determination of thiolic compounds as mercury complexes by cold vapor atomic absorption spectrometry and its application to wines. Talanta 2008, 74, 936–943. [Google Scholar] [CrossRef]

- Gashevskaya, A.S.; Dorozhko, E.V.; Korotkova, E.I.; Pashkovskaya, E.A.; Voronova, O.A.; Plotnikov, E.V.; Derina, K.V.; Lipskikh, O.I. Voltammetric Method for Determination of Glutathione on a Gold-Carbon-Containing Electrode. Inorg. Mater. 2020, 56, 1362–1368. [Google Scholar] [CrossRef]

- Martinović, A.; Kukoč-Modun, L.; Radić, N. Kinetic Spectrophotometric Determination of Thiols and Ascorbic Acid. Anal. Lett. 2007, 40, 805–815. [Google Scholar] [CrossRef]

- Kukoc-Modun, L.; Biocic, M.; Radić, N. Determination of penicillamine, tiopronin and glutathione in pharmaceutical formulations by kinetic spectrophotometry. Acta Pharm. 2021, 71, 619–630. [Google Scholar] [CrossRef]

- Martinović, A.; Radić, N. Kinetic Potentiometric Determination of some Thiols with Iodide Ion-Sensitive Electrode. Anal. Lett. 2007, 40, 2851–2859. [Google Scholar] [CrossRef]

- Price, G.A.; Mallik, D.; Organ, M.G. Process Analytical Tools for Flow Analysis: A Perspective. J. Flow Chem. 2017, 7, 82–86. [Google Scholar] [CrossRef]

- Warman, M.; Hammond, S. Process analysis in the pharmaceutical industry. In Pharmaceutical Analysis; Lee, D.C., Webb, M.L., Eds.; CRC Press: Boca Raton, FL, USA, 2003; pp. 324–356. [Google Scholar]

- Ruzicka, J.; Marshall, G.D. Sequential injection: A new concept for chemical sensors, process analysis and laboratory assays. Anal. Chim. Acta 1990, 237, 329–343. [Google Scholar] [CrossRef]

- Waseem, A.; Yaqoob, M.; Nabi, A. Flow-injection Determination of Cysteine, N-Acetyl Cysteine and Glutathione in Pharmaceuticals via Potassium Ferricyanide-Fe(III) Spectrophotometric System. Chem. Res. Chin. Univ. 2010, 26, 893–898. [Google Scholar]

- Supharoek, S.-A.; Youngvises, N.; Jakmunee, J. A Simple Microfluidic Integrated with an Optical Sensor for Micro Flow Injection Colorimetric Determination of Glutathione. Anal. Sci. 2012, 28, 651–656. [Google Scholar] [CrossRef]

- Kukoc-Modun, L.; Biocic, M.; Radić, N. Flow-injection Determination of Glutathione, Penicillamine and Tiopronin Based on the Reduction of Copper(II)-neocuproine Reagent. Croat. Chem. Acta 2020, 93, 133–138. [Google Scholar] [CrossRef]

- Ensafi, A.A.; Khayamian, T.; Hasanpour, F. Determination of glutathione in hemolysed erythrocyte by flow injection analysis with chemiluminescence detection. J. Pharm. Biomed. Anal. 2008, 48, 140–144. [Google Scholar] [CrossRef]

- Wang, L.; Li, Y.; Zhao, D.; Zhu, C. A Novel Enhancing Flow-Injection Chemiluminescence Method for the Determination of Glutathione Using the Reaction of Luminol with Hydrogen Peroxide. Microchim. Acta 2003, 141, 41–45. [Google Scholar] [CrossRef]

- Dong, Y.; Su, M.; Chen, P.; Sun, H. Chemiluminescence of carbon dots induced by diperiodato-nicklate (IV) in alkaline solution and its application to a quenchometric flow-injection assays of paracetamol, L-cysteine and glutathione. Microchim. Acta 2015, 182, 1071–1077. [Google Scholar] [CrossRef]

- Lu, C.; Li, Q.; Chen, S.; Zhao, L.; Zheng, Z. Gold nanorod-catalyzed luminol chemiluminescence and its selective determination of glutathione in the cell extracts of Saccharomyces cerevisiae. Talanta 2011, 85, 476–481. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Chen, Y.; Zhu, Q.; Wang, F.; Wang, L.; Li, Y. Sensitive chemiluminescence method for the determination of glutathione, l-cysteine and 6-mercaptopurine. Microchim. Acta 2008, 163, 263–269. [Google Scholar] [CrossRef]

- Ahmed, Z.; Yaqoob, M.; Asghar, M.; Ali, S.; Munawar, N.; Achakzai, A.K.K.; Nabi, A. Flow-Injection Lucigenin–Cu(III) Complex Chemiluminescence Determination of Cysteine and Glutathione in Pharmaceutical Formulations. J. Anal. Chem. 2021, 76, 466–475. [Google Scholar] [CrossRef]

- Cox, J.A.; Gray, T.J. Flow-injection amperometry of cysteine and glutathione at an electrode modified with a ruthenium-containing inorganic film. Electroanalysis 1990, 2, 107–111. [Google Scholar] [CrossRef]

- Mao, L.; Yamamoto, K. Amperometric Biosensor for Glutathione Based on Osmium-Polyvinylpyridine Gel Polymer and Glutathione Sulfhydryl Oxidase. Electroanalysis 2000, 12, 577–582. [Google Scholar] [CrossRef]

- Ravi, S.D.; Narayanan, S.S. Amperometric Sensor for Glutathione Based on a Mechanically Immobilized Cobalt Hexacyanoferrate Modified Electrode. Bull. Chem. Soc. Jpn. 2002, 75, 501–505. [Google Scholar] [CrossRef]

- Zitka, O.; Huska, D.; Krizkova, S.; Adam, V.; Chavis, G.J.; Trnkova, L.; Horna, A.; Hubalek, J.; Kizek, R. An Investigation of Glutathione-Platinum(II) Interactions by Means of the Flow Injection Analysis Using Glassy Carbon Electrode. Sensors 2007, 7, 1256–1270. [Google Scholar] [CrossRef]

- Shankaran, D.D.; Narayanan, S.S. Mechanically Immobilized Copper Hexacyanoferrate Modified Electrode for Electrocatalysis Amperometric Determination of Glutathione. Bull. Korean Chem. Soc. 2001, 22, 816–820. [Google Scholar]

- Kolar, M.; Dobcnik, D.; Radić, N. Potentiometric flow-injection determination of vitamin C and glutathione with a chemically prepared tubular silver electrode. Pharmazie 2000, 55, 913–916. [Google Scholar] [PubMed]

- Evgen’ev, M.I.; Garmonov, S.Y.; Shakirova, L.S. Flow-Injection Analysis of Pharmaceuticals. J. Anal. Chem. 2001, 56, 313–323. [Google Scholar] [CrossRef]

- Rocha, F.R.P.; Nóbrega, J.A.; Filho, O.F. Flow analysis strategies to greener analytical chemistry. An overview. Green Chem. 2001, 3, 216–220. [Google Scholar] [CrossRef]

- Araujo, A.R.T.S.; Saraiva, M.L.M.F.S.; Lima, J.L.F.C. Determination of total and oxidized glutathione in human whole blood with a sequential injection analysis system. Talanta 2008, 74, 1511–1519. [Google Scholar] [CrossRef]

- Zacharis, C.K.; Tzanavaras, P.D. High throughput automated determination of glutathione based on the formation of a UV-absorbing thioacrylate derivative. Comb. Chem. High Throughput Screen. 2010, 13, 461–468. [Google Scholar] [CrossRef]

- Besada, A.; Tadros, N.B.; Gawargious, Y.A. Copper(II)-neocuproine as colour reagent for some biologically active thiols: Spectrophotometric determination of cysteine, penicillamine, glutathione, and 6-mercaptopurine. Microchim. Acta 1989, 99, 143–146. [Google Scholar] [CrossRef]

- British Pharmacopoeia; The Stationery Office: London, UK, 2018.

- Kolev, S.D. Theoretical basis of flow injection analysis. In Advances in Flow Injection Analysis and Related Techniques, 1st ed.; Kolev, S.D., McKlevie, I.D., Eds.; Elsevier: Amsterdam, The Netherlands, 2008; pp. 47–49. [Google Scholar]

- El-Kemary, M.; Nagy, N.; El-Mehasseb, I. Nickel oxide nanoparticles: Synthesis and spectral studies of interactions with glucose. Mater. Sci. Semicond. Process. 2013, 16, 1747–1752. [Google Scholar] [CrossRef]

- Orlowska, M.; Koutchma, T.; Grapperhaus, M.; Gallagher, J.; Schaefer, R.; Defelice, C. Continuous and Pulsed Ultraviolet Light for Nonthermal Treatment of Liquid Foods. Part 1: Effects on Quality of Fructose Solution, Apple Juice, and Milk. Food Bioprocess Technol. 2013, 6, 1580–1592. [Google Scholar] [CrossRef]

- Bui, T.Q.; Ton, S.N.-C.; Duong, A.T.; Tran, H.T. Size-dependent magnetic responsiveness of magnetite nanoparticles synthesised by co-precipitation and solvothermal methods. J. Sci. Adv. Mater. Devices 2018, 3, 107–112. [Google Scholar] [CrossRef]

| Step | Valve Position | Flow Rate, µL min−1 | Volume, µL | Description |

|---|---|---|---|---|

| 1 | 7 | 3000 | 150 | Aspiration of reagent solution to the holding coil |

| 2 | 6 | 3000 | 200 | Aspiration of sample solution to the holding coil |

| 3 | 8 | 3000 | 3000 | Propelling of the reaction mixture to the flow cell |

| Studied Parameters | Initial Value | Studied Range | Optimal Value |

|---|---|---|---|

| Aspiration sequence | RS, GSH | RS, GSH; GSH, RS | RS, GSH |

| Carrier flow rate, µL min−1 | 5000 | 1000–8000 | 3000 |

| Reagent volume, µL | 200 | 50–450 | 150 |

| Sample volume, µL | 200 | 50–450 | 200 |

| Holding coil length, μL | 1000 | 500; 1000 | 500 |

| Reaction coil length, cm | 65 | 35–125 | 50 |

| ldetection, nm | Linear Range, mol L−1 | LOD, mol L−1 | RSD, % | Sampling Rate, h−1 | Sample | Ref. |

|---|---|---|---|---|---|---|

| 412 | 1.0 × 10−7–3.0 × 10−6 | 3.1 × 10−8 | <5.00 | 13 | blood | [46] |

| 285 | 4.9 × 10−7–2.3 × 10−4 | 1.6 × 10−7 | 3.00 | 100 | pharmaceuticals | [47] |

| 458 | 6.0 × 10−7–8.0 × 10−5 | 2.0 × 10−7 | 3.80 | 60 | pharmaceuticals | present |

| Excipient | Molar Ratio of GSH to Excipient | Peak Absorbance; SD (n = 3) | Relative Error, % |

|---|---|---|---|

| Glucose | 1:500 | 0.141; 0.001 | −2.9 |

| Fructose | 1:500 | 0.148; 0.004 | 1.8 |

| Lactose | 1:500 | 0.147; 0.009 | 1.3 |

| KNO3 | 1:500 | 0.140; 0.002 | −3.5 |

| Na2SO4 | 1:500 | 0.140; 0.006 | −3.5 |

| Boric acid | 1:500 | 0.142; 0.005 | −2.7 |

| Sodium citrate | 1:10 | 0.138; 0.003 | −4.9 |

| Sample | Added, mg | Found (b), mg | Recovery, % |

|---|---|---|---|

| L-glutathione (a) | 0 | 50.3 ± 0.9 | – |

| 50 | 96.5 ± 1.1 | 96.5 | |

| 100 | 149.7 ± 0.5 | 99.8 | |

| 150 | 195.8 ± 1.3 | 97.9 | |

| 200 | 254.0 ± 1.5 | 101.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biocic, M.; Kraljević, T.; Spassov, T.G.; Kukoc-Modun, L.; Kolev, S.D. Sequential Injection Analysis Method for the Determination of Glutathione in Pharmaceuticals. Sensors 2024, 24, 5677. https://doi.org/10.3390/s24175677

Biocic M, Kraljević T, Spassov TG, Kukoc-Modun L, Kolev SD. Sequential Injection Analysis Method for the Determination of Glutathione in Pharmaceuticals. Sensors. 2024; 24(17):5677. https://doi.org/10.3390/s24175677

Chicago/Turabian StyleBiocic, Maja, Tomislav Kraljević, Tony G. Spassov, Lea Kukoc-Modun, and Spas D. Kolev. 2024. "Sequential Injection Analysis Method for the Determination of Glutathione in Pharmaceuticals" Sensors 24, no. 17: 5677. https://doi.org/10.3390/s24175677