Impact of Channel Thickness and Doping Concentration for Normally-Off Operation in Sn-Doped β-Ga2O3 Phototransistors

Abstract

:1. Introduction

2. Materials and Methods

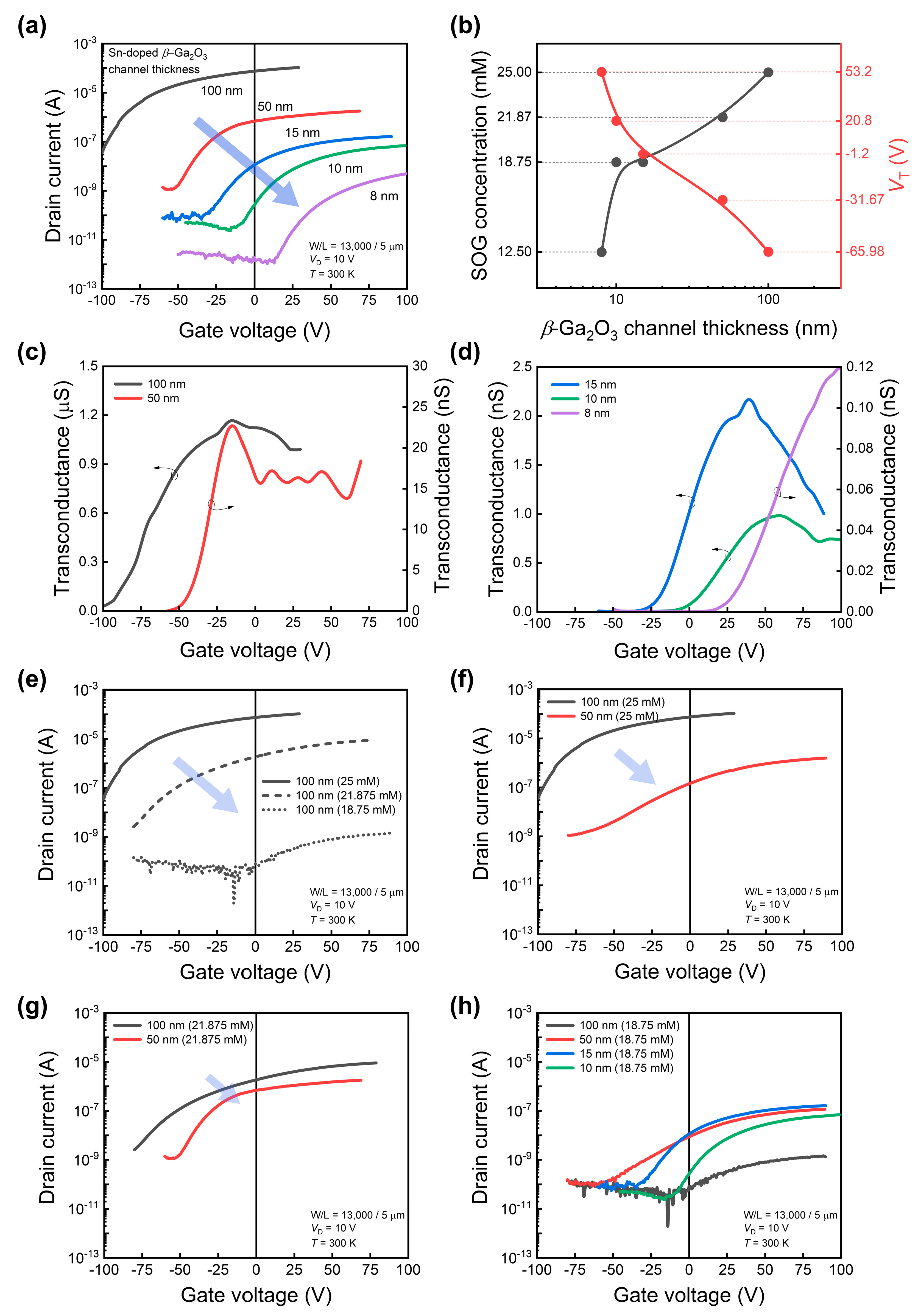

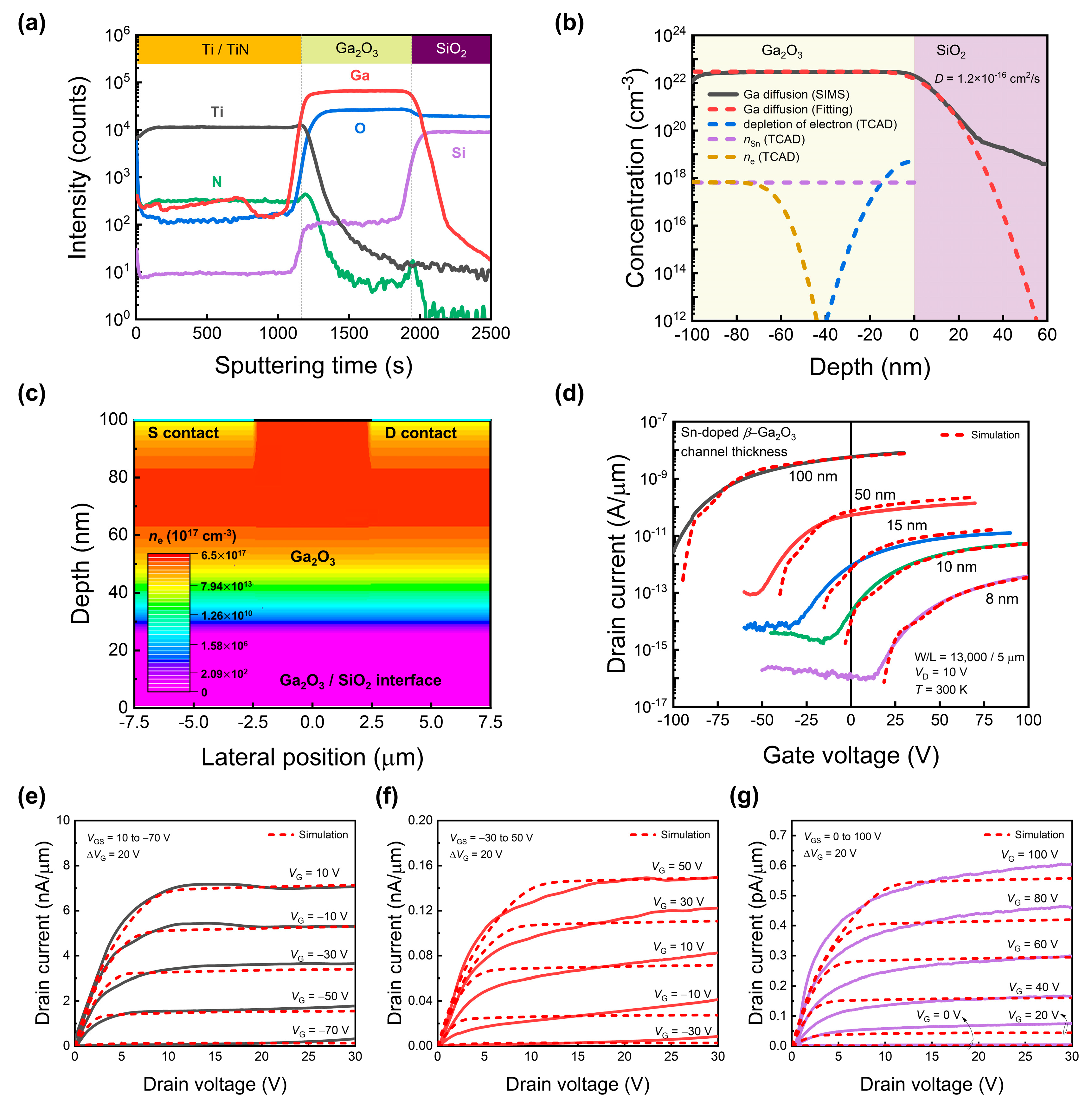

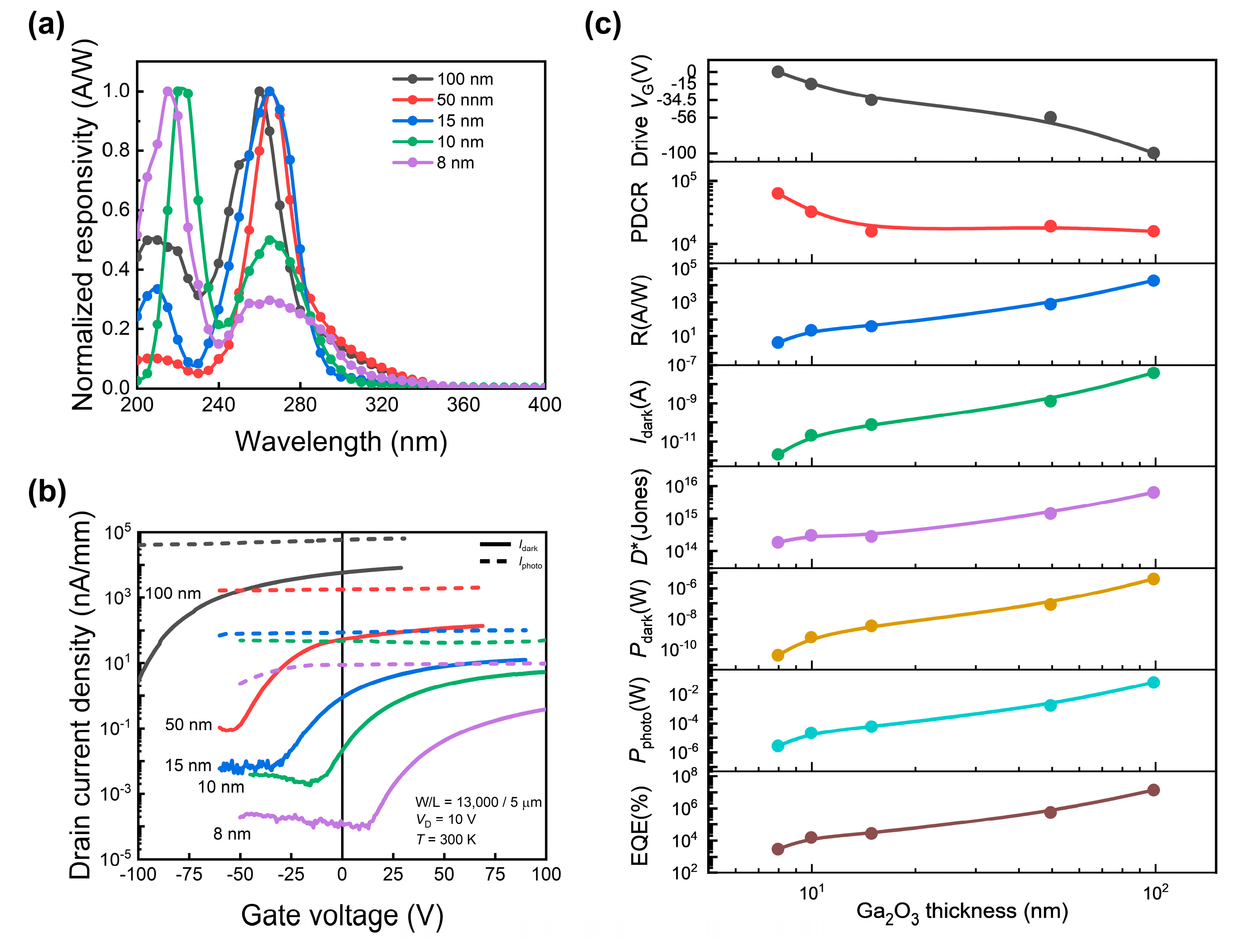

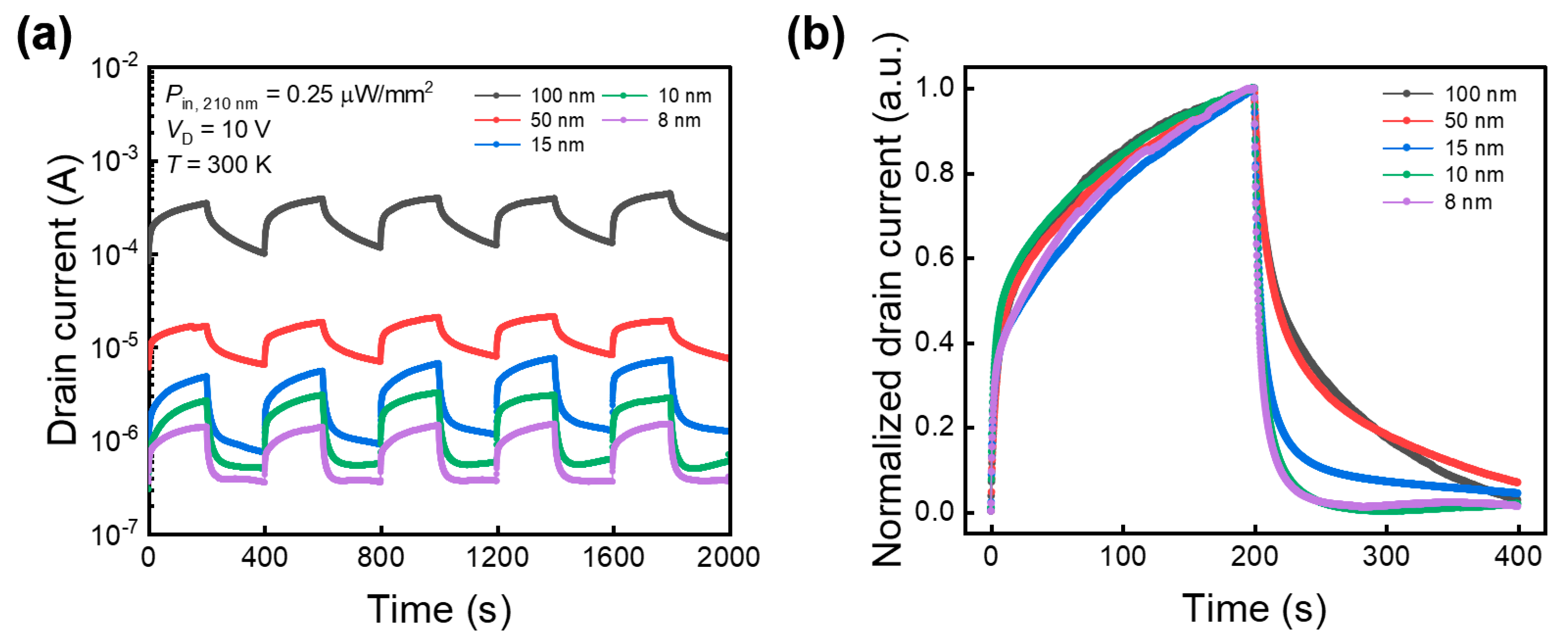

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Higashiwaki, M.; Jessen, G.H. Guest editorial: The dawn of gallium oxide microelectronics. Appl. Phys. Lett. 2018, 112, 060401. [Google Scholar] [CrossRef]

- Yamaguchi, K. First principles study on electronic structure of β-Ga2O3. Solid State Commun. 2004, 131, 739–744. [Google Scholar] [CrossRef]

- Dong, L.; Jia, R.; Xin, B.; Peng, B.; Zhang, Y. Effects of oxygen vacancies on the structural and optical properties of β-Ga2O3. Sci. Rep. 2017, 7, 40160. [Google Scholar] [CrossRef]

- Víllora, E.G.; Yamaga, M.; Inoue, T.; Yabasi, S.; Masui, Y.; Sugawara, T.; Fukuda, T. Optical spectroscopy study on β-Ga2O3. Jpn. J. Appl. Phys. 2002, 41, L622–L625. [Google Scholar] [CrossRef]

- Razeghi, M. Short-wavelength solar-blind detectors-status, prospects, and markets. Proc. IEEE 2002, 90, 1006–1014. [Google Scholar] [CrossRef]

- Sang, L.; Liao, M.; Sumiya, M. A Comprehensive review of semiconductor ultraviolet photodetectors: From thin film to one-dimensional nanostructures. Sensors 2013, 13, 10482–10518. [Google Scholar] [CrossRef] [PubMed]

- Guo, D.; Wu, Z.; Li, P.; An, Y.; Liu, H.; Guo, X.; Yan, H.; Wang, G.; Sun, C.; Li, L.; et al. Fabrication of β-Ga2O3 thin films and solar-blind photodetectors by laser MBE technology. Opt. Mater. Express 2014, 4, 1067. [Google Scholar] [CrossRef]

- Malik, M.; Iqbal, M.A.; Choi, J.R.; Pham, P.V. 2D Materials for efficient photodetection: Overview, mechanisms, performance and UV-IR range applications. Front. Chem. 2022, 10, 905404. [Google Scholar] [CrossRef]

- Yadav, P.V.K.; Ajitha, B.; Kumar Reddy, Y.A.; Sreedhar, A. Recent advances in development of nanostructured photodetectors from ultraviolet to infrared region: A Review. Chemosphere 2021, 279, 130473. [Google Scholar] [CrossRef]

- Arora, K.; Goel, N.; Kumar, M.; Kumar, M. Ultrahigh performance of self-powered β-Ga2O3 thin film solar-blind photodetector grown on cost-effective Si substrate using high-temperature seed layer. ACS Photonics 2018, 5, 2391–2401. [Google Scholar] [CrossRef]

- Bae, J.; Jeon, D.-W.; Park, J.-H.; Kim, J. High responsivity solar-blind metal-semiconductor-metal photodetector based on α-Ga2O3. J. Vac. Sci. Technol. A 2021, 39, 033410. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, Y.; Seo, D.; Park, J.-H.; Jeon, D.-W.; Hwang, W.S.; Shin, M. Alpha-phase gallium oxide-based UVC photodetector with high sensitivity and visible blindness. APL Mater. 2023, 11, 061107. [Google Scholar] [CrossRef]

- Mi, W.; Tang, J.; Chen, X.; Li, X.; Li, B.; Luo, L.; Zhou, L.; Chen, R.; Wang, D.; Zhao, J. Preparation and UV detection performance of Ti-doped Ga2O3/intrinsic-Ga2O3/p-Si PIN photodiodes. J. Mater. Sci. Mater. Electron. 2023, 34, 774. [Google Scholar] [CrossRef]

- Vasquez, J.M.T.; Ashai, A.; Lu, Y.; Khandelwal, V.; Rajbhar, M.; Kumar, M.; Li, X.; Sarkar, B. A self-powered and broadband UV PIN photodiode employing a NiOx layer and a β-Ga2O3 heterojunction. J. Phys. D Appl. Phys. 2023, 56, 065104. [Google Scholar] [CrossRef]

- Kim, H.; Kim, K.; Hong, J. High performance deep ultraviolet P-i-n self-powered photodetector based on p-NiO/i-β-Ga2O3/n-β-Ga2O3 with controlled a fermi level and used an intrinsic β-Ga2O3 Layer. IEEE Sens. J. 2024, 24, 17613–17621. [Google Scholar] [CrossRef]

- Nandi, A.; Rana, K.S.; Bag, A. Design and analysis of P-GaN/N-Ga2O3 based junction barrier Schottky diodes. IEEE Trans. Electron. Devices 2021, 68, 6052–6058. [Google Scholar] [CrossRef]

- Liu, Z.; Tang, W. A Review of Ga2O3 deep-ultraviolet metal–semiconductor Schottky photodiodes. J. Phys. D Appl. Phys. 2023, 56, 093002. [Google Scholar] [CrossRef]

- Suzuki, R.; Nakagomi, S.; Kokubun, Y.; Arai, N.; Ohira, S. Enhancement of responsivity in solar-blind β-Ga2O3 photodiodes with a Au Schottky contact fabricated on single crystal substrates by annealing. Appl. Phys. Lett. 2009, 94, 222102. [Google Scholar] [CrossRef]

- Watahiki, T.; Yuda, Y.; Furukawa, A.; Yamamuka, M.; Takiguchi, Y.; Miyajima, S. Heterojunction p-Cu2O/n-Ga2O3 diode with high breakdown voltage. Appl. Phys. Lett. 2017, 111, 222104. [Google Scholar] [CrossRef]

- Nakagomi, S.; Momo, T.; Takahashi, S.; Kokubun, Y. Deep ultraviolet photodiodes based on β-Ga2O3/SiC heterojunction. Appl. Phys. Lett. 2013, 103, 072105. [Google Scholar] [CrossRef]

- Chi, P.-F.; Lin, F.-W.; Lee, M.-L.; Sheu, J.-K. High-responsivity solar-blind photodetectors formed by Ga2 O3/p-GaN bipolar heterojunctions. ACS Photonics 2022, 9, 1002–1007. [Google Scholar] [CrossRef]

- Kim, S.; Oh, S.; Kim, J. Ultrahigh deep-UV sensitivity in graphene-gated β-Ga2O3 phototransistors. ACS Photonics 2019, 6, 1026–1032. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Yang, L.; Li, S.; Zhang, S.; Li, K.; Li, P.; Guo, Y.; Tang, W. Enhancement-mode normally-off β-Ga2O3:Si metal-semiconductor field-effect deep-ultraviolet phototransistor. Semicond. Sci. Technol. 2022, 37, 015001. [Google Scholar] [CrossRef]

- Yoon, Y.; Kim, Y.; Hwang, W.S.; Shin, M. Biological UV photoreceptors-inspired Sn-Doped polycrystalline β-Ga2O3 optoelectronic synaptic phototransistor for neuromorphic computing. Adv. Electron. Mater. 2023, 9, 2300098. [Google Scholar] [CrossRef]

- Yoon, Y.; Hwang, W.S.; Shin, M. Solar-blind ultrathin Sn-doped polycrystalline Ga2O3 UV phototransistor for normally off operation. Adv. Photonics Res. 2022, 3, 2100316. [Google Scholar] [CrossRef]

- Liang, H.; Han, Z.; Mei, Z. Recent progress of deep ultraviolet photodetectors using amorphous gallium oxide thin films. Phys. Status Solidi A 2021, 218, 2000339. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, W.; Huang, F. Gallium oxide solar-blind ultraviolet photodetectors: A Review. J. Mater. Chem. C Mater. 2019, 7, 8753–8770. [Google Scholar] [CrossRef]

- Kaur, D.; Kumar, M. A strategic review on gallium oxide based deep-ultraviolet photodetectors: Recent progress and future prospects. Adv. Opt. Mater. 2021, 9, 2002160. [Google Scholar] [CrossRef]

- Wong, M.H.; Lin, C.-H.; Kuramata, A.; Yamakoshi, S.; Murakami, H.; Kumagai, Y.; Higashiwaki, M. Acceptor doping of β-Ga2O3 by Mg and N ion implantations. Appl. Phys. Lett. 2018, 113, 102103. [Google Scholar] [CrossRef]

- Kyrtsos, A.; Matsubara, M.; Bellotti, E. On the feasibility of p-Type Ga2O3. Appl. Phys. Lett. 2018, 112, 032108. [Google Scholar] [CrossRef]

- Neal, A.T.; Mou, S.; Rafique, S.; Zhao, H.; Ahmadi, E.; Speck, J.S.; Stevens, K.T.; Blevins, J.D.; Thomson, D.B.; Moser, N.; et al. Donors and deep acceptors in β-Ga2O3. Appl. Phys. Lett. 2018, 113, 062101. [Google Scholar] [CrossRef]

- Robertson, J.; Clark, S.J. Limits to doping in oxides. Phys. Rev. B 2011, 83, 075205. [Google Scholar] [CrossRef]

- Petti, L.; Münzenrieder, N.; Vogt, C.; Faber, H.; Büthe, L.; Cantarella, G.; Bottacchi, F.; Anthopoulos, T.D.; Tröster, G. Metal oxide semiconductor thin-film transistors for flexible electronics. Appl. Phys. Rev. 2016, 3, 021303. [Google Scholar] [CrossRef]

- Yu, X.; Marks, T.J.; Facchetti, A. Metal oxides for optoelectronic applications. Nat. Mater. 2016, 15, 383–396. [Google Scholar] [CrossRef] [PubMed]

- Walsh, A.; Butler, K.T. Prediction of electron energies in metal oxides. Acc. Chem. Res. 2014, 47, 364–372. [Google Scholar] [CrossRef]

- Kamimura, T.; Nakata, Y.; Wong, M.H.; Than, P.H.; Higashiwaki, M. Nitrogen-Doped Channel β-Ga2O3 MOSFET with Normally-Off Operation. In Proceedings of the 2019 Compound Semiconductor Week (CSW), Nara, Japan, 19–23 May 2019; p. 1. [Google Scholar]

- Chabak, K.D.; McCandless, J.P.; Moser, N.A.; Green, A.J.; Mahalingam, K.; Crespo, A.; Hendricks, N.; Howe, B.M.; Tetlak, S.E.; Leedy, K.; et al. Recessed-gate enhancement-mode β-Ga2O3 MOSFETs. IEEE Electron. Device Lett. 2018, 39, 67–70. [Google Scholar] [CrossRef]

- Kachhawa, P.; Chaturvedi, N. A simulation approach for depletion and enhancement mode in β-Ga2O3 MOSFET. IETE Tech. Rev. 2022, 39, 1410–1418. [Google Scholar] [CrossRef]

- Chen, X.; Li, F.; Hess, H.L. Trench gate β-Ga2O3 MOSFETs: A review. Eng. Res. Express 2023, 5, 012004. [Google Scholar] [CrossRef]

- Zhou, H.; Si, M.; Alghamdi, S.; Qiu, G.; Yang, L.; Peide, D.Y. High-Performance Depletion/Enhancement-mode β-Ga2O3 on Insulator (GOOI) Field-Effect Transistors with Record Drain Currents of 600/450 mA/mm. IEEE Electron. Device Lett. 2016, 38, 103–106. [Google Scholar] [CrossRef]

- Sharma, R.; Patnaik, A.; Sharma, P. Impact of doping concentration and recess depth to achieve enhancement mode operation in β-Ga2O3 MOSFET. Microelectron. J. 2023, 135, 105755. [Google Scholar] [CrossRef]

- Gurbán, S.; Sulyok, A.; Menyhárd, M.; Baradács, E.; Parditka, B.; Cserháti, C.; Erdélyi, Z. Interface induced diffusion. Sci. Rep. 2021, 11, 9308. [Google Scholar] [CrossRef] [PubMed]

- Laemmle, A.; Wuerz, R.; Schwarz, T.; Cojocaru-Mirédin, O.; Choi, P.P.; Powalla, M. Investigation of the diffusion behavior of sodium in Cu (In, Ga) Se2 layers. J. Appl. Phys. 2014, 115, 154501. [Google Scholar] [CrossRef]

- Yoon, Y.; Kim, S.; Lee, I.G.; Cho, B.J.; Hwang, W.S. Electrical and photocurrent properties of a polycrystalline Sn-doped β-Ga2O3 thin film. Mater. Sci. Semicond. Process. 2021, 121, 105430. [Google Scholar] [CrossRef]

- Higashiwaki, M.; Sasaki, K.; Murakami, H.; Kumagai, Y.; Koukitu, A.; Kuramata, A.; Yamakoshi, S. Recent progress in Ga2O3 power devices. Semicond. Sci. Technol. 2016, 31, 034001. [Google Scholar] [CrossRef]

- Kotecha, R.; Metzger, W.; Mather, B.; Narumanchi, S.; Zakutayev, A. Modeling and analysis of gallium oxide vertical transistors. ECS J. Solid State Sci. Technol. 2019, 8, Q3202. [Google Scholar] [CrossRef]

- Janowitz, C.; Scherer, V.; Mohamed, M.; Krapf, A.; Dwelk, H.; Manzke, R.; Van de Walle, C.G. Experimental electronic structure of In2O3 and Ga2O3. New J. Phys. 2011, 13, 085014. [Google Scholar] [CrossRef]

- Shockley, W.T.R.W.; Read, W.T., Jr. Statistics of the recombinations of holes and electrons. Phys. Rev. 1952, 87, 835. [Google Scholar] [CrossRef]

- Ma, N.; Tanen, N.; Verma, A.; Guo, Z.; Luo, T.; Xing, H.G.; Jena, D. Intrinsic electron mobility limits in β-Ga2O3. Appl. Phys. Lett. 2016, 109, 212101. [Google Scholar] [CrossRef]

- Park, J.; Hong, S.M. Simulation study of enhancement mode multi-gate vertical gallium oxide MOSFETs. ECS J. Solid State Sci. Technol. 2019, 8, Q3116. [Google Scholar] [CrossRef]

- Jang, C.H.; Atmaca, G.; Cha, H.Y. Normally-off β-Ga2O3 MOSFET with an epitaxial drift layer. Micromachines 2022, 13, 1185. [Google Scholar] [CrossRef]

- Xiao, X.; Liang, L.; Pei, Y.; Yu, J.; Duan, H.; Chang, T.-C.; Cao, H. Solution-processed amorphous Ga2O3:CdO TFT-type deep-UV photodetectors. Appl. Phys. Lett. 2020, 116, 192102. [Google Scholar] [CrossRef]

- Duan, H.; Javaid, K.; Liang, L.; Huang, L.; Yu, J.; Zhang, H.; Gao, J.; Zhuge, F.; Chang, T.-C.; Cao, H. Broadband optoelectronic synaptic thin-film transistors based on oxide semiconductors. Phys. Status Solidi Rapid Res. Lett. 2020, 14, 1900630. [Google Scholar] [CrossRef]

- Dongre, B.; Carrete, J.; Wen, S.; Ma, J.; Li, W.; Mingo, N.; Madsen, G.K. Combined treatment of phonon scattering by electrons and point defects explains the thermal conductivity reduction in highly-doped Si. J. Mater. Chem. 2020, 8, 1273–1278. [Google Scholar] [CrossRef]

- Turney, J.E.; McGaughey, A.J.; Amon, C.H. In-plane phonon transport in thin films. J. Appl. Phys. 2010, 107, 024317. [Google Scholar] [CrossRef]

- Cao, R.; Sun, K.; Liu, C.; Mao, Y.; Guo, W.; Ouyang, P.; Meng, Y.; Tian, R.; Xie, L.; Lü, X.; et al. Structurally Flexible 2D Spacer for Suppressing the Electron–Phonon Coupling Induced Non-Radiative Decay in Perovskite Solar Cells. Nanomicro Lett. 2024, 16, 178. [Google Scholar] [CrossRef]

- Ni, Y.; Zhang, S.; Sun, L.; Liu, L.; Wei, H.; Xu, Z.; Xu, W.; Xu, W. A low-dimensional hybrid pin heterojunction neuromorphic transistor with ultra-high UV sensitivity and immediate switchable plasticity. Appl. Mater. Today 2021, 25, 101223. [Google Scholar] [CrossRef]

- Gong, J.; Wei, H.; Ni, Y.; Zhang, S.; Du, Y.; Xu, W. Methylammonium halide-doped perovskite artificial synapse for light-assisted environmental perception and learning. Mater. Today Phys. 2021, 21, 100540. [Google Scholar] [CrossRef]

- Ahn, J.; Ma, J.; Lee, D.; Lin, Q.; Park, Y.; Lee, O.; Heo, J. Ultrahigh deep-ultraviolet responsivity of a β-Ga2O3/MgO heterostructure-based phototransistor. ACS Photonics 2021, 8, 557–566. [Google Scholar] [CrossRef]

- Qin, Y.; Long, S.; He, Q.; Dong, H.; Jian, G.; Zhang, Y.; Liu, M. Amorphous gallium oxide-based gate-tunable high-performance thin film phototransistor for solar-blind imaging. Adv. Electron. Mater. 2019, 5, 1900389. [Google Scholar] [CrossRef]

- Qin, Y.; Dong, H.; Long, S.; He, Q.; Jian, G.; Zhang, Y.; Liu, M. Enhancement-Mode β-Ga2O 3 Metal–Oxide–Semiconductor Field-Effect Solar-Blind Phototransistor with Ultrahigh Detectivity and Photo-to-Dark Current Ratio. IEEE Electron. Device Lett. 2019, 40, 742–745. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, Y.; Li, Z.; Feng, Q.; Zhang, Y.; Chen, D.; Hao, Y. High performance gate tunable solar blind ultraviolet phototransistors based on amorphous Ga2O3 films grown by mist chemical vapor deposition. Nano Sel. 2021, 2, 2112–2120. [Google Scholar] [CrossRef]

- Li, Z.; Feng, Z.; Xu, Y.; Feng, Q.; Zhu, W.; Chen, D.; Hao, Y. High performance β-Ga2O 3 solar-blind metal–oxide–semiconductor field-effect phototransistor with hafnium oxide gate dielectric process. IEEE Electron. Device Lett. 2021, 42, 545–548. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, X.; Ding, M.; Tan, P.; Hou, X.; Zhang, Z.; Long, S. High-detectivity β-Ga2O3 microflake solar-blind phototransistor for weak light detection. IEEE Electron. Device Lett. 2021, 42, 383–386. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J. Highly selective ozone-treated β-Ga2O3 solar-blind deep-UV photodetectors. Appl. Phys. Lett. 2020, 117, 261101. [Google Scholar] [CrossRef]

- Han, Z.; Liang, H.; Huo, W.; Zhu, X.; Du, X.; Mei, Z. Boosted UV photodetection performance in chemically etched amorphous Ga2O3 thin-film transistors. Adv. Opt. Mater. 2020, 8, 1901833. [Google Scholar] [CrossRef]

- Pintor-Monroy, M.I.; Reyes-Banda, M.G.; Avila-Avendano, C.; Quevedo-Lopez, M.A. Tuning electrical properties of amorphous Ga2O3 thin films for deep UV phototransistors. IEEE Sens. J. 2021, 21, 14807–14814. [Google Scholar] [CrossRef]

- Liu, Y.; Du, L.; Liang, G.; Mu, W.; Jia, Z.; Xu, M.; Song, A. Ga2O3 field-effect-transistor-based solar-blind photodetector with fast response and high photo-to-dark current ratio. IEEE Electron. Device Lett. 2018, 39, 1696–1699. [Google Scholar] [CrossRef]

- Roh, Y.; Heo, G.; Whang, S.E. A survey on data collection for machine learning: A big data-ai integration perspective. IEEE Trans. Knowl. Data Eng. 2019, 33, 1328–1347. [Google Scholar] [CrossRef]

- Uddin, S.; Lu, H. Dataset meta-level and statistical features affect machine learning performance. Sci. Rep. 2024, 14, 1670. [Google Scholar] [CrossRef]

| Planes | Lattice Spacing [Å] | Planes | Lattice Spacing [Å] | ||

|---|---|---|---|---|---|

| JCPDS | 8 nm Sn-Doped Polycrystalline β-Ga2O3 | JCPDS | 100 nm Sn-Doped Polycrystalline β-Ga2O3 | ||

| (−401) | 2.929 | 2.920 | (111) | 2.549 | 2.549 |

| (−111) | 2.675 | 2.665 | (−311) | 2.343 | 2.356 |

| (002) | 2.817 | 2.857 | (400) | 2.971 | 2.998 |

| (112) | 1.978 | 1.962 | (401) | 2.403 | 2.385 |

| β-Ga2O3 Thickness [nm] | SOG Solution Concentration [mM] | Doping Weight |

|---|---|---|

| 100 | 25 | 1 |

| 50 | 21.875 | 0.875 |

| 15 | 18.75 | 0.75 |

| 10 | 18.75 | 0.75 |

| 8 | 12.5 | 0.5 |

| Material Parameters | Values | Unit | Source |

| Dielectric constant | 10 | unitless | [45] |

| Electron affinity | 4 | eV | [46] |

| Electron density of state (300 K) | 3.72 × 1018 | cm−3 | [47] |

| Electron density of state (300 K) | 3.72 × 1018 | cm−3 | [47] |

| Shockley–Read–Hall Recombination (SRG) Model | Values | Unit | Source |

| Specifies SRH lifetime for electrons | 1.2 × 10−8 | s | [48] |

| Specifies SRH lifetime for holes | 1.2 × 10−8 | s | [48] |

| Parameter | β-Ga2O3 Thickness [nm] | ||||

|---|---|---|---|---|---|

| 100 | 50 | 15 | 10 | 8 | |

| VT [V] | −65.98 | −31.67 | −1.2 | 20.8 | 53.2 |

| Mobility [cm2/V∙s] | 3.81 × 10−3 | 5.23 × 10−5 | 7.6 × 10−6 | 2.89 × 10−6 | 3.94 × 10−7 |

| On–off ratio | - | 1.66 × 103 | 2.93 × 103 | 3.7 × 103 | 4.73 × 103 |

| Drive VG [V] | −100 | −56 | −34.5 | −15 | 0 |

| PDCR | 1.57 × 104 | 1.90 × 104 | 1.55 × 104 | 3.20 × 104 | 6.19 × 104 |

| R [A/W] | 1.73 × 104 | 7.08 × 102 | 34.2 | 19.4 | 3.7 |

| Idark [A] | 3.39 × 10−8 | 1.15 × 10−9 | 6.75 × 10−11 | 1.86 × 10−11 | 1.84 × 10−12 |

| D* [Jones] | 5.87 × 1015 | 1.31 × 1015 | 2.60 × 1014 | 2.80 × 1014 | 1.71 × 1014 |

| Pdark [W] | 3.20 × 10−6 | 6.78 × 10−8 | 2.84 × 10−9 | 5.03 × 10−10 | 3.31 × 10−11 |

| Pphoto [W] | 5.01 × 10−2 | 1.29 × 10−3 | 4.42 × 10−5 | 1.61 × 10−5 | 2.05 × 10−6 |

| EQE [%] | 1.02 × 107 | 4.18 × 105 | 2.02 × 104 | 1.14 × 104 | 2.19 × 103 |

| Channel Thickness [nm] | Drive VG [V] | R [A/W] | Idark [A] | PDCR | D* [Jones] | Ref. |

|---|---|---|---|---|---|---|

| 8 | 0 | 3.7 | 1.84 × 10−12 | 6.19 × 104 | 1.71 × 1014 | This work |

| 100 | −100 | 1.73 × 104 | 3.39 × 10−8 | 1.57 × 104 | 5.87 × 1015 | This work |

| 280 | −8 | 2.6 × 103 | 1.2 × 10−13 | 6 × 108 | 9.7 × 1013 | [22] |

| 270 | −20 | 2.4 × 107 | 6.7 × 10−12 | - | 1.7 × 1015 | [59] |

| 208 | −30 | 4.1 × 103 | 2 × 10−11 | - | 2.57 × 1013 | [60] |

| 200 | −5 | 3 × 103 | 7 × 10−13 | 1.1 × 106 | 1.3 × 1016 | [61] |

| 267 | −10 | 2.3 × 103 | ≈1.5 × 10−9 | 6.67 × 103 | 1.87 × 1014 | [62] |

| 112 | −27 | 1.43 × 107 | ≈4.8 × 10−13 | 6.9 × 107 | 1.1 × 1019 | [63] |

| 217 | −10 | 1.17 × 105 | 2.7 × 10−14 | 1.08 × 107 | 1.19 × 1018 | [64] |

| 381 | −39.5 | 1.93 × 106 | 4.35 × 10−11 | 3.1 × 108 | 1.9 × 1015 | [65] |

| 400 | 10 | 5.67 × 103 | ≈1 × 10−12 | 5.7 × 107 | 1.87 × 1015 | [66] |

| 59 | 0 | 1 × 102 | 1 × 10−13 | ≈3 × 108 | 1 × 1015 | [67] |

| 30 | 0.2 | 2.17 | 1.61 × 10−12 | ≈1 × 105 | 1.71 × 1012 | [52] |

| 142 | −20 | 4.79 × 105 | 9.91 × 10−12 | 1 × 105 | 6.69 × 1014 | [68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, Y.; Kim, Y.; Shin, M. Impact of Channel Thickness and Doping Concentration for Normally-Off Operation in Sn-Doped β-Ga2O3 Phototransistors. Sensors 2024, 24, 5822. https://doi.org/10.3390/s24175822

Yoon Y, Kim Y, Shin M. Impact of Channel Thickness and Doping Concentration for Normally-Off Operation in Sn-Doped β-Ga2O3 Phototransistors. Sensors. 2024; 24(17):5822. https://doi.org/10.3390/s24175822

Chicago/Turabian StyleYoon, Youngbin, Yongki Kim, and Myunghun Shin. 2024. "Impact of Channel Thickness and Doping Concentration for Normally-Off Operation in Sn-Doped β-Ga2O3 Phototransistors" Sensors 24, no. 17: 5822. https://doi.org/10.3390/s24175822