Error Analysis and Modeling of a Large Component Assembly Monitoring System Based on Multi-Sensor Fusion

Abstract

1. Introduction

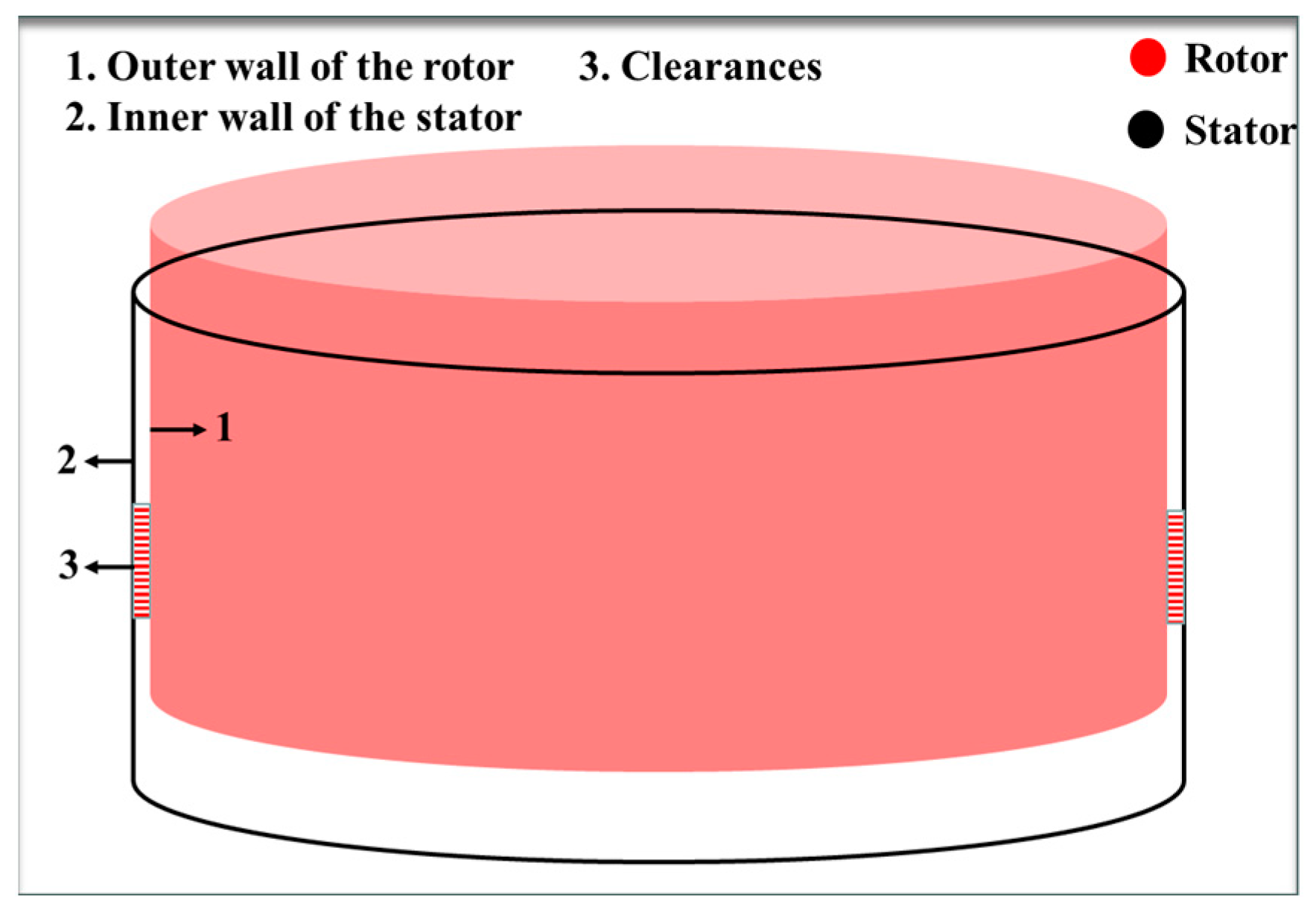

2. Rotor Lifting Monitoring Program

2.1. Analysis of Rotor Lifting Process

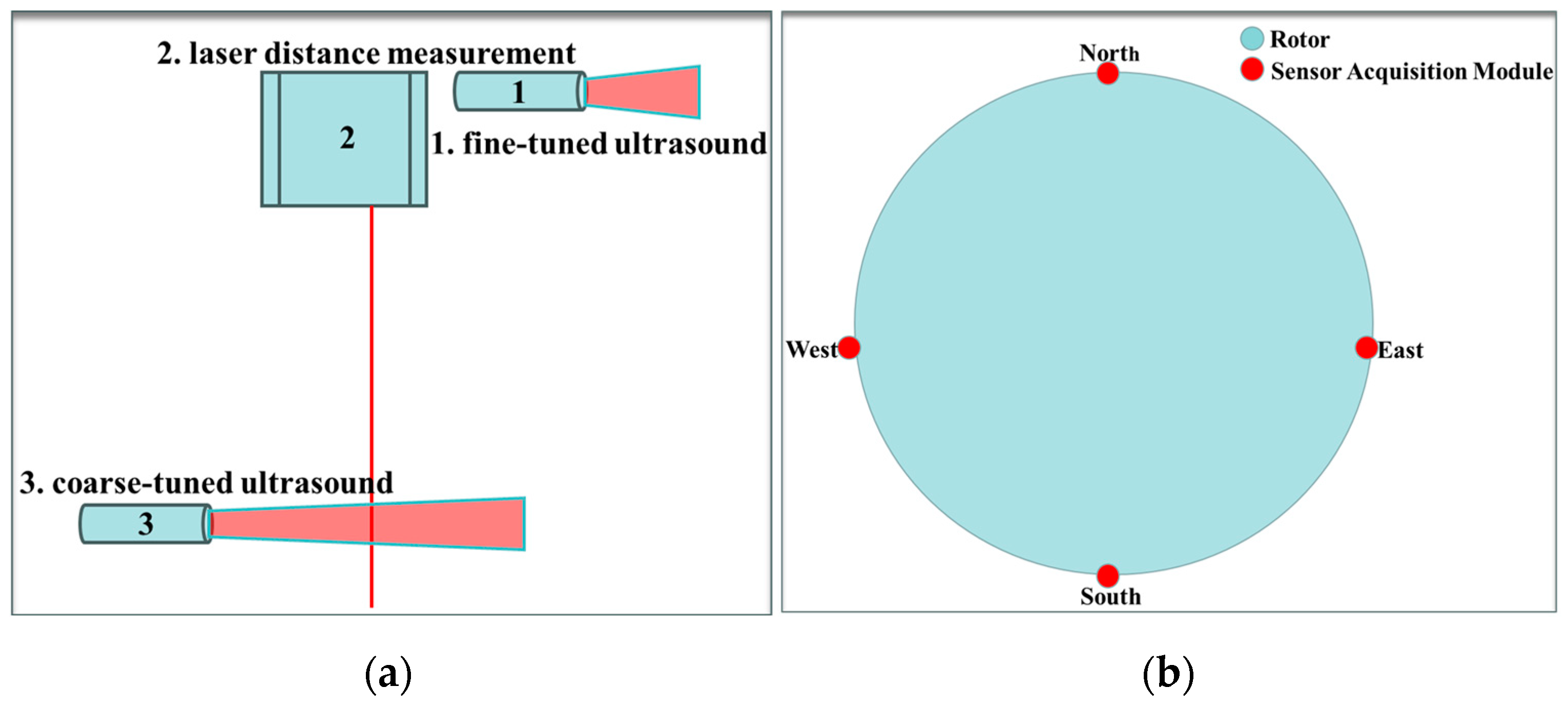

2.2. Principle of Position Monitoring

3. Error Analysis and Modeling of Position Monitoring Systems

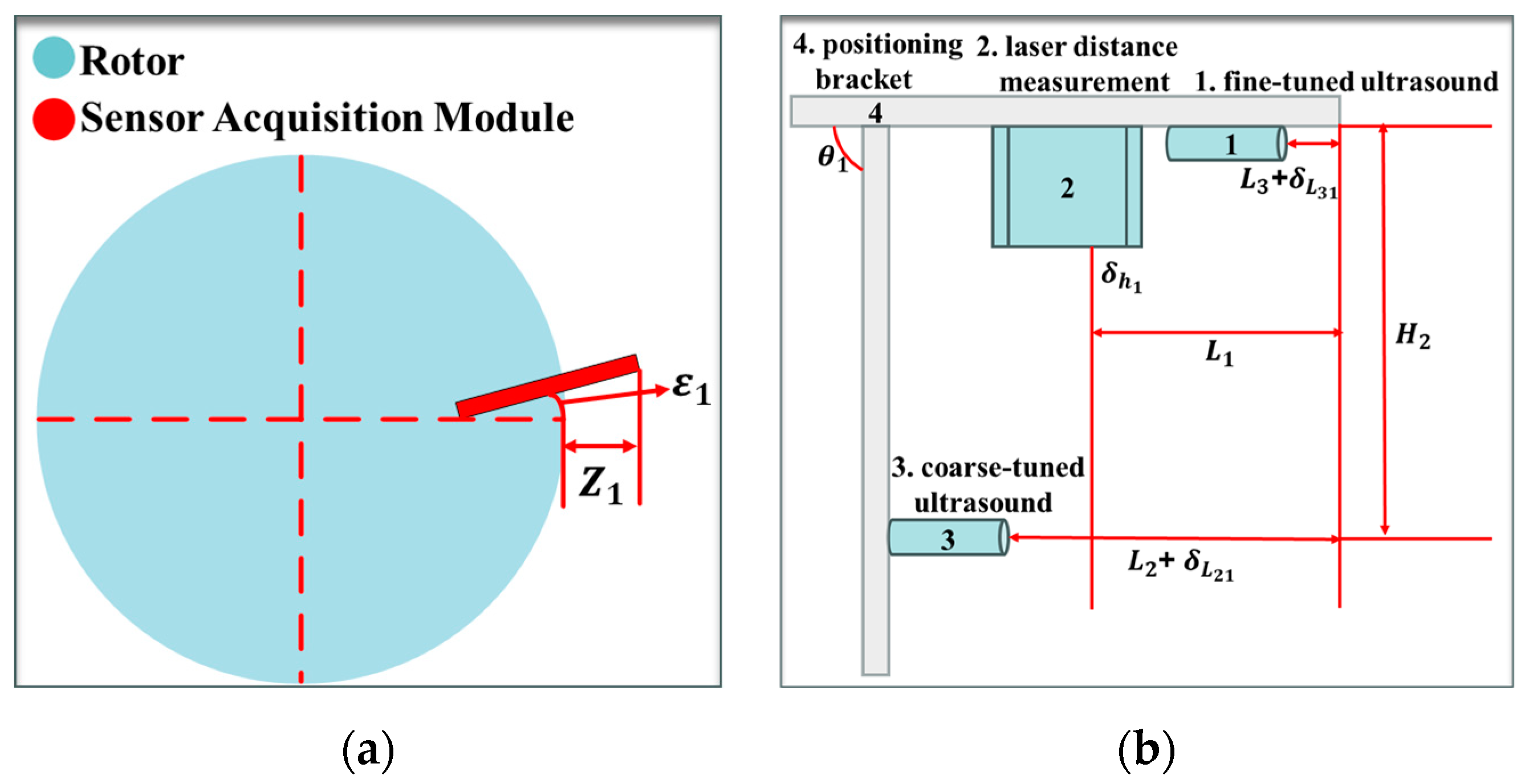

3.1. Error Source Analysis

3.2. Error Modeling

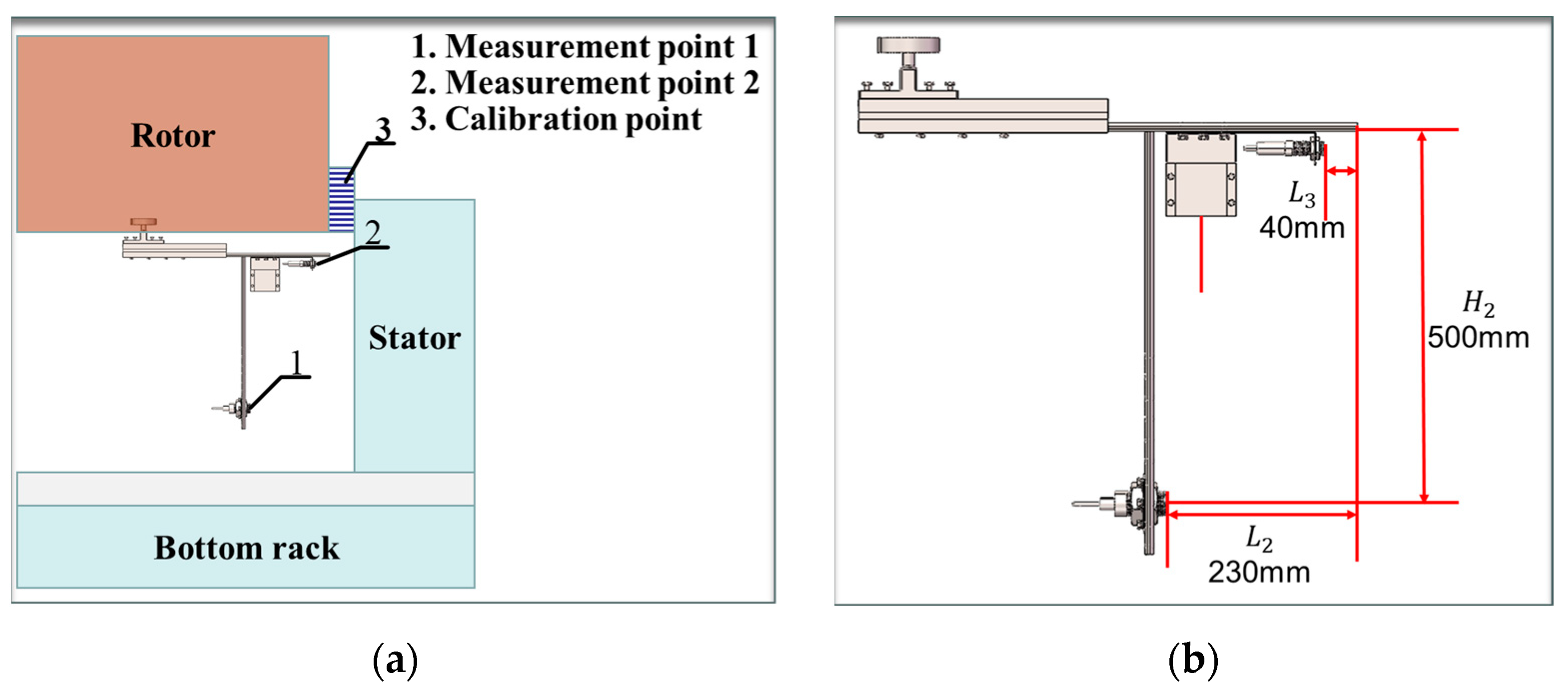

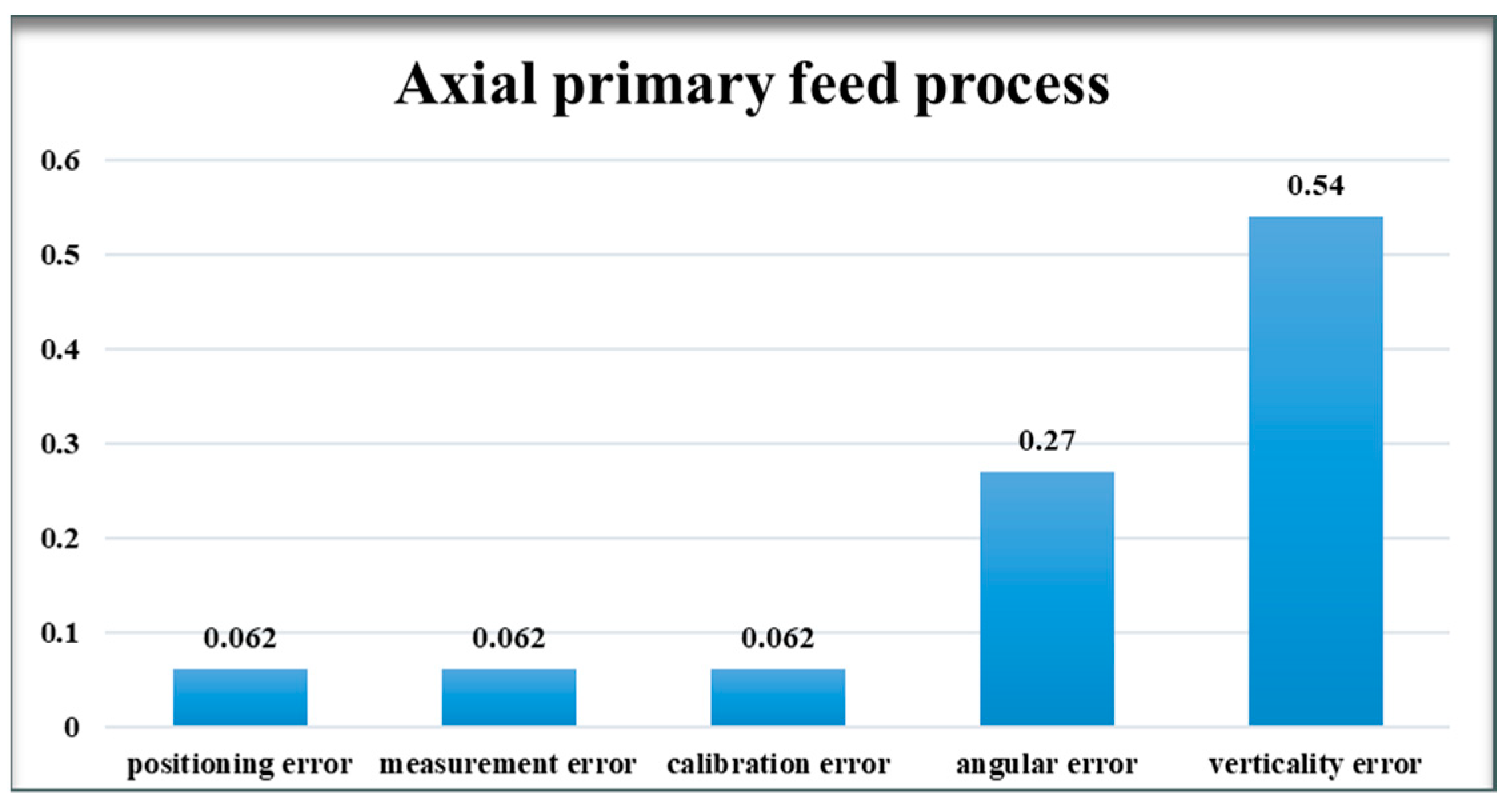

3.2.1. Modeling of Errors during Axial Primary Feeds

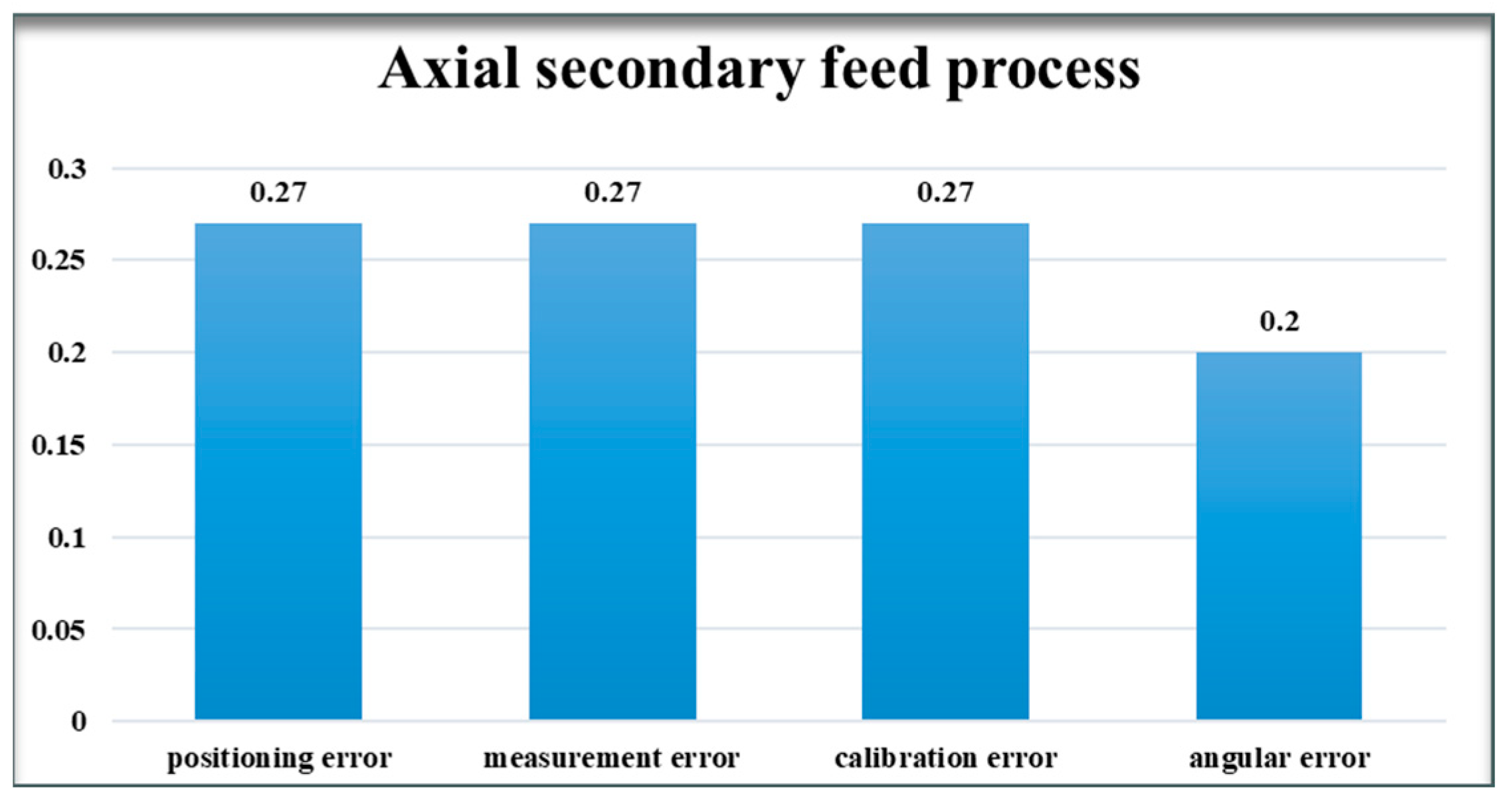

3.2.2. Modeling of Errors during Axial Secondary Feeds

4. Model Validation and Analysis

4.1. Model Verification

4.1.1. Axial Primary Feed Process

4.1.2. Axial Secondary Feed Process

4.2. Model Analysis

4.2.1. Improved Installation Accuracy

4.2.2. Error Compensation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mu, X.; Yuan, B.; Wang, Y.; Sun, W.; Liu, C.; Sun, Q. Novel Application of Mapping Method from Small Displacement Torsor to Tolerance: Error Optimization Design of Assembly Parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 955–967. [Google Scholar] [CrossRef]

- Mei, Y.; Sun, C.; Li, C.; Liu, Y.; Tan, J. Research on Intelligent Assembly Method of Aero-Engine Multi-Stage Rotors Based on SVM and Variable-Step AFSA-BP Neural Network. Adv. Eng. Inform. 2022, 54, 101798. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, M.; Sun, C.; Hu, M.; Chen, D.; Liu, Z.; Tan, J. A Method to Minimize Stage-by-Stage Initial Unbalance in the Aero Engine Assembly of Multistage Rotors. Aerosp. Sci. Technol. 2019, 85, 270–276. [Google Scholar] [CrossRef]

- Raptis, T.P.; Passarella, A.; Conti, M. Data Management in Industry 4.0: State of the Art and Open Challenges. IEEE Access 2019, 7, 97052–97093. [Google Scholar] [CrossRef]

- Ezpeleta, I.; Pujana, U.; Isasa, I.; Ayerbe, J.; Justel, D. New Design for Assembly (DfA) Methodology for Large and Heavy Parts Assembled on Site. Procedia CIRP 2021, 100, 145–150. [Google Scholar] [CrossRef]

- Treinen, T.; Kolla, S.S.V.K. Augmented Reality for Quality Inspection, Assembly and Remote Assistance in Manufacturing. Procedia Comput. Sci. 2024, 232, 533–543. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, L.; Shuai, J.; Zhang, R.; Li, Y. Data-Driven and AR Assisted Intelligent Collaborative Assembly System for Large-Scale Complex Products. Procedia CIRP 2020, 93, 1049–1054. [Google Scholar] [CrossRef]

- Pang, J.; Zheng, P.; Li, S.; Liu, S. A Verification-Oriented and Part-Focused Assembly Monitoring System Based on Multi-Layered Digital Twin. J. Manuf. Syst. 2023, 68, 477–492. [Google Scholar] [CrossRef]

- Peng, G.; Sun, Y.; Xu, S. Development of an Integrated Laser Sensors Based Measurement System for Large-Scale Components Automated Assembly Application. IEEE Access 2018, 6, 45646–45654. [Google Scholar] [CrossRef]

- Price, L.C.; Chen, J.; Park, J.; Cho, Y.K. Multisensor-Driven Real-Time Crane Monitoring System for Blind Lift Operations: Lessons Learned from a Case Study. Autom. Constr. 2021, 124, 103552. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, J.; Cho, Y.K.; Kim, K.; Zhang, S.; Perez, E. Vision-Based Load Sway Monitoring to Improve Crane Safety in Blind Lifts. J. Struct. Integr. Maint. 2018, 3, 233–242. [Google Scholar] [CrossRef]

- Wu, X.; Marshall, L.; Sharma, A. Quantifying Input Error in Hydrologic Modeling Using the Bayesian Error Analysis with Reordering (BEAR) Approach. J. Hydrol. 2021, 598, 126202. [Google Scholar] [CrossRef]

- Jiang, P.; Jia, F.; Wang, Y.; Zheng, M. Real-Time Quality Monitoring and Predicting Model Based on Error Propagation Networks for Multistage Machining Processes. J. Intell. Manuf. 2014, 25, 521–538. [Google Scholar] [CrossRef]

- Yang, J.; Heogh, W.; Ju, H.; Kang, S.; Jang, T.-S.; Jung, H.-D.; Jahazi, M.; Han, S.C.; Park, S.J.; Kim, H.S.; et al. Functionally Graded Structure of a Nitride-Strengthened Mg2Si-Based Hybrid Composite. J. Magnes. Alloys 2024, 12, 1239–1256. [Google Scholar] [CrossRef]

- Mikhailov, M.G. A Method of Assembling a Vertical Hydrogenerator Rotor with a Hydroturbine Rotor. Power Technol. Eng. 2017, 51, 294–297. [Google Scholar] [CrossRef]

- Zhou, J.; Peng, X.; Li, R.; Xu, Y.; Liu, H.; Chen, D. Experimental and Finite Element Analysis to Investigate the Vibration of Oblique-Stud Stator Frame in a Large Hydropower Generator Unit. Energies 2017, 10, 2175. [Google Scholar] [CrossRef]

- Li, R.; Li, C.; Peng, X.; Wei, W. Electromagnetic Vibration Simulation of a 250-MW Large Hydropower Generator with Rotor Eccentricity and Rotor Deformation. Energies 2017, 10, 2155. [Google Scholar] [CrossRef]

- Ma, J.; Lu, D.; Zhao, W. Assembly Errors Analysis of Linear Axis of CNC Machine Tool Considering Component Deformation. Int. J. Adv. Manuf. Technol. 2016, 86, 281–289. [Google Scholar] [CrossRef]

- Tang, L.; Jia, X.; Ma, H.; Liu, S.; Chen, Y.; Tao, T.; Chen, L.; Wu, J.; Li, C.; Wang, X.; et al. Microwave Absolute Distance Measurement Method with Ten-Micron-Level Accuracy and Meter-Level Range Based on Frequency Domain Interferometry. Sensors 2023, 23, 7898. [Google Scholar] [CrossRef]

- Urooj, S.; Lata, S.; Ahmad, S.; Mehfuz, S.; Kalathil, S. Cryptographic Data Security for Reliable Wireless Sensor Network. Alex. Eng. J. 2023, 72, 37–50. [Google Scholar] [CrossRef]

- Saveetha, P.; Robinson, Y.H.; Shanmuganathan, V.; Kadry, S.; Nam, Y. Hybrid Energy-Based Secured Clustering Technique for Wireless Sensor Networks. J. Internet Technol. 2022, 23, 21–31. [Google Scholar] [CrossRef]

- Ardanza, A.; Moreno, A.; Segura, Á.; de la Cruz, M.; Aguinaga, D. Sustainable and Flexible Industrial Human Machine Interfaces to Support Adaptable Applications in the Industry 4.0 Paradigm. Int. J. Prod. Res. 2019, 57, 4045–4059. [Google Scholar] [CrossRef]

- Juarez-Salazar, R.; Giron, A.; Zheng, J.; Diaz-Ramirez, V.H. Key Concepts for Phase-to-Coordinate Conversion in Fringe Projection Systems. Appl. Opt. 2019, 58, 4828–4834. [Google Scholar] [CrossRef] [PubMed]

- Nath, J.K.; Nath, S.; Sarmah, K.C. Design of a Microcontroller Based Temperature Measurement and Control System Using PWM Technology. Des. Microcontroller Based Temp. Meas. Control Syst. Using PWM Technol. 2016, 5, 5081–5093. [Google Scholar]

- Wilkinson, M.; Schreiber, U.; Procházka, I.; Moore, C.; Degnan, J.; Kirchner, G.; Zhongping, Z.; Dunn, P.; Shargorodskiy, V.; Sadovnikov, M.; et al. The next Generation of Satellite Laser Ranging Systems. J. Geod. 2019, 93, 2227–2247. [Google Scholar] [CrossRef]

- McGarry, J.F.; Hoffman, E.D.; Degnan, J.J.; Cheek, J.W.; Clarke, C.B.; Diegel, I.F.; Donovan, H.L.; Horvath, J.E.; Marzouk, M.; Nelson, A.R.; et al. NASA’s Satellite Laser Ranging Systems for the Twenty-First Century. J. Geod. 2019, 93, 2249–2262. [Google Scholar] [CrossRef]

- Qiu, Z.; Lu, Y.; Qiu, Z. Review of Ultrasonic Ranging Methods and Their Current Challenges. Micromachines 2022, 13, 520. [Google Scholar] [CrossRef]

- Chiu, Y.; Wang, C.; Gong, D.; Li, N.; Ma, S.; Jin, Y. A Novel Ultrasonic TOF Ranging System Using AlN Based PMUTs. Micromachines 2021, 12, 284. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Niu, X. Estimate the Pitch and Heading Mounting Angles of the IMU for Land Vehicular GNSS/INS Integrated System. IEEE Trans. Intell. Transp. Syst. 2021, 22, 6503–6515. [Google Scholar] [CrossRef]

- Bai, S.; Lai, J.; Lyu, P.; Xu, X.; Liu, M.; Huang, K. A System-Level Self-Calibration Method for Installation Errors in A Dual-Axis Rotational Inertial Navigation System. Sensors 2019, 19, 4005. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, Q.; Chen, X.; Fan, L.; Cheng, C.-T. Bias-Error Accumulation Analysis for Inertial Navigation Methods. IEEE Signal Process. Lett. 2022, 29, 299–303. [Google Scholar] [CrossRef]

- Ruellas, A.C.d.O.; Tonello, C.; Gomes, L.R.; Yatabe, M.S.; Macron, L.; Lopinto, J.; Goncalves, J.R.; Garib Carreira, D.G.; Alonso, N.; Souki, B.Q.; et al. Common 3-Dimensional Coordinate System for Assessment of Directional Changes. Am. J. Orthod. Dentofacial Orthop. 2016, 149, 645–656. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Nearing, G.S.; Peters-Lidard, C.D.; Harrison, K.W.; Tang, L. Performance Metrics, Error Modeling, and Uncertainty Quantification. Mon. Weather Rev. 2016, 144, 607–613. [Google Scholar] [CrossRef]

| Types of Errors | East | South | West | North |

|---|---|---|---|---|

| Positioning | ||||

| Measurement | ||||

| Angular | ||||

| Perpendicularity | ||||

| Calibration |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Lu, F.; Jiao, T.; Yu, J.; Chang, F. Error Analysis and Modeling of a Large Component Assembly Monitoring System Based on Multi-Sensor Fusion. Sensors 2024, 24, 5992. https://doi.org/10.3390/s24185992

Guo Z, Lu F, Jiao T, Yu J, Chang F. Error Analysis and Modeling of a Large Component Assembly Monitoring System Based on Multi-Sensor Fusion. Sensors. 2024; 24(18):5992. https://doi.org/10.3390/s24185992

Chicago/Turabian StyleGuo, Zhenggang, Feng Lu, Tizhao Jiao, Jingqi Yu, and Fu Chang. 2024. "Error Analysis and Modeling of a Large Component Assembly Monitoring System Based on Multi-Sensor Fusion" Sensors 24, no. 18: 5992. https://doi.org/10.3390/s24185992

APA StyleGuo, Z., Lu, F., Jiao, T., Yu, J., & Chang, F. (2024). Error Analysis and Modeling of a Large Component Assembly Monitoring System Based on Multi-Sensor Fusion. Sensors, 24(18), 5992. https://doi.org/10.3390/s24185992