1. Introduction

A structural health monitoring (SHM) system integrates strategically placed sensors to gather essential data about the structure and its environment, enabling a comprehensive assessment of its overall condition [

1]. The primary aim is not only to evaluate the structural integrity, but also to monitor and check the system’s performance in operational scenarios [

2]. The combination of SHM and non-destructive testing offers detailed insight into the structural conditions, optimizing maintenance strategies and ensuring long-term safety [

3]. Shape sensing is a specific branch of SHM dedicated to the real-time reconstruction of the displacement field of a structure from a set of in situ strain measurements. It allows for the continuous tracking of both static and dynamic responses within the system [

4]. Furthermore, reconstructing the displacement field serves as an initial step in assessing stresses across either the entire structure or specific regions [

5]. The attention towards shape-sensing techniques has increased alongside the advent of new strain sensor technologies. In addition to traditional strain gauges, contemporary solutions incorporate fiber optic sensors (FOSs). FOSs offer notable advantages, such as insensitivity to electromagnetic radiation, light weight, small size, great sensitivity and resolution, and suitability to be embedded into structures [

6] These sensors have found numerous shape-sensing applications in civil and aerospace engineering [

7].

The methods for solving shape-sensing problems can be broadly classified into four categories [

8]. The first category encompasses analytical approaches, such as Ko’s displacement theory [

9], which involves direct or numerical integration of experimentally measured strain. The second category includes methods that utilize continuous basis functions to approximate displacements. Modal methods (MM) [

10,

11], for example, fall into this class as they use known spatial functions like mode shapes to describe the displacement field, with unknown weights determined through a curve-fitting process using experimental strains. The third category involves computational models that use artificial neural networks (ANNs) [

12]. The fourth, and last, class is represented by the inverse finite element method (iFEM), developed by Tessler and Spangler [

13]. This technique is based on the least-squares variational principle and finite element discretization. Ko’s displacement theory is limited to beam-like structures as it relies on the kinematic assumptions in the Euler–Bernoulli theory. On the other hand, methods employing ANNs have not been applied widely due to their results being heavily reliant on training datasets. Thus, among the four classes, MM and iFEM exhibit higher general applicability to various kinds of structures. Few studies in the literature focus on comparing these two approaches. For instance, ref. [

14] provides an experimental comparison for a stiffened panel equipped with fiber optic sensors, while ref. [

15] presents numerical analysis involving iFEM, MM, and Ko’s theory for a composite wingbox. These works emphasize that MM is a useful tool in the presence of uncertainties, since it is less influenced by them, although it achieves a lower reconstruction accuracy than iFEM. Other than its high accuracy, the inverse finite element method’s key strengths lie in its ability to monitor the displacement field even under unknown loading conditions and material properties [

16], along with its computational speed which enables real-time applications.

Over the past decade, a variety of inverse elements has been developed on the basis of the first-order shear deformation theory (FSDT). Among the FSDT-based iFEM elements is a three-node inverse-shell element, designated as iMIN3 [

17]; a four-node quadrilateral inverse-shell element, denoted as iQS4 [

18]; an eight-node curved inverse shell element, referred to as iCS8 [

19]; and a two-node inverse-beam element [

20]. In addition, Kefal and Oterkus [

21] have introduced a novel isogeometric inverse element (iKLS), which utilizes Non-Uniform Rational B-Splines (NURBS) as shape functions to achieve a geometrically exact representation of curved thin shell structures. Subsequently, this isogeometric approach has also been extended to the reconstruction of the displacement field in beam-like geometries [

22,

23]. The abovementioned elements enable real-time monitoring of isotropic structures like beams, plates, and shells by means of the inverse finite element method. More recently, a novel class of elements [

24] has been introduced, leveraging the refined zig-zag theory [

25], to exploit the iFEM technique in moderately thick sandwich and laminated composite structures. Over the last few years, iFEM has found both numerical and/or experimental applications in shape-sensing analyses across various interesting case studies, including marine vessels [

26], offshore wind turbine towers [

27], and stiffened panels [

14,

28,

29].

The precision of the inverse finite element method in reconstructing the displacement field is significantly influenced by the number of sensors used. The installation of hundreds of sensors, required to achieve a low error, may be prohibitively expensive and is to be avoided in particular industries, like aerospace, where weight is an important factor to be taken into account. Thus, it may be useful to make use of pre-extrapolation techniques to obtain the input strain field on a more refined mesh from a reduced number of sensors. Notable works addressing this issue include those by Abdollahzdeh et al. [

30] and Kefal et al. [

31]. The first study employed polynomial extrapolation to approximate the strain field from sensor data, while the latter utilized a smoothing procedure based on the minimization of penalized least-squares functionals, known as smoothing element analysis (SEA) [

32]. SEA discretizes the structural domain using least-squares finite elements, where the variable to be smoothed (e.g., stress or strain) is interpolated within each element using piecewise continuous functions. Oboe et al. [

33] conducted a comparison between these two pre-extrapolation techniques on a plate subjected to a compressive load. The authors observed that SEA demonstrated a higher level of adaptability to the input strain field, allowing it to achieve more versatile results.

The accuracy of pre-extrapolation performed with SEA depends on the sensor placement and on the complexity of the strain field. For example, the uniform distribution of sensors on the structure may not optimally reconstruct the strain field since it might not correctly identify its peaks. Consequently, optimizing sensor placement becomes crucial to enhance the effectiveness of the pre-extrapolation process under specific loading conditions. Within the iFEM framework, various studies have focused on optimizing sensor placement. As an example, Zhao et al. [

34] utilized particle swarm optimization (PSO) to derive optimal sensor schemes for beam structures based on eigenvalue analysis. Ghasemzadeh et al. [

35] employed a genetic algorithm to strategically position sensors on selected inverse elements within the mesh of simple 2D and 3D structures under concentrated and distributed loads. Their approach aimed at minimizing the error in the reconstructed displacement field as the objective function. However, this study did not incorporate any pre-extrapolation mechanism, and each optimization was conducted based on a single predefined load (a sensor pattern was optimal only for a single loading condition). In contrast, Roy et al. [

36] explored the reconstruction of two mode shapes of a cantilevered plate using iFEM pre-extrapolated with SEA. Although they considered efficient and easy-to-implement sensor placement patterns, these were not the result of an optimization process.

In this study, we achieve full-field displacement reconstruction using iFEM with pre-extrapolated SEA strains as input. To enhance the effectiveness of pre-extrapolation, we introduce an innovative approach employing a genetic algorithm to optimize sensor placement, aiming to closely match the pre-extrapolated strain field with the actual one. Ensuring the validity of the sensor pattern across diverse loading conditions, the optimization process is multi-objective, utilizing the well-established non-dominated sorting genetic algorithm (NSGA-II [

37]). Specifically, we focus on analyzing a cantilevered rectangular plate and a square plate clamped on all four sides, optimizing sensor placement for the improved reconstruction of a pre-selected set of vibration mode shapes. A comparative analysis is conducted between the displacement field reconstructions obtained through our proposed methodology, the conventional iFEM, and the combined use of the iFEM and SEA with a uniformly distributed sensor pattern. The results from our approach reveal a significant enhancement in monitoring capabilities compared to the standard iFEM algorithm, despite utilizing the same number of sensors.

2. Theoretical Background

2.1. Inverse Finite Element Method

Within the iFEM framework, the structural domain is discretized with a set of inverse finite elements. The algorithm computes the nodal displacements of the discretized mesh, taking into account the structure’s geometry, boundary conditions, and a set of in situ strain measurements.

In the present work, an element formulation based on the first-order shear deformation theory has been adopted. Therefore, the displacement field can be described in terms of the membrane displacements,

and

, the deflection

, as well as the rotations around the mid-plane axis

and

, expressed by

and

, respectively (

denotes the mid-plane coordinates). The Cartesian displacement components are written as:

where

indicates the through-the-thickness coordinate.

The strain field is obtained by derivation of the kinematic variables:

where

,

, and

are the membrane, bending, and transverse shear section strains, respectively.

The goal of the inverse finite element method is to determine the nodal degrees of freedom values that minimize the error between the reconstructed strain field and the one measured using a discrete set of points. For a single inverse element, the error in the reconstruction is quantified by means of a weighted least-squares functional, defined as follows:

where the superscript

is used to denote the values measured from an in situ strain sensor. In Equation (3)

,

, and

are positive-valued weighting constants associated with membrane strains, bending curvatures, and shear strains, respectively. In the present work, the structure’s geometry is discretized with four-node inverse elements, known in the literature as iQS4 (displayed in

Figure 1a). The kinematic variables inside each element are, thus, interpolated using a set of anisoparametric [

38] shape functions:

In this context,

denotes the matrix of the shape functions, and

is the vector representing the nodal degrees of freedom for each element. A single element is characterized by 24 DOF, consisting of three displacements and three rotations per node. It should be noted that

denotes the drilling rotation of the i-th node. Although not considered a kinematic variable in the FSDT formulation, it is utilized in the element interpolation of membrane displacements. By substituting Equation (4) into Equation (2), the numerical strain components can be expressed as the product between the matrices

,

, and

containing the derivatives of the shape functions, and the element nodal displacements

.

If an element is equipped with

strain sensors, the least-squares functional can be rewritten by means of the Euclidean norm, as follows:

By inserting Equation (5) into the functional of Equation (6) and minimizing it with respect to

, one obtains a system of linear equations:

with

Given a structure equipped with a set of surface-mounted strain sensors, the experimental membrane and curvature strains at the i-th measurement point (

Figure 1b) can be derived as follows:

The superscripts and refer to the quantities corresponding to the top and bottom surface, respectively. It is not mandatory to equip every element in the mesh with sensors; the iFEM technique remains numerically stable even if certain elements lack in situ strain measurements. In such instances, the associated weights are assigned smaller values, e.g., (otherwise they are set to unity). In general, transverse shear strains cannot be directly measured using surface-mounted strain gauges: therefore, is considered as , and the corresponding weight, , is selected to be small.

The matrices

and

, computed for each element within the domain, can be assembled into a system of linear equations for the global degrees of freedom:

where

is a matrix depending on the shape functions and strain-sensor locations, whereas

is a vector which encompasses the measured data. The matrix

is computed and inverted only once (after applying the appropriate boundary conditions) in the monitoring process, while the vector

needs to be updated each time new strain measures are acquired.

2.2. Smoothing Element Analysis

To enhance the precision and cost effectiveness of shape-sensing analysis, especially when dealing with a limited number of sensors, a viable strategy involves pre-extrapolating the structure’s strain field. The inverse problem is then addressed by means of the iFEM, utilizing the pre-extrapolated data as an input [

39]. This approach enables the use of a finer mesh with a large number of measurement samples, ensuring higher accuracy in the reconstruction of the displacement field.

Smoothing element analysis (SEA) is a robust technique, which can be employed to pre-extrapolate the input strain field. The numerical formulation of SEA relies on a variational principle employing a penalized discrete least-squares (PDLS) functional [

40]. The algorithm adopts a finite element approach, in which the geometry is discretized into a triangular mesh. Let us define a general measured strain as

(which could be

, for example), while the corresponding strain after smoothing is denoted as

. For a single mesh element (shown in

Figure 2), the PDLS functional is expressed as:

Here, is the total number of measurements within the element; and represent the partial derivative operator with respect to and ; and are the analytical counterparts of the partial derivatives of the experimental strain along directions and , respectively. The first term in the equation is a discrete least-squares functional, which enforces a match between the extrapolated strain field and the experimental strain data. The second term introduces a penalty constraint functional, which depends on the dimensionless parameter . For large values of (e.g., ), such term ensures the limiting condition of continuity for . The third term serves as a regularization functional, relying on the positive parameter . This term imposes an additional constraint on the derivatives and , the severity of which is governed by the value of the parameter . Particularly, when the sampled data is reasonably accurate, should be significatively small with respect to (e.g., ).

The field variables are expressed with an anisoparametric interpolation within each element:

where

,

,

are the vectors of the nodal DOF of the element,

is a row vector of linear shape functions, while

and

are the row vectors of quadratic shape functions. We can define

, an array containing the nine unknowns of each element. By substituting Equation (13) into the functional of Equation (12), the condition for which

is minimized can be written as:

Note, that if an element does not have any input strain, both and the first term of will be absent, and the second and third term of Equation (15) will be the only ones contributing to the element stiffness matrix.

After discretizing the geometry with multiple smoothing elements, a global system of equations is assembled, which can easily be solved for the unknown nodal degrees of freedom of the mesh (i.e., the strain field, and its derivatives in each node). Although the imposition of boundary conditions is not mandatory in smoothing element analysis, they may be applied if the exact solution is known in specific regions [

33]. Once the linear system is solved, it is possible to compute the strain field at any arbitrary point in the domain by means of the shape functions.

2.3. Multi-Objective Genetic Algorithm

A genetic algorithm (GA) is a heuristic optimization approach inspired by natural selection principles [

41]. The process involves initiating a population, conducting reproduction, mutating genes, and applying natural selection to attain an optimal population. In a GA, a chromosome (or individual) represents a potential solution to the problem the algorithm is trying to solve. Chromosomes are composed of discrete units known as genes. Each gene regulates specific features of the chromosome. A GA operates with a collection of chromosomes, forming a population that is typically initialized randomly.

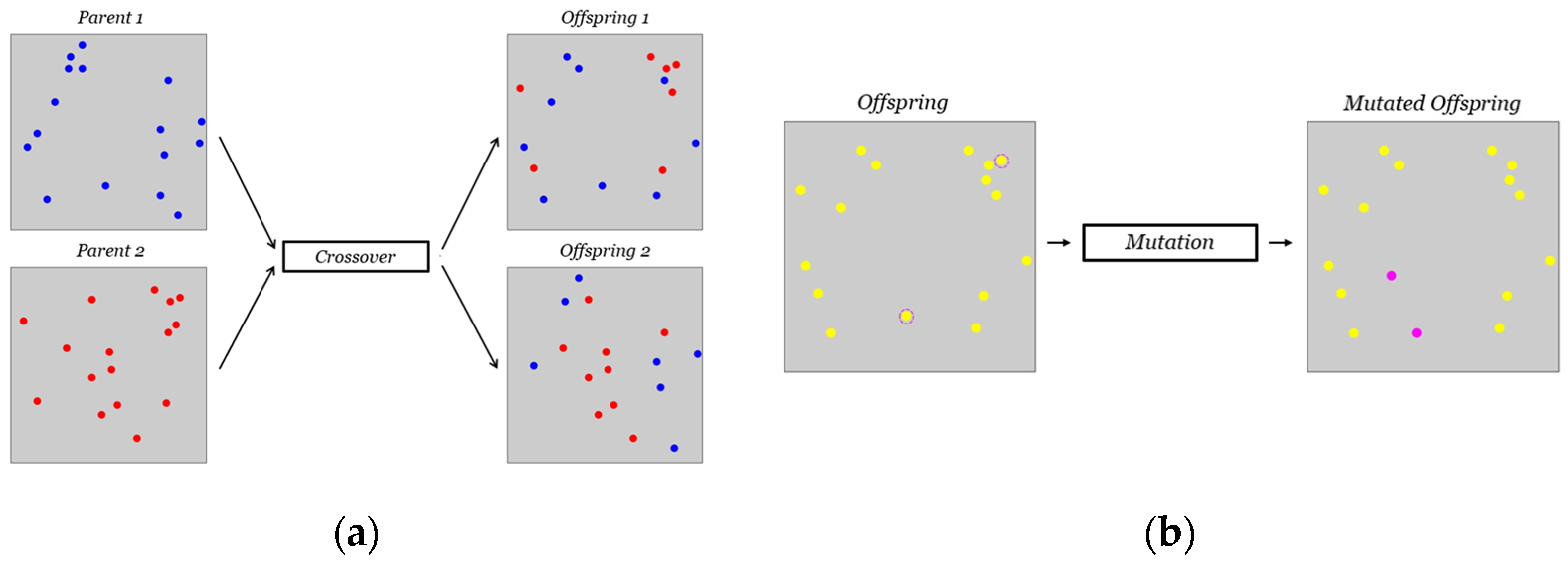

As the search progresses, the population evolves to include increasingly fit solutions, until convergence is reached. A GA employs two key operators for generating new solutions from existing ones: crossover and mutation [

42]. In the crossover process, two chromosomes, known as parents, are combined to produce an offspring. The parents are chosen using a selection operator that favors fitter individuals from the existing population. Through the iterative application of the crossover operator, genes from superior chromosomes are more likely to be incorporated into the population, contributing to the overall convergence to a favorable solution. The mutation operator introduces random changes to the characteristics of the chromosomes. Mutation is pivotal in a GA as it injects genetic diversity into the population, aiding the search in escaping local optima. By combining these mechanisms, a GA dynamically refines its population, iteratively improving solutions to reach an optimal outcome.

For multi-objective optimization problems, attaining a solution that is optimal for every objective is often impossible [

43]. Instead, the concept of Pareto domination and Pareto optimal solutions are introduced. NSGA-II, a multi-objective genetic algorithm, serves as an optimization tool to find a Pareto-optimal set of solutions. NSGA-II works similarly to a single-objective GA, but incorporates specific operations in the selection process [

44]:

Fast non-dominated sorting approach: The population is sorted into different non-dominated fronts. Individuals in the first non-dominated front are identified, and their rank is set to 1. The remaining individuals in the population, excluding those with rank 1, continue to be sorted using the same procedure. This process continues until all fronts are identified.

Crowding distance assignment: Individuals with the same rank are arranged based on the crowding distance, which represents the average distance between a solution and its neighboring solutions on the front in the objective space.

Selection operator: The binary tournament selection is employed to choose the parents. Two individuals are randomly selected from the population, and if their ranks differ, the one with the smaller rank is chosen. If their ranks are the same, the individual with the larger crowding distance is selected. This method ensures a more even distribution of solutions along the Pareto front, preventing overcrowding in specific regions.

2.4. Proposed Methodology

In this study, SEA is employed to pre-extrapolate the strain field, which serves as input for the inverse finite element method. Through the smoothing process, a continuous description of the strain field is produced, allowing the application of the iFEM on a fine mesh. The use of a fine mesh is theoretically feasible even with a relatively low number of sensors in the standard iFEM, as the weights of the individual elements can be adjusted to account for the presence or absence of a measurement. However, maintaining a sufficient ratio between the number of elements with strain data and the total number of elements in the mesh is crucial to avoid a significant degradation of the results. Therefore, employing SEA allows the use of particularly dense meshes, where each element has measurement data, ensuring high accuracy. To obtain good results though, it is crucial that the pre-extrapolated strain field closely approximates the real one. To accomplish this, we optimize the sensor placement process by means of a genetic algorithm. Since a structure can undergo various loading conditions, it makes sense to perform a multi-objective optimization based on multiple operational scenarios. Therefore, the proposed optimization strategy involves the use of NSGA-II. For the case studies under consideration, we optimized the sensor placement to enable SEA to accurately reconstruct the deformation fields associated with a specific set of structural mode shapes. We made this choice since it is generally possible to decompose a general linear state of deformation into a sum of weighted mode shapes.

The starting point in the process is the finite element (FE) model of the structure (in our case a plate), which serves a dual purpose: it generates the discrete strain data (simulating what would be read by actual sensors in real-world applications) and provides a reference for evaluating the accuracy of the results obtained from the shape-sensing code. A modal analysis is performed on the FE model, allowing us to extract the first

natural modes of the structure. The number of sensors to be placed on the structure, denoted as

, is determined a priori. It is chosen in such a way that the measurement points are sufficient for pre-extrapolating the strain field in an appropriate manner, considering both the field behavior and the error level; consequently, a more complex strain field requires a higher number of installed sensors. Certainly, the number of measurement points was limited to a reasonable value, ensuring that the use of pre-extrapolation remains beneficial. Therefore, the goal of the optimization is to find a set of Pareto optimal sensor positions. The possible locations for the sensors are selected among the centroids of four-node quadrilateral shell elements in the FE mesh. Once the number of sensors to be installed is determined, a generic chromosome is defined by a matrix of

rows. Each row (gene) is a vector

of the coordinates extracted from the set of centroids belonging to the FE mesh. The number of individuals in the population is referred to as

. The initial population is randomly generated, with care taken to avoid the rare event of duplicating the same individual in the process. In a subsequent step, the fitness of each chromosome is evaluated. Thus, for each chromosome, the six strain components

are reconstructed through smoothing element analysis, and the pre-extrapolated values are compared with the FEM ones at a set of sampling points for each target mode. In this work, since all the considered cases exhibit zero membrane strain, the objective function to minimize is chosen as the sum of the root mean square error in the SEA extrapolation across the three curvature components for a single mode:

where

is the number of sampling points in which the rms error is evaluated and

are the weights associated with the rms error of each component. In our study, each weight was set to 1, although, in general, it is theoretically possible to make more suitable choices based on the deformation field to be pre-extrapolated. Since we are in a multi-objective optimization context, we will need to evaluate

different fitness functions (one for each mode shape), with the goal of finding the Pareto optimal solutions.

In this study, the sampling points have been selected as a subset of the centroids of the FE mesh. In principle, the entire set of centroids could be used for this purpose, but given the large number, it leads to a significant increase in computational time when running the genetic algorithm. In

Figure 3a, a square plate with the FE mesh and the set of centroids from which possible sensor coordinates are extracted is presented as an example, while in

Figure 3b, a subset of sampling points is illustrated.

After evaluating the fitness of each individual in the population, a ranking is performed based on the Pareto fronts and crowding distance, as described in the previous section. To create the next generation, the parents are selected through binary tournament selection. Crossover can occur with a probability denoted as

. The present study employs a uniform crossover, in which each gene is selected randomly from one of the corresponding genes of the parent chromosomes with equal probability. In

Figure 4a, an example of such crossover in our problem is illustrated. The blue and red dot patterns on the left represent Parent 1 and Parent 2, respectively. Following the crossover, the two resulting children inherit some sensor positions from Parent 1 (blue dots) and the remaining positions from Parent 2 (red dots). After the reproduction phase, some offspring may undergo a mutation process. For each offspring, a random real number between 0 and 1 is drawn, and if it exceeds

, the mutation probability, then the mutation occurs. In this work, mutation involves changing the positions of

random sensors belonging to the individual’s pattern with other random positions, among the set of centroids in the FE model. Moreover,

, the number of mutated genes, varies between 1 and

(it should not be too high otherwise its effects may be too disruptive). In the studied cases, the value

varied depending on the number of sensors to be installed on the structure.

Figure 4b shows an example of the mutation in our approach: on the left, the individual before mutation with two circled sensors randomly chosen to undergo the process; on the right, the individual after mutation, with the purple dots indicating the new positions of the two mutated sensors.

At the end of the mutation process, elitism is applied to form the new population for reproduction, keeping only the best

individuals among the parents, offspring, and mutated individuals. A ranking is needed to choose the best

solutions and, thus, the non-dominated sorting and crowding distance are employed. The use of elitism ensures that there is no loss of good genes between generations, leading to a monotonic convergence into the optimal solution. The selection, crossover, mutation, and elitism operators are applied at each iteration of the genetic algorithm until convergence, or a maximum number of iterations is reached, at which point the whole process is terminated. In

Figure 5, a flowchart that depicts the main steps in the optimization process is depicted.