Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling

Abstract

1. Introduction

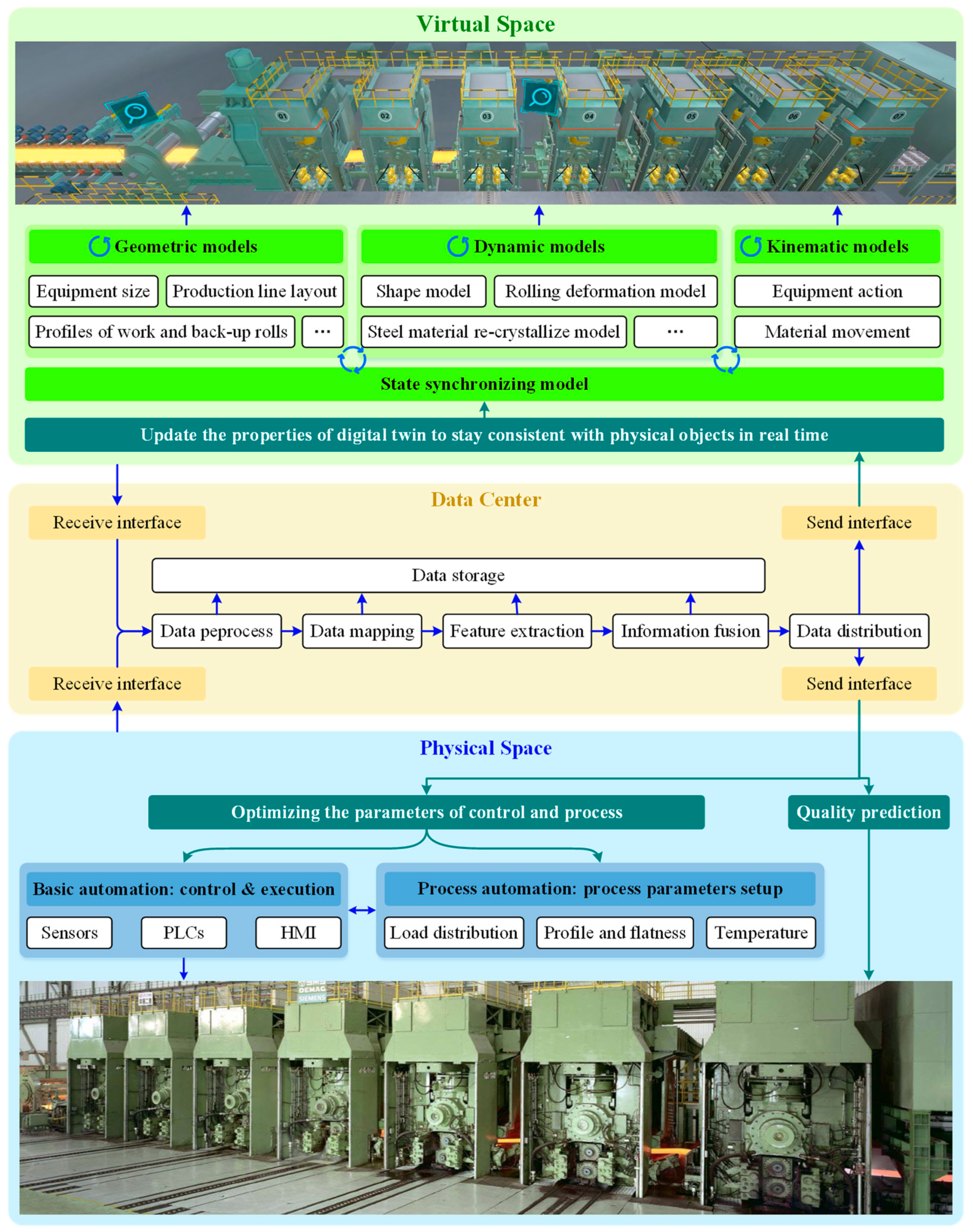

2. System Architecture

2.1. Structure of Digital Twin

2.2. Varying Contact Rolling

2.3. Establishment of Shape Model

3. Implementation

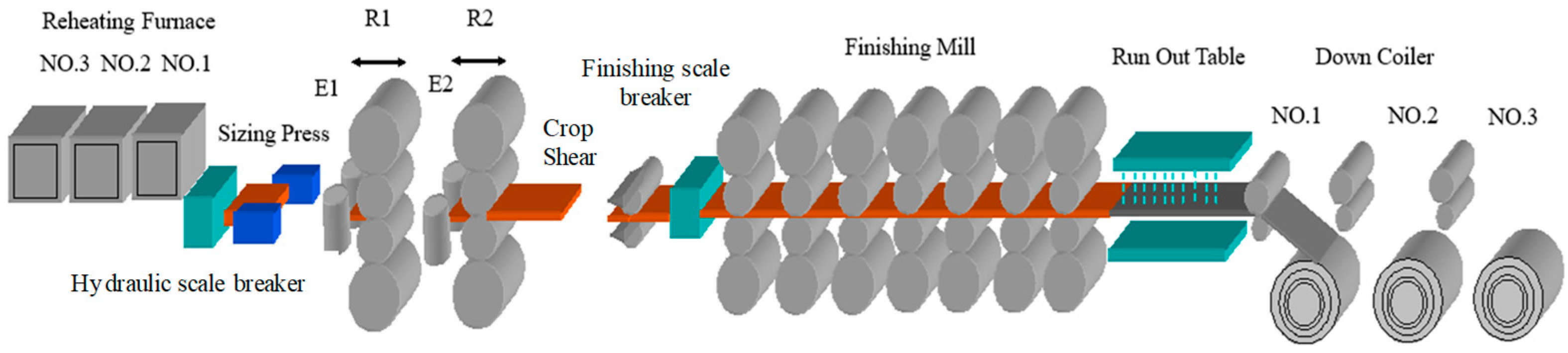

3.1. Industrial Context

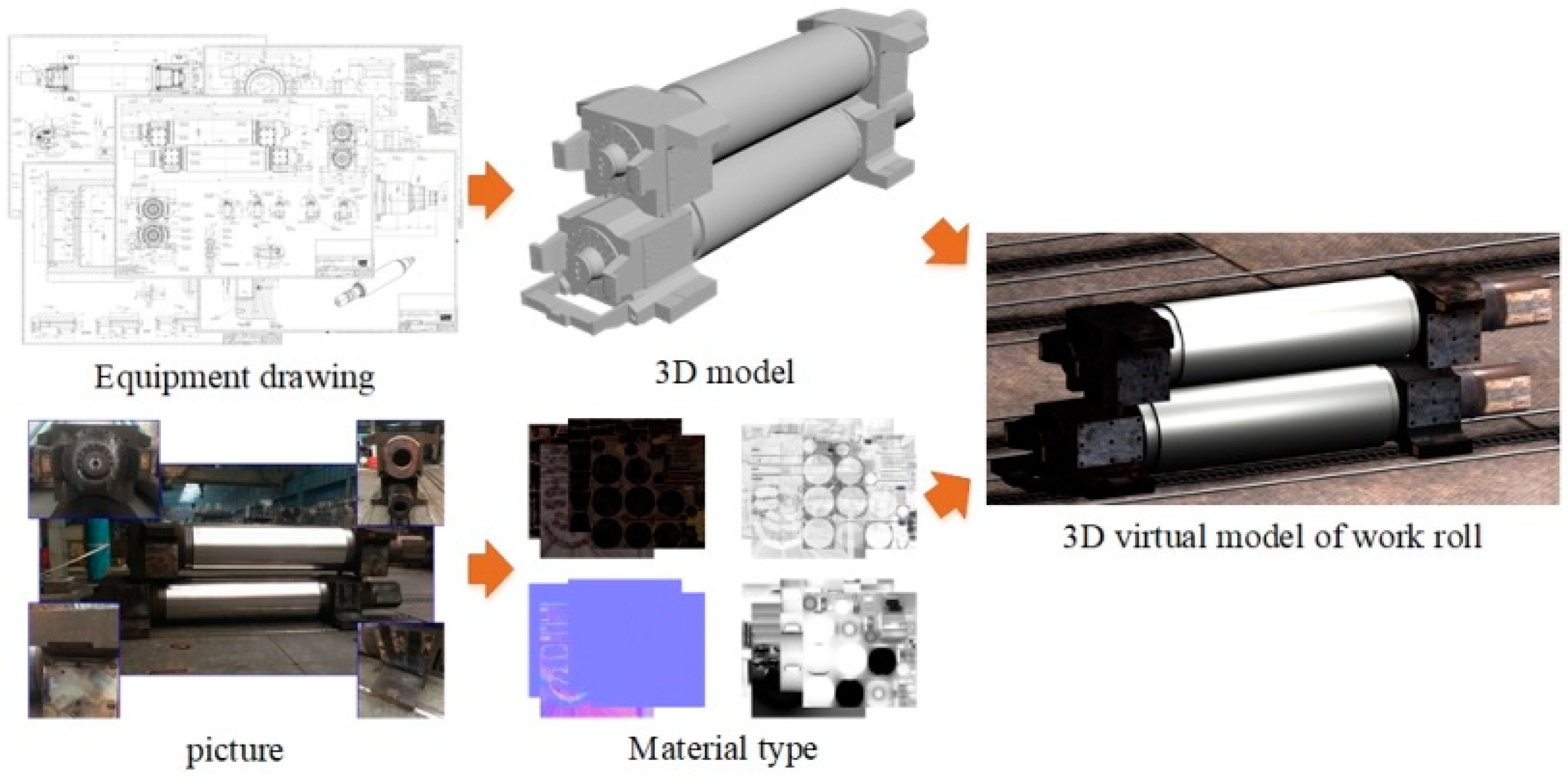

3.2. Construction of Digital Twin

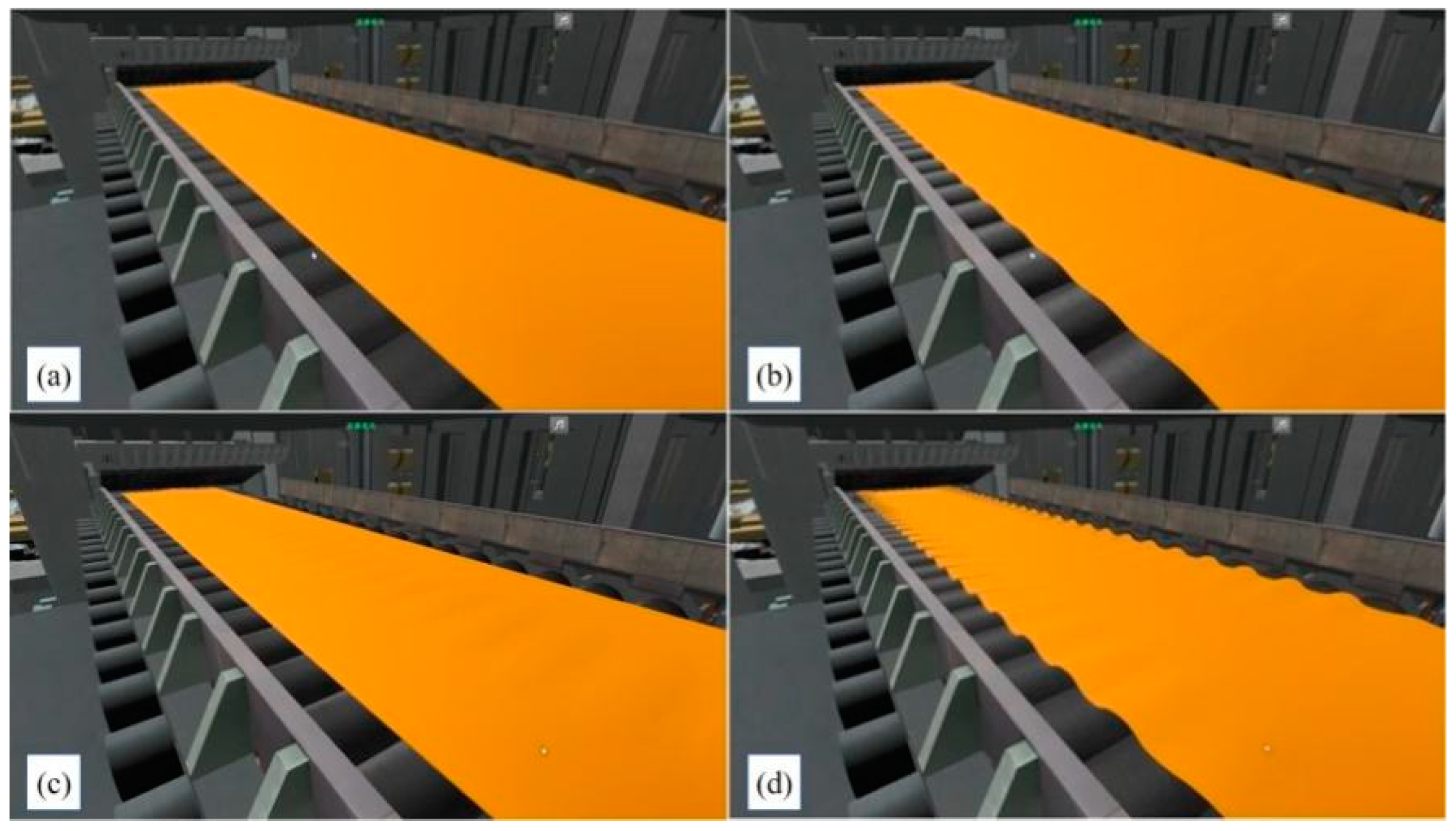

3.3. Simulation and Results

4. Conclusions and Outlook

- (1)

- The shape model introduced considers the metal flow and the stress relaxation between stands; the residual stress influence factor is proposed, and the shape preset strategy is given. Compared with the traditional shape preset strategy, this model can give full play to the control ability of each stand with the application of varying contact rolling.

- (2)

- Combined with digital twin technology, the digital twin framework of the shape model is proposed, which realizes the deep integration between physical time–space and virtual time–space. With the support of an actual industrial background, the parameters of the shape model are updated iteratively by utilizing historical production data, and the digital twin of the shape model is completed.

- (3)

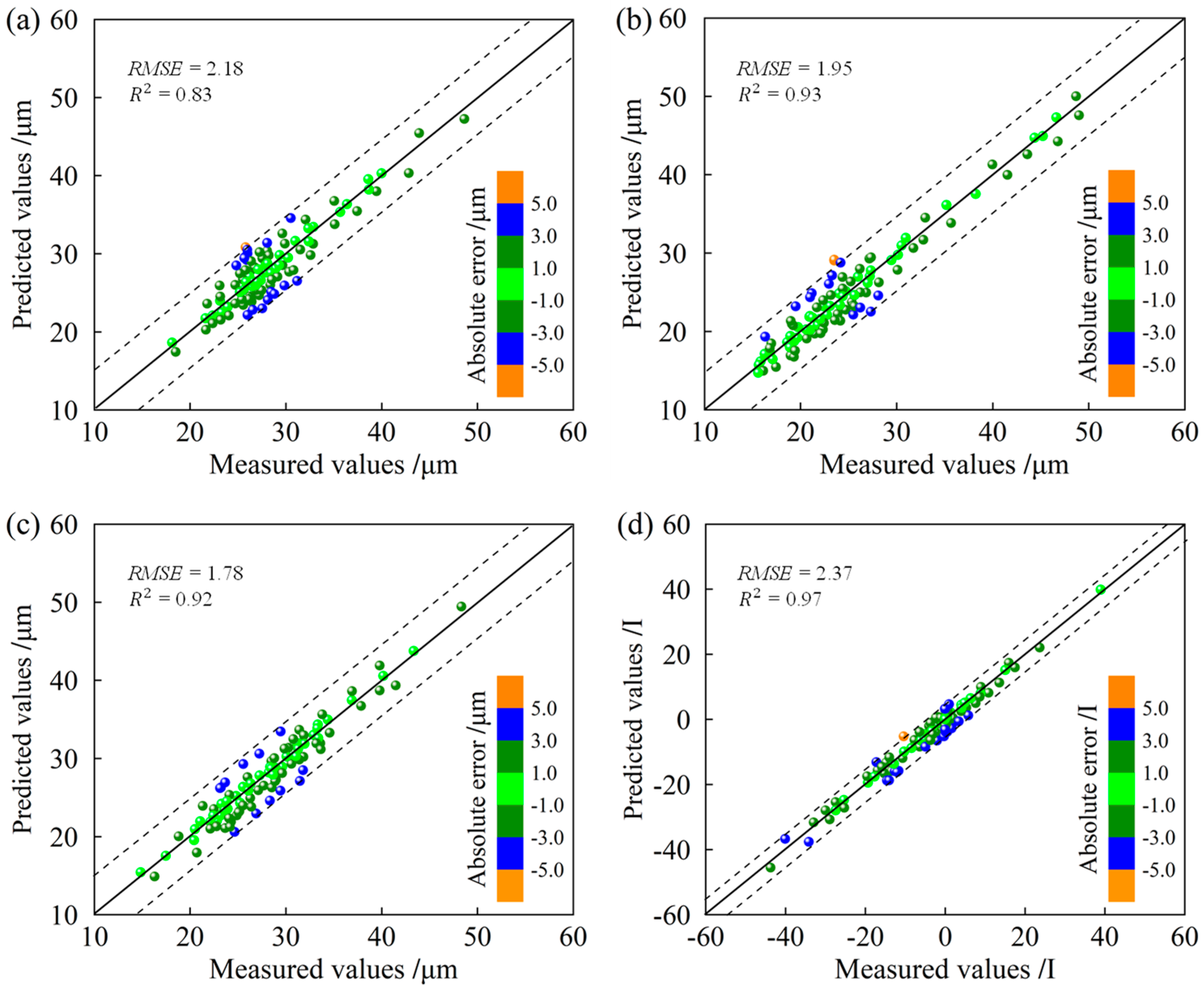

- Combined with the production schedule, the rolling effects of the hot strip are simulated. The raw material information is used as input, and different shape results are obtained, which can assist the operator when modifying and improving the presetting operation. The prediction absolute errors of crown and flatness are less than 5 μm and 5 I-units, respectively. These results prove that the proposed shape simulation model with strong prediction performance can be effectively applied to hot rolling production. In addition, the proposed model provides operators with a reference for the parameter settings of actual production and promotes the intelligent application of a shape control strategy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ono, H.; Watanabe, T.; Yoshimoto, K.; Kaga, S. Industrial application of the HCX-MILL to hot strip mills. Hitachi Rev. 1996, 45, 271–278. [Google Scholar]

- Yasuda, K.; Narita, K.; Kobayashi, K.; Maeno, I. Shape controllability in new 6-high mill (UC-4 mill) with small diameter work rolls. ISIJ Int. 1991, 31, 594–598. [Google Scholar] [CrossRef]

- Bald, W.; Beisemann, G.; Feldmann, H.; Schultes, T. Continuously variable crown (CVC) rolling. Iron Steel Eng. 1987, 64, 32–41. [Google Scholar]

- Aratani, H.; Ozono, R.; Nakano, T. Expansion of pair cross mill applications to hot and cool rolling mills. Iron Steel Eng. 1993, 70, 32–37. [Google Scholar]

- Sun, W.Q.; Li, B.; Shao, J. Research on crown & flatness allocation strategy of hot rolling mills. Int. J. Simul. Model. 2016, 15, 327–340. [Google Scholar]

- Moazeni, B.; Salimi, M. Investigations on relations between shape defects and thickness profile variations in thin flat rolling. Int. J. Adv. Manuf. Technol. 2014, 77, 1315–1331. [Google Scholar] [CrossRef]

- Wang, Q.L.; Sun, J.; Liu, Y.M.; Wang, P.F.; Zhang, D.H. Analysis of symmetrical flatness actuator efficiencies for UCM cold rolling mill by 3d elastic–plastic FEM. Int. J. Adv. Manuf. Technol. 2017, 92, 1371–1389. [Google Scholar] [CrossRef]

- Jelali, M.; Muller, U.; Wolff, A.; Ungerer, W.; Thiemann, G. Advanced measurement and flatness control for hot strip mills. Metall. Res. Technol. 2002, 99, 517–522. [Google Scholar] [CrossRef]

- Li, Y.L.; Cao, J.G.; Kong, N.; Wen, D.; Ma, H.H.; Zhou, Y.S. The effects of lubrication on profile and flatness control during ASR hot strip rolling. Int. J. Adv. Manuf. Technol. 2017, 91, 2725–2732. [Google Scholar] [CrossRef]

- Song, L.B.; Xu, D.; Liu, P.F.; Zhou, J.H.; Yan, H.Q.; Li, J.D.; He, H.N.; Yu, H.J.; Wang, X.C.; Yang, Q. A novel mechanism fusion data control method for slab camber in hot rolling. J. Iron Steel Res. Int. 2023, 30, 960–970. [Google Scholar] [CrossRef]

- Ji, Y.F.; Song, L.B.; Yuan, H.; Li, H.Y.; Peng, W.; Sun, J. Prediction of strip section shape for hot-rolled based on mechanism fusion data model. Appl. Soft Comput. 2023, 146, 110670. [Google Scholar] [CrossRef]

- Song, L.B.; Xu, D.; Wang, X.C.; Yang, Q.; Ji, Y.F. Application of machine learning to predict and diagnose for hot-rolled strip crown. Int. J. Adv. Manuf. Technol. 2022, 120, 881–890. [Google Scholar]

- Ding, C.Y.; Sun, J.; Li, X.J.; Peng, W.; Zhang, D.H. A high-precision and transparent step-wise diagnostic framework for hot-rolled strip crown. J. Manuf. Syst. 2023, 71, 144–157. [Google Scholar]

- Napoleone, A.; Macchi, M.; Pozzetti, A. A review on the characteristics of cyber-physical systems for the future smart factories. J. Manuf. Syst. 2020, 54, 305–335. [Google Scholar]

- Lee, J.; Davari, H.; Singh, J.; Pandhare, V. Industrial artificial intelligence for industry 4.0-based manufacturing systems. Manuf. Lett. 2018, 18, 20–23. [Google Scholar]

- Lu, Y.Q.; Xu, X.; Wang, L.H. Smart manufacturing process and system automation-a critical review of the standards and envisioned scenarios. J. Manuf. Syst. 2020, 56, 312–325. [Google Scholar]

- Shao, G.D.; Helu, M. Framework for a digital twin in manufacturing: Scope and requirements. Manuf. Lett. 2020, 24, 105–107. [Google Scholar]

- Guo, D.Q.; Zhong, R.Y.; Lin, P.; Lyu, Z.Y.; Rong, Y.M.; Huang, G.Q. Digital twin-enabled graduation intelligent manufacturing system for fixed-position assembly islands. Robot. Comput. Integr. Manuf. 2020, 63, 101917. [Google Scholar] [CrossRef]

- Yi, Y.; Yan, Y.H.; Liu, X.J.; Ni, Z.H.; Feng, J.D.; Liu, J.S. Digital twin-based smart assembly process design and application framework for complex products and its case study. J. Manuf. Syst. 2021, 58, 94–107. [Google Scholar] [CrossRef]

- Sun, X.M.; Bao, J.S.; Li, J.; Zhang, Y.M.; Liu, S.M.; Zhou, B. A digital twin-driven approach for the assembly-commissioning of high precision products. Robot. Comput. Integr. Manuf. 2020, 61, 101839. [Google Scholar] [CrossRef]

- Zhuang, C.B.; Gong, J.C.; Liu, J.H. Digital twin-based assembly data management and process traceability for complex products. J. Manuf. Syst. 2020, 58, 118–131. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human-robot collaborative assembly. CIRP Ann. Manuf. Technol. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Zhang, K.; Qu, T.; Zhou, D.J.; Jiang, H.F.; Lin, Y.X.; Li, P.Z.; Guo, H.F.; Liu, Y.; Li, C.D.; Huang, G.Q. Digital twin-based opti-state control method for a synchronized production operation system. Robot. Comput. Integr. Manuf. 2020, 63, 101892. [Google Scholar] [CrossRef]

- Murphy, A.; Taylor, C.; Acheson, C.; Butterfield, J.; Jin, Y.; Higgins, P.; Higgins, C. Representing financial data streams in digital simulations to support data flow design for a future Digital Twin. Robot. Comput. Integr. Manuf. 2020, 61, 101853. [Google Scholar] [CrossRef]

- Knapp, G.L.; Mukherjee, T.; Zuback, J.S.; Wei, H.L.; Palmer, T.A.; De, A.; Debroy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar]

- Wang, Q.Y.; Jiao, W.H.; Zhang, Y.M. Deep learning-empowered digital twin for visualized weld joint growth monitoring and penetration control. J. Manuf. Syst. 2020, 57, 429–439. [Google Scholar] [CrossRef]

- Tong, X.; Liu, Q.; Pi, S.W.; Xiao, Y. Real-time machining data application and service based on IMT digital twin. J. Intell. Manuf. 2020, 31, 1113–1132. [Google Scholar] [CrossRef]

- Wang, C.P.; Erkorkmaz, K.; McPhee, J.; Engin, S. In-process digital twin estimation for high-performance machine tools with coupled multibody dynamics. CIRP Ann. Manuf. Technol. 2020, 69, 321–324. [Google Scholar]

- Tao, F.; Zhang, M.; Liu, Y.S.; Nee, A.Y.C. Digital twin driven prognostic and health management for complex equipment. CIRP Ann. Manuf. Technol. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Luo, W.C.; Hu, T.L.; Ye, Y.X.; Zhang, C.R.; Wei, Y.L. A hybrid predictive maintenance approach for CNC machine tool driven by Digital Twin. Robot. Comput. Integr. Manuf. 2020, 65, 101974. [Google Scholar] [CrossRef]

- Sun, W.Q.; Shao, J.; He, A.R. Design and shape control ability simulation of new generation varying contact length backup roll in hot rolling. Int. J. Multimed. Ubiquitous Eng. 2016, 11, 381–390. [Google Scholar] [CrossRef]

- Wang, X.C.; Yang, Q.; Sun, Y.Z. Rectangular section control technology for silicon steel rolling. J. Iron Steel Res. Int. 2015, 22, 185–191. [Google Scholar] [CrossRef]

- Zhao, J.W.; Wang, X.C.; Yang, Q.; Wang, Q.N.; Liu, C.; Song, G.Y. High precision shape model and presetting strategy for strip hot rolling. J. Mater. Process Technol. 2018, 265, 99–111. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Y.N.; Liang, X.K.; She, Y. The effect of Nb on recrystallization behavior of a Nb micro-alloyed steel. Mat. Sci. Eng. A 2008, 474, 254–260. [Google Scholar] [CrossRef]

| Parameter | Stand | Value | Unit |

|---|---|---|---|

| Backup roll length | F1~F7 | 2250 | mm |

| Work roll length | F1~F7 | 2250 | mm |

| Work roll shifting | F1~F7 | ±150 | mm |

| Backup roll diameter | F1~F7 | 1600/1440 | mm |

| Work roll diameter | F1~F4 | 850/765 | mm |

| F5~F7 | 760/685 | mm | |

| Work roll bending force | F1~F7 | 1500 | kN |

| Max rolling force | F1~F4 | 50,000 | kN |

| F5~F7 | 40,000 | kN |

| Steel Grade | Parameters | Range | Unit |

|---|---|---|---|

| SPHC-W1 | Slab thickness | 230 | mm |

| Finish rolling thickness | 2.3–3.5 | mm | |

| Finish rolling entry temperature | 980–1040 | °C | |

| Finish rolling exit temperature | 850–906 | °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Li, J.; Sun, Y.; Song, L.; Yang, Q.; Wang, X. Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling. Sensors 2024, 24, 614. https://doi.org/10.3390/s24020614

Sun Y, Li J, Sun Y, Song L, Yang Q, Wang X. Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling. Sensors. 2024; 24(2):614. https://doi.org/10.3390/s24020614

Chicago/Turabian StyleSun, Youzhao, Jingdong Li, Yamin Sun, Lebao Song, Quan Yang, and Xiaochen Wang. 2024. "Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling" Sensors 24, no. 2: 614. https://doi.org/10.3390/s24020614

APA StyleSun, Y., Li, J., Sun, Y., Song, L., Yang, Q., & Wang, X. (2024). Modeling and Simulation of Shape Control Based on Digital Twin Technology in Hot Strip Rolling. Sensors, 24(2), 614. https://doi.org/10.3390/s24020614