Design and Implementation of Digital Calibration Certificate for RFID Tag Storage

Abstract

1. Introduction

- 1.

- Propose DCC meta-model DCC-Lite suitable for RFID tag storage, and, at the same time, take the means of compression and storing DCCs in tag groups to solve the problem of limited RFID tag storage space;

- 2.

- Develop DCC-RFID processing system to realize the process in 1;

- 3.

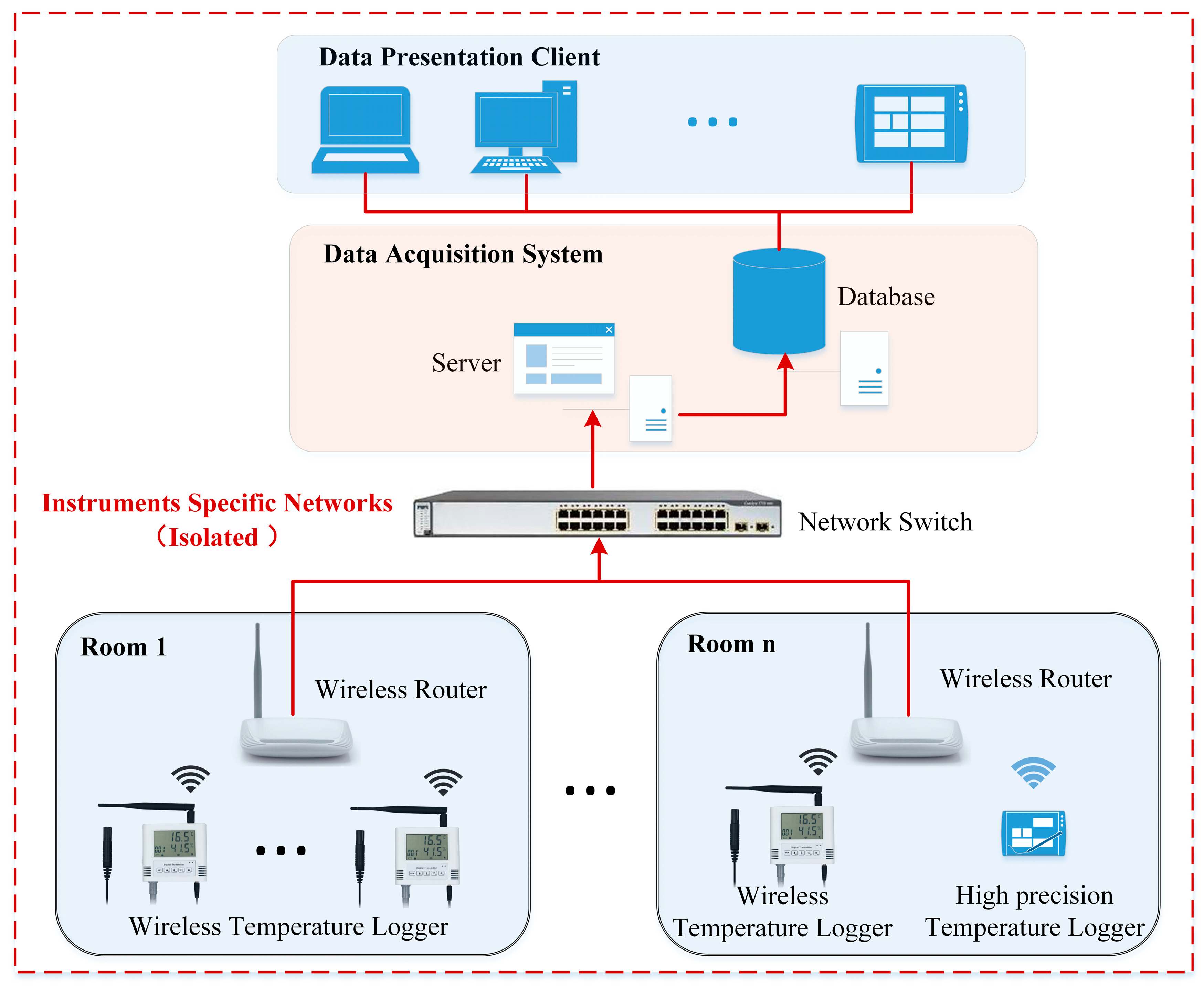

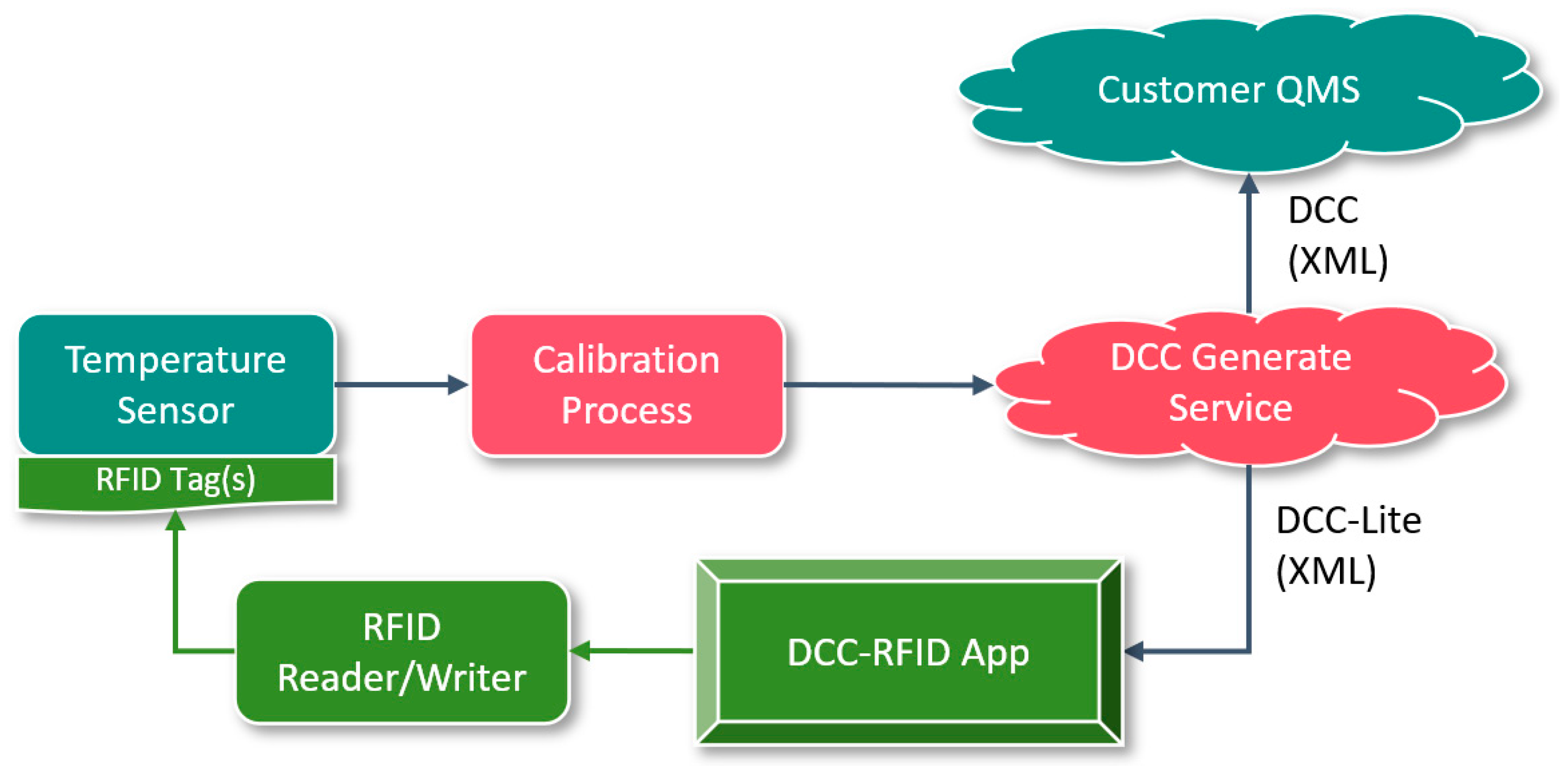

- Develop a wireless temperature acquisition system, together with the DCC-RFID app, to realize the whole process of applying DCCs with RIFD tags as a storage carrier in wireless temperature acquisition scenarios and verify the effectiveness of the system by comparing it with the measurement data of a reference temperature sensor with higher accuracy.

2. Design

2.1. Design Principles and Application Scenarios

- The DCC designed for storage in RFID tags should be compatible with the general DCC format and capable of successful parsing by standard DCC parsing programs;

- The storage solution should be applicable to most measurement equipment. It should require minimal modification of existing equipment, enabling the seamless integration of DCCs at the physical level;

- The storage program should try to use common technology and tools, minimizing the technical barriers involved in implementation.

2.2. Design of DCC-Lite Meta-Model

2.3. Key Technologies

2.3.1. Compression

2.3.2. Use RFID Tag Group

3. Implementation

3.1. Generation of DCC-Lite

3.2. Write DCC-Lite to RFID Tags

- : Number of RFID tags required, n is an integer, round up to an integer;

- : Capacity occupied by DCC-Lite after compression, in bytes;

- : Capacity of a single RFID tag, in bytes;

- : Capacity used by the start character, in bytes.

- 1.

- Compress the DCC-Lite (XML) using Zlib;

- 2.

- Calculate the capacity of the compressed DCC-Lite, the capacity of a single RFID tag, and the capacity of start characters;

- 3.

- Calculate the required number of RFID tags, rounded up to an integer;

- 4.

- Split the compressed DCC-Lite into n data blocks and add start characters at the beginning of each data block and the capacity of each data block (start characters included), except the last one is the RFID tag capacity;

- 5.

- Clear the contents of the RFID tags;

- 6.

- Write data blocks to the corresponding RFID tags sequentially through an RFID reader/writer.

3.3. Read DCC-Lite from RFID Tags

- 1.

- Read each RFID tag on the measurement instrument using an RFID reader/writer and save them individually;

- 2.

- Extract the serial numbers of the tags from the start characters and delete the start characters. Arrange the data blocks in ascending order;

- 3.

- Assemble each data block to form a complete compressed DCC-Lite file;

- 4.

- Decompress the DCC-Lite file using the Zlib library.

4. Testing and Validation

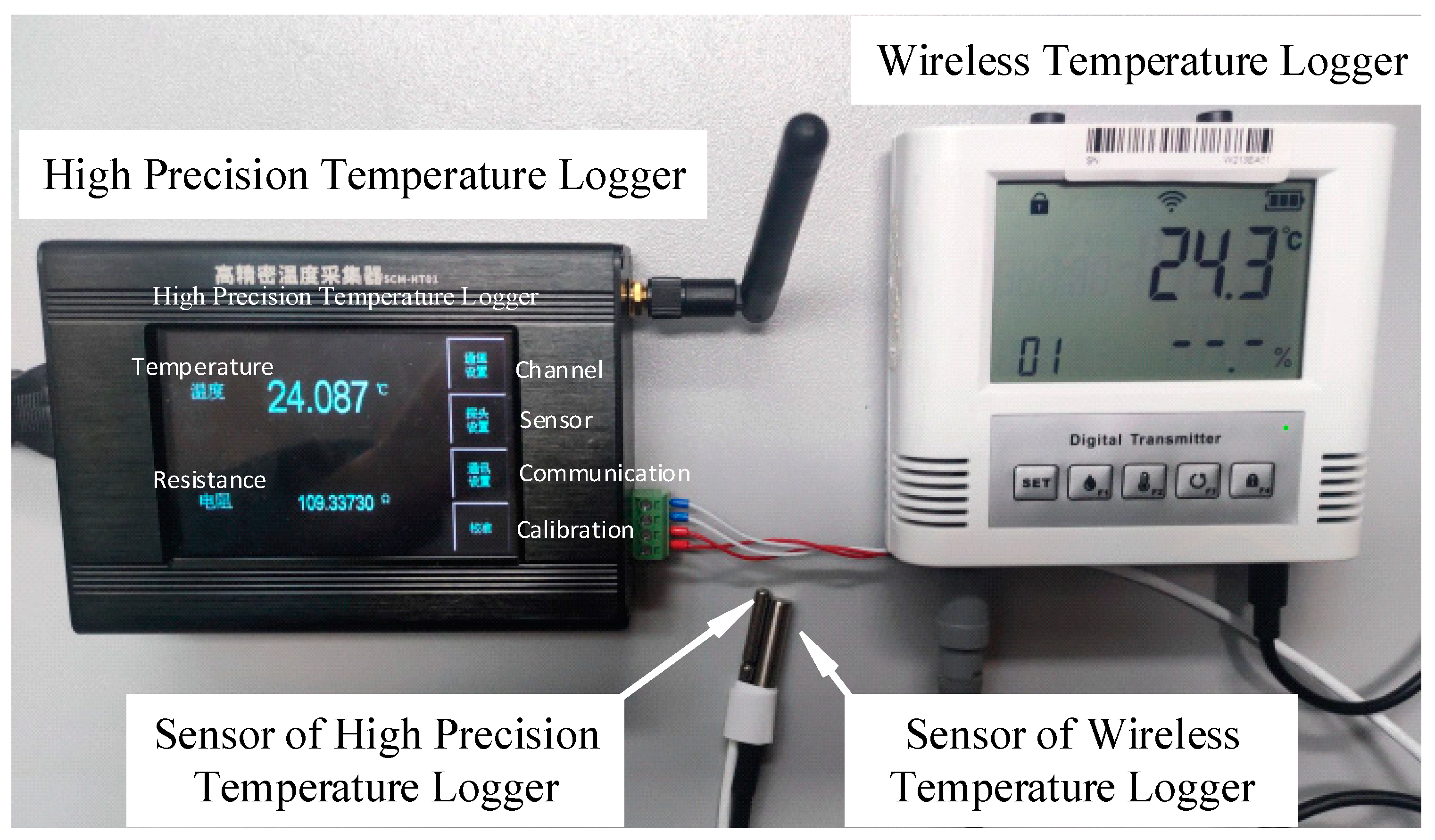

4.1. Test System Setup

4.2. Sensor DCC Write into RFID Tags

4.3. Sensor DCC Read and Run

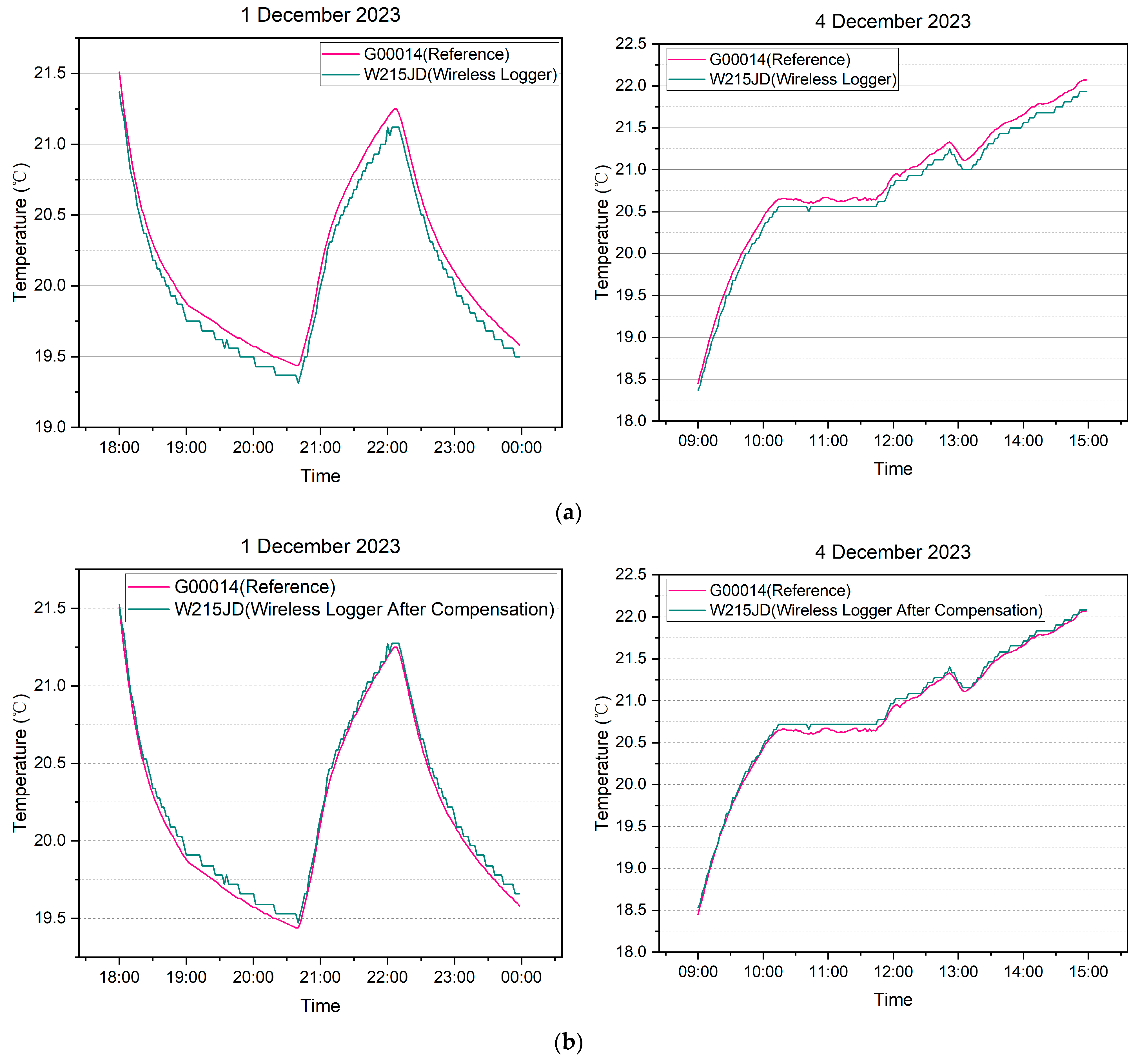

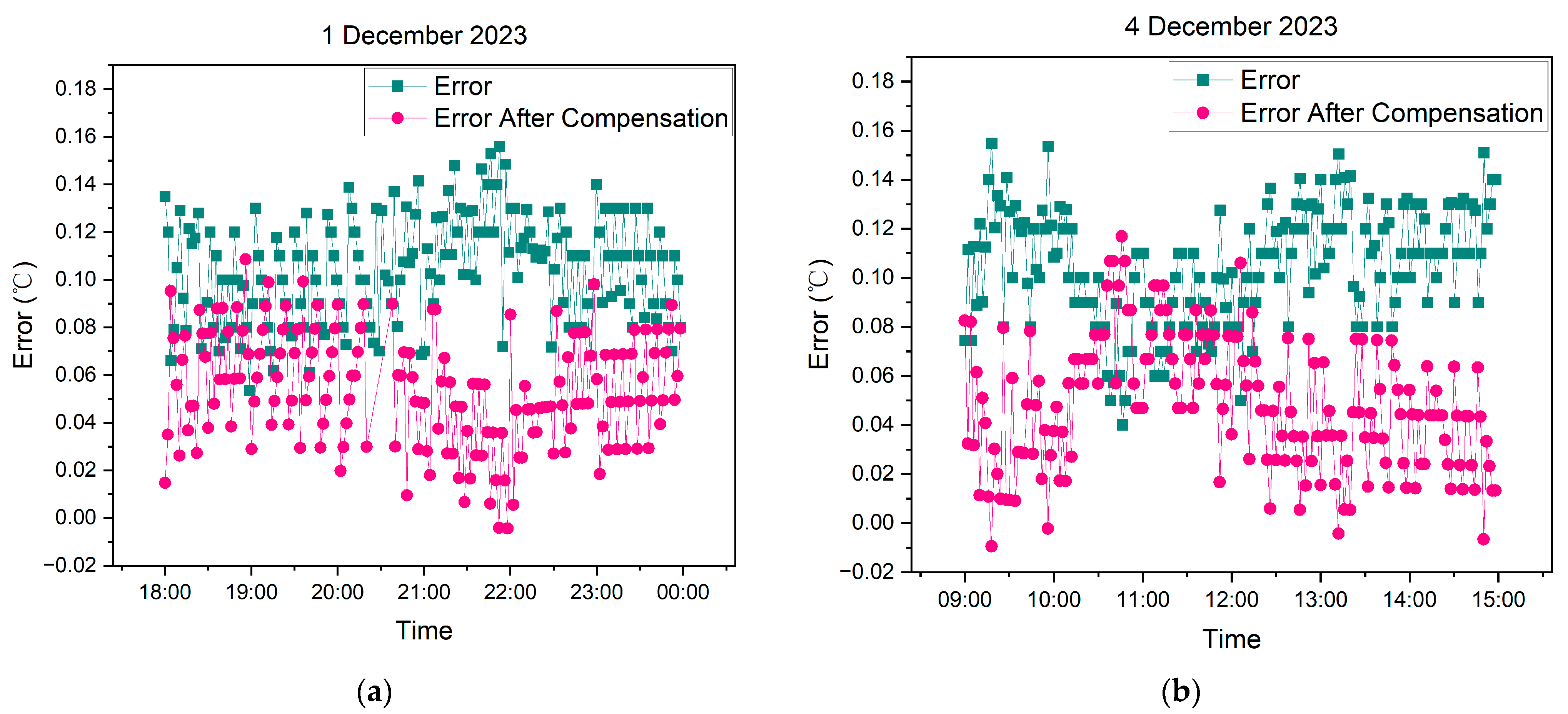

- xc: The measured value after compensation of the temperature logger;

- xm: The measured value obtained from the temperature logger;

- yc: The compensation value corresponding to xm;

- xn: The temperature value of the calibration point n, where n is an integer not less than 2;

- yn: The compensation value corresponding to the calibration point n;

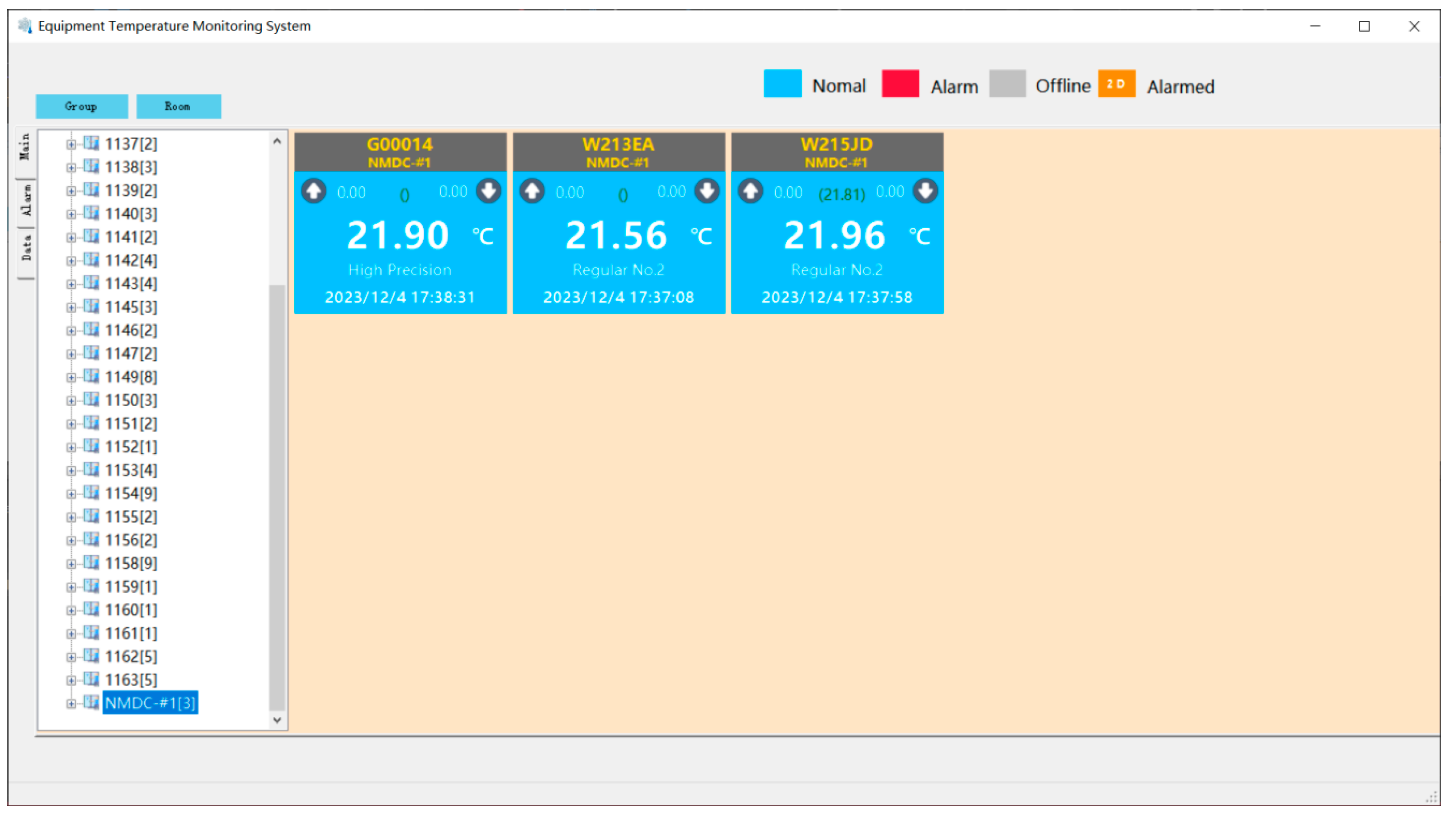

4.4. System Operation

5. Results and Discussion

6. Conclusions

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbosa, C.R.H.; Sousa, M.C.; Almeida, M.F.L.; Calili, R.F. Smart Manufacturing and Digitalization of Metrology: A Systematic Literature Review and a Research Agenda. Sensors 2022, 22, 6114. [Google Scholar] [CrossRef] [PubMed]

- Hanisch, R.; Chalk, S.; Coulon, R.; Cox, S.; Emmerson, S.; Sandoval, F.; Forbes, A.; Frey, J.; Hall, B.; Hartshorn, R.; et al. Stop squandering data: Make units of measurement machine-readable. Nature 2022, 605, 222–224. [Google Scholar] [CrossRef] [PubMed]

- BIPM. Report on the Actions Taken by the CIPM towards a “CIPM Strategy 2030+”. Available online: https://www.bipm.org/documents/20126/17315032/CIPM-Strategy-2030.pdf/0870523b-cd7e-568e-a96a-adf78ff9edde?t=1664547939013 (accessed on 1 August 2024).

- BIPM. Resolution 2 of the 27th CGPM (2022). Available online: https://www.bipm.org/en/cgpm-2022/resolution-2 (accessed on 1 August 2024).

- BIPM. Joint Statement of Intent on the Digital Transformation in the International Scientific and Quality Infrastructure. Available online: https://www.bipm.org/documents/20126/42177518/Joint-Statement-Digital-Transformation.pdf (accessed on 1 August 2024).

- Werhahn, O.; Dudle, G. Evaluation Report—Survey on Digital Transformation. Available online: https://www.bipm.org/documents/20126/82507584/RapportBIPM-2023-01.pdf/ff5aac7a-56d7-4ff7-7de1-04d024fedb65 (accessed on 1 August 2024).

- BIPM. International Vocabulary of Metrology—Basic and General Concepts and Associated Terms (VIM) 3rd Edition. Available online: https://www.bipm.org/documents/20126/2071204/JCGM_200_2012.pdf/f0e1ad45-d337-bbeb-53a6-15fe649d0ff1 (accessed on 1 August 2024).

- Hackel, S.; Härtig, F.; Schrader, T.; Scheibner, A.; Loewe, J.; Doering, L.; Gloger, B.; Jagieniak, J.; Hutzschenreuter, D.; Söylev-Öktem, G. The fundamental architecture of the DCC. Meas. Sens. 2021, 18, 100354. [Google Scholar] [CrossRef]

- Engel, T. GEMIMEG-II—How metrology can go digital. Meas. Sci. Technol. 2023, 34, 104002. [Google Scholar] [CrossRef]

- Mustapää, T.; Nummiluikki, J.; Viitala, R. Digitalization of Calibration Data Management in Pharmaceutical Industry Using a Multitenant Platform. Appl. Sci. 2022, 12, 7531. [Google Scholar] [CrossRef]

- Lin, M.-X.; Hsieh, T.-H. Geometric Error Parameterization of a CMM via Calibrated Hole Plate Archived Utilizing DCC Formatting. Appl. Sci. 2023, 13, 6344. [Google Scholar] [CrossRef]

- Mustapää, T.; Tunkkari, H.; Taponen, J.; Immonen, L.; Heeren, W.; Baer, O.; Brown, C.; Viitala, R. Secure Exchange of Digital Metrological Data in a Smart Overhead Crane. Sensors 2022, 22, 1548. [Google Scholar] [CrossRef] [PubMed]

- Mustapää, T.; Nikander, P.; Hutzschenreuter, D.; Viitala, R. Metrological Challenges in Collaborative Sensing: Applicability of Digital Calibration Certificates. Sensors 2020, 20, 4730. [Google Scholar] [CrossRef] [PubMed]

- Bruns, T.; Nordholz, J.; Röske, D.; Schrader, T. A demonstrator for measurement workflows using digital calibration certificates (DCCs). Meas. Sens. 2021, 18, 100208. [Google Scholar] [CrossRef]

- Nummiluikki, J.; Saxholm, S.; Kärkkäinen, A.; Koskinen, S. Digital Calibration Certificate in an industrial application. Acta IMEKO 2023, 12, 6. [Google Scholar] [CrossRef]

- Černilová, B.; Linda, M.; Kuře, J.; Hromasová, M.; Chotěborský, R.; Krunt, O. Validation of an IoT System Using UHF RFID Technology for Goose Growth Monitoring. Agriculture 2024, 14, 76. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.-A.; Jiao, G.; Dang, P.; Nie, G.; Liu, Z.; Sun, J. Review of Wireless RFID Strain Sensing Technology in Structural Health Monitoring. Sensors 2023, 23, 6925. [Google Scholar] [CrossRef] [PubMed]

- Naciri, L.; Gallab, M.; Soulhi, A.; Merzouk, S.; Di Nardo, M. Digital Technologies’ Risks and Opportunities: Case Study of an RFID System. Appl. Syst. Innov. 2023, 6, 54. [Google Scholar] [CrossRef]

- Mulloni, V.; Marchi, G.; Gaiardo, A.; Valt, M.; Donelli, M.; Lorenzelli, L. Applications of Chipless RFID Humidity Sensors to Smart Packaging Solutions. Sensors 2024, 24, 2879. [Google Scholar] [CrossRef] [PubMed]

- Hackel, S.; Schönhals, S.; Doering, L.; Engel, T.; Baumfalk, R. The Digital Calibration Certificate (DCC) for an End-to-End Digital Quality Infrastructure for Industry 4.0. Science 2023, 5, 11. [Google Scholar] [CrossRef]

- Boschung, G.; Wollensack, M.; Zeier, M.; Blaser, C.; Hof, C.; Stathis, M.; Blattner, P.; Stuker, F.; Basic, N.; Grasso Toro, F. PDF/A-3 solution for digital calibration certificates. Meas. Sens. 2021, 18, 100282. [Google Scholar] [CrossRef]

- Phuaknoi, P.; Mongkolsuttirat, K.; Chantawong, N.; Limthunyalak, W.; Buajarern, J. Implementation of Digital CalibrationCertificate at NlMT. In Proceedings of the 2nd DCC-Conference 2022, Berlin, Germany, 1–3 March 2022; pp. 39–43. [Google Scholar]

- Yamazawa, K. Development of PDF based Digital Calibration Certificates at NMlJ, AIST. In Proceedings of the 3rd DCC-Conference 2023, Berlin, Germany, 28 February–2 May 2023; pp. 138–146. [Google Scholar]

- Gadelrab, M.S.; Abouhogail, R.A. Towards a new generation of digital calibration certificate: Analysis and survey. Measurement 2021, 181, 109611. [Google Scholar] [CrossRef]

- Hacker, S.G.; Härtig, F.; Hornig, J.; Wiedenhöfer, T. The Digital Calibration Certificate. Available online: https://oar.ptb.de/files/download/310.20170403.pdf (accessed on 1 August 2024).

- Hackel, S.; Schönhals, S.; Gloger, B.; Doering, L.; Jagieniak, J.; Demir, M.-A.; Jordan, M.; Söylev Öktem, G.; Loewe, J.; Mienert, K.; et al. Digitization Versus Digitalization & Digital Transformation in the Field of Calibrationsand Their Subsequent Use. Available online: https://oar.ptb.de/resources/show/10.7795/120.20240126 (accessed on 1 August 2024).

- Demir, M.-A.; Jordan, M.; Krah, T.; Schönhals, S.; Hackel, S.; Härtig, F.; Schrader, T.; Loewe, J.; Doering, L.; Gloger, B.; et al. A HUMAN READABLE FORM OF THE DCC. In Proceedings of the First International IMEKO TC6 Conference on Metrology and Digital Transformation, Berlin, Germany, 19–21 September 2022; pp. 1–4. [Google Scholar]

- PTB. dcc_gp_humidity_v1.0_with_hr_pdf.xml. Available online: https://dccwiki.ptb.de/goodpractice/humidity/dcc_gp_humidity_v1.0_with_hr_pdf.xml (accessed on 1 August 2024).

- PTB. dcc_gp_temperature_simplified_v12.xml. Available online: https://dccwiki.ptb.de/goodpractice/temperature/dcc_gp_temperature_simplified_v12.xml (accessed on 1 August 2024).

- ifm. ID Tags. Available online: https://www.ifm.cn/cn/en/category/220_030_020_030_070#/best/1/100 (accessed on 25 September 2024).

- Roelofs, G. A Massively Spiffy Yet Delicately Unobtrusive Compression Library. Available online: https://www.zlib.net/ (accessed on 1 August 2024).

- Simens. pydcc. Available online: https://github.com/siemens/pydcc (accessed on 1 August 2024).

- Feldspar, A. An Explanation of the Deflate Algorithm. Available online: https://www.zlib.net/feldspar.html (accessed on 1 August 2024).

- PTB. Good Practice-Digital Calibration Certificate Wiki. Available online: https://dccwiki.ptb.de/en/gp_home (accessed on 1 August 2024).

- NIM. NIM DCC Generation System. Available online: https://dcc.nmdc.ac.cn/dcc-web/wizard/ (accessed on 1 August 2024).

- NIM. DCC Base API. Available online: https://dcc.nmdc.ac.cn/dcc-doc/v1/dcc-base/swagger-ui/index.html (accessed on 1 August 2024).

- ISO/IEC 17025:2017; General Requirements for the Competence of Testing and Calibration Laboratories. ISO: Geneva, Switzerland, 2017.

- Kan, K.; Xiong, X.; Fang, X. A Method for Using RFID Tags as Carriers for Digital Calibration Certificates and Its System. ZL 2023 1 1505359.X, 3 April 2024. [Google Scholar]

| GP Name | Volume before Compress (Bytes) | Volume after Compress (Bytes) | Compress Ratio (%) |

|---|---|---|---|

| dcc_gp_temperature_simplified_v12 | 15,538 | 3529 | 77.3 |

| dcc_gp_temperature_typical_v12 | 19,688 | 4464 | 77.3 |

| dcc_gp_temperature_typical_adjustment_v12 | 24,675 | 4697 | 81.0 |

| dcc_gp_temperatur_resistance_v12 | 20,920 | 4889 | 76.6 |

| dcc_gp_temperature_extensive_v12 | 32,154 | 5550 | 82.7 |

| dcc_gp_humidity_v1.0 | 34,531 | 6614 | 80.8 |

| dcc_gp_humidity_v1.0_with_hr_html | 100,994 | 21,428 | 78.8 |

| dcc_gp_humidity_v1.0_with_hr_pdf | 2,054,591 | 1,534,460 | 25.3 |

| Indication Value (°C) | Reference Value (°C) | Compensation Value (°C) | MPE (°C) | Expanded Uncertainty (°C) |

|---|---|---|---|---|

| −0.2 | 0.01 | 0.21 | ±0.5 | 0.1 |

| 23.0 | 23.15 | 0.15 | ±0.5 | 0.1 |

| 59.6 | 59.94 | 0.34 | ±0.5 | 0.1 |

| Data | MAE | MSE | RMSE | |

|---|---|---|---|---|

| 1 December 2023 | Measured Value | 0.105 | 0.011 | 0.107 |

| After Compensation | 0.056 | 0.004 | 0.060 | |

| 4 December 2023 | Measured Value | 0.105 | 0.012 | 0.107 |

| After Compensation | 0.048 | 0.003 | 0.055 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kan, K.; Wang, S.; Liu, Z.; Xiong, X. Design and Implementation of Digital Calibration Certificate for RFID Tag Storage. Sensors 2024, 24, 6626. https://doi.org/10.3390/s24206626

Kan K, Wang S, Liu Z, Xiong X. Design and Implementation of Digital Calibration Certificate for RFID Tag Storage. Sensors. 2024; 24(20):6626. https://doi.org/10.3390/s24206626

Chicago/Turabian StyleKan, Kan, Shuaizhe Wang, Zilong Liu, and Xingchuang Xiong. 2024. "Design and Implementation of Digital Calibration Certificate for RFID Tag Storage" Sensors 24, no. 20: 6626. https://doi.org/10.3390/s24206626

APA StyleKan, K., Wang, S., Liu, Z., & Xiong, X. (2024). Design and Implementation of Digital Calibration Certificate for RFID Tag Storage. Sensors, 24(20), 6626. https://doi.org/10.3390/s24206626