IoT Leak Detection System for Onshore Oil Pipeline Based on Thermography

Abstract

:1. Introduction

2. Methods

2.1. Monitoring Systems for Leak Detection

2.2. Proposed Architecture

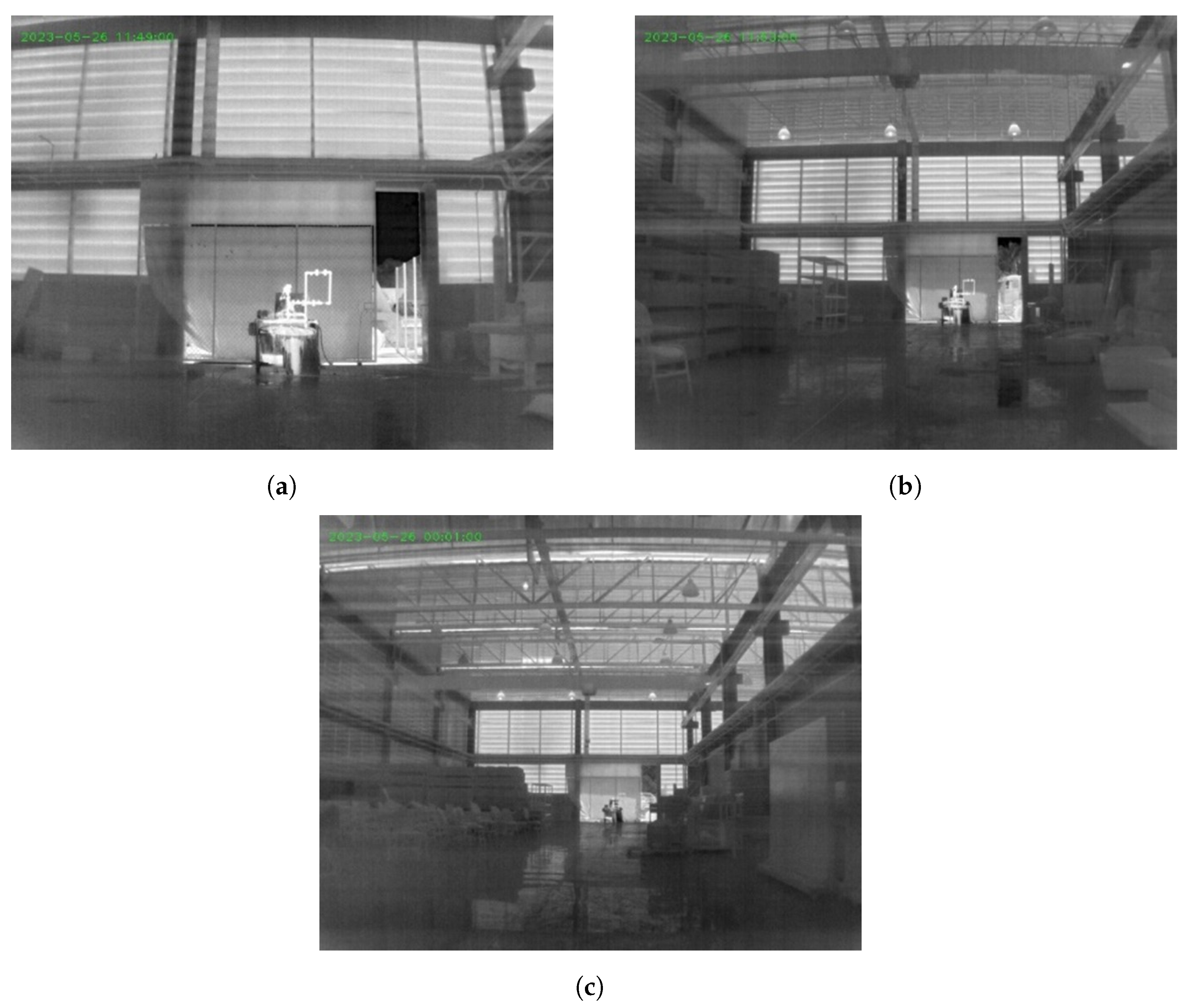

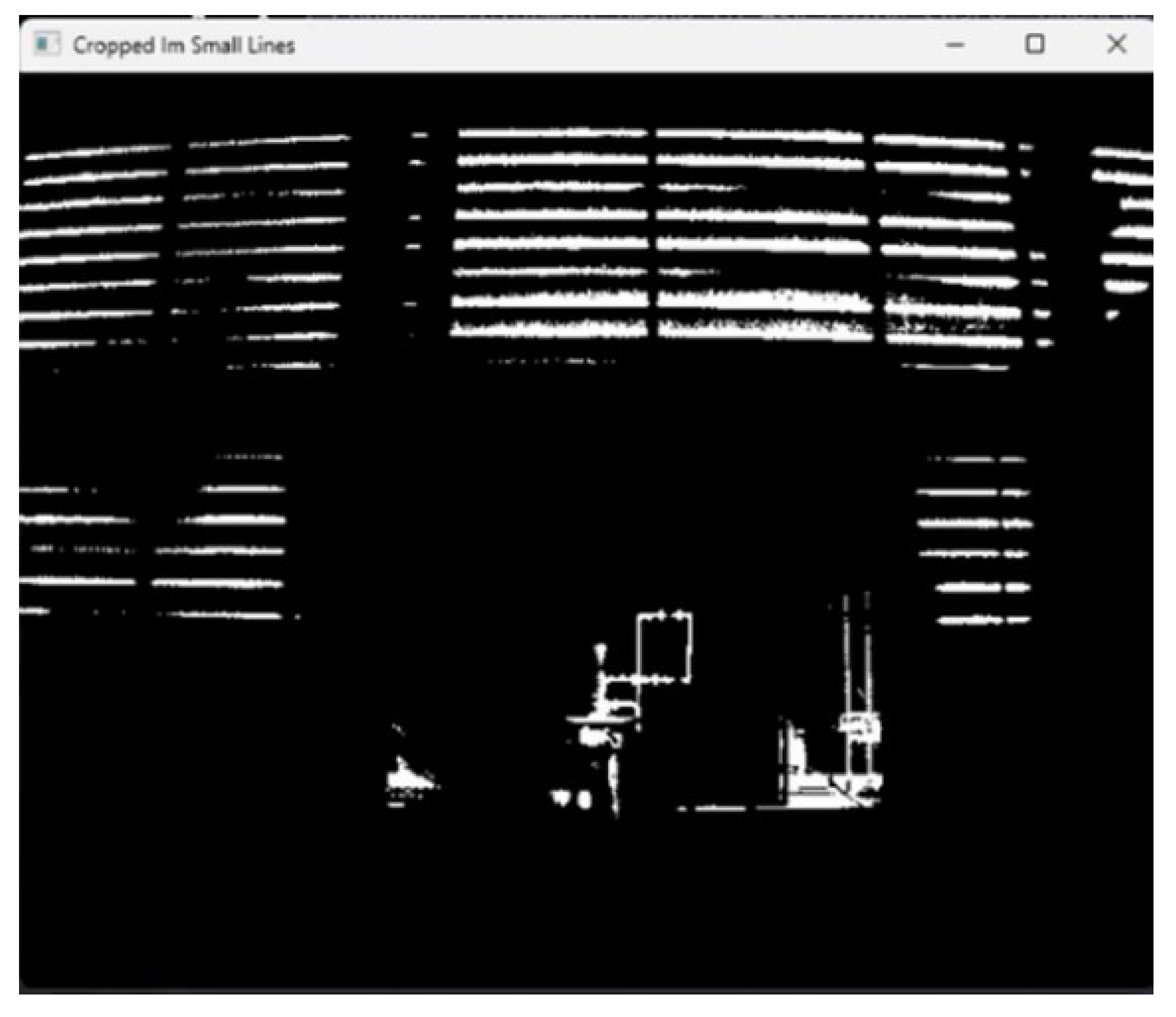

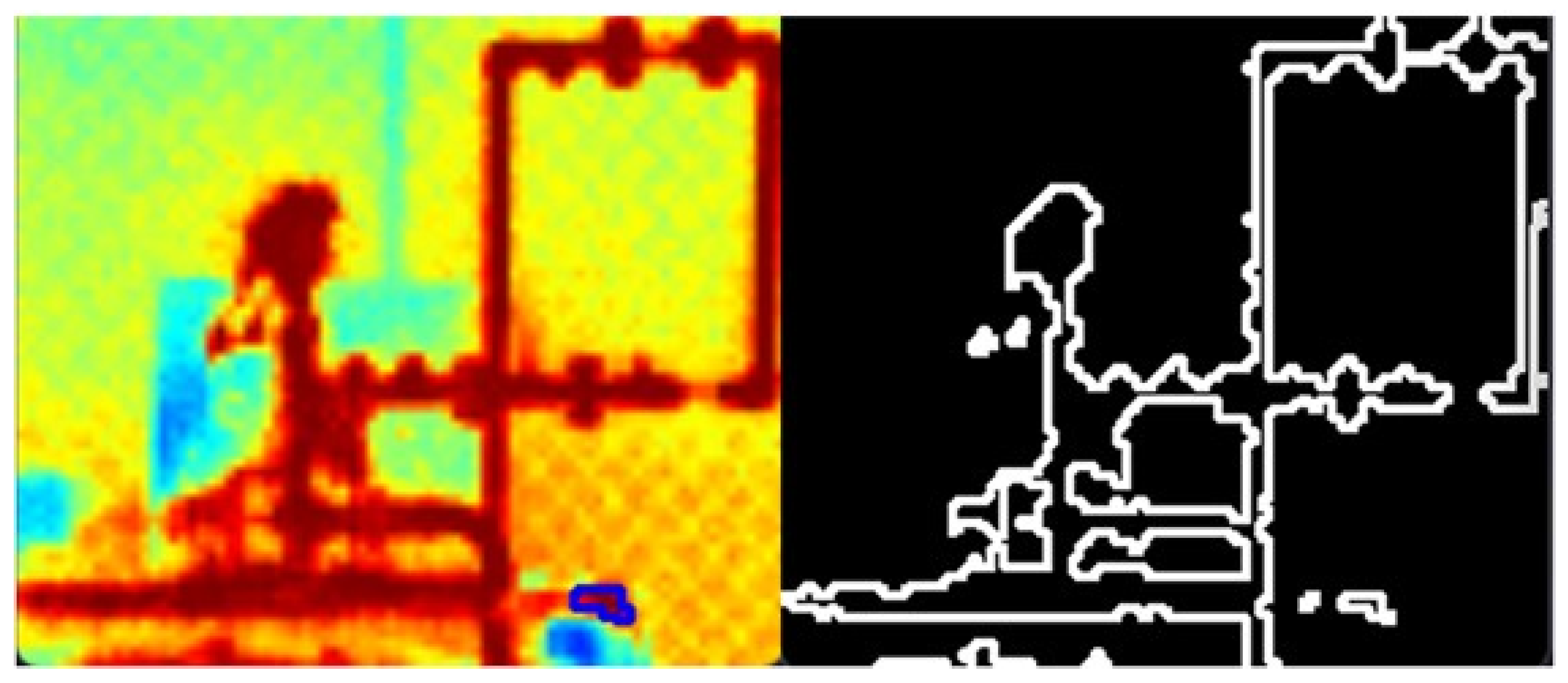

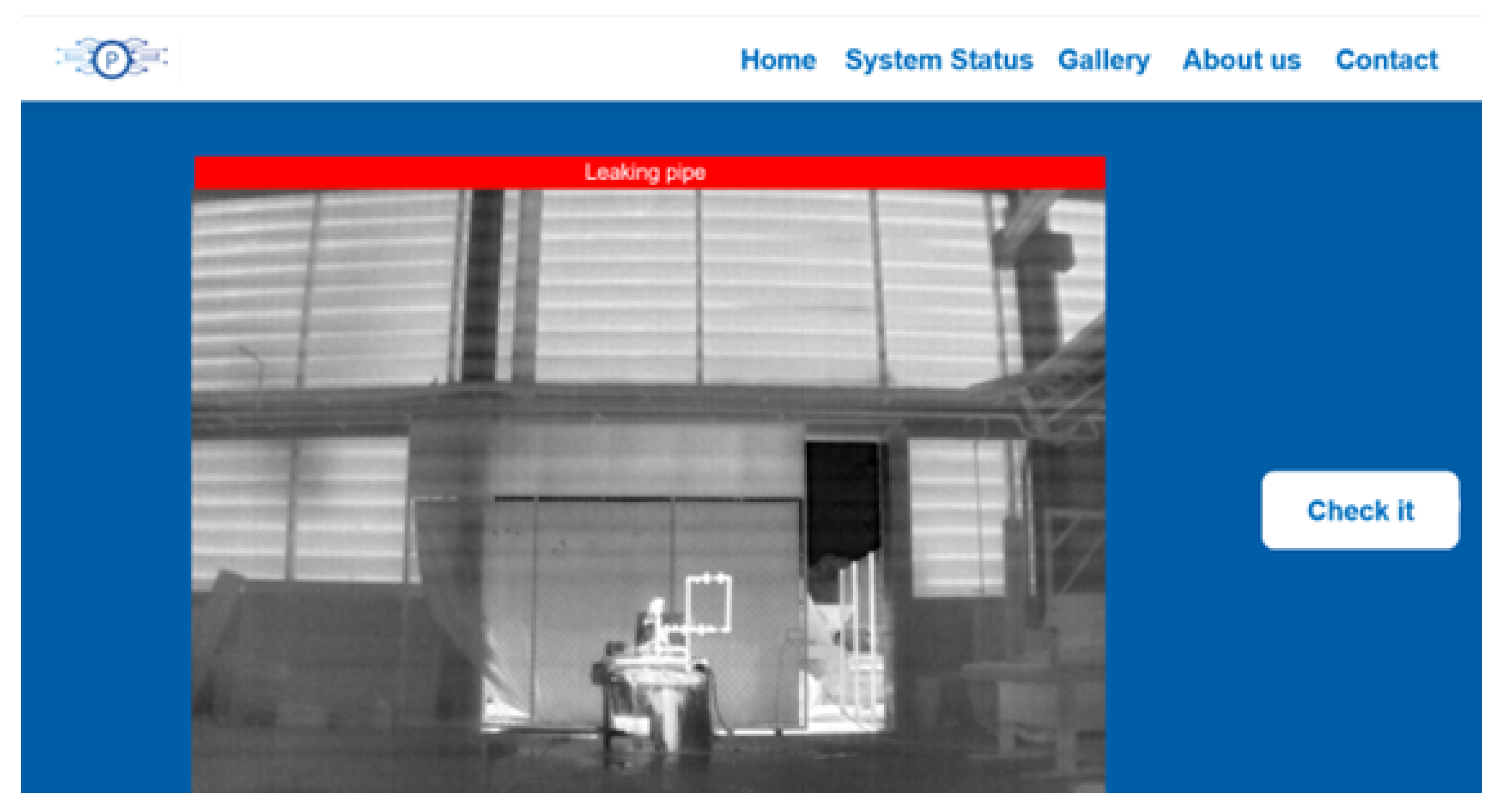

2.3. Proof of Concept (PoC)

2.4. Validation and Testing

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sweeney, M. Terrain and geohazard challenges for remote region onshore pipelines: Risk management, Geoteams and Ground Models. Q. J. Eng. Geol. Hydrogeol. 2017, 50, 13–52. [Google Scholar] [CrossRef]

- Patidar, A.K.; Jain, P.; Dhasmana, P.; Choudhury, T. Impact of global events on crude oil economy: A comprehensive review of the geopolitics of energy and economic polarization. GeoJournal 2024, 89, 50. [Google Scholar] [CrossRef]

- Miesner, T.O. Economic, Social, Environmental, and Sustainability Aspects of Pipelines. In Handbook of Pipeline Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 57–70. [Google Scholar]

- Wu, T.; Chen, Y.; Deng, Z.; Shen, L.; Xie, Z.; Liu, Y.; Zhu, S.; Liu, C.; Li, Y. Oil pipeline leakage monitoring developments in China. J. Pipeline Sci. Eng. 2023, 3, 100129. [Google Scholar] [CrossRef]

- Biezma, M.; Andrés, M.; Agudo, D.; Briz, E. Most fatal oil & gas pipeline accidents through history: A lessons learned approach. Eng. Fail. Anal. 2020, 110, 104446. [Google Scholar]

- Korlapati, N.V.S.; Khan, F.; Noor, Q.; Mirza, S.; Vaddiraju, S. Review and analysis of pipeline leak detection methods. J. Pipeline Sci. Eng. 2022, 2, 100074. [Google Scholar] [CrossRef]

- Raman, R.; Panchbhai, A. Real-Time Video Management for Gas Pipeline Breakage Detection Robot Using IoT. In Proceedings of the 2024 4th International Conference on Innovative Practices in Technology and Management (ICIPTM), Noida, India, 21–23 February 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar]

- Kuaban, G.S.; Czachórski, T.; Gelenbe, E.; Pecka, P.; Nkemeni, V.; Czekalski, P. Energy performance of Internet of Things (IoT) networks for pipeline monitoring. In Proceedings of the 2024 International Wireless Communications and Mobile Computing (IWCMC), Athens, Greece, 10–14 March 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1490–1497. [Google Scholar]

- FIRJAN. Ambiente Onshore de Petróleo e Gás no Brasil; Report; FIRJAN—The Industry Federation of the State of Rio de Janeiro: Rio de Janeiro, Brazil, 2018. (In Portuguese) [Google Scholar]

- Mendes, A.P.d.A.; Teixeira, C.A.N.; Rocio, M.A.R.; Prates, H.F. Produção de petróleo terrestre no Brasil. 2019. Available online: https://web.bndes.gov.br/bib/jspui/handle/1408/16961 (accessed on 26 January 2021). (In Portuguese)

- Adegboye, M.A.; Fung, W.K.; Karnik, A. Recent advances in pipeline monitoring and oil leakage detection technologies: Principles and approaches. Sensors 2019, 19, 2548. [Google Scholar] [CrossRef] [PubMed]

- Bhaskaran, P.E.; Maheswari, C.; Thangavel, S.; Ponnibala, M.; Kalavathidevi, T.; Sivakumar, N. IoT Based monitoring and control of fluid transportation using machine learning. Comput. Electr. Eng. 2021, 89, 106899. [Google Scholar] [CrossRef]

- Maia, D.M.; Melo, T.R.d.; Mirre, R.C.; Lepikson, H.A. Selecting the detection method for a remote leaks detection monitoring system at onshore oil production fields. Blucher Eng. Proc. 2023, 10, 140–146. [Google Scholar] [CrossRef]

- Lu, H.; Iseley, T.; Behbahani, S.; Fu, L. Leakage detection techniques for oil and gas pipelines: State-of-the-art. Tunn. Undergr. Space Technol. 2020, 98, 103249. [Google Scholar] [CrossRef]

- Zhang, J. Designing a cost-effective and reliable pipeline leak-detection system. Pipes Pipelines Int. 1997, 42, 20–26. [Google Scholar]

- Xu, J.; Nie, Z.; Shan, F.; Li, J.; Luo, Y.; Yuan, Q.; Chen, H. Leak detection methods overview and summary. In ICPTT 2012: Better Pipeline Infrastructure for a Better Life; ASCE: Reston, VA, USA, 2013; pp. 1034–1050. [Google Scholar]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental study on leak detection and location for gas pipeline based on acoustic method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Bond, L.J. Fundamentals of ultrasonic inspection. In ASM Handbook, Volume 17: Nondestructive Evaluation of Materials; ASM International: Almere, The Netherlands, 2018. [Google Scholar]

- Ghavamian, A.; Mustapha, F.; Baharudin, B.H.T.; Yidris, N. Detection, localisation and assessment of defects in pipes using guided wave techniques: A review. Sensors 2018, 18, 4470. [Google Scholar] [CrossRef] [PubMed]

- Prisutova, J.; Krynkin, A.; Tait, S.; Horoshenkov, K. Use of fibre-optic sensors for pipe condition and hydraulics measurements: A review. CivilEng 2022, 3, 85–113. [Google Scholar] [CrossRef]

- Aljuaid, K.G.; Albuoderman, M.A.; AlAhmadi, E.A.; Iqbal, J. Comparative review of pipelines monitoring and leakage detection techniques. In Proceedings of the 2020 2nd International Conference on Computer and Information Sciences (ICCIS), Sakaka, Saudi Arabia, 13–15 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Manekiya, M.H.; Arulmozhivarman, P. Leakage detection and estimation using IR thermography. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, Tamilnadu, India, 6–8 April 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1516–1519. [Google Scholar]

- Yussof, N.A.M.; Ho, H.W. Review of water leak detection methods in smart building applications. Buildings 2022, 12, 1535. [Google Scholar] [CrossRef]

- Fahimipirehgalin, M.; Trunzer, E.; Odenweller, M.; Vogel-Heuser, B. Automatic visual leakage detection and localization from pipelines in chemical process plants using machine vision techniques. Engineering 2021, 7, 758–776. [Google Scholar] [CrossRef]

- Junie, P.; Dinu, O.; Eremia, C.; Stefanoiu, D.; Petrescu, C.; Savulescu, I. A wsn based monitoring system for oil and gas transportation through pipelines. IFAC Proc. Vol. 2012, 45, 1796–1801. [Google Scholar] [CrossRef]

- Sethi, P.; Sarangi, S.R. Internet of things: Architectures, protocols, and applications. J. Electr. Comput. Eng. 2017, 2017, 9324035. [Google Scholar] [CrossRef]

- Mekki, K.; Bajic, E.; Chaxel, F.; Meyer, F. A comparative study of LPWAN technologies for large-scale IoT deployment. ICT Express 2019, 5, 1–7. [Google Scholar] [CrossRef]

- Al-Amri, S.S.; Kalyankar, N.V. Image segmentation by using threshold techniques. arXiv 2010, arXiv:1005.4020. [Google Scholar]

- Shapiro, L.; George, C. Stockman g: Computer Vision; Prentice Hall: Hoboken, NJ, USA, 2002. [Google Scholar]

| Classification | Detection Technique | GU | GL | GS | OL | OS |

|---|---|---|---|---|---|---|

| Hardware-based method | Lidar system | x x | ||||

| Diode laser absorption | x | x | ||||

| Millimeter wave radar system | x | x | ||||

| Thermal imaging | x | x | x | |||

| Spectral imaging | x | x | ||||

| Sound wave method | x | x | x | x | x | |

| Ultrasonic guided wave method | x | x | x | x | x | |

| Sonar system method | x | x | ||||

| Acoustic guided wave method | x | x | x | x | x | |

| Ultrasonic method | x | x | x | x | x | |

| Distributed optical fiber sensor method | x | x | x | x | x | |

| Tracer method | x | x | x | |||

| SmartBall method | x | x | x | x | x | |

| Ultrasonic flowmeter method | x | x | x | x | x | |

| Dynamic pressure transmitter method | x | x | x | x | x | |

| GPR | x | x | x | |||

| Cable method | x | |||||

| Sniffer method | x | x | ||||

| Vapor sampling method | x | x | x |

| Methods | Description | Advantages | Disadvantages |

|---|---|---|---|

| Acoustic emission | When a leak occurs, the acoustic signal and the background noise reach the sensors and are compared with the profiles of acoustic wave signals present in the system [17]. | The detection has higher sensitivity and accurate positioning [4]. It is easy to use and install as it does not require system shutdown for installation or calibration [11]. | The effect of noise from other sources can easily mask the actual leak sound [11]. In addition, the type of piping material interferes with leak recognition. |

| Ultrasonic | The ultrasonic method is characterized by being hardware-based, acoustic, and non-invasive. A common way of applying the technique is to use a pulsar, a transducer, and a device to display the captured signals [18]. | This method has a fast response and high sensitivity, low detection cost, and low power consumption [14]. | Its implementation requires extensive knowledge and careful application by experienced technicians. Couplants are required to provide effective transfer of energy between the transducers and the piping. Reference standards are also needed, both for equipment calibration and for fault characterization [18]. |

| Guided Wave Ultrasonic | For leak detection, a ring of piezoelectric transducers is installed around the duct. When there is a need to carry out the inspection, a device is attached that controls the transducers, causing them to emit pulses and receive them back [19]. | This method has a shorter inspection time and less labor demand. It presents itself as a great proposal to monitor long lengths of pipeline due to the ability of guided waves (lamb waves) to propagate in materials such as steel [14]. | Currently there is little variety in the market for standard devices, which have high costs. Another difficulty is related to data processing: defining the ideal frequency for the emission of guided waves and comparing it with the received signals is a process that requires specialized technical knowledge. It requires pre-calibration. |

| Distributed Optical Fiber | The most common choice of fiber optic sensors in hydraulic applications is scattering-based (Rayleigh and Brillouin scattering-based sensors) and wavelength-modulated (fiber Bragg grating) [20]. | The sensors require no electrical power and have low optical transmission losses and little signal decay. The same fiber can be used to detect and transmit information [20]. | Interference is required in the pipes to install the sensors. |

| SmartBall | This is a comprehensive sensing technology that includes an array of acoustic sensors, accelerometers, magnetometers, ultrasonic transmitters, temperature sensors, and more. These sensors roll inside the pipe following the fluid flow [14]. | The technology can be used for pipes of any material, and the sensitivity of leakage detection is high [14]. | Under different working pressures, the minimum detectable leakage of the SmartBall is different. The presence of an operator is required to insert the SmartBalls, in addition to the limitations of internal access to pipes with junctions, diversions, and manifolds, characteristic of oil production fields. |

| Vapor sampling | It consists of taking hydrocarbon vapor samples near the monitored pipeline to determine the oil leak based on the measured gas concentration. This method can use a vapor monitoring system or mobile detector device [14,21]. | This technique is particularly suitable for detecting small concentrations of diffuse gas [14]. | The cost is high and requires many sensors in long pipelines [21]. Gases such as biogas in the soil may cause false alarms [14]. |

| Thermal Imaging | The method uses an infrared camera to analyze changes in thermal radiation around the pipeline [14] in the infrared range of 900–1400 nanometers [22]. | Increasing use of technology for remote monitoring of unmanned plants market trend for the search for visual solutions. The technique is not affected by the materials or sizes of the tubes and their connections [23]. | Area surface conditions, solar radiation, cloud cover, and ambient temperature can impact the capabilities of this method [23]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mascarenhas Maia, D.; Silva Mendes, J.V.; Almeida Miranda Silva, J.P.; Freire Bastos, R.; dos Santos Silva, M.; Coelho Mirre, R.; Rodrigues de Melo, T.; Lepikson, H.A. IoT Leak Detection System for Onshore Oil Pipeline Based on Thermography. Sensors 2024, 24, 6960. https://doi.org/10.3390/s24216960

Mascarenhas Maia D, Silva Mendes JV, Almeida Miranda Silva JP, Freire Bastos R, dos Santos Silva M, Coelho Mirre R, Rodrigues de Melo T, Lepikson HA. IoT Leak Detection System for Onshore Oil Pipeline Based on Thermography. Sensors. 2024; 24(21):6960. https://doi.org/10.3390/s24216960

Chicago/Turabian StyleMascarenhas Maia, Danielle, João Vitor Silva Mendes, João Pedro Almeida Miranda Silva, Rodrigo Freire Bastos, Matheus dos Santos Silva, Reinaldo Coelho Mirre, Thamiles Rodrigues de Melo, and Herman Augusto Lepikson. 2024. "IoT Leak Detection System for Onshore Oil Pipeline Based on Thermography" Sensors 24, no. 21: 6960. https://doi.org/10.3390/s24216960

APA StyleMascarenhas Maia, D., Silva Mendes, J. V., Almeida Miranda Silva, J. P., Freire Bastos, R., dos Santos Silva, M., Coelho Mirre, R., Rodrigues de Melo, T., & Lepikson, H. A. (2024). IoT Leak Detection System for Onshore Oil Pipeline Based on Thermography. Sensors, 24(21), 6960. https://doi.org/10.3390/s24216960