Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment

Abstract

1. Introduction

1.1. Operational Challenges of Underground Mines

1.2. Why Is Underground Mine Monitoring Needed? A Growing Safety Issue

- Tunnels and ramp deformation at various depths (prevent accidents due to rock bursting).

- Movement across surface cracks in tunnels and ramps.

- Air quality in tunnels (prevent inhalation of dust and harmful gases).

- Horizontal and vertical accelerations induced by seismic activity.

- Groundwater quantity measurement in tunnels.

- Groundwater quality measurement in tunnels.

- Groundwater level measurement in reservoirs.

- Global positioning system for vehicles or mine operators.

- Among others.

1.3. Why Underground Mine Wireless Monitoring Is More Cost-Effective and Mark a Road Map to Sustainability

- No wiring required: a wired configuration may require a large distance equivalent to meters of cable to connect different sensors or gauges. With installation costs ranging from USD $15 to USD $30 per meter, a wired system can become very expensive if connections span thousands of meters. Wireless systems, powered by batteries, photovoltaic panels, or local power, eliminate the need for conduits and hardwiring, thereby removing these costs.

- Significant reduction in the installation costs: installing a wired system with 75 or 100 m of conduit can cost up to USD $2000, while a comparable wireless system might cost only a few hundred dollars per sensor or gauge, according to the vendor and application characteristics. Wired systems require new cables, trenching, hardware, and labor for repairs or reconfigurations. In contrast, wireless systems can be easily expanded without additional hardware. Furthermore, a wireless system can be configured in the office on the ground, reducing on-site labor by 60% to 80%.

- Effective operation in complex terrains: wired systems may face limitations in areas where cables cannot be run, such as open-pit mines, underground mines, or across properties not owned by the mining company. Wireless monitoring systems, using industrial transceiver nodes, provide powerful, long-range data transmission, maintaining signal strength through challenging terrain, structures, or adverse weather conditions. These systems can operate unattended for years, even in harsh environments, such as extreme hydrometeorological events caused by climate change.

- Complete collection of data without data loss: If a wired system fails due to issues like humidity conditions, corrosion, cut wires, or other adverse conditions, operators may not be alerted to the failure, leading to suboptimal operations or problems until the instrumentation is restored. Wireless systems, however, can be programmed with communication link alarms to alert operators if data transmission is interrupted. Preventative maintenance can be more effectively managed through wireless diagnostics, avoiding most problems.

- Versatility with different sensors: wireless monitoring configurations with open physical design criteria allow users to integrate various types of sensors to monitor different parameters. This flexibility means that sensors can be added or removed as needed to measure parameters, such as deformation, humidity, temperature, water level, and gasses, among others. Users can select the most appropriate sensor for each application, consolidating data from different sensors into a single interface.

1.4. A New Era in the Technological Context of Mining

- Personnel tracking: use of proximity sensors (e.g., beacons) to locate front-line workers in the operation.

- Augmented reality and virtual reality: displays essential safety and maintenance data on glasses (e.g., equipment data, alerts, and procedure checklists, among others).

- Environmental monitoring: sensors and detectors to track key metrics (e.g., oxygen levels, heat, and hazardous gases, among others) and high-definition cameras to record procedures and provide real-time instructions when needed (e.g., when performing maintenance tasks underground).

- Biometric monitoring: devices containing sensors worn by the workforce to capture information about employee health status (e.g., heart rate, concentration, fatigue levels, repetitive biometric movements, and load weights, among others)

1.5. Scope of the Review

- RQ1: What are the main IoT technologies that allow the transmission of data collected by sensors implemented in underground mines according to Scopus and Web of Science publications?

- RQ2: What are the main publications in Scopus and Web of Science on the use of wireless sensor systems through LoRaWAN technology in underground mines?

- RQ3: What are the main characteristics, advantages, and disadvantages of a sensor system using cables and wireless for implementation in underground mines?

- RQ4: What are the main characteristics, potentialities, and limitations of each of the IoT technologies identified for implementation in underground mines?

- RQ5: What are the main design criteria to define the architecture of the LoRaWAN IoT technology to be applied in underground mines?

- RQ6: What should be the typical network topology of the LoRaWAN IoT technology to be applied in underground mines?

- RQ7: What are the sensors to be used with the LoRaWAN IoT technology to be applied in underground mines?

- RQ8: What are the technological advances, knowledge gaps, and future perspectives of LoRaWAN IoT technology to be applied in underground mines?

2. Literature Review—IoT Sensors and Wireless Connectivity System Applications

2.1. Research Methodology

2.1.1. Preliminary Search

2.1.2. Literature Screening

2.1.3. Literature Study

2.2. State-of-the-Art

- Narrowband Internet of Things (NB-IoT),

- Sigfox,

- Category M (CAT-M),

- Long Range (LoRa),

- Long-Term Evolution (LTE).

3. Comparison of Different Technologies for Wireless Monitoring in Underground Mine Environments

3.1. Understanding Wire and Wireless Monitoring System Used in Underground Mines

- Fiber optic and/or coaxial cable (conventional wire system): communication systems based on fiber optics and/or coaxial cable have been used routinely in the mining industry. These systems’ advantages are (i) they allow the automatic control of variables, (ii) they allow real-time diagnosis, (iii) they offer stable operation with low maintenance, (iv) they allow control during post-operation, (v) they can transmit data over long distances, and (vi) they can transmit large amounts of data (high transfer rate compared to other wired systems) [13,14,20] (See Figure 4).

- Radio communication (non-conventional wireless system): these systems allow communication at anytime, anywhere, and on any device. Their advantages include (i) simultaneous communication to several receivers and (ii) the capacity to transmit early community warnings [42].

3.2. Comparative Analysis of IoT Technologies Applications in Underground Mining

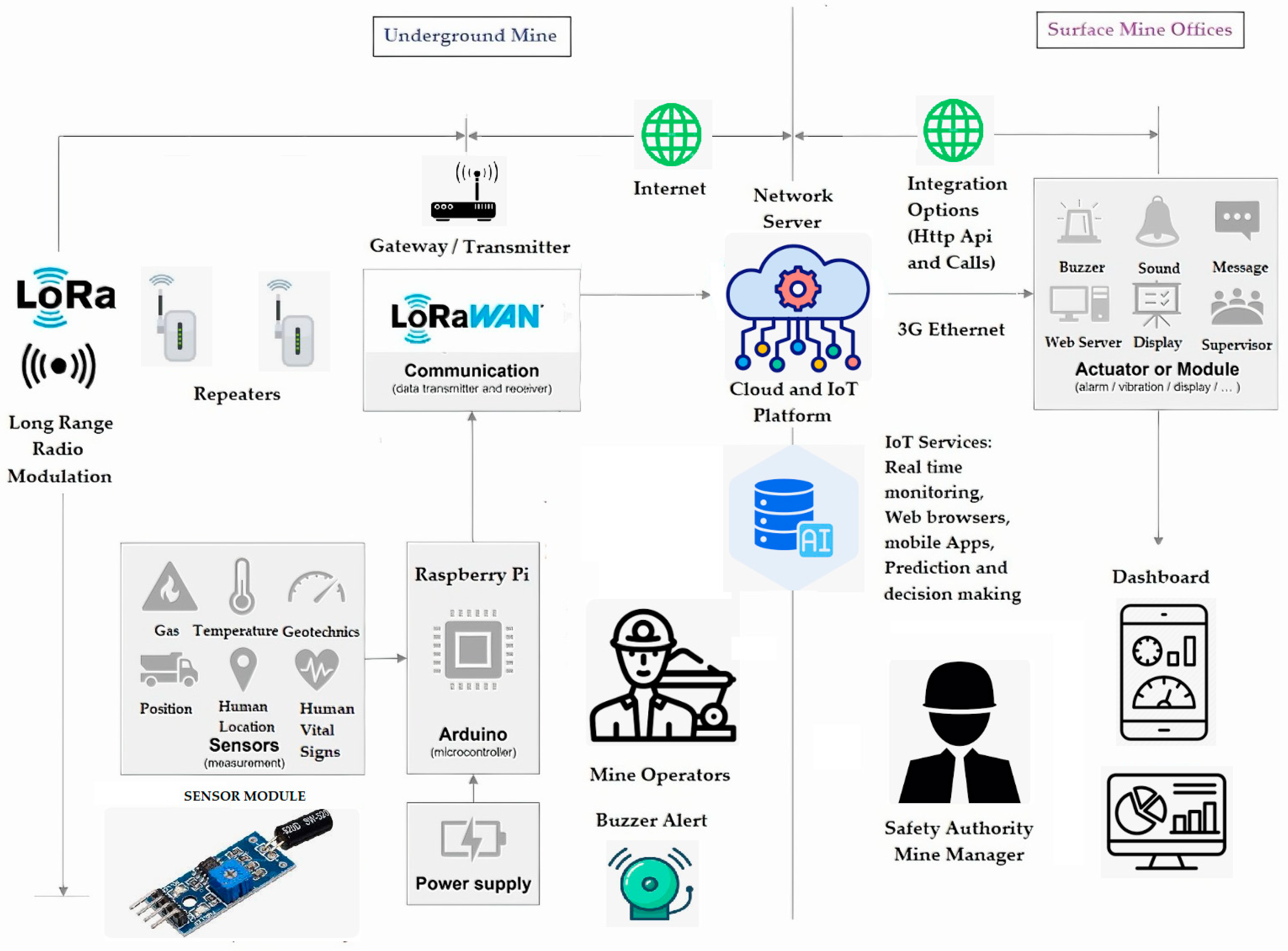

4. Underground Mine IoT LoRaWAN-Based WSN Monitoring System

4.1. Definition of Design Criteria for IoT Sensors and Wireless Connectivity Ecosystem Network Architecture

- Kumar et al., 2023, [21], in the research entitled Development of LoRa Communication System for Effective Transmission of Data from Underground Coal Mines, mentions the following idea: “The LoRaWAN network’s topology is star-of-stars in terms of its own architecture and is comprised of three primary parts network servers, gateways (GWs), and end nodes. End nodes require gateways (GWs) to connect to the network server (or data server)”,

- Branch, 2022, [22], in the research entitled Measurements and Models of 915 MHz LoRa Radio Propagation in an Underground Gold Mine, mentions the following considerations: “Research into LoRa has mostly emphasized its applications. LoRa is particularly well suited to agriculture. Farms where distances are a maximum of a few kilometres match LoRa’s single hop star architecture well. Agriculture applications have included soil moisture monitoring, livestock location and behaviour, and some aquaculture applications”.

- Aziz, 2020, [38], in the research entitled A Study on Industrial IoT for the Mining Industry: Synthesized Architecture and Open Research Direction, affirms some key issues as following: “The layered architecture addresses the current challenges in the mining industry by offering a remotely controlled, automated, and interoperable environment to improve communication, data access, and data management. The architecture considers each mine site as an IIoT edge, which addresses all serious and complex issues by local edge gateway, name a few as asset management, monitoring and diagnosis, provisioning and deployment, and interoperability between different systems and devices. There is a need for an IIoT architecture for the mining industry that follows the industrial guidelines defined by standard bodies and adopted by a large number of vendors”.

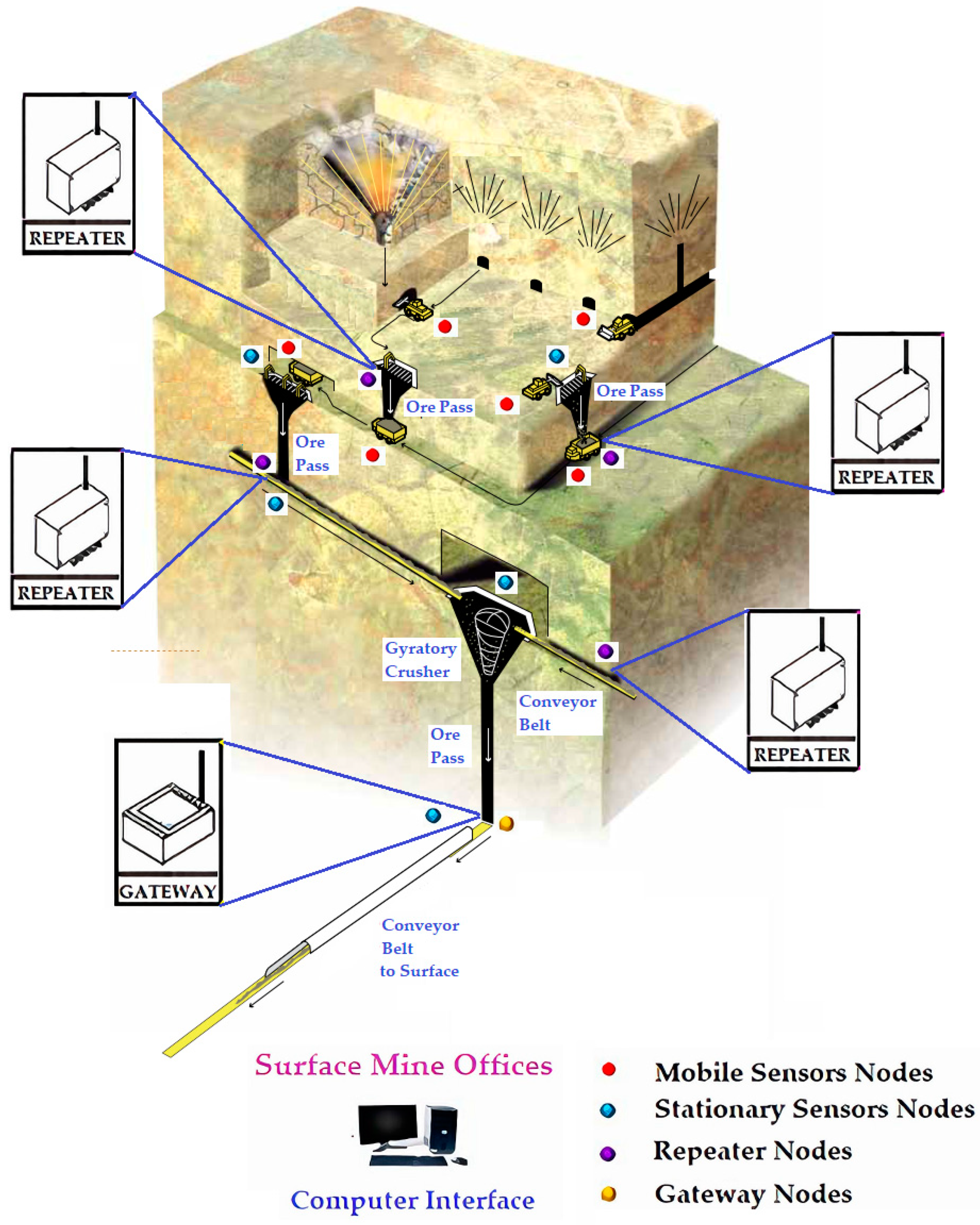

4.2. Definition of Network Topology for IoT Sensors and Wireless Connectivity Ecosystem

- Surface mining projects: when connecting sensors and the Internet of Things in surface mining infrastructures, the IoT LoRaWAN-based WSN system can be implemented through a single loop with a Star-type topology. This means that when it is required to install a real-time monitoring system in remote areas that are difficult to access on the surface, this technology can do so without the use of repeaters. When there are no geographical obstacles or infrastructure barriers, IoT LoRaWAN-based WSNs in these cases can have a range of 15 km of network coverage, more than any other comparable system. This makes this technology ideal for monitoring large-scale civil infrastructure, such as mining.

- Underground mining projects: when connecting sensors and the Internet of Things in underground mining infrastructure environments, the IoT LoRaWAN-based WSN system can be implemented through several loops with a Tree-type topology. This means that when it is necessary to install a real-time monitoring system in areas with physical obstacles with complex topography with the presence of walls, curves, or long tunnels, this technology can do so in those intricate topologies with the use of repeaters. When there are topographic obstacles, ramps, walls, galleries, tunnels, curves, and ventilation shafts, among others, IoT LoRaWAN-based WSNs in these cases can have a range of 10 km of network coverage, more than any other comparable system. The key component of this system is the repeaters due to the linear nature of communications in these environments, which allow the signal from a node to be received and retransmitted (see Figure 7). This is how repeaters can be strategically installed in the network of tunnels and galleries of the underground mine to overcome all types of physical obstacles (see Figure 8). This makes this technology ideal for monitoring complex infrastructures in large-scale inhospitable environments, such as underground mining.

4.3. Definition of IoT Sensors to Be Implemented in Underground Mine Environment

- Ground movements: extensometer-type sensors can monitor ground movements inside the tunnels using wireless digital data recorders to transmit the data.

- Convergence control in underground mine infrastructure: wireless laser-tilt-type sensors can support the supervision of convergence in access ramps, tunnels, and galleries.

- Monitoring the stability of the pillars between chambers: sensors allow for control of the load cells that can be installed on the rock pillars in order to evaluate the accumulation pressure due to surrounding excavations.

- Monitoring of the load on the anchor bolts in the rock: through sensors placed in the rock corresponding to load cells connected to a variety of wireless recorders, which can be located in places where the structures are at risk of rock fall.

- Study of soil movements in excavation areas: it is possible to safely connect several bolts using wireless digital data loggers and thus transmit data from the sensors.

- Control of cracks in tunnels: through the use of cracking meter-type sensors, it is possible to monitor the evolution of surface cracks in tunnels and thus collect the data using digital recorders.

5. Discussion

5.1. Technological Advances

- Low power: the devices are optimized to operate in low-power mode and can last up to 10 years with minimal maintenance.

- High capacity: IoT LoRaWAN-based WSN servers can handle millions of messages from hundreds of nodes, resulting in significant operational cost savings.

- Comprehensive security: IoT LoRaWAN-based WSNs guarantee secure communication between the end device and the application server. It is a reliable system that can transmit data from sensors at the underground level of the mine to the surface.

- Early detection: the system can detect an anomaly and give a warning signal to the surface.

- Operational robustness: the solution can withstand adverse weather conditions and is ideal for underground environments and high altitudes.

- Adaptability of on-premises or cloud server configuration: you can choose between a single-network on-premises server configuration or a multi-network cloud configuration with expanded IoT LoRaWAN-based WSN features depending on the characteristics and needs of the underground mine.

- Flexibility of network topologies: networks used through IoT LoRaWAN-based WSNs can be a single-hop configuration or a multi-hop configuration as required by underground mine conditions.

- Cost-effective solution: IoT LoRaWAN-based WSN is a low-cost, robust solution with low power demand and long range.

- Mobility: as it is a wireless communications system, it is possible to easily adjust and move the sensors.

- Reliability: as a wireless communications system is used, it can monitor any corner and corner in an underground mine compared to a wired system.

5.2. Knowledge Gaps

5.3. Future Perspectives

- Providing a standardized open technology stack that is fully scalable and compatible with established corporate standards.

- Launching a range of robust, self-contained, Lithium-ion Battery-powered (LiB) wireless nodes that can read most existing market devices.

- Developing products that are compatible with visualization software and third-party devices.

- Interacting with regulatory frameworks and contributing to industry best practices.

- Designing tools to manage networks and data.

- Interoperability and integration with different ICTs.

- Scalability: starting with a demonstration system and moving to an industrial-scale system.

- Security: improving the safety of the systems against collapse or adverse climate conditions.

- Digital twins: more connections with simulation devices like digital twins are needed to provide different scenarios of underground mine operations.

- Free space attenuation factor: doubling the distance, LoRaWAN’s free space attenuation increases by 6 dB. In addition to the power loss caused by the LoRaWAN range, the reflection, and refraction of radio waves off objects can also cause radio waves to overlap.

- Structural damping factor: the attenuation of radio signals as they pass through different obstacles affects the reception of transmitted signals and ensures that the signal range is greatly reduced.

- Fresnel zone factor: it is essential to establish as straight a line of sight as possible between the transmitter and receiver if an underground mine project wants to cover long distances effectively and get a good balance of power transmission. Certain areas of the space between the lines of sight of the radio transmission are Fresnel regions. Wave propagation will be negatively affected if there are objects in these areas, despite the usual visual contact between the transmitting and receiving antennas. For each object in the Fresnel belt, the signal level drops, and the LoRaWAN range is reduced.

- One of the main limitations of LoRaWAN is the relatively high latency. Networks and devices communicate with each other using data packets. However, these data packets are not always transferred immediately, as they consume battery power and network coverage. Latency is the delay time in data transfer after a transfer request is made. A low-latency device “connects” to the network more often than a high-latency device. For example, a smart sensor detects excessive deformation of support in an underground mine tunnel and needs to send an alert to the network. If this sensor has high latency, it does not transfer data to the network frequently, and it may take a few minutes before the network receives the alert. If the sensor has low latency, the network will receive the alert much sooner.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BATs | Best Available Technologies |

| BAPs | Best Applicable Practices |

| BEPs | Best Environmental Practices |

| IT | Information Technology |

| OT | Operational Technology |

| ICTs | Information and Communication Technologies |

| AI | Artificial Intelligence |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things |

| DT | Digital Twins |

| FoS | Factor of Safety |

| M2M | Machine to Machine |

| PPEs | Personal Protection Elements |

| LiB | Lithium-ion Battery |

| WSNs | Wireless Sensor Networks |

| GSM | Global System for Mobile Communications |

| 3G | Third-Generation Cellular Technology—Mobile Network that Combines Digital Voice Signals and Mobile Data |

| 4G | Fourth-Generation Cellular Technology—Mobile Network that Supports BroadBand Mobile Data |

| 5G | First-Generation Cellular Technology—Mobile Network that Provides More Connectivity and Faster Connection Speeds |

| ISM | Industrial, Scientific, and Medical |

| APPs | Software Applications |

| Wi-Fi | Wireless Fidelity |

| LAN | Local Area Networks |

| WAN | Wide-Area Network |

| NB-IoT | NarrowBand Internet of Things |

| CAT-M | Category M |

| LTE | Long Term Evolution |

| LoRa | Long Range Communication (Physical Layer) |

| LoRaWAN | Long Range Wide Area Network (Communication Protocol and Physical Layer) |

| MAC | Media Access Control (Address) |

| IP | Internet Protocol (Address) |

| KPI | Key Performance Indicator |

| ALARP | As Low As Reasonably Practicable |

| masl | Meters above sea level |

References

- do Carmo Reis Cavalcanti, M.; Nahas Ribeiro, W.; Cabral dos Santos Junior, M. Engineering Challenges for Safe and Sustainable Underground Occupation. Infrastructures 2023, 8, 42. [Google Scholar] [CrossRef]

- Sanmiquel, L.; Rossell, J.M.; Vintró, C. Study of Spanish mining accidents using data mining techniques. Saf. Sci. 2015, 75, 49–55. [Google Scholar] [CrossRef]

- Lööw, J.; Abrahamsson, L.; Johansson, J. Mining 4.0—The Impact of New Technology from a Work Place Perspective. Min. Metall. Explor. 2019, 36, 701–707. [Google Scholar] [CrossRef]

- Qiang, X.; Li, G.; Hou, J.; Zhang, X.; Liu, Y. Intelligent Safety Risk Analysis and Decision-Making System for Underground Metal Mines Based on Big Data. Sustainability 2023, 15, 10086. [Google Scholar] [CrossRef]

- Osinergmin. Guía de Criterios Geomecánicos para Diseño, Construcción, Supervisión y Cierre de Labores Subterráneas; Osinergmin: Lima, Peru, 2017. [Google Scholar]

- Sadeghi, S.; Soltanmohammadlou, N.; Nasirzadeh, F. Applications of wireless sensor networks to improve occupational safety and health in underground mines. J. Saf. Res. 2022, 83, 8–25. [Google Scholar] [CrossRef]

- Ali, M.H.; Al-Azzawi, W.K.; Jaber, M.; Abd, S.K.; Alkhayyat, A.; Rasool, Z.I. Improving coal mine safety with internet of things (IoT) based Dynamic Sensor Information Control System. Phys. Chem. Earth 2022, 128, 103225. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Wang, L.; Qu, F.; Shao, A.; Zhao, L.; Wang, H.; Yue, X.; Li, Y.; Yan, W.; et al. Research progress and prospects of intelligent technology in underground mining of hard rock mines. Green Smart Min. Eng. 2024, 1, 12–26. [Google Scholar] [CrossRef]

- Levintal, E.; Ganot, Y.; Taylor, G.; Freer-Smith, P.; Suvocarev, K.; Dahlke, H.E. An underground, wireless, open-source, low-cost system for monitoring oxygen, temperature, and soil moisture. Soil Discuss. 2022, 8, 85–97. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Oñate, E. Factors influencing safety on construction projects (Fscps): Types and categories. Int. J. Environ. Res. Public Health 2021, 18, 10884. [Google Scholar] [CrossRef]

- Woźniak, J.; Pactwa, K.; Szczęśniewicz, M.; Ciapka, D. Declaration of the Sustainable Development Goals of Mining Companies and the Effect of Their Activities in Selected Areas. Sustainability 2022, 14, 16422. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, D.; Hötzel, J. IoT Based information and communication system for enhancing underground mines safety and productivity: Genesis, taxonomy and open issues. Ad Hoc Netw. 2018, 78, 115–129. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Guzmán, V.; Catriñir, P.; Atencio, E. Sensor Technologies for Safety Monitoring in Mine Tailings Storage Facilities: Solutions in the Industry 4.0 Era. Minerals 2024, 14, 446. Available online: https://www.mdpi.com/2075-163X/14/5/446 (accessed on 27 October 2024). [CrossRef]

- Cacciuttolo, C.; Guzmán, V.; Catriñir, P.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Low-Cost Sensors Technologies for Monitoring Sustainability and Safety Issues in Mining Activities: Advances, Gaps, and Future Directions in the Digitalization for Smart Mining. Sensors 2023, 23, 6846. [Google Scholar] [CrossRef] [PubMed]

- World Sensing. IoT Remote Monitoring Solution Portfolio–Underground Mining [Internet]. 2022. Available online: www.worldsensing.com (accessed on 27 October 2024).

- Majstorovic, V.; Simeunovic, V.; Miskovic, Z.; Mitrovic, R.; Stosic, D.; Dimitrijevic, S. Smart Manufacturing as a framework for Smart Mining. Procedia CIRP 2021, 104, 188–193. [Google Scholar] [CrossRef]

- Barnewold, L.; Lottermoser, B.G. Identification of digital technologies and digitalisation trends in the mining industry. Int. J. Min. Sci. Technol. 2020, 30, 747–757. [Google Scholar] [CrossRef]

- Nwaila, G.T.; Frimmel, H.E.; Zhang, S.E.; Bourdeau, J.E.; Tolmay, L.C.K.; Durrheim, R.J.; Ghorbani, Y. The minerals industry in the era of digital transition: An energy-efficient and environmentally conscious approach. Resour. Policy 2022, 78, 102851. [Google Scholar] [CrossRef]

- Arratia-Solar, A.; Paredes, D. Commodity price and fatalities in mining–Evidence from copper regions in Chile. Resour. Policy. 2023, 82, 103489. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Marinovic, A. Experiences of Underground Mine Backfilling Using Mine Tailings Developed in the Andean Region of Peru: A Green Mining Solution to Reduce Socio-Environmental Impacts. Sustainability 2023, 15, 12912. [Google Scholar] [CrossRef]

- Kumar, P.P.; Paul, P.S.; Ananda, M. Development of LoRa Communication System for Effective Transmission of Data from Underground Coal Mines. Processes 2023, 11, 1691. [Google Scholar] [CrossRef]

- Branch, P. Measurements and Models of 915 MHz LoRa Radio Propagation in an Underground Gold Mine. Sensors 2022, 22, 8653. [Google Scholar] [CrossRef]

- Musonda, S.K.; Ndiaye, M.; Libati, H.M.; Abu-Mahfouz, A.M. Reliability of LoRaWAN Communications in Mining Environments: A Survey on Challenges and Design Requirements. J. Sens. Actuator Netw. 2024, 13, 16. [Google Scholar] [CrossRef]

- Gong, H.; Su, D.; Zeng, S.; Chen, X. Advancements in digital twin modeling for underground spaces and lightweight geometric modeling technologies. Autom. Constr. 2024, 165, 105578. [Google Scholar] [CrossRef]

- Ikeda, H.; Kolade, O.; Mahboob, M.A.; Cawood, F.T.; Kawamura, Y. Communication of Sensor Data in Underground Mining Environments: An Evaluation of Wireless Signal Quality over Distance. Mining 2021, 1, 211–223. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W.; Han, D.; Kim, Y.-I. An integrated environment monitoring system for underground coal mines-Wireless Sensor Network subsystem with multi-parameter monitoring. Sensors 2014, 14, 13149–13170. [Google Scholar] [CrossRef]

- Aguirre-Jofré, H.; Eyre, M.; Valerio, S.; Vogt, D. Low-cost internet of things (IoT) for monitoring and optimising mining small-scale trucks and surface mining shovels. Autom. Constr. 2021, 131, 103918. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Alam MSBin Hoque, M.; Lameesa, A.; Afrin, S.; Farah, T.; Kabir, M.; Shafiullah, G.M.; Muyeen, S.M. Industrial Internet of Things enabled technologies, challenges, and future directions. Comput. Electr. Eng. 2023, 110, 108847. [Google Scholar] [CrossRef]

- Carvalho, R.; Correia, N.; Al-Tam, F. Mobility planning of LoRa gateways for edge storage of IoT data. Comput. Netw. 2023, 221, 109521. [Google Scholar] [CrossRef]

- Branch, P.; Li, B.; Zhao, K. A LoRa-Based Linear Sensor Network for Location Data in Underground Mining. Telecom 2020, 1, 68–79. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A. An event reporting and early-warning safety system based on the internet of things for underground coal mines: A case study. Appl. Sci. 2017, 7, 925. [Google Scholar] [CrossRef]

- Kim, S.M.; Choi, Y.; Suh, J. Applications of the open-source hardware Arduino platform in the mining industry: A review. Appl. Sci. 2020, 10, 5018. [Google Scholar] [CrossRef]

- Lee, W.H.; Kim, H.; Lee, C.H.; Kim, S.M. Development of Digital Device Using ZigBee for Environmental Monitoring in Underground Mines. Appl. Sci. 2022, 12, 11927. [Google Scholar] [CrossRef]

- Lee, W.H.; Han, S.S.; Kim, S.M. Three-Dimensional Model-Based Line-of-Sight Analysis for Optimal Installation of IoT Monitoring Devices in Underground Mines. Appl. Sci. 2023, 13, 12535. [Google Scholar] [CrossRef]

- Medina, F.; Ruiz, H.; Espíndola, J.; Avendaño, E. Deploying IIoT Systems for Long-Term Planning in Underground Mining: A Focus on the Monitoring of Explosive Atmospheres. Appl. Sci. 2024, 14, 1116. [Google Scholar] [CrossRef]

- Kianfar, A.E.; Sherikar, M.; Gilerson, A.; Skora, M.; Stankiewicz, K.; Mitra, R.; Clausen, E. Designing a Monitoring System to Observe the Innovative Single-Wire and Wireless Energy Transmitting Systems in Explosive Areas of Underground Mines. Energies 2022, 15, 576. [Google Scholar] [CrossRef]

- Duarte, J.; Rodrigues, F.; Branco, J.C. Sensing Technology Applications in the Mining Industry—A Systematic Review. Int. J. Environ. Res. Public Health 2022, 19, 2334. [Google Scholar] [CrossRef]

- Aziz, A.; Schelén, O.; Bodin, U. A Study on Industrial IoT for the Mining Industry: Synthesized Architecture and Open Research Directions. Internet Things 2020, 1, 529–550. [Google Scholar] [CrossRef]

- de Cassia Pedrosa Santos, R.; da Silva, J.M.; Junior, W.A.; Pinto, C.L.; Oliveira, M.M.; Mazzinghy, D.B. Development of a Low-Cost Device for Monitoring Ventilation Parameters (Temperature, Humidity and Pressure) in Underground Environments to Increase Operational Safety Using IoT. Mining 2022, 2, 746–756. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A. An internet of things system for underground mine air quality pollutant prediction based on azure machine learning. Sensors 2018, 18, 930. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A.; Lee, Y.S. Hybrid blockchain and internet-of-things network for underground structure health monitoring. Sensors 2018, 18, 4268. [Google Scholar] [CrossRef]

- Theissen, M.; Kern, L.; Hartmann, T.; Clausen, E. Use-Case-Oriented Evaluation of Wireless Communication Technologies for Advanced Underground Mining Operations. Sensors 2023, 23, 3537. [Google Scholar] [CrossRef]

- Inostroza, F.; Parra-Tsunekawa, I.; Ruiz-del-Solar, J. Robust Localization for Underground Mining Vehicles: An Application in a Room and Pillar Mine. Sensors 2023, 23, 8059. [Google Scholar] [CrossRef] [PubMed]

- Iturralde, D.; Guaña-Moya, J.; Játiva, P.P.; Sánchez, I.; Ijaz, M.; Dehghan Firoozabadi, A.; Zabala-Blanco, D. A New Internet of Things Hybrid VLC/RF System for m-Health in an Underground Mining Industry. Sensors 2024, 24, 31. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Chen, W.; Zhang, X.; Zhang, X.; Yang, G. Real-Time Monitoring of Underground Miners’ Status Based on Mine IoT System. Sensors 2024, 24, 739. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y. Bluetooth beacon-based mine production management application to support ore haulage operations in underground mines. Sustainability 2021, 13, 2281. [Google Scholar] [CrossRef]

- Sofia, D.; Giuliano, A.; Gioiella, F.; Barletta, D.; Poletto, M. Modeling of an air quality monitoring network with high space-time resolution. Comput. Aided Chem. Eng. 2018, 43, 193–198. [Google Scholar]

- Skrzypkowski, K.; Gómez, R.; Zagórski, K.; Zagórska, A.; Gómez-Espina, R. Review of Underground Mining Methods in World-Class Base Metal Deposits: Experiences from Poland and Chile. Energies 2023, 16, 148. [Google Scholar] [CrossRef]

- Nakamura, K.; Manzoni, P.; Redondi, A.; Longo, E.; Zennaro, M.; Cano, J.C.; Calafate, C.T. A LoRa-based protocol for connecting IoT edge computing nodes to provide small-data-based services. Digit. Commun. Netw. 2022, 8, 257–266. [Google Scholar] [CrossRef]

- Daintree Networks. Getting Started with ZigBee and IEEE 802.15.4. 2010. Available online: www.daintree.net (accessed on 27 October 2024).

- Std 802.15.1-2005; Part 15.1: Wireless Medium Access Control (MAC) and Physical Layer (PHY) Specifications for Wireless Personal Area Networks (WPANs). IEEE Standards Association: Piscataway, NY, USA, 2005. [CrossRef]

- Liu, R.; Beevi, K.T.A.; Dorrance, R.; Dasalukunte, D.; Kristem, V.; Santana Lopez, M.A.; Min, A.W.; Azizi, S.; Park, M.; Carlton, B.R. An 802.11ba-Based Wake-Up Radio Receiver With Wi-Fi Transceiver Integration. J. Solid-State Circuits 2020, 55, 1151–1164. [Google Scholar] [CrossRef]

- Fraile, L.P.; Tsampas, S.; Mylonas, G.; Amaxilatis, D. A Comparative Study of LoRa and IEEE 802.15.4-Based IoT Deployments Inside School Buildings. IEEE Access 2020, 8, 160957–160981. [Google Scholar] [CrossRef]

- Jabbar, W.A.; Subramaniam, T.; Ong, A.E.; Shu’Ib, M.I.; Wu, W.; de Oliveira, M.A. LoRaWAN-Based IoT System Implementation for Long-Range Outdoor Air Quality Monitoring. Internet Things 2022, 19, 100540. [Google Scholar] [CrossRef]

- Alipio, M.; Bures, M. Current testing and performance evaluation methodologies of LoRa and LoRaWAN in IoT applications: Classification, issues, and future directives. Internet Things 2024, 25, 101053. [Google Scholar] [CrossRef]

- Ting, Y.T.; Chan, K.Y. Optimising performances of LoRa based IoT enabled wireless sensor network for smart agriculture. J. Agric. Food Res. 2024, 16, 101093. [Google Scholar] [CrossRef]

- Arratia, B.; Rosas, E.; Calafate, C.T.; Cano, J.C.; Cecilia, J.M.; Manzoni, P. AlLoRa: Empowering environmental intelligence through an advanced LoRa-based IoT solution. Comput. Commun. 2024, 218, 44–58. [Google Scholar] [CrossRef]

- Wu, X.; Li, H.; Wang, B.; Zhu, M. Review on Improvements to the Safety Level of Coal Mines by Applying Intelligent Coal Mining. Sustainability 2022, 14, 16400. [Google Scholar] [CrossRef]

- Janjuhah, H.T.; Ishfaque, M.; Mehmood, M.I.; Kontakiotis, G.; Shahzad, S.M.; Zarkogiannis, S.D. Integrated underground mining hazard assessment, management, environmental monitoring, and policy control in Pakistan. Sustainability 2021, 13, 13505. [Google Scholar] [CrossRef]

- Clarkson, L.; Williams, D.; Seppälä, J. Real-time monitoring of tailings dams. Georisk 2021, 15, 113–127. [Google Scholar] [CrossRef]

- Adelantado, F.; Vilajosana, X.; Tuset-Peiro, P.; Martinez, B.; Melià-Seguí, J.; Watteyne, T. Understanding the Limits of LoRaWAN. IEEE Commun. Mag. 2017, 55, 34–40. [Google Scholar] [CrossRef]

- Povalac, A.; Kral, J.; Arthaber, H.; Kolar, O.; Novak, M. Exploring LoRaWAN Traffic: In-Depth Analysis of IoT Network Communications. Sensors 2023, 23, 7333. [Google Scholar] [CrossRef]

- Polonelli, T.; Brunelli, D.; Marzocchi, A.; Benini, L. Slotted ALOHA on LoRaWAN-design, analysis, and deployment. Sensors 2019, 19, 838. [Google Scholar] [CrossRef]

| Searching Index | Content |

|---|---|

| Time | 2017–2024 |

| Database | Scopus and Web of Science |

| Title/Subject-Abstract | “IoT” AND “LoRa” AND “LoRaWAN” AND “sensor” AND “Underground Mine” |

| Publication Type | “Article” and “Review Article” |

| Data Extraction Index 1 | Sensor IoT Name |

| Data Extraction Index 2 | Connectivity Type |

| Data Extraction Index 3 | Parameter/Measurement |

| Data Extraction Index 4 | Implementation Status |

| # | Publication Name/Authors | Sensor IoT Name | Connectivity Type | Parameter/ Measurement | Implementation Status |

|---|---|---|---|---|---|

| 1 | Development of LoRa Communication System for Effective Transmission of Data from Underground Coal Mines/ Kumar et al., 2023, [21] | Gas monitoring sensors | LoRaWAN | CH4, CO2, and CO | Underground coal mines—operation |

| 2 | Measurements and Models of 915 MHz LoRa Radio Propagation in an Underground Gold Mine/ Branch, 2022, [22] | Gas monitoring sensors | LoRaWAN | CH4, CO2, and CO | Underground gold mine—operation |

| 3 | A LoRa-Based Linear Sensor Network for Location Data in Underground Mining/ Branch and Zhao, 2020, [30] | Personnel and vehicle position | LoRaWAN | Location of mine operators and vehicles | Underground mine—operation |

| 4 | An Event Reporting and Early-Warning Safety System Based on the Internet of Things for Underground Coal Mines: A Case Study/ Jo and Khan, 2017, [31] | Sensors for control the air quality | Zigbee and Bluetooth | Temperature, humidity, CH4, CO2, and CO | Hassan Kishore coal underground mine—operation |

| 5 | Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review/ Kim et al., 2020, [32] | Sensors for gas, humidity, temperature, and accelerometer | GSM, Bluetooth, Wi-Fi, and ZigBee | Parameters linked to measures of atmospheric and geological information | Non-specified |

| 6 | Development of Digital Device Using ZigBee for Environmental Monitoring in Underground Mines/ Lee et al., 2022, [33] | Sensors for detecting changes in vibration and dust before and after blasting | Zigbee | Parameters linked to vibration and dust emission. | Samdo underground mine—operation |

| 7 | Three-Dimensional Model-Based Line-of-Sight Analysis for Optimal Installation of IoT Monitoring Devices in Underground Mines/ Lee et al., 2023, [34] | Sensors to monitoring the line of sight (LOS) must be connected without obstacles | Zigbee | Monitoring the parameter of line of sight (LOS) must be connected with-out obstacles | Samdo underground mine—operation |

| 8 | Deploying IIoT Systems for Long-Term Planning in Underground Mining: A Focus on the Monitoring of Explosive Atmospheres/ Medina et al., 2024, [35] | Sensors for monitoring early detection of hazardous gases and mitigation of explosion risks | Zigbee | Parameters to detect hazards gases and explosion risks | Coal underground mine—operation |

| 9 | Designing a Monitoring System to Observe the Innovative Single-Wire and Wireless Energy Transmitting Systems in Explosive Areas of Underground Mines/ Kianfar et al., 2022, [36] | Sensors to detect hazards gases and humidity | Wi-Fi | Parameters to detect hazards gases and humidity | Explosive areas of underground mines—operation |

| 10 | Sensing Technology Applications in the Mining Industry—A Systematic Review/ Duarte et al., 2022, [37] | Sensors to detect geotechnical hazards, toxics gases, and humidity | LoRaWAN, Wi-Fi, Bluetooth, Zigbee, GSM | Parameters to detect geotechnical hazards, toxics gases, and humidity | Open-pit mines and underground mines—operation |

| 11 | A Study on Industrial IoT for the Mining Industry: Synthesized Architecture and Open Research Directions/ Aziz et al., 2020, [38] | Wireless sensor network (WSN) | Zigbee | Parameters to detect geotechnical hazards, toxic gases, and humidity | Open-pit mines and underground mines—operation |

| 12 | Reliability of LoRaWAN Communications in Mining Environments: A Survey on Challenges and Design Requirements/ Musonda et al., 2024, [23] | Sensors to detect geotechnical hazards, toxic gases, and humidity | LoRaWAN, Wi-fi, Zigbee, Bluetooth, 5G | Parameters to detect geotechnical hazards, toxic gases, and humidity | Underground mine—operation |

| 13 | Communication of Sensor Data in Underground Mining Environments: An Evaluation of Wireless Signal Quality over Distance/ Ikeda et al., 2021, [25] | Strain gauge sensor installed in a narrow reef stope, horizontal tunnel, and vertical shaft area | Wi-Fi | Parameters to detect deformations and displacements in tunnels | Underground mine—operation |

| 14 | Development of a Low-Cost Device for Monitoring Ventilation Parameters (Temperature, Humidity and Pressure) in Underground Environments to Increase Operational Safety Using IoT/ Pedrosa Santos et al., 2022, [39] | Low-cost sensors to monitor temperature, humidity, and pressure | 4G | Parameters for monitoring gases, such as CH4, NOX, NH3, H2S, SO2, and NOX, among others | Underground mine—operation |

| 15 | An Integrated Environment Monitoring System for Underground Coal Mines—Wireless Sensor Network Subsystem with Multi-Parameter Monitoring/ Zhang et al., 2014, [26] | Sensors for monitoring smoke, coal dust, temperature, and humidity | Zigbee | Parameters for monitoring are particle matter and gases, among others. | Underground coal mine—operation |

| 16 | An Internet of Things System for Underground Mine Air Quality Pollutant Prediction Based on Azure Machine Learning/ Jo and Khan, 2018, [40] | Sensors for monitoring air quality | Zigbee | Parameters to be monitored, with CH4, CO, SO2, and H2S as the most influencing gases | Underground mine—operation |

| 17 | Hybrid Blockchain and Internet-of-Things Network for Underground Structure Health Monitoring/ Jo et al., 2018, [41] | Sensors for monitoring geotechnical and environment issues | Wi-Fi | Parameters to be monitored displacement, strain, and temperature | Underground mine—operation |

| 18 | Use-Case-Oriented Evaluation of Wireless Communication Technologies for Advanced Underground Mining Operations/ Theissen et al., 2023, [42] | Sensors for monitoring geotechnical and environment issues | LoRa, Bluetooth, Wi-Fi, 5G | Parameters to be monitored, displacement, strain, and temperature | Underground mine—operation |

| 19 | Robust Localization for Underground Mining Vehicles: An Application in a Room and Pillar Mine/ Inostroza et al., 2023, [43] | Sensors for monitoring 2D LIDAR | 4G | Parameters to be monitored, 2D representations/maps of the environment | Underground mine—operation |

| 20 | A New Internet of Things Hybrid VLC/RF System for m-Health in an Underground Mining Industry/ Iturralde et al., 2024, [44] | Sensors to monitor vital signals of mine operators | Zigbee, Wi-Fi, Bluetooth | Parameters to be monitored pulse rate, respiratory rate, and body temperature | Underground mine—operation |

| 21 | Real-Time Monitoring of Underground Miners’ Status Based on Mine IoT System/ Jiang et al., 2024, [45] | Sensors to monitor gases and vital signals of mine operators | Bluetooth, 5G | Parameters to be monitored, toxic gases, pulse rate, respiratory rate, and body temperature | Underground mine—operation |

| 22 | Bluetooth Beacon-Based Mine Production Management Application to Support Ore Haulage Operations in Underground Mines/ Park and Choi, 2021, [46] | Sensors to monitor ore haulage vehicles | Bluetooth | Parameters to be monitored in real-time position of vehicles | Underground mine—operation |

| LAN | Cellular | Low Power WAN | |||

|---|---|---|---|---|---|

| Short-Range Communicating Devices | Long-Range with Power with M2M | Long-Range with Battery and IoT | |||

| Examples: Zigbee, Bluetooth, and Wi-Fi, among others. | Examples: GSM (Global System for Mobile Communications), 3G, 4G, and 5G, among others. | Examples: LoRaWAN, Sigfox, LTE, NB-IoT, and CAT-M, among others. | |||

| Advantages: -Mobile -In-home -Short-range -Factory automation | Disadvantages: -Battery life -Long range | Advantages: -Long-range -High data-rate -Coverage | Disadvantages: -Battery life | Advantages: -Long-range -Long battery -Low-cost | Disadvantages: High data-rate |

| Attributes/IoT Technology | Zigbee | Bluetooth | Wi-Fi | GSM | LoRaWAN |

|---|---|---|---|---|---|

| System resource requirements | 4 KB–32 KB | >250 KB | >1 MB | >16 MB | >16 MB |

| Power waste | Low | Common | Common | High | Low |

| Battery Life | 100–1000 days | 1–7 days | 1–5 days | 1–7 days | 5–10 years |

| Number of nodes in local network | 6500 | 7 | 30 | 1000 | 1000 |

| Data rate | 20–250 Kbps | 1000 Kbps | 11,000 Kbps | 64–128 Kbps | 0.3–50 Kbps |

| Communication distance | 10–100 m | 1–100 m | 1–100 m | 1000 m | 10,000–20,000 m (*) |

| Data power | 12.3 dBm | −20 to +20 dBm | 23 to 26 dBm | Up to 6 W | 10–30 dBm |

| Frequency bands | 784 MHz, 868 MHz, 915 MHz, 2.4 GHz | 2.4–2.485 GHz | 900 MHz, 2.4 GHz, 5 GHz, 6 GHz | 3.3–4.2 GHz, 24–54 GHz | 470–510 MHz, 863–870 MHz, 902–928 MHz |

| Power consumption | 10–100 mW | 100 mW, 2.5 mW and 1 mW, BLE: 0.01–0.5 W | 9–12 W | 1000 W to 20 KW | −137 to −150 dBm |

| Standards | IEEE 802.15.4 [50] | IEEE 802.15.1 [51] | IEEE 802.11 [52] | IEEE 802.11 [52] | IEEE 802.15.4 [53] |

| Advantages | Reliability, low-cost, low power consumption | Low-cost and easy to operate | High speed and adaptability | Good transmission quality and large coverage range | Uses fewer gateways, ultra-low power consumption, adaptive rate of data transmission |

| Disadvantages | Suitable for indoor applications only, short-range depends on cellular coverage for off-site monitoring; prone to network interference and channel noise and not very secure | Range of up to 100 m, energy-inefficient in real-time applications and drains battery if left on, slower data transmission rate, security vulnerabilities | Relies on Ethernet as backbone; high power consumption and low capacity in terms of the number of devices supported; practically, with one access point at 2.4 GHz, the range is short, within 200–300 m | Unavailable in remote locations where mines exist, high power consumption, devices are more complex, not suitable for energy-constrained IoT devices, coverage distance is short underground | Aloha MAC protocol can cause data collisions and increase delay, requires a subscription with a single vendor, unsuitable for video surveillance due to low data rates |

| Applications | Wireless detection and control | Short-distance data transmission | Many data transmissions, such as web access and video | Voice and data transmission | Long-range data transmission |

| Network Topology | Typical Connectivity | Sensor Failure Consequences | Critical Component | Favorite Application in Mining Facilities |

|---|---|---|---|---|

| Point-to-point | Hardwired | Total system failure, if one sensor fails | Connection between two points | Mining camps |

| Bus | Hardwired | Total system failure, if one sensor fails | Collision avoidance system to resolve issues when two nodes simultaneously send data | Mining roads and mining camps |

| Linear | Hardwired | Failure of those depending on that node, if one sensor fails | Node dependence to propagate the data | Metallurgical process plant |

| Star | Wireless | Localized to a single node, if one sensor fails | Intelligent central node | Mine tailings storage facility, road mine network, and metallurgical process plant |

| Tree | Wireless | Failure of those depending on that node, if one sensor fails | Processing power as the node gets further from the root node | Underground mine and open pit mine |

| Mesh | Wireless | Localized to a single node, if one sensor fails | Self-healing ability, redirecting data along different paths if a node fails | Underground mine and mine tailings storage facility |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cacciuttolo, C.; Atencio, E.; Komarizadehasl, S.; Lozano-Galant, J.A. Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment. Sensors 2024, 24, 6971. https://doi.org/10.3390/s24216971

Cacciuttolo C, Atencio E, Komarizadehasl S, Lozano-Galant JA. Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment. Sensors. 2024; 24(21):6971. https://doi.org/10.3390/s24216971

Chicago/Turabian StyleCacciuttolo, Carlos, Edison Atencio, Seyedmilad Komarizadehasl, and Jose Antonio Lozano-Galant. 2024. "Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment" Sensors 24, no. 21: 6971. https://doi.org/10.3390/s24216971

APA StyleCacciuttolo, C., Atencio, E., Komarizadehasl, S., & Lozano-Galant, J. A. (2024). Internet of Things Long-Range-Wide-Area-Network-Based Wireless Sensors Network for Underground Mine Monitoring: Planning an Efficient, Safe, and Sustainable Labor Environment. Sensors, 24(21), 6971. https://doi.org/10.3390/s24216971