Wind-Speed-Adaptive Resonant Piezoelectric Energy Harvester for Offshore Wind Energy Collection

Abstract

1. Introduction

2. Theoretical Principles

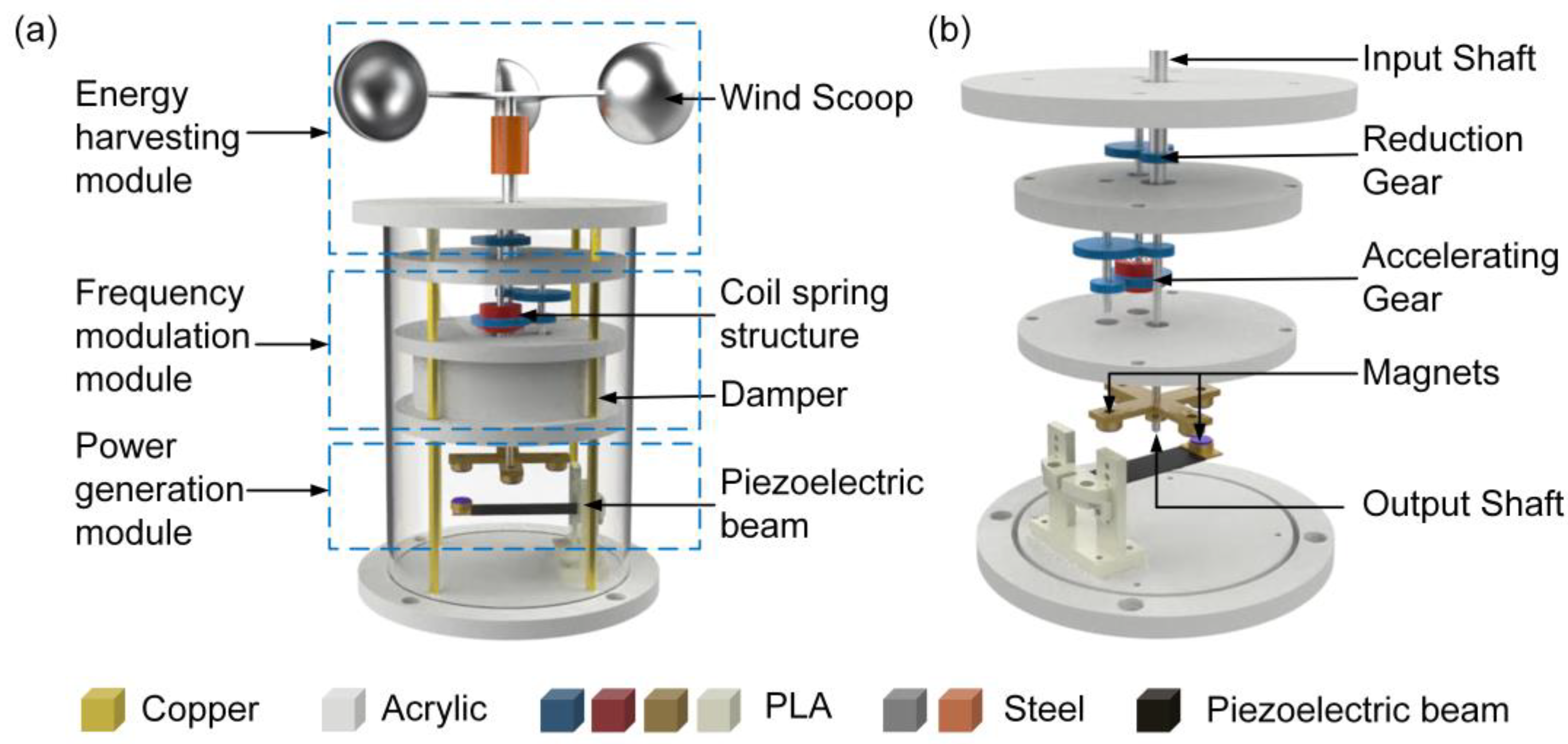

2.1. Structural Design

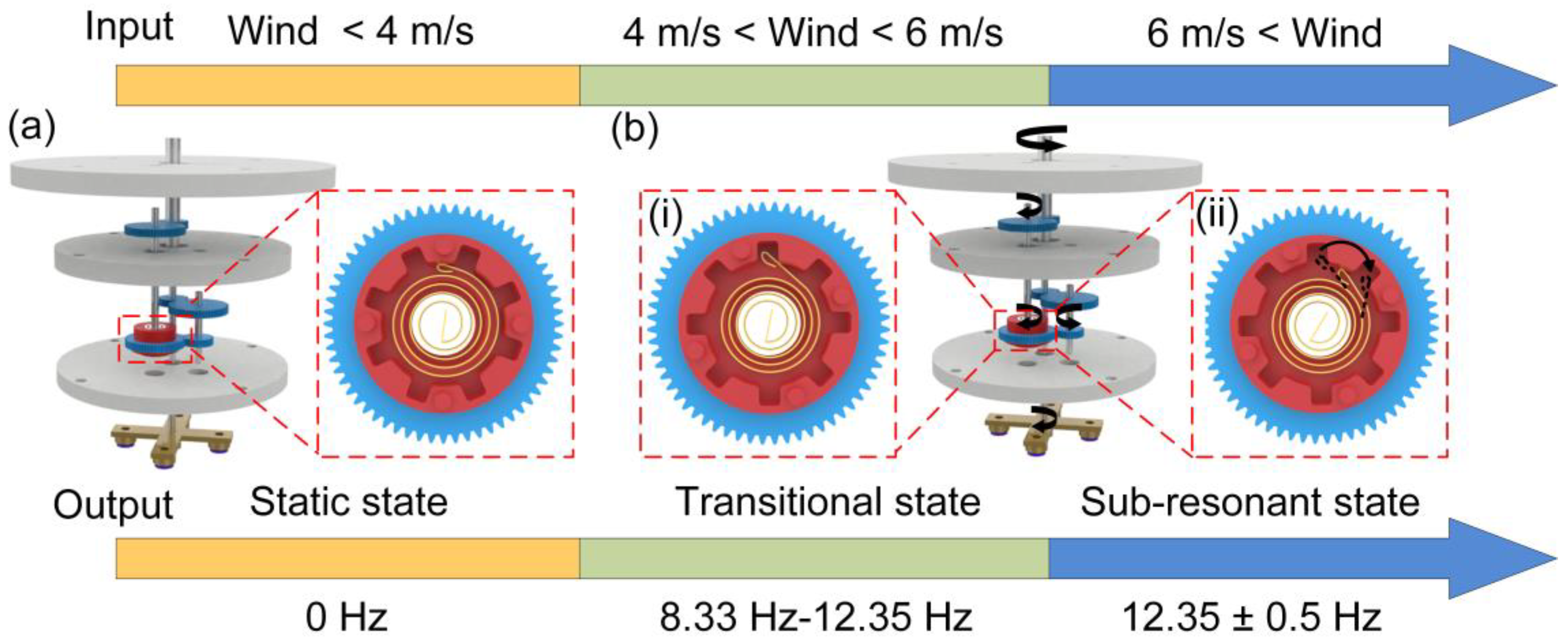

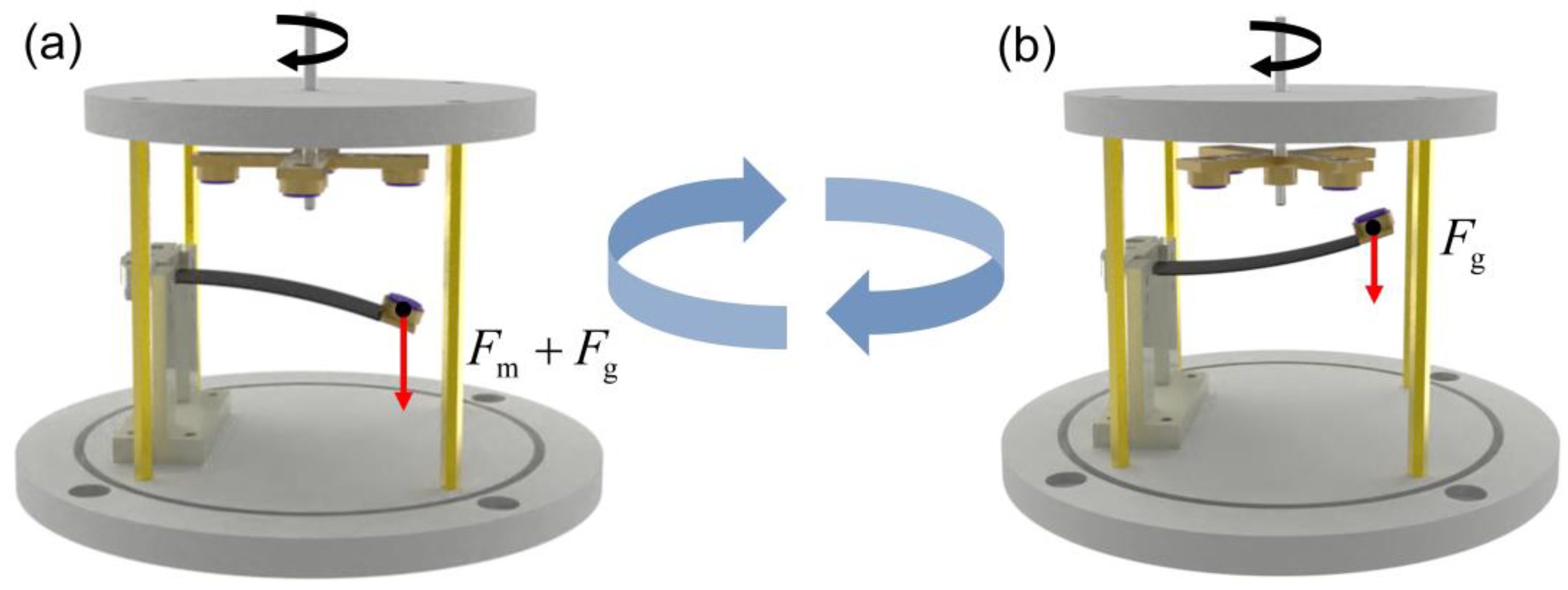

2.2. Working Principle

2.3. Theory Analysis

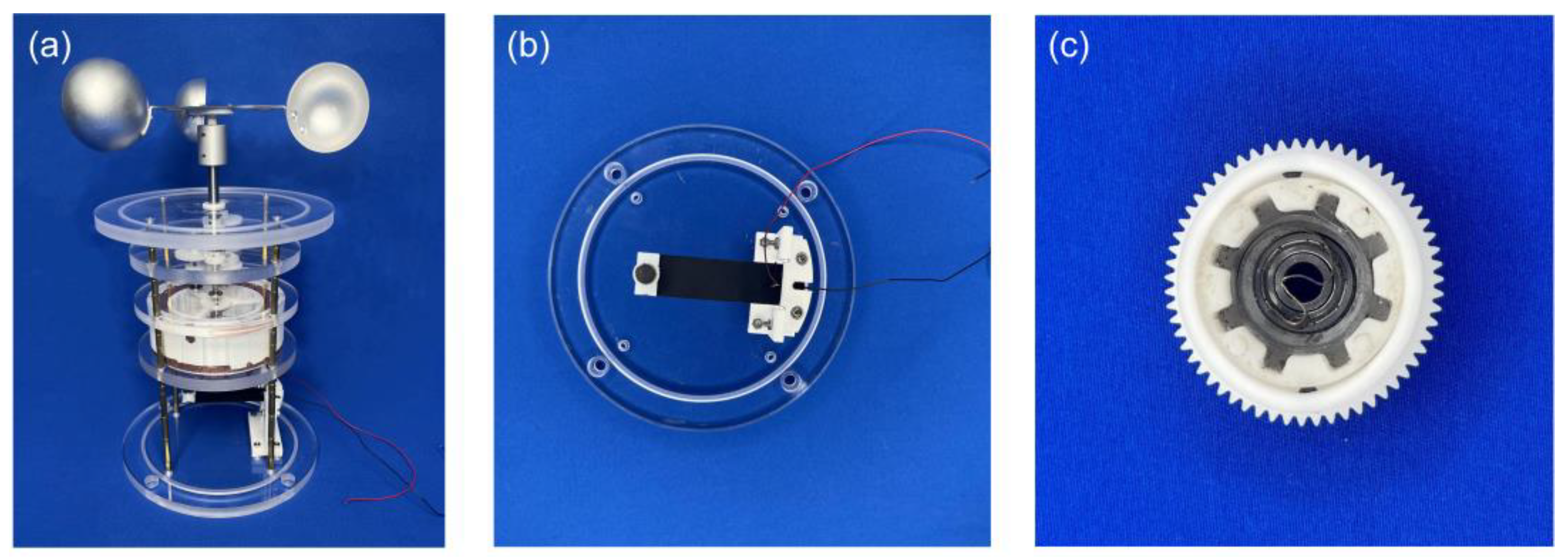

2.4. Fabrication of the A-PEH

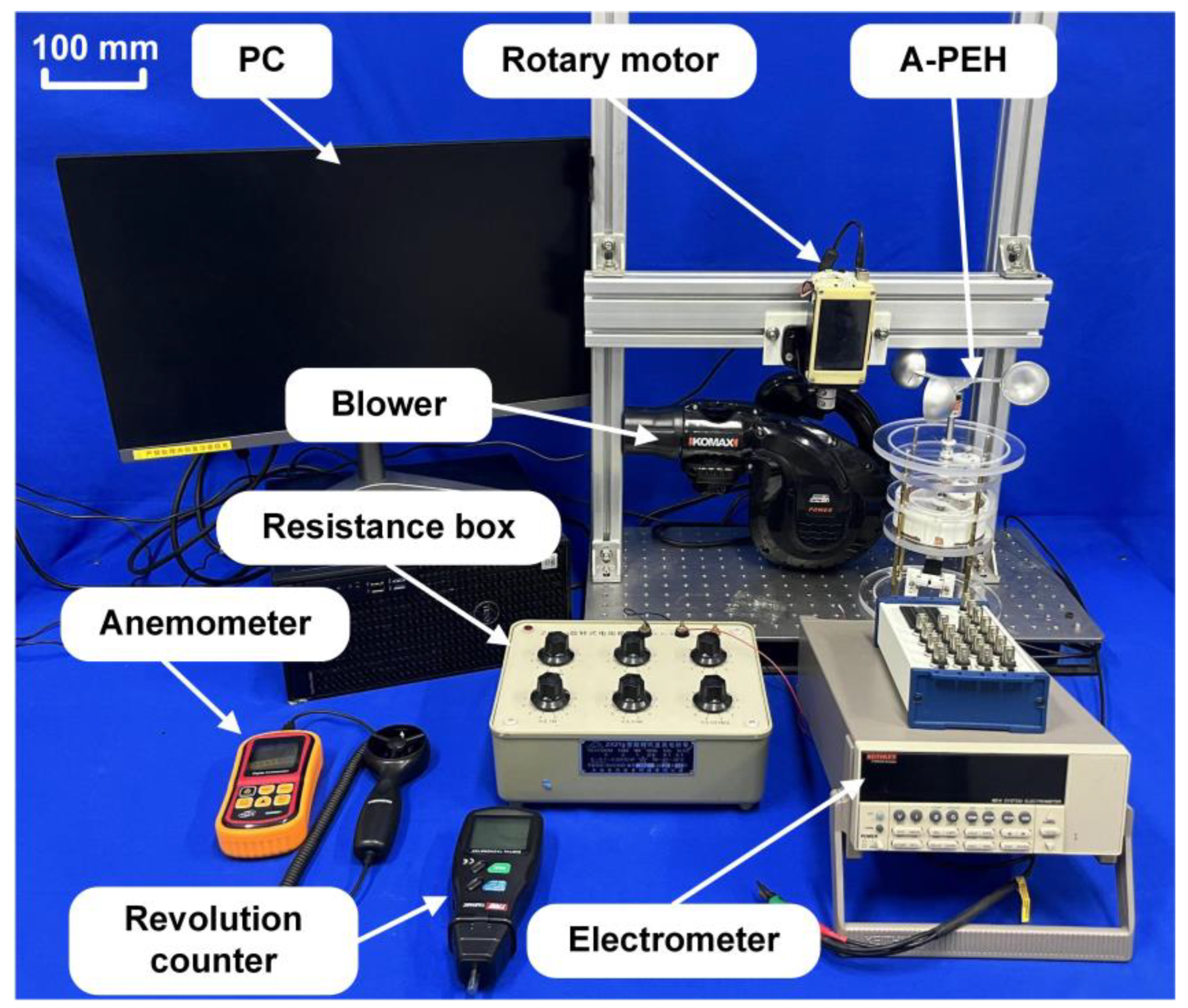

3. Experimental Section

4. Results and Discussion

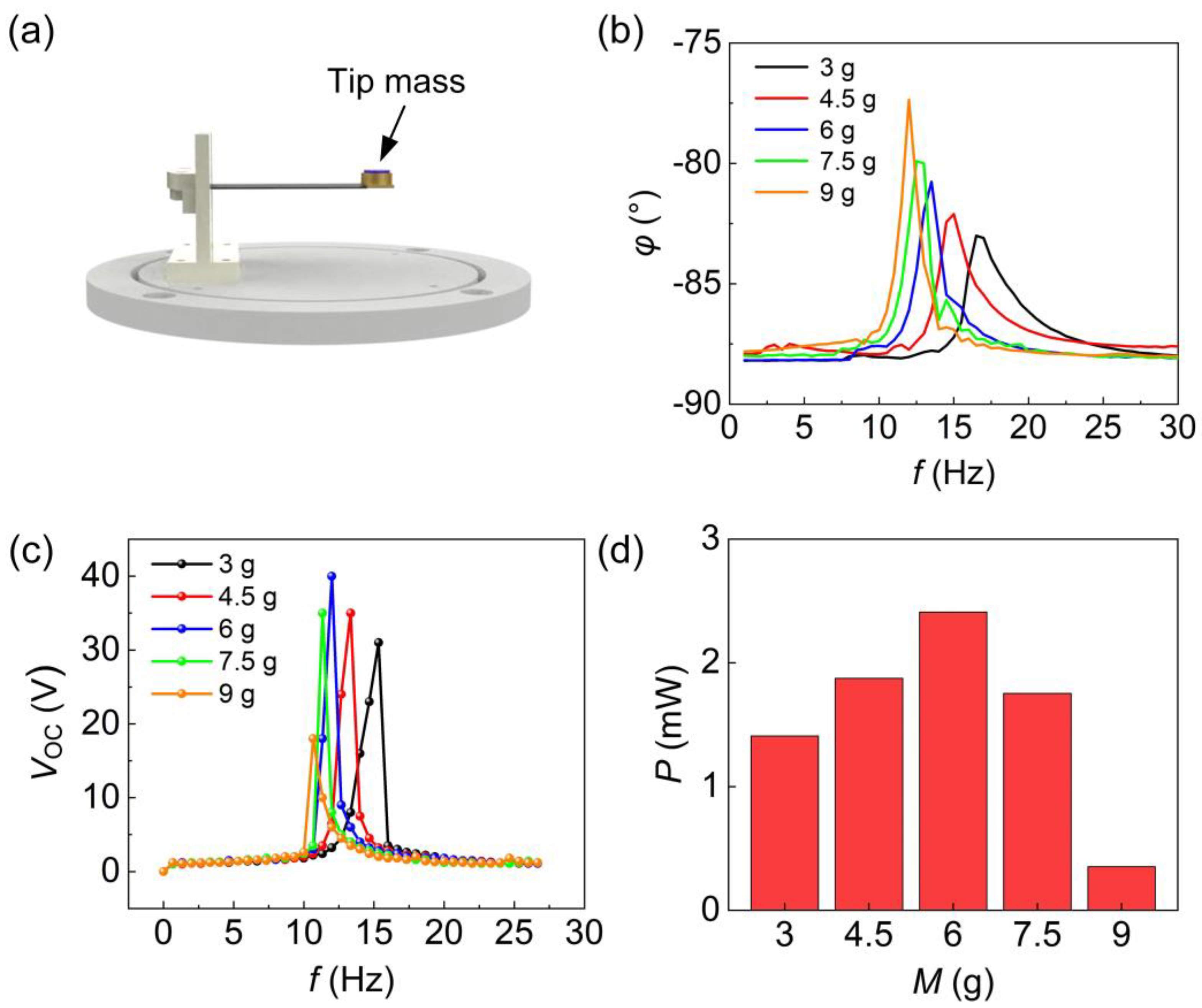

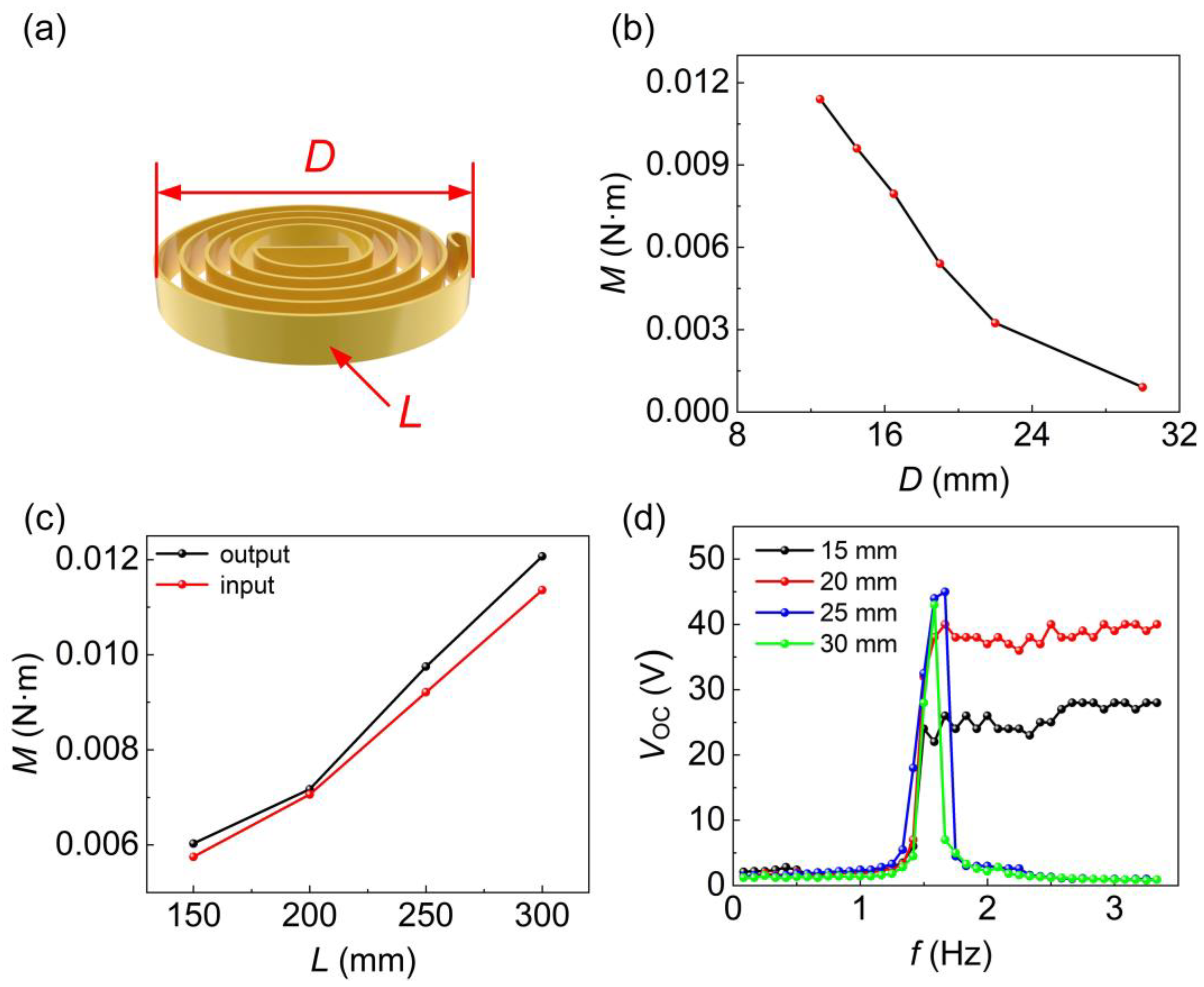

4.1. Parameter Optimization

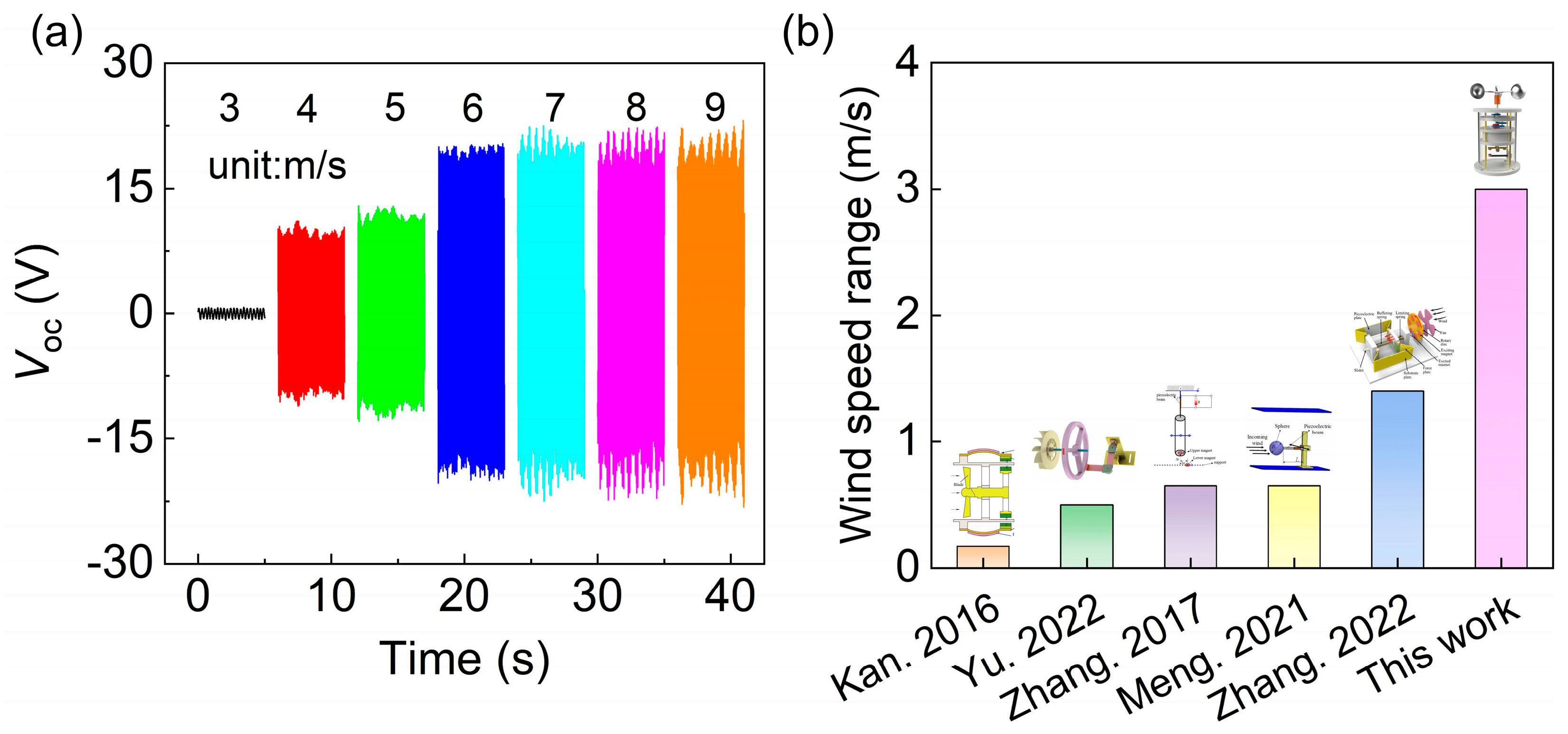

4.2. Performance

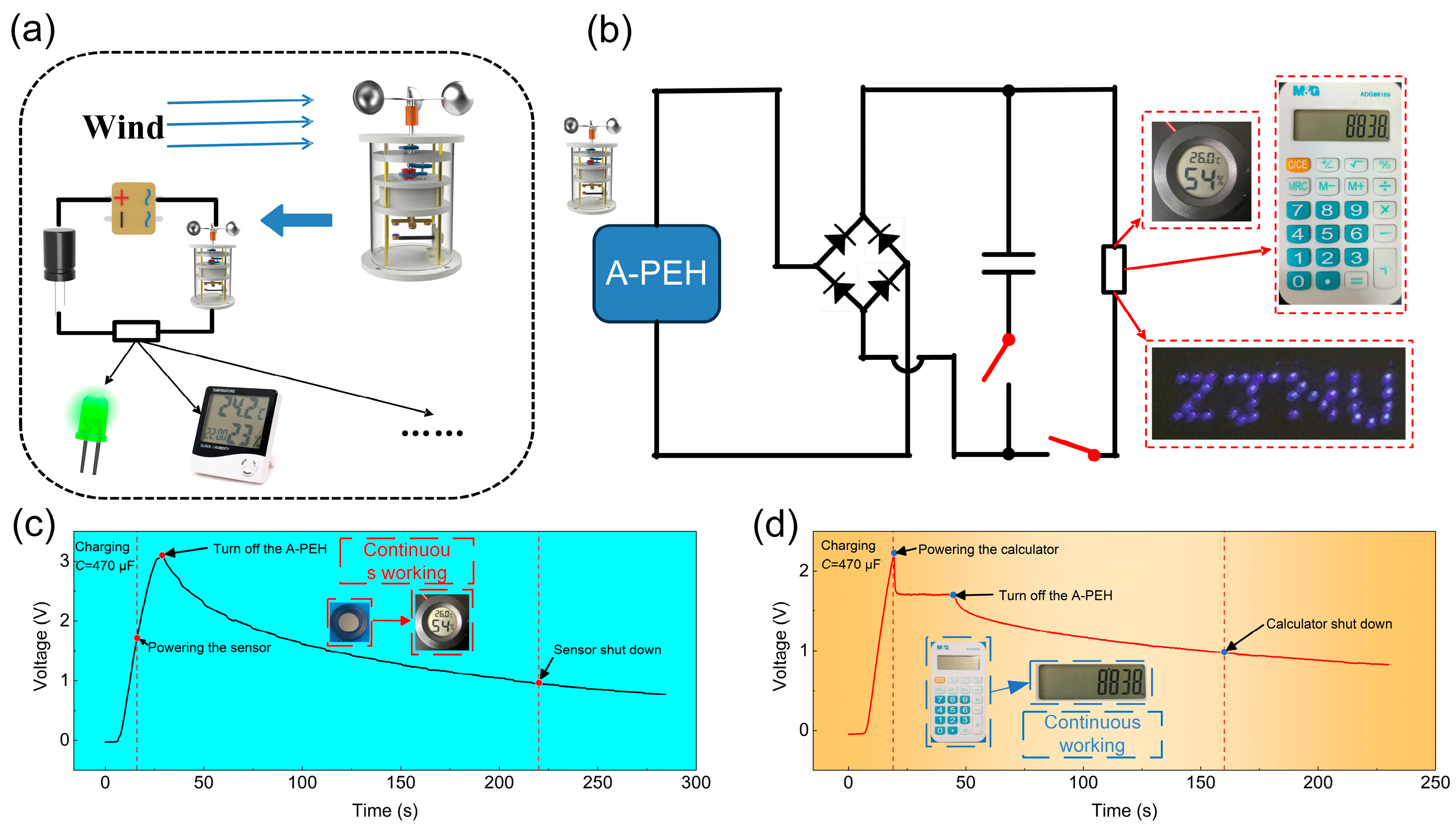

4.3. Application Demonstration

5. Conclusions

- i.

- The optimal tip mass of the piezoelectric beam is 6 g, and the optimal coil length in the spring structure is 20 mm.

- ii.

- When the rotational frequency of the input shaft exceeds 1.57 Hz, the device’s output excitation frequency stabilizes at approximately 12.35 Hz, enabling the A-PEH to sustain a sub-resonant state. In this state, the A-PEH yields an open-circuit voltage of 40 V and an average output power of 0.64 mW.

- iii.

- In different wind speed scenarios, the starting wind speed for the A-PEH is 4 m/s. When the wind speed surpasses 6 m/s, the A-PEH can sustain a sub-resonant state, showcasing excellent energy harvesting capacity in offshore wind environments with average wind speeds surpassing 5.5 m/s.

- iv.

- The A-PEH has successfully demonstrated its capability to power low-power electronic devices by efficiently storing the generated electrical energy.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beiter, P.; Musial, W.; Kilcher, L.; Maness, M.; Smith, A. An Assessment of the Economic Potential of Offshore Wind in the United States from 2015 to 2030. 2017. Available online: https://www.nrel.gov/docs/fy17osti/67675.pdf (accessed on 9 February 2024).

- Deng, X.; Xu, W.; Xu, Y.; Shao, Y.; Wu, X.; Yuan, W.; Qin, Z. Offshore wind power in China: A potential solution to electric-ity transformation and carbon neutrality. Fundam. Res. 2022, in press. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, X.; Luo, Y.; Xu, M. The validation analysis of QuikSCAT wind speed and the wind distribution in China’s offshore areas. Haiyang Xuebao 2013, 35, 76–86. [Google Scholar]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A comprehensive review on vibration based micro power generators using electromagnetic and piezoelectric transducer mechanisms. Energy Convers. Manag. 2015, 106, 728–747. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerator (TENG)—Sparking an Energy and Sensor Revolution. Adv. Energy Mater. 2020, 10, 202000137. [Google Scholar] [CrossRef]

- Briscoe, J.; Dunn, S. Piezoelectric nanogenerators–A review of nanostructured piezoelectric energy harvesters. Nano Energy 2015, 14, 15–29. [Google Scholar] [CrossRef]

- Barrero-Gil, A.; Alonso, G.; Sanz-Andres, A. Energy harvesting from transverse galloping. J. Sound Vib. 2010, 329, 2873–2883. [Google Scholar] [CrossRef]

- Abdelmoula, H.; Abdelkefi, A. The potential of electrical impedance on the performance of galloping systems for energy harvesting and control applications. J. Sound Vib. 2016, 370, 191–208. [Google Scholar] [CrossRef]

- Tan, T.; Yan, Z.; Lei, H. Optimization and performance comparison for galloping-based piezoelectric energy harvesters with alternating-current and direct-current interface circuits. Smart Mater. Struct. 2017, 26, 075007. [Google Scholar] [CrossRef]

- Sun, W.; Jang, H.; Seok, J. Magnetically coupled piezoelectric galloping-based energy harvester using a tandem configuration. Mech. Syst. Signal Process. 2021, 161, 107952. [Google Scholar] [CrossRef]

- Abdelkefi, A.; Nayfeh, A.H.; Hajj, M.R. Modeling and analysis of piezoaeroelastic energy harvesters. Nonlinear Dyn. 2011, 67, 925–939. [Google Scholar] [CrossRef]

- McCarthy, J.; Watkins, S.; Deivasigamani, A.; John, S. Fluttering energy harvesters in the wind: A review. J. Sound Vib. 2016, 361, 355–377. [Google Scholar] [CrossRef]

- Dunnmon, J.; Stanton, S.; Mann, B.; Dowell, E. Power extraction from aeroelastic limit cycle oscillations. J. Fluids Struct. 2011, 27, 1182–1198. [Google Scholar] [CrossRef]

- McCarthy, J.; Deivasigamani, A.; Watkins, S.; John, S.; Coman, F.; Petersen, P. On the visualisation of flow structures downstream of fluttering piezoelectric energy harvesters in a tandem configuration. Exp. Therm. Fluid Sci. 2014, 57, 407–419. [Google Scholar] [CrossRef]

- Zhao, D.; Hu, X.; Tan, T.; Yan, Z.; Zhang, W. Piezoelectric galloping energy harvesting enhanced by topological equivalent aerodynamic design. Energy Convers. Manag. 2020, 222, 113260. [Google Scholar] [CrossRef]

- Wang, J.; Geng, L.; Zhou, S.; Zhang, Z.; Lai, Z.; Yurchenko, D. Design, modeling and experiments of broadband tristable galloping piezoelectric energy harvester. Acta Mech. Sin. 2020, 36, 592–605. [Google Scholar] [CrossRef]

- Li, X.; Li, Z.; Bi, C.; Liu, B.; Su, Y. Study on Wind Energy Harvesting Effect of a Vehicle-Mounted Piezo-Electromagnetic Hy-brid Energy Harvester. IEEE Access 2020, 8, 167631–167646. [Google Scholar] [CrossRef]

- Cheng, T.; Fu, X.; Liu, W.; Lu, X.; Chen, X.; Wang, Y.; Bao, G. Airfoil-based cantilevered polyvinylidene fluoride layer gener-ator for translating amplified air-flow energy. Renew. Energy 2019, 135, 399–407. [Google Scholar] [CrossRef]

- Naseer, R.; Dai, H.; Abdelkefi, A.; Wang, L. Piezomagnetoelastic energy harvesting from vortex-induced vibrations using monostable characteristics. Appl. Energy 2017, 203, 142–153. [Google Scholar] [CrossRef]

- Wang, J.; Hu, G.; Su, Z.; Li, G.; Zhao, W.; Tang, L.; Zhao, L. A cross-coupled dual-beam for multi-directional energy har-vesting from vortex induced vibrations. Smart Mater. Struct. 2019, 28, 12LT02. [Google Scholar] [CrossRef]

- Lai, Z.; Wang, S.; Zhu, L.; Zhang, G.; Wang, J.; Yang, K.; Yurchenko, D. A hybrid piezo-dielectric wind energy harvester for high-performance vortex-induced vibration energy harvesting. Mech. Syst. Signal Process. 2020, 150, 107212. [Google Scholar] [CrossRef]

- Zhu, H.; Yao, J.; Ma, Y.; Zhao, H.; Tang, Y. Simultaneous CFD evaluation of VIV suppression using smaller control cylinders. J. Fluids Struct. 2015, 57, 66–80. [Google Scholar] [CrossRef]

- Kan, J.; Fan, C.; Wang, S.; Zhang, Z.; Wen, J.; Huang, L. Study on a piezo-windmill for energy harvesting. Renew. Energy 2016, 97, 210–217. [Google Scholar] [CrossRef]

- Yu, G.; He, L.; Zhou, J.; Liu, L.; Zhang, B.; Cheng, G. Study on mirror-image rotating piezoelectric energy harvester. Renew. Energy 2021, 178, 692–700. [Google Scholar] [CrossRef]

- Na, Y.; Lee, M.-S.; Lee, J.W.; Jeong, Y.H. Wind energy harvesting from a magnetically coupled piezoelectric bimorph canti-lever array based on a dynamic magneto-piezo-elastic structure. Appl. Energy 2020, 264, 114710. [Google Scholar] [CrossRef]

- Karami, M.A.; Farmer, J.R.; Inman, D.J. Parametrically excited nonlinear piezoelectric compact wind turbine. Renew. Energy 2013, 50, 977–987. [Google Scholar] [CrossRef]

- Zhang, L.B.; Abdelkefi, A.; Dai, H.L.; Naseer, R.; Wang, L. Design and experimental analysis of broadband energy har-vesting from vortex-induced vibrations. J. Sound Vib. 2017, 408, 210–219. [Google Scholar] [CrossRef]

- Meng, X.K.; Lu, Z.; Dai, H.L.; Abdelkefi, A. Comparative experimental investigation and effectiveness of sphere- and cyl-inder-based piezoelectric energy harvesters. Smart Mater. Struct. 2021, 30, 08LT01. [Google Scholar] [CrossRef]

- Yu, G.; He, L.; Wang, S.; Tian, X.; Zheng, X.; Cheng, G. Experiments and Analysis of a Nonlinear Sickle-Shaped Cantilever Beam Piezoelectric Energy Harvester for Wind Energy Harvesting. Phys. Status Solidi (a) 2022, 219, 2200363. [Google Scholar] [CrossRef]

- Kan, J.; Wang, J.; Wu, Y.; Chen, S.; Wang, S.; Jiang, Y.; Zhang, Z. Energy harvesting from wind by an axially retractable bracket-shaped piezoelectric vibrator excited by magnetic force. Energy 2022, 240, 122495. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Park, J. Compliant Joint Actuator with Dual Spiral Springs. IEEE/ASME Trans. Mech. 2013, 18, 1839–1844. [Google Scholar] [CrossRef]

- Muñoz-Guijosa, J.M.; Fernández Caballero, D.; Rodríguez de la Cruz, V.; Muñoz Sanz, J.L.; Echávarri, J. Generalized spiral torsion spring model. Mech. Mach. Theory 2012, 51, 110–130. [Google Scholar] [CrossRef]

- Xu, C.; Ren, B.; Liang, Z.; Chen, J.; Zhang, H.; Yue, Q.; Xu, Q.; Zhao, X.; Luo, H. Nonlinear output properties of cantilever driving low frequency piezoelectric energy harvester. Appl. Phys. Lett. 2012, 101, 223503. [Google Scholar] [CrossRef]

| Ref. | Output Voltage (V) | Average Power (mW) | Peak Power (mW) | Sub-Resonant Wind Speed Range (m/s) |

|---|---|---|---|---|

| Kan. et al. [23] | 37.2 | / | / | 5.8–5.97 |

| Yu. et al. [29] | 36.8 | / | 0.563 | 11.9–12.4 |

| Zhang. et al. [27] | / | 0.15 | / | 2.9–3.55 |

| Meng. et al. [28] | 14 | 0.19 | / | 5.1–5.75 |

| Zhang. et al. [30] | 37.6 | / | 2.13 | 8.7–10.1 |

| This work | 20 | 0.64 | 2.5 | 6–9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Pan, Z.; Zhou, J.; Wang, Y.; Ma, J.; Li, J.; Hu, Y.; Wen, J.; Wang, X. Wind-Speed-Adaptive Resonant Piezoelectric Energy Harvester for Offshore Wind Energy Collection. Sensors 2024, 24, 1371. https://doi.org/10.3390/s24051371

Wu W, Pan Z, Zhou J, Wang Y, Ma J, Li J, Hu Y, Wen J, Wang X. Wind-Speed-Adaptive Resonant Piezoelectric Energy Harvester for Offshore Wind Energy Collection. Sensors. 2024; 24(5):1371. https://doi.org/10.3390/s24051371

Chicago/Turabian StyleWu, Weijian, Zhen Pan, Jiangtao Zhou, Yingting Wang, Jijie Ma, Jianping Li, Yili Hu, Jianming Wen, and Xiaolin Wang. 2024. "Wind-Speed-Adaptive Resonant Piezoelectric Energy Harvester for Offshore Wind Energy Collection" Sensors 24, no. 5: 1371. https://doi.org/10.3390/s24051371

APA StyleWu, W., Pan, Z., Zhou, J., Wang, Y., Ma, J., Li, J., Hu, Y., Wen, J., & Wang, X. (2024). Wind-Speed-Adaptive Resonant Piezoelectric Energy Harvester for Offshore Wind Energy Collection. Sensors, 24(5), 1371. https://doi.org/10.3390/s24051371