Self-Powered Intelligent Water Droplet Monitoring Sensor Based on Solid–Liquid Triboelectric Nanogenerator

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of SL-TENGS

2.2. Establishment of Sensors Based on the SL-TENG

2.3. Measurements

3. Results and Discussion

3.1. Working Principle of the SL-TENG

3.2. Investigation on the Output Law of the SL-TENG

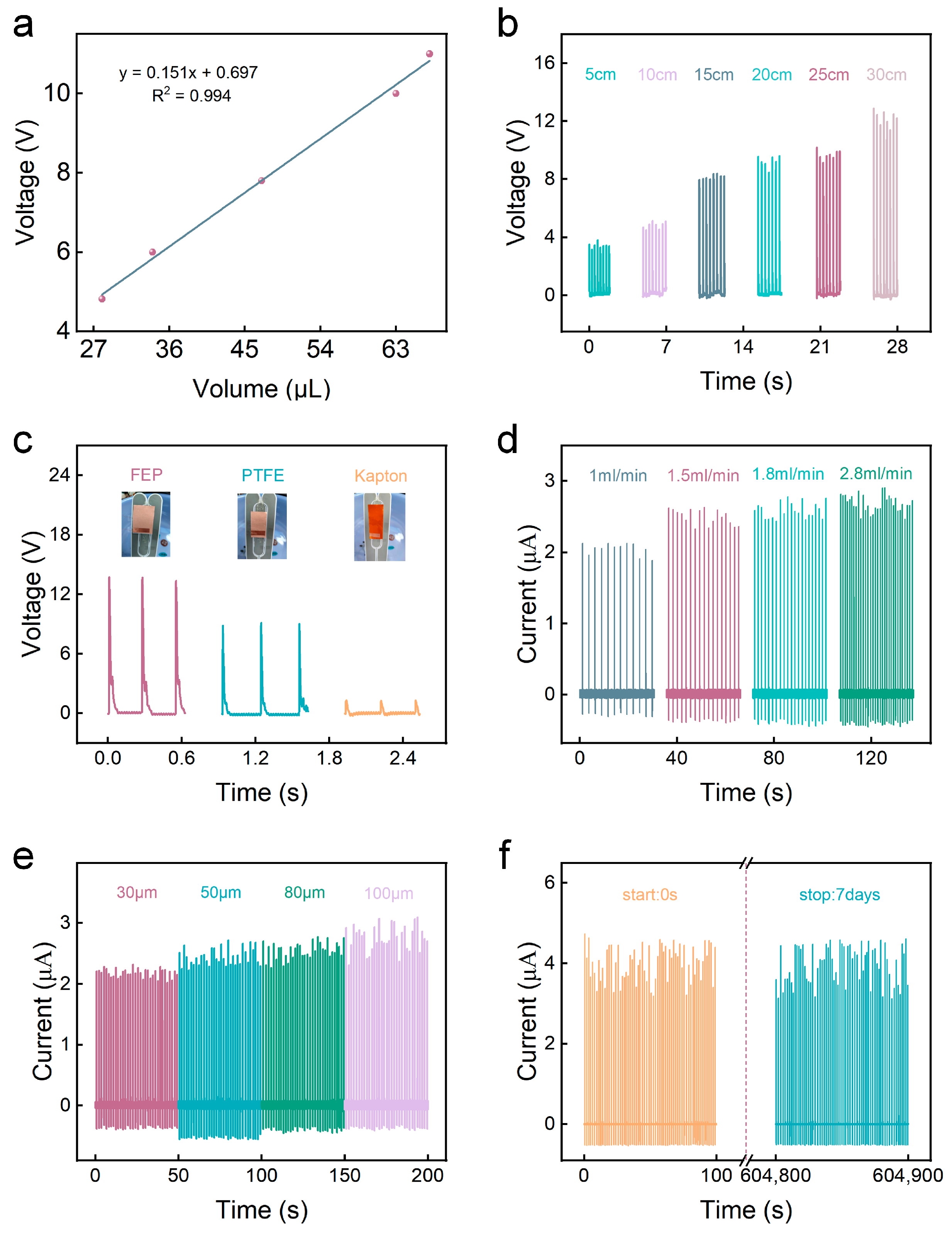

3.3. Rainfall Test Characteristics and Signal Acquisition System of Water Droplet Monitoring Sensor

3.3.1. Output Performance of the SL-TENG under Different Rainfall

3.3.2. The Wireless Processing System of the Water Droplet Monitoring Sensor

3.4. System Debugging and Complex Environment Testing of the Water Droplet Monitoring Sensor

3.5. Assisted Rainwater Monitoring

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Lin, L.; Wang, Z.L. Nanoscale Triboelectric-Effect-Enabled Energy Conversion for Sustainably Powering Portable Electronics. Nano Lett. 2012, 12, 6339–6346. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Jiang, C.; Song, Y.; Shao, B.; Wu, Y.; Song, Z.; Song, T.; Wang, Y.; Sun, B. Integrating hydrovoltaic device with triboelectric nanogenerator to achieve simultaneous energy harvesting from water droplet and vapor. Nano Energy 2022, 100, 107495. [Google Scholar] [CrossRef]

- Lin, Z.H.; Cheng, G.; Lee, S.; Pradel, K.C.; Wang, Z.L. Harvesting Water Drop Energy by a Sequential Contact-Electrification and Electrostatic-Induction Process. Adv. Mater. 2014, 26, 4690–4696. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Zhao, Z.; Zhang, C.; Yuan, W.; Wu, Z.; Wang, J.; Wang, Z.L. All-Weather Droplet-Based Triboelectric Nanogenerator for Wave Energy Harvesting. ACS Nano 2021, 15, 13200–13208. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, L.; Yang, X.; Hong, H.; Yang, Q.; Wang, J.; Tang, Q. Cumulative charging behavior of water droplet driven freestanding triboelectric nanogenerators toward hydrodynamic energy harvesting. J. Mater. Chem. A 2020, 8, 7880–7888. [Google Scholar] [CrossRef]

- Zhong, W.; Xu, L.; Zhan, F.; Wang, H.; Wang, F.; Wang, Z.L. Dripping Channel Based Liquid Triboelectric Nanogenerators for Energy Harvesting and Sensing. ACS Nano 2020, 14, 10510–10517. [Google Scholar] [CrossRef]

- Feng, M.; Kong, X.; Feng, Y.; Li, X.; Luo, N.; Zhang, L.; Du, C.; Wang, D. A New Reversible Thermosensitive Liquid–Solid TENG Based on a P(NIPAM-MMA) Copolymer for Triboelectricity Regulation and Temperature Monitoring. Small 2022, 18, 2201442. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Wen, Y.; Yang, L.; Zhao, Z.; Guo, Y.; Guo, X. Monitoring on triboelectric nanogenerator and deep learning method. Nano Energy 2022, 92, 106698. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, S.; Zheng, M.; Wang, Z.L. Triboelectric Nanogenerator as a Probe for Measuring the Charge Transfer between Liquid and Solid Surfaces. ACS Nano 2021, 15, 14830–14837. [Google Scholar] [CrossRef]

- Li, Z.; Yang, D.; Zhang, Z.; Lin, S.; Cao, B.; Wang, L.; Wang, Z.L.; Yin, F. A droplet-based electricity generator for large-scale raindrop energy harvesting. Nano Energy 2022, 100, 107443. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Cai, H.; Yao, M.; Zhang, H.; Guo, L.; Lv, Z.; Li, M.; Lu, X.; Ren, C.; et al. A Single-Droplet Electricity Generator Achieves an Ultrahigh Output Over 100 V without Pre-Charging. Adv. Mater. 2021, 33, 2105761. [Google Scholar] [CrossRef]

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Zhang, C.; Song, Y.; Deng, X.; Leung, M.; Yang, Z.; Xu, R.X.; et al. A droplet-based electricity generator with high instantaneous power density. Nature 2020, 578, 392–396. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Gu, H.; Lu, K.; Ye, S.; Xu, W.; Zheng, H.; Song, Y.; Liu, C.; Jiao, J.; Wang, Z.; et al. A universal single electrode droplet-based electricity generator (SE-DEG) for water kinetic energy harvesting. Nano Energy 2021, 82, 105735. [Google Scholar] [CrossRef]

- Dong, J.; Xu, C.; Zhu, L.; Zhao, X.; Zhou, H.; Liu, H.; Xu, G.; Wang, G.; Zhou, G.; Zeng, Q.; et al. A high voltage direct current droplet-based electricity generator inspired by thunderbolts. Nano Energy 2021, 90, 106567. [Google Scholar] [CrossRef]

- Xu, W.; Li, X.; Brugger, J.; Liu, X. Study of the enhanced electricity output of a sliding droplet-based triboelectric nanogenerator for droplet sensor design. Nano Energy 2022, 98, 107166. [Google Scholar] [CrossRef]

- Dong, K.; Deng, J.; Zi, Y.; Wang, Y.C.; Xu, C.; Zou, H.; Ding, W.; Dai, Y.; Gu, B.; Sun, B.; et al. 3D Orthogonal Woven Triboelectric Nanogenerator for Effective Biomechanical Energy Harvesting and as Self-Powered Active Motion Sensors. Adv. Mater. 2017, 29, 1702648. [Google Scholar] [CrossRef] [PubMed]

- Dong, K.; Wu, Z.; Deng, J.; Wang, A.C.; Zou, H.; Chen, C.; Hu, D.; Gu, B.; Sun, B.; Wang, Z.L. A Stretchable Yarn Embedded Triboelectric Nanogenerator as Electronic Skin for Biomechanical Energy Harvesting and Multifunctional Pressure Sensing. Adv. Mater. 2018, 30, 1804944. [Google Scholar] [CrossRef]

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A Hierarchically Nanostructured Cellulose Fiber-Based Triboelectric Nanogenerator for Self-Powered Healthcare Products. Adv. Funct. Mater. 2018, 28, 1805540. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C.; Zou, H.; Che, L.; Sun, P.; Yan, J.; Liu, W.; Xu, Z.; Yang, W.; Dong, L.; et al. Integrated wearable smart sensor system for real-time multi-parameter respiration health monitoring. Cell Rep. Phys. Sci. 2023, 4, 101191. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, H.; Cao, S.; Yuan, Z.; Ding, J.; Sang, S. Tube-based triboelectric nanogenerator for self-powered detecting blockage and monitoring air pressure. Nano Energy 2018, 52, 71–77. [Google Scholar] [CrossRef]

- Shen, H.; Lei, H.; Gu, M.; Miao, S.; Gao, Z.; Sun, X.; Sun, L.; Chen, G.; Huang, H.; Chen, L.; et al. A Wearable Electrowetting on Dielectrics Sensor for Real-Time Human Sweat Monitor by Triboelectric Field Regulation. Adv. Funct. Mater. 2022, 32, 2204525. [Google Scholar] [CrossRef]

- Liu, H.; Dong, J.; Zhou, H.; Yang, X.; Xu, C.; Yao, Y.; Zhou, G.; Zhang, S.; Song, Q. Real-Time Acid Rain Sensor Based on a Triboelectric Nanogenerator Made of a PTFE–PDMS Composite Film. ACS Appl. Electron. Mater. 2021, 3, 4162–4171. [Google Scholar] [CrossRef]

- Xu, W.; Zhou, X.; Hao, C.; Zheng, H.; Liu, Y.; Yan, X.; Yang, Z.; Leung, M.; Zeng, X.C.; Xu, R.X.; et al. SLIPS-TENG: Robust triboelectric nanogenerator with optical and charge transparency using a slippery interface. Natl. Sci. Rev. 2019, 6, 540–550. [Google Scholar] [CrossRef]

- Zhang, L.M.; Han, C.B.; Jiang, T.; Zhou, T.; Li, X.H.; Zhang, C.; Wang, Z.L. Multilayer wavy-structured robust triboelectric nanogenerator for harvesting water wave energy. Nano Energy 2016, 22, 87–94. [Google Scholar] [CrossRef]

- Zhang, Q.; Jiang, C.; Li, X.; Dai, S.; Ying, Y.; Ping, J. Highly Efficient Raindrop Energy-Based Triboelectric Nanogenerator for Self-Powered Intelligent Greenhouse. ACS Nano 2021, 15, 12314–12323. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Y.; Zhang, N.; Zou, H.; Liu, R.; Tao, C.; Fan, X.; Wang, Z.L. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 2016, 1, 16138. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.; Kim, T.Y.; Khan, U.; Kim, S.-W. Water droplet-driven triboelectric nanogenerator with superhydrophobic surfaces. Nano Energy 2019, 58, 579–584. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, B.; Guo, H.; Wu, Z.; Zou, H.; Yang, J.; Wang, Z.L. Super-robust and frequency-multiplied triboelectric nanogenerator for efficient harvesting water and wind energy. Nano Energy 2019, 64, 103908. [Google Scholar] [CrossRef]

- Xiong, J.; Lin, M.F.; Wang, J.; Gaw, S.L.; Parida, K.; Lee, P.S. Wearable All-Fabric-Based Triboelectric Generator for Water Energy Harvesting. Adv. Energy Mater. 2017, 7, 1701243. [Google Scholar] [CrossRef]

- Zhang, S.L.; Xu, M.; Zhang, C.; Wang, Y.-C.; Zou, H.; He, X.; Wang, Z.; Wang, Z.L. Rationally designed sea snake structure based triboelectric nanogenerators for effectively and efficiently harvesting ocean wave energy with minimized water screening effect. Nano Energy 2018, 48, 421–429. [Google Scholar] [CrossRef]

- Chen, H.X. Design of Rain Sensor Based on Optical Principle. Appl. Mech. Mater. 2014, 668–669, 977–980. [Google Scholar] [CrossRef]

- Helseth, L.E. A water droplet-powered sensor based on charge transfer to a flow-through front surface electrode. Nano Energy 2020, 73, 104809. [Google Scholar] [CrossRef]

- Hu, S.; Shi, Z.; Zheng, R.; Ye, W.; Gao, X.; Zhao, W.; Yang, G. Superhydrophobic Liquid–Solid Contact Triboelectric Nanogenerator as a Droplet Sensor for Biomedical Applications. ACS Appl. Mater. Interfaces 2020, 12, 40021–40030. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, J.; Li, J.; Ma, J.; Hu, Y.; Lu, F.; He, X.; Wen, J.; Cheng, T. Tipping-bucket self-powered rain gauge based on triboelectric nanogenerators for rainfall measurement. Nano Energy 2022, 98, 107234. [Google Scholar] [CrossRef]

- Zeng, Y.; Luo, Y.; Lu, Y.; Cao, X. Self-powered rain droplet sensor based on a liquid-solid triboelectric nanogenerator. Nano Energy 2022, 98, 107316. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Gao, X.; Mao, Y.; Hu, C.; Long, K.; Sun, C.; Guo, S. Self-Powered Droplet Sensor Based on Triboelectric Nanogenerator toward the Internet-of-Things (IoT) Alarm System. ACS Appl. Electron. Mater. 2023, 5, 6026–6036. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Xia, Z.; Wang, J.; Yao, H.; Shen, Q.; Yang, H. A humidity- and environment-resisted high-performance triboelectric nanogenerator with superhydrophobic interface for energy harvesting and sensing. Nano Energy 2023, 109, 108300. [Google Scholar] [CrossRef]

- Panayanthatta, N.; Clementi, G.; Ouhabaz, M.; Costanza, M.; Margueron, S.; Bartasyte, A.; Basrour, S.; Bano, E.; Montes, L.; Dehollain, C.; et al. A Self-Powered and Battery-Free Vibrational Energy to Time Converter for Wireless Vibration Monitoring. Sensors 2021, 21, 7503. [Google Scholar] [CrossRef]

- The Perfluoro-Compound NEC-1700. Available online: https://www.paiqinano.com/wp-content/uploads/2021/11/NEC-1700-TDS.pdf (accessed on 27 February 2024).

- Uijlenhoet, R.; Stricker, J.N.M. A consistent rainfall parameterization based on the exponential raindrop size distribution. J. Hydrol. 1999, 218, 101–127. [Google Scholar] [CrossRef]

| Different State | Frequency (Hz) | Amplitude (V) | Qsi (nC) | Vse (mL) |

|---|---|---|---|---|

| Light rain | 0.62 | 4.14 | 1.5 | 25.0821 |

| Middle rain | 1.00 | 8.37 | 3.5 | 61.5686 |

| Heavy rain | 1.67 | 16.62 | 5.0 | 201.9780 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Guo, L.; Ding, Z.; Zhao, Z.; Liu, C.; Che, L. Self-Powered Intelligent Water Droplet Monitoring Sensor Based on Solid–Liquid Triboelectric Nanogenerator. Sensors 2024, 24, 1761. https://doi.org/10.3390/s24061761

Zhu L, Guo L, Ding Z, Zhao Z, Liu C, Che L. Self-Powered Intelligent Water Droplet Monitoring Sensor Based on Solid–Liquid Triboelectric Nanogenerator. Sensors. 2024; 24(6):1761. https://doi.org/10.3390/s24061761

Chicago/Turabian StyleZhu, Lijie, Likang Guo, Zhi Ding, Zhengqian Zhao, Chaoran Liu, and Lufeng Che. 2024. "Self-Powered Intelligent Water Droplet Monitoring Sensor Based on Solid–Liquid Triboelectric Nanogenerator" Sensors 24, no. 6: 1761. https://doi.org/10.3390/s24061761