A High-Performance Flexible Hydroacoustic Transducer Based on 1-3 PZT-5A/Silicone Rubber Composite

Abstract

1. Introduction

2. Design of the Flexible Piezoelectric Composite Hydroacoustic Transducer

2.1. Structure of the Flexible Piezoelectric Composite Hydroacoustic Transducer

2.2. Finite Element Analysis of the Flexible Piezoelectric Composite Hydroacoustic Transducer

3. Fabrication and Measurement of the Flexible Piezoelectric Composite Hydroacoustic Transducer

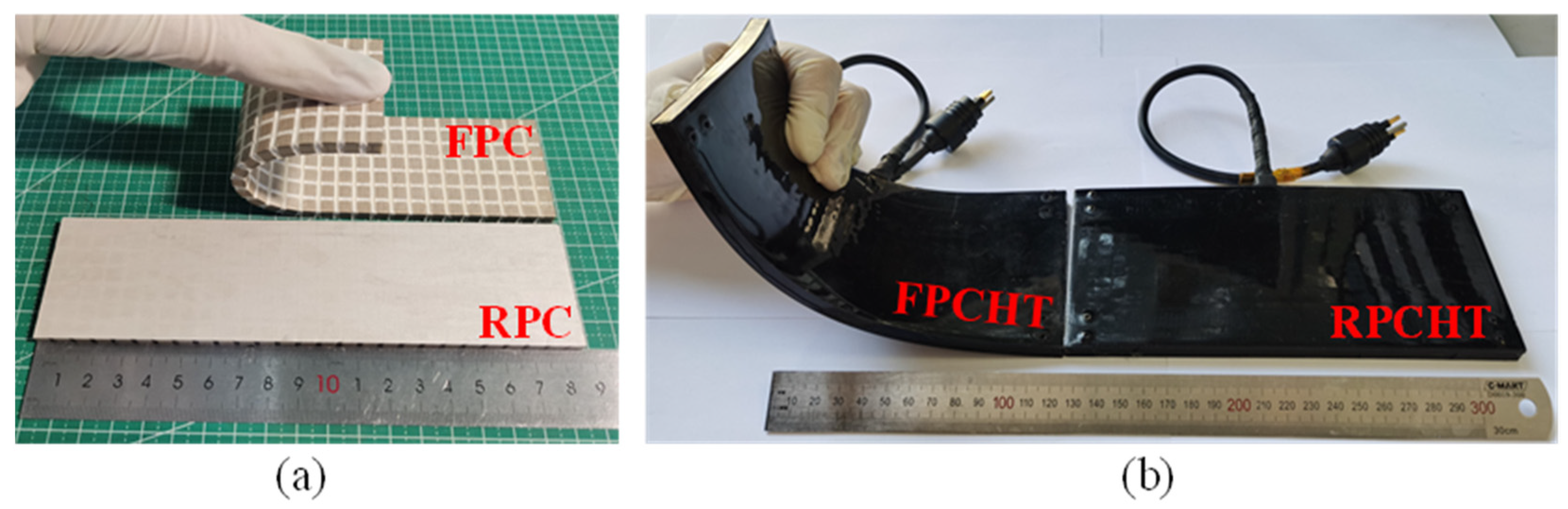

3.1. Fabrication of the Flexible Piezoelectric Composite Hydroacoustic Transducer

3.2. Measurement of the Flexible Piezoelectric Composite Hydroacoustic Transducer

4. Result and Discussion

4.1. Performance Characterization of the Flexible Piezoelectric Composites

4.2. Performance Characterization of the Flexible Piezoelectric Composite Hydroacoustic Transducer

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Martins, M.S.; Faria, C.L.; Matos, T.; Goncalves, L.M.; Cabral, J.; Silva, A.; Jesus, S.M. Wideband and Wide Beam Polyvinylidene Difluoride (PVDF) Acoustic Transducer for Broadband Underwater Communications. Sensors 2019, 19, 3991. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q.; He, Z.; Xu, H. Research and Experimental Verification of a Flextensional Disk Transducer Based on Relaxor Ferroelectric Single Crystals. IEEE Sens. J. 2022, 22, 19431–19438. [Google Scholar] [CrossRef]

- Rong, T.; Wang, C. Research on a stacked high-sensitivity hydroacoustic transducer. Sens. Rev. 2023, 43, 72–82. [Google Scholar] [CrossRef]

- Ehrenberg, J. Two applications for a dual-beam transducer in hydroacoustic fish assessment systems. In Proceedings of the Ocean’74-IEEE International Conference on Engineering in the Ocean Environment, Halifax, Nova Scotia, 21–23 August 1974; IEEE: Piscataway, NJ, USA, 1974; pp. 152–155. [Google Scholar]

- Uchino, K. Piezoelectric ceramics for transducers. In Ultrasonic Transducers; Elsevier: Amsterdam, The Netherlands, 2012; pp. 70–116. [Google Scholar]

- Trolier-McKinstry, S.; Zhang, S.J.; Bell, A.J.; Tan, X.L. High-Performance Piezoelectric Crystals, Ceramics, and Films. Annu. Rev. Mater. Res. 2018, 48, 191–217. [Google Scholar] [CrossRef]

- Li, F.; Cabral, M.J.; Xu, B.; Cheng, Z.X.; Dickey, E.C.; LeBeau, J.M.; Wang, J.L.; Luo, J.; Taylor, S.; Hackenberger, W.; et al. Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3 single crystals. Science 2019, 364, 264–268. [Google Scholar] [CrossRef]

- Zhang, S.J.; Li, F.; Jiang, X.N.; Kim, J.; Luo, J.; Geng, X.C. Advantages and challenges of relaxor-PbTiO3 ferroelectric crystals for electroacoustic transducers—A review. Prog. Mater. Sci. 2015, 68, 1–66. [Google Scholar] [CrossRef] [PubMed]

- Yamashita, Y.; Karaki, T.; Lee, H.Y.; Wan, H.T.; Kim, H.P.; Jiang, X.N. A Review of Lead Perovskite Piezoelectric Single Crystals and Their Medical Transducers Application. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2022, 69, 3048–3056. [Google Scholar] [CrossRef] [PubMed]

- Bauer, S.; Bauer, F. Piezoelectric polymers and their applications. In Piezoelectricity: Evolution and Future of a Technology; Springer: Berlin/Heidelberg, Germany, 2008; pp. 157–177. [Google Scholar]

- Ting, R.Y. A review on the development of piezoelectric composites for underwater acoustic transducer applications. IEEE Trans. Instrum. Meas. 1992, 41, 64–67. [Google Scholar] [CrossRef]

- Zhen, Y.H.; Li, J.F.; Zhang, H.L. Electrical and elastic properties of 1-3 PZT/epoxy piezoelectric composites. J. Electroceramics 2008, 21, 410–413. [Google Scholar] [CrossRef]

- Newnham, R.; Skinner, D.; Cross, L. Connectivity and piezoelectric-pyroelectric composites. Mater. Res. Bull. 1978, 13, 525–536. [Google Scholar] [CrossRef]

- Tressler, J.F. Piezoelectric transducer designs for sonar applications. In Piezoelectric and Acoustic Materials for Transducer Applications; Springer: Berlin/Heidelberg, Germany, 2008; pp. 217–239. [Google Scholar]

- Howarth, T.R.; Ting, R.Y. Electroacoustic evaluations of 1–3 piezocomposite SonoPanel/sup TM/materials. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2000, 47, 886–894. [Google Scholar] [CrossRef]

- Zhong, C.; Xu, J.N.; Hao, S.H.; Zhang, Y.J.; Wang, L.K.; Qin, L. High-frequency wide beam underwater transducer based on 1-3 piezocomposite. Ferroelectr. Lett. Sect. 2021, 48, 93–103. [Google Scholar] [CrossRef]

- Hao, S.H.; Wang, H.W.; Zhong, C.; Wang, L.K.; Zhang, H. Research and Fabrication of High-Frequency Broadband and Omnidirectional Transmitting Transducer. Sensors 2018, 18, 2347. [Google Scholar] [CrossRef]

- Wang, Y.C.; Lin, X.J.; Li, J.N.; Huang, S.F.; Cheng, X. Effect of structural parameters and stability of constituent materials on the performance of 1-3 spherical crown piezocomposite and transducer. Sens. Actuators A-Phys. 2018, 278, 18–24. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, L.K.; Qin, L.; Zhong, C.; Hao, S.H. Spherical-Omnidirectional Piezoelectric Composite Transducer for High- Frequency Underwater Acoustics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 1791–1796. [Google Scholar] [CrossRef]

- Skinner, D.; Newnham, R.; Cross, L. Flexible composite transducers. Mater. Res. Bull. 1978, 13, 599–607. [Google Scholar] [CrossRef]

- Tang, T.X.; Shen, Z.H.; Wang, J.; Xu, S.Q.; Jiang, J.X.; Chang, J.H.; Guo, M.F.; Fan, Y.J.; Xiao, Y.; Dong, Z.H.; et al. Stretchable polymer composites with ultrahigh piezoelectric performance. Natl. Sci. Rev. 2023, 10, nwad177. [Google Scholar] [CrossRef]

- Kim, T.; Cui, Z.; Chang, W.Y.; Kim, H.; Zhu, Y.; Jiang, X.N. Flexible 1–3 Composite Ultrasound Transducers with Silver-Nanowire-Based Stretchable Electrodes. IEEE Trans. Ind. Electron. 2020, 67, 6955–6962. [Google Scholar] [CrossRef]

- Peng, C.; Chen, M.Y.; Sim, H.K.; Zhu, Y.; Jiang, X.N. A Flexible Piezo-Composite Ultrasound Blood Pressure Sensor with Silver Nanowire-based Stretchable Electrodes. In Proceedings of the IEEE 15th International Conference on Nano/Micro Engineered and Molecular System (NEMS), San Diego, CA, USA, 27–30 September 2020; pp. 143–146. [Google Scholar]

- Azani, M.R.; Hassanpour, A.; Torres, T. Benefits, Problems, and Solutions of Silver Nanowire Transparent Conductive Electrodes in Indium Tin Oxide (ITO)-Free Flexible Solar Cells. Adv. Energy Mater. 2020, 10, 2002536. [Google Scholar] [CrossRef]

- Hao, S.H.; Zhong, C.; Zhang, Y.J.; Chen, Y.X.; Wang, L.K.; Qin, L. Flexible 1–3 Piezoelectric Composites with Soft Embedded Conductive Interconnects for Underwater Acoustic Transducers. ACS Appl. Electron. Mater. 2023, 5, 2686–2695. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Elasticity Constant (×1010 N/m2) | Piezoelectric Constant (C/m2) | Relative Permittivity |

|---|---|---|---|---|

| PZT-5A | 7750 | |

| Polymer | Density (kg/m3) | Young’s Modulus (Pa) | Poisson’s Ratio |

|---|---|---|---|

| silicon rubber | 1000 | 2.55 × 106 | 0.48 |

| epoxy resin | 1050 | 3.6 × 109 | 0.35 |

| Thickness | FPCHT | RPCHT |

|---|---|---|

| Transducer | 9.56 mm | 9.5 mm |

| Sensitive core | 5.12 mm | 5.04 mm |

| Island-bridge electrode | 0.06 mm | 0.02 mm |

| Waterproof layer | 2.22 mm | 2.23 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, S.; Zhong, C.; Wang, L.; Qin, L. A High-Performance Flexible Hydroacoustic Transducer Based on 1-3 PZT-5A/Silicone Rubber Composite. Sensors 2024, 24, 2081. https://doi.org/10.3390/s24072081

Hao S, Zhong C, Wang L, Qin L. A High-Performance Flexible Hydroacoustic Transducer Based on 1-3 PZT-5A/Silicone Rubber Composite. Sensors. 2024; 24(7):2081. https://doi.org/10.3390/s24072081

Chicago/Turabian StyleHao, Shaohua, Chao Zhong, Likun Wang, and Lei Qin. 2024. "A High-Performance Flexible Hydroacoustic Transducer Based on 1-3 PZT-5A/Silicone Rubber Composite" Sensors 24, no. 7: 2081. https://doi.org/10.3390/s24072081

APA StyleHao, S., Zhong, C., Wang, L., & Qin, L. (2024). A High-Performance Flexible Hydroacoustic Transducer Based on 1-3 PZT-5A/Silicone Rubber Composite. Sensors, 24(7), 2081. https://doi.org/10.3390/s24072081