Impact of Solid Materials in the Gap Space between Driving Electrodes in a MEMS Tri-Electrode Electrostatic Actuator

Abstract

1. Introduction

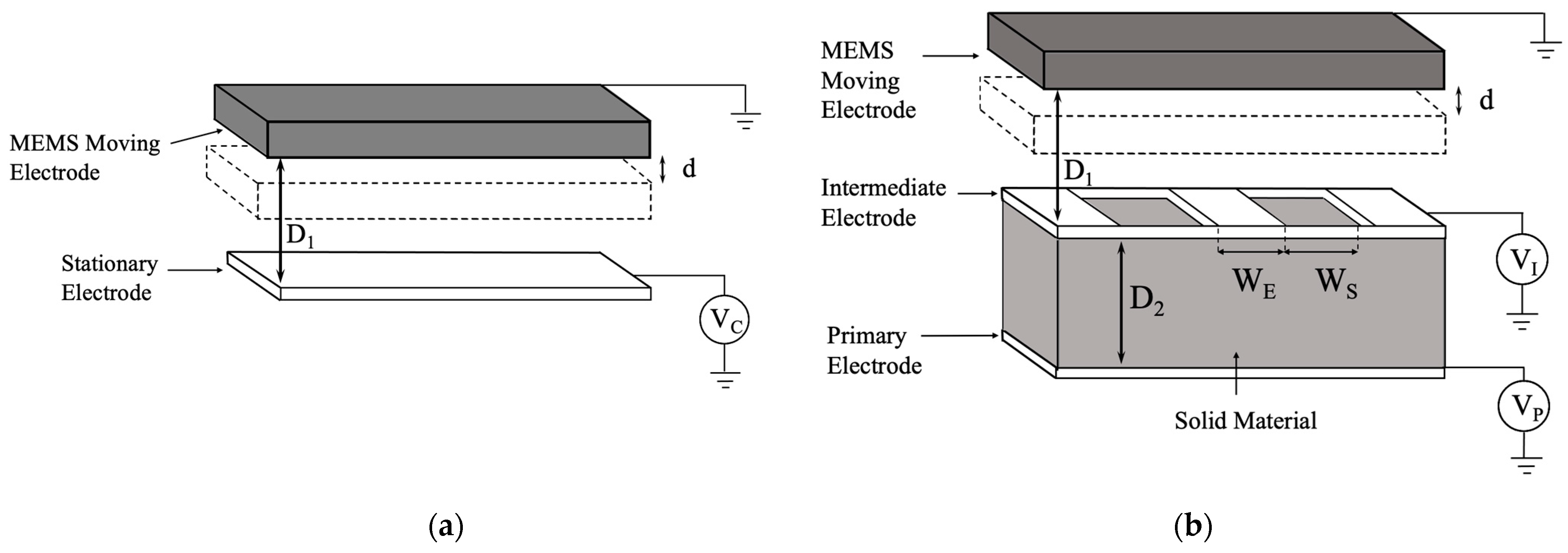

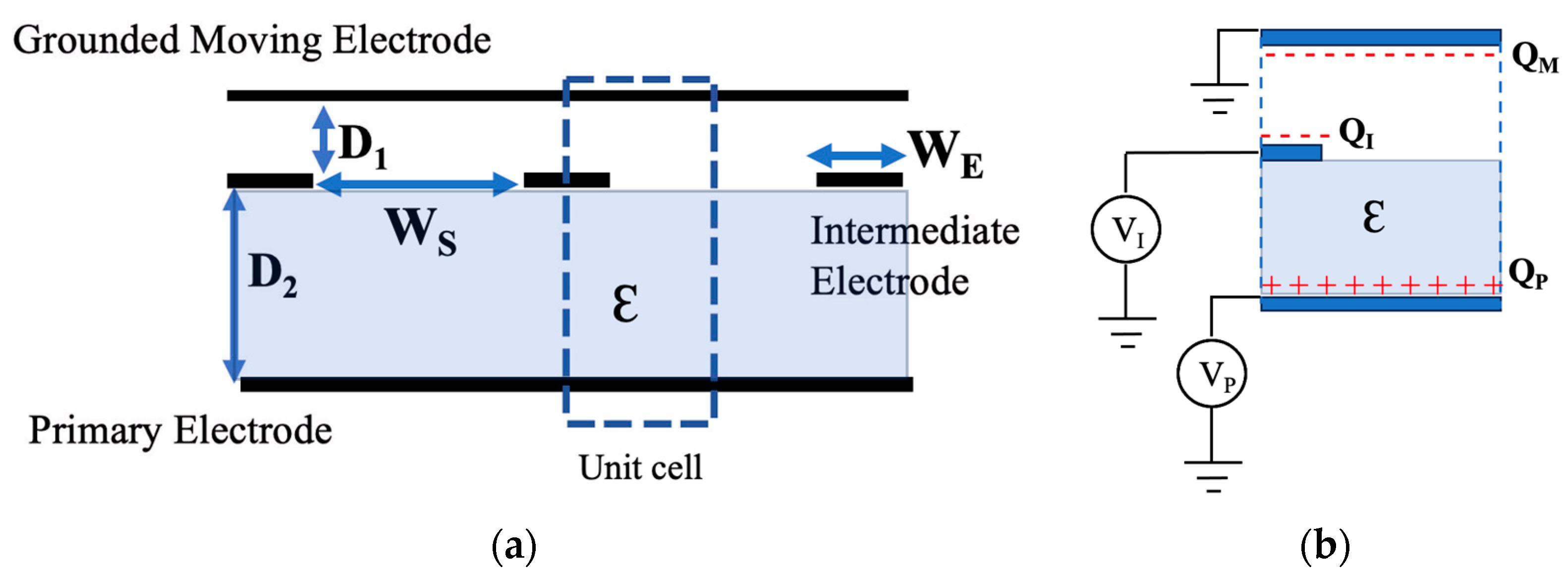

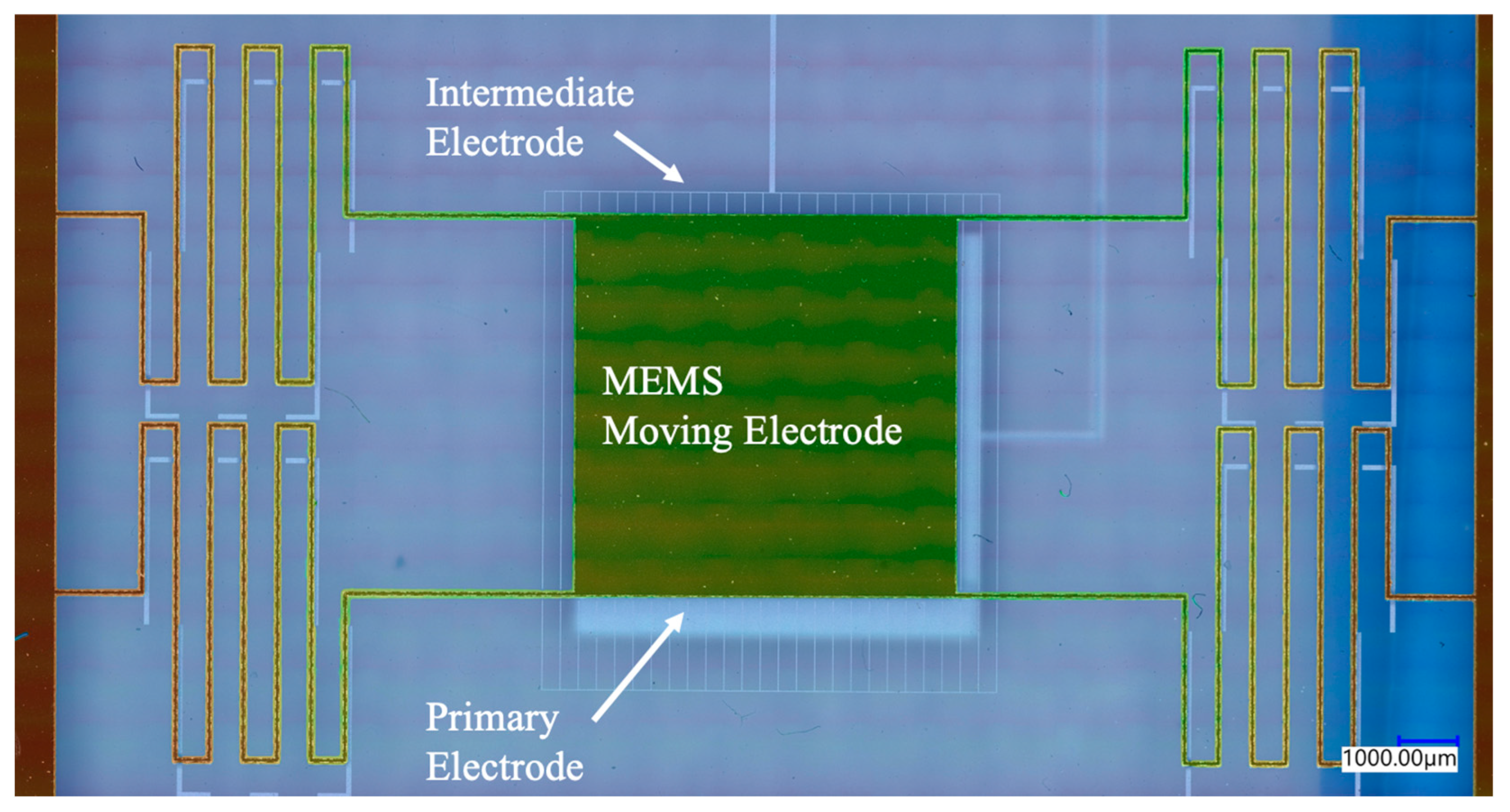

2. Tri-Electrode Topology

2.1. Tri-Electrode Configuration

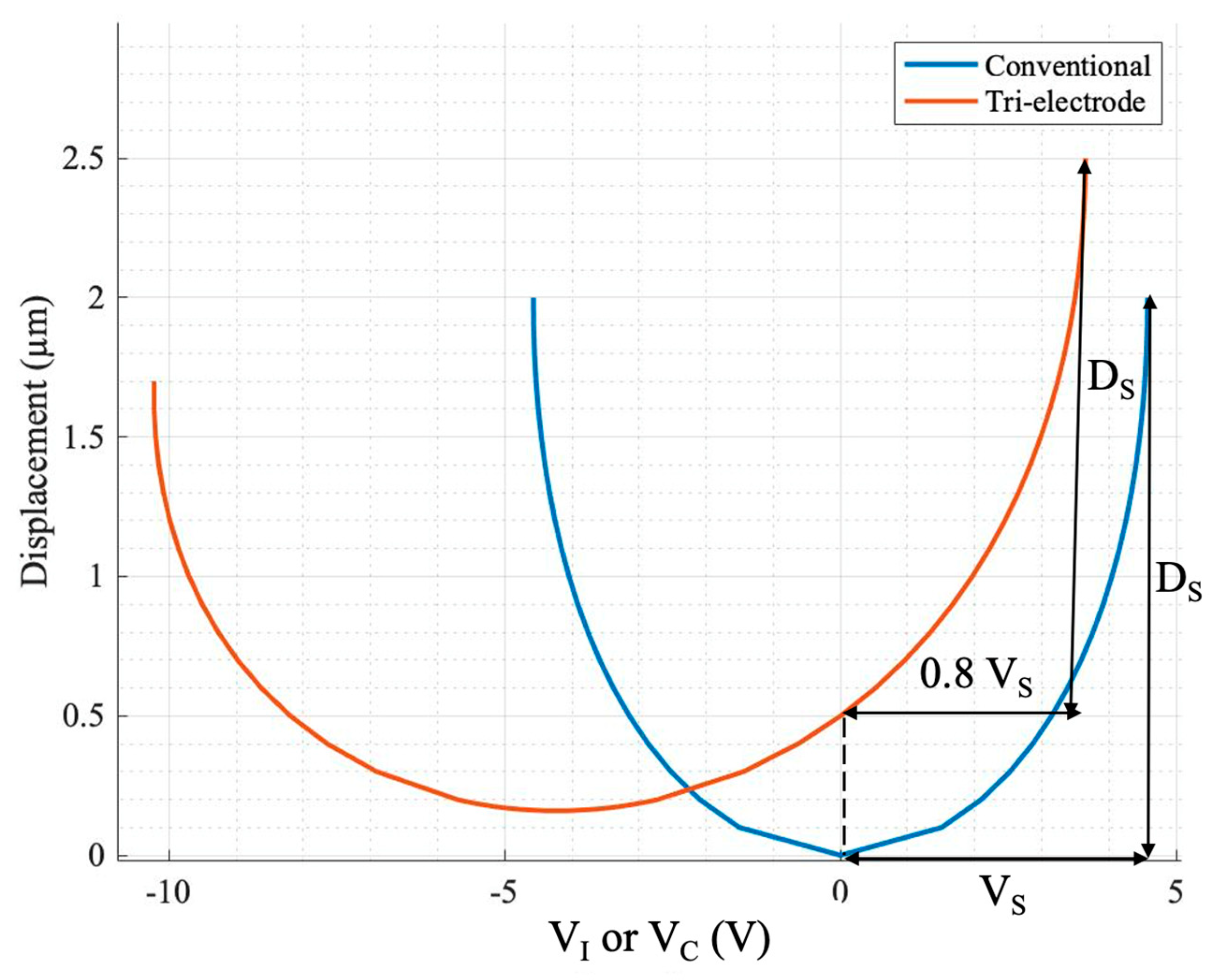

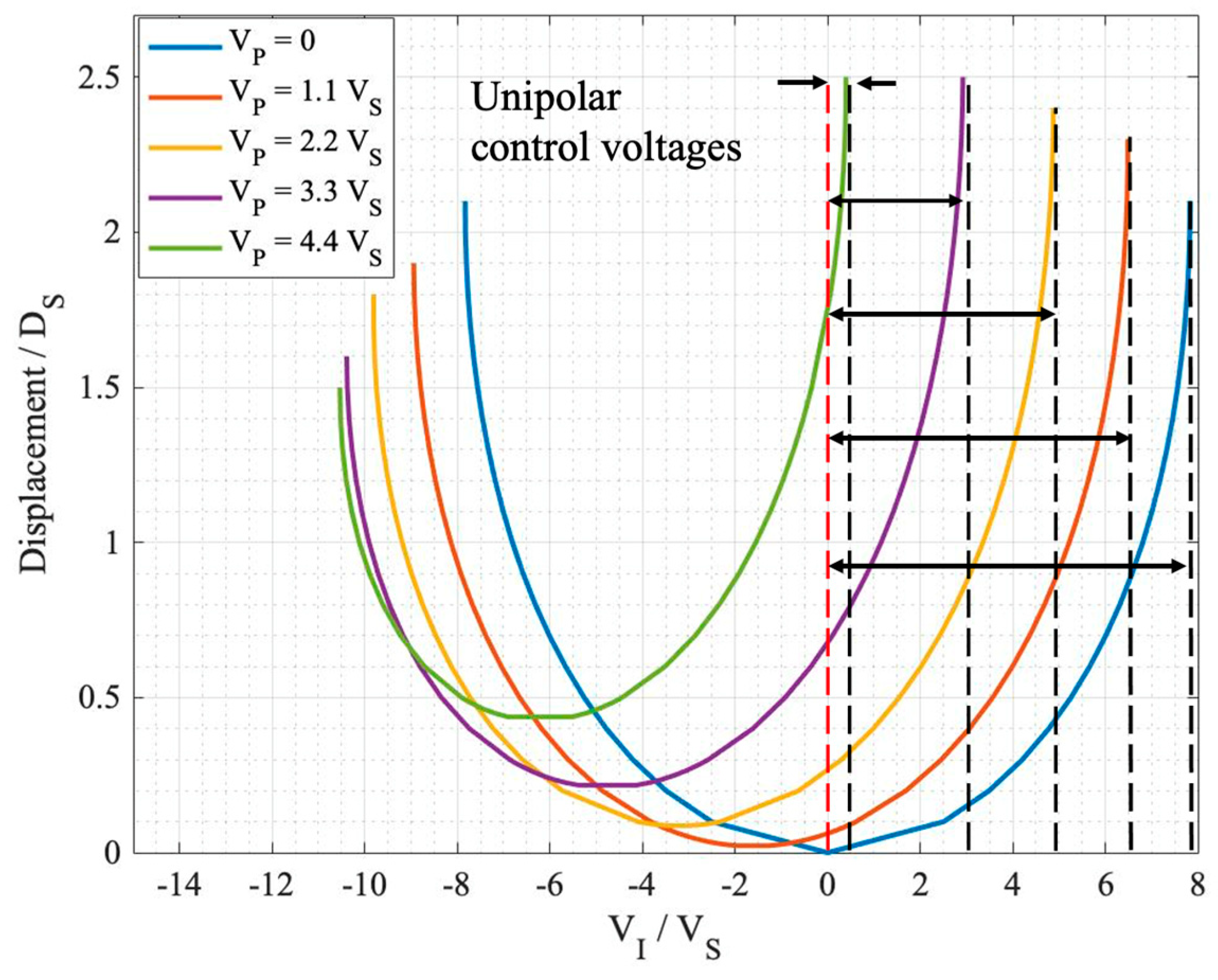

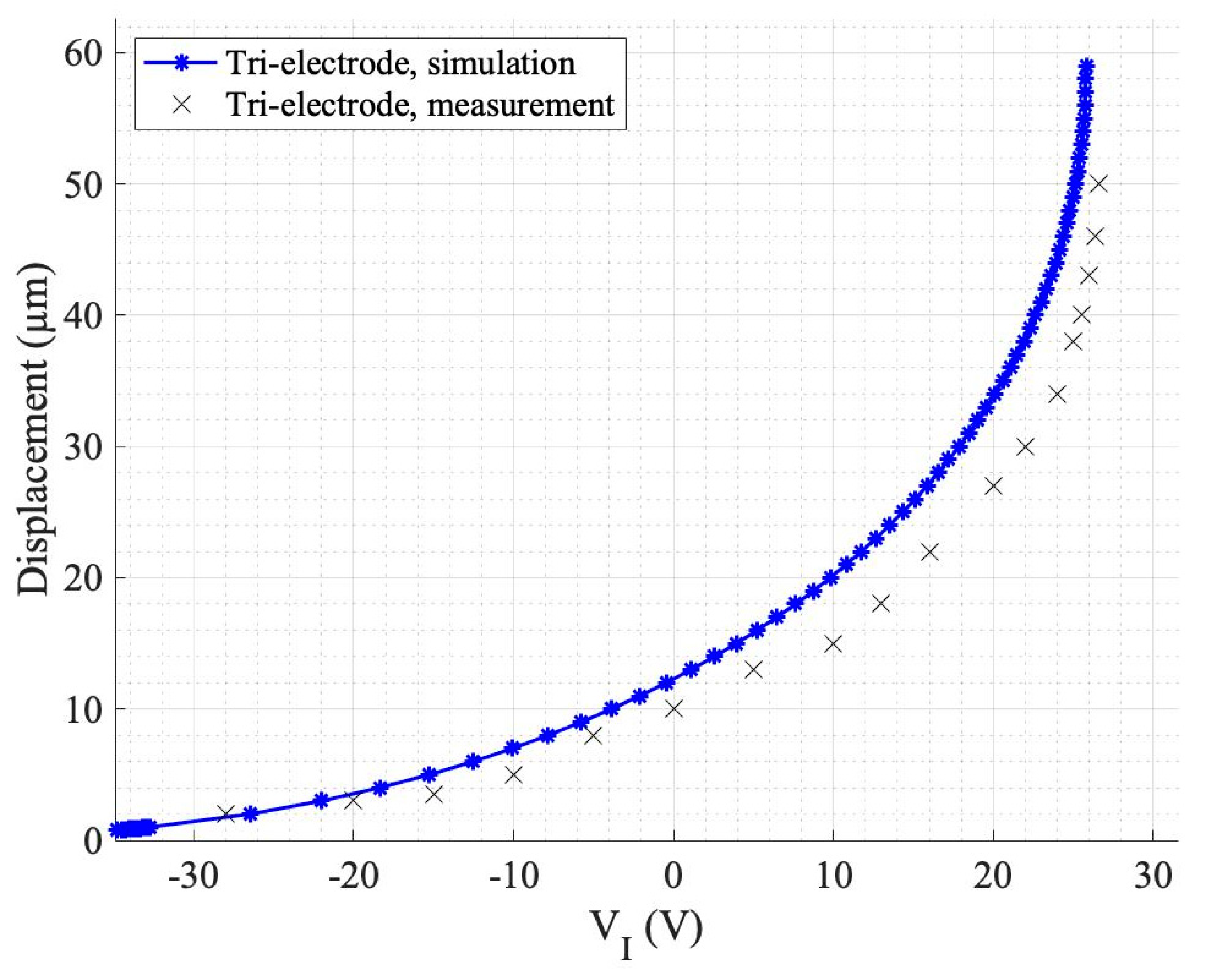

2.2. Tri-Electrode Response Curve

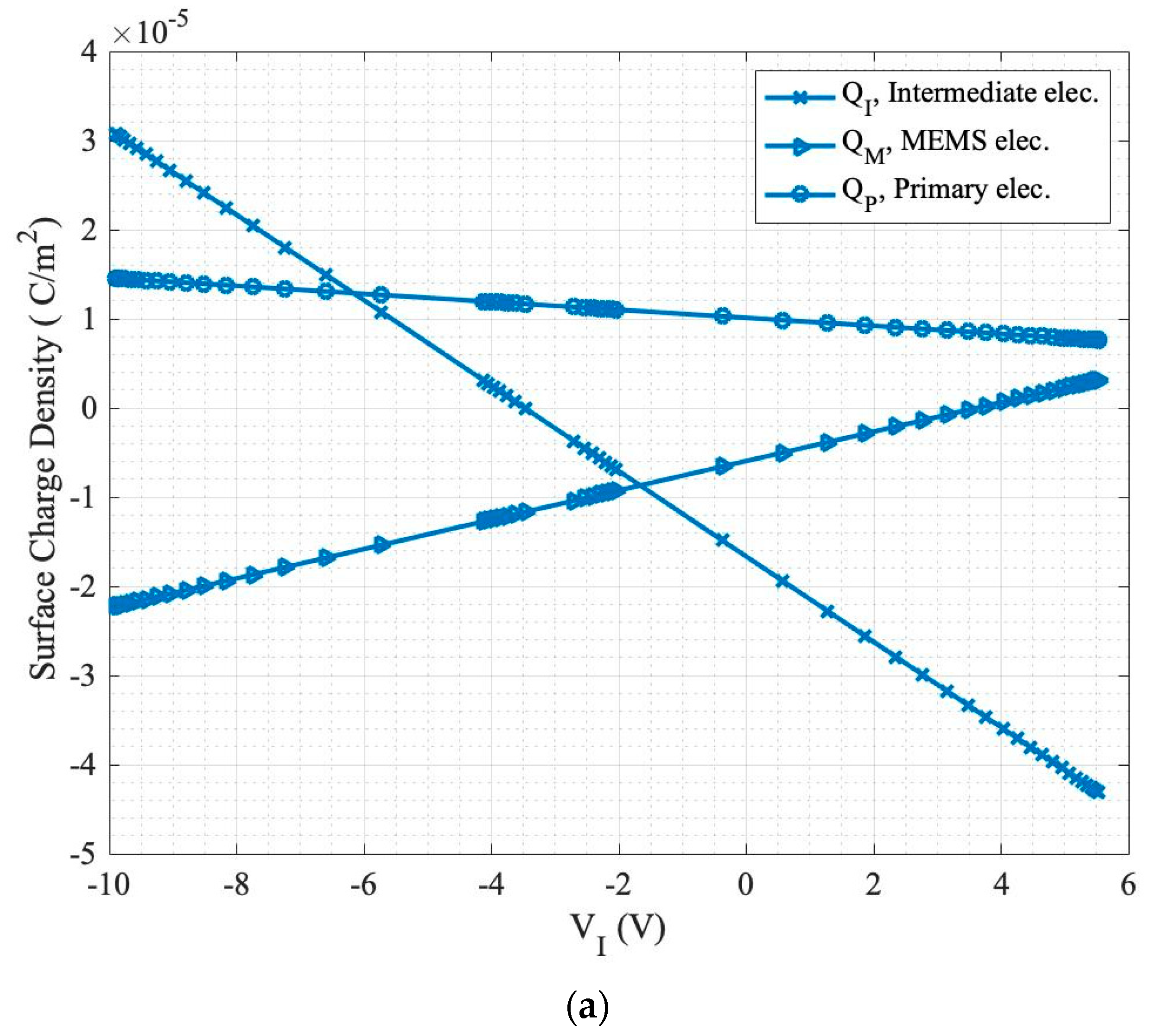

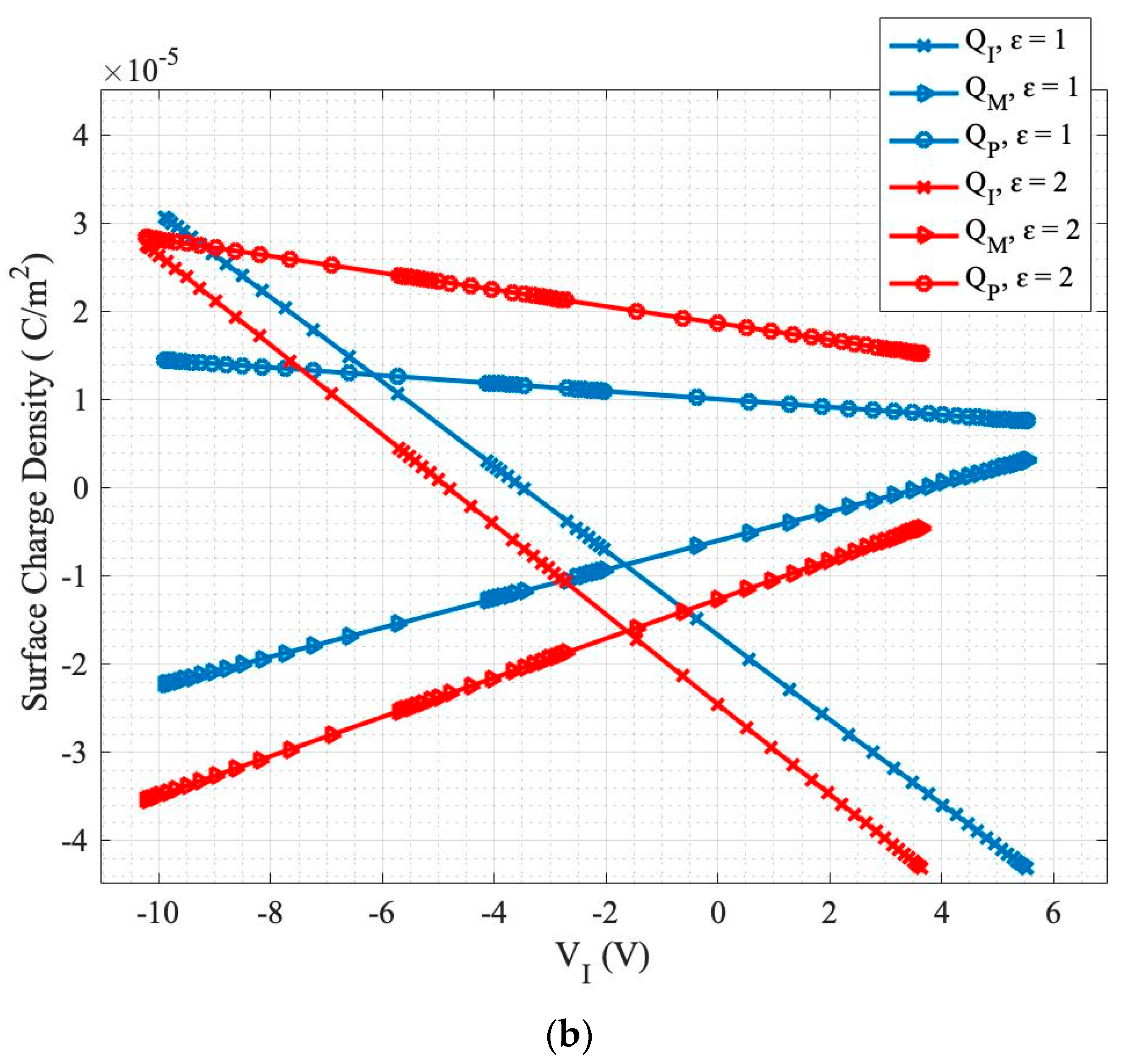

2.3. Tri-Electrode Charge Analysis

- The charge on the primary electrode declines, but always stays positive.

- When comparing the stored surface charges on the MEMS and primary electrodes (shown in Figure 4a), it can be seen that the charges have opposite polarities. The highest difference occurs at VI = −10 V, which is the negative snap-down voltage. As VI increases toward 5.5 V, the positive snap-down voltage, the charge values converge to a very close value. This observation suggests that increasing VI results in a greater proportion of electric forces being directed towards the MEMS electrode, while less energy is dissipated within the solid material separating the intermediate and primary electrodes.

- The intermediate electrode’s surface charge density declines at a higher rate than the other two electrodes’ changes. As it is a smaller electrode, it should accumulate charges faster to balance the overall zero charge.

- For comparison, the surface charge density of a conventional two-electrode topology exhibits identical values for the charge per unit area at ±VI, yet with opposite polarities. This can be concluded from the analytical solutions in the literature.

3. Numerical Analysis

4. Discussion

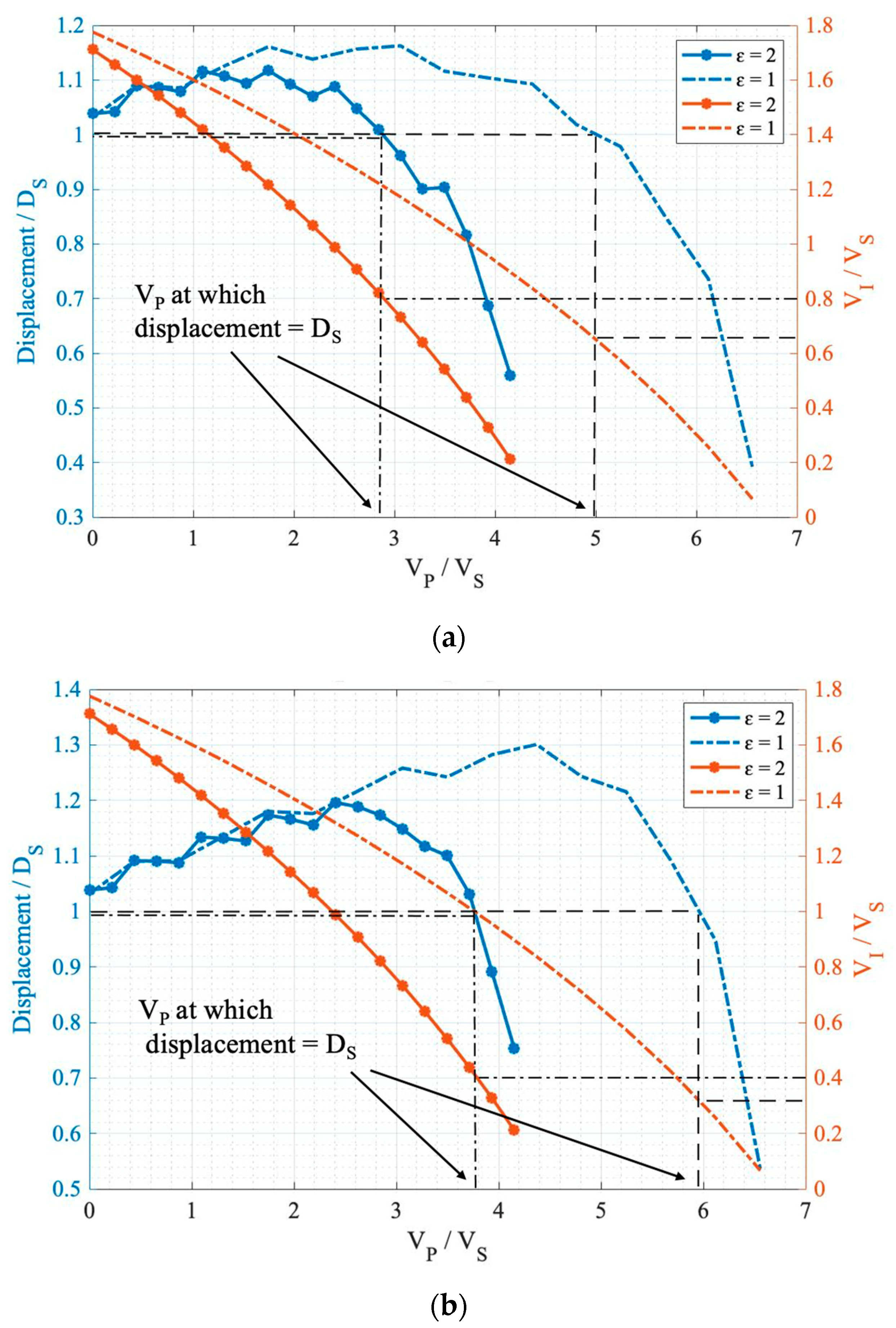

4.1. Unipolar

4.2. Bipolar

4.3. Maximum Displacement

4.4. Numerical Results Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohd Ghazali, F.A.; Hasan, M.N.; Rehman, T.; Nafea, M.; Mohamed Ali, M.S.; Takahata, K. MEMS Actuators for Biomedical Applications: A Review. J. Micromech. Microeng. 2020, 30, 073001. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, X.; Kundu, S.; Nag, A.; Afsarimanesh, N.; Sapra, S.; Mukhopadhyay, S.C.; Han, T. Silicon-Based Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 2908. [Google Scholar] [CrossRef]

- Song, P.; Ma, Z.; Ma, J.; Yang, L.; Wei, J.; Zhao, Y.; Zhang, M.; Yang, F.; Wang, X. Recent Progress of Miniature MEMS Pressure Sensors. Micromachines 2020, 11, 56. [Google Scholar] [CrossRef]

- Fong, C.-F.; Dai, C.-L.; Wu, C.-C. Fabrication and Characterization of a Micro Methanol Sensor Using the CMOS-MEMS Technique. Sensors 2015, 15, 27047–27059. [Google Scholar] [CrossRef]

- Asri, M.I.A.; Hasan, M.N.; Fuaad, M.R.A.; Yunos, Y.M.; Ali, M.S.M. MEMS Gas Sensors: A Review. IEEE Sens. J. 2021, 21, 18381–18397. [Google Scholar] [CrossRef]

- Tsai, C.; Tsai, J. MEMS Optical Switches and Interconnects. Displays 2015, 37, 33–40. [Google Scholar] [CrossRef]

- Hajare, R.; Reddy, V.; Srikanth, R. MEMS Based Sensors—A Comprehensive Review of Commonly Used Fabrication Techniques. Mater. Today Proc. 2022, 49, 720–730. [Google Scholar] [CrossRef]

- Cao, T.; Hu, T.; Zhao, Y. Research Status and Development Trend of MEMS Switches: A Review. Micromachines 2020, 11, 694. [Google Scholar] [CrossRef]

- Morkvenaite-Vilkonciene, I.; Bucinskas, V.; Subaciute-Zemaitiene, J.; Sutinys, E.; Virzonis, D.; Dzedzickis, A. Development of Electrostatic Microactuators: 5-Year Progress in Modeling, Design, and Applications. Micromachines 2022, 13, 1256. [Google Scholar] [CrossRef]

- Velosa-Moncada, L.; Aguilera-Cortés, L.; González-Palacios, M.; Raskin, J.-P.; Herrera-May, A. Design of a Novel MEMS Microgripper with Rotatory Electrostatic Comb-Drive Actuators for Biomedical Applications. Sensors 2018, 18, 1664. [Google Scholar] [CrossRef]

- Feng, J.; Liu, C.; Zhang, W.; Han, J.; Hao, S. Mechanical Behaviors Research and the Structural Design of a Bipolar Electrostatic Actuation Microbeam Resonator. Sensors 2019, 19, 1348. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.; Younis, M.I. RF MEMS Electrostatically Actuated Tunable Capacitors and Their Applications: A Review. J. Micromech. Microeng. 2022, 32, 013002. [Google Scholar] [CrossRef]

- Mirzazadeh, R.; Eftekhar Azam, S.; Mariani, S. Micromechanical Characterization of Polysilicon Films through On-Chip Tests. Sensors 2016, 16, 1191. [Google Scholar] [CrossRef] [PubMed]

- Chuang, W.-C.; Lee, H.-L.; Chang, P.-Z.; Hu, Y.-C. Review on the Modeling of Electrostatic MEMS. Sensors 2010, 10, 6149–6171. [Google Scholar] [CrossRef]

- Poletkin, K.; Asadollahbaik, A.; Kampmann, R.; Korvink, J. Levitating Micro-Actuators: A Review. Actuators 2018, 7, 17. [Google Scholar] [CrossRef]

- Leroy, E.; Hinchet, R.; Shea, H. Multimode Hydraulically Amplified Electrostatic Actuators for Wearable Haptics. Adv. Mater. 2020, 32, 2002564. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, S.; Younis, M.I. Resonator-Based M/NEMS Logic Devices: Review of Recent Advances. Sens. Actuators A Phys. 2020, 302, 111821. [Google Scholar] [CrossRef]

- Errando-Herranz, C.; Takabayashi, A.Y.; Edinger, P.; Sattari, H.; Gylfason, K.B.; Quack, N. MEMS for Photonic Integrated Circuits. IEEE J. Select. Top. Quantum Electron. 2020, 26, 8200916. [Google Scholar] [CrossRef]

- Quack, N.; Takabayashi, A.Y.; Sattari, H.; Edinger, P.; Jo, G.; Bleiker, S.J.; Errando-Herranz, C.; Gylfason, K.B.; Niklaus, F.; Khan, U.; et al. Integrated Silicon Photonic MEMS. Microsyst. Nanoeng. 2023, 9, 27. [Google Scholar] [CrossRef]

- Naito, Y.; Nakamura, K.; Uenishi, K. Laterally Movable Triple Electrodes Actuator toward Low Voltage and Fast Response RF-MEMS Switches. Sensors 2019, 19, 864. [Google Scholar] [CrossRef]

- Chen, S.; Tan, M.W.M.; Gong, X.; Lee, P.S. Low-Voltage Soft Actuators for Interactive Human–Machine Interfaces. Adv. Intell. Syst. 2022, 4, 2100075. [Google Scholar] [CrossRef]

- Sattari, H.; Takabayashi, A.Y.; Edinger, P.; Verheyen, P.; Gylfason, K.B.; Bogaerts, W.; Quack, N. Low-Voltage Silicon Photonic MEMS Switch with Vertical Actuation. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 298–301. [Google Scholar] [CrossRef]

- Shanthi, G.; Srinivasa Rao, K.; Girija Sravani, K. Design and Analysis of a RF MEMS Shunt Switch Using U-Shaped Meanders for Low Actuation Voltage. Microsyst. Technol. 2020, 26, 3783–3791. [Google Scholar] [CrossRef]

- Zhu, Y.; Pal, J. Low-Voltage and High-Reliability RF MEMS Switch with Combined Electrothermal and Electrostatic Actuation. Micromachines 2021, 12, 1237. [Google Scholar] [CrossRef] [PubMed]

- Verma, S.K.; Mitra, B. Pull-in Voltage Reduction in Electrostatic Airgap Actuator Using 12 NM-Ultrathin Internal Dielectric Transduction. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems (MEMS), Munich, Germany, 15–19 January 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 689–692. [Google Scholar] [CrossRef]

- Allameh, M.; Shafai, C. Tri-Electrode MEMS Electrostatic Actuator with Lower Control Voltage and Higher Stroke for Actuator Array Implementations. J. Electrost. 2021, 114, 103635. [Google Scholar] [CrossRef]

- Allameh, M.; Park, B.; Shafai, C. Enhanced Travel Range Bipolar Tri-Electrode Electrostatic Actuator Using Extended Background Electrode. In MOEMS and Miniaturized Systems XXI; Piyawattanametha, W., Park, Y.-H., Zappe, H., Eds.; SPIE: San Francisco, CA, USA, 2022; p. 25. [Google Scholar] [CrossRef]

- Allameh, M.; Zhou, Y.; Chen, T.; Chrusch, D.; Park, B.; Shafai, C. Experimental Analysis of a Low Controlling Voltage Tri-Electrode MEMS Electrostatic Actuator for Array Applications. J. Micromech. Microeng. 2023, 33, 035008. [Google Scholar] [CrossRef]

- Allameh, M.; Park, B.; Shafai, C. Low Voltage Tri-electrode Electrostatic Actuator Using Solid Gap-Spacing Materials. In Proceedings of the Eurosensors, Lecce, Italy, 10–13 September 2023. [Google Scholar]

- Allameh, M.; Park, B.; Shafai, C. Performance study of MEMS tri-electrode electrostatic actuator with glass and SU-8 between intermediate and primary electrodes. In Proceedings of the Micro and Nano Engineering (MNE), Leuven, Belgium, 19–23 September 2022. [Google Scholar]

- He, Z.; Xie, J.; Liao, Z.; Ma, Y.; Zhang, M.; Zhang, W.; Yue, H.; Gao, X. Hierarchical Porous Structure Contained Composite Polyimide Film with Enhanced Dielectric and Water Resistance Properties for Dielectric Material. Prog. Org. Coat. 2021, 151, 106030. [Google Scholar] [CrossRef]

- ATLAS Design and Technology. Available online: https://www.atlascables.com/design-insulation.html (accessed on 24 February 2024).

- Aastha; Kaur, A.; Dhillon, A.S.; Sidhu, E. Performance Analysis of Microstrip Patch Antenna Employing Acrylic, Teflon and Polycarbonate as Low Dielectric Constant Substrate Materials. In Proceedings of the 2016 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 23–25 March 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 2090–2093. [Google Scholar] [CrossRef]

- Chang, S.; Kuan, H.; Wu, H.; Yang, R.; Weng, M. Determination of Microwave Dielectric Constant by Two Microstrip Line Method Combined with EM Simulation. Micro Opt. Technol. Lett. 2006, 48, 2199–2201. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, Y.; Lu, H.; Yu, F. Dielectric Properties and Crystalline Characteristics of Borosilicate Glasses. J. Non-Cryst. Solids 2008, 354, 1128–1132. [Google Scholar] [CrossRef]

- Li, B.; Bian, H.; Fang, Y. Microstructure, Thermal, Mechanical, and Dielectric Properties of BaO–CaO–Al2O3–B2O3–SiO2 Glass-Ceramics. IOP Conf. Ser. Mater. Sci. Eng. 2017, 275, 012032. [Google Scholar] [CrossRef]

- Ucar, M.H.B.; Uras, E. A Compact Modified Two-Arm Rectangular Spiral Implantable Antenna Design for ISM Band Biosensing Applications. Sensors 2023, 23, 4883. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| D1 | Gap between MEMS and intermediate electrode |

| D2 | Gap between primary and intermediate electrode |

| WS | Perforation width of the intermediate electrode |

| WE | Electrode width of the intermediate electrode |

| VP | Voltage applied to the primary electrode (fixed voltage) |

| VI | Voltage applied to the intermediate electrode |

| ɛ | Dielectric constant of the material in D2 region |

| d | The amount of distance travelled by the MEMS electrode |

| Parameter | Value |

|---|---|

| D1 | 6 µm |

| D2 | 10 µm |

| WS | 15 µm |

| WE | 5 µm |

| VP | 13.2 V |

| ɛ | 2 |

| Material | Dielectric Constant | Ref. |

|---|---|---|

| Air | 1 | [31] |

| Microporous Polytetrafluoroethylene (PTFE) | 1.5 | [32] |

| Teflon | 2 | [33] |

| FR4 | 4.2 | [34] |

| Glass | 6.2 | [35,36] |

| Rogers 3210 | 10.2 | [37] |

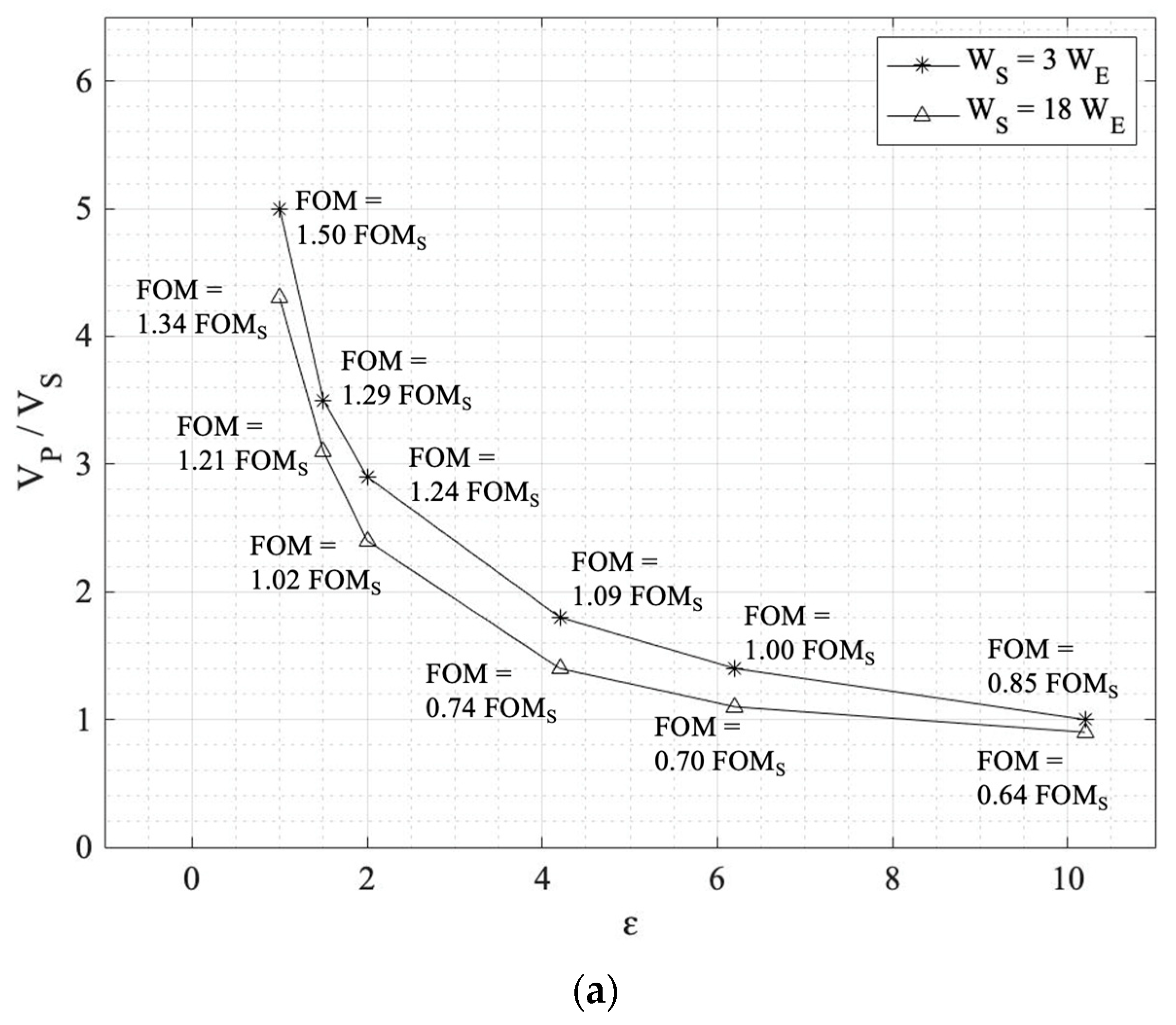

| ε | FOMu/FOMS | FOMb/FOMS | Max. Displacement/DS | |||

|---|---|---|---|---|---|---|

| WS = 3 WE | WS = 18 WE | WS = 3 WE | WS = 18 WE | WS = 3 WE | WS = 18 WE | |

| 1 | 1.50 (VP = 5.0 VS) | 1.34 (VP = 4.3 VS) | 3.10 (VP = 6.0 VS) | 2.70 (VP = 4.8 VS) | 1.30 (VP = 4.4 VS) | 1.62 (VP = 5.0 VS) |

| 1.5 | 1.29 (VP = 3.5 VS) | 1.21 (VP = 3.1 VS) | 2.62 (VP = 4.5 VS) | 2.26 (VP = 3.5 VS) | 1.25 (VP = 2.8 VS) | 1.46 (VP = 3.1 VS) |

| 2 | 1.24 (VP = 2.9 VS) | 1.02 (VP = 2.4 VS) | 2.41 (VP = 3.8 VS) | 2.08 (VP = 2.9 VS) | 1.19 (VP = 2.4 VS) | 1.35 (VP = 2.6 VS) |

| 4.2 | 1.09 (VP = 1.8 VS) | 0.74 (VP = 1.4 VS) | 2.12 (VP = 2.5 VS) | 1.59 (VP = 2.0 VS) | 1.11 (VP = 1.7 VS) | 1.20 (VP = 1.7 VS) |

| 6.2 | 1.00 (VP = 1.4 VS) | 0.70 (VP = 1.1 VS) | 1.60 (VP = 2.1 VS) | 1.25 (VP = 1.6 VS) | 1.08 (VP = 0.9 VS) | 1.13 (VP = 0.9 VS) |

| 10.2 ± 0.2 | 0.85 (VP = 1.0 VS) | 0.64 (VP = 0.9 VS) | 1.20 (VP = 1.6 VS) | 1.12 (VP = 1.4 VS) | 1.04 (VP = 0.4 VS) | 1.08 (VP = 0.6 VS) |

| Parameter | Value |

|---|---|

| D1 | 140 µm |

| D2 | 490 µm |

| WS | 300 µm |

| WE | 16.7 µm |

| VP | 109 V |

| ɛ | 3.82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allameh, M.; Park, B.; Shafai, C. Impact of Solid Materials in the Gap Space between Driving Electrodes in a MEMS Tri-Electrode Electrostatic Actuator. Sensors 2024, 24, 2743. https://doi.org/10.3390/s24092743

Allameh M, Park B, Shafai C. Impact of Solid Materials in the Gap Space between Driving Electrodes in a MEMS Tri-Electrode Electrostatic Actuator. Sensors. 2024; 24(9):2743. https://doi.org/10.3390/s24092743

Chicago/Turabian StyleAllameh, Mehdi, Byoungyoul Park, and Cyrus Shafai. 2024. "Impact of Solid Materials in the Gap Space between Driving Electrodes in a MEMS Tri-Electrode Electrostatic Actuator" Sensors 24, no. 9: 2743. https://doi.org/10.3390/s24092743

APA StyleAllameh, M., Park, B., & Shafai, C. (2024). Impact of Solid Materials in the Gap Space between Driving Electrodes in a MEMS Tri-Electrode Electrostatic Actuator. Sensors, 24(9), 2743. https://doi.org/10.3390/s24092743