Sensor for a Solid–Liquid Tribological System

Abstract

:1. Introduction

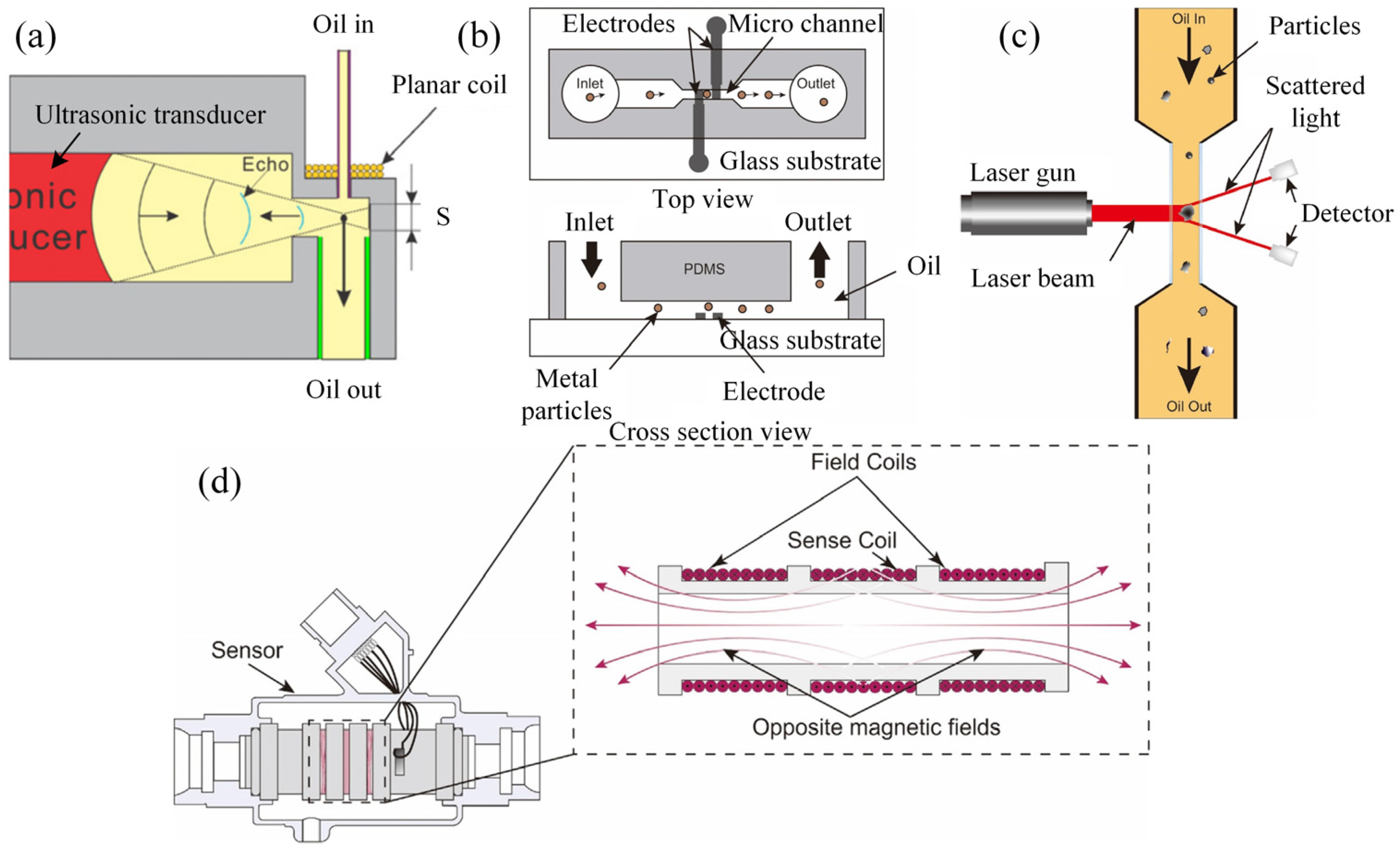

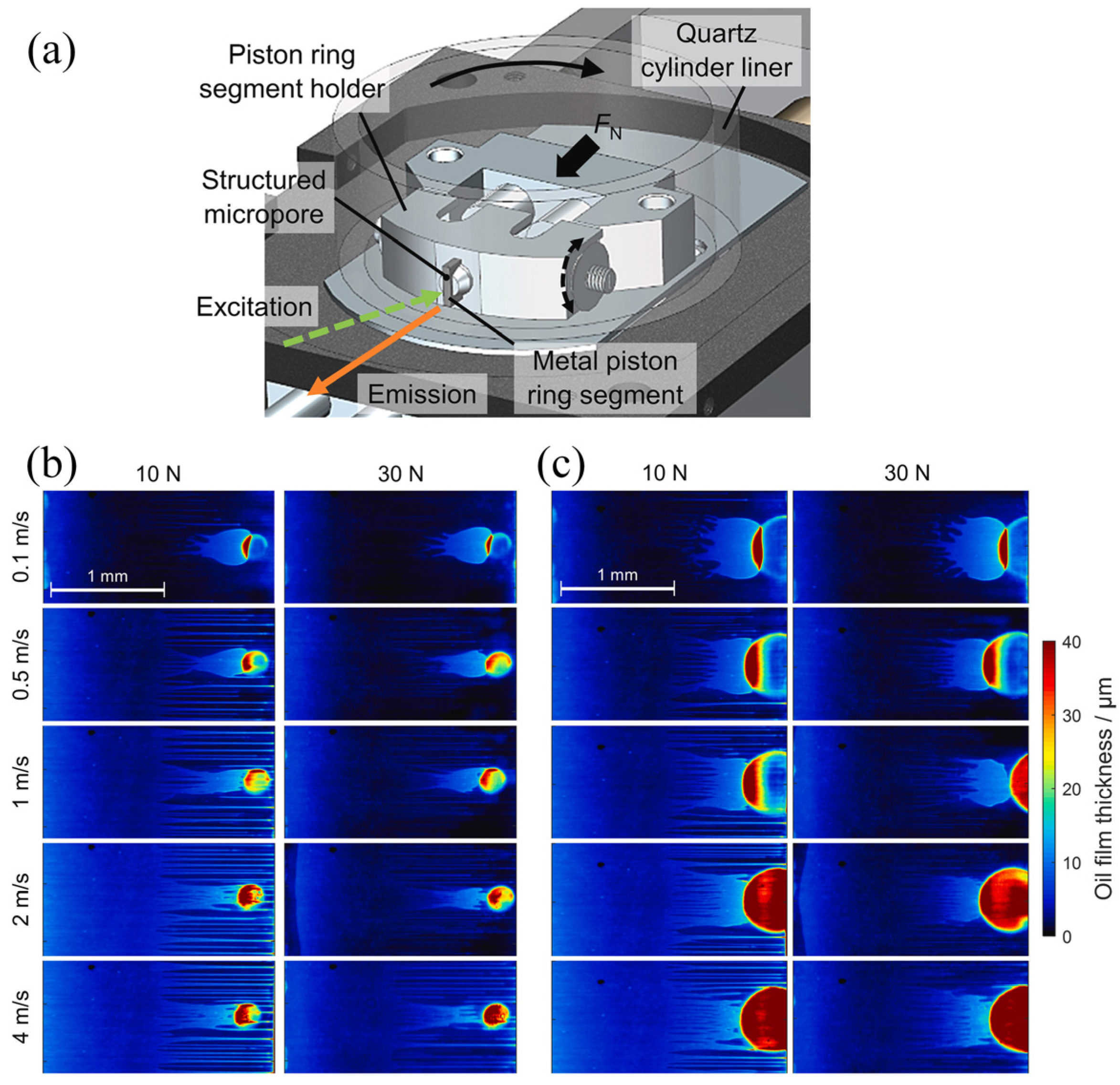

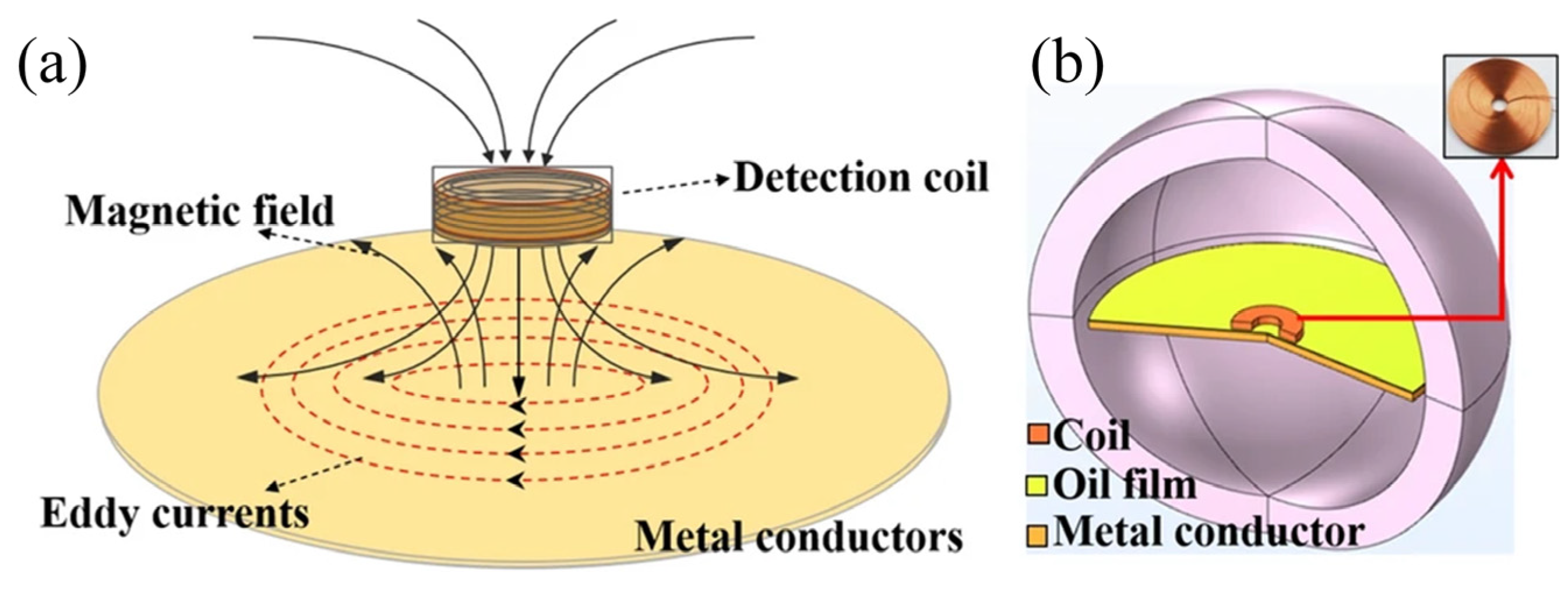

2. Probing Lubricant Properties

3. Probing Friction and Wear Properties

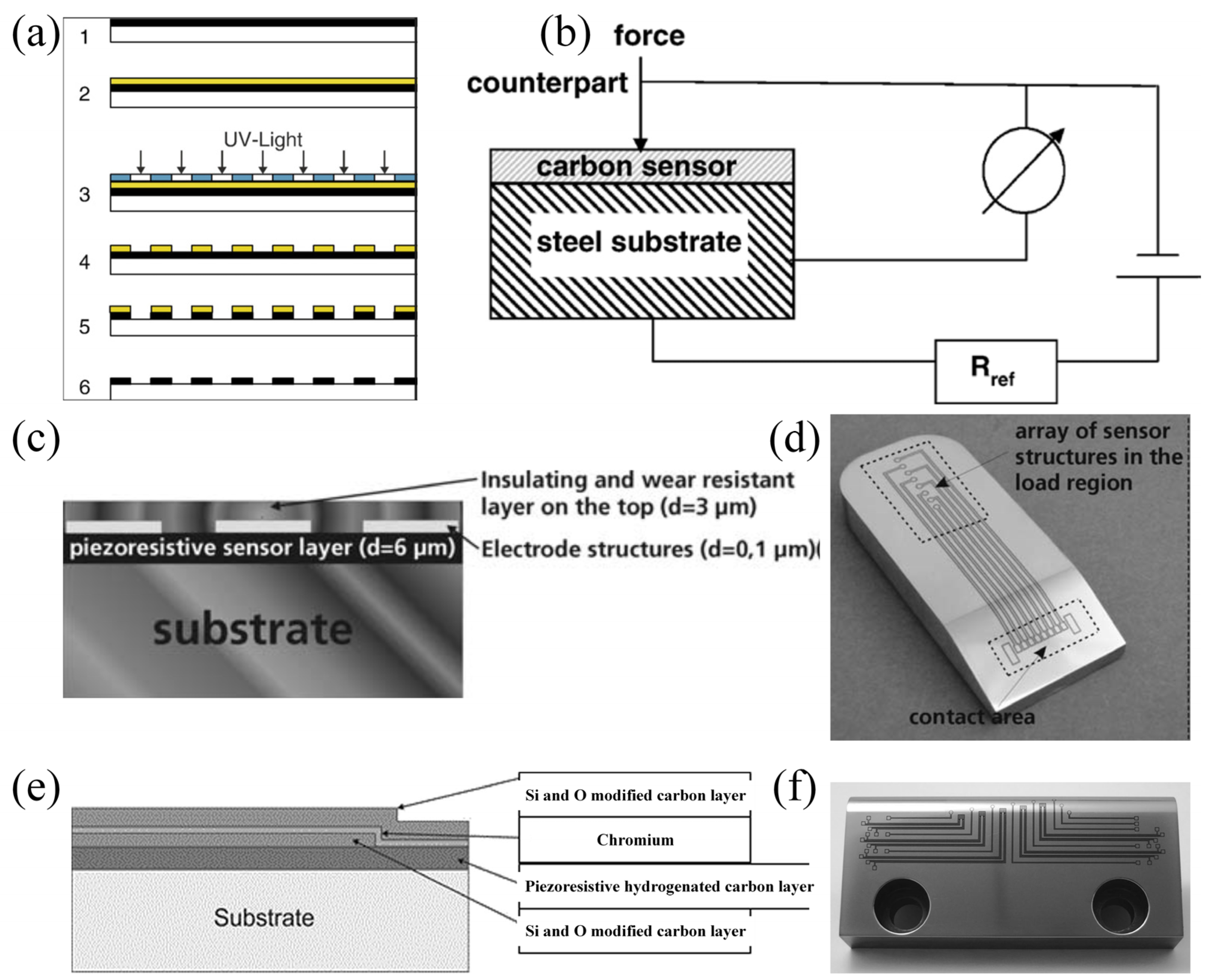

4. Coating-Based Sensors

5. Self-Powered Sensors

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.; Liu, M.; Ma, L. Origin of friction and the new frictionless technology—Superlubricity: Advancements and future outlook. Nano Energy 2021, 86, 106092. [Google Scholar] [CrossRef]

- Sakhamuri, M.S.D.; Harvey, T.J.; Vierneusel, B.; Wood, R.J.K. Wear induced changes in surface topography during running-in of rolling-sliding contacts. Wear 2023, 522, 204685. [Google Scholar] [CrossRef]

- Hamdan, S.H.; Lee, C.T.; Lee, M.B.; Chong, W.W.F.; Chong, C.T.; Sanip, S.M. Synergistic nano-tribological interaction between zinc dialkyldithiophosphate (ZDDP) and methyl oleate for biodiesel-fueled engines. Friction 2021, 9, 612–626. [Google Scholar] [CrossRef]

- Chern, S.-Y.; Ta, T.-N.; Horng, J.-H.; Wu, Y.-S. Wear and vibration behavior of ZDDP-Containing oil considering scuffing failure. Wear 2021, 478–479, 203923. [Google Scholar] [CrossRef]

- Zhang, J.; Ewen, J.P.; Spikes, H.A. Substituent effects on the mechanochemical response of zinc dialkyldithiophosphate. Mol. Syst. Des. Eng. 2022, 7, 1045–1055. [Google Scholar] [CrossRef]

- Zhang, J.; Ewen, J.P.; Ueda, M.; Wong, J.S.S.; Spikes, H.A. Mechanochemistry of Zinc Dialkyldithiophosphate on Steel Surfaces under Elastohydrodynamic Lubrication Conditions. ACS Appl. Mater. Interfaces 2020, 12, 6662–6676. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Acero, J.; Kessler, F.; Costa, H.; Cousseau, T. The effect of ethanol fuel dilution on oil performance and MoDTC tribofilms formation and composition. Friction 2024, 12, 2108–2125. [Google Scholar] [CrossRef]

- Duan, L.; Li, J.; Duan, H. Nanomaterials for lubricating oil application: A review. Friction 2023, 11, 647–684. [Google Scholar] [CrossRef]

- Jiang, H.; Hou, X.; Qian, Y.; Liu, H.; Ali, M.K.A.; Dearn, K.D. A tribological behavior assessment of steel contacting interface lubricated by engine oil introducing layered structural nanomaterials functionalized by oleic acid. Wear 2023, 524–525, 204675. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Y.; Liu, B.; Yu, L.; Tong, Y.; Yan, M.; Yang, Z.; Hao, Y.; Shangguan, L.; Zhang, S.; et al. Research progresses of nanomaterials as lubricant additives. Friction 2024, 12, 1347–1391. [Google Scholar] [CrossRef]

- Cui, Y.; Xue, S.; Liu, Z.; Wang, T.; Liu, S.; Ye, Q.; Zhou, F.; Liu, W. Synergistic effect of MXene and PTFE with multi-structure as lubricant additives for tribological applications. Carbon 2024, 220, 118896. [Google Scholar] [CrossRef]

- Duan, L.; Jia, D.; Li, J.; Liu, J.; Duan, H. Nanostructured lubricant additives for titanium alloy: Lubrication by the solid-liquid interface with Coulomb repulsion. Friction 2024, 12, 1564–1579. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Liu, Y.; Wang, W. Graphene superlubricity: A review. Friction 2023, 11, 1953–1973. [Google Scholar] [CrossRef]

- Yun, J.; Lee, S.J. Lubricant-infused anodic aluminum oxide surface (AAO-LIS) for durable slipperiness under harsh conditions. Surf. Coat. Technol. 2024, 477, 130283. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, J.; Zhang, X.; Hao, J.; Liu, W. WS2-Ti-based solid-liquid synergetic lubricating coating with super-high wear resistance for space application. Surf. Coat. Technol. 2024, 476, 130245. [Google Scholar] [CrossRef]

- Akakuru, O.U.; Martin-Alarcon, L.; Bryant, S.; Trifkovic, M. Unraveling Water-Based Lubrication with Carbon Dots of Asphaltene Origin. ACS Appl. Mater. Interfaces 2024, 16, 16699–16711. [Google Scholar] [CrossRef]

- Han, T.; Zhang, S.; Zhang, C. Unlocking the secrets behind liquid superlubricity: A state-of-the-art review on phenomena and mechanisms. Friction 2022, 10, 1137–1165. [Google Scholar] [CrossRef]

- Erdemir, A.; Martin, J.M.; Luo, J. Superlubricity, 2nd ed.; Erdemir, A., Martin, J.M., Luo, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. xvii–xix. [Google Scholar]

- Klein, J.; Kumacheva, E.; Mahalu, D.; Perahia, D.; Fetters, L.J.J.N. Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature 1994, 370, 634–636. [Google Scholar] [CrossRef]

- Chen, M.; Briscoe, W.H.; Armes, S.P.; Klein, J. Lubrication at Physiological Pressures by Polyzwitterionic Brushes. Science 2009, 323, 1698. [Google Scholar] [CrossRef]

- Raviv, U.; Giasson, S.; Kampf, N.; Gohy, J.-F.; Jerome, R.; Klein, J.J.N. Lubrication by charged polymers. Nature 2003, 425, 163–165. [Google Scholar] [CrossRef] [PubMed]

- Adibnia, V.; Olszewski, M.; De Crescenzo, G.; Matyjaszewski, K.; Banquy, X. Superlubricity of Zwitterionic Bottlebrush Polymers in the Presence of Multivalent Ions. J. Am. Chem. Soc. 2020, 142, 14843–14847. [Google Scholar] [CrossRef] [PubMed]

- Tomizawa, H.; Fischer, T.E. Friction and Wear of Silicon Nitride and Silicon Carbide in Water: Hydrodynamic Lubrication at Low Sliding Speed Obtained by Tribochemical Wear. ASLE Trans. 1987, 30, 41–46. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Luo, J. Superlubricity Behavior with Phosphoric Acid–Water Network Induced by Rubbing. Langmuir 2011, 27, 9413–9417. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, C.; Luo, J. Superlubricity Achieved with Mixtures of Polyhydroxy Alcohols and Acids. Langmuir 2013, 29, 5239–5245. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, C.; Ma, L.; Liu, Y.; Luo, J. Superlubricity Achieved with Mixtures of Acids and Glycerol. Langmuir 2013, 29, 271–275. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, W.; Zhang, Y.; Zhao, X.; Ma, S.; Scaraggi, M.; Zhou, F. Robust Super-Lubricity for Novel Cartilage Prototype Inspired by Scallion Leaf Architecture. Adv. Funct. Mater. 2024, 34, 2310271. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Miao, K.; Zhang, K.; Zheng, W.; Chen, C. Macroscale Robust Superlubricity on Metallic NbB2. Adv. Sci. 2022, 9, 2103815. [Google Scholar] [CrossRef]

- Yi, S.; Chen, X.; Li, J.; Liu, Y.; Ding, S.; Luo, J. Macroscale superlubricity of Si-doped diamond-like carbon film enabled by graphene oxide as additives. Carbon 2021, 176, 358–366. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Ge, X.; Yi, S.; Wang, H.; Liu, Y.; Luo, J. Macroscale Superlubricity Achieved on the Hydrophobic Graphene Coating with Glycerol. ACS Appl. Mater. Interfaces 2020, 12, 18859–18869. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, J.; Li, J.; Yi, S.; Ge, X.; Zhang, X.; Luo, J. Shear-Induced Interfacial Structural Conversion Triggers Macroscale Superlubricity: From Black Phosphorus Nanoflakes to Phosphorus Oxide. ACS Appl. Mater. Interfaces 2021, 13, 31947–31956. [Google Scholar] [CrossRef]

- Markova, L.V.; Myshkin, N.K.; Kong, H.; Han, H.G. On-line acoustic viscometry in oil condition monitoring. Tribol. Int. 2011, 44, 963–970. [Google Scholar] [CrossRef]

- Heinisch, M.; Voglhuber-Brunnmaier, T.; Reichel, E.K.; Dufour, I.; Jakoby, B. Application of resonant steel tuning forks with circular and rectangular cross sections for precise mass density and viscosity measurements. Sens. Actuators A Phys. 2015, 226, 163–174. [Google Scholar] [CrossRef]

- Saluja, A.; Kalonia, D.S. Measurement of fluid viscosity at microliter volumes using quartz impedance analysis. AAPS PharmSciTech 2004, 5, 68–81. [Google Scholar] [CrossRef]

- Smiechowski, M.F.; Lvovich, V.F. Iridium oxide sensors for acidity and basicity detection in industrial lubricants. Sens. Actuators B Chem. 2003, 96, 261–267. [Google Scholar] [CrossRef]

- Soleimani, M.; Sophocleous, M.; Glanc, M.; Atkinson, J.; Wang, L.; Wood, R.J.K.; Taylor, R.I. Engine oil acidity detection using solid state ion selective electrodes. Tribol. Int. 2013, 65, 48–56. [Google Scholar] [CrossRef]

- Soleimani, M.; Sophocleous, M.; Wang, L.; Atkinson, J.; Hosier, I.L.; Vaughan, A.S.; Taylor, R.I.; Wood, R.J.K. Base oil oxidation detection using novel chemical sensors and impedance spectroscopy measurements. Sens. Actuators B Chem. 2014, 199, 247–258. [Google Scholar] [CrossRef]

- Hyodo, T.; Yuto, M.; Tanigawa, H.; Tsuruoka, M.; Sakamoto, H.; Ueda, T.; Kamada, K.; Shimizu, Y. Solid-State ISFET-Based Sensors Capable of Measuring Acidity of Lubricants. ECS Trans. 2020, 98, 59–66. [Google Scholar] [CrossRef]

- Mujahid, A.; Dickert, F.L. Monitoring automotive oil degradation: Analytical tools and onboard sensing technologies. Anal. Bioanal. Chem. 2012, 404, 1197–1209. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Schuller, R.B.; Gundersen, T.; Halleraker, M.; Engebretsen, B. Measurement of water concentration in oil/water dispersions with a circular single-electrode capacitance probe. IEEE Trans. Instrum. Meas. 2004, 53, 1378–1383. [Google Scholar] [CrossRef]

- Raadnui, S.; Kleesuwan, S. Low-cost condition monitoring sensor for used oil analysis. Wear 2005, 259, 1502–1506. [Google Scholar] [CrossRef]

- Holzki, M.; Fouckhardt, H.; Klotzbücher, T. Evanescent-field fiber sensor for the water content in lubricating oils with sensitivity increase by dielectrophoresis. Sens. Actuators A Phys. 2012, 184, 93–97. [Google Scholar] [CrossRef]

- Liu, C.; Tang, X.; Yu, T.; Wang, T.; Lu, Z.; Yu, W. Measurement of moisture content in lubricating oils of high-speed rail gearbox by Vis-NIR spectroscopy. Optik 2020, 224, 165694. [Google Scholar] [CrossRef]

- Delta Services Industrials. Lubricant Aeration. Available online: http://www.deltabeam.net/en/product/lubricant-aeration (accessed on 20 September 2021).

- Kimura, Y.; Kato, N.; Kataoka, T.; Takahashi, K.; Kikuchi, T. Bubble Behavior in Engine Lubricant. Int. J. Automot. Eng. 2011, 2, 149–153. [Google Scholar] [CrossRef] [PubMed]

- Cao, W.; Dong, G.; Xie, Y.-B.; Peng, Z. Prediction of wear trend of engines via on-line wear debris monitoring. Tribol. Int. 2018, 120, 510–519. [Google Scholar] [CrossRef]

- Roylance, B.J.; Williams, J.A.; Dwyer-Joyce, R. Wear debris and associated wear phenomena—Fundamental research and practice, Proceedings of the Institution of Mechanical Engineers. Part J J. Eng. Tribol. 2000, 214, 79–105. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. An integrated ultrasonic–inductive pulse sensor for wear debris detection. Smart Mater. Struct. 2012, 22, 025003. [Google Scholar] [CrossRef]

- Nemarich, C.; Whitesel, H.; Sarkady, A. On-Line Wear Particle Monitoring Based on Ultrasonic Detection and Discrimination. Mater. Eval. 1988, 50, 525–530. [Google Scholar]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of precursor wear debris in lubrication systems. In Proceedings of the 2000 IEEE Aerospace Conference (Cat. No.00TH8484), Big Sky, MT, USA, 18–25 March 2000; Volume 6, pp. 73–77. [Google Scholar]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive Coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Harvey, T.J.; Wood, R.J.K.; Powrie, H.E.G. Electrostatic wear monitoring of rolling element bearings. Wear 2007, 263, 1492–1501. [Google Scholar] [CrossRef]

- Craig, M.; Harvey, T.J.; Wood, R.J.K.; Masuda, K.; Kawabata, M.; Powrie, H.E.G. Advanced condition monitoring of tapered roller bearings, Part 1. Tribol. Int. 2009, 42, 1846–1856. [Google Scholar] [CrossRef]

- Mao, H.; Zuo, H.; Wang, H. Electrostatic sensor application for on-line monitoring of wind turbine gearboxes. Sensors 2018, 18, 3574. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Zuo, H.; Sun, J.; Wang, L. Electrostatic monitoring of wind turbine gearbox on oil-lubricated system. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 3649–3664. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Y.-B.; Yuan, C.-J.; Li, Z.-Y. Research on an on-line ferrograph. Wear 1992, 153, 323–330. [Google Scholar] [CrossRef]

- Yan, L.; ShiZhu, W.; YouBai, X.; Fang, Z. Advances in research on a multi-channel on-line ferrograph. Tribol. Int. 1997, 30, 279–282. [Google Scholar] [CrossRef]

- Noria, Automatic Particle Counters for Fluid Contamination Control. Available online: https://www.machinerylubrication.com/Read/351/particle-counters (accessed on 12 December 2024).

- Sun, J.; Wang, L.; Li, J.; Li, F.; Li, J.; Lu, H. Online oil debris monitoring of rotating machinery: A detailed review of more than three decades. Mech. Syst. Signal Process. 2021, 149, 107341. [Google Scholar] [CrossRef]

- Wu, T.H.; Mao, J.H.; Wang, J.T.; Wu, J.Y.; Xie, Y.B. A New On-Line Visual Ferrograph. Tribol. Trans. 2009, 52, 623–631. [Google Scholar] [CrossRef]

- Wu, T.H.; Wang, J.Q.; Wu, J.Y.; Xie, Y.B.; Mao, J.H. Wear Characterization by an On-Line Ferrograph Image. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 23–34. [Google Scholar] [CrossRef]

- Harkemanne, E.; Berten, O.; Hendrick, P. Analysis and Testing of Debris Monitoring Sensors for Aircraft Lubrication Systems. Proceedings 2018, 2, 461. [Google Scholar] [CrossRef]

- Masom, R.A. The development, proving and application of an in-line metal particle detector (MPD). Br. J. Nondestr. Test. 1985, 27, 159–166. [Google Scholar]

- Muir, D.; Howe, B. In-line oil debris monitor (ODM) for the advanced tactical fighter engine. SAE Tech. Pap. 1996, 961308. [Google Scholar]

- Du, L.; Zhe, J.; Carletta, J.E.; Veillette, R.J. Inductive Coulter counting: Detection and differentiation of metal wear particles in lubricant. Smart Mater. Struct. 2010, 19, 057001. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. A 3×3 wear debris sensor array for real time lubricant oil conditioning monitoring using synchronized sampling. Mech. Syst. Signal Process. 2017, 83, 296–304. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. A high sensitivity wear debris sensor using ferrite cores for online oil condition monitoring. Meas. Sci. Technol. 2017, 28, 075102. [Google Scholar] [CrossRef]

- van de Voort, F.; Sedman, J.; Pinchuk, D. An Overview of Progress and New Developments in FTIR Lubricant Condition Monitoring Methodology. J. ASTM Int. 2011, 8, JAI103344. [Google Scholar] [CrossRef]

- Wu, T.; Wu, H.; Du, Y.; Peng, Z. Progress and trend of sensor technology for on-line oil monitoring. Sci. China Technol. Sci. 2013, 56, 2914–2926. [Google Scholar] [CrossRef]

- Adams, M.J.; Romeo, M.J.; Rawson, P. FTIR analysis and monitoring of synthetic aviation engine oils. Talanta 2007, 73, 629–634. [Google Scholar] [CrossRef] [PubMed]

- Gary, H.R.W.; Darrell, C. X-Ray Fluorescence Spectroscopy—The Next Generation of Wear Debris Analysis. Available online: https://www.machinerylubrication.com/Read/86/x-ray-fluorescence-spectroscopy (accessed on 12 December 2024).

- Liskiewicz, T.; Sherrington, I.; Khan, T.; Liu, Y. Advances in sensing for real-time monitoring of tribological parameters. Tribol. Int. 2023, 189, 108965. [Google Scholar] [CrossRef]

- Yaldız, S.; Ünsaçar, F. Design, development and testing of a turning dynamometer for cutting force measurement. Mater. Des. 2006, 27, 839–846. [Google Scholar] [CrossRef]

- Gomez, M.F.; Schmitz, T.L. Displacement-based dynamometer for milling force measurement. Procedia Manuf. 2019, 34, 867–875. [Google Scholar] [CrossRef]

- Zhang, T.; Lin, T.; Fu, L. Analytical and experimental study on acoustic-vibration characteristics of double-helical planetary gear transmission systems with multi-field coupling effect. Mech. Syst. Signal Process. 2025, 224, 112143. [Google Scholar] [CrossRef]

- Natali, C.; Stuppioni, U.; Battarra, M.; Blum, A.; Dalpiaz, G.; Mucchi, E. A novel experimental method for measuring oil film thickness in balanced vane pumps. Measurement 2024, 227, 114254. [Google Scholar] [CrossRef]

- Jin, Y.; Guo, Z.; Li, Z.; Han, C.; Liu, T.; Yang, G. Propagation characteristics of acoustic emission signals in solid-liquid-solid coupling interface. Measurement 2023, 213, 112686. [Google Scholar] [CrossRef]

- Dai, P.; Liang, X.; Wang, J.; Wang, F.; Niu, L. The acoustic-vibration characteristics of cylindrical roller bearings with raceway failures: Simulation and experiment. Measurement 2024, 234, 114918. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Bao, M.; Wang, L.; He, Y.; Zhang, C.; Gu, L.; Yu, H.; Zhang, Y.; Zheng, D.; et al. An accurate measurement method for center oil film thickness in high-speed roller bearing using ultrasound. Tribol. Int. 2024, 196, 109726. [Google Scholar] [CrossRef]

- Dou, P.; Yang, P.; Zheng, P.; Jia, Y.; Wu, T.; Wang, S.; Yu, M. Ultrasound enabled simultaneous measurement of coating wear depth and lubricant film thickness in a sliding bearing. Measurement 2025, 240, 115602. [Google Scholar] [CrossRef]

- Zheng, P.; Wei, S.; Dou, P.; Gao, X.; Wu, T.; Yu, M.; Lei, Y. High-accuracy ultrasonic measurement of oil film thickness in sliding bearings considering surface thin coating. Tribol. Int. 2025, 202, 110343. [Google Scholar] [CrossRef]

- Gohar, R.; Cameron, A. Optical Measurement of Oil Film Thickness under Elasto-hydrodynamic Lubrication. Nature 1963, 200, 458–459. [Google Scholar] [CrossRef]

- Luo, J.; Wen, S.; Huang, P. Thin film lubrication. Part I. Study on the transition between EHL and thin film lubrication using a relative optical interference intensity technique. Wear 1996, 194, 107–115. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, S.; Zhao, Z. Optical analysis of ball-on-ring mode test rig for oil film thickness measurement. Friction 2016, 4, 324–334. [Google Scholar] [CrossRef]

- Wigger, S.; Füßer, H.-J.; Fuhrmann, D.; Schulz, C.; Kaiser, S.A. Quantitative two-dimensional measurement of oil-film thickness by laser-induced fluorescence in a piston-ring model experiment. Appl. Opt. 2016, 55, 269–279. [Google Scholar] [CrossRef]

- Cheong, J.; Wigger, S.; Füßer, H.-J.; Kaiser, S.A. The oil film around a cylindrical micropore in a sliding contact visualized by fluorescence microscopy on a tribometer. Tribol. Int. 2022, 165, 107309. [Google Scholar] [CrossRef]

- Yuan, X.; Li, H.; Zhang, T.; Li, Z.; Zhang, S. A Synchronous Sensing Method of Measuring Lubricating Oil Film Thickness and Temperature by Using Eddy Current Effect. Tribol. Lett. 2024, 72, 68. [Google Scholar] [CrossRef]

- Dan, L.; Mathew, J. Tool wear and failure monitoring techniques for turning—A review. Int. J. Mach. Tools Manuf. 1990, 30, 579–598. [Google Scholar] [CrossRef]

- Hahn, F.W. Thin film wear sensors. Wear 1981, 74, 157–164. [Google Scholar] [CrossRef]

- Kreider, K.G.; Ruff, A.W. Materials for thin-film wear sensors. Surf. Coat. Technol. 1996, 86–87, 557–563. [Google Scholar] [CrossRef]

- Ruff, A.W.; Kreider, K.G. Deposited thin-film wear sensors: Materials and design. Wear 1997, 203–204, 187–195. [Google Scholar] [CrossRef]

- Sakka, M.M.; Bahri, A.; Antar, Z.; Elleuch, K.; Ponthiaux, P.; Drees, D.; Celis, J.P. Thermal Wear Sensing System: Proof of the Concept. J. Mater. Eng. Perform. 2018, 27, 4635–4644. [Google Scholar] [CrossRef]

- Biehl, S.; Lüthje, H.; Bandorf, R.; Sick, J.-H. Multifunctional thin film sensors based on amorphous diamond-like carbon for use in tribological applications. Thin Solid Film. 2006, 515, 1171–1175. [Google Scholar] [CrossRef]

- Biehl, S.; Rumposch, C.; Bräuer, G.; Hoffmeister, H.-W.; Luig, M. Development of a novel piezoresistive thin film sensor system based on hydrogenated carbon. Microsyst. Technol. 2014, 20, 989–993. [Google Scholar] [CrossRef]

- Biehl, S.; Rumposch, C.; Paetsch, N.; Bräuer, G.; Weise, D.; Scholz, P.; Landgrebe, D. Multifunctional thin film sensor system as monitoring system in production. Microsyst. Technol. 2016, 22, 1757–1765. [Google Scholar] [CrossRef]

- Biehl, S.; Staufenbiel, S.; Hauschild, F.; Albert, A. Novel measurement and monitoring system for forming processes based on piezoresistive thin film systems. Microsyst. Technol. 2010, 16, 879–883. [Google Scholar] [CrossRef]

- Rasmussen, I.L.; Guibert, M.; Belin, M.; Martin, J.M.; Mikkelsen, N.J.; Pedersen, H.C.; Schou, J. Wear monitoring of protective nitride coatings using image processing. Surf. Coat. Technol. 2010, 204, 1970–1972. [Google Scholar] [CrossRef]

- Rasmussen, I.L.; Guibert, M.; Martin, J.M.; Belin, M.; Mikkelsen, N.J.; Pedersen, H.C.; Schou, J. Optical Detections From Worn and Unworn Titanium Compound Surfaces. Tribol. Lett. 2009, 37, 15. [Google Scholar] [CrossRef]

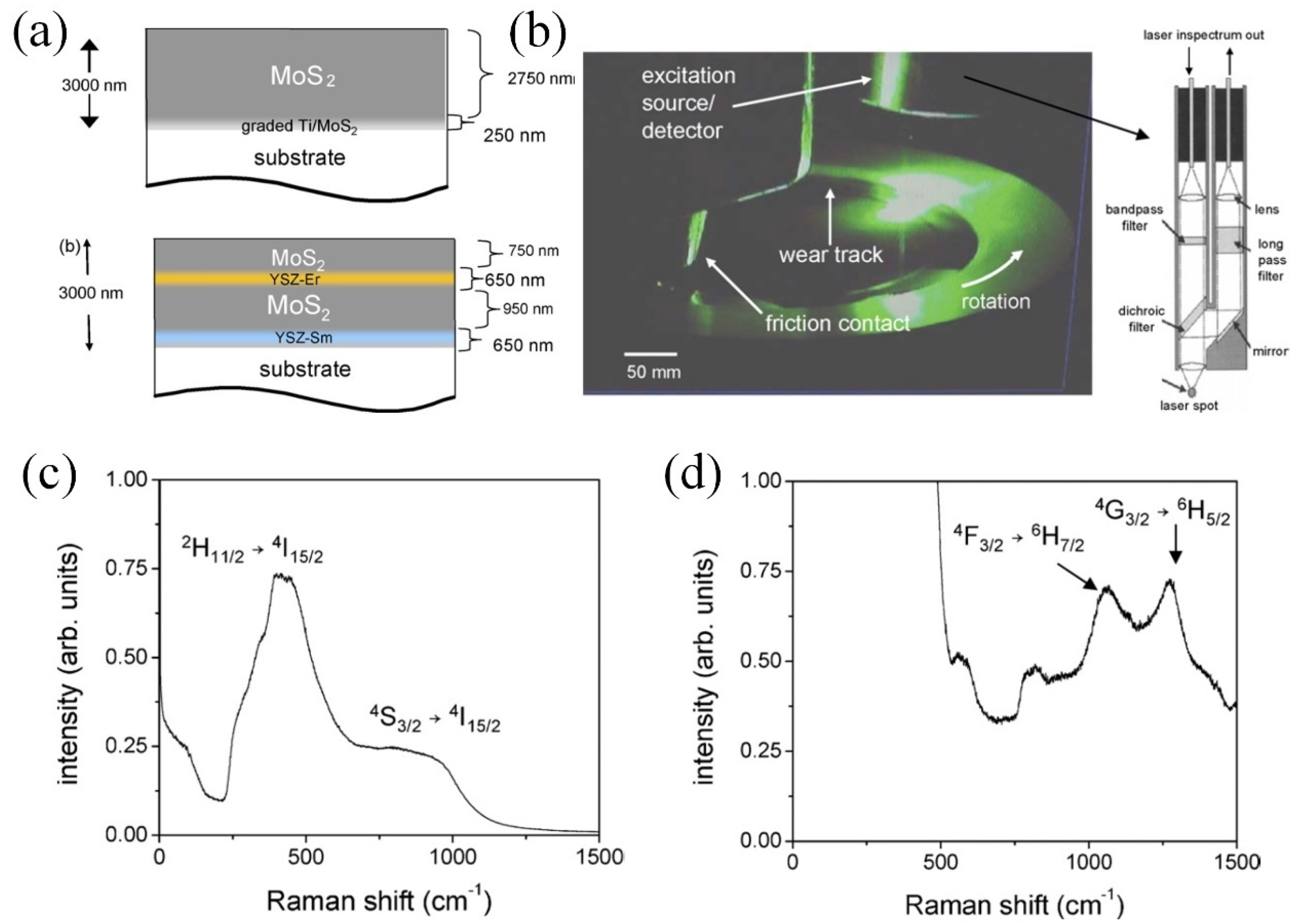

- Muratore, C.; Clarke, D.R.; Jones, J.G.; Voevodin, A.A. Smart tribological coatings with wear sensing capability. Wear 2008, 265, 913–920. [Google Scholar] [CrossRef]

- Fang, L.; Yin, A.; Zhu, S.; Ding, J.; Chen, L.; Zhang, D.; Pu, Z.; Liu, T. On the potential of Er-doped AlN film as luminescence sensing layer for multilayer Al/AlN coating health monitoring. J. Alloys Compd. 2017, 727, 735–743. [Google Scholar] [CrossRef]

- Fang, L.; Jiang, Y.; Zhu, S.; Ding, J.; Zhang, D.; Yin, A.; Chen, P. Substrate Temperature Dependent Properties of Sputtered AlN:Er Thin Film for In-Situ Luminescence Sensing of Al/AlN Multilayer Coating Health. Materials 2018, 11, 2196. [Google Scholar] [CrossRef]

- Salee, A.; Hirata, A. Demonstration of Wear Monitoring of Amorphous Carbon Films with Epoxy Resin Underlayer Containing Phosphor. Tribol. Online 2013, 8, 265–271. [Google Scholar] [CrossRef]

- Salee, A.; Aono, Y.; Hirata, A. Development of amorphous carbon coating with luminescent silica/CdSe/ZnS quantum dots underlayer for wear monitoring. Precis. Eng. 2014, 38, 673–679. [Google Scholar] [CrossRef]

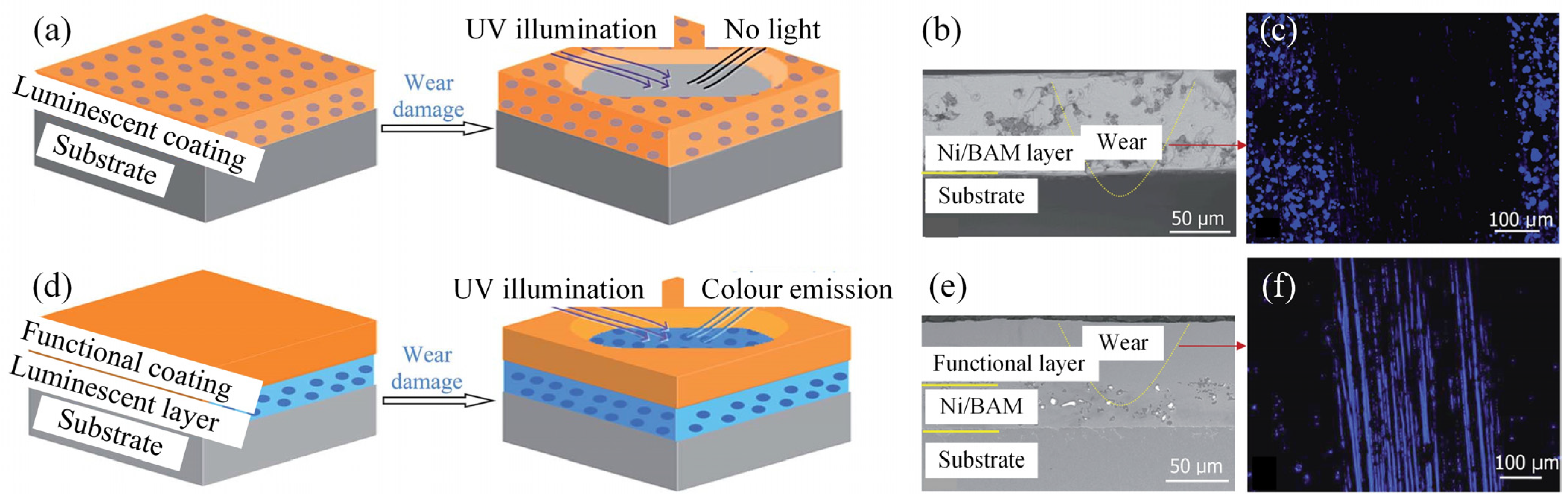

- He, Y.; Wang, S.-C.; Walsh, F.C.; Li, W.-S.; He, L.; Reed, P.A.S. The monitoring of coating health by in situ luminescent layers. RSC Adv. 2015, 5, 42965–42970. [Google Scholar] [CrossRef]

- He, L.; Wu, X.-Y.; Li, W.-S.; Zhang, M.-N.; Liu, S.-J. Self-sensing tribological coating with phosphor particles for wear indicator. Rare Met. 2018, 42, 2462–2469. [Google Scholar] [CrossRef]

- Goldfarb, M.; Barth, E.J.; Gogola, M.A.; Wehrmeyer, J.A. Design and energetic characterization of a liquid-propellant-powered actuator for self-powered robots. IEEE/ASME Trans. Mechatron. 2003, 8, 254–262. [Google Scholar] [CrossRef]

- James, E.P.; Tudor, M.J.; Beeby, S.P.; Harris, N.R.; Glynne-Jones, P.; Ross, J.N.; White, N.M. An investigation of self-powered systems for condition monitoring applications. Sens. Actuators A Phys. 2004, 110, 171–176. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Jie, Y.; Ma, J.; Chen, Y.; Cao, X.; Wang, N.; Wang, Z.L. Efficient Delivery of Power Generated by a Rotating Triboelectric Nanogenerator by Conjunction of Wired and Wireless Transmissions Using Maxwell’s Displacement Currents. Adv. Energy Mater. 2018, 8, 1802084. [Google Scholar] [CrossRef]

- Tang, W.; Han, Y.; Han, C.B.; Gao, C.Z.; Cao, X.; Wang, Z.L. Self-Powered Water Splitting Using Flowing Kinetic Energy. Adv. Mater. 2015, 27, 272–276. [Google Scholar] [CrossRef] [PubMed]

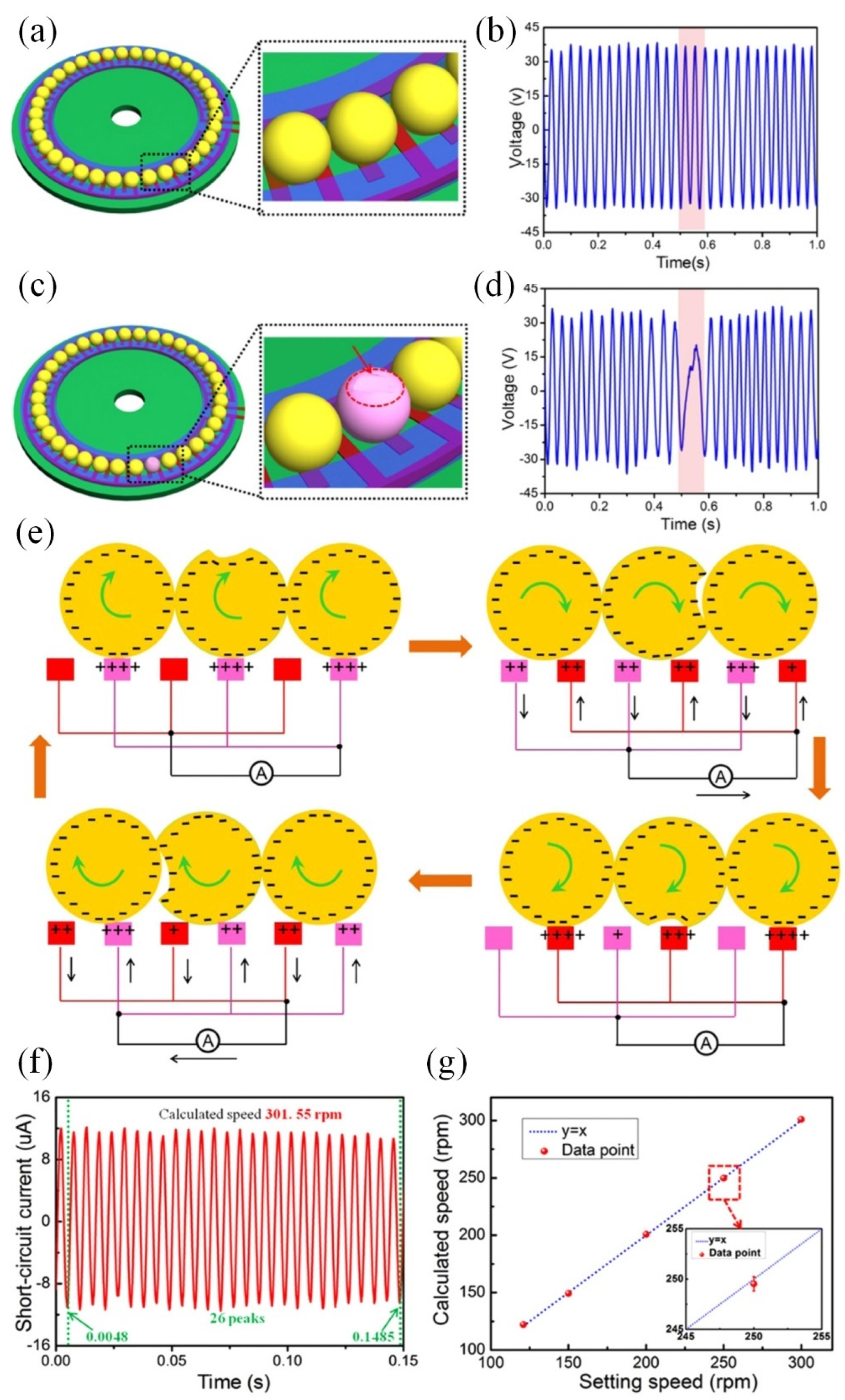

- Ren, Y.; Liu, G.; Yang, H.; Tong, T.; Xu, S.; Zhang, L.; Luo, J.; Zhang, C.; Xie, G. Dynamic wear sensor array based on single-electrode triboelectric nanogenerators. Nano Energy 2020, 68, 104303. [Google Scholar] [CrossRef]

- Li, X.H.; Han, C.B.; Jiang, T.; Zhang, C.; Wang, Z.L. A ball-bearing structured triboelectric nanogenerator for nondestructive damage and rotating speed measurement. Nanotechnology 2016, 27, 085401. [Google Scholar] [CrossRef]

- Han, Q.; Ding, Z.; Qin, Z.; Wang, T.; Xu, X.; Chu, F. A triboelectric rolling ball bearing with self-powering and self-sensing capabilities. Nano Energy 2020, 67, 104277. [Google Scholar] [CrossRef]

- Suh, I.; Jeon, J.; Park, M.; Young, H.; Park, J.; Kim, S. Recent Studies on Solid–Liquid Contact Electrification. ACS Appl. Electron. Mater. 2024, 6, 4826–4842. [Google Scholar] [CrossRef]

- Xia, K.; Yu, M. Highly robust and efficient metal-free water cup solid–liquid triboelectric nanogenerator for water wave energy harvesting and ethanol detection. Chem. Eng. J. 2025, 503, 157938. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, L.; Wang, W.; Xu, H.; Cheng, J.; Wu, X.; Liu, Y.; Zhang, X.; Wang, D. High-performance pneumatic solid–liquid triboelectric nanogenerator. Nano Energy 2024, 123, 109391. [Google Scholar] [CrossRef]

- Wang, K.; Wang, X.; Sun, Y.; Wu, Z.; Zhang, H.; Xiao, K.; Du, J.; Li, J.; Luo, J. Macroscopic liquid superlubric triboelectric nanogenerator: An in-depth understanding of solid-liquid interfacial charge behavior. Nano Energy 2024, 129, 110038. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Yu, Z.; Fan, Z.; Wang, S.; Xiang, Y.; Liu, Y.; Wang, Z. Sensor for a Solid–Liquid Tribological System. Sensors 2025, 25, 437. https://doi.org/10.3390/s25020437

Zhang R, Yu Z, Fan Z, Wang S, Xiang Y, Liu Y, Wang Z. Sensor for a Solid–Liquid Tribological System. Sensors. 2025; 25(2):437. https://doi.org/10.3390/s25020437

Chicago/Turabian StyleZhang, Ruize, Zeyang Yu, Zhikai Fan, Shanshan Wang, Yihui Xiang, Yanfei Liu, and Zhongnan Wang. 2025. "Sensor for a Solid–Liquid Tribological System" Sensors 25, no. 2: 437. https://doi.org/10.3390/s25020437

APA StyleZhang, R., Yu, Z., Fan, Z., Wang, S., Xiang, Y., Liu, Y., & Wang, Z. (2025). Sensor for a Solid–Liquid Tribological System. Sensors, 25(2), 437. https://doi.org/10.3390/s25020437