Design and Validation of a Dielectric Method-Based Composite Material Curing Monitoring Platform

Abstract

:1. Introduction

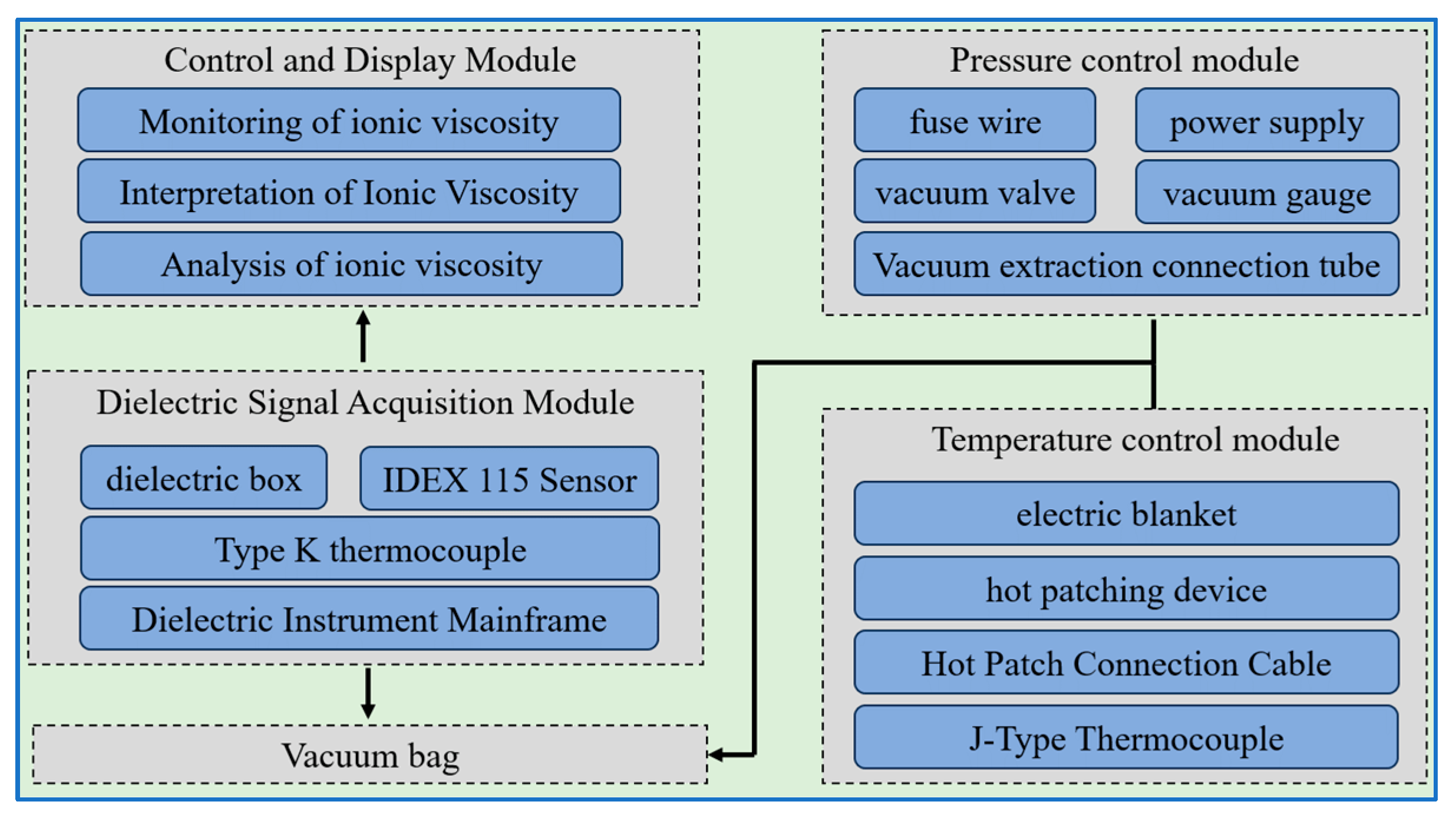

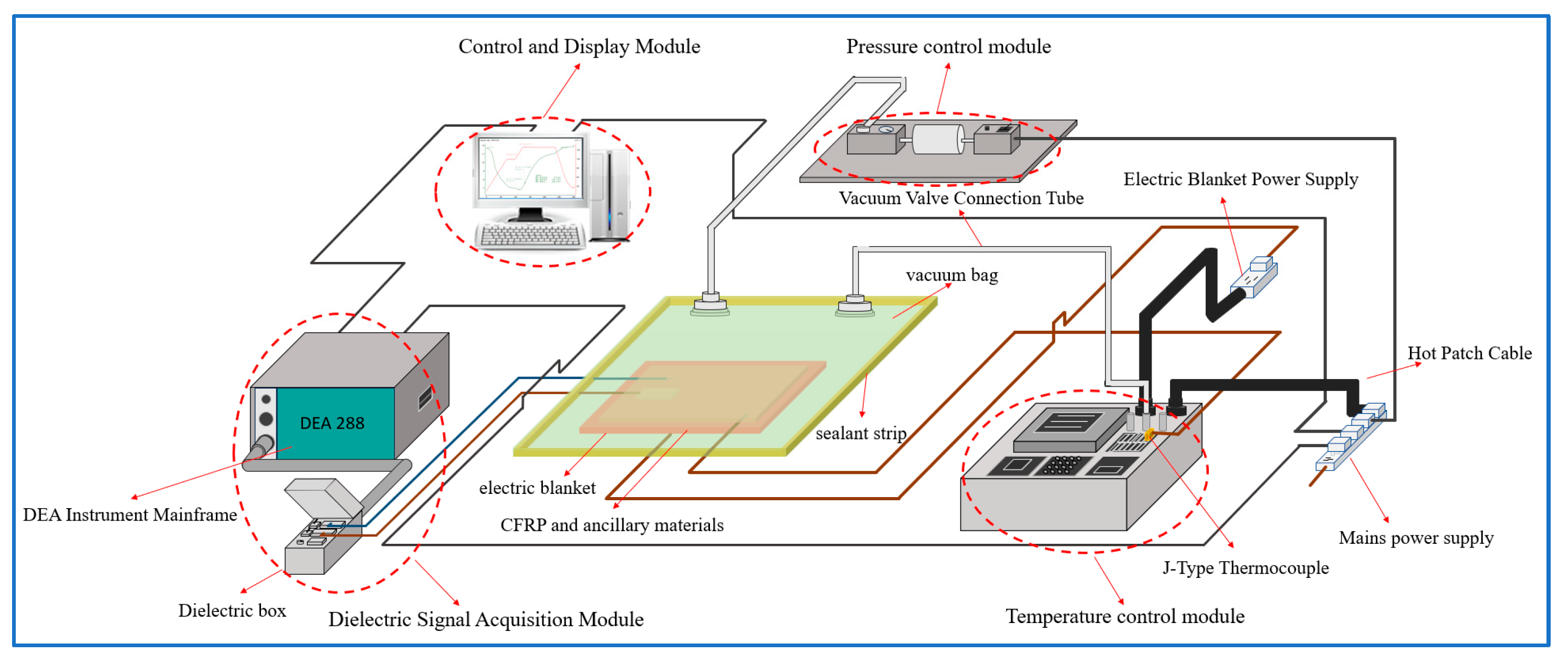

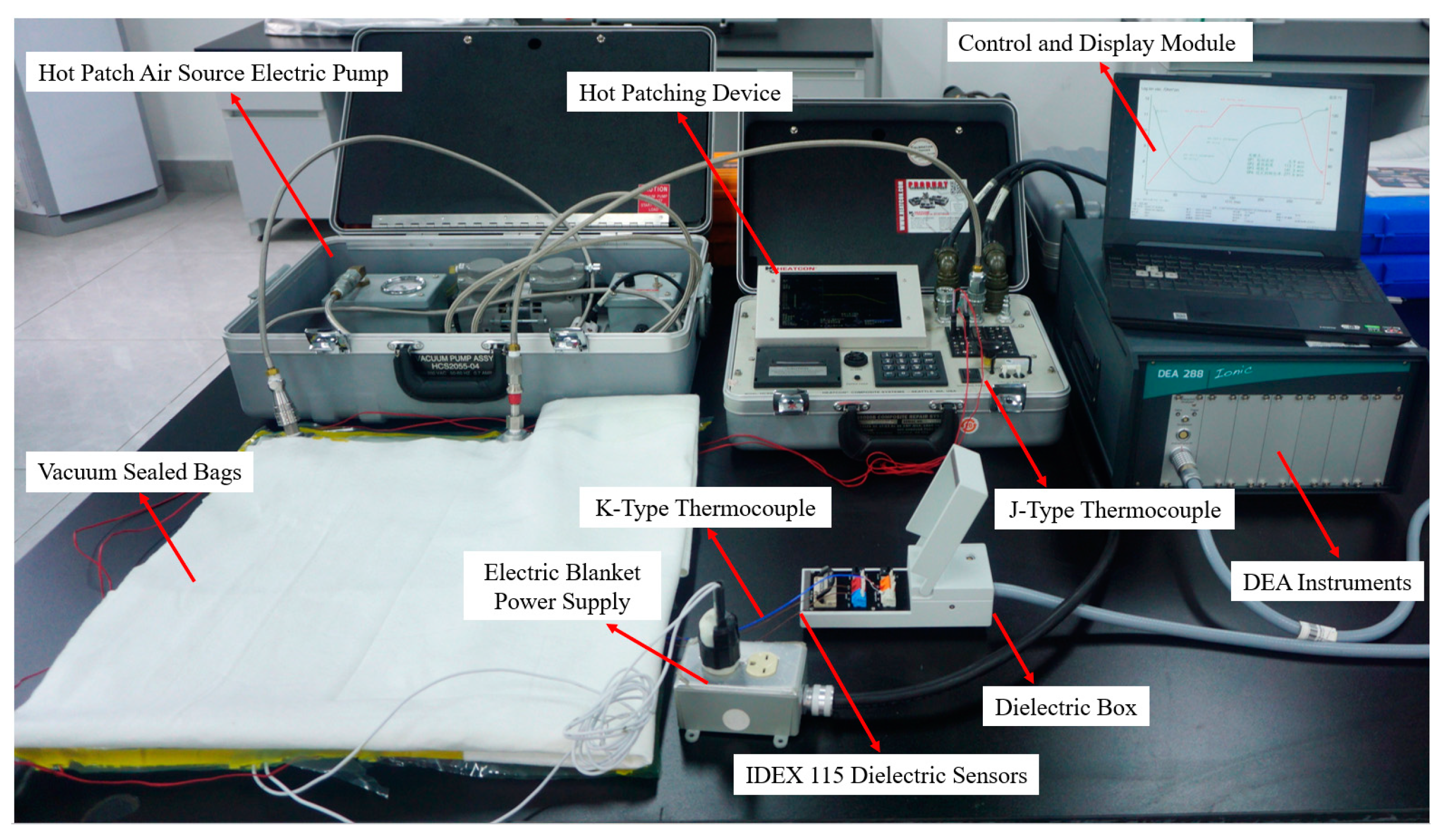

2. Design of a Composite Material Curing Monitoring Platform

2.1. Platform Design Principles

2.2. Platform Hardware Design

2.2.1. Temperature Control Module

2.2.2. Pressure Control Module

2.2.3. Dielectric Signal Acquisition Module

2.2.4. Control and Display Module

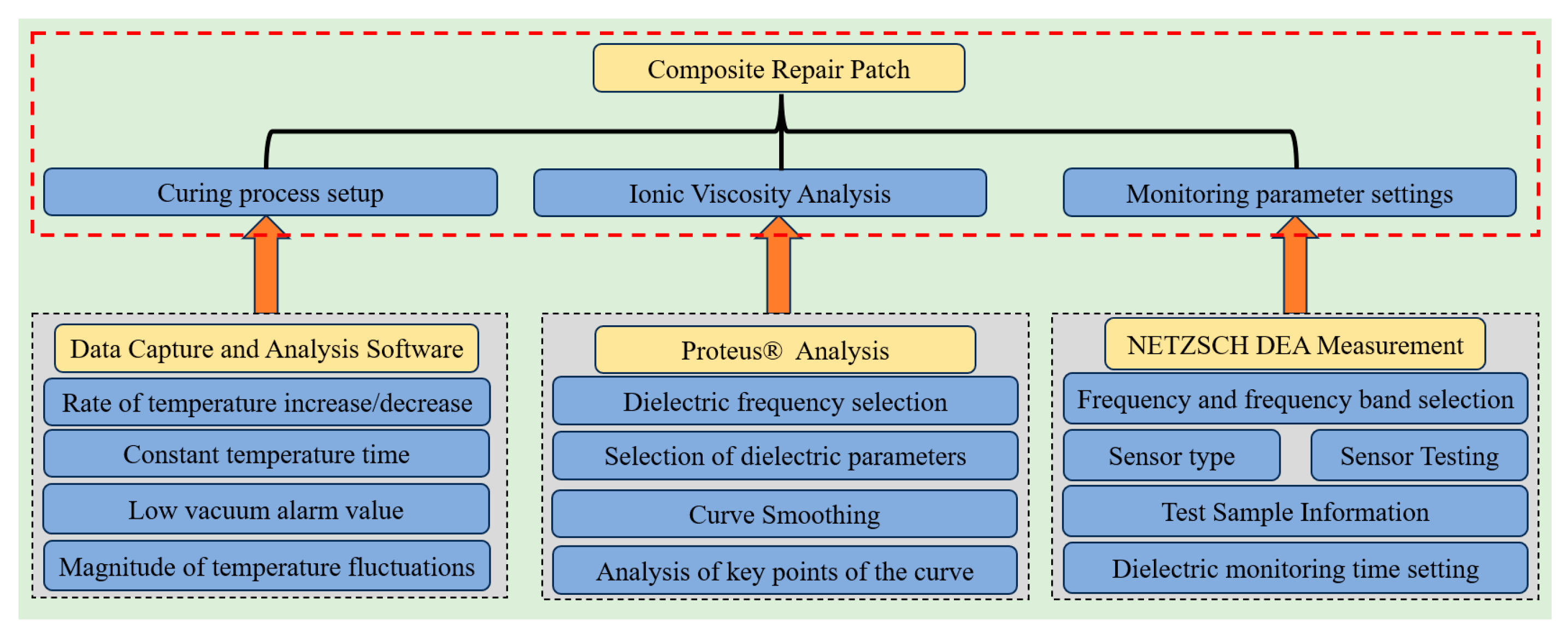

2.3. Platform Software Construction

3. Composite Curing Monitoring Platform Integration and Application

3.1. Integration of Curing Monitoring Platforms

3.2. Sample Preparation

3.3. Platform Parameters Configuration

3.4. Experimental Methods

3.4.1. Platform Reproducibility Testing

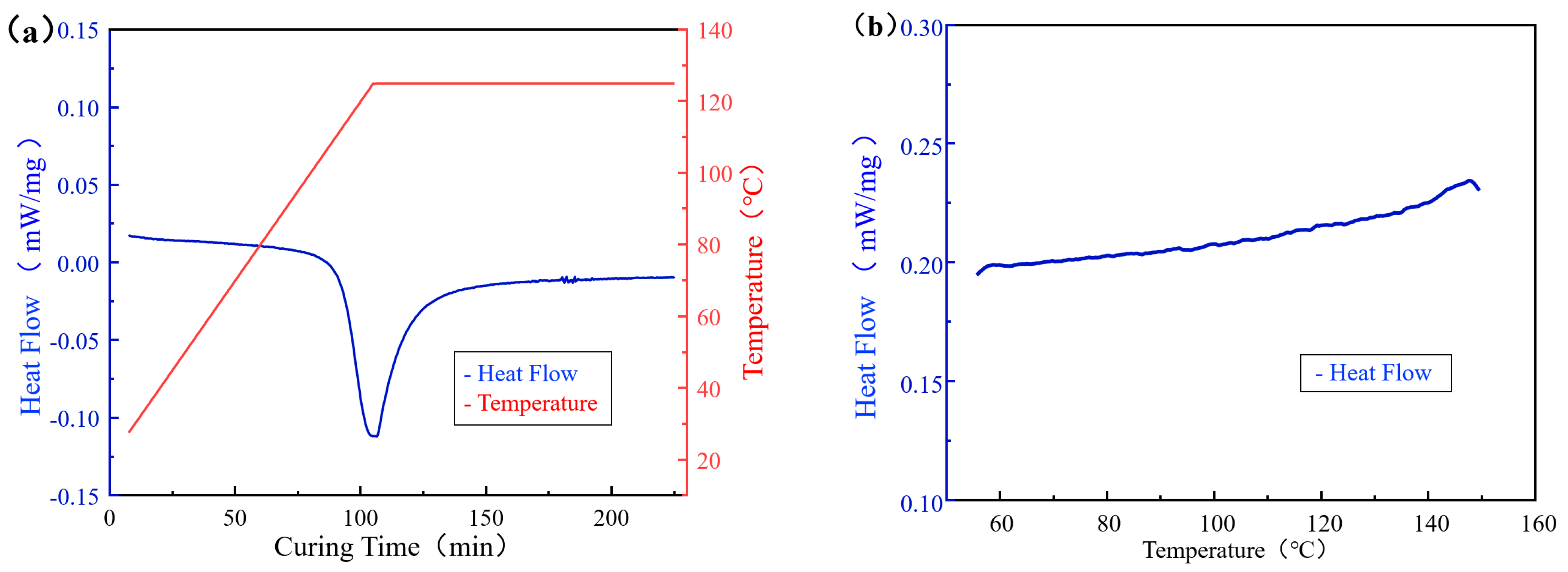

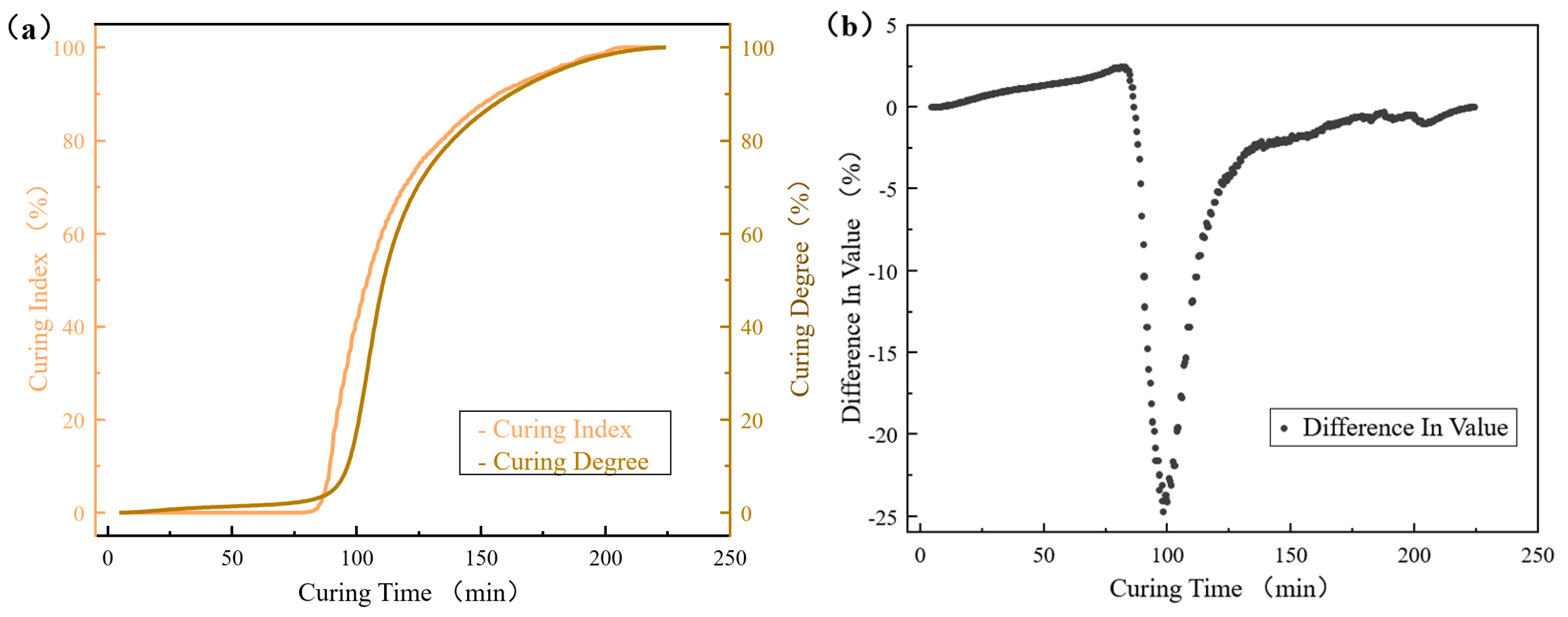

3.4.2. Determination of the Curing Index

3.4.3. Curing Degree Acquisition

4. Results and Discussion

4.1. Analysis of the Platform’s Monitoring Reproducibility

4.2. Access and Validation Platform Curing Index

5. Conclusions

- (1)

- The platform demonstrates high repeatability in monitoring the ionic viscosity of the same patch during the curing process. This stability suggests its applicability in consistently monitoring the curing of composite material patches in aircraft structural repairs.

- (2)

- The curing index obtained from the platform closely aligns with the actual changes in the degree of cure of the patch, indicating that the measured curing index can effectively represent the actual degree of cure. The platform accurately monitors the ionic viscosity throughout the curing process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seo, J.; Kim, D.C.; Park, H.; Kang, Y.S.; Park, H.W. Advancements and Challenges in the Carbon Fiber-Reinforced Polymer (CFRP) Trimming Process. Int. J. Precis. Eng. Manuf. Technol. 2023, 11, 1341–1360. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; de Barros, S. Bonded repair of composite structures in aerospace application: A review on environmental issues. Appl. Adhes. Sci. 2018, 6, 3. [Google Scholar] [CrossRef]

- Hosseini-Toudeshky, H.; Sheibanian, F.; Sabzy, P.; Jalalvand, M. Comprehensive progressive damage analyses of mixed-mode repaired panels: How composite patch sizes and layups affects restarting fatigue crack growth. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 3244–3260. [Google Scholar] [CrossRef]

- Sorrentino, L.; Polini, W.; Bellini, C. To design the cure process of thick composite parts: Experimental and numerical results. Adv. Compos. Mater. 2013, 23, 225–238. [Google Scholar] [CrossRef]

- Kim, S.S.; Murayama, H.; Kageyama, K.; Uzawa, K.; Kanai, M. Study on the curing process for carbon/epoxy composites to reduce thermal residual stress. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1197–1202. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Wang, Y.Q.; Li, X. Effect of multiple curing on properties of composites. Mater. Rep. 2018, 32, 273–275. Available online: https://kns.cnki.net/kcms2/article/abstract?v=sKJ9SXrFdEpTfhcGQXwi1JYTCt9zqcGjvAzZInuF1QJEKFNYXIEfcmGw5y6zXcNLKhNUxdGOgR00D-nltSfzs3dFT1b58DcLYGit11fYt3k0tvyiys-nvt7JByFOJ-PBSLALwz8jEx1FSpwLpf3qo2zxk4DclQIg2cOJIgLUj7dZK3hOKHhGDmil2cUoIA53Vwl6NQYjwkA=&uniplatform=NZKPT&language=CHS (accessed on 27 January 2025).

- Zhou, Y.X.; Li, B.; Li, C.L.; Xiang, B.L.; Xia, W.; Li, S.J. Influence and mechanism of multiple curing on mechanical properties of composites. Plast. Sci. Technol. 2022, 50, 60–63. [Google Scholar] [CrossRef]

- Shen, Y.; Lu, Y.; Liu, S.T.; He, X.Z. Online monitoring method for curing degree of aircraft composite components. Aeronaut. Manuf. Technol. 2021, 64, 76–85. [Google Scholar] [CrossRef]

- Ramly, R.; Kuntjoro, W.; Rahman, M.K.A. Using Embedded Fiber Bragg Grating (FBG) Sensors in Smart Aircraft Structure Materials. Procedia Eng. 2012, 41, 600–606. [Google Scholar] [CrossRef]

- Raponi, O.d.A.; de Souza, B.R.; Barbosa, L.C.M.; Junior, A.C.A. Thermal, rheological, and dielectric analyses of the polymerization reaction of a liquid thermoplastic resin for infusion manufacturing of composite materials. Polym. Test. 2018, 71, 32–37. [Google Scholar] [CrossRef]

- Luo, S.; Wang, G.; Wang, Y.; Xu, Y.; Luo, Y. Carbon nanomaterials enabled fiber sensors: A structure-oriented strategy for highly sensitive and versatile in situ monitoring of composite curing process. Compos. Part B Eng. 2019, 166, 645–652. [Google Scholar] [CrossRef]

- Pommer, C.; Sinapius, M. A Novel Approach to Monitoring the Curing of Epoxy in Closed Tools by Use of Ultrasonic Spectroscopy. Sensors 2017, 18, 96. [Google Scholar] [CrossRef]

- Kinet, D.; Mégret, P.; Goossen, K.W.; Qiu, L.; Heider, D.; Caucheteur, C. Fiber Bragg Grating Sensors toward Structural Health Monitoring in Composite Materials: Challenges and Solutions. Sensors 2014, 14, 7394–7419. [Google Scholar] [CrossRef]

- Zhang, H.; An, L. Progress in Dielectrophoretic Assembly of Carbon Nanotubes for Sensing Application. MATEC Web Conf. 2016, 67, 06071. [Google Scholar] [CrossRef]

- Aggelis, D.; Paipetis, A. Monitoring of resin curing and hardening by ultrasound. Constr. Build. Mater. 2011, 26, 755–760. [Google Scholar] [CrossRef]

- Kim, H.G. Dielectric cure monitoring for glass/polyester prepreg composites. Compos. Struct. 2002, 57, 91–99. [Google Scholar] [CrossRef]

- Kim, D.; Centea, T.; Nutt, S.R. In-situ cure monitoring of an out-of-autoclave prepreg: Effects of out-time on viscosity, ge-lation and vitrification. Compos. Sci. Technol. 2014, 102, 132–138. [Google Scholar] [CrossRef]

- Hardis, R.; Jessop JL, P.; Peters, F.E.; Kessler, M.R. Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos. Part A Appl. Sci. Manuf. 2013, 49, 100–108. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Chen, D.; Zheng, Y.B.; Zhou, K.; Yang, Z.Y.; Wu, Z.J. Piezoelectric transducers based curing monitoring of resin matrix composites. Acta Mater. Compos. Sin. 2020, 37, 2776–2781. [Google Scholar] [CrossRef]

- Luo, W.; Song, Z.M.; Cheng, Y.; Chen, G.Y.; Yang, L.Y.; Wen, Y.H. Application of Dielectric Analysis in Curing Process of Carbon Fiber Reinforced Bismaleimide Composites. Aeronaut. Manuf. Technol. 2020, 63, 48–52. [Google Scholar] [CrossRef]

- Han, Y.; Wang, J.; Zhang, H.; Zhao, S.; Ma, Q.; Wang, Z. Electrochemical impedance spectroscopy (EIS): An efficiency method to monitor resin curing processes. Sens. Actuators A Phys. 2016, 250, 78–86. [Google Scholar] [CrossRef]

- Demleitner, M.; Sanchez-Vazquez, S.A.; Raps, D.; Bakis, G.; Pflock, T.; Chaloupka, A.; Schmölzer, S.; Altstädt, V. Dielectric analysis monitoring of thermoset curing with ionic liquids: From modeling to the prediction in the resin transfer molding process. Polym. Compos. 2019, 40, 4500–4509. [Google Scholar] [CrossRef]

- Yan, S.; Zeizinger, H.; Merten, C.; Schmauder, S. In-situ investigation of dielectric properties and reaction kinetics of a glass-fiber-reinforced epoxy composite material using dielectric analysis. Polym. Eng. Sci. 2021, 61, 1673–1684. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Q.; Liu, D.; Fan, J.; Zhang, Q.; Chen, W. In situ monitoring of epoxy resin curing process: Using glass transition as a bridge. Polym. Test. 2022, 117, 107871. [Google Scholar] [CrossRef]

- Yang, Y.; Chiesura, G.; Luyckx, G.; Vervust, T.; Bossuyt, F.; Kaufmann, M.; Degrieck, J.; Vanfleteren, J. Development of a Dielectric Sensor System for the On-line Cure Monitoring of Composites. Procedia Technol. 2014, 15, 631–637. [Google Scholar] [CrossRef]

- Raponi, O.d.A.; de Souza, B.R.; Junior, J.E.B.; Junior, A.C.A.; Guimarães, A. Dielectric analysis as a low-complexity methodology for tracking prepreg out-time and its effects on the curing cycle. J. Compos. Mater. 2019, 53, 4035–4042. [Google Scholar] [CrossRef]

- Sernek, M.; Kamke, F.A. Application of dielectric analysis for monitoring the cure process of phenol formaldehyde adhesive. Int. J. Adhes. Adhes. 2007, 27, 562–567. [Google Scholar] [CrossRef]

- Gao, T.L.; Yu, J.H.; Xu, Y.J. Dynamic Modeling of Curing Process of Carbon/Epoxy Prepreg. Mech. Sci. Technol. Aerspace Eng. 2022, 41, 1128–1135. [Google Scholar] [CrossRef]

- De Wang, S.; Lu, L.C.; Cheng, X. CFSC for Positive and Negative Temperature Sensing by Resistivity Measurement. Adv. Mater. Res. 2010, 168–170, 1153–1157. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Gao, L.; Jia, Y. Effects of key thermophysical properties on the curing uniformity of carbon fiber reinforced resin composites. e-Polymers 2018, 18, 19–26. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Yin, X.; Li, S.; Liu, S.; Zhang, R.; Cao, Y.; Yang, B.; Huang, H. Design and Validation of a Dielectric Method-Based Composite Material Curing Monitoring Platform. Sensors 2025, 25, 1686. https://doi.org/10.3390/s25061686

Yang W, Yin X, Li S, Liu S, Zhang R, Cao Y, Yang B, Huang H. Design and Validation of a Dielectric Method-Based Composite Material Curing Monitoring Platform. Sensors. 2025; 25(6):1686. https://doi.org/10.3390/s25061686

Chicago/Turabian StyleYang, Wenfeng, Xinguang Yin, Shaolong Li, Shuaicai Liu, Ran Zhang, Yu Cao, Bowen Yang, and Hongshuai Huang. 2025. "Design and Validation of a Dielectric Method-Based Composite Material Curing Monitoring Platform" Sensors 25, no. 6: 1686. https://doi.org/10.3390/s25061686

APA StyleYang, W., Yin, X., Li, S., Liu, S., Zhang, R., Cao, Y., Yang, B., & Huang, H. (2025). Design and Validation of a Dielectric Method-Based Composite Material Curing Monitoring Platform. Sensors, 25(6), 1686. https://doi.org/10.3390/s25061686