Measurement of TBM Disc Cutter Wear Using Eddy-Current Sensor in Different TBM Chamber Conditions: Insights from Laboratory Tests

Abstract

:1. Introduction

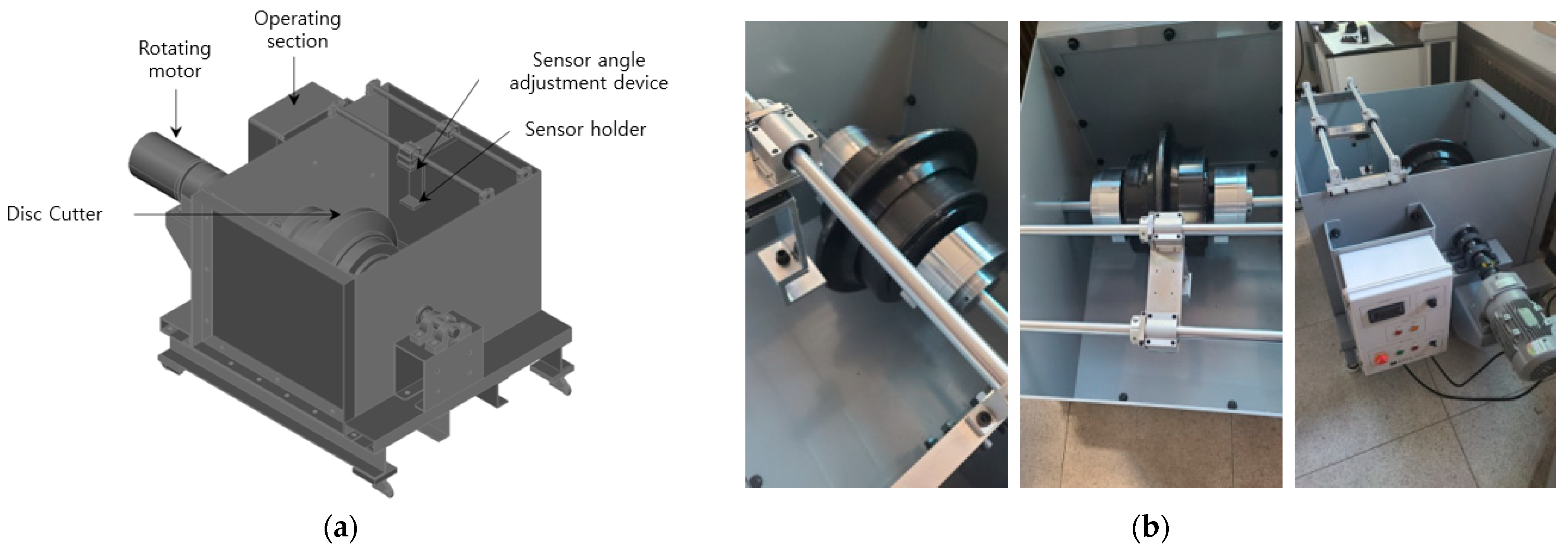

2. Materials and Methods

2.1. Eddy-Current Sensor

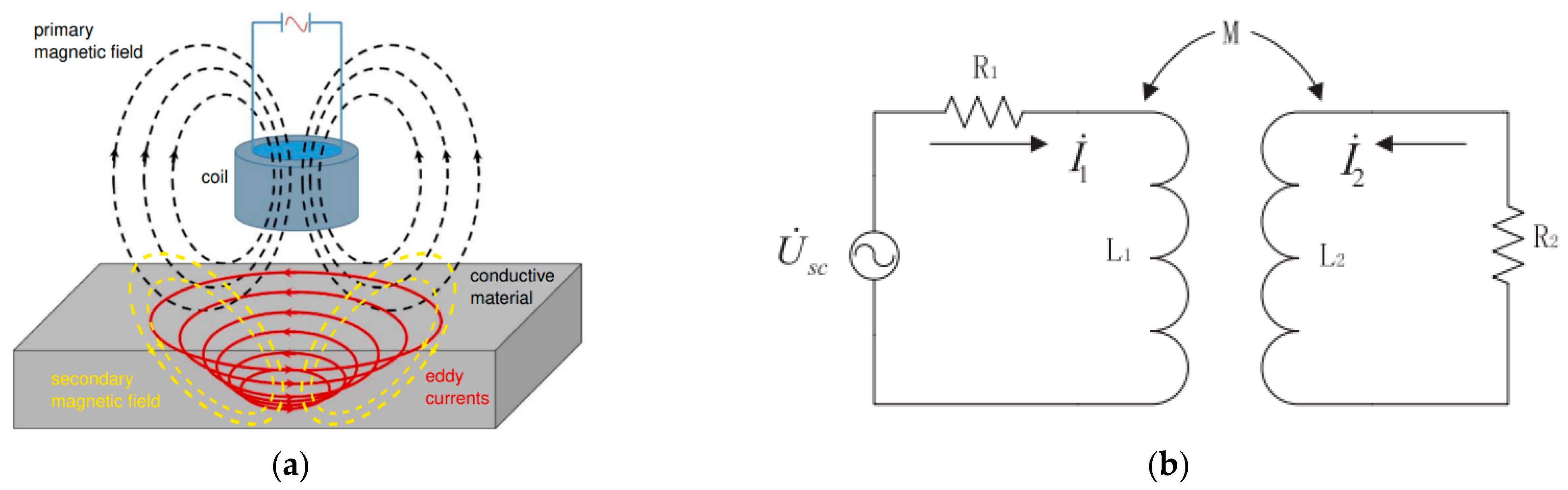

2.1.1. Principles of an Eddy-Current Sensor

2.1.2. Structure of an Eddy-Current Sensor

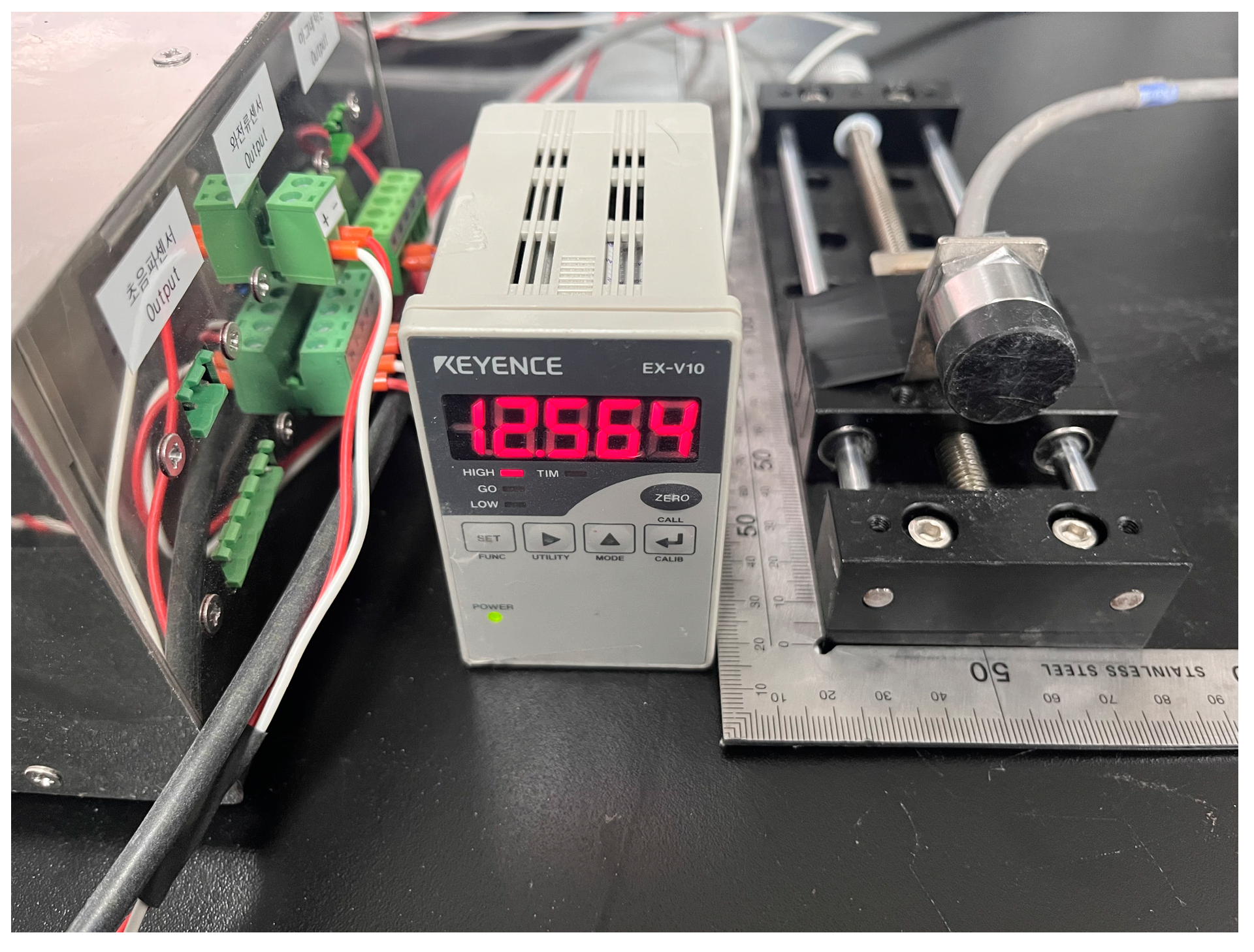

2.1.3. Selection of an Eddy-Current Sensor

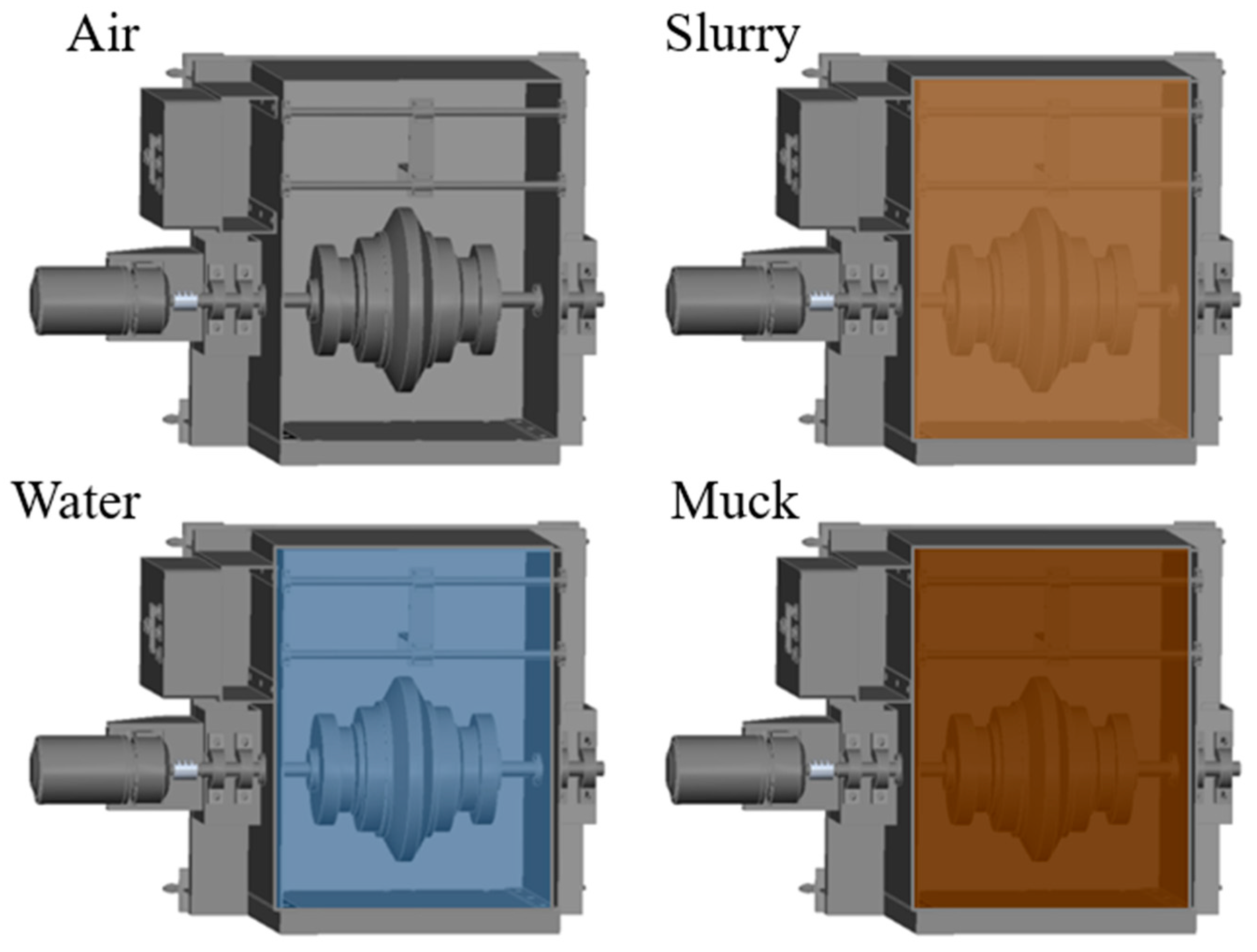

2.2. Experimental Procedures

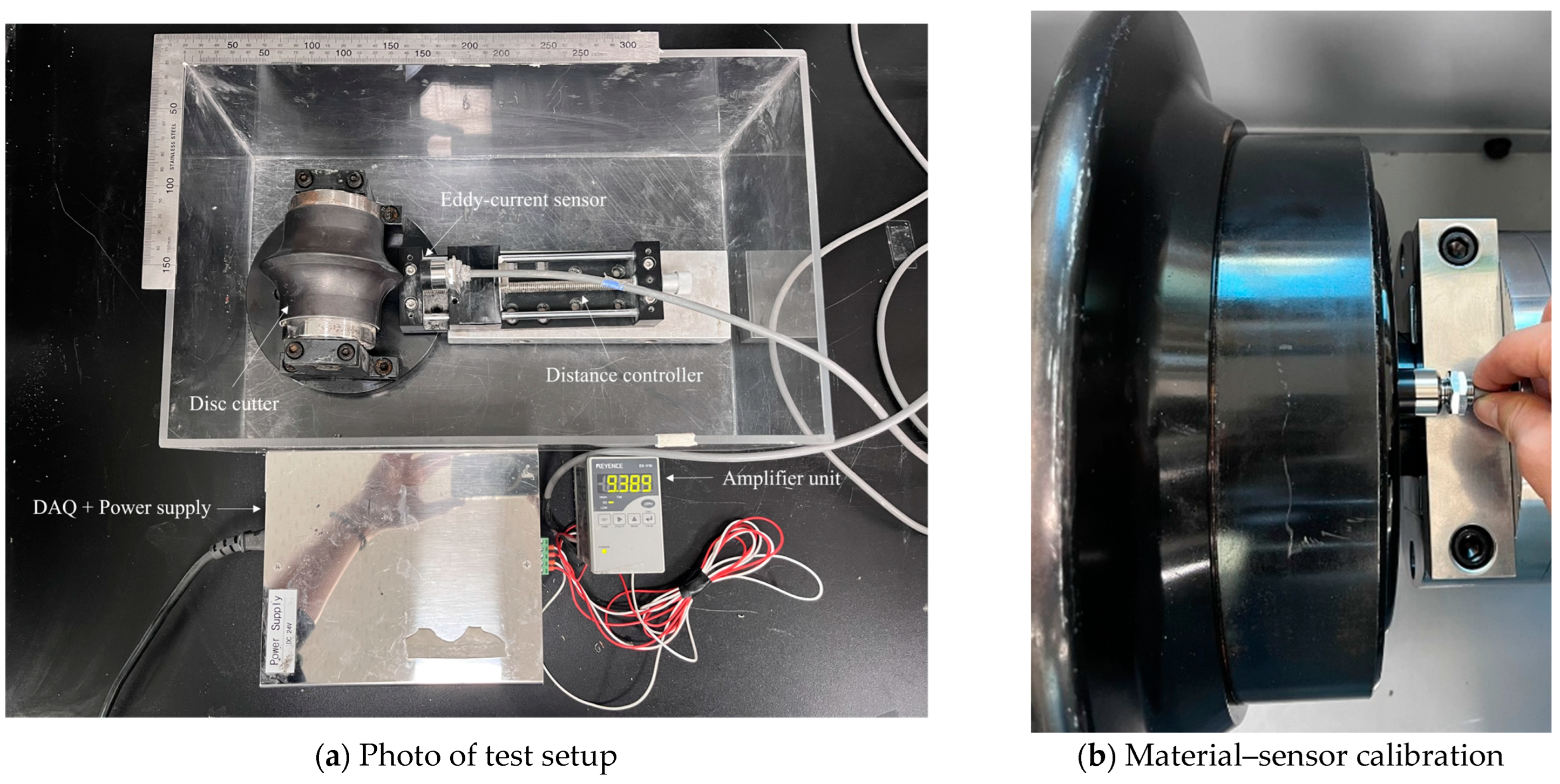

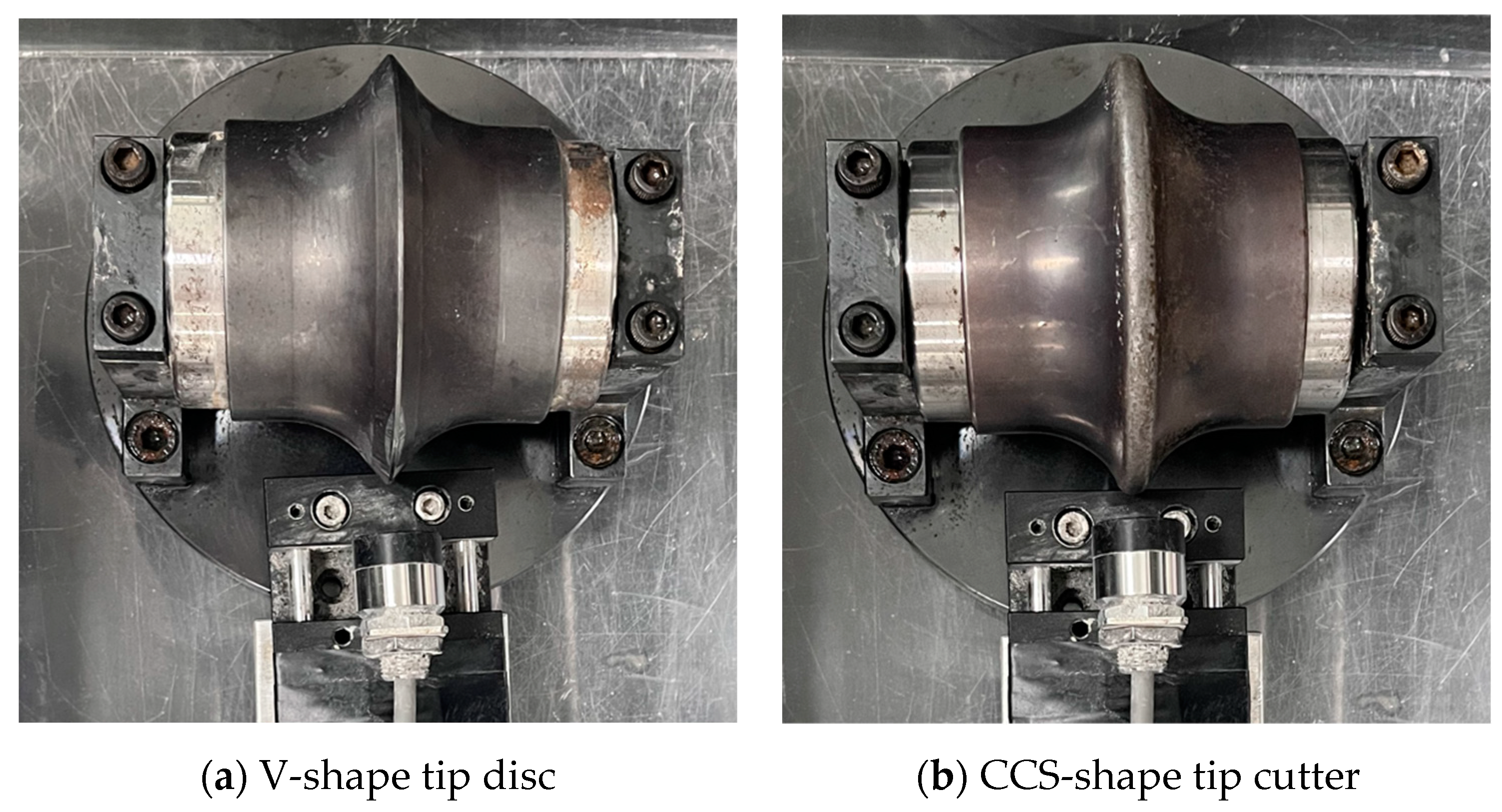

2.2.1. Preliminary Test for Small Discs

2.2.2. Test for 17-Inch Discs

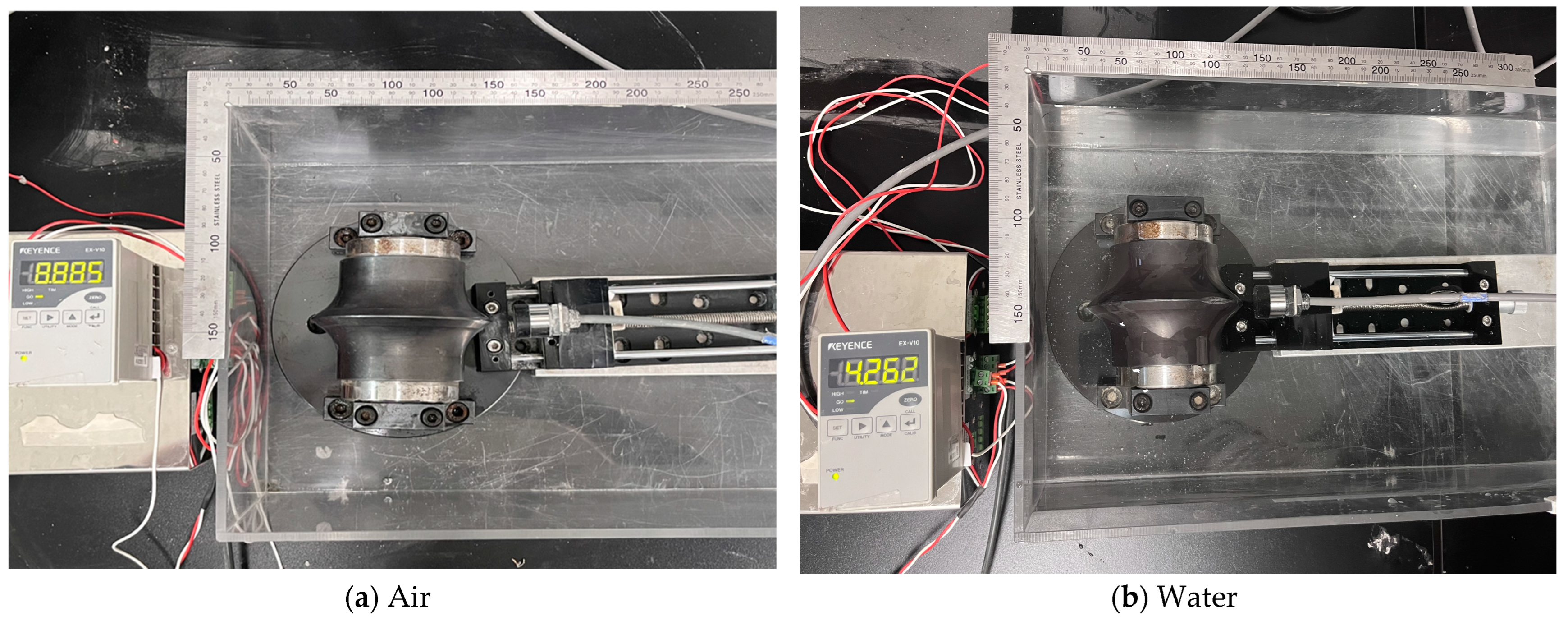

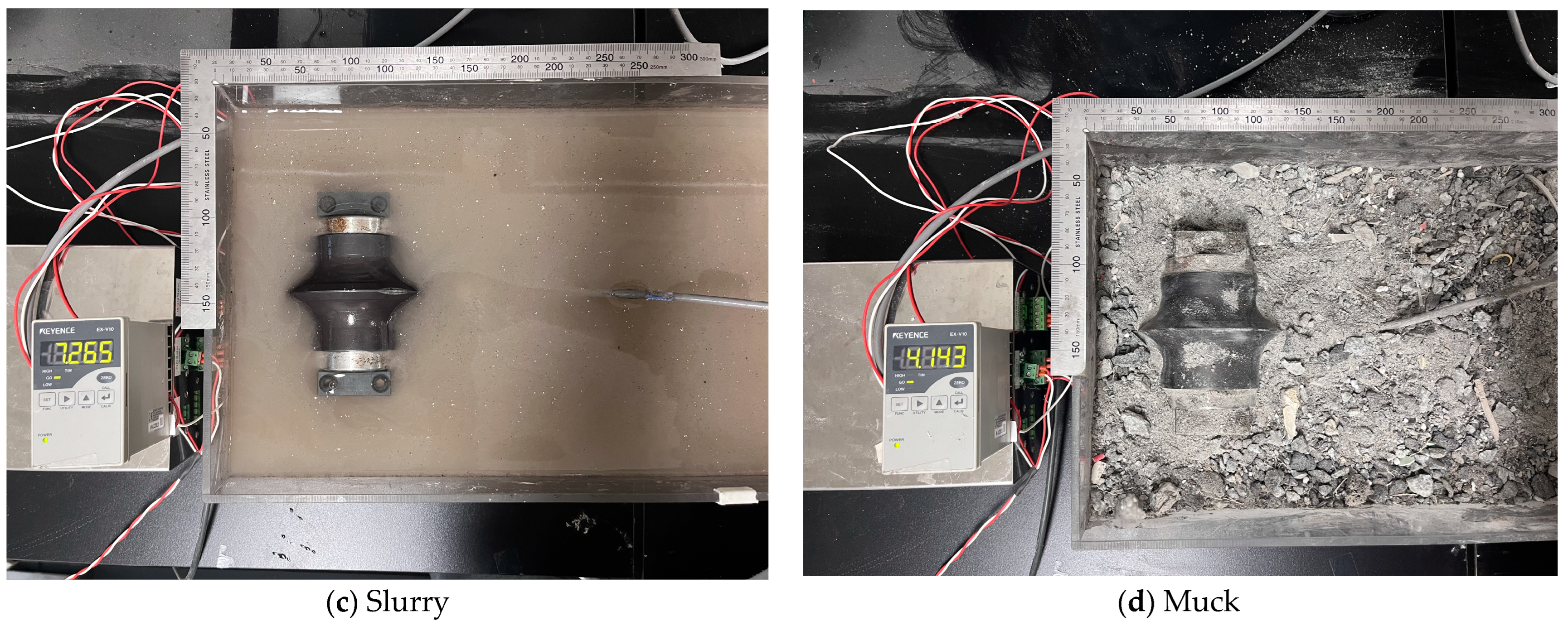

2.2.3. Measurement Environments

3. Results

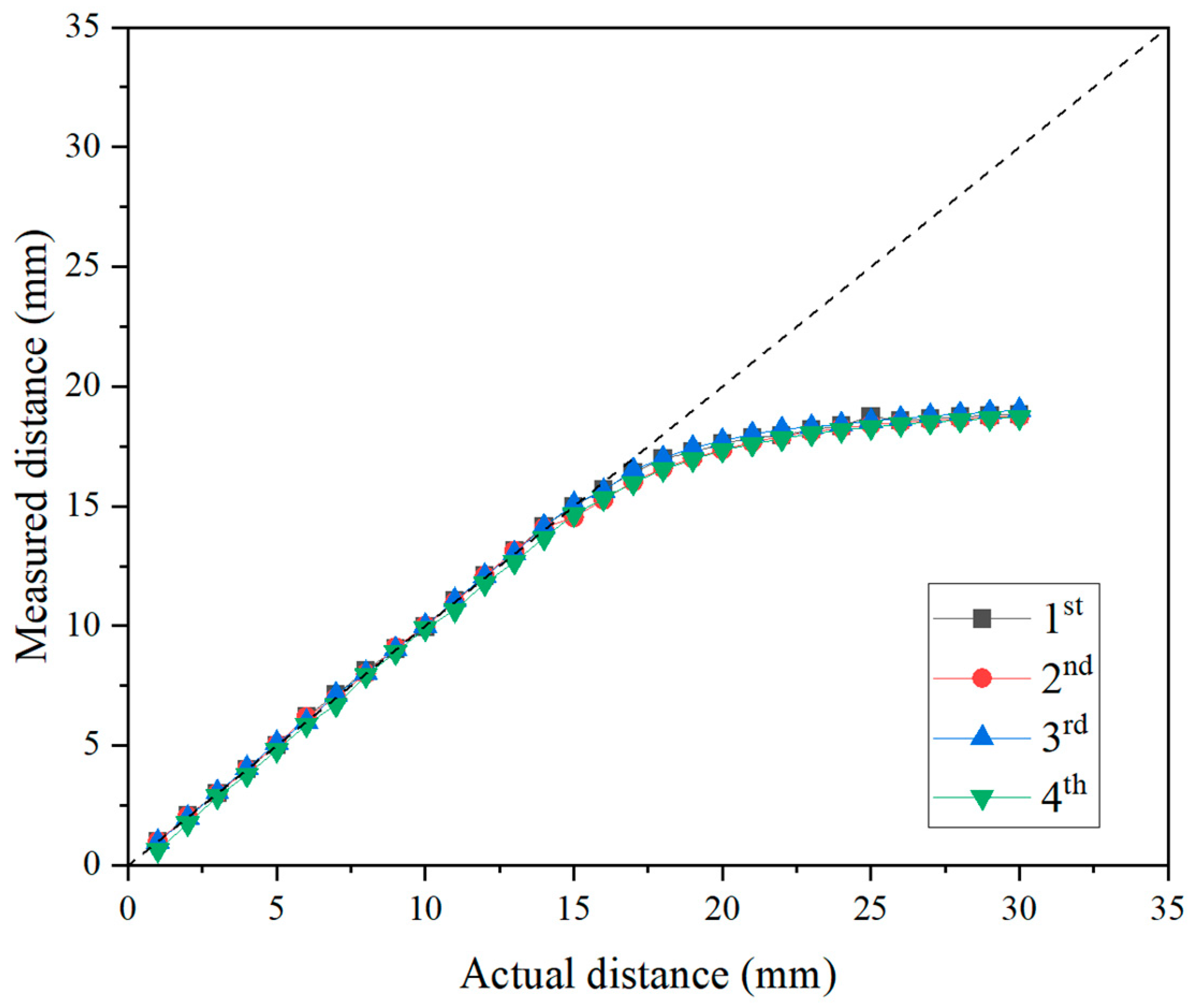

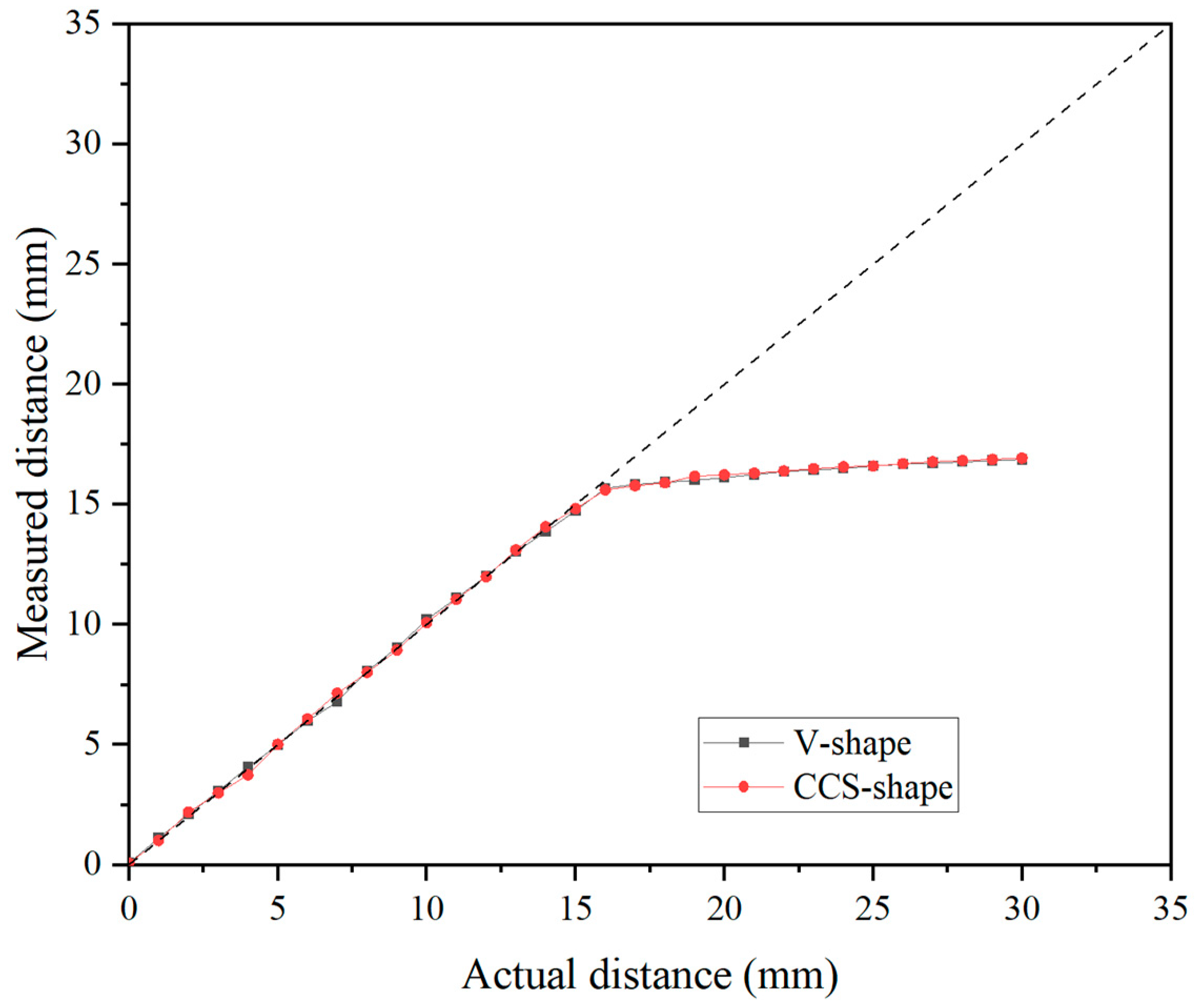

3.1. Preliminary Test for Small Disc Cutter

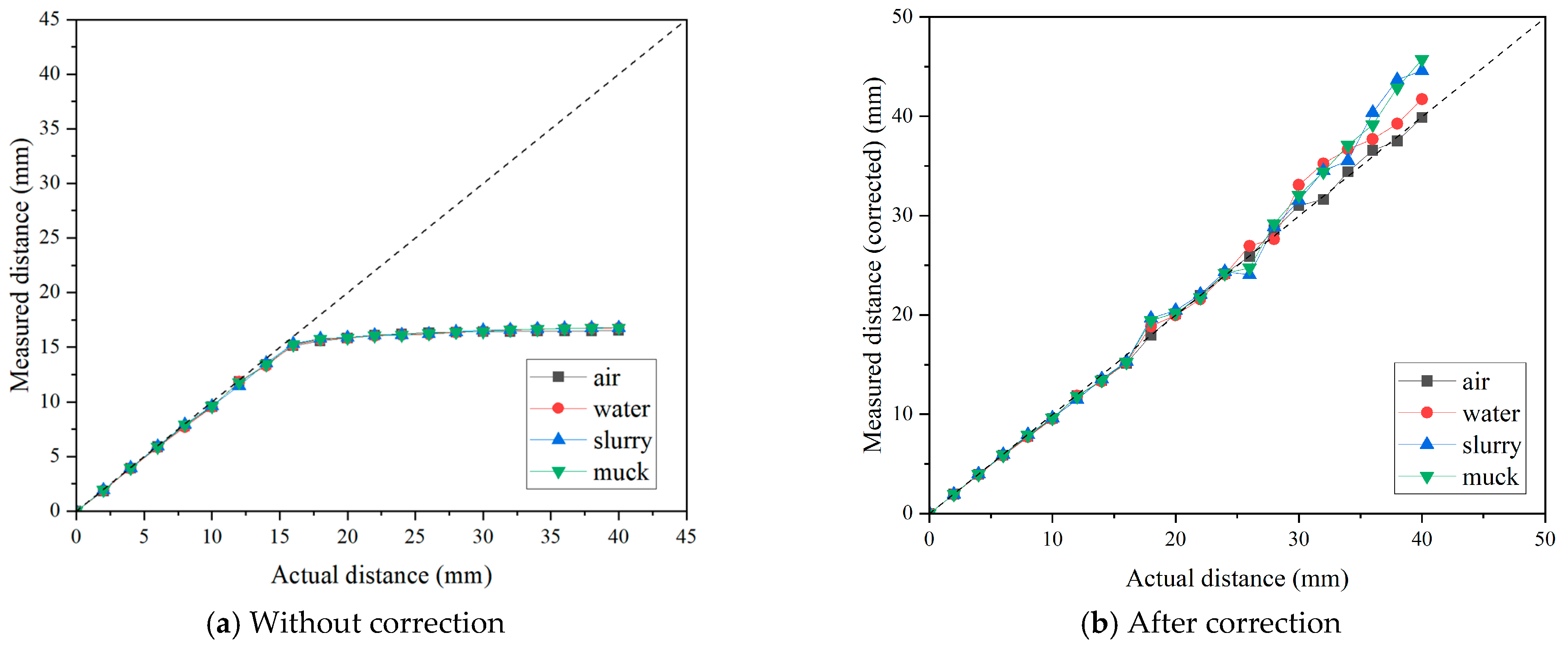

3.1.1. Accuracy in Distance Measurement

3.1.2. Effect of Measurement Media

3.2. Seventeen-Inch Disc Cutters

3.2.1. Effect of Measurement Media

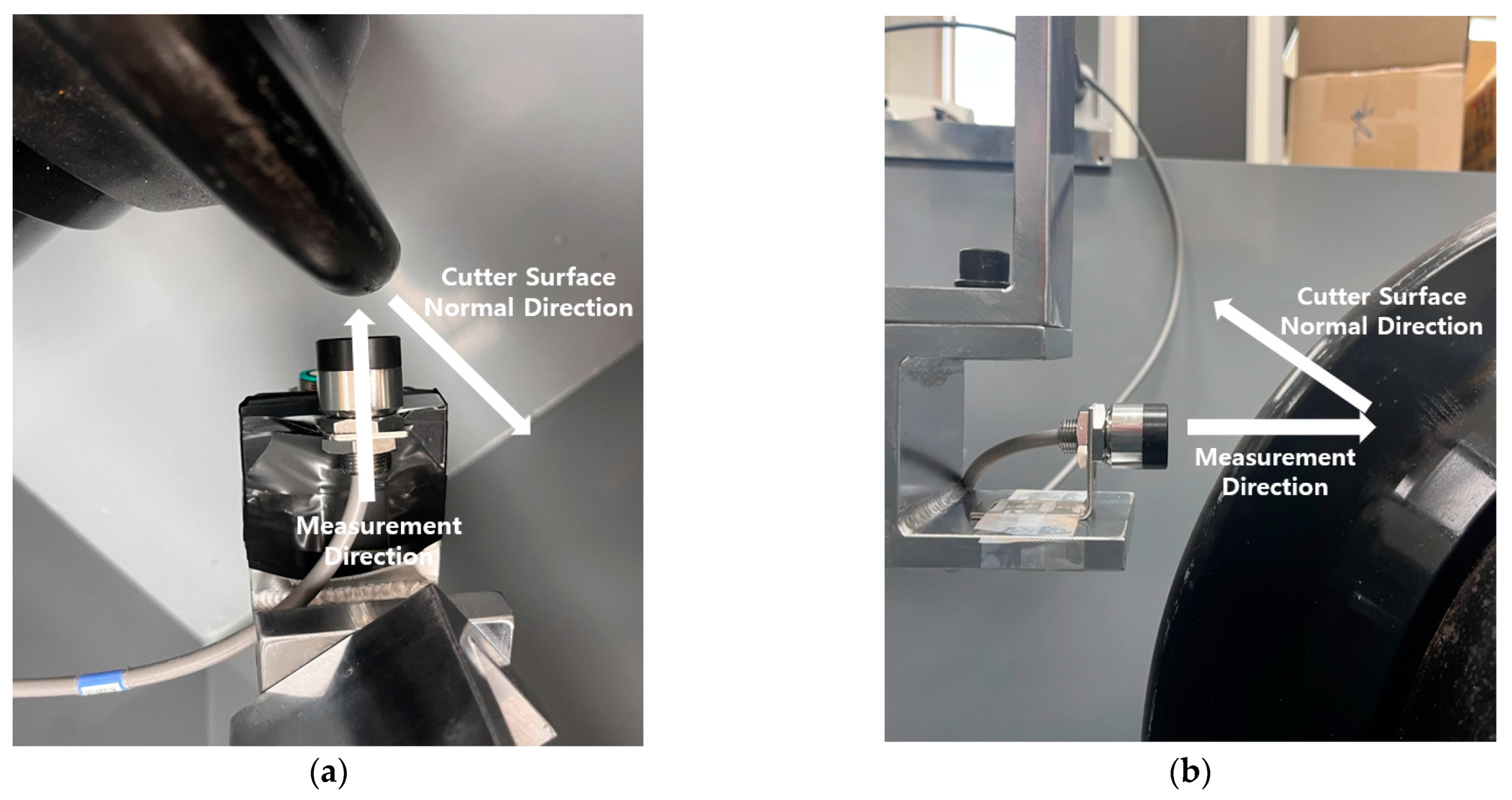

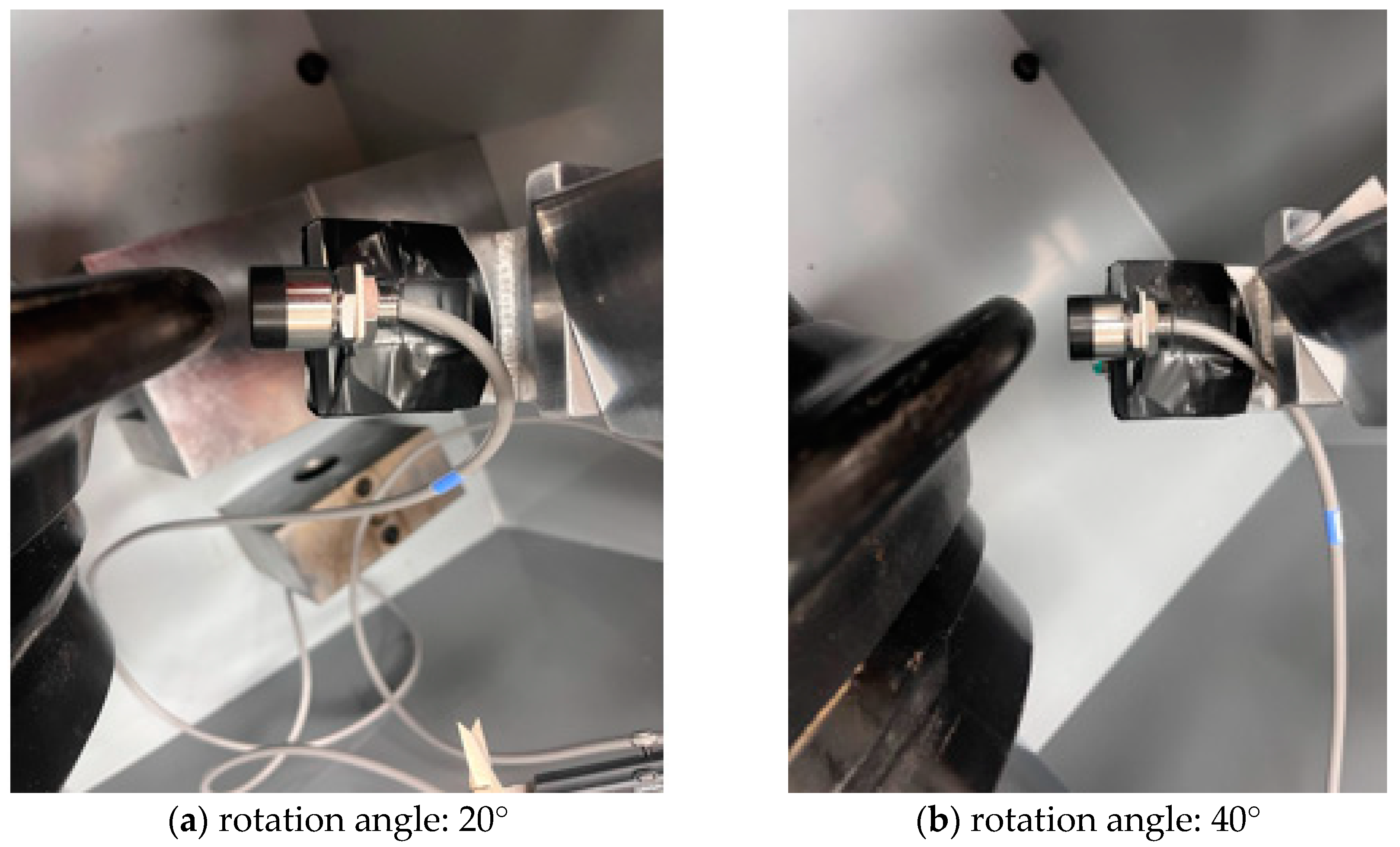

3.2.2. Effect of Measurement Angles

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jeong, H.-Y.; Cho, J.-W.; Jeon, S.; Rostami, J. Performance assessment of hard rock TBM and rock boreability using punch penetration test. Rock Mech. Rock Eng. 2016, 49, 1517–1532. [Google Scholar] [CrossRef]

- Gehring, K. Prognosis of advance rates and wear for underground mechanized excavations. Felsbau 1995, 13, 439–448. (In Germany) [Google Scholar]

- Bruland, A. Hard Rock Tunnel Boring. Ph.D. Dissertation, Norwegian University of Science and Technology, Trondheim, Norway, 1998. [Google Scholar]

- Rostami, J.; Ozdemir, L.; Bruland, A.; Dahl, F. Review of issues related to Cerchar abrasivity testing and their implications on investigations and cutter cost estimates. In Proceedings of the Rapid Excavation and Tunnelling Conference (RETC), Seattle, WA, USA, 27–29 June 2005; pp. 738–751. [Google Scholar]

- Farrokh, E.; Kim, D.Y. A discussion on hard rock TBM cutter wear and cutter head intervention interval length evaluation. Tunn. Undergr. Space Technol. 2018, 81, 336–357. [Google Scholar]

- Guo, J.; Wang, Y.; Liu, J.; Niu, J. The Research and Design of a New Shield Cutter Wear Detection System. Adv. Mater. Res. 2013, 711, 381–384. [Google Scholar]

- Lan, H.; Xia, Y.; Ji, Z.; Fu, J.; Miao, B. Online monitoring device of disc cutter wear—Design and field test. Tunn. Undergr. Space Technol. 2019, 89, 284–294. [Google Scholar]

- Gong, Q.; Wu, F.; Wang, D.; Qiu, H.; Yin, L. Development and Application of Cutterhead Working Status Monitoring System for Shield TBM Tunnelling. Rock Mech. Rock Eng. 2021, 54, 1731–1753. [Google Scholar] [CrossRef]

- Sun, Z.; Li, D.; Zhang, J. Wireless real-time disc cutter wear monitoring system for composite shield machine. Tunn. Constr. 2016, 36, 485–489. (In Chinese) [Google Scholar]

- Li, D.; Sun, Z.; Ren, D.; Sun, W. Study of application of Eddy-current Sensor to Disc-cutter Wear Monitoring System of Shield Machines. Tunn. Constr. 2016, 36, 766–770. [Google Scholar]

- Kurose, H.; Miyagi, D.; Takahashi, N.; Uchida, N.; Kawanaka, K. 3-D eddy current analysis of induction heating apparatus considering heat emission, heat conduction, and temperature dependence of magnetic characteristics. IEEE Trans. Magn. 2009, 45, 1847–1850. [Google Scholar]

- Xue, X.; Dong, Y.; Wu, X. Motion induced eddy current sensor for non-intrusive vibration measurement. IEEE Sens. J. 2019, 20, 735–744. [Google Scholar]

- Wendler, F.; Munjal, R.; Waqas, M.; Laue, R.; Härtel, S.; Awiszus, B.; Kanoun, O. Eddy Current Sensor System for Tilting Independent In-Process Measurement of Magnetic Anisotropy. Sensors 2021, 21, 2652. [Google Scholar] [CrossRef] [PubMed]

- Gruber, G.; Schweighofer, B.; Berger, M.; Leitner, T.; Kloesch, G.; Wegleiter, H. Eddy Current Position Measurement in Harsh Environments: A Temperature Compensation and Calibration Approach. Sensors 2024, 24, 1483. [Google Scholar] [CrossRef] [PubMed]

- Spurek, M.A.; Luong, V.H.; Spierings, A.B.; Lany, M.; Santi, G.; Revaz, B.; Wegener, K. Relative Density Measurement of PBF-Manufactured 316L and AlSi10Mg Samples via Eddy Current Testing. Metals 2021, 11, 1376. [Google Scholar] [CrossRef]

- Wang, F.; Men, C.H.; Kong, X.W.; Meng, L.X. Optimum design and application research of eddy current sensor for measurement of TBM disc cutter wear. Sensors 2019, 19, 4230. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Yuan, S.; Liu, M. Design and analysis of an eddy current displacement sensor with extended linear range. Sens. Actuators A Phys. 2024, 368, 115100. [Google Scholar] [CrossRef]

- Wang, K.; Xie, Y.; Sun, L. Study on nonlinear compensation of eddy current sensor based on support vector machine. In Proceedings of the 2009 IEEE International Symposium on Industrial Electronics, Seoul, Republic of Korea, 5–8 July 2009; pp. 133–137. [Google Scholar] [CrossRef]

- Liu, W.; Liang, B.; Jia, Z.; Feng, D.; Jiang, X.; Li, X.; Zhou, M. High-Accuracy Calibration Based on Linearity Adjustment for Eddy Current Displacement Sensor. Sensors 2018, 18, 2842. [Google Scholar] [CrossRef] [PubMed]

| Measurement Range | Sampling Speed | Measurement Precision | Sensor Head Diameter | Weight | Waterproof Grade |

|---|---|---|---|---|---|

| 10 mm | 15,000 num/s | 2 μm | Ȼ 22 × 35 mm | 200 g | IP67 |

| Range (mm) | Correction Functions (y = a + bx) | Accuracy (%) | |||

|---|---|---|---|---|---|

| Air | Water | Slurry | Muck | ||

| 0–16 | y = x | 99.2 | 98.6 | 98.4 | 97.5 |

| 16–22 | y = −31.457 + 2.977x | ||||

| 22–28 | y = −164.19 + 10.297x | ||||

| 28–34 | y = −583.77 + 32.729x | ||||

| Range (mm) | Correction Functions (y = a + bx) | Accuracy (%) | |||

|---|---|---|---|---|---|

| Air | Water | Slurry | Muck | ||

| 0–16 | y = x | 98.1 | 95.9 | 95.0 | 94.9 |

| 16–22 | y = −99.318 + 7.532x | ||||

| 22–26 | y = −253.37 + 17.101x | ||||

| 26–32 | y = −775.95 + 49.101x | ||||

| 32–40 | y = −1660.73 + 102.891x | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, M.; Ju, M.; Kim, J.; Jeong, H. Measurement of TBM Disc Cutter Wear Using Eddy-Current Sensor in Different TBM Chamber Conditions: Insights from Laboratory Tests. Sensors 2025, 25, 2045. https://doi.org/10.3390/s25072045

Park M, Ju M, Kim J, Jeong H. Measurement of TBM Disc Cutter Wear Using Eddy-Current Sensor in Different TBM Chamber Conditions: Insights from Laboratory Tests. Sensors. 2025; 25(7):2045. https://doi.org/10.3390/s25072045

Chicago/Turabian StylePark, Minsung, Minseok Ju, Jungjoo Kim, and Hoyoung Jeong. 2025. "Measurement of TBM Disc Cutter Wear Using Eddy-Current Sensor in Different TBM Chamber Conditions: Insights from Laboratory Tests" Sensors 25, no. 7: 2045. https://doi.org/10.3390/s25072045

APA StylePark, M., Ju, M., Kim, J., & Jeong, H. (2025). Measurement of TBM Disc Cutter Wear Using Eddy-Current Sensor in Different TBM Chamber Conditions: Insights from Laboratory Tests. Sensors, 25(7), 2045. https://doi.org/10.3390/s25072045