Improving the Dissolution Rate and Bioavailability of Curcumin via Co-Crystallization

Abstract

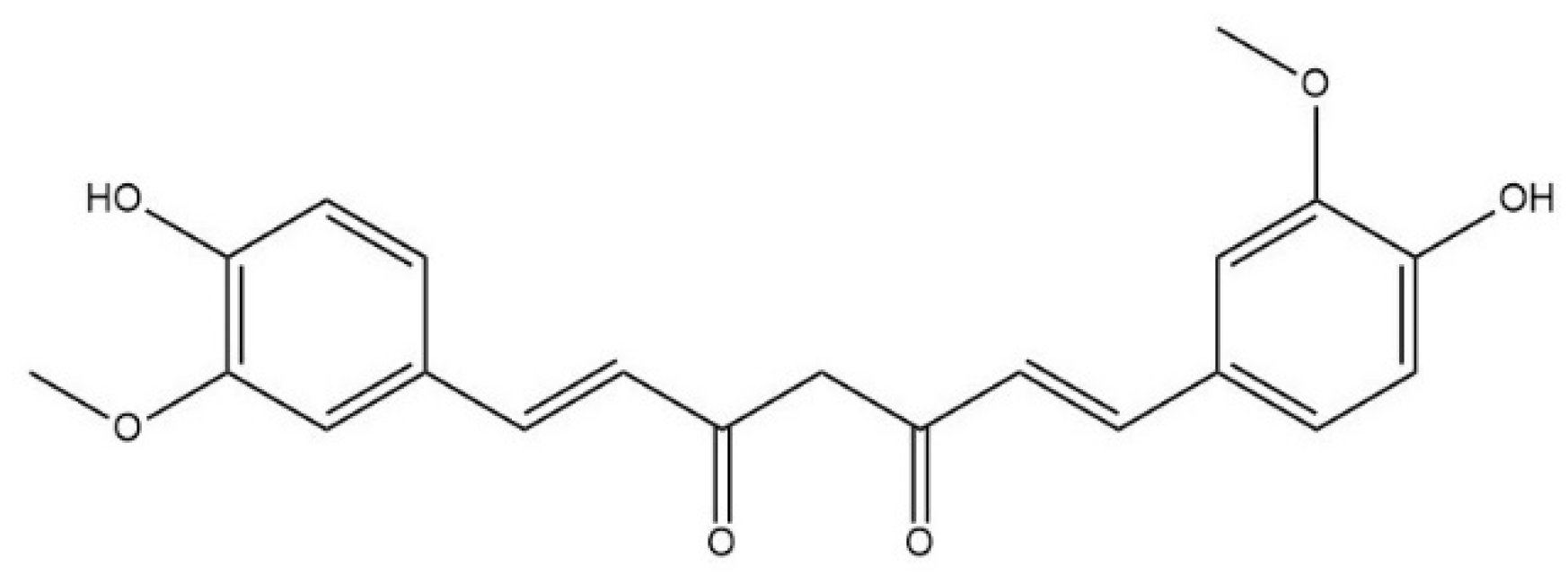

:1. Introduction

2. Results

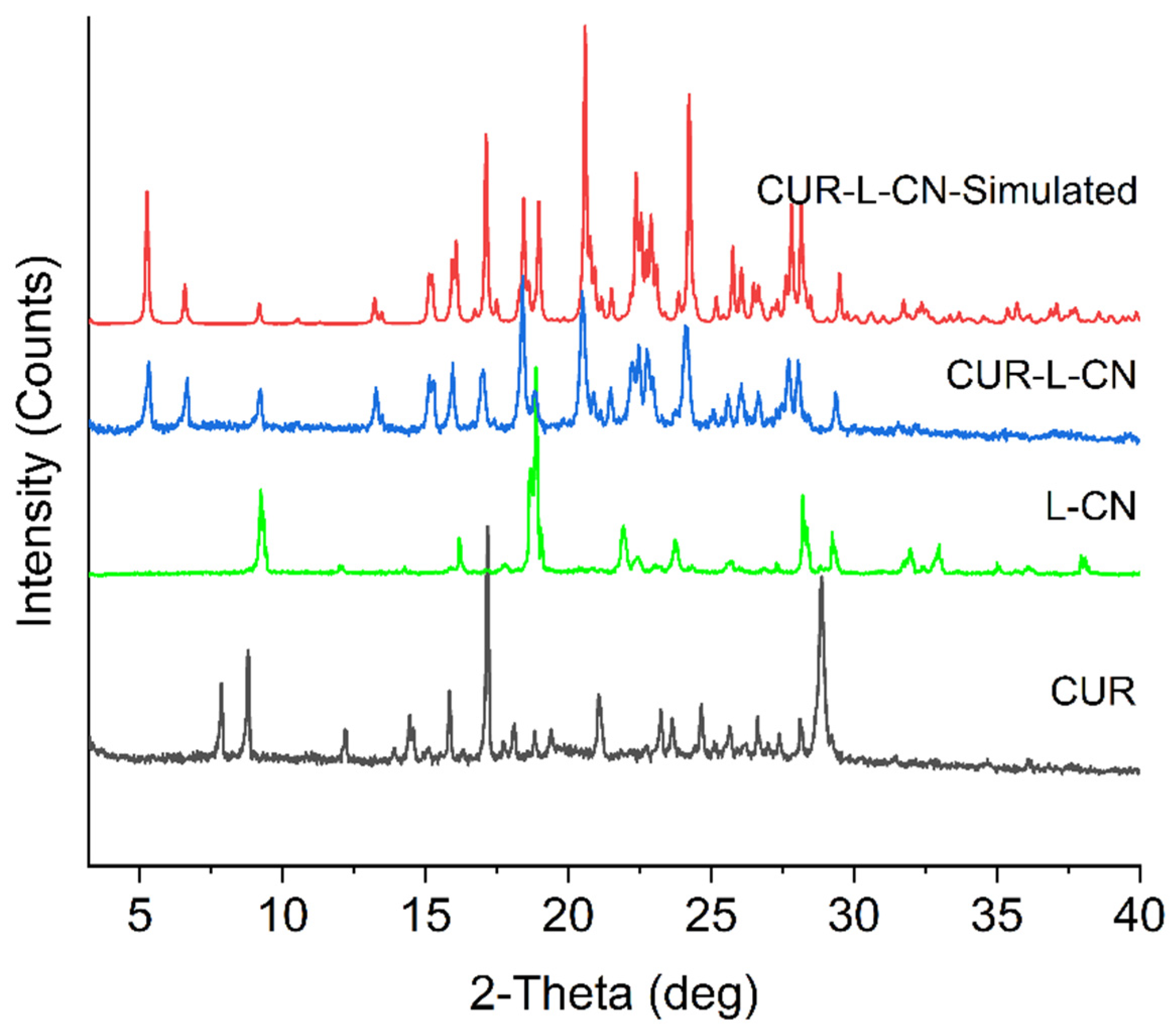

2.1. PXRD Analysis and Confirmation of Co-Crystal Formation

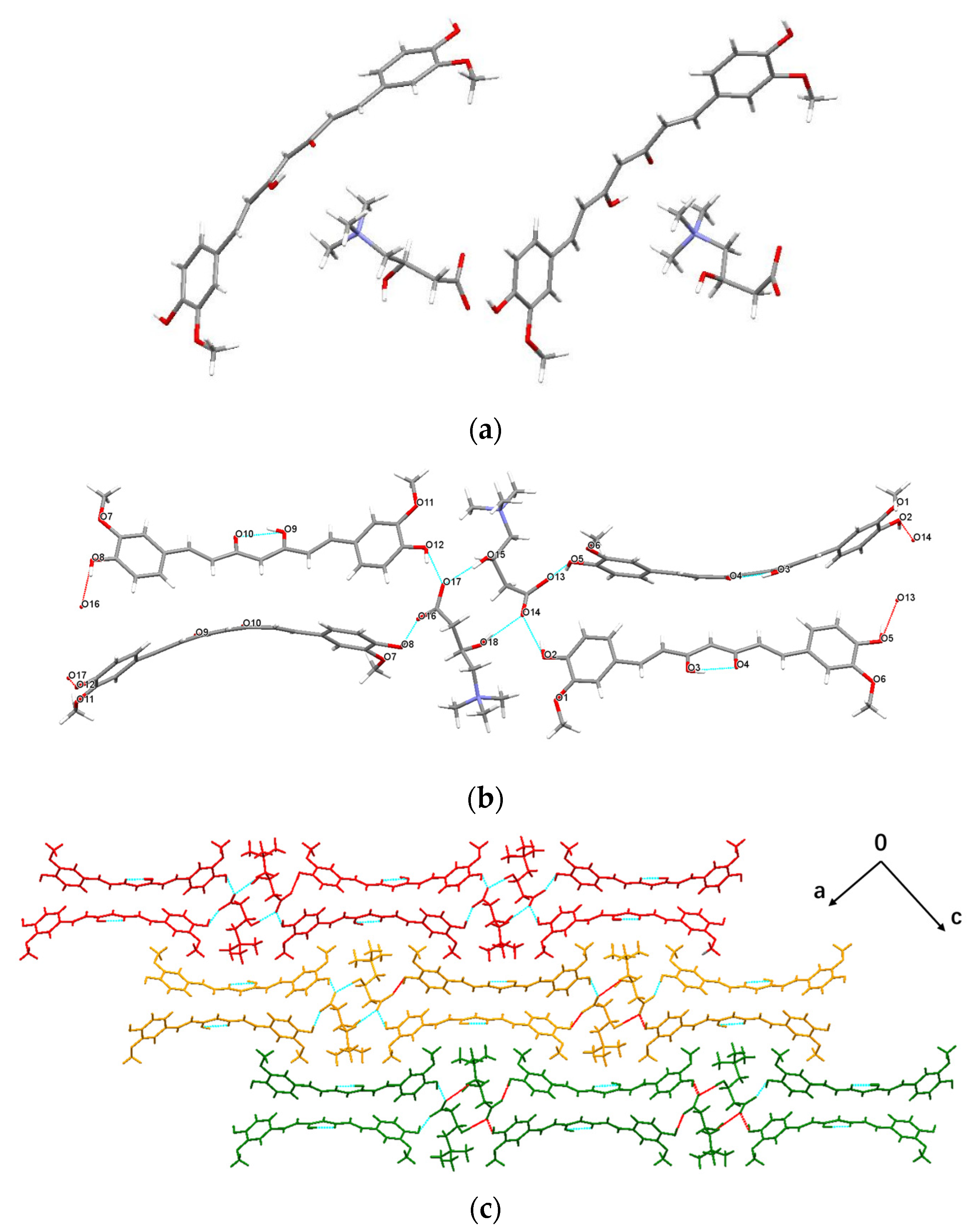

2.2. Crystal Structure Analysis

2.3. Thermal Analysis

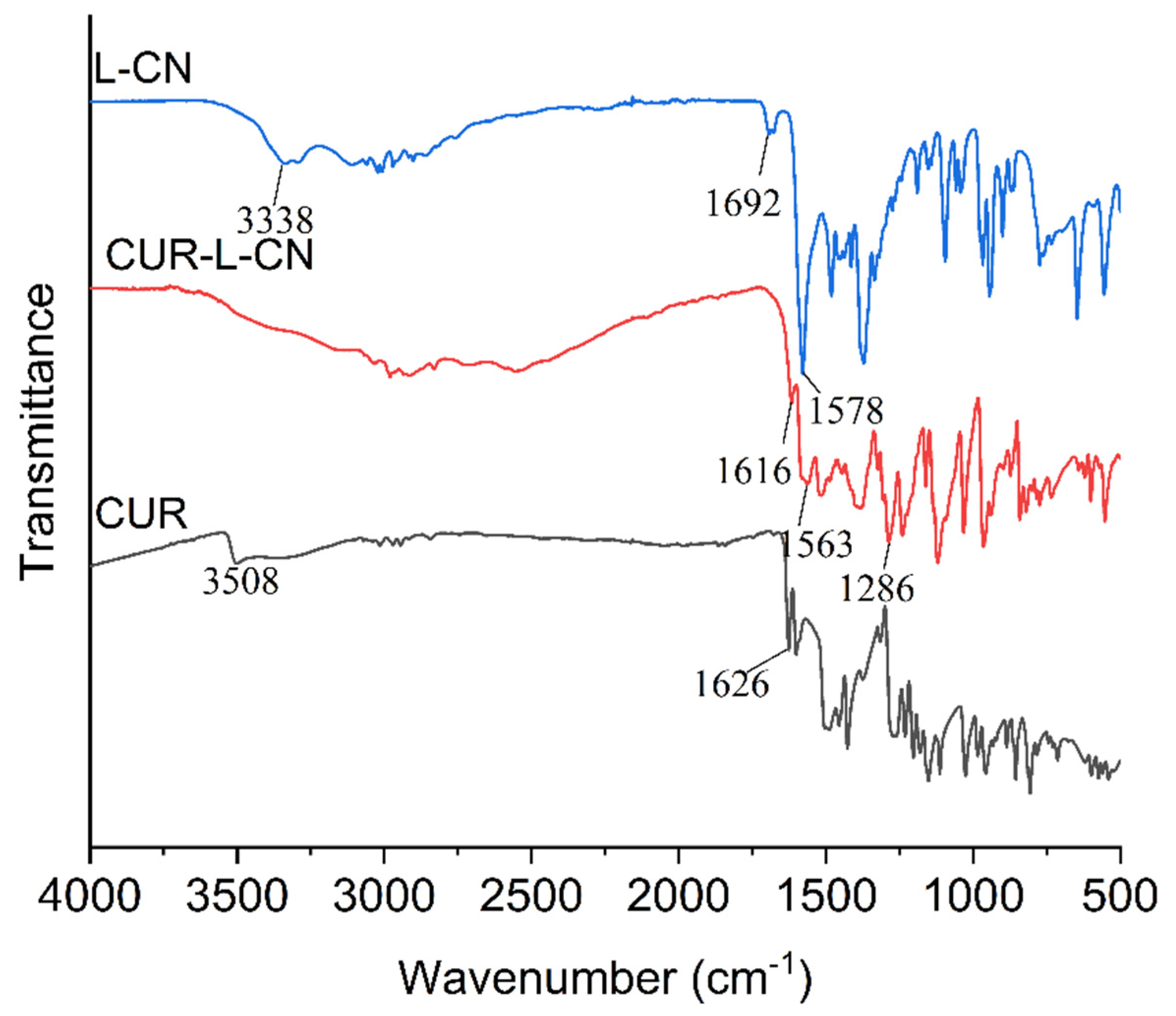

2.4. FTIR Spectroscopy

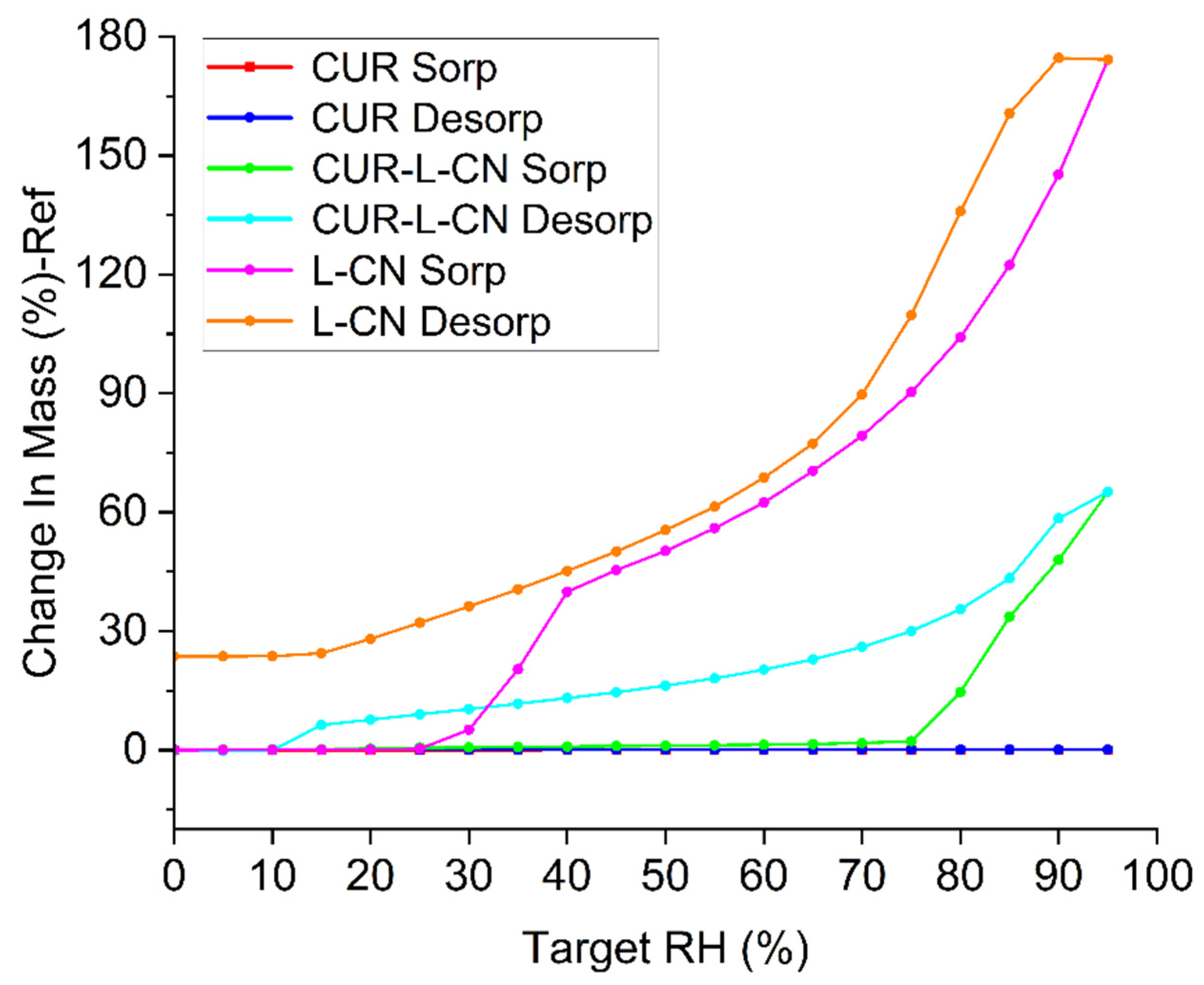

2.5. Hygroscopicity and Stability

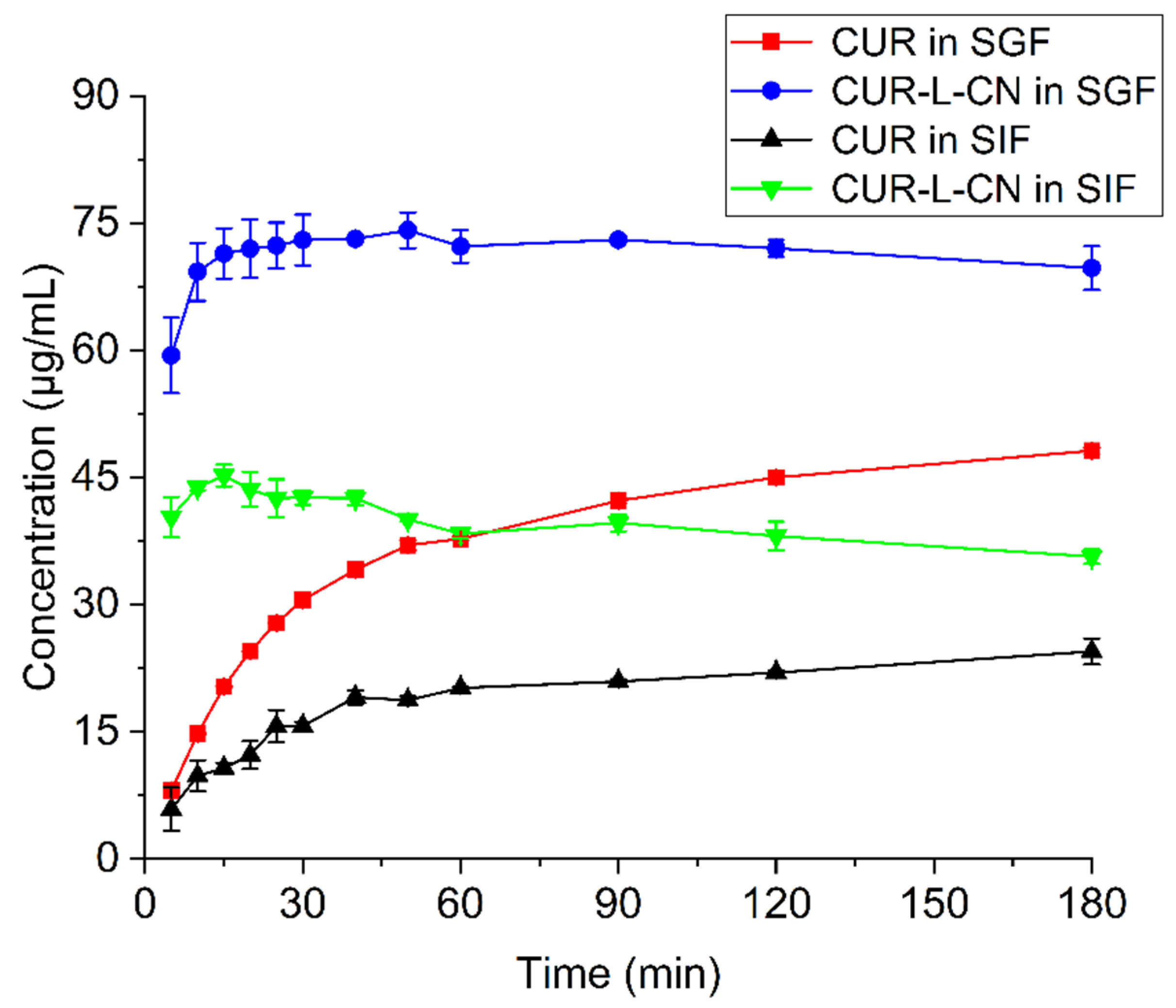

2.6. Powder Dissolution Studies

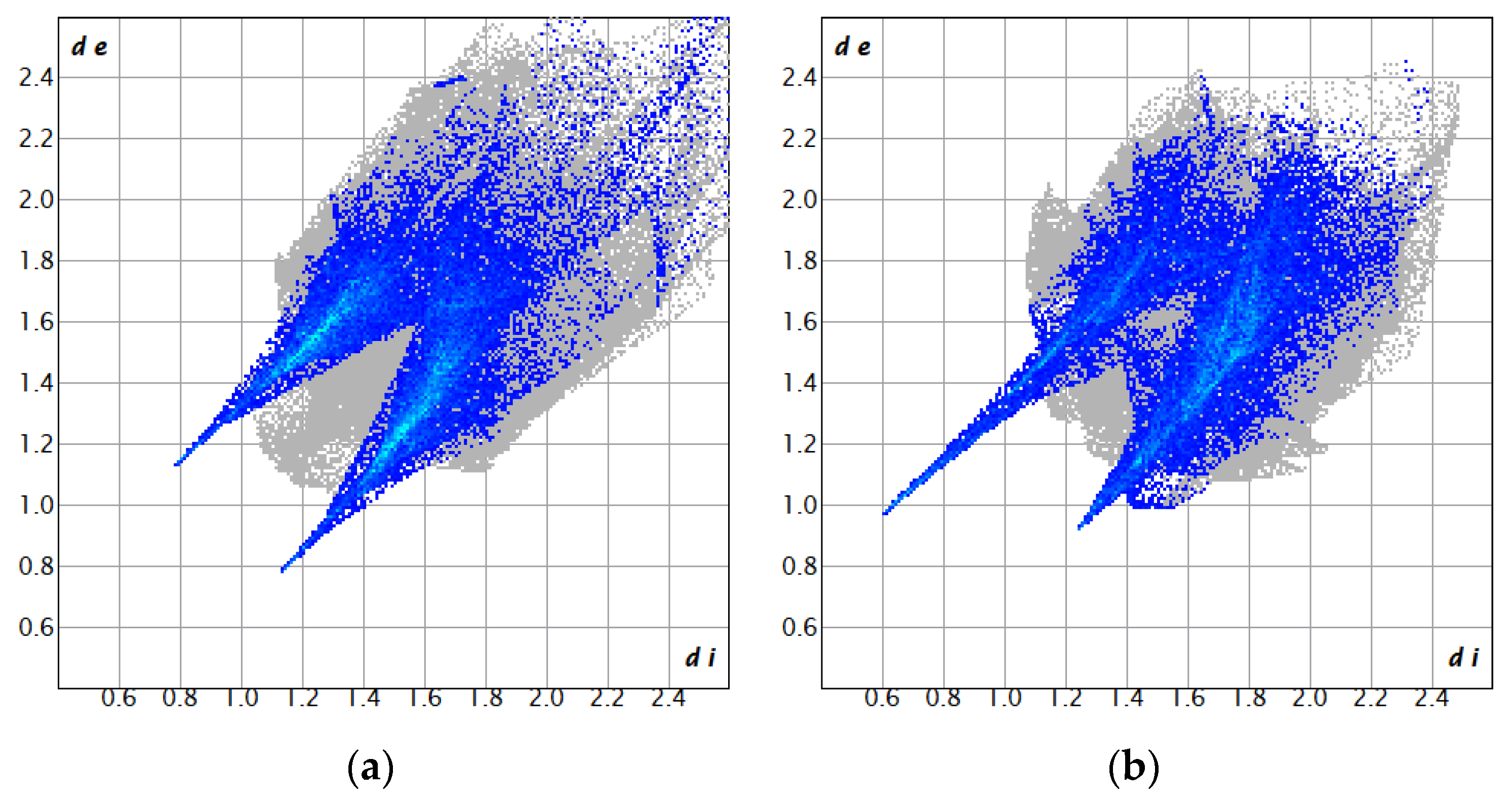

2.7. Hirshfeld Surface Analysis

2.8. Wettability Test

2.9. In Vivo Bioavailability

3. Discussion

4. Materials and Methods

4.1. Materials

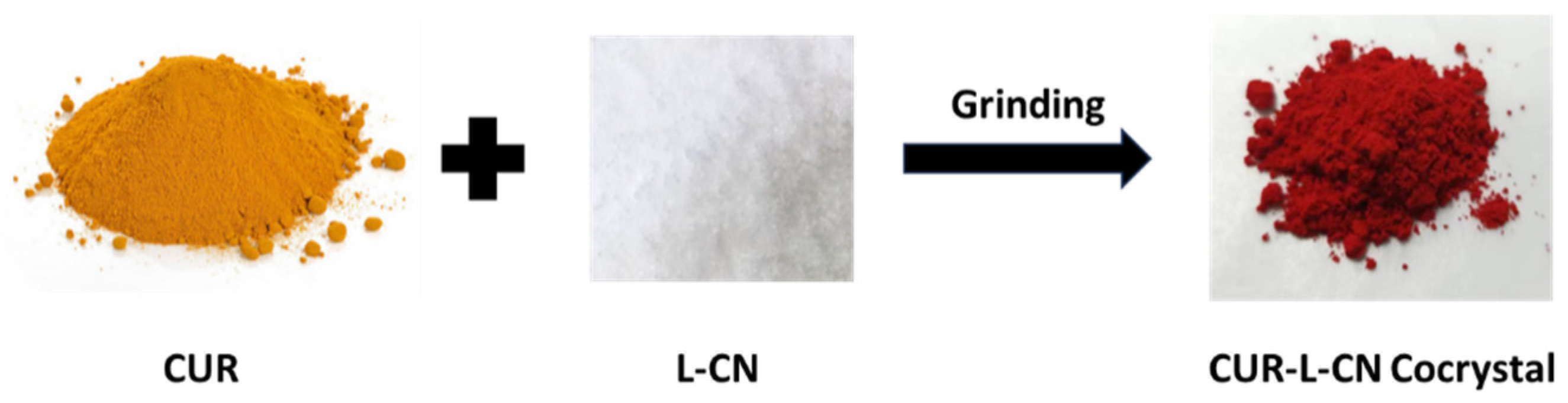

4.2. Preparation of CUR-L-CN Co-Crystal

4.3. Preparation of Single Crystal

4.4. PXRD

4.5. SCXRD

4.6. DSC

4.7. TGA

4.8. FTIR Spectroscopy

4.9. DVS

4.10. Stability Test

4.11. Powder Dissolution Studies

4.12. Wettability Test

4.13. HPLC Analysis

4.14. Pharmacokinetic Study

4.15. Bioanalytical Method

4.16. Data Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeng, Y.; Luo, Y.; Wang, L.; Zhang, K.; Peng, J.; Fan, G. Therapeutic Effect of Curcumin on Metabolic Diseases: Evidence from Clinical Studies. Int. J. Mol. Sci. 2023, 24, 3323. [Google Scholar] [CrossRef]

- Kunnumakkara, A.B.; Harsha, C.; Banik, K.; Vikkurthi, R.; Sailo, B.L.; Bordoloi, D.; Gupta, S.C.; Aggarwal, B.B. Is curcumin bioavailability a problem in humans: Lessons from clinical trials. Expert Opin. Drug Metab. Toxicol. 2019, 15, 705–733. [Google Scholar] [CrossRef] [PubMed]

- Cicero, A.F.G.; Sahebkar, A.; Fogacci, F.; Bove, M.; Giovannini, M.; Borghi, C. Effects of phytosomal curcumin on anthro-pometric parameters, insulin resistance, cortisolemia and non-alcoholic fatty liver disease indices: A double-blind, place-bo-controlled clinical trial. Eur. J. Nutr. 2020, 59, 477–483. [Google Scholar] [CrossRef] [PubMed]

- Hariri, M.; Gholami, A.; Mirhafez, S.R.; Bidkhori, M.; Sahebkar, A. A pilot study of the effect of curcumin on epigenetic changes and DNA damage among patients with non-alcoholic fatty liver disease: A randomized, double-blind, placebo-controlled, clinical trial. Complement. Ther. Med. 2020, 51, 102447. [Google Scholar] [CrossRef] [PubMed]

- Thota, R.N.; Acharya, S.H.; Garg, M.L. Curcumin and/or omega-3 polyunsaturated fatty acids supplementation reduces insulin resistance and blood lipids in individuals with high risk of type 2 diabetes: A randomised controlled trial. Lipids Health Dis. 2019, 18, 31. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, A.; Selvarajan, S.; Kamalanathan, S.; Kadhiravan, T.; Prasanna Lakshmi, N.C.; Adithan, S. Effect of Curcuma longa on vascular function in native Tamilians with type 2 diabetes mellitus: A randomized, double-blind, parallel arm, placebo-controlled trial. Phytother. Res. 2019, 33, 1898–1911. [Google Scholar] [CrossRef] [PubMed]

- Jazayeri-Tehrani, S.A.; Rezayat, S.M.; Mansouri, S.; Qorbani, M.; Alavian, S.M.; Daneshi-Maskooni, M.; Hosseinzadeh-Attar, M.J. Nano-curcumin improves glucose indices, lipids, inflammation, and Nesfatin in overweight and obese patients with non-alcoholic fatty liver disease (NAFLD): A double-blind randomized placebo-controlled clinical trial. Nutr. Metab. 2019, 16, 8. [Google Scholar] [CrossRef] [PubMed]

- Saraf-Bank, S.; Ahmadi, A.; Paknahad, Z.; Maracy, M.; Nourian, M. Effects of curcumin on cardiovascular risk factors in obese and overweight adolescent girls: A randomized clinical trial. Sao Paulo Med. J. 2019, 137, 414–422. [Google Scholar] [CrossRef] [PubMed]

- Saraf-Bank, S.; Ahmadi, A.; Paknahad, Z.; Maracy, M.; Nourian, M. Effects of curcumin supplementation on markers of in-flammation and oxidative stress among healthy overweight and obese girl adolescents: A randomized placebo-controlled clinical trial. Phytother. Res. 2019, 33, 2015–2022. [Google Scholar] [CrossRef]

- Alizadeh, F.; Javadi, M.; Karami, A.A.; Gholaminejad, F.; Kavianpour, M.; Haghighian, H.K. Curcumin nanomicelle improves semen parameters, oxidative stress, inflammatory biomarkers, and reproductive hormones in infertile men: A randomized clinical trial. Phytother. Res. 2018, 32, 514–521. [Google Scholar] [CrossRef] [PubMed]

- Ng, Q.X.; Koh, S.S.H.; Chan, H.W.; Ho, C.Y.X. Clinical Use of Curcumin in Depression: A Meta-Analysis. J. Am. Med. Dir. Assoc. 2017, 18, 503–508. [Google Scholar] [CrossRef] [PubMed]

- Al-Karawi, D.; Al Mamoori, D.A.; Tayyar, Y. The Role of Curcumin Administration in Patients with Major Depressive Disorder: Mini Meta-Analysis of Clinical Trials. Phytother. Res. 2016, 30, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Sharifi, S.; Bagherniya, M.; Khoram, Z.; Ebrahimi Varzaneh, A.; Atkin, S.L.; Jamialahmadi, T.; Sahebkar, A.; Askari, G. Efficacy of curcumin plus piperine co-supplementation in moderate-to-high hepatic steatosis: A double-blind, randomized, placebo-controlled clinical trial. Phytother. Res. 2023, 37, 2217–2229. [Google Scholar] [CrossRef] [PubMed]

- Panahi, Y.; Kianpour, P.; Mohtashami, R.; Soflaei, S.S.; Sahebkar, A. Efficacy of phospholipidated curcumin in nonalcoholic fatty liver disease: A clinical study. J. Asian Nat. Prod. Res. 2019, 21, 798–805. [Google Scholar] [CrossRef] [PubMed]

- Nga, W.S.; Shenye, H.; Wing, N.W. Cocrystallization of curcumin with benzenediols and benzenetriols via rapid solvent removal. Cryst. Growth Des. 2018, 18, 5534–5546. [Google Scholar]

- Anand, P.; Kunnumakkara, A.B.; Newman, R.A.; Aggarwal, B.B. Bioavailability of curcumin: Problems and promises. Mol. Pharm. 2007, 4, 807–818. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Y.; Yu, Q.; Huang, Y.; Zhu, Q.; Chen, Z.; Wu, W.; Yi, T.; Lu, Y. Pickering Emulsions Enhance Oral Bioavailability of Curcumin Nanocrystals: The Effect of Oil Types. Pharmaceutics 2023, 15, 1341. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.; Chen, L.; Qamar, M.; Wen, Y.; Li, L.; Zhang, J.; Li, X.; Assadpour, E.; Esatbeyoglu, T.; Kharazmi, M.S. The bioavailability, metabolism and microbial modulation of curcumin-loaded nanodelivery systems. Adv. Colloid Interface Sci. 2023, 318, 102933. [Google Scholar] [CrossRef]

- Purpura, M.; Lowery, R.P.; Wilson, J.M.; Mannan, H.; Münch, G.; Razmovski-Naumovski, V. Analysis of different innovative formulations of curcumin for improved relative oral bioavailability in human subjects. Eur. J. Nutr. 2018, 57, 929–938. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.Y.; Lin, L.C.; Tseng, T.Y.; Wang, S.C.; Tsai, T.H. Oral bioavailability of curcumin in rat and the herbal analysis from Curcuma longa by LC-MS/MS. J. Chromatogr. B. Analyt. Technol. Biomed. Life Sci. 2007, 853, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Dei Cas, M.; Ghidoni, R. Dietary Curcumin: Correlation between Bioavailability and Health Potential. Nutrients 2019, 11, 2147. [Google Scholar] [CrossRef] [PubMed]

- Ipar, V.S.; Dsouza, A.; Devarajan, P.V. Enhancing Curcumin Oral Bioavailability Through Nanoformulations. Eur. J. Drug Metab. Pharmacokinet. 2019, 44, 459–480. [Google Scholar] [CrossRef] [PubMed]

- Bisht, S.; Feldmann, G.; Soni, S.; Ravi, R.; Karikar, C.; Maitra, A.; Maitra, A. Polymeric nanoparticle-encapsulated curcumin (“nanocurcumin”): A novel strategy for human cancer therapy. J. Nanobiotechnology 2007, 5, 3. [Google Scholar] [CrossRef] [PubMed]

- Maiti, K.; Mukherjee, K.; Gantait, A.; Saha, B.P.; Mukherjee, P.K. Curcumin-phospholipid complex: Preparation, therapeutic evaluation and pharmacokinetic study in rats. Int. J. Pharm. 2007, 330, 155–163. [Google Scholar] [CrossRef] [PubMed]

- Mai, N.N.S.; Otsuka, Y.; Kawano, Y.; Hanawa, T. Preparation and Characterization of Solid Dispersions Composed of Cur-cumin, Hydroxypropyl Cellulose and/or Sodium Dodecyl Sulfate by Grinding with Vibrational Ball Milling. Pharmaceuticals 2020, 13, 383. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Wei, Y.; Lee, R.J.; Zhao, L. Liposomal curcumin and its application in cancer. Int. J. Nanomed. 2017, 12, 6027–6044. [Google Scholar] [CrossRef] [PubMed]

- Shoba, G.; Joy, D.; Joseph, T.; Majeed, M.; Rajendran, R.; Srinivas, P.S. Influence of piperine on the pharmacokinetics of curcumin in animals and human volunteers. Planta. Med. 1998, 64, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhai, G.X.; Zhao, Y.; Lou, H.X. Absorption of curcumin microemulsion in vivo. Chin. Tradit. Herbal Drugs 2007, 38, 368–372. [Google Scholar]

- Wang, P.; Li, H.; Lin, Z.; Luo, H.; Luo, W. Comparing the Effect of Piperine and Ilepcimide on the Pharmacokinetics of Curcumin in SD Rats. Front. Pharmacol. 2021, 12, 725362. [Google Scholar] [CrossRef]

- Khalil, N.M.; Nascimento, T.C.F.D.; Casa, D.M.; Dalmolin, L.F.; de Mattos, A.C.; Hoss, I.; Romano, M.A.; Mainardes, R.M. Pharmacokinetics of curcumin-loaded PLGA and PLGA–PEG blend nanoparticles after oral administration in rats. Colloids Surf. B Biointerfaces 2013, 101, 353–360. [Google Scholar] [CrossRef] [PubMed]

- Dal Magro, C.; dos Santos, A.E.; Ribas, M.M.; Aguiar, G.P.S.; Volfe, C.R.B.; Lopes, M.L.L.C.; Siebel, A.M.; Müller, L.G.; Bortoluzzi, A.J.; Lanza, M.; et al. Production of curcumin-resveratrol cocrystal using cocrystallization with supercritical solvent. J. Supercrit. Fluid. 2021, 171, 105190. [Google Scholar] [CrossRef]

- Pantwalawalkar, J.; More, H.; Bhange, D.; Patil, U.; Jadhav, N. Novel curcumin ascorbic acid cocrystal for improved solubility. J. Drug Deliv. Sci. Technol. 2021, 61, 102233. [Google Scholar] [CrossRef]

- Sathisaran, I.; Devidas Bhatia, D.; Vishvanath Dalvi, S. New curcumin-trimesic acid cocrystal and anti-invasion activity of curcumin multicomponent solids against 3D tumor models. Int. J. Pharm. 2020, 587, 119667. [Google Scholar] [CrossRef] [PubMed]

- Chow, S.F.; Shi, L.; Ng, W.W.; Leung, K.H.Y.; Nagapudi, K.; Sun, C.C.; Chow, A.H.L. Kinetic Entrapment of a Hidden Curcumin Cocrystal with Phloroglucinol. Cryst. Growth Des. 2014, 14, 5079–5089. [Google Scholar] [CrossRef]

- Shen, R.; Zhang, J.; Wang, X. Cocrystal of curcumin with 4,4′-bipyridine toward improved dissolution: Design, structure analysis, and solid-state characterization. J. Mol. Struct. 2023, 1284, 135348. [Google Scholar] [CrossRef]

- Guangying, L.; Jishi, Y.; Joung, J.G.; Kan, Z.; Kim, H.M.; Kim, J.S.; Kim, M.J.; Ryu, H.C.; Seo, H.K.; Shigang, Z. Solid Compound Used as Oral Composition for Preventing or Eliminating Hangover, Comprises Curcuminoid or Turmeric (Curcuma Longa) Extract, and L-Carnitine, Which Has Excellent In-Vivo Absorption Rate then Conventional Curcumin Powder. Patent KR2018026612, 13 March 2018. [Google Scholar]

- Fallah, F.; Mahdavi, R. L-Carnitine and synbiotic co-supplementation: Beneficial effects on metabolic-endotoxemia, me-ta-inflammation, and oxidative-stress biomarkers in obese patients: A double blind, randomized, controlled clinical trial. Food. Funct. 2023, 14, 2172–2187. [Google Scholar] [CrossRef] [PubMed]

- Sangouni, A.A.; Sasanfar, B.; Ghadiri-Anari, A.; Hosseinzadeh, M. Effect of l-carnitine supplementation on liver fat content and cardiometabolic indices in overweight/obese women with polycystic ovary syndrome: A randomized controlled trial. Clin. Nutr. ESPEN 2021, 46, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Nouri-Vaskeh, M.; Afshan, H.; Malek Mahdavi, A.; Alizadeh, L.; Fan, X.; Zarei, M. Curcumin ameliorates health-related quality of life in patients with liver cirrhosis: A randomized, double-blind placebo-controlled trial. Complement. Ther. Med. 2020, 49, 102351. [Google Scholar] [CrossRef] [PubMed]

- Mahanty, A.; Mohanty, S.; Mohanty, B.P. Dietary supplementation of curcumin augments heat stress tolerance through up-regulation of nrf-2-mediated antioxidative enzymes and hsps in Puntius sophore. Fish Physiol. Biochem. 2017, 43, 1131–1141. [Google Scholar] [CrossRef] [PubMed]

- Doberenz, J.; Birkenfeld, C.; Kluge, H.; Eder, K. Effects of L-carnitine supplementation in pregnant sows on plasma concen-trations of insulin-like growth factors, various hormones and metabolites and chorion characteristics. J. Anim. Physiol. Anim. Nutr. 2006, 90, 487–499. [Google Scholar] [CrossRef] [PubMed]

- Sanphui, P.; Goud, N.R.; Khandavilli, U.B.R.; Sreenu, B.; Ashwini, N. New polymorphs of curcumin. Chem. Commun. 2011, 47, 5013–5015. [Google Scholar] [CrossRef]

- Mark, D.E.; Nadeesh, M.; William, J. Cocrystal Dissociation in the Presence of Water: A General Approach for Identifying Stable Cocrystal Forms. J. Pharm. Sci. 2014, 103, 2865–2870. [Google Scholar]

- Tonnesen, H.H.; Karlsen, J. Studies on curcumin and curcuminoids. VI. Kinetics of curcumin degradation in aqueous solution. Z. Fur Lebensm. Unters. Und Forsch. 1985, 180, 402–404. [Google Scholar]

- Manfred, M.; Erika, P.; Simone, I.S.; Julia, S.D. Curcumin Uptake and Metabolism. BioFactors 2013, 39, 14–20. [Google Scholar]

- Macrae, C.F.; Bruno, I.J.; Chisholm, J.A.; Edgington, P.; McCabe, P.; Pidcock, E.; Rodriguez-Monge, L.; Taylor, R.; Streek, J.V.d.; Wood, P.A. Mercury CSD 2.0—New features for the visualization and investigation of crystal structures. J. Appl. Crysallogr. 2008, 41, 466–470. [Google Scholar] [CrossRef]

| Name | CUR-L-CN |

|---|---|

| Formula | C56H70N2O18 |

| Formula weight (Da) | 1059.14 |

| T (K) * | 170 |

| Crystal system | Monoclinic |

| Space group | P21 |

| a (Å) | 17.1370(11) |

| b(Å) | 5.6406(4) |

| c/Å | 27.393(2) |

| α (°) | 90 |

| β (°) | 101.063(2) |

| γ (°) | 90 |

| V (Å3) | 2598.7(3) |

| Z | 2 |

| Dcal (g/cm3) | 1.354 |

| Rint | 0 |

| λ (Mo-Kα, Å) | 0.71073 |

| Independent reflns | 10414 |

| GOOF | 1.045 |

| R1 | 0.1051 |

| wR2 | 0.1587 |

| CCDC number | 2,333,746 |

| CUR | CUR-L-CN | |

|---|---|---|

| Tmax (min) * | 90 | 20 |

| Cmax (ng·mL−1) | 67.9 | 727.8 |

| AUC0–8 (ng·h·mL−1) | 109.9 | 692.5 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zheng, C.; Tian, F.; Xiao, Z.; Sun, Z.; Lu, L.; Dai, W.; Zhang, Q.; Mei, X. Improving the Dissolution Rate and Bioavailability of Curcumin via Co-Crystallization. Pharmaceuticals 2024, 17, 489. https://doi.org/10.3390/ph17040489

Wang H, Zheng C, Tian F, Xiao Z, Sun Z, Lu L, Dai W, Zhang Q, Mei X. Improving the Dissolution Rate and Bioavailability of Curcumin via Co-Crystallization. Pharmaceuticals. 2024; 17(4):489. https://doi.org/10.3390/ph17040489

Chicago/Turabian StyleWang, Hao, Chenxuan Zheng, Fanyu Tian, Ziyao Xiao, Zhixiong Sun, Liye Lu, Wenjuan Dai, Qi Zhang, and Xuefeng Mei. 2024. "Improving the Dissolution Rate and Bioavailability of Curcumin via Co-Crystallization" Pharmaceuticals 17, no. 4: 489. https://doi.org/10.3390/ph17040489