Energy Conservation and Production Efficiency Enhancement in Herbal Medicine Extraction: Self-Adaptive Decision-Making Boiling Judgment via Acoustic Emission Technology

Abstract

1. Introduction

2. Results

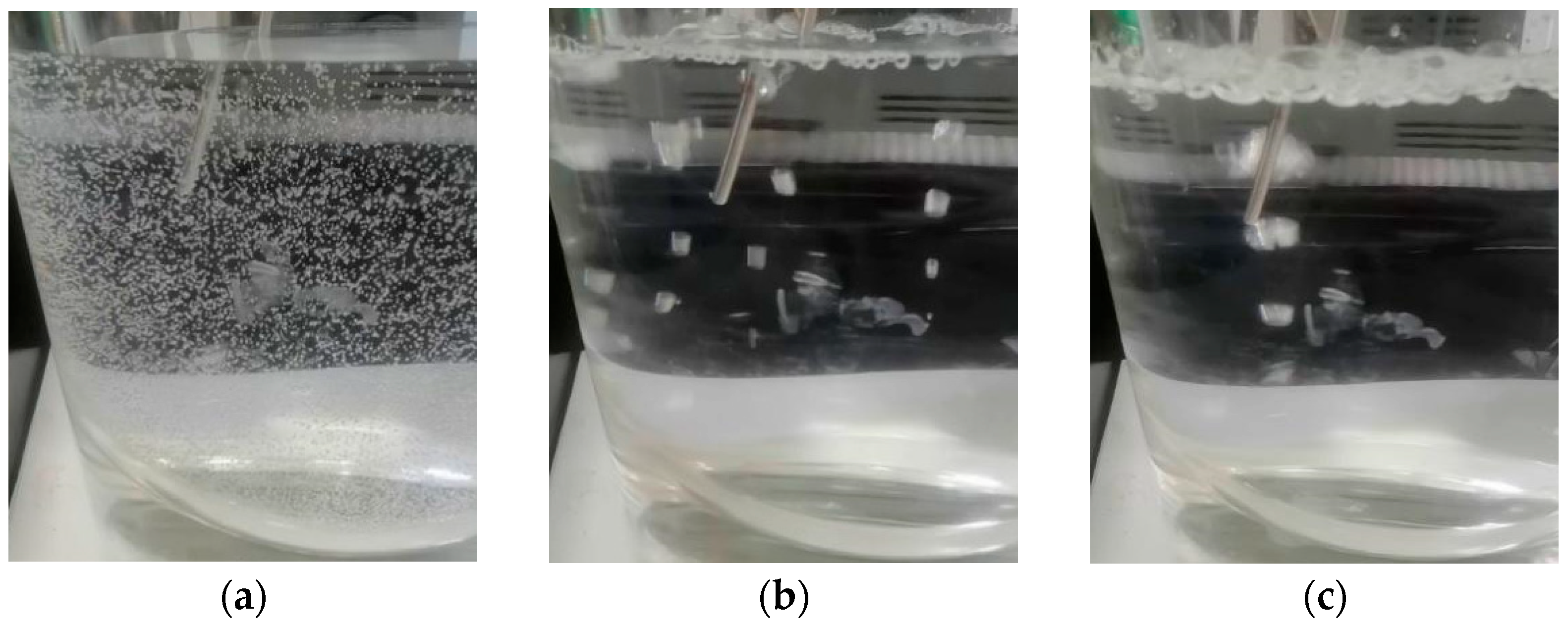

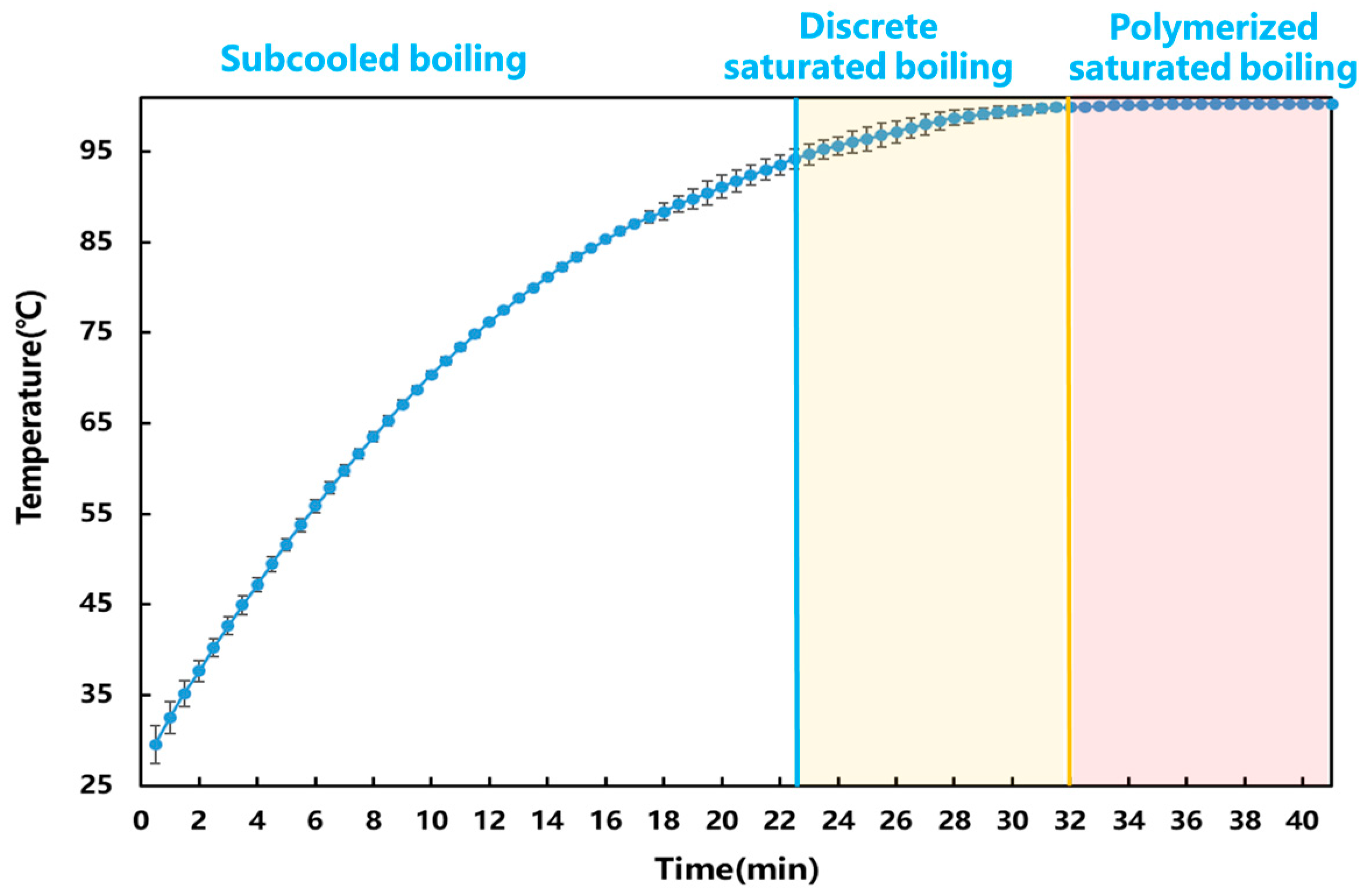

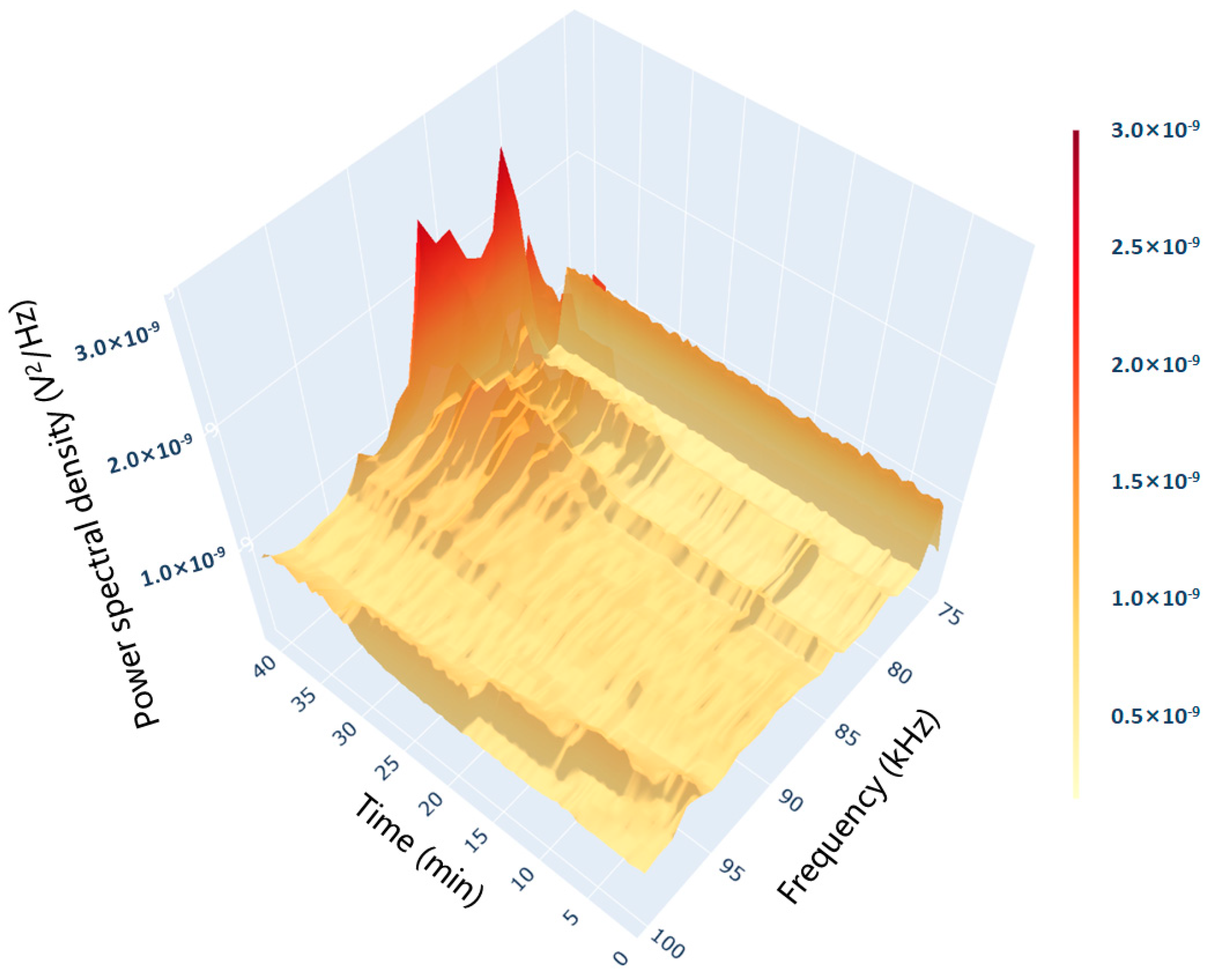

2.1. Relationship Between AE Signal and Boiling Behavior in Pure Water

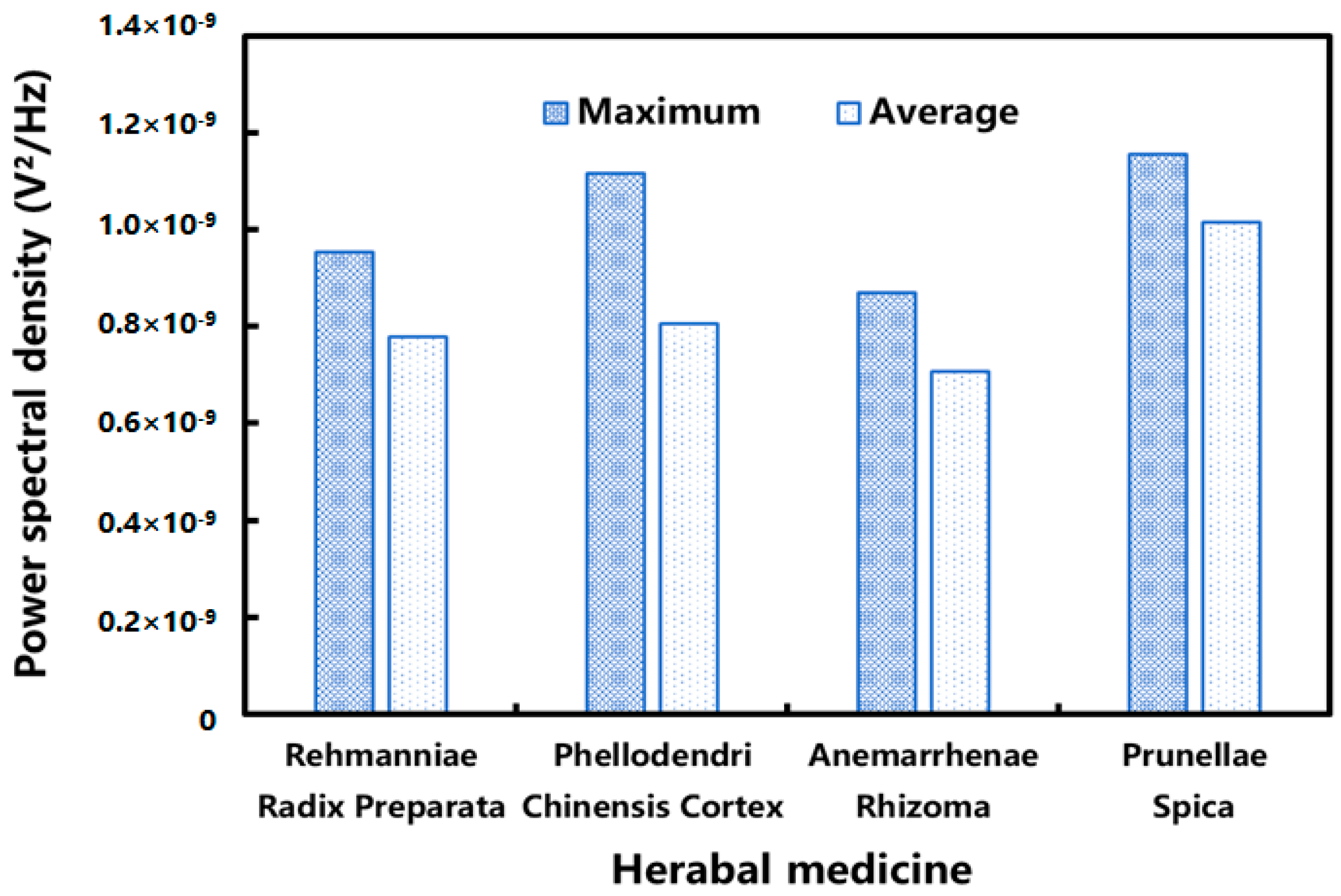

2.2. Stage-Wise Correlation Analysis Between AE Signals and Boiling Behavior During the Aqueous Extraction of Different Herbs

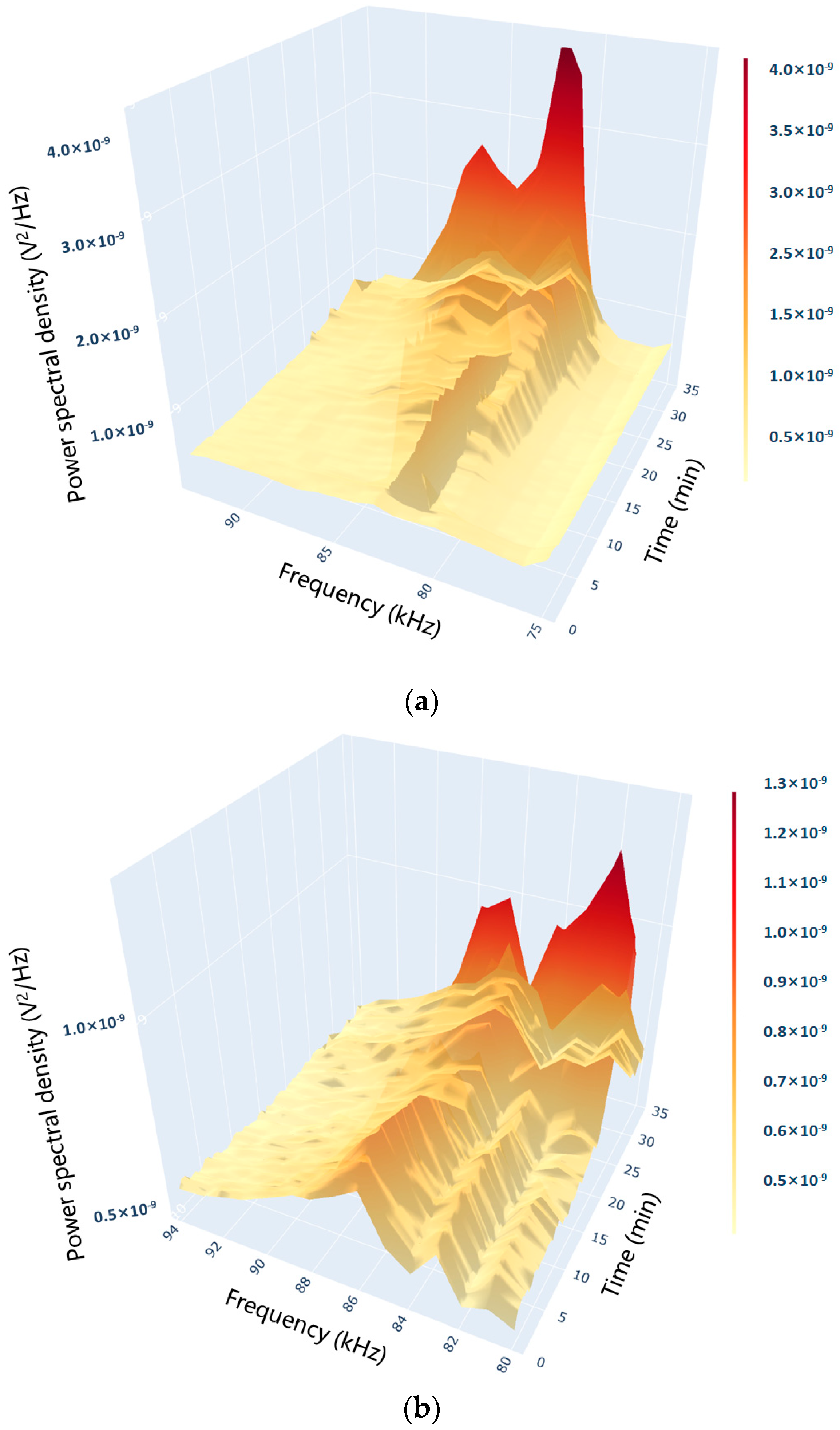

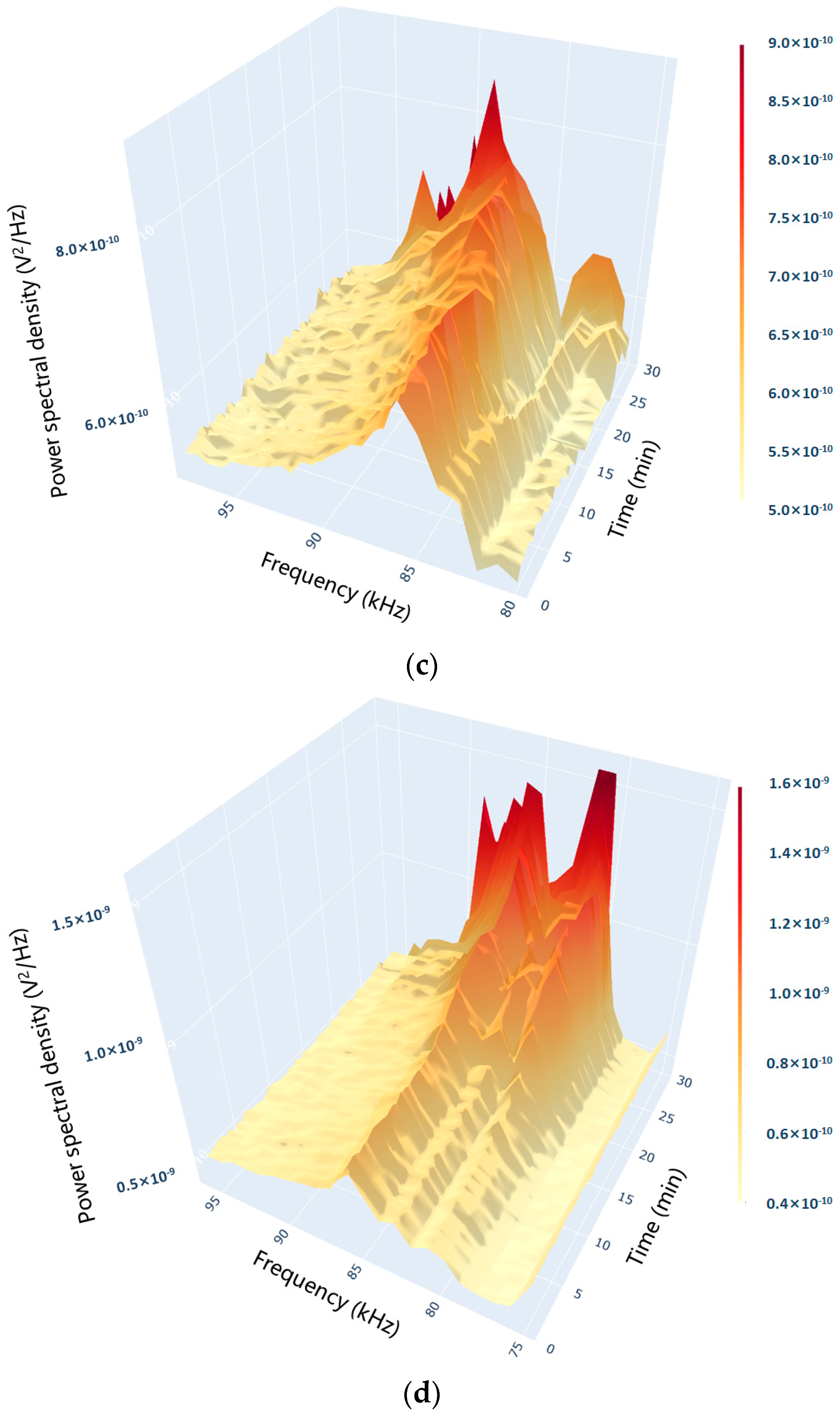

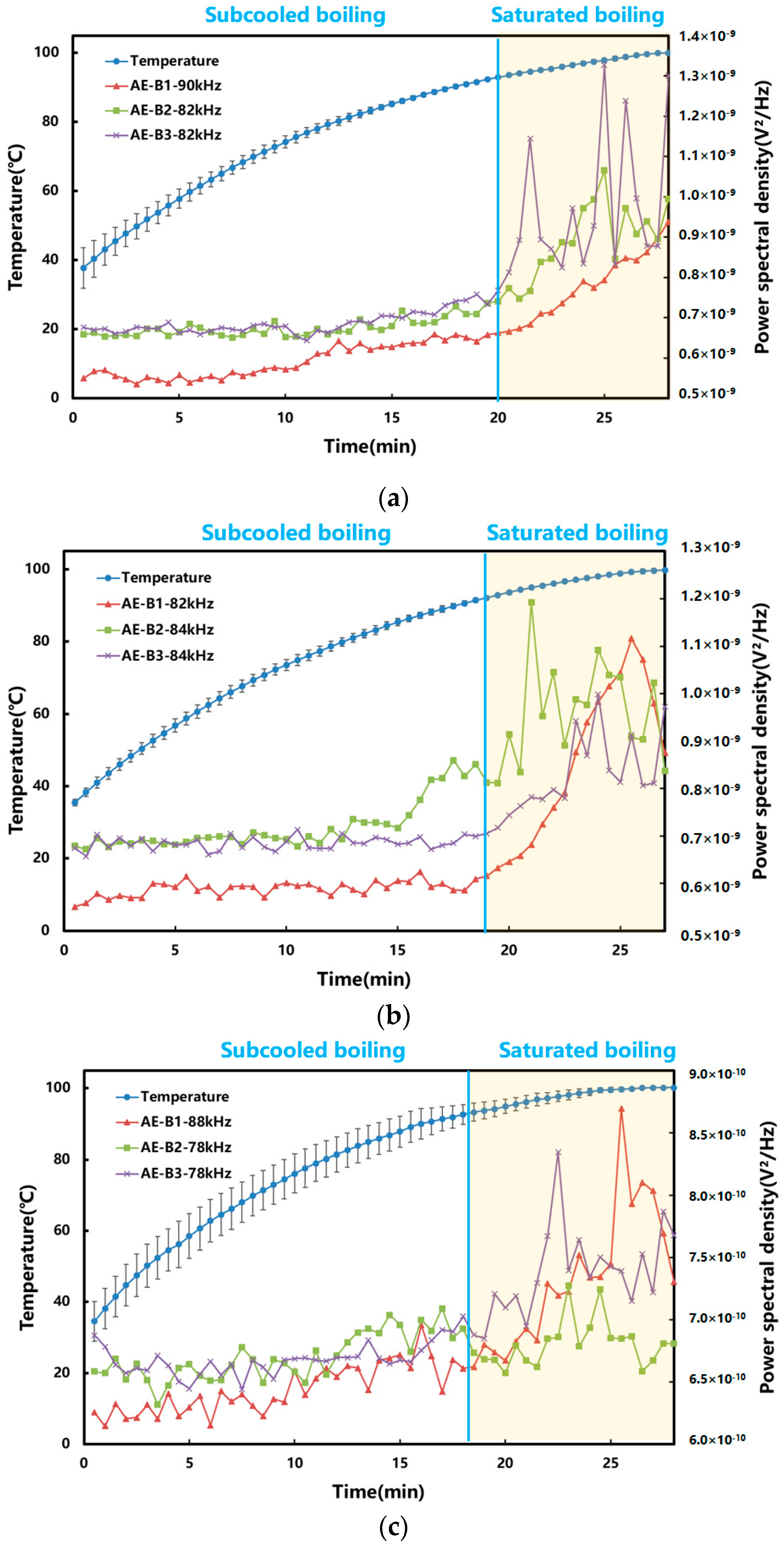

2.2.1. Characterization of Boiling by “Signature Frequency”

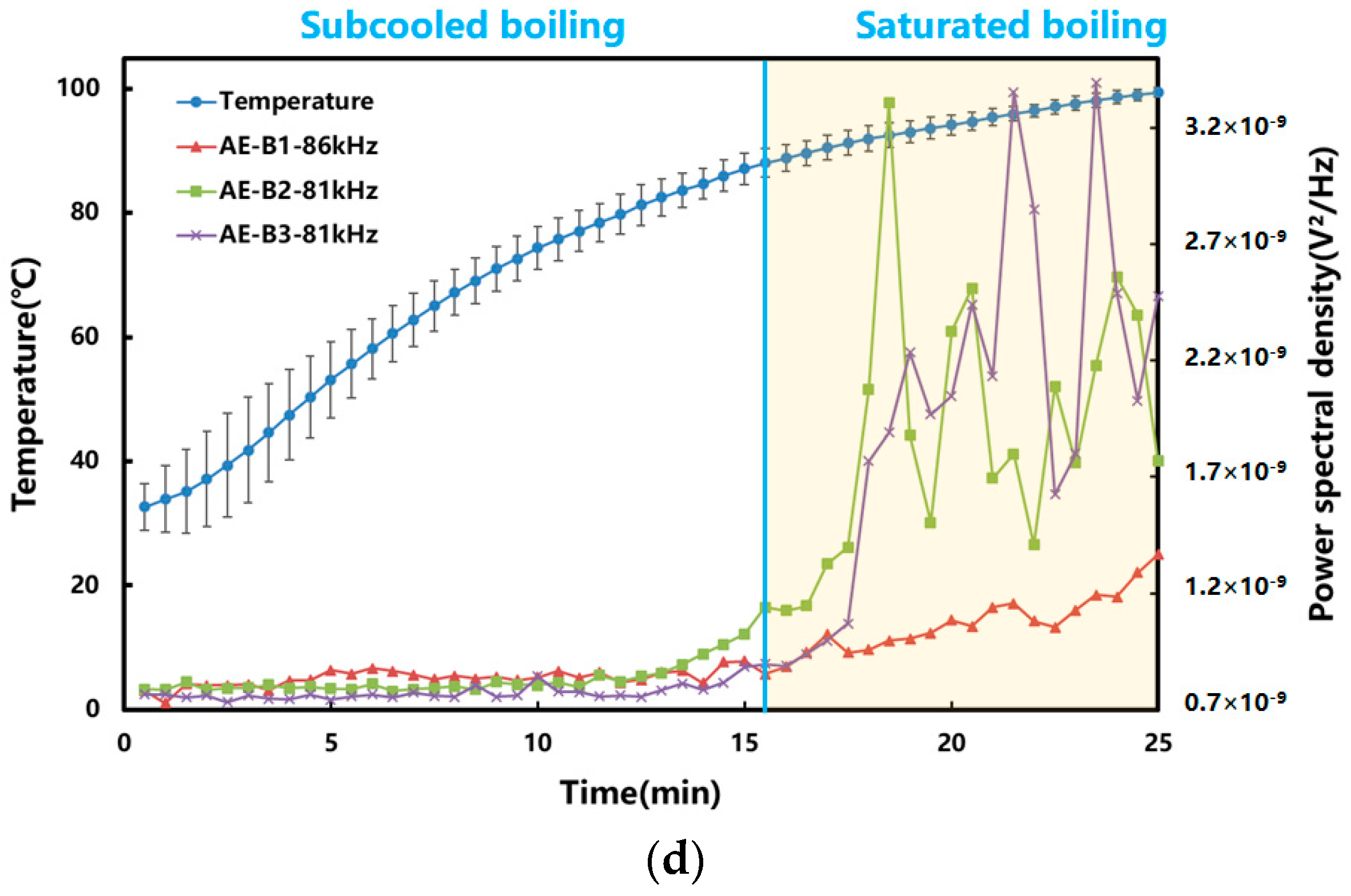

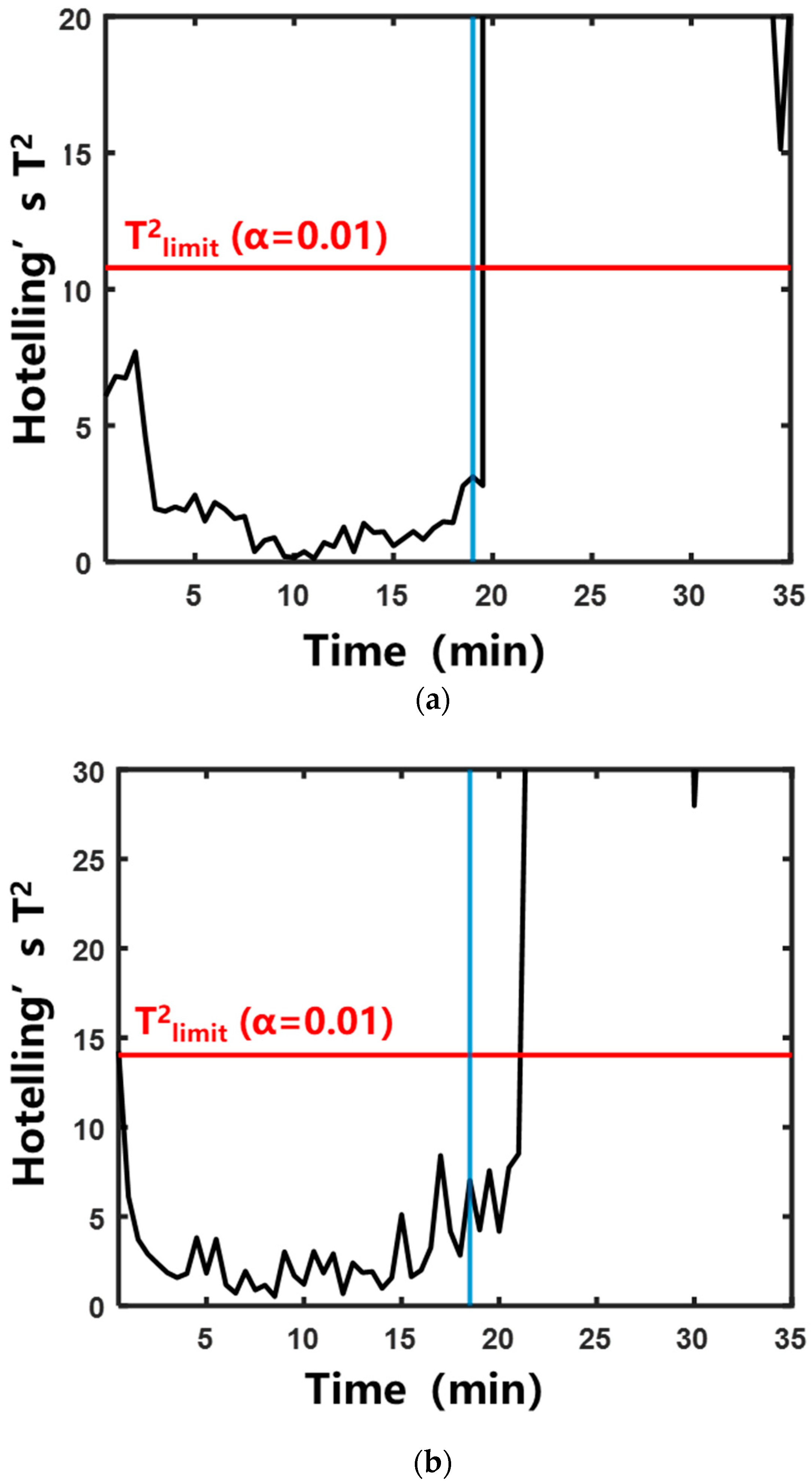

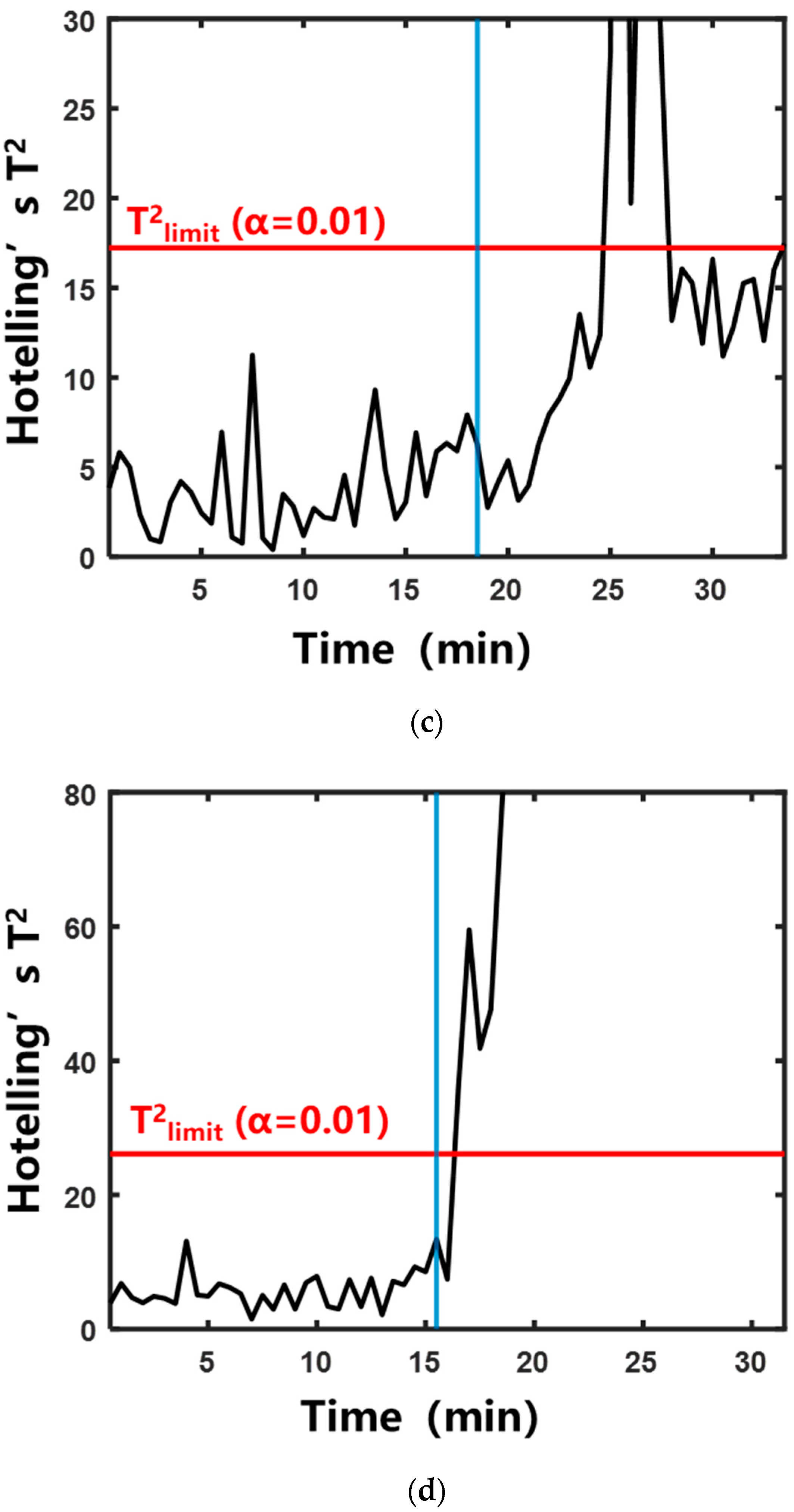

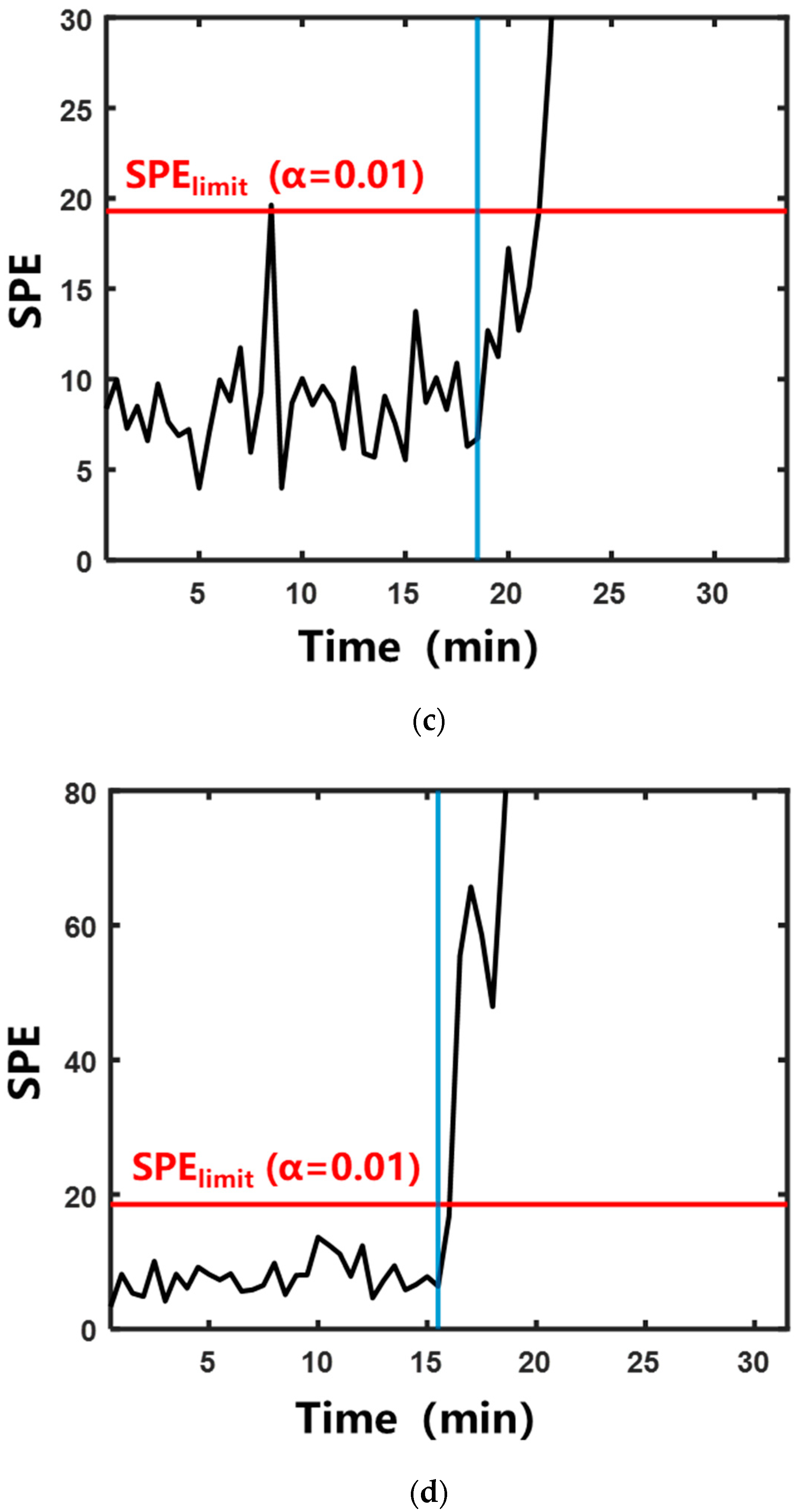

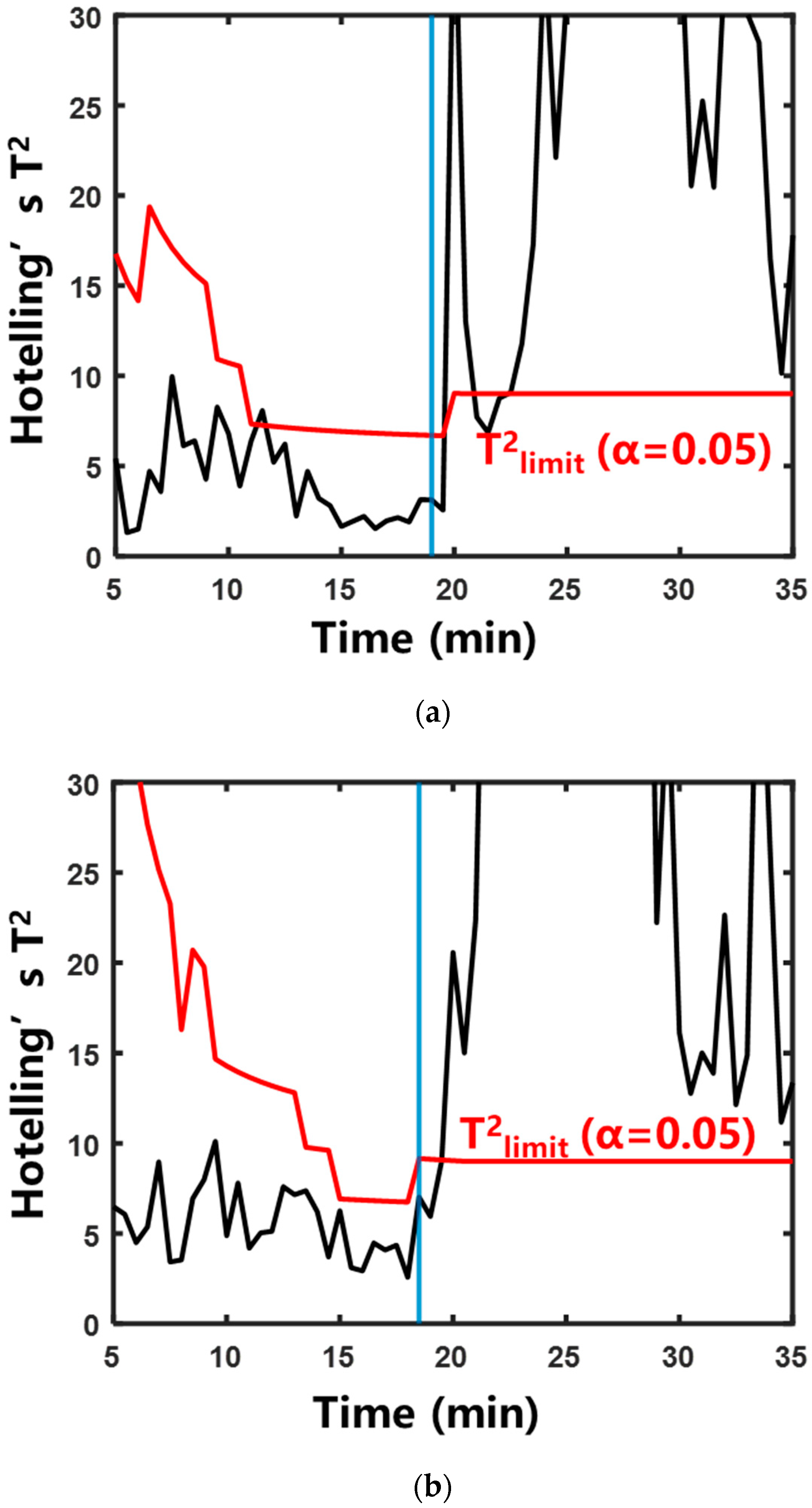

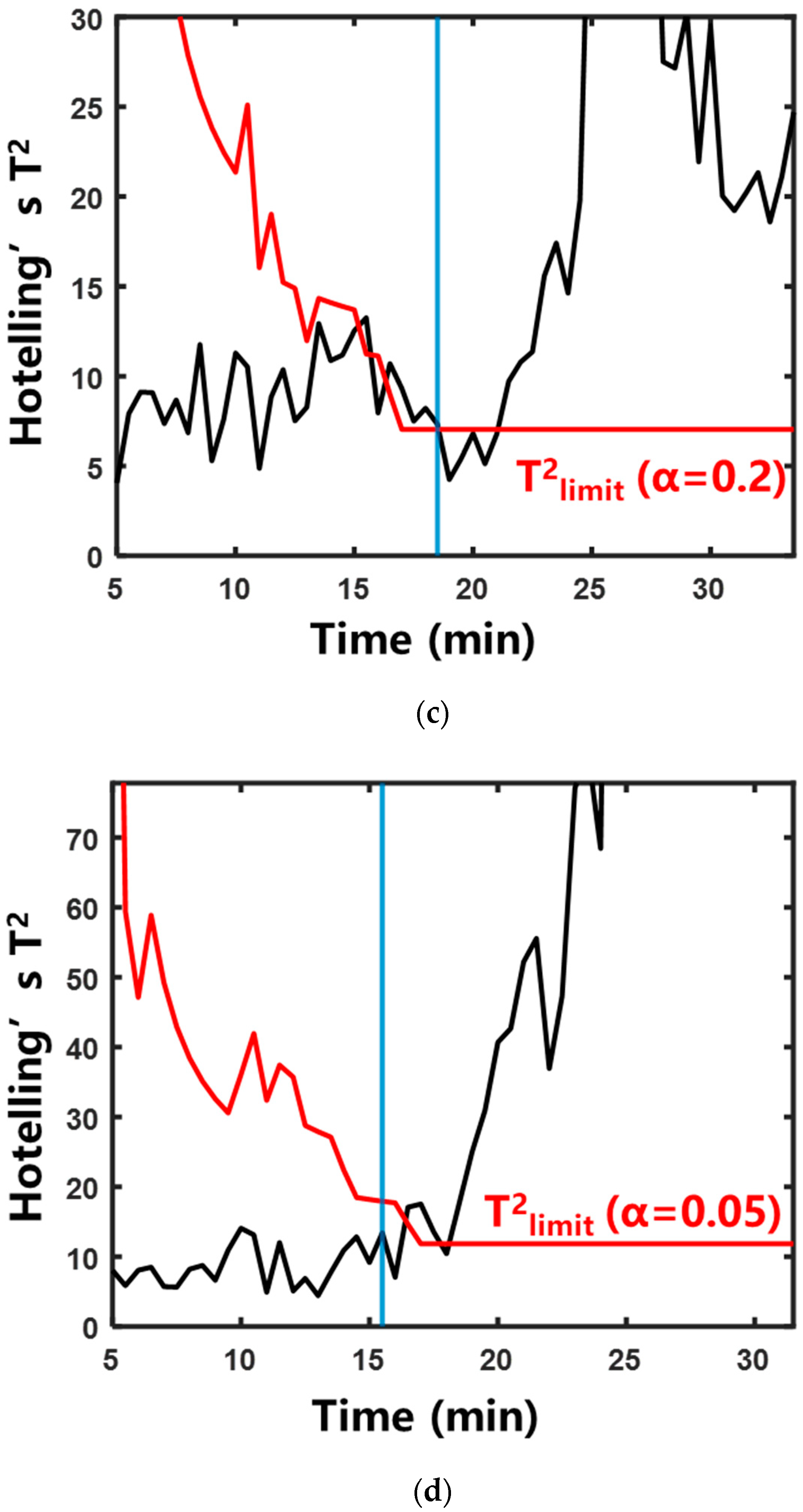

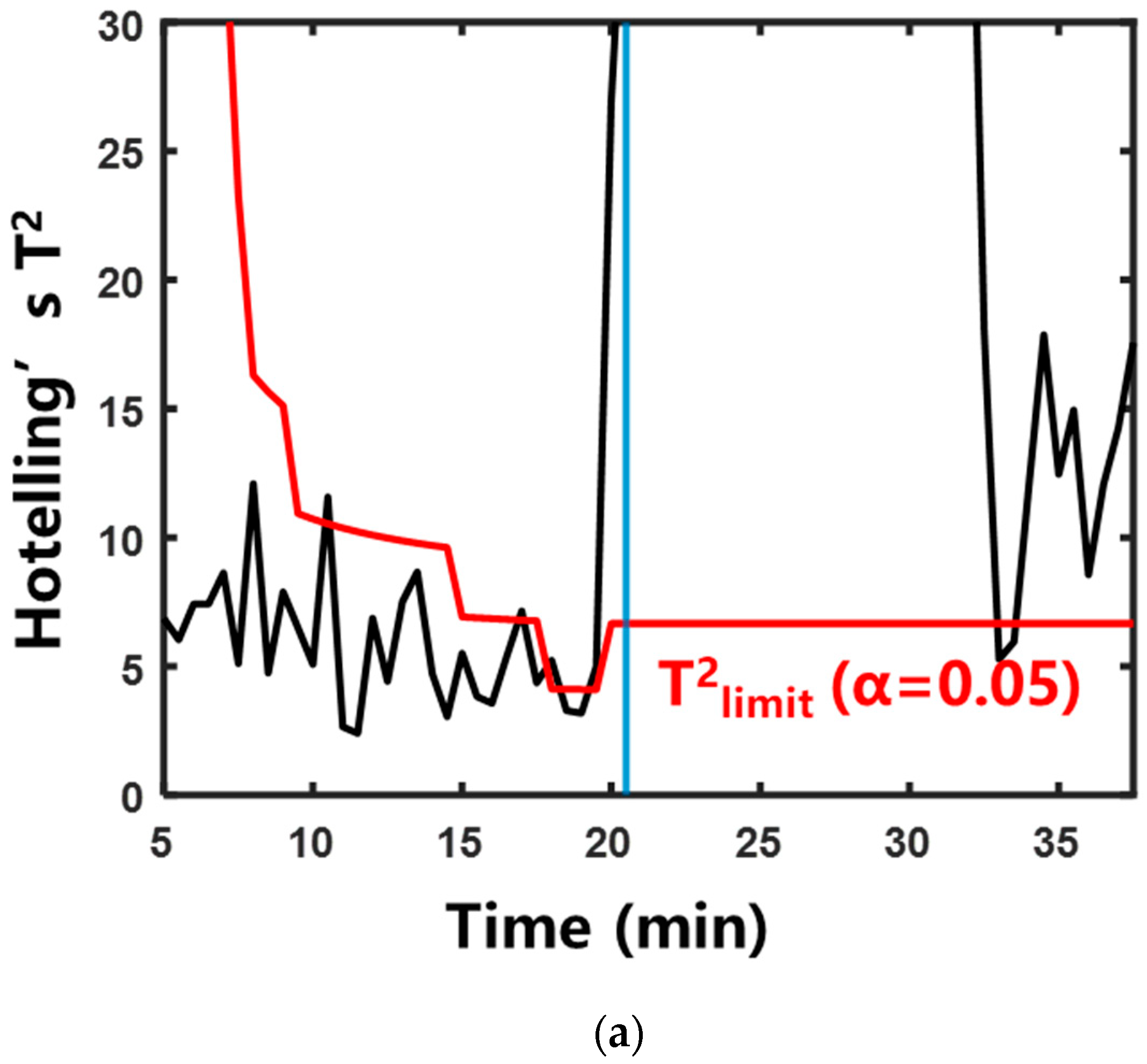

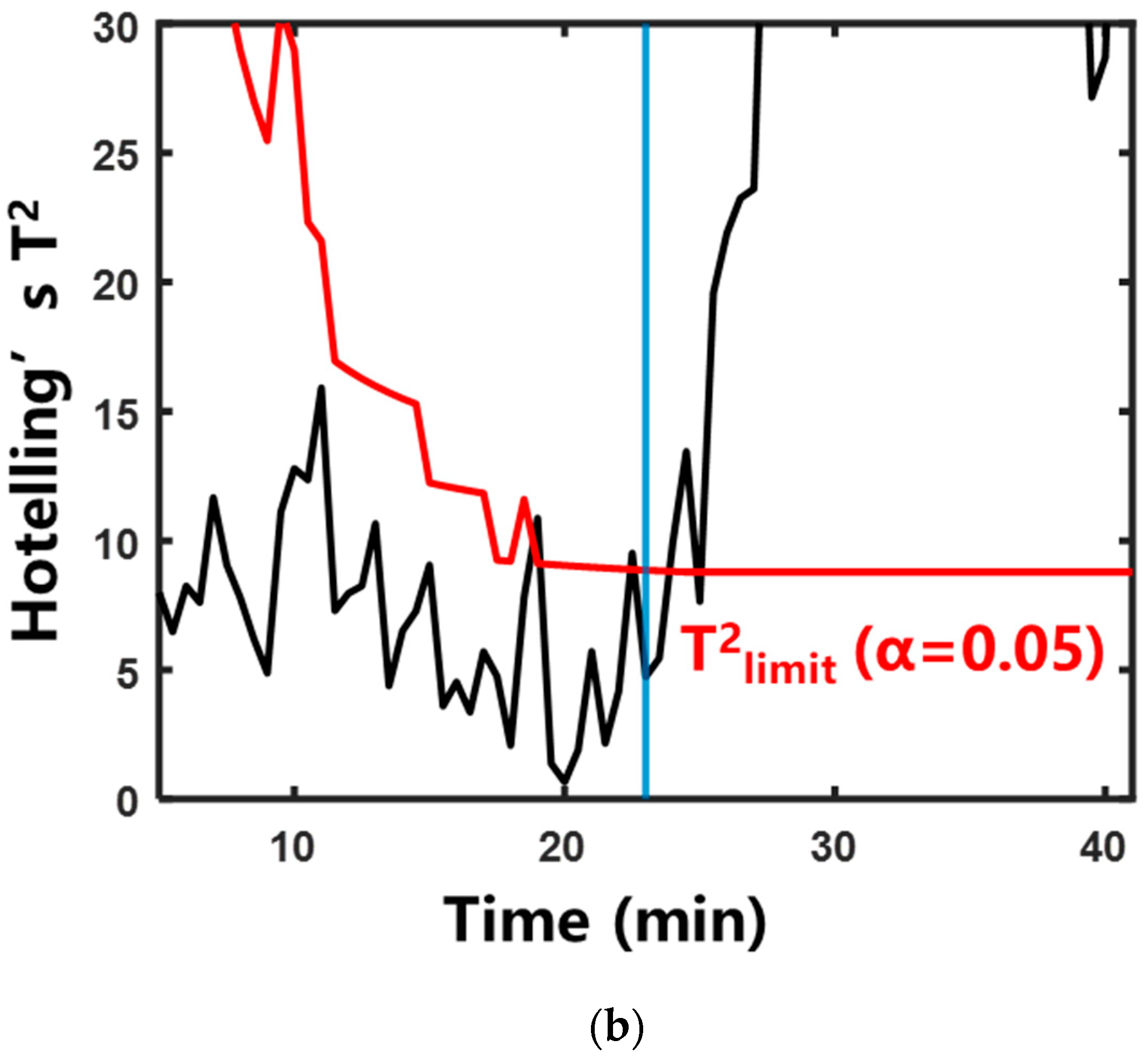

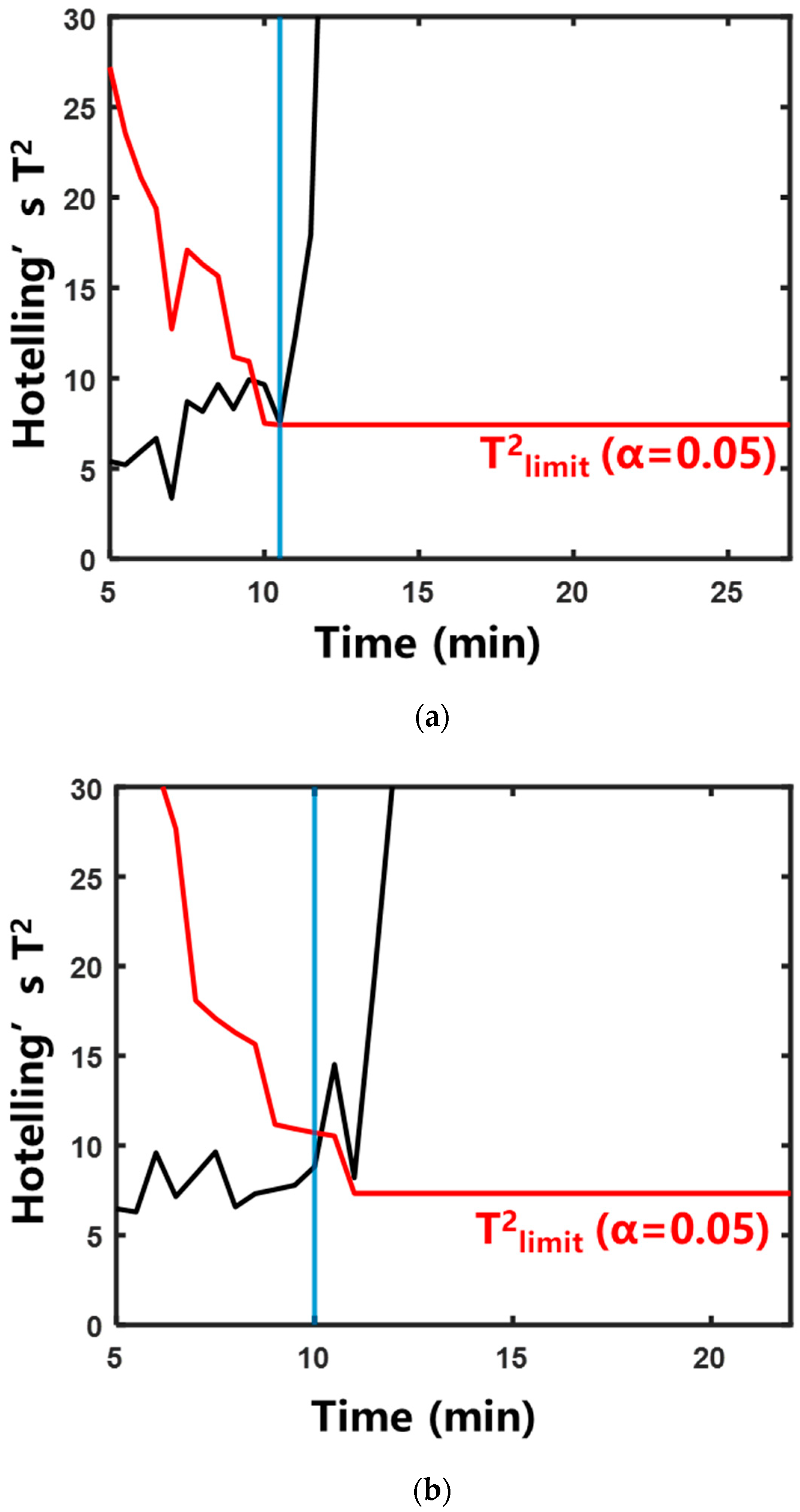

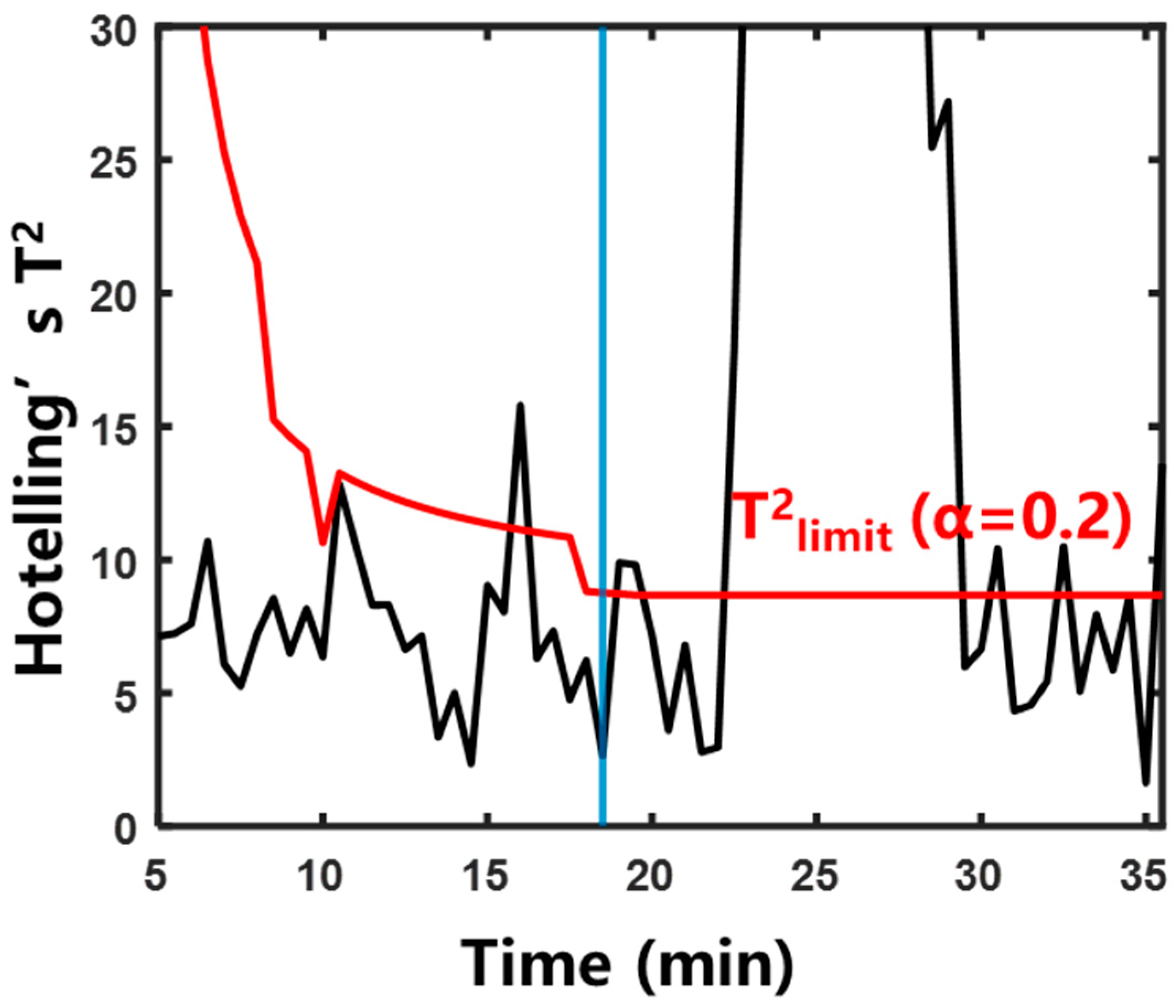

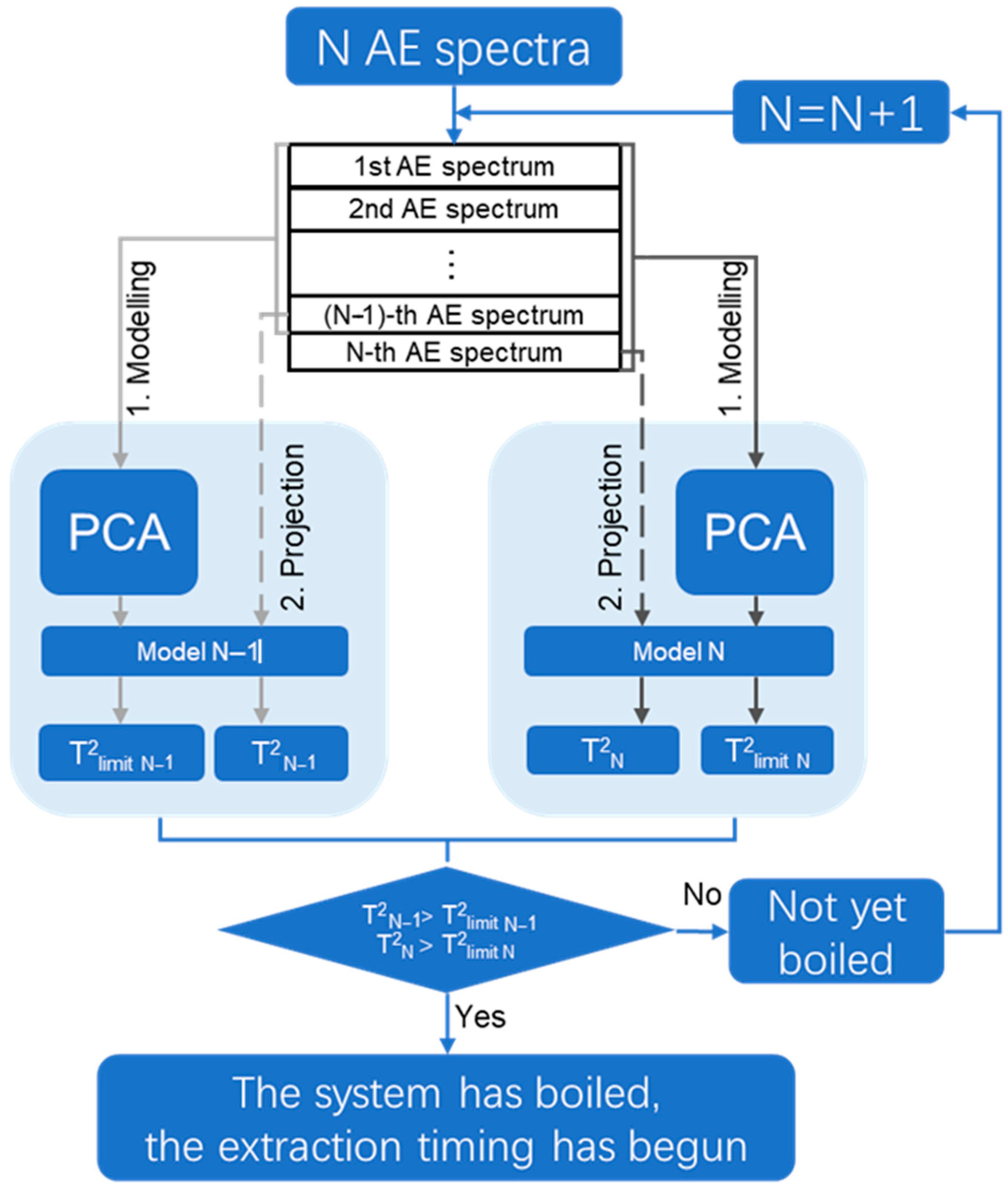

2.2.2. Characterization of Boiling by Multivariate Statistical Analysis

2.2.3. Characterization of Boiling by BoilStart

2.3. BoilStart Predictive Capability Evaluation

2.3.1. Extraction System Mass

2.3.2. Heating Medium Temperature

2.4. Application of BoilStart in Dabuyin Wan

3. Discussion

3.1. Advantages of BoilStart

3.2. Influence of Herb Characteristics on AE Signals

3.3. Hotelling’s T2 for AE Monitoring

3.4. Limitations and Future Work

4. Materials and Methods

4.1. Selection of Experimental Medicinal Materials

4.2. Experimental Setup

4.3. Performance Evaluation of BoilStart

4.4. Data Analysis

4.4.1. Data Pre-Processing

4.4.2. Multivariate Statistical Analysis

4.4.3. BoilStart

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AE | acoustic emission |

| PCA | principal component analysis |

References

- Miao, H. The Dynamic Predictive Control of Chinese Medicine Extraction Process based on Digital Twin. Master’s Thesis, Tianjin University of Traditional Chinese Medicine, Tianjin, China, 2023. [Google Scholar]

- Fu, H.; Teng, K.; Shen, Y.; Zhao, J.; Qu, H. Quantitative Analysis of Moisture Content and Particle Size in a Fluidized Bed Granulation Process Using near Infrared Spectroscopy and Acoustic Emission Combined with Data Fusion Strategies. Spectrochim. Acta Part. A Mol. Biomol. Spectrosc. 2024, 305, 123441. [Google Scholar] [CrossRef]

- Hu, Z.; Ding, K.; Zhou, J.; Wu, G. Early Fatigue Damage Evolution and Crack Recognition in Low-Cycle Metal Fatigue Testing Based on Acoustic Emission Monitoring. Int. J. Fatigue 2025, 201, 109182. [Google Scholar] [CrossRef]

- Ingle, V.V.; Prem, P.R. Acoustic Emission Examination of 3D Printed Ultra-High Performance Concrete with and without Coarse Aggregate under Fresh and Hardened States. J. Build. Eng. 2025, 111, 113491. [Google Scholar] [CrossRef]

- Ansari, M.J.; Roccisano, A.; Arcondoulis, E.J.G.; Schulz, C.; Schläfer, T.; Hall, C. Relationship between Associated Acoustic Emission and Crack Position during Directed Energy Deposition of a Metal Matrix Composite. J. Manuf. Process. 2025, 147, 177–190. [Google Scholar] [CrossRef]

- Fulek, R.; Ramm, S.; Kiera, C.; Pein-Hackelbusch, M.; Odefey, U. A Machine Learning Approach to Qualitatively Evaluate Different Granulation Phases by Acoustic Emissions. Pharmaceutics 2023, 15, 2153. [Google Scholar] [CrossRef]

- Solanki, L.K.; Munzni, B.K.; Vidyarthi, U.S. Acoustic Emission, a Non-Destructive Technique-an Overview. IJRASET 2024, 12, 1423–1430. [Google Scholar] [CrossRef]

- Shang, Z.; Udayakumar, S.; Wang, H.; Li, X.; Wang, J.; Ji, X.; Wang, X.; Zhang, B.; Ren, X.; Pahlevani, F.; et al. 3D Microstructure and Corrosion Behavior of Porous Co-Al-Cr Intermetallic Fabricated via Rapid Low-Energy Self-Exothermic Reaction for Advanced Filtration Applications. Sep. Purif. Technol. 2025, 378, 134520. [Google Scholar] [CrossRef]

- Dehane, A.; Merouani, S.; Hamdaoui, O. Carbon Tetrachloride (CCl4) Sonochemistry: A Comprehensive Mechanistic and Kinetics Analysis Elucidating How CCl4 Pyrolysis Improves the Sonolytic Degradation of Nonvolatile Organic Contaminants. Sep. Purif. Technol. 2021, 275, 118614. [Google Scholar] [CrossRef]

- Yildirim, K.; Kozjek, D.; Vanwersch, P.; Nagarajan, B.; Castagne, S. Exploring Material Removal Dynamics during Femtosecond Laser Micromachining by In-Situ Acoustic Emission Monitoring with Physics-Based and Data-Driven Analysis. Opt. Laser Technol. 2025, 192, 113721. [Google Scholar] [CrossRef]

- Alam, Q.; Raj, R.; Upadhyay, A.; Assam, A. On the Origin and Nature of Acoustic Emissions from Bubbles Departing an Underwater Nozzle. Phys. Fluids 2025, 37, 041703. [Google Scholar] [CrossRef]

- Meng, M.; Li, X.; Zhang, H.; Li, F. Theoretical Study of Acoustic Field Caused by Single Bubble Behavior. Phys. Fluids 2025, 36, 123378. [Google Scholar] [CrossRef]

- Zhang, B.; Gong, S.; Wu, Y.; Xiong, Z.; Ma, W. Numerical Simulation for Pressure Fluctuations Caused by the Growth of a Single Boiling Bubble. Appl. Therm. Eng. 2024, 254, 123902. [Google Scholar] [CrossRef]

- Hobold, G.M.; Alexandre, K.S. Machine Learning Classification of Boiling Regimes with Low Speed, Direct and Indirect Visualization. Int. J. Heat Mass Transf. 2018, 25, 1296–1309. [Google Scholar] [CrossRef]

- Hobold, G.M.; Alexandre, K.S. Visualization-Based Nucleate Boiling Heat Flux Quantification Using Machine Learning. Int. J. Heat Mass Transf. 2019, 134, 511–520. [Google Scholar] [CrossRef]

- Soibam, J.; Scheiff, V.; Aslanidou, I.; Kyprianidis, K.; Fdhila, R.B. Application of Deep Learning for Segmentation of Bubble Dynamics in Subcooled Boiling. Int. J. Multiph. Flow 2023, 169, 104589. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, J.; Huai, X.; Cheng, K. Highly Stable Subcooled Flow Boiling Enabled by an Opposed Wall Jet Design. Int. J. Heat Mass Transf. 2023, 216, 124562. [Google Scholar] [CrossRef]

- Seo, S.B.; Bang, I.C. Acoustic Analysis on the Dynamic Motion of Vapor-Liquid Interface for the Identification of Boiling Regime and Critical Heat Flux. Int. J. Heat Mass Transf. 2019, 131, 1138–1146. [Google Scholar] [CrossRef]

- Barathula, S.; Chaitanya, S.; Srinivasan, K. Evaluation of Machine Learning Models in the Classification of Pool Boiling Regimes up to Critical Heat Flux Based on Boiling Acoustics. Int. J. Heat Mass Transf. 2023, 201, 123623. [Google Scholar] [CrossRef]

- Tang, J.; Xie, G.; Bao, J.; Mo, Z.; Liu, H.; Du, M. Experimental Study of Sound Emission in Subcooled Pool Boiling on a Small Heating Surface. Chem. Eng. Sci. 2018, 188, 179–191. [Google Scholar] [CrossRef]

- Lim, D.Y.; Bang, I.C. A Novel Non-Destructive Acoustic Approach for Investigating Pool Boiling Phenomena. Int. J. Heat Mass Transf. 2024, 222, 125166. [Google Scholar] [CrossRef]

- Baek, S.H.; Wu, K.; Shim, H.-S.; Lee, D.H.; Kim, J.G.; Hur, D.H. Acoustic Emission Monitoring of Water Boiling on Fuel Cladding Surface at 1 Bar and 130 Bar. Measurement 2017, 109, 18–26. [Google Scholar] [CrossRef]

- Sinha, K.N.R.; Kumar, V.; Kumar, N.; Thakur, A.; Raj, R. Deep Learning the Sound of Boiling for Advance Prediction of Boiling Crisis. Cell Rep. Phys. Sci. 2021, 2, 100382. [Google Scholar] [CrossRef]

- Dunlap, C.; Pandey, H.; Weems, E.; Hu, H. Nonintrusive Heat Flux Quantification Using Acoustic Emissions during Pool Boiling. Appl. Therm. Eng. 2023, 228, 120558. [Google Scholar] [CrossRef]

- Suriyaprasaad, B.; Upadhyay, A.; Thakur, A.; Raj, R. Explainable Boiling Acoustics Analysis Using Grad-CAM and YAMNet for Robust Pool Boiling Regime Classification. Appl. Therm. Eng. 2025, 278, 127220. [Google Scholar] [CrossRef]

- Sinha, K.N.R.; Kumar, V.; Kumar, N.; Thakur, A.; Raj, R. Dataset for Boiling Acoustic Emissions: A Tool for Data Driven Boiling Regime Prediction. Data Brief 2024, 52, 109793. [Google Scholar] [CrossRef]

- Sinha, K.N.R.; Ranjan, D.; Kumar, N.; Raza, Q.; Raj, R. Simultaneous Audio-Visual-Thermal Characterization of Transition Boiling Regime. Exp. Therm. Fluid Sci. 2020, 118, 110162. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, B.; Sui, T.; Hou, H.; Zhao, P.; Lv, B.; Xue, J. Radial Compression Characteristics and Damage Evolution of Three-Layer SiC/SiC Composite Tubes Based on Acoustic Emission. J. Eur. Ceram. Soc. 2025, 45, 117673. [Google Scholar] [CrossRef]

- Baek, S.H.; Shim, H.-S.; Kim, J.G.; Hur, D.H. Visualization and Acoustic Emission Monitoring of Nucleate Boiling on Rough and Smooth Fuel Cladding Surfaces at Atmospheric Pressure. Nucl. Eng. Des. 2018, 330, 429–436. [Google Scholar] [CrossRef]

- Ueki, Y.; Ara, K. Proof of Concept of Acoustic Detection of Boiling Inception and State Transition Using Deep Neural Network. Int. Commun. Heat Mass Transf. 2021, 129, 105675. [Google Scholar] [CrossRef]

- Wang, X.; Liu, K.; Ying, Z. Study on the Acoustic Emission Frequency of Salicylic Acid Crystal Growth Based on Beam Vibration. Ultrasonics 2025, 151, 107620. [Google Scholar] [CrossRef]

- Nishant Ranjan Sinha, K.; Ranjan, D.; Raza, Q.; Kumar, N.; Kaner, S.; Thakur, A.; Raj, R. In-Situ Acoustic Detection of Critical Heat Flux for Controlling Thermal Runaway in Boiling Systems. Int. J. Heat Mass Transf. 2019, 138, 135–143. [Google Scholar] [CrossRef]

- Alhashan, T.; Addali, A.; Amaral Teixeira, J.; Elhashan, S. Identifying Bubble Occurrence during Pool Boiling Employing Acoustic Emission Technique. Appl. Acoust. 2018, 132, 191–201. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, N.; Zhou, H.; Zheng, Z.; Zhang, X.; Lv, Z.; Yu, J. A Novel Damage Model on the Acoustic Emission Characteristics of Weakly Cemented Soft Rock under Alkaline Water-Enriched Environment. Rock Mech. Bull. 2025, 5, 100221. [Google Scholar] [CrossRef]

- Bachir, A.A.; Zeqi, C.; Marior, L.F.; Jonathan, B.E.; Mitra, A. Real-Time Optical and Acoustic Characterization of Phase-Shift Droplets for Drug-Delivery Applications. ACS Appl. Mater. Interfaces 2025, 17, 51737. [Google Scholar] [CrossRef]

- Announcement on the Release of the 2022 Electricity Carbon Dioxide Emission Factor. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk01/202412/t20241226_1099413.html (accessed on 5 October 2025).

- Hou, J.; Li, D.; Ma, L.; Wei, N.; Huang, L.; Zhao, X.; Wei, J.; Hao, N. Coupling Zinc Oxide Nanopatterns with Low-Power Acoustics for Synergistic Two-Phase Cooling Enhancement. Chem. Eng. J. 2025, 508, 161081. [Google Scholar] [CrossRef]

- Mao, L.; Zhou, W.; Hu, X.; He, Y.; Zhang, G.; Zhang, L.; Fu, R. Pool Boiling Performance and Bubble Dynamics on Graphene Oxide Nanocoating Surface. Int. J. Therm. Sci. 2020, 147, 106154. [Google Scholar] [CrossRef]

- Kim, H.; Kang, Y.; Jin, B.; Lee, M.; An, H. Anti-Inflammatory Capacity of a Medicinal Herb Extract, Anemarrhena Asphodeloides, on In Vivo and In Vitro Models-Induced Atopic Dermatitis. Heliyon 2024, 10, e37935. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Hu, W.; Abdel Samie, M.A.; Cui, H.; Lin, L. An Overview of Tea Saponin as a Surfactant in Food Applications. Crit. Rev. Food Sci. Nutr. 2024, 64, 12922–12934. [Google Scholar] [CrossRef]

- Roh, Y.; Heo, G.; Whang, S.E. A Survey on Data Collection for Machine Learning: A Big Data—AI Integration Perspective. IEEE Trans. Knowl. Data Eng. 2021, 33, 1328–1347. [Google Scholar] [CrossRef]

- Rafiei, M.H.; Gauthier, L.V.; Adeli, H.; Takabi, D. Self-Supervised Learning for Electroencephalography. IEEE Trans. Neural Netw. Learn. Syst. 2024, 35, 1457–1471. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, D.; Lu, G.; Zhou, B.; Li, J.; Zhang, S. Efficient Adaptive Label Refinement for Label Noise Learning. Neurocomputing 2025, 639, 130305. [Google Scholar] [CrossRef]

- Smeliansky, R.L.; Stepanov, E.P. Machine Learning to Control Network Powered by Computing Infrastructure. Dokl. Math. 2024, 109, 183–190. [Google Scholar] [CrossRef]

- Liang, Y.; Hu, Z.; Li, K. Power Consumption Model Based on Feature Selection and Deep Learning in Cloud Computing Scenarios. IET Commun. 2020, 14, 1610–1618. [Google Scholar] [CrossRef]

- Liu, D.; Yu, H.; Chai, Y. Low-Power Computing with Neuromorphic Engineering. Adv. Intell. Syst. 2021, 3, 2000150. [Google Scholar] [CrossRef]

- Wang, Y. Research for Flow Field and Noise Source Characteristics of Valve in Steam Pipe. Master’s Thesis, Harbin Engineering University, Harbin, China, 2011. [Google Scholar]

- Pandey, H.; Mehrabi, H.; Williams, A.; Mira-Hernández, C.; Coridan, R.H.; Hu, H. Acoustic Sensing for Investigating Critical Heat Flux Enhancement during Pool Boiling on Electrodeposited Copper Foams. Appl. Therm. Eng. 2024, 236, 121807. [Google Scholar] [CrossRef]

- Periodogram—Periodogram Power Spectral Density Estimate—MATLAB. Available online: https://www.mathworks.com/help/signal/ref/periodogram.html (accessed on 9 July 2025).

| Extraction Herbal | Time When Temperature Reached 100 °C (min) | Entered Saturated Boiling | Hotelling’s T2 (min) | SPE (min) | |

|---|---|---|---|---|---|

| Time (min) | Temperature (°C) | ||||

| Rehmanniae Radix Preparata | 27.7 ± 0.8 | 19.7 ± 0.6 | 92.5 ± 0.5 | 20.5 ± 0.5 | 20.5 ± 0.5 |

| Phellodendri Chinensis Cortex | 27.2 ± 1.6 | 18.8 ± 0.3 | 91.9 ± 0.8 | 20.5 ± 0.9 | 19.7 ± 0.3 |

| Anemarrhenae Rhizoma | 25.3 ± 1.3 | 18.0 ± 0.5 | 92.8 ± 2.2 | 22.2 ± 2.8 | 16.0 ± 6.7 |

| Prunellae Spica | 25.8 ± 1.0 | 15.8 ± 0.3 | 88.5 ± 2.7 | 16.8 ± 0.3 | 16.8 ± 0.6 |

| Extraction Herbal | Herb Mass (g) | Heating Medium Temperature (°C) | Time When Temperature Reached 100 °C (min) | Entered Saturated Boiling | Boiling Time Determined with BoilStart (min) | (min) | (%) | |

|---|---|---|---|---|---|---|---|---|

| Time (min) | Temperature (°C) | |||||||

| Rehmanniae Radix Preparata | 100 | 125 | 27.7 ± 0.8 | 19.7 ± 0.6 | 92.5 ± 0.5 | 21.5 ± 1.0 | 1.8 ± 0.6 | 22.2 ± 5.2 |

| 120 | 125 | 30.0 ± 2.2 | 20.7 ± 0.3 | 92.2 ± 2.3 | 22.0 ± 1.7 | 1.7 ± 1.0 | 26.1 ± 10.7 | |

| 140 | 125 | 34.7 ± 1.0 | 23.3 ± 0.3 | 91.2 ± 2.1 | 25.3 ± 0.8 | 2.0 ± 0.5 | 26.9 ± 3.1 | |

| 100 | 130 | 19.7 ± 0.8 | 11.7 ± 1.0 | 88.1 ± 2.7 | 13.7 ± 2.8 | 2.0 ± 1.7 | 30.1 ± 16.4 | |

| 100 | 135 | 17.0 ± 0.5 | 10.8 ± 0.8 | 87.1 ± 4.2 | 12.3 ± 2.1 | 1.5 ± 1.3 | 27.6 ± 11.0 | |

| Phellodendri Chinensis Cortex | 100 | 125 | 27.2 ± 1.6 | 18.8 ± 0.3 | 91.9 ± 0.8 | 20.8 ± 0.6 | 2.0 ± 0.5 | 23.1 ± 5.5 |

| Anemarrhenae Rhizoma | 100 | 125 | 25.3 ± 1.3 | 18.0 ± 0.5 | 92.8 ± 2.2 | 16.2 ± 1.2 | 1.8 ± 0.8 | 36.2 ± 2.7 |

| Prunellae Spica | 100 | 125 | 25.8 ± 1.0 | 15.8 ± 0.3 | 88.5 ± 2.7 | 17.7 ± 0.8 | 1.8 ± 0.6 | 31.6 ± 0.3 |

| Dabuyin Wan | 100 | 125 | 29.2 ± 1.0 | 19.3 ± 0.8 | 91.3 ± 1.2 | 20.8 ± 1.2 | 1.5 ± 0.5 | 28.6 ± 1.6 |

| Extracted Herbs | Herb Mass (g) | Heating Medium Temperature (°C) | pH |

|---|---|---|---|

| Rehmanniae Radix Preparata | 100.0; 100.1; 100.0 | 125.0 | 4.776 ± 0.045 |

| 120.0; 120.2; 120.1 | 125.0 | 4.659 ± 0.070 | |

| 140.1; 140.1; 140.0 | 125.0 | 4.721 ± 0.107 | |

| 100.2; 100.1; 100.1 | 130.0 | 4.605 ± 0.043 | |

| 100.0; 100.0; 100.1 | 135.0 | 4.580 ± 0.042 | |

| Phellodendri Chinensis Cortex | 100.0; 100.1; 100.2 | 125.0 | 5.042 ± 0.047 |

| Anemarrhenae Rhizoma | 100.0; 100.0; 100.2 | 125.0 | 5.445 ± 0.094 |

| Prunellae Spica | 100.2; 100.2; 100.2 | 125.0 | 6.088 ± 0.057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, J.; Fu, H.; Qu, H.; Gong, X. Energy Conservation and Production Efficiency Enhancement in Herbal Medicine Extraction: Self-Adaptive Decision-Making Boiling Judgment via Acoustic Emission Technology. Pharmaceuticals 2025, 18, 1556. https://doi.org/10.3390/ph18101556

Lan J, Fu H, Qu H, Gong X. Energy Conservation and Production Efficiency Enhancement in Herbal Medicine Extraction: Self-Adaptive Decision-Making Boiling Judgment via Acoustic Emission Technology. Pharmaceuticals. 2025; 18(10):1556. https://doi.org/10.3390/ph18101556

Chicago/Turabian StyleLan, Jing, Hao Fu, Haibin Qu, and Xingchu Gong. 2025. "Energy Conservation and Production Efficiency Enhancement in Herbal Medicine Extraction: Self-Adaptive Decision-Making Boiling Judgment via Acoustic Emission Technology" Pharmaceuticals 18, no. 10: 1556. https://doi.org/10.3390/ph18101556

APA StyleLan, J., Fu, H., Qu, H., & Gong, X. (2025). Energy Conservation and Production Efficiency Enhancement in Herbal Medicine Extraction: Self-Adaptive Decision-Making Boiling Judgment via Acoustic Emission Technology. Pharmaceuticals, 18(10), 1556. https://doi.org/10.3390/ph18101556