Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment

Abstract

:1. Introduction

2. Emissions

2.1. Tyres

2.1.1. Tyre Composition

2.1.2. Particle Generation

2.1.3. Size of Wear and Tear

2.2. National Estimates on the Amount of Wear and Tear from Tyres

2.2.1. The Netherlands

2.2.2. Sweden

2.2.3. Norway

2.2.4. Denmark

2.2.5. Germany

2.2.6. United Kingdom

2.2.7. Italy

2.2.8. Japan

2.2.9. China

2.2.10. India

2.2.11. Australia

2.2.12. USA

2.2.13. Brazil

2.3. Global per Capita Tyre Wear and Tear

2.4. Airplane Tyres

2.5. Artificial Turf as a Secondary Source of Tyre Rubber to the Environment

2.6. Other Plastic Emissions Related to Vehicle Transport

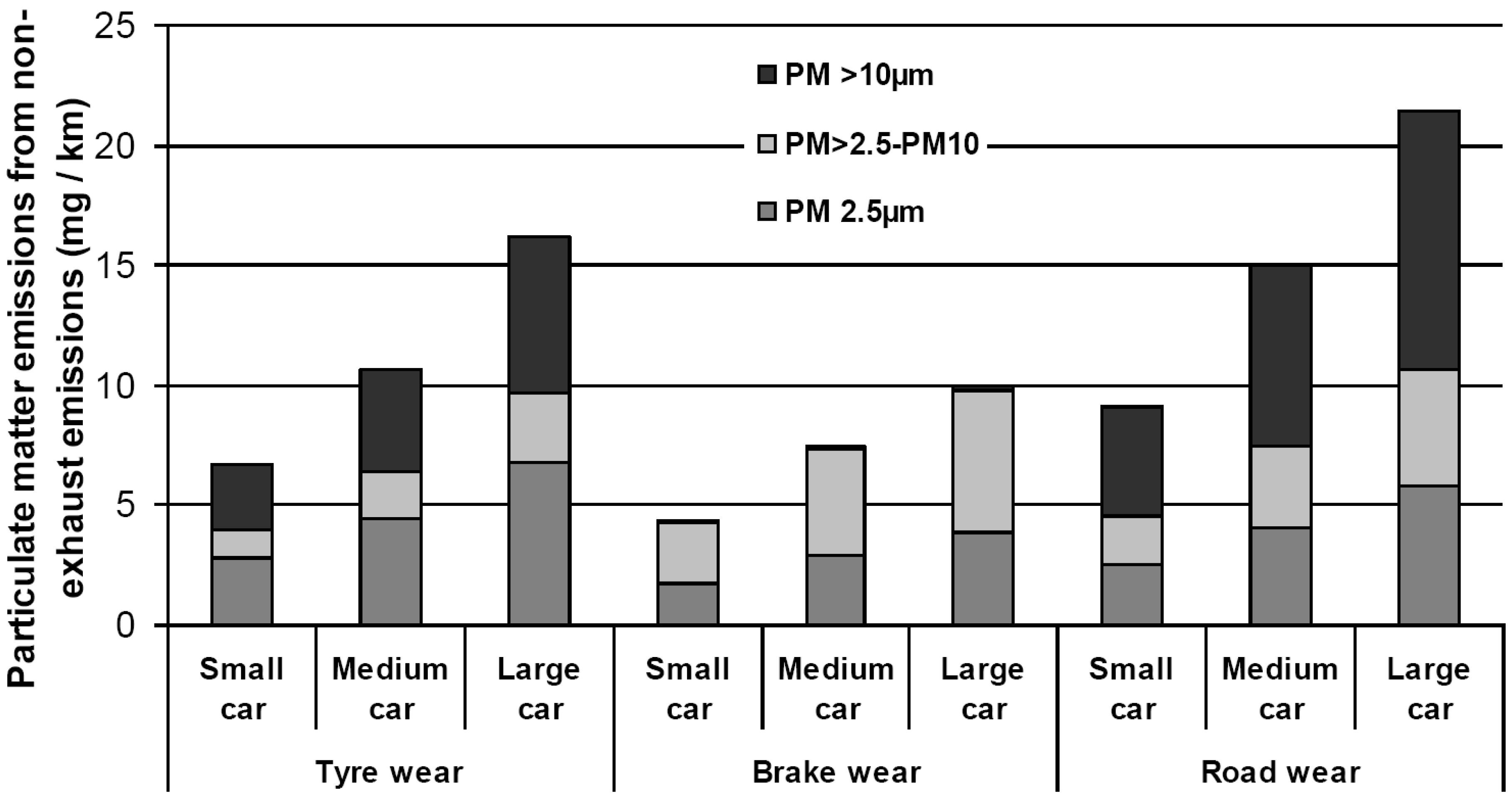

2.6.1. Brakes

2.6.2. Road Markings

2.7. Historic Increase of Tyre Wear and Tear

3. Pathways into the Environment

3.1. Transport by Runoff

3.1.1. Waste Water Treatment Plants

3.1.2. Amounts of Wear Particles Reaching Surface Waters

3.1.3. Transport by Rivers

3.2. Contribution of Tyre Wear and Tear to Plastic in the Oceans J

3.3. Transport by Air

4. Health Effects

4.1. Health Effects from Inhalation

4.2. Health Effects from Food Intake

5. Mitigation

5.1. Wear Resistant Tyres

5.2. Electric Cars

5.3. Self-Driving Cars

5.4. Sewers and Waste Water Treatment Plant Efficiency

5.5. Open Asphalt Concrete

6. Conclusions

Acknowledgments

Conflicts of Interest

References

- Plastics Europe. Plastics the Facts 2015. An Analysis of European Latest Plastics Production, Demand and Waste Data; Plastics Europe: Association of Plastic Manufacturers: Brussels, Belgium, 2016; p. 38. [Google Scholar]

- United Nations Environment Assembly (UNEP). Marine Plastic Debris & Microplastics—Global Lessons and Research to Inspire Action and Guide Policy Change; UNEP: Nairobi, Kenya, 2016. [Google Scholar]

- Malaysian Rubber Export Promotion Council (MREPC). World Production, Consumption and Trade of Rubber. Available online: http://www.mrepc.com/industry/industry.php#q2 (accessed on 27 August 2017).

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef] [PubMed]

- Lavers, J.L.; Bond, A.L. Exceptional and rapid accumulation of anthropogenic debris on one of the world’s most remote and pristine islands. PNAS 2017, 114, 6052–6055. [Google Scholar] [CrossRef] [PubMed]

- Wagner, M.; Scherer, C.; Alvarez-Muñoz, D.; Brennholt, N.; Bourrain, X.; Buchinger, S.; Fries, E.; Grosbois, C.; Klasmeier, J.; Marti, T.; et al. Microplastics in freshwater ecosystems: What we know and what we need to know. Environ. Sci. Eur. 2014, 26, 12. [Google Scholar] [CrossRef] [PubMed]

- Chae, Y.; An, Y.-J. Effects of micro- and nanoplastics on aquatic ecosystems: Current research trends and perspectives. Mar. Pollut. Bull. 2017. [Google Scholar] [CrossRef] [PubMed]

- Nakki, P.; Setala, O.; Lehtiniemi, M. Bioturbation transports secondary microplastics to deeper layers in soft marine sediments of the northern Baltic Sea. Mar. Pollut. Bull. 2017, 119, 255–261. [Google Scholar] [CrossRef] [PubMed]

- Verschoor, A.J. Towards a Definition of Microplastics. Considerations for the Specification of Physico-Chemical Properties; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2015; p. 42. [Google Scholar]

- Sundt, P.; Schulze, P.-E.; Syversen, F. Sources of Microplastics-Pollution to the Marine Environment; Mepex Consult AS: Asker, Norway, 2014; p. 108. [Google Scholar]

- Essel, R.; Engel, L.; Carus, M.; Ahrens, R.H. Sources of Microplastics Relevant to Marine Protection in Germany Texte 64/2015; Report No. (UFA-FB) 002147/E; Umweltbundesamt: Dessau-Roßlau, Germany, 2015. [Google Scholar]

- Lassen, C.; Hansen, S.F.; Magnusson, K.; Hartmann, N.B.; Rehne Jensen, P.; Nielsen, T.G.; Brinch, A. Microplastics: Occurrence, Effects and Sources of Releases to the Environment in Denmark; Danish Environmental Protection Agency: Copenhagen, Denmark, 2015. [Google Scholar]

- Kole, P.J.; Löhr, A.; Ragas, A. Autobandenslijtstof: Een verwaarloosde bron van microplastics? Milieu 2015, 5, 39–41. [Google Scholar]

- Okel, T.A.; Rueby, J.A. Silica morphology and functionality: Addressing winter tire performance. Rubber World 2016, 253, 21–52. [Google Scholar]

- Besseling, E.; Quik, J.T.; Sun, M.; Koelmans, A.A. Fate of nano- and microplastic in freshwater systems: A modeling study. Environ. Pollut. 2017, 220, 540–548. [Google Scholar] [CrossRef] [PubMed]

- United States Federal Highway Administration. User guidelines for Waste and Byproduct Materials in Pavement Construction; Publication Number: FHWA-RD-97-148; US Federal Highway Administration: Washington, DC, USA, 2016.

- Banerjee, S.; Mandal, A.; Rooby, J. Studies on mechanical properties of tyre rubber concrete. SSRG Int. J. Civ. Eng. 2016, 3, 18–21. [Google Scholar] [CrossRef]

- Dumne, S.M. An experimental study on performance of recycled tyre rubber-filled concrete. Int. J. Eng. Res. Technol. 2013, 4, 766–772. [Google Scholar]

- Alexandrova, O.; Kaloush, K.; Allen, J. Impact of asphalt rubber friction course overlays on tire wear emissions and air quality models for Phoenix, Arizona, airshed. Transp. Res. Rec. J. Transp. Res. Board 2007, 2011, 98–106. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Non-Exhaust Traffic Related Emissions. Brake and Tyre Wear PM; European Commission, Joint Research Centre, Institute of Energy and Transport: Ispra, Italy, 2014. [Google Scholar]

- Kreider, M.L.; Panko, J.M.; McAtee, B.L.; Sweet, L.I.; Finley, B.L. Physical and chemical characterization of tire-related particles: Comparison of particles generated using different methodologies. Sci. Total Environ. 2010, 408, 652–659. [Google Scholar] [CrossRef] [PubMed]

- Aatmeeyata; Kaul, D.S.; Sharma, M. Traffic generated non-exhaust particulate emissions from concrete pavement: A mass and particle size study for two wheelers and small cars. Atmos. Environ. 2009, 43, 5691–5697. [Google Scholar] [CrossRef]

- Dahl, A.; Gharibi, A.; Swietlicki, E.; Gudmundsson, A.; Bohgard, M.; Ljungman, A.; Blomqvistd, G.; Gustafsson, M. Traffic-generated emissions of ultrafine particles from pavement-tire interface. Atmos. Environ. 2006, 40, 1314–1323. [Google Scholar] [CrossRef]

- Long, C.M.; Nascarella, M.A.; Valberg, P.A. Carbon black vs. Black carbon and other airborne materials containing elemental carbon: Physical and chemical distinctions. Environ. Pollut. 2013, 181, 271–286. [Google Scholar] [CrossRef] [PubMed]

- Continental Carbon. Tire Rubber Carbon Blacks. Available online: http://www.continentalcarbon.com/rubber-carbon-black-tire-grades.asp (accessed on 1 April 2017).

- Norman, D.T. Rubber Grade Carbon Blacks; Witco Corporation, Concarb Division: Houston, TX, USA, 2001. [Google Scholar]

- Mathissen, M.; Scheer, V.; Vogt, R.; Benter, T. Investigation on the potential generation of ultrafine particles from the tire-road interface. Atmos. Environ. 2011, 45, 6172–6179. [Google Scholar] [CrossRef]

- European Union. Directive 2000/53/EC of the European Parliament and of the council of 18 September 2000 on end-of life vehicles. Off. J. Eur. Union 2000, 43, 34–42. [Google Scholar]

- Van Duijnhove, N.; Denier van der Gon, H.; Hulskotte, J. Emissieschattingen Diffuse Bronnen Emissieregistratie-Bandenslijtage Wegverkeer-Versie Mei 2014; DELTARES en TNO: Delft, The Netherlands, 2014. [Google Scholar]

- Klein, J.; Molnár-int Veld, H.; Geilenkirchen, G.; Hulskotte, J.; Ligterink, N.; Kadijk, G.; De Boer, R. Methods for Calculating the Emissions of Transport in The Netherlands; Statistics Netherlands: The Hague, The Netherlands; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands; TNO: Delft, The Netherlands; RWS Centre for Transport and Navigation (WVL): The Hague, The Netherlands, 2017. [Google Scholar]

- Verschoor, A.; De Poorter, L.; Dröge, R.; Kuenen, J.; De Valk, E. Emission of Microplastics and Potential Mitigation Measures. Abrasive Cleaning Agents, Paints and Tyre Wear; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Magnusson, K.; Eliasson, K.; Fråne, A.; Haikonen, K.; Hultén, J.; Olshammar, M.; Stadmark, J.; Voisin, A. Swedish Sources and Pathways for Microplastics to the Marine Environment; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2016. [Google Scholar]

- Swedish Chemicals Agency (KEMI). HA Oils in Automotive Tyres—Prospects for a National Ban; Swedish National Chemicals Inspectorate: Solna, Sweden, 2003. [Google Scholar]

- Luhana, L.; Sokhi, R.; Warner, L.; Mao, H.; Boulter, P.; McCrae, I.; Wright, J.; Osborn, D. Characterisation of Exhaust Particulate Emissions from Road Vehicles; Measurement of Non-Exhaust Particulate Matter; European Commission—DG TrEn, 5th Framework Programme: Brussels, Belgium, 2004. [Google Scholar]

- UNECE Working Party on Pollution and Energy (GRPE). Informal Document GRPE-65–20, (65th GRPE, 15–18 January 2013, Agenda Item 16) Transmitted by the Expert from the Russian Federation; GRPE: Geneva, Switzerland, 2013. [Google Scholar]

- Fauser, P.; Tjell, J.C.; Mosbaek, H.; Pilegaard, K. Tire-tread and bitumen particle concentrations in aerosol and soil samples. Pet. Sci. Technol. 2002, 20, 127–141. [Google Scholar] [CrossRef]

- Hillenbrand, T.; Toussaint, D.; Böhm, E.; Fuchs, S.; Scherer, U.; Rudolphi, A.; Hoffmann, M.; Kreißig, J.; Kotz, C. Einträge von Kupfer, Zink und Blei in Gewässer und Böden—Analyse der Emissionspfade und Möglicher Emissionsminderungsmaßnahmen; Umweltbundesamt: Dessau, Germany, 2005. [Google Scholar]

- Radke, S. Verkehr in Zahlen 2014/2015; Bundesministerium für Verkehr und Digitale Infrastruktur: Bonn, Germany, 2015. [Google Scholar]

- Baumann, W.; Ismeier, M. Kautschuk und Gummi: Daten und Fakten zum Umweltschutz; Springer: Berlin, Germany, 1998. [Google Scholar]

- Environment Agency News. Tyres in the environment: Executive summary. Sci. Total Environ. 1999, 234, 243–245. [Google Scholar]

- Humby, P. Overview of the UK Population. Available online: https://www.ons.gov.uk/peoplepopulationandcommunity/populationandmigration/populationestimates/articles/overviewoftheukpopulation/february2016 (accessed on 1 April 2017).

- Central Intelligence Agency (CIA). The World Factbook. Available online: https://www.cia.gov/library/publications/resources/the-world-factbook/ (accessed on 5 March 2017).

- Milani, M.; Pucillo, F.P.; Ballerini, M.; Camatini, M.; Gualtieri, M.; Martino, S. First evidence of tyre debris characterization at the nanoscale by focused ion beam. Mater. Charact. 2004, 52, 283–288. [Google Scholar] [CrossRef]

- Yamashita, M.; Yamanaka, S. Dust resulting from tire wear and the risk of health hazards. J. Environ. Prot. 2013, 4, 509–515. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Global Status Report on Road Safety 2015; WHO: Geneva, Switzerland, 2015. [Google Scholar]

- Huo, H.; Zhang, Q.; He, K.; Yao, Z.; Wang, M. Vehicle-use intensity in China: Current status and future trend. Energy Policy 2011, 43, 6–16. [Google Scholar] [CrossRef]

- Baidya, S.; Borken-Kleefeld, J. Atmospheric emissions from road transportation in India. Energy Policy 2009, 37, 3812–3822. [Google Scholar] [CrossRef]

- United States Department of Energy. Maps and Data-Average Annual Vehicle Miles Traveled of Major Vehicle Categories. Available online: http://www.afdc.energy.gov/data/10309 (accessed on 26 April 2017).

- Councell, T.B.; Duckenfield, K.U.; Landa, E.R.; Callender, E. Tire-wear particles as a source of zinc to the environment. Environ. Sci. Technol. 2004, 38, 4206–4214. [Google Scholar] [CrossRef] [PubMed]

- United States Census Bureau. Population Profile of the United States 1999. Available online: https://www.census.gov/prod/2001pubs/p23–205.pdf (accessed on 1 July 2017).

- Tadano, Y.S.; Mazza, R.A.; Tomaz, E. Evaluation of Air Quality: Simulation of Air Pollutants Dispersion in Paulinia (Brazil) Using ISCST3. In Proceedings of the 21st Brazilian Congress of Mechanical Engineering, Natal, Brazil, 24–28 October 2011; ABCM: Natal, Brazil, 2011. [Google Scholar]

- World Health Organization (WHO). Registered Vehicles. Available online: http://apps.who.int/gho/data/node.main.A995 (accessed on 25 April 2017).

- Vessel Tracking. Maersk Mc Kinney Moller-Container Ship. Available online: http://www.vesseltracking.net/article/maersk-mc-kinney-moller-container-ship (accessed on 10 May 2017).

- Van De Riet, P.; Bouquet, M. Warme banden en harde landingen. Op de Bok 2012, 84, 6–12. [Google Scholar]

- Brady, C. Boeing 737 Detailed Technical Data. Available online: http://www.b737.org.uk/techspecsdetailed.htm (accessed on 28 April 2017).

- Dutch Central Statistics Bureau (CBS). Centraal Bureau Voor de Statistiek. Available online: http://statline.cbs.nl/StatWeb/publication/?PA=37478hvv (accessed on 28 April 2017).

- Oomen, A.G.; De Groot, G.M. Beoordeling gezondheidsrisico’s Door Sporten op Kunstgrasvelden Met Rubbergranulaat; Rijksinstituut voor Volksgezondheid en Milieu: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Grigoratos, T.; Martini, G. Brake wear particle emissions: A review. Environ. Sci. Pollut. Res. Int. 2015, 22, 2491–2504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Davis, S.C.; Diegel, S.W.; Boundy, R.G. Transportation Energy Data Book: Edition 35; Office of Energy Efficiency and Renewable Energy, U.S. Department of Energy: Oak Ridge, TN, USA, 2016.

- Davis, S.C. Transportation Energy Data Book: Edition 17; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1997; p. 280. [Google Scholar]

- Walsh, M.P. Controlling motor vehicle emissions. Platin. Met. Rev. 1989, 33, 194–212. [Google Scholar]

- Oosterom, E.; Hermans, R. Riolering in Beeld-Benchmark Rioleringszorg 2013; Stichting Rionet: Ede, The Netherlands, 2013. [Google Scholar]

- Magnusson, K.; Wahlberg, C. Mikroskopiska Skräppartiklar i Vatten Från Avloppsreningsverk; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2014. [Google Scholar]

- Magnusson, K. Mikroskräp i Avloppsvatten Från tre Norska Avloppsreningsverk; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2014. [Google Scholar]

- Leslie, H.A.; Brandsma, S.H.; Van Velzen, M.J.M.; Vethaak, A.D. Microplastics en route: Field measurements in the Dutch river delta and Amsterdam canals, wastewater treatment plants, North Sea sediments and biota. Environ. Int. 2017, 101, 133–142. [Google Scholar] [CrossRef] [PubMed]

- Nizzetto, L.; Futter, M.; Langaas, S. Are Agricultural Soils Dumps for Microplastics of Urban Origin? 0013-936X; ACS Publications: Washington, DC, USA, 2016. [Google Scholar]

- Van der Wal, M.; Van der Meulen, M.D.; Roex, E.W.M.; Wolthuis, Y.; Tweehuysen, G.; Vethaak, A.D. Summary Report Plastic Litter in Rhine Meuse and Scheldt Contribution to Plastic Litter in the North Sea; Deltares: Delft, The Netherlands, 2013. [Google Scholar]

- Schuchardt, B.; Beilfuß, S.; Reincke, T.; Hofmann, O.; Ziebarth, N.; Liebezeit, G.; Dubaish, F. Müll in der Nordsee–Pilotprojekt zur Relevanz des Eintragspfades Ästuar am Beispiel der Unterweser-Untersuchung vor dem Hintergrund der Meeresstrategie-Rahmenrichtlinie (MSRL); Bioconsult Schuchardt & Scholle GbR: Bremen, Germany, 2013. [Google Scholar]

- Wasserstraßen- und Schifffahrtsamt Bremerhaven (WSV). Strömung. Available online: http://www.wsa-bremerhaven.de/bau_und_unterhaltung/gewaesserkunde/Stroemung/index.html (accessed on 8 July 2017).

- Nizzetto, L.; Bussi, G.; Futter, M.N.; Butterfield, D.; Whitehead, P.G. A theoretical assessment of microplastic transport in river catchments and their retention by soils and river sediments. Environ. Sci. Process. Impacts 2016, 18, 1050–1059. [Google Scholar] [CrossRef] [PubMed]

- Thorpe, A.; Harrison, R.M. Sources and properties of non-exhaust particulate matter from road traffic: A review. Sci. Total Environ. 2008, 400, 270–282. [Google Scholar] [CrossRef] [PubMed]

- Dall’Osto, M.; Beddows, D.C.S.; Gietl, J.K.; Olatunbosun, O.A.; Yang, X.; Harrison, R.M. Characteristics of tyre dust in polluted air: Studies by single particle mass spectrometry (ATOFMS). Atmos. Environ. 2014, 94, 224–230. [Google Scholar] [CrossRef]

- Ketzel, M.; Omstedt, G.; Johansson, C.; During, I.; Pohjola, M.; Oettl, D.; Gidhagen, L.; Wahlin, P.; Lohmeyer, A.; Haakana, M.; et al. Estimation and validation of PM2.5/PM10 exhaust and non-exhaust emission factors for practical street pollution modelling. Atmos. Environ. 2007, 41, 9370–9385. [Google Scholar] [CrossRef]

- Dall’Osto, M. Personal Communication with Manuel Dall’Osto; Ragas, A., Ed.; Institut de Ciències del Mar: Barcelona, Spain, 2017. [Google Scholar]

- Fu, P.Q.; Kawamura, K.; Chen, J.; Charrière, B.; Sempéré, R. Organic molecular composition of marine aerosols over the Arctic Ocean in summer: Contributions of primary emission and secondary aerosol formation. Biogeosciences 2013, 10, 653–667. [Google Scholar] [CrossRef]

- Rakkestad, K.E.; Dye, C.J.; Yttri, K.E.; Holme, J.A.; Hongslo, J.K.; Schwarze, P.E.; Becher, R. Phthalate levels in Norwegian indoor air related to particle size fraction. J. Environ. Monit. 2007, 9, 1419–1425. [Google Scholar] [CrossRef] [PubMed]

- Kumata, H.; Mori, M.; Takahashi, S.; Takamiya, S.; Tsuzuki, M.; Uchida, T.; Fujiwara, K. Valuation of hydrogenated resin acids as molecular markers for tire-wear debris in urban environments. Environ. Sci. Technol. 2011, 45, 9990–9997. [Google Scholar] [CrossRef] [PubMed]

- Ni, H.G.; Lu, F.H.; Luo, X.L.; Tian, H.Y.; Zeng, E.Y. Occurrence, phase distribution, and mass loadings of benzothiazoles in riverine runoff of the Pearl River Delta, China. Environ. Sci. Technol. 2008, 42, 1892–1897. [Google Scholar] [CrossRef] [PubMed]

- Avagyan, R.; Sadiktsis, I.; Bergvall, C.; Westerholm, R. Tire tread wear particles in ambient air—A previously unknown source of human exposure to the biocide 2-mercaptobenzothiazole. Environ. Sci. Pollut. Res. Int. 2014, 21, 11580–11586. [Google Scholar] [CrossRef] [PubMed]

- Panko, J.M.; Chu, J.; Kreider, M.L.; Unice, K.M. Measurement of airborne concentrations of tire and road wear particles in urban and rural areas of France, Japan, and the United States. Atmos. Environ. 2013, 72, 192–199. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Review of Evidence on Health Aspects of Air Pollution—REVIHAAP Project; Copenhagen, Denmark, 2013; p. 309. [Google Scholar]

- Geiser, M.; Schürch, S.; Gehr, P. Influence of surface chemistry and topography of particles on their immersion into the lung’s surface-lining layer. J. Appl. Physiol. 2003, 94, 1793–1801. [Google Scholar] [CrossRef] [PubMed]

- Wright, S.L.; Kelly, F.J. Plastic and human health: A micro issue? Environ. Sci. Technol. 2017, 51, 6634–6647. [Google Scholar] [CrossRef] [PubMed]

- Des Rieux, A.; Ragnarsson, E.G.; Gullberg, E.; Preat, V.; Schneider, Y.J.; Artursson, P. Transport of nanoparticles across an in vitro model of the human intestinal follicle associated epithelium. Eur. J. Pharm. Sci. 2005, 25, 455–465. [Google Scholar] [CrossRef] [PubMed]

- Gottipolu, R.R.; Landa, E.R.; Schladweiler, M.C.; McGee, J.K.; Ledbetter, A.D.; Richards, J.H.; Wallenborn, G.J.; Kodavanti, U.P. Cardiopulmonary responses of intratracheally instilled tire particles and constituent metal components. Inhal. Toxicol. 2008, 20, 473–484. [Google Scholar] [CrossRef] [PubMed]

- Gualtieri, M.; Rigamonti, L.; Galeotti, V.; Camatini, M. Toxicity of tire debris extracts on human lung cell line A549. Toxicol. In Vitro 2005, 19, 1001–1008. [Google Scholar] [CrossRef] [PubMed]

- Claiborn, C.S.; Larson, T.; Sheppard, L. Testing the metals hypothesis in Spokane, Washington. Environ. Health Perspect. 2002, 110 (Suppl. 4), 547–552. [Google Scholar] [CrossRef] [PubMed]

- Gustafsson, M.; Blomqvist, G.; Gudmundsson, A.; Dahl, A.; Swietlicki, E.; Bohgard, M.; Lindbom, J.; Ljungman, A. Properties and toxicological effects of particles from the interaction between tyres, road pavement and winter traction material. Sci. Total Environ. 2008, 393, 226–240. [Google Scholar] [CrossRef] [PubMed]

- Karlsson, H.; Lindbom, J.; Ghafouri, B.; Lindahl, M.; Tagesson, C.; Gustafsson, M.; Ljungman, A.G. Wear particles from studded tires and granite pavement induce pro-inflammatory alterations in human monocyte-derived macrophages: A proteomic study. Chem. Res. Toxicol. 2011, 24, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Gerlofs-Nijland, M.E.; Dormans, J.A.; Bloemen, H.J.; Leseman, D.L.; John, A.; Boere, F.; Kelly, F.J.; Mudway, I.S.; Jimenez, A.A.; Donaldson, K.; et al. Toxicity of coarse and fine particulate matter from sites with contrasting traffic profiles. Inhal. Toxicol. 2007, 19, 1055–1069. [Google Scholar] [CrossRef] [PubMed]

- Kreider, M.L.; Panko, J.M. Effects of subacute inhalation exposure to tire and road wear particles in rats. In Proceedings of the 48th Congress of the European Societies of Toxicology (EUROTOX 2012), Stockholm, Sweden, 17–20 June 2012. [Google Scholar]

- Kreider, M.; Panko, J.; McDonald, J.D.; McAtee, B.L.; Finley, B.L.; Seagrave, J. Effects of Intratracheal Instillation of Tire and Road Wear Particles (TRWP) and Tread Particles (TP) on Inflammation and Cytotoxicity in Rat Lung: A Comparative Toxicity Study; Society of Toxicology (SOT) Annual Meeting: Washington, DC, USA, 2009. [Google Scholar]

- Kreider, M.L.; Doyle-Eisele, M.; Russell, R.G.; McDonald, J.D.; Panko, J.M. Evaluation of potential for toxicity from subacute inhalation of tire and road wear particles in rats. Inhal. Toxicol. 2012, 24, 907–917. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). Ambient Air Pollution: A Global Assessment of Exposure and Burden of Disease; World Health Organization: Geneva, Switzerland, 2016. [Google Scholar]

- Eerkes-Medrano, D.; Thompson, R.C.; Aldridge, D.C. Microplastics in freshwater systems: A review of the emerging threats, identification of knowledge gaps and prioritisation of research needs. Water Res. 2015, 75, 63–82. [Google Scholar] [CrossRef] [PubMed]

- International Maritime Organisation (IMO). Sources, Fate and Effects of Microplastics; IMO: London, UK, 2015. [Google Scholar]

- Rillig, M.C. Microplastic in terrestrial ecosystems and the soil? Environ. Sci. Technol. 2012, 46, 6453–6454. [Google Scholar] [CrossRef] [PubMed]

- Liebezeit, G.; Liebezeit, E. Origin of synthetic particles in honeys. Pol. J. Food Nutr. Sci. 2015, 65, 143–147. [Google Scholar] [CrossRef]

- Bouwmeester, H.; Hollman, P.C.; Peters, R.J. Potential health impact of environmentally released micro- and nanoplastics in the human food production chain: Experiences from nanotoxicology. Environ. Sci. Technol. 2015, 49, 8932–8947. [Google Scholar] [CrossRef] [PubMed]

- Van Cauwenberghe, L.; Janssen, C.R. Microplastics in bivalves cultured for human consumption. Environ. Pollut. 2014, 193, 65–70. [Google Scholar] [CrossRef] [PubMed]

- Powell, J.J.; Faria, N.; Thomas-McKay, E.; Pele, L.C. Origin and fate of dietary nanoparticles and microparticles in the gastrointestinal tract. J. Autoimmun. 2010, 34, J226–J233. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, A.; Berzhkovskii, A.; Nossal, R. Efficiency of cellular uptake of nanoparticles via receptor-mediated endocytosis. arXiv, 2014; arXiv:arXiv:1411.7348. [Google Scholar]

- Walczak, A.P.; Kramer, E.; Hendriksen, P.J.; Helsdingen, R.; Van der Zande, M.; Rietjens, I.M.; Bouwmeester, H. In vitro gastrointestinal digestion increases the translocation of polystyrene nanoparticles in an in vitro intestinal co-culture model. Nanotoxicology 2015, 9, 886–894. [Google Scholar] [CrossRef] [PubMed]

- Sinnecker, H.; Krause, T.; Koelling, S.; Lautenschlager, I.; Frey, A. The gut wall provides an effective barrier against nanoparticle uptake. Beilstein J. Nanotechnol. 2014, 5, 2092–2101. [Google Scholar] [CrossRef] [PubMed]

- McGill, S.L.; Smyth, H.D. Disruption of the mucus barrier by topically applied exogenous particles. Mol. Pharm. 2010, 7, 2280–2288. [Google Scholar] [CrossRef] [PubMed]

- Mantecca, P.; Sancini, G.; Moschini, E.; Farina, F.; Gualtieri, M.; Rohr, A.; Miserocchi, G.; Palestini, P.; Camatini, M. Lung toxicity induced by intratracheal instillation of size-fractionated tire particles. Toxicol. Lett. 2009, 189, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Marsili, L.; Coppola, D.; Bianchi, N.; Maltese, S.; Bianchi, M.; Fossi, M.C. Release of polycyclic aromatic hydrocarbons and heavy metals from rubber crumb in synthetic turf fields: Preliminary hazard assessment for athletes. J. Environ. Anal. Toxicol. 2015, 5, 1–9. [Google Scholar]

- International Agency for Research on Cancer (IARC). Carbon Black, Titanium Dioxide, and Talc; IARC Press: Lyon, France, 2010; Volume 93. [Google Scholar]

- Gualtieri, M.; Andrioletti, M.; Vismara, C.; Milani, M.; Camatini, M. Toxicity of tire debris leachates. Environ. Int. 2005, 31, 723–730. [Google Scholar] [CrossRef] [PubMed]

- Wik, A.; Dave, G. Acute toxicity of leachates of tire wear material to Daphnia magna—Variability and toxic components. Chemosphere 2006, 64, 1777–1784. [Google Scholar] [CrossRef] [PubMed]

- European Union Regulation (EC) no 1222/2009 of the European Parliament and of the council of 25 November 2009 on the labelling of tyres with respect to fuel efficiency and other essential parameters. Off. J. Eur. Union 2009, 52, 46–58.

- Noordermeer, J.W.M. Personal Communication with Jacques W.M. Noordermeer, em. Professor of Elastomer Technology and Engineering; Kole, P.J., Ed.; University of Twente: Enschede, The Netherlands, 2017. [Google Scholar]

- Simons, A. Road transport: New life cycle inventories for fossil-fuelled passenger cars and non-exhaust emissions in ecoinvent V3. Int. J. Life Cycle Assess. 2013, 21, 1299–1313. [Google Scholar] [CrossRef]

- Timmers, V.R.J.H.; Achten, P.A.J. Non-exhaust PM emissions from electric vehicles. Atmos. Environ. 2016, 134, 10–17. [Google Scholar] [CrossRef]

- Verbeek, R.P.; Bolech, M.; Van Gijlswijk, R.N.; Spreen, J. Energie- en Milieu-Aspecten van Elektrische Personenvoertuigen; TNO Report: TNO 2015 R10386; TNO: Delft, The Netherlands, 2015. [Google Scholar]

- Miller, P. Automotive lithium-ion batteries. State of the art and future developments in lithium-ion battery packs for passenger car applications. Johns. Matthey Technol. Rev. 2015, 59, 4–13. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Boulter, P. EMEP/EEA Air Pollutant Emissions Inventory Guidebook 2009: Road Vehicle Tyre and Brake Wear; Road Surface Wear; European Environment Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Suárez-Iglesias, O.; Collado, S.; Oulego, P.; Diaz, M. Graphene-family nanomaterials in wastewater treatment plants. Chem. Eng. J. 2017, 313, 121–135. [Google Scholar] [CrossRef]

- Herbort, A.F.; Schuhen, K. A concept for the removal of microplastics from the marine environment with innovative host-guest relationships. Environ. Sci. Pollut. Res. Int. 2017, 24, 11061–11065. [Google Scholar] [CrossRef] [PubMed]

- Boucher, J.; Friot, D. Primary Microplastics in the Oceans: A Global Evaluation of Sources; IUCN: Gland, Switzerland, 2017. [Google Scholar]

- McDevitt, J.P.; Criddle, C.S.; Morse, M.; Hale, R.C.; Bott, C.B.; Rochman, C.M. Addressing the issue of microplastics in the wake of the Microbead-Free Waters Act—A new standard can facilitate improved policy. Environ. Sci. Technol. 2017, 51, 6611–6617. [Google Scholar] [CrossRef] [PubMed]

| Wear mg/km | Mileage in 2012 Built-Up Area (×106 km) | Mileage in 2012 Rural Roads (×106 km) | Mileage in 2012 Motorways (×106 km) | Total Wear 2012 tonnes/year | Corrected for 95% Trapped in Motorways | |

|---|---|---|---|---|---|---|

| Passenger car | 100 | 20,876 | 36,472 | 45,349 | 10,270 | 6263 |

| Articulated lorry | 495 | 274 | 867 | 3418 | 2257 | 762 |

| Lorry | 600 | 406 | 525 | 1434 | 1419 | 659 |

| Other | 1084 | 1084 | ||||

| Total | 15,030 | 8768 |

| Urban Roads | Rural Roads | Highway Roads | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Wear mg/km | Total Mileage in 2012 (×106 km) | Total Wear 2012 tonnes/year | Wear mg/km | Total Mileage in 2012 (×106 km) | Total Wear 2012 tonnes/year | Wear (mg/km) | Total Mileage in 2012 (×106 km) | Total Wear 2012 tonnes/year | |

| Moped | 13 | 1608 | 21 | 9 | 690 | 6 | 10 | 0 | 0 |

| Motorcycle | 60 | 393 | 24 | 39 | 1100 | 43 | 47 | 1089 | 51 |

| Passenger car | 132 | 20,959 | 2767 | 85 | 36,622 | 3113 | 104 | 45,541 | 4736 |

| Van | 159 | 2670 | 425 | 102 | 5331 | 544 | 125 | 8649 | 1081 |

| Lorry | 850 | 412 | 350 | 546 | 533 | 291 | 668 | 1453 | 971 |

| Truck | 658 | 277 | 182 | 423 | 876 | 371 | 517 | 3455 | 1786 |

| Bus | 415 | 354 | 147 | 267 | 207 | 55 | 326 | 82 | 27 |

| Special vehicle light | 159 | 22 | 3 | 102 | 44 | 4 | 125 | 72 | 9 |

| Special vehicle heavy | 850 | 59 | 50 | 546 | 76 | 41 | 668 | 210 | 140 |

| Total | 26,754 | 3969 | 45,479 | 4468 | 60,551 | 8801 | |||

| Based on Annual Mileage: Magnusson and Colleagues [32] | Based on Tyres Sold: Swedish National Chemicals Inspectorate [33] | |||||

|---|---|---|---|---|---|---|

| Wear mg/km | Total Mileage in 2012 (×106 km) | Total Wear 2012 Tonnes/Year | Mass of Tyres Consumed Annually kg | Weight Loss (17%) kg | Total Wear 2002 tonnes/year | |

| Passenger car | 50 | 62,940 | 3147 | |||

| Bus/lorry | 700 | 14,416 | 10,091 | |||

| Total | 77,356 | 13,238 | 60,000,000 | 10,000,000 | 10,000 | |

| Based on Annual Mileage: Sundt and Colleagues [10] Using United Nations Economic Commission for Europe (UNECE) Data | Based on Annual Mileage: Sundt and Colleagues [10] Using Data by Luhana and Colleagues [34] | Based on Disposed Tyres: Sundt and Colleagues [10] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wear mg/km | Total Mileage in 2013 (×106 km) | Total Wear 2013 tonnes/year | Wear mg/km | Total Mileage in 2013 (×106 km) | Total Wear 2013 tonnes/year | Weight of Disposed Tyres | Times Re-Treaded | Weight Loss from New | Total Wear 2013 tonnes/year | |

| Passenger car | 132 | 30,000 | 3960 | 100 | 30,000 | 3000 | 42,000 | 0 | 12.5% | 6000 |

| Heavy transport | 712 | 5000 | 3560 | 712 | 5000 | 3560 | 10,000 | 2.5 | 12.5% | 3571 |

| Total | 35,000 | 7520 | 35,000 | 6560 | 52,000 | 9571 | ||||

| Based on Annual Mileage: Lassen and Colleagues [12] Using UNECE Data [35] | Based on Annual Mileage: Lassen and Colleagues [12] Using Data by Luhana and Colleagues [34] | Based on Tyres Sold: Fauser and Colleagues [36] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Wear (mg/km) | Total Mileage in 2014 (×106 km) | Total Wear 2014 tonnes/year | Wear (mg/km) | Total Mileage in 2014 (×106 km) | Total Wear 2014 tonnes/year | Number of Tyres Consumed Annually | Weight Loss per Tyre kg | Total Wear 1990 tonnes/year | |

| Passenger car | 132 | 35,800 | 4726 | 100 | 35,800 | 3580 | 1,900,000 | 2.4 | 4560 |

| Light commercial | 204 | 7400 | 1510 | 204 | 7400 | 1510 | 0 | ||

| Commercial car | 712 | 2000 | 1424 | 712 | 2000 | 1424 | 250,000 | 11 | 2750 |

| Total | 45,200 | 7660 | 45,200 | 6514 | 7310 | ||||

| Wear (mg/km) [37] | Total Wear 2001/2002 tonnes/year [37] | Total Mileage in 2013 (×106 km) [38] | Total Wear 2013 tonnes/year | |

|---|---|---|---|---|

| Moped | 22.5 | 88 | 4700 | 106 |

| Motorcycle | 45 | 621 | 12,300 | 689 |

| Passenger car | 90 | 46,017 | 615,100 | 55,359 |

| Bus | 700 | 2590 | 3300 | 2310 |

| Lorry | 700 | 43,540 | 64,300 | 45,010 |

| Articulated lorry | 1200 | 16,440 | 16,700 | 20,040 |

| Other | 180 | 2124 | 9300 | 1674 |

| Total | 111,420 | 725,700 | 125,188 |

| Number of Vehicles in 1995 | Wear per Tyre mg/km | Average Number of Tyres | Average Mileage in 1995 km | Total Wear 1995 tonnes/year | |

|---|---|---|---|---|---|

| Passenger car | 40,500,000 | 20 | 4 | 14,200 | 46,008 |

| Bus | 46,900 | 32 | 6 | 46,900 | 422 |

| Lorry < 7.5 tonnes | 1,961,000 | 36 | 5 | 25,000 | 8825 |

| Lorry > 7.5 tonnes | 254,000 | 21 | 9 | 70,000 | 3360 |

| Articulated lorry | 124,100 | 18 | 15 | 82,000 | 2748 |

| Total | 61,363 |

| Number of Vehicles | Tyres/Vehicle | Total Number of Tyres | Wear and Tear in cm³/Tyre | Total Wear m³ | Total Wear m³ as Reported in [44] | |

|---|---|---|---|---|---|---|

| Motorcycle | 3,402,405 | 2 | 6,806,810 | 1136 | 7733 | (7733) |

| Light vehicle | 24,756,432 | 4 | 99,025,728 | 1780 | 176,266 | (176,266) |

| Normal vehicle | 43,350,396 | 4 | 173,401,584 | 2880 | 499,397 | (4,993,966) |

| Truck/bus | 2,790,562 | 10 | 27,905,620 | 5484 | 153,034 | (1,666,803) |

| Trailer | 2,463,607 | 14 | 34,490,498 | 5973 | 206,012 | (1,891,459) |

| Total | 76,763,402 | 1,042,442 | (8,736,183) |

| Number Vehicles | Annual Mileage | Wear and Tear g/km | Wear and Tear Tonnes | |

|---|---|---|---|---|

| Cars and 4-wheeled light vehicles | 137,406,846 | 19,400 | 0.132 | 352,000 |

| Motorised 2- and 3-wheelers | 95,326,138 | 5600 | 0.007 | 3740 |

| Heavy lorries | 5,069,292 | 60,000 | 1.068 | 325,000 |

| Other (light duty lorries) | 12,335,936 | 30,000 | 0.204 | 75,500 |

| Total | 250,138,212 | 756,240 |

| Number Vehicles [45] | Annual Mileage [47] | Wear and Tear g/km [22,35] | Wear and Tear Tonnes | |

|---|---|---|---|---|

| Cars and 4-wheeled light vehicles | 38,338,015 | 10,275 | 0.132 | 51,998 |

| Motorised 2- and 3-wheelers | 115,419,175 | 6600 | 0.007 | 5332 |

| Heavy trucks | 4,056,885 | 50,075 | 1.068 | 216,963 |

| Buses (light duty trucks) | 1,676,503 | 53,745 | 0.204 | 18,381 |

| Total | 159,490,578 | 292,674 |

| Number Vehicles [45] | Annual Mileage km [48] | Wear and Tear g/km [22,35] | Wear and Tear Tonnes | |

|---|---|---|---|---|

| Cars and 4-wheeled light vehicles | 245,669,103 | 18,095 | 0.132 | 586,800 |

| Motorised 2- and 3-wheelers | 8,437,502 | 3899 | 0.007 | 230 |

| Heavy lorries | 10,270,693 | 109,685 | 1.068 | 1,203,000 |

| Buses (light duty lorries) | 666,064 | 54,803 | 0.204 | 7450 |

| Total | 265,043,362 | 1,797,480 |

| Number Vehicles [45] | Annual Mileage [51] | Wear and Tear g/km [22,35] | Wear and Tear Tonnes | |

|---|---|---|---|---|

| Cars and 4-wheeled light vehicles | 54,175,378 | 20,000 | 0.132 | 143,023 |

| Motorised 2- and 3-wheelers | 21,597,261 | 5200 | 0.007 | 786 |

| Heavy trucks | 2,488,680 | 51,500 | 1.068 | 136,882 |

| Buses | 888,393 | 73,500 | 0.204 | 13,320 |

| Other | 2,451,017 | ? | ? | - |

| Total | 81,600,729 | 294,011 |

| Number of Capita [42] | Number of Cars [52] | Total Emission from Tyres (tonnes/year) | Emission per Capita/year (kg) | |

|---|---|---|---|---|

| The Netherlands | 17,016,967 | 9,612,273 | 8834 | 0.52 |

| Norway | 5,265,158 | 3,671,885 | 7884 | 1.5 |

| Sweden | 9,880,604 | 5,755,952 | 13,238 | 1.3 |

| Denmark | 5,593,785 | 2,911,147 | 6721 | 1.2 |

| Germany | 80,722,792 | 52,391,000 | 92,594 | 1.1 |

| United Kingdom | 64,430,428 | 35,582,650 | 63,000 | 0.98 |

| Italy | 62,007,540 | 51,269,218 | 50,000 | 0.81 |

| Japan | 126,702,133 | 76,763,402 | 239,762 | 1.9 |

| China | 1,373,541,278 | 250,138,212 | 756,240 | 0.55 |

| India | 1,266,883,598 | 159,490,578 | 292,674 | 0.23 |

| Australia | 22,992,654 | 17,180,596 | 20,000 | 0.87 |

| USA | 323,995,528 | 265,043,362 | 1,524,740 | 4.7 |

| Brazil | 205,823,665 | 81,600,729 | 294,011 | 1.4 |

| Total | 3,564,856,130 | 1,011,411,004 | 3,369,698 | 0.95 |

| Particles Passing the Sewers | |

|---|---|

| Sweden | 19.8% |

| Norway | 5.3% |

| The Netherlands | 28% |

| A: Total Plastic into Oceans (tonnes/year) [4] | B: Tyre Wear and Tear into Oceans (tonnes/year) | % Tyre Wear and Tear of Total (B/(A + B)) | Per Capita Tyre Wear and Tear Emission (kg/year/person) | |

|---|---|---|---|---|

| The Netherlands (pop. 17,016,967) | 27,700 | 261 (0.9%) | 0.9% | 0.015 |

| Norway (pop. 5,265,158) | 8400 | 3942 (31.9%) | 31.9% | 0.75 |

| Petrol Version | Weight [kg] | E-Version | Weight [kg] | Extra Weight E-Version |

|---|---|---|---|---|

| Volkswagen high Up! petrol | 958 | Volkswagen e-Up! | 1114 | 16% |

| Volkswagen Golf 1.4 TSI | 1205 | Volkswagen E-Golf | 1485 | 23% |

| Ford Focus | 1380 | Ford Focus Electric | 1674 | 21% |

| Mercedes-Benz B 250 | 1465 | Mercedes-Benz B 250 e | 1725 | 18% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.A.J.; Ragas, A.M.J. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. https://doi.org/10.3390/ijerph14101265

Kole PJ, Löhr AJ, Van Belleghem FGAJ, Ragas AMJ. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. International Journal of Environmental Research and Public Health. 2017; 14(10):1265. https://doi.org/10.3390/ijerph14101265

Chicago/Turabian StyleKole, Pieter Jan, Ansje J. Löhr, Frank G. A. J. Van Belleghem, and Ad M. J. Ragas. 2017. "Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment" International Journal of Environmental Research and Public Health 14, no. 10: 1265. https://doi.org/10.3390/ijerph14101265

APA StyleKole, P. J., Löhr, A. J., Van Belleghem, F. G. A. J., & Ragas, A. M. J. (2017). Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. International Journal of Environmental Research and Public Health, 14(10), 1265. https://doi.org/10.3390/ijerph14101265