Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate

2.2. Inoculum

2.3. Analytical Methods

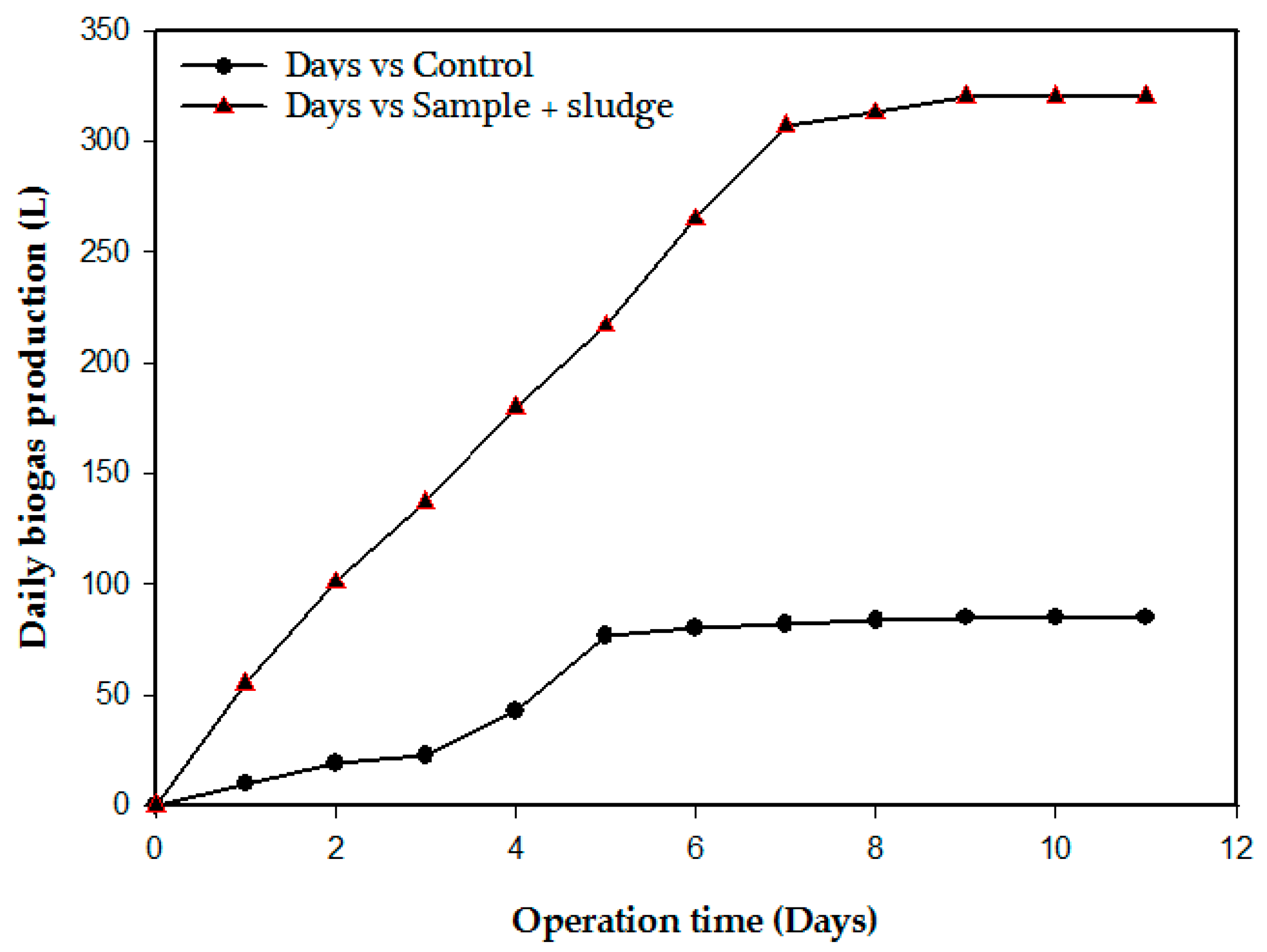

2.4. Biochemical Methane Potential Test (BMP)

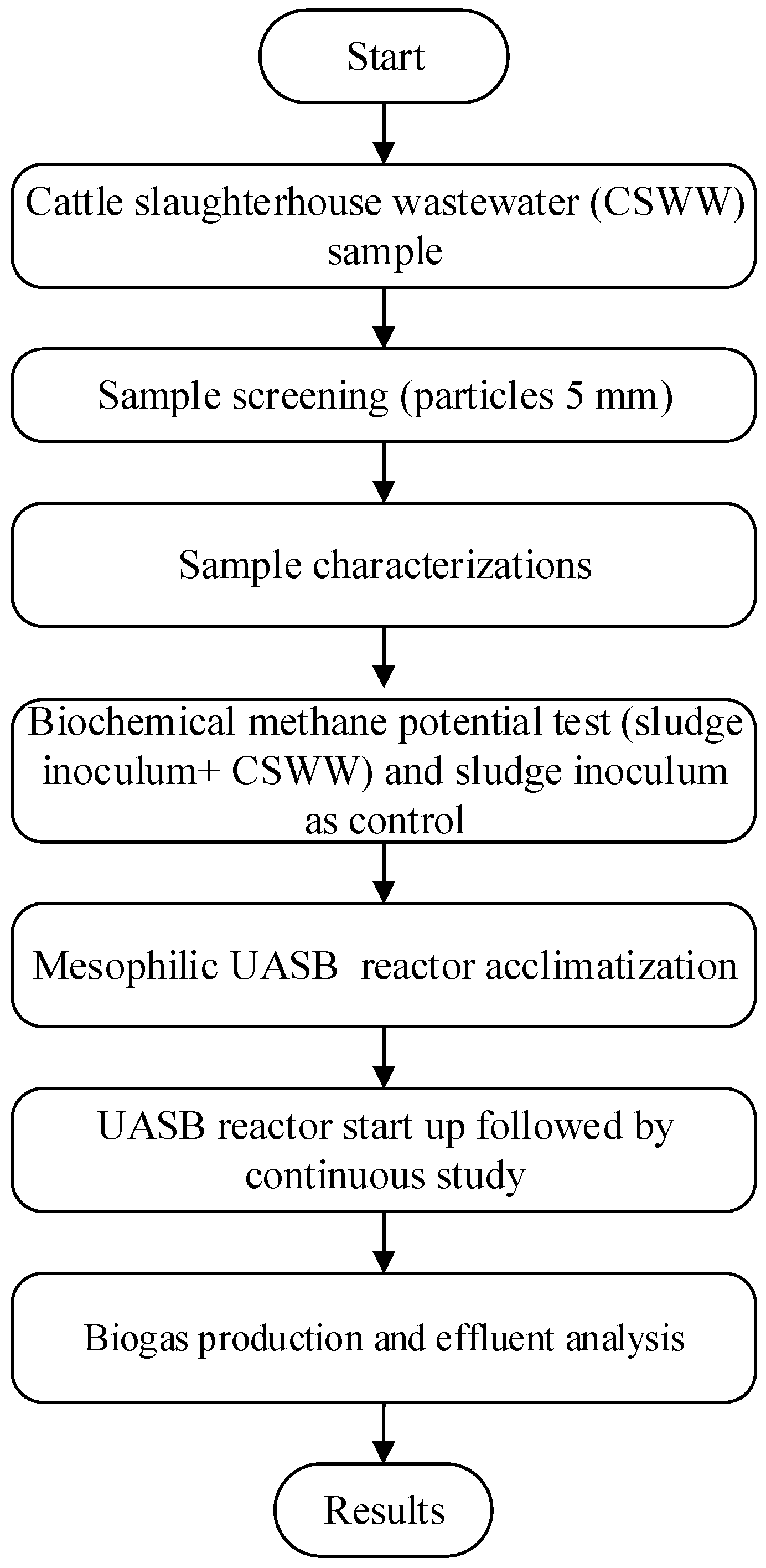

2.5. Experimental Process Flow

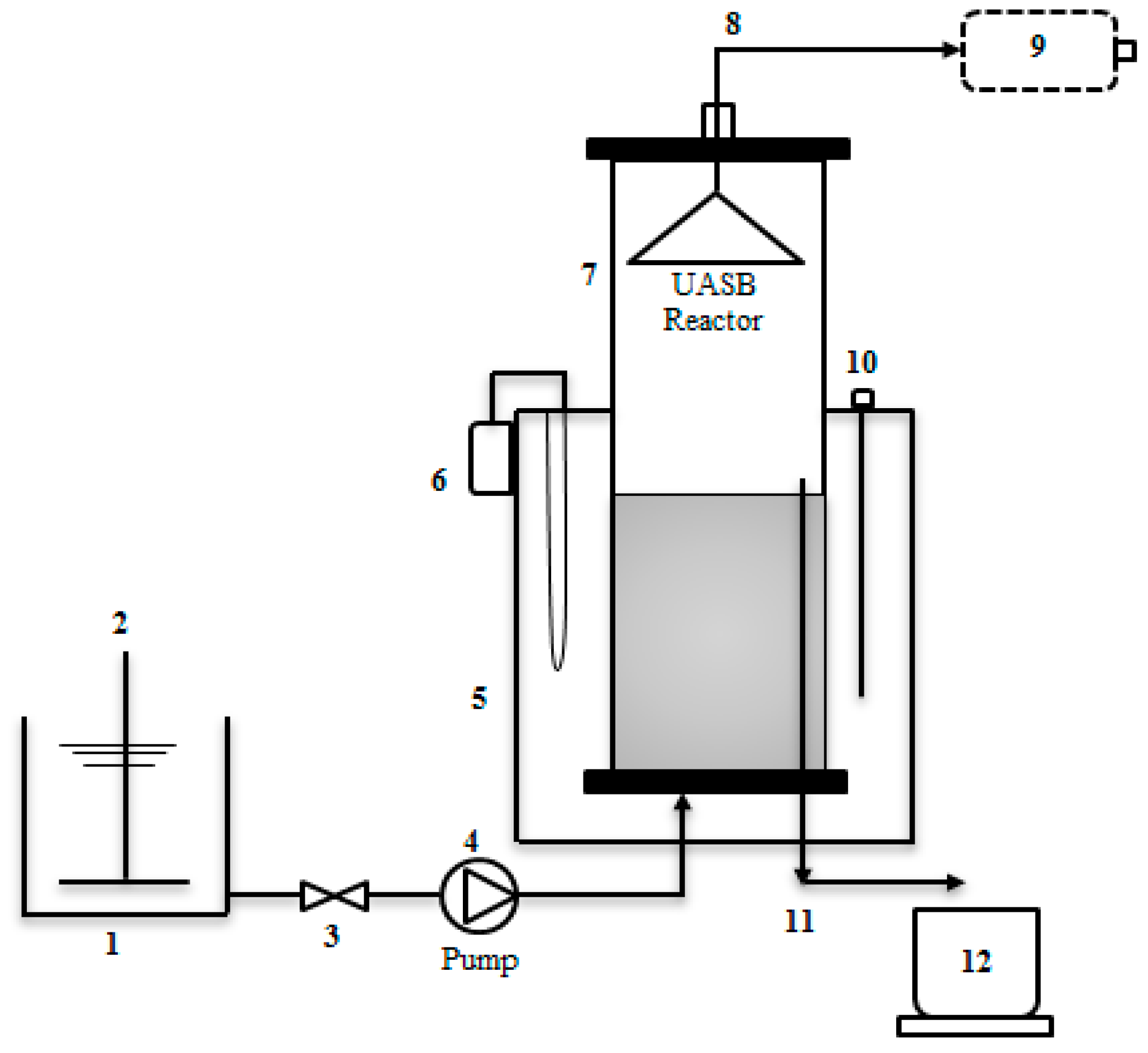

2.6. UASB Reactor Set-Up

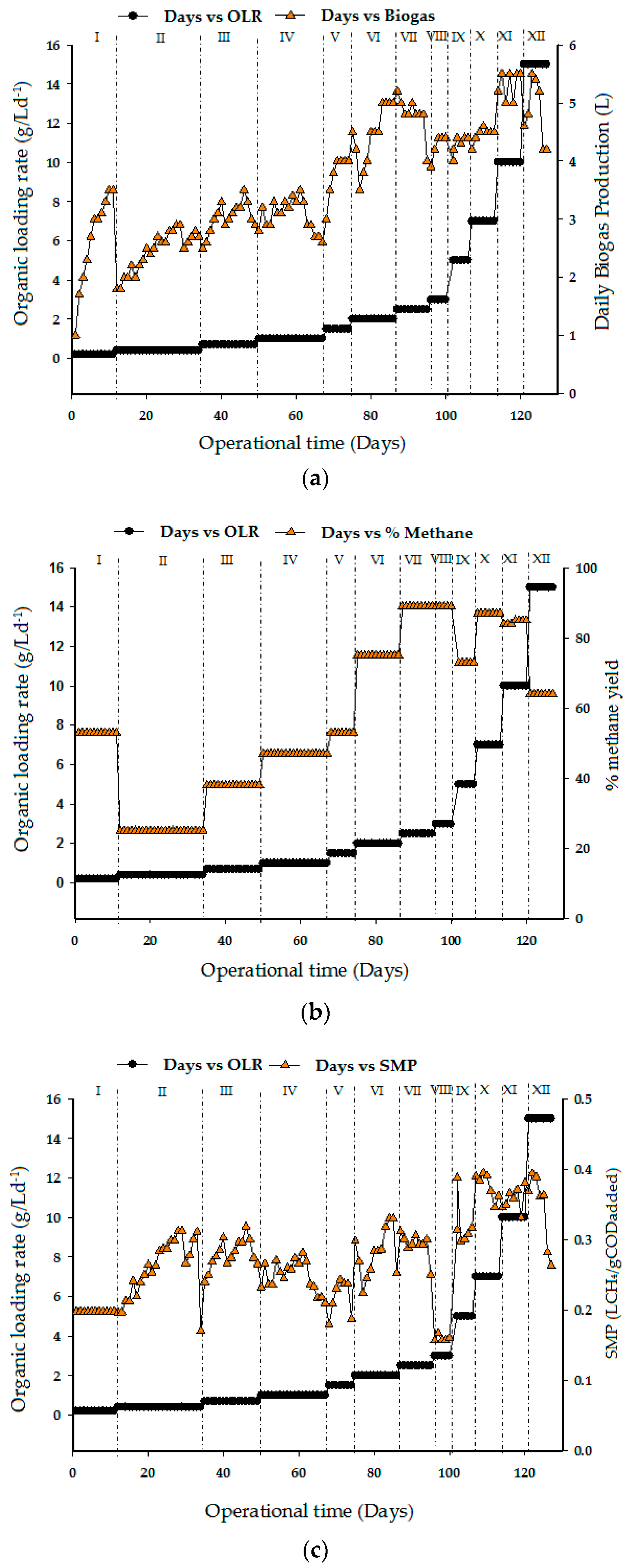

2.7. Mesophilic UASB Reactor Performance Study on CSWW

2.8. Scanning Electron Microscopy Analysis

3. Results and Discussion

3.1. Biochemical Methane Potential of CSWW

3.2. Effect of Organic Loading Rate on COD and SCOD Removal Efficiency

3.3. Biogas Production, Percentage of Methane Yield, and Specific Methane Production

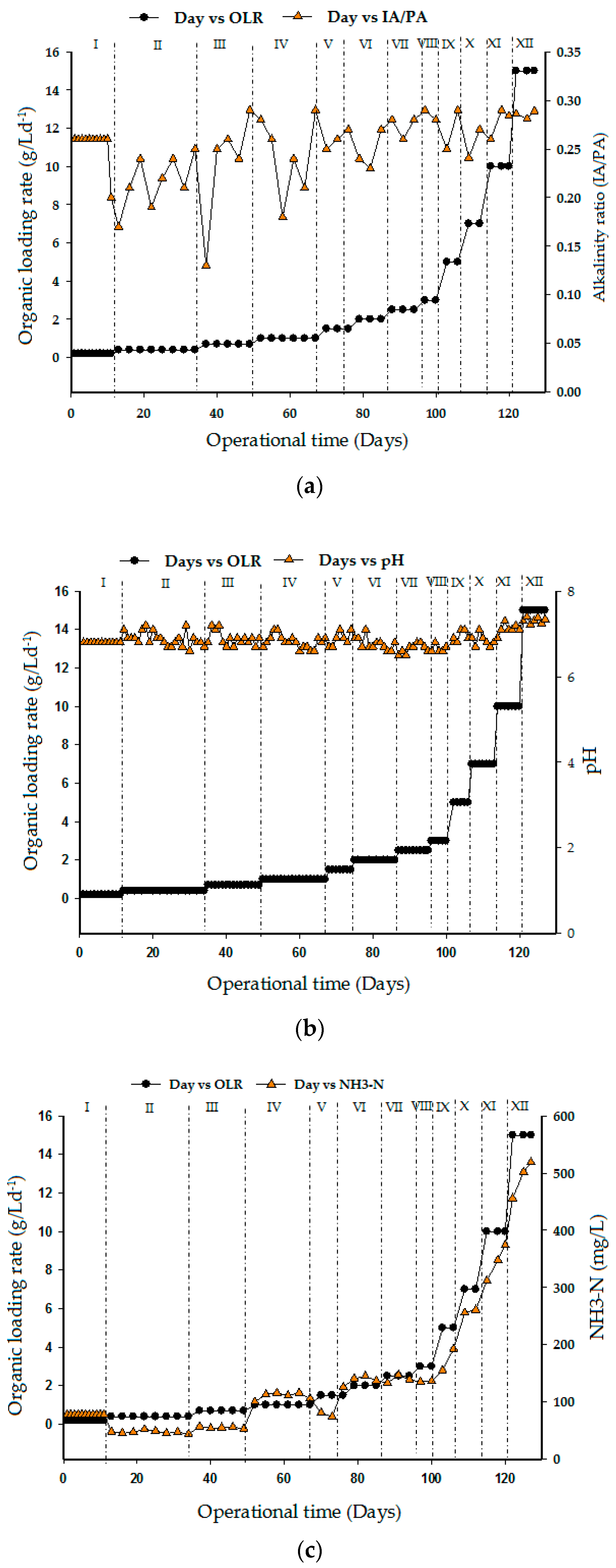

3.4. Effect of Alkalinity, pH, and Ammonia Nitrogen

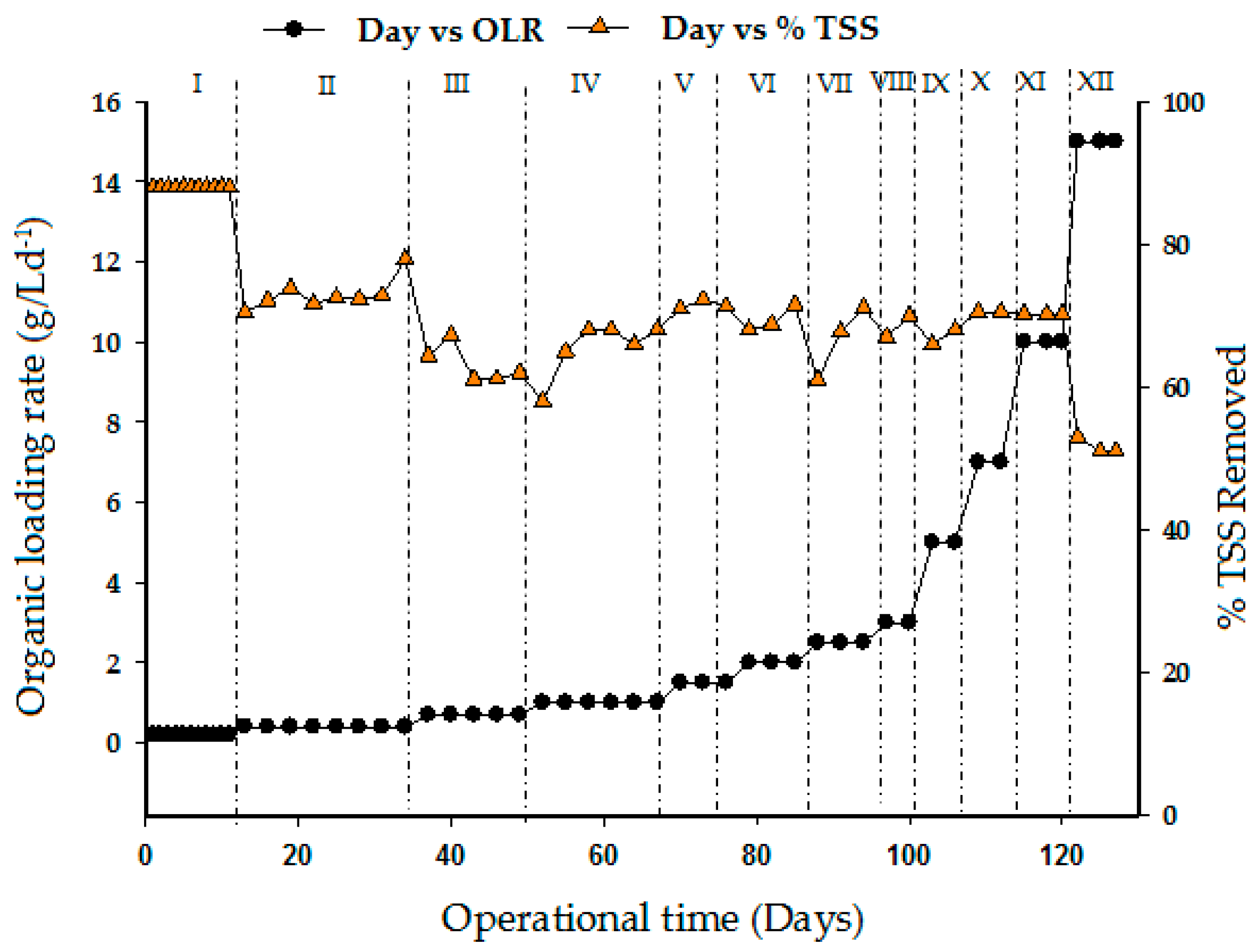

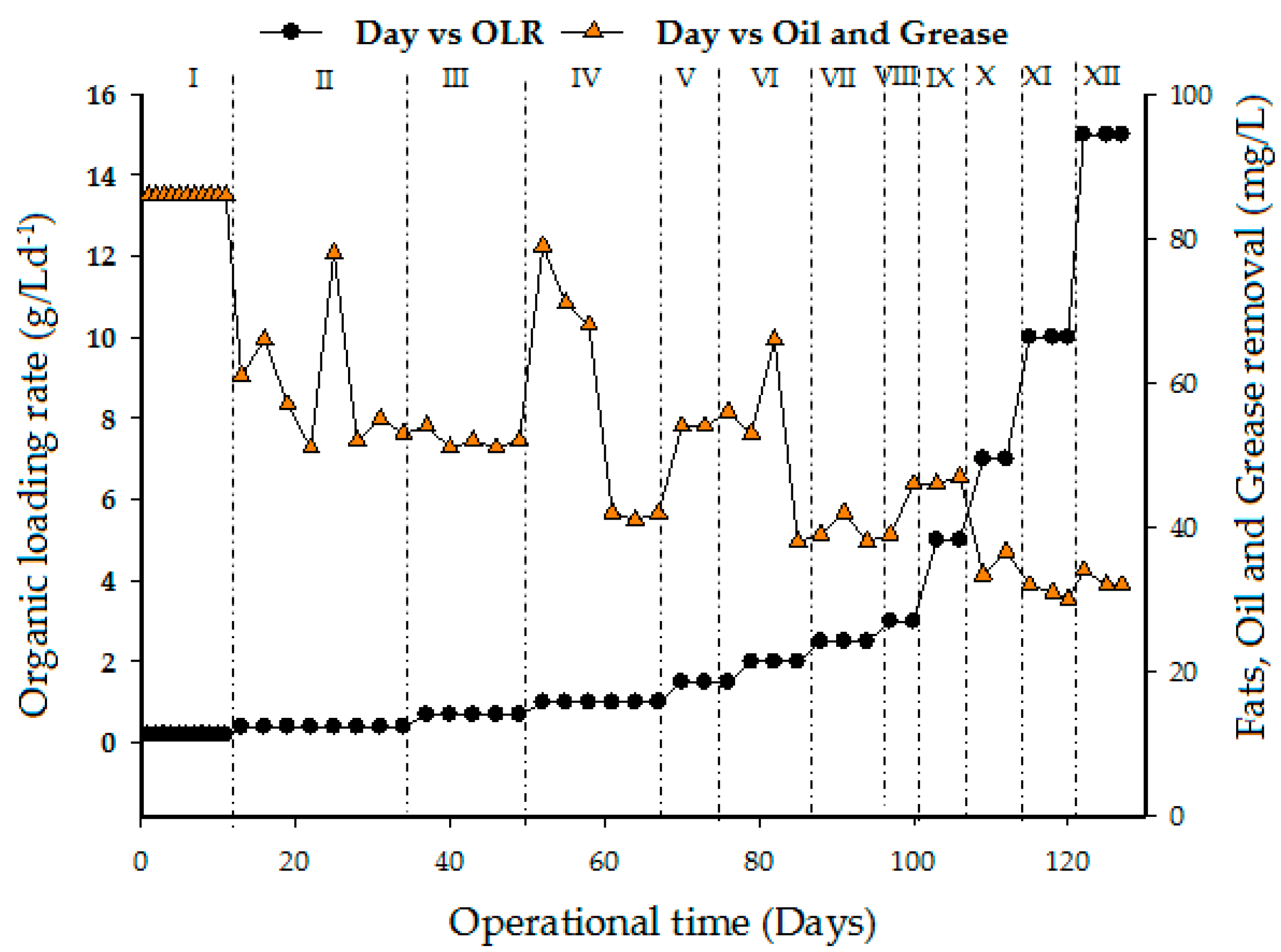

3.5. Total Suspended Solid and Oil and Grease Removal Profile

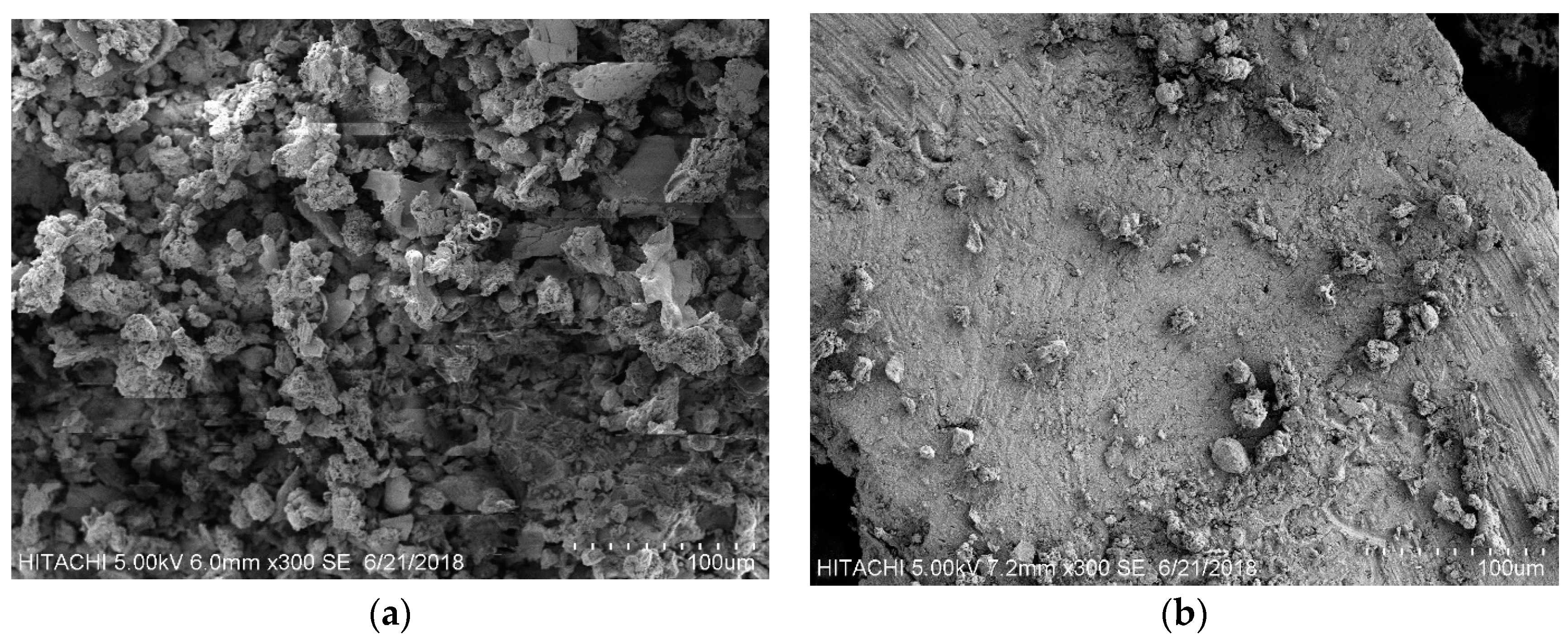

3.6. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BOD | Biochemical oxygen demand |

| BMP | Biochemical methane potential |

| COD | Chemical oxygen demand |

| CSWW | Cattle slaughterhouse wastewater |

| FOG | Fats, oil, and grease |

| HRT | Hydraulic retention time |

| OLR | Organic loading rat |

| SCOD | Soluble chemical oxygen demand |

| TSS | Total suspended solid |

| UASB | Upflow anaerobic sludge blanket |

| VSS | Volatile suspended solid |

References

- Mattioli, A.; Boscaro, D.; Venezia, F.D.; Santacroce, F.C.; Pezzuolo, A.; Sartori, L.; Bolzonella, D. Biogas from Residual Grass: A Territorial Approach for Sustainable Bioenergy Production. Waste Biomass Valorization 2017, 8, 47–56. [Google Scholar] [CrossRef]

- Boscaro, D.; Andrea, P.; Luigi, S.; Francesco, M.; Andrea, M.; David, B.; Stefano, G. Evaluation of the Energy and Greenhouse Gases Impacts of Grass Harvested on Riverbanks for Feeding Anaerobic Digestion Plants. J. Clean. Prod. 2018, 172, 4099–4109. [Google Scholar] [CrossRef]

- Jensen, P.D.; Yap, S.D.; Boyle-Gotla, A.; Janoschka, J.; Carney, C.; Pidou, M.; Batstone, D.J. Anaerobic membrane bioreactors enable high rate treatment of slaughterhouse wastewater. Biochem. Eng. J. 2015, 7, 132–141. [Google Scholar] [CrossRef]

- Aziz, H.; Puat, N.; Alazaiza, M.; Hung, Y.T. Poultry Slaughterhouse Wastewater Treatment Using Submerged Fibers in an Attached Growth Sequential Batch Reactor. Int. J. Environ. Res. Public Health 2018, 15, 1734. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, M.I.; Ejaz, O.; Ali, A.; Durrani, M.A.Q.J.; Khan, I.A. Anaerobic digestion of waste from a slaughterhouse. J. Environ. Chem. Eng. 2014, 2, 1317–1320. [Google Scholar] [CrossRef]

- Luostarinen, S.; Luste, S.; Sillanpää, M. Increased biogas production at wastewater treatment plants through co-digestion of sewage sludge with grease trap sludge from a meat processing plant. Bioresour. Technol. 2014, 100, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Cirne, D.; Paloumet, X.; Björnsson, L.; Alves, M.M.; Mattiasson, B. Anaerobic digestion of lipid-rich waste-Effects of lipid concentration. Renew. Energy 2007, 32, 965–975. [Google Scholar] [CrossRef]

- Technical Development Document for the Final Effluent Limitations Guidelines and Standards for the Meat and Poultry Products Point Source Category (40 CFR 432); United States Environmental Protection Agency: Washington, DC, USA, 2004.

- Kist, L.T.; El Moutaqi, S.; Machado, E.L. Cleaner production in the management of water use at a poultry slaughterhouse of Vale do Taquari. Brazil: A case study. J. Clean. Prod. 2009, 17, 1200–1205. [Google Scholar] [CrossRef]

- Ciro, B.-L.; Mehrab, M. Slaughterhouse Wastewater: Treatment, Management and Resource Recovery. Phys.-Chem. Wastewater Treat. Resour. Recover. 2017, 154–173. [Google Scholar] [CrossRef]

- Jensen, P.D.; Mehta, C.M.; Carney, C.; Batstone, D. Recovery of energy and nutrient resources from cattle paunch waste using temperature phased anaerobic digestion. Waste Manag. 2016, 51, 72–80. [Google Scholar] [CrossRef] [PubMed]

- Mittal, G. Treatment of wastewater from abattoirs before land application—A review. Bioresour. Technol. 2006, 97, 1119–1135. [Google Scholar] [CrossRef] [PubMed]

- Bustillo-Lecompte, C.; Mehrvar, M. Treatment of an actual slaughterhouse wastewater by integration of biological and advanced oxidation processes: Modeling, optimization, and cost-effectiveness analysis. J. Environ. Manag. 2016, 182, 651–666. [Google Scholar] [CrossRef] [PubMed]

- Bugallo, P.M.; Andrade, L.C.; de la Torre, M.A.; López, R.T. Analysis of the slaughterhouses in Galicia (NW Spain). Sci. Total Environ. 2014, 481, 656–661. [Google Scholar] [CrossRef] [PubMed]

- Gebreeyessus, G.D.; Jenicek, P. Thermophilic versus Mesophilic Anaerobic Digestion of Sewage Sludge: A Comparative Review. Bioengineering 2016, 3, 15. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Guo, W.; Ngo, H.H.; Lee, D.-J.; Tung, K.-L.; Jin, P.; Wang, J.; Wu, Y. Challenges in biogas production from anaerobic membrane bioreactors. Renew. Energy 2016, 98, 120–134. [Google Scholar] [CrossRef]

- Braguglia, C.M.; Gallipoli, A.; Gianico, A.; Pagliaccia, P. Anaerobic bioconversion of food waste into energy: A critical review. Bioresour. Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Aryal, N.; Kvist, T. Alternative of Biogas Injection into the Danish Gas Grid System—A Study from Demand Perspective. Chem. Eng. 2018, 2, 43. [Google Scholar] [CrossRef]

- Salminen, E.A.; Rintala, J.A. Semi-continuous anaerobic digestion of solid poultry slaughterhouse waste: Effect of hydraulic retention time and loading Semi-continuous anaerobic digestion of solid poultry slaughterhouse waste: Effect of hydraulic retention time and loading. Water Res. 2002, 36, 3175–3182. [Google Scholar] [CrossRef]

- Masse, L.; Massé, D.I.; Kennedy, K.J.; Chou, S.P. Neutral fat hydrolysis and long-chain fatty acid oxidation during anaerobic digestion of slaughterhouse wastewater. Biotechnol. Bioeng. 2002, 79, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Hamawand, I.; Ghadouani, A.; Bundschuh, J.; Hamawand, S.; Al Juboori, R.A.; Chakrabarty, S.; Yusaf, T. A Critical Review on Processes and Energy Profile of the Australian Meat Processing Industry. Energies 2017, 10, 731. [Google Scholar] [CrossRef]

- Standard Methods for the Examination of Water and Wastewater; American Public Health Association, Water Environment Federation: Washington, DC, USA, 2005.

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef] [PubMed]

- De Souza Guimarães, C.; da Silva Maia, D.R.; Serra, E.G. Construction of biodigesters to optimize the production of biogas from anaerobic co-digestion of food waste and sewage. Energies 2018, 11, 870. [Google Scholar] [CrossRef]

- Lettinga, G. Anaerobic digestion and wastewater treatment systems. J. Microbiol. 1995, 1964, 3–28. [Google Scholar] [CrossRef]

- Idrus, S.; Banks, C.J.; Heaven, S. Assessment of the potential for biogas production from wheat straw leachate in upflow anaerobic sludge blanket digesters. Water Sci. Technol. 2012, 66, 2737–2744. [Google Scholar] [CrossRef] [PubMed]

- Michaud, S.; Bernet, N.; Buffière, P.; Roustan, M.; Moletta, R. Methane yield as a monitoring parameter for the start-up of anaerobic fixed film reactors. Water Res. 2002, 36, 1385–1391. [Google Scholar] [CrossRef]

- Najafpour, G.D.; Zinatizadeh, A.A.L.; Mohamed, A.R.; Hasain Isa, M.; Nasrollahzadeh, H. High-rate anaerobic digestion of palm oil mill effluent in an upflow anaerobic sludge-fixed film bioreactor. Process Biochem. 2006, 41, 370–379. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, L.; Chi, L.; Long, X.; Mei, Z.; Zhang, Z. Startup and operation of anaerobic reactor treating palm oil mill effluent. J. Environ. Sci. 2008, 20, 658–663. [Google Scholar] [CrossRef]

- Ghaniyari-Benis, S.; Borja, R.; Monemian, S.A.; Goodarzi, V. Anaerobic treatment of synthetic medium-strength wastewater using a multistage biofilm reactor. Bioresour. Technol. 2009, 100, 1740–1745. [Google Scholar] [CrossRef] [PubMed]

- Sowmeyan, R.; Swaminathan, G. Evaluation of inverse anaerobic fluidized bed reactor for treating high strength organic wastewater. Bioresour. Technol. 2008, 99, 3877–3880. [Google Scholar] [CrossRef] [PubMed]

- Rajab, A.R.; Salim, M.R.; Sohaili, J.; Anuar, A.N.; Salmiati; Lakkaboyana, S.K. Performance of integrated anaerobic/aerobic sequencing batch reactor treating poultry slaughterhouse wastewater. Chem. Eng. J. 2017, 313, 967–974. [Google Scholar] [CrossRef]

- Rajakumar, R.; Meenambal, T. Comparative study on start-up performance of HUASB and AF reactors treating poultry slaughterhouse wastewater. Int. J. Environ. Res. 2008, 2, 401–410. [Google Scholar]

- Mijalova Nacheva, P.; Reyes Pantoja, M.; Lomelí Serrano, E.A. Treatment of slaughterhouse wastewater in upflow anaerobic sludge blanket reactor. Water Sci. Technol. 2011, 63, 877–884. [Google Scholar] [CrossRef] [PubMed]

- Marcos, A.; Al-Kassir, A.; Cuadros, F.; Yusaf, T. Treatment of slaughterhouse waste water mixed with serum from lacteal industry of extremadura in Spain to produce clean energy. Energies 2017, 10, 765. [Google Scholar] [CrossRef]

- Kwarciak-kozłowska, A.; Bohdziewicz, J.; Mielczarek, K.; Krzywicka, A. The Application of Uasb Reactor in Meat Industry Wastewater Treatment. Civ. Environ. Eng. Rep. 2011, 7, 119–128. [Google Scholar]

- Buendía, I.; Fernández, F.J.; Villaseñor, J.; Rodríguez, L. Biodegradability of meat industry wastes under anaerobic and aerobic conditions. Water Res. 2008, 42, 3767–3774. [Google Scholar] [CrossRef] [PubMed]

- Sakar, S.; Yetilmezsoy, K.; Kocak, E. Anaerobic digestion technology in poultry and livestock waste treatment—A literature review. Waste Manag. Res. 2009, 27, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Tangkathitipong, P.; Intanoo, P.; Butpan, J.; Chavadej, S. Separate production of hydrogen and methane from biodiesel wastewater with added glycerin by two-stage anaerobic sequencing batch reactors (ASBR). Renew. Energy 2017, 113, 1077–1085. [Google Scholar] [CrossRef]

- Bitton, G. Wastewater Microbiology, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Mata-Alvarez, J. Biomethanization of the Organic Fraction of Municipal Solid Wastes; IWA: London, UK, 2003. [Google Scholar]

- Musa, M.A.; Idrus, S.; Man, H.C.; Daud, N.N.N. Wastewater Treatment and Biogas Recovery Using Anaerobic Membrane Bioreactors (AnMBRs): Strategies and Achievements. Energies 2018, 11, 1675. [Google Scholar] [CrossRef]

- Tawfik, A.; Sobhey, M.; Badawy, M. Treatment of a combined dairy and domestic wastewater in an up-flow anaerobic sludge blanket (UASB) reactor followed by activated sludge (AS system). Desalination 2008, 227, 167–177. [Google Scholar] [CrossRef]

- Klaucans, E.; Karlis, S. Problems with Fat, Oil, and Grease (FOG) in Food Industry Wastewaters and Recovered FOG Recycling Methods Using Anaerobic Co-Digestion: A Short Review. Key Eng. Mater. 2018, 762, 61–68. [Google Scholar] [CrossRef]

- Environmental Requirements: Department of Environment Ministry of Natural Resources and Environment Wisma Sumber Asli, Precinct 4. In A Guide for Investors; Federal Government Administrative Centre: Putra Jaya, Malaysia, 2010.

- Wu, J.; Afridi, Z.U.R.; Cao, Z.P.; Zhang, Z.L.; Poncin, S.; Li, H.Z.; Zuo, J.E.; Wang, K.J. Size effect of anaerobic granular sludge on biogas production: A micro scale study. Bioresour. Technol. 2016, 202, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Rosli, N.S.; Idrus, S.; Daud, N.N.; Ahsan, A. Assessment of potential biogas production from rice straw leachate in upflow anaerobic sludge blanket reactor (UASB). Int. J. Smart Grid Clean Energy 2016, 5, 135–143. [Google Scholar] [CrossRef]

| Parameter | World Bank | EU | USA | Canada | Colombia | China | India | Australia |

|---|---|---|---|---|---|---|---|---|

| BOD5 (mg/L) | 30 | 25 | 16–26 | 5–30 | 50 | 20–100 | 30–100 | 5–20 |

| COD (mg/L) | 125 | 125 | n.a. | n.a. | 150 | 100–300 | 250 | 40 |

| TN (mg/L) | 10 | 10–15 | 4–8 | 1.25 | 10 | 15–20 | 10–50 | 10–20 |

| TOC (mg/L) | n.a. | n.a. | n.a. | n.a. | n.a. | 20–60 | n.a. | 10 |

| TP (mg/L) | 2 | 1–2 | n.a. | 1.00 | n.a. | 0.1–1.0 | 5 F | 2 |

| TSS (mg/L) | 50 | 35–36 | 20–30 | 5–30 | 50 | 20–30 | 100 | 5–20 |

| pH | 6–9 | n.a. | 6–9 | 6–9 | 6–9 | 6–9 | 5.5–9 | 5–9 |

| Temperature (°C change) | n.a. | n.a. | n.a. | <1 °C | n.a. | n.a. | <5 °C | <2 °C |

| Parameter | Unit | Average Value |

|---|---|---|

| BOD5 | mg/L | 6345 ± 86 |

| COD | mg/L | 14,720 ± 312 |

| SCOD | mg/L | 767 ± 121 |

| TS | mg/L | 7800 ± 86 |

| TSS | mg/L | 1955 ± 65 |

| TDS | mg/L | 635 ± 23 |

| VSS | mg/L | 1320 ± 32 |

| pH | mg/L | 6.66 ± 1 |

| FOG | mg/L | 205.6 ± 12 |

| NH3-N | mg/L | 69 ± 2 |

| TN | mg/L | 780 ± 16 |

| Color | Pt Co | 500 ± 5 |

| Turbidity | FAU | 576 ± 11 |

| Temperature | °C | 27.2 ± 2 |

| Alkalinity | mg/L as CaCO3 | 485 ± 14 |

| Material | Quantity | Unit |

|---|---|---|

| Yeast (granular form) | 23 | g |

| Urea | 2 | g |

| Sugar | 11.5 | g |

| Ammonium phosphate (NH4)2HPO4 | 3.4 | g |

| Full cream milk | 144 | mL |

| Raw blood from cattle slaughter point | 5.75 | mL |

| Tap water | Full to 1 L |

| Fixed Parameter | Units | Value | ||||

|---|---|---|---|---|---|---|

| Temperature | °C | 35 ± 1 | ||||

| HRT | hr. | 24 | ||||

| pH | ‒ | 6.5 | ||||

| Experimental Run | Day | Influent COD concentration (g/L) | Feed flow rate (L/d) | Maximum COD removal efficiency | OLR (g/L d−1) | Average effluent pH |

| (%) | ||||||

| Batch feed | ||||||

| Stage I | 1–11 | 0.4 | 3 | 98.6 | 0.2 | 6.7 |

| Continuous feed | ||||||

| Stage II | 11–34 | 0.8 | 3 | 90.3 | 0.4 | 6.95 |

| Stage III | 34–49 | 1.4 | 3 | 80.4 | 0.7 | 6.87 |

| Stage IV | 49–67 | 2 | 3 | 73.6 | 1.0 | 6.63 |

| Stage V | 67–74 | 3 | 3 | 71.0 | 1.5 | 6.72 |

| Stage VI | 74–86 | 4 | 3 | 70.2 | 2.0 | 6.85 |

| Stage VII | 86–95 | 5 | 3 | 73.0 | 2.5 | 6.77 |

| Stage VIII | 95–100 | 6 | 3 | 70.0 | 3.0 | 6.60 |

| Stage IX | 100–106 | 10 | 3 | 72.5 | 5.0 | 6.7 |

| Stage X | 106–113 | 14 | 3 | 72.1 | 7.0 | 6.8 |

| Stage XI | 113–120 | 20 | 3 | 65.0 | 10.0 | 7.1 |

| Stage XII | 120–127 | 30 | 3 | 42.0 | 15.0 | 7.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musa, M.A.; Idrus, S.; Hasfalina, C.M.; Daud, N.N.N. Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate. Int. J. Environ. Res. Public Health 2018, 15, 2220. https://doi.org/10.3390/ijerph15102220

Musa MA, Idrus S, Hasfalina CM, Daud NNN. Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate. International Journal of Environmental Research and Public Health. 2018; 15(10):2220. https://doi.org/10.3390/ijerph15102220

Chicago/Turabian StyleMusa, Mohammed Ali, Syazwani Idrus, Che Man Hasfalina, and Nik Norsyahariati Nik Daud. 2018. "Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate" International Journal of Environmental Research and Public Health 15, no. 10: 2220. https://doi.org/10.3390/ijerph15102220

APA StyleMusa, M. A., Idrus, S., Hasfalina, C. M., & Daud, N. N. N. (2018). Effect of Organic Loading Rate on Anaerobic Digestion Performance of Mesophilic (UASB) Reactor Using Cattle Slaughterhouse Wastewater as Substrate. International Journal of Environmental Research and Public Health, 15(10), 2220. https://doi.org/10.3390/ijerph15102220