Influence of Carrier Filling Ratio on the Advanced Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrifying MBBR

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Denitrifying MBBR and Carrier

2.2. WWTP Effluent Characteristics and Experimental Design

2.3. Sample Collection and Analysis

2.4. Biofilm Characteristics

2.4.1. Biomass

2.4.2. Scanning Electron Microscopy (SEM)

2.4.3. qPCR and T-RFLP Analysis

3. Results and Discussion

3.1. Effects of FR on COD removal

3.2. Effects of FR on Nitrogen Removal

3.2.1. Effects of FR on Ammonium, Nitrite Conversion and TN Removal

3.2.2. Effects of FR on Nitrate Removal

3.3. Effects of FR on Microbial Community

3.3.1. Effects of FR on Biomass

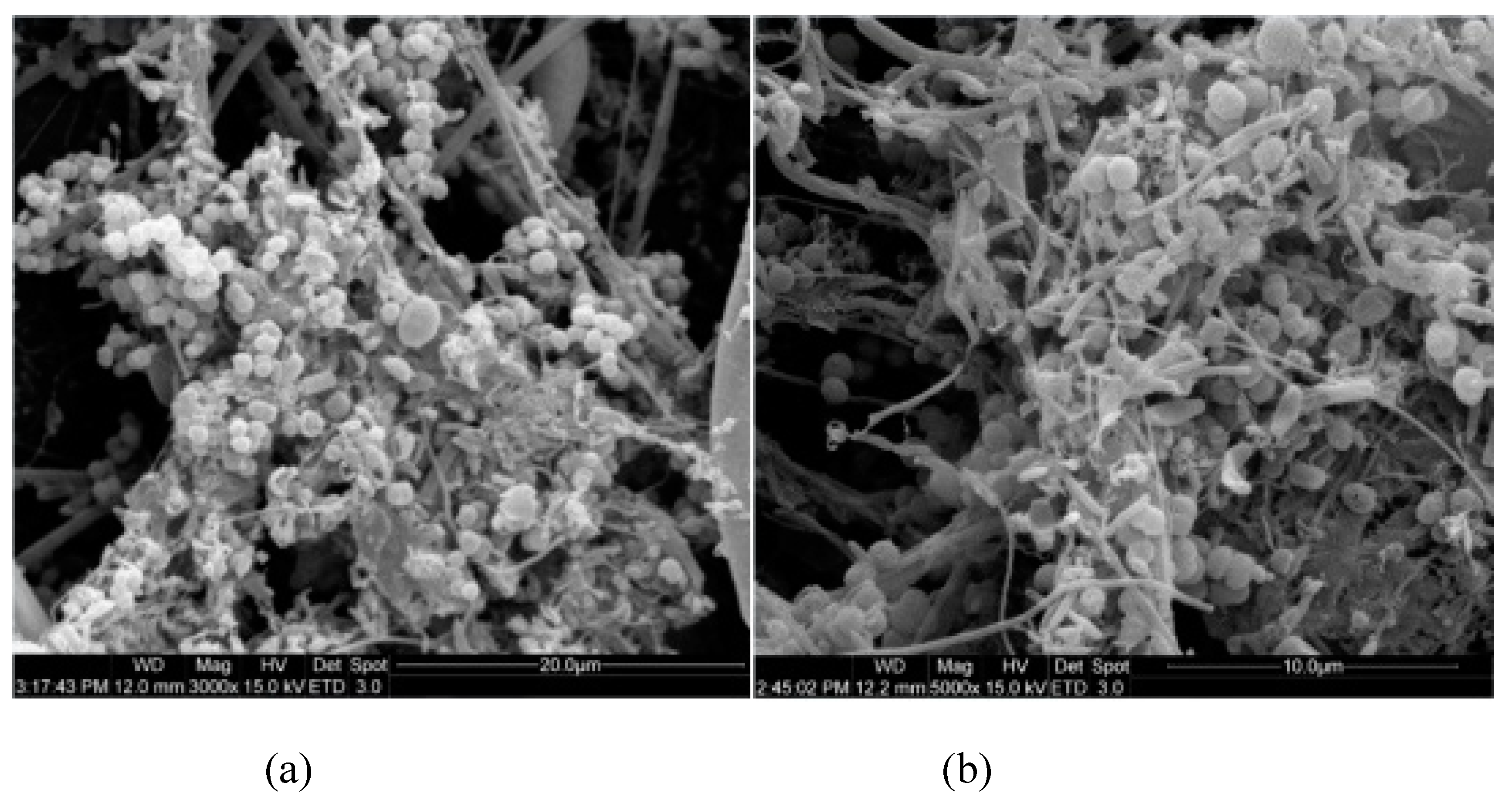

3.3.2. Effects of FR on Biofilm Thickness and Appearance

3.3.3. Effects of FR on Microbial Abundance

3.3.4. Effects of FR on Microbial Community Diversity

3.4. Analysis about the Application to Other Scale Reactors

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- SEPA; AQSIQ. Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant; Ministry of Ecology and Environment: Beijing, China, 2002. [Google Scholar]

- SEPA; AQSIQ. Environmental Quality Standards for Surface Water; Ministry of Ecology and Environment: Beijing, China, 2002. [Google Scholar]

- Liu, C.; Li, J.; Chen, W.; Chen, B.; Qiu, B. Treatment Efficiency of Secondary Effluent by Combined Process of Contact Filtration and Magnetic Ion Exchange Resin. China Water Wastewater 2011, 27, 13–15. [Google Scholar]

- Feng, Q.; Wen, S.; Bai, X.; Chang, W.; Cui, C.; Zhao, W. Surface modification of smithsonite with ammonia to enhance the formation of sulfidization products and its response to flotation. Miner. Eng. 2019, 137, 1–9. [Google Scholar] [CrossRef]

- Feng, Q.; Wen, S.; Deng, J.; Zhao, W. Combined DFT and XPS investigation of enhanced adsorption of sulfide species onto cerussite by surface modification with chloride. Appl. Surf. Sci. 2017, 425, 8–15. [Google Scholar] [CrossRef]

- Bhamidimarri, R.; Shilton, A.; Armstrong, I.; Jacobson, P.; Scarlet, D. Constructed wetlands for wastewater treatment: The New Zealand experience. Water Sci. Technol. 1991, 24, 247–253. [Google Scholar] [CrossRef]

- Horne, A.J. Nitrogen removal from waste treatment pond or activated sludge plant effluents with free surface wetlands. Water Sci. Technol. 1995, 31, 341–351. [Google Scholar] [CrossRef]

- Ødegaard, H.; Mende, U.; Skjerping, E.O.; Simonsen, S.; Strube, R.; Bundgaard, E. Compact tertiary treatment based on the combination of MBBR and contained hollow fibre UF-membranes. Desalin. Water Treat. 2012, 42, 80–86. [Google Scholar] [CrossRef]

- Rusten, B.; Eikebrokk, B.; Ulgenes, Y.; Lygren, E. Design and operations of the Kaldnes moving bed biofilm reactors. Aquac. Eng. 2006, 34, 322–331. [Google Scholar] [CrossRef]

- Young, B.; Delatolla, R.; Kennedy, K.; Laflamme, E.; Stintzi, A. Low temperature MBBR nitrification: Microbiome analysis. Water Res. 2017, 111, 224–233. [Google Scholar] [CrossRef]

- Casas, M.E.; Chhetri, R.K.; Ooi, G.; Hansen, K.M.S.; Litty, K.; Christensson, M.; Kragelund, C.; Andersen, H.R.; Kai, B. Biodegradation of pharmaceuticals in hospital wastewater by staged Moving Bed Biofilm Reactors (MBBR). Water Res. 2015, 83, 293–302. [Google Scholar] [CrossRef]

- Falås, P.; Baillon-Dhumez, A.; Andersen, H.R.; Ledin, A.; Jansen, J.L.C. Suspended biofilm carrier and activated sludge removal of acidic pharmaceuticals. Water Res. 2012, 46, 1167–1175. [Google Scholar] [CrossRef]

- Hapeshi, E.; Lambrianides, A.; Koutsoftas, P.; Kastanos, E.; Michael, C.; Fatta-Kassinos, D. Investigating the fate of iodinated X-ray contrast media iohexol and diatrizoate during microbial degradation in an MBBR system treating urban wastewater. Environ. Sci. Pollut. Res. 2013, 20, 3592–3606. [Google Scholar] [CrossRef] [PubMed]

- Torresi, E.; Fowler, S.J.; Polesel, F.; Bester, K.; Andersen, H.R.; Smets, B.F.; Plósz, B.G.; Christensson, M. Biofilm Thickness Influences Biodiversity in Nitrifying MBBRs-Implications on Micropollutant Removal. Environ. Sci. Technol. 2016, 50, 9279–9288. [Google Scholar] [CrossRef] [PubMed]

- Abtahi, S.M.; Petermann, M.; Flambard, A.J.; Beaufort, S.; Terrisse, F.; Trotouin, T.; Cassan, C.J.; Albasi, C. Micropollutants removal in tertiary moving bed biofilm reactors (MBBRs): Contribution of the biofilm and suspended biomass. Sci. Total Environ. 2018, 643, 1464–1480. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, S.; Sun, D.; Chung, J.S. Treatment of pesticide wastewater by moving-bed biofilm reactor combined with Fenton-coagulation pretreatment. J. Hazard. Mater. 2007, 144, 577–584. [Google Scholar] [CrossRef] [PubMed]

- DeBarbadillo, C.; Bates, J.; Chan, T.; Steichen, M.; Wallis-Lage, C. Experiences in Using MBBR and Denitrification Filters for Nitrogen Removal. Proc. Water Environ. Fed. 2010, 2010, 254–264. [Google Scholar] [CrossRef]

- Rusten, B.; Hem, L.J.; Odegaard, H. Nitrogen removal from dilute wastewater in cold climate using moving-bed biofilm reactors. Water Environ. Res. 1995, 67, 65–74. [Google Scholar] [CrossRef]

- Labelle, M.A.; Juteau, P.; Jolicoeur, M.; Villemur, R.; Parent, S.; Comeau, Y. Seawater denitrification in a closed mesocosm by a submerged moving bed biofilm reactor. Water Res. 2005, 39, 3409–3417. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, H.; Hang, Q.; Deng, Y.; Liu, K.; Li, C.; Zheng, S. Comparison of the MBBR denitrification carriers for advanced nitrogen removal of wastewater treatment plant effluent. Environ. Sci. Pollut. Res. Int. 2015, 22, 13970. [Google Scholar] [CrossRef]

- Yuan, Q.; Wang, H.C.; Zheng, S.; Hang, Q.; Liu, K.; Li, C. Influence of C/N Ratio on MBBR denitrification for advanced nitrogen removal of wastewater treatment plant effluent. Desalin. Water Treat. 2017, 66, 158–165. [Google Scholar] [CrossRef]

- Liu, K.; Wang, H.Y.; Ma, M.J.; Zhang, C.; Yuan, Q.; Hang, Q.; Li, C. Influence of Temperature on Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrification MBBR. Res. Environ. Sci. 2016, 29, 877–886. [Google Scholar]

- Li, L.; Yan, G.; Wang, H.; Chu, Z.; Li, Z.; Ling, Y.; Wu, T. Denitrification and microbial community in MBBR using A. donax as carbon source and biofilm carriers for reverse osmosis concentrate treatment. J. Environ. Sci. 2019, 84, 133–143. [Google Scholar] [CrossRef] [PubMed]

- Deng, L.; Guo, W.; Ngo, H.H.; Zhang, X.; Wang, X.C.; Zhang, Q.; Rong, C. New functional biocarriers for enhancing the performance of a hybrid moving bed biofilm reactor—membrane bioreactor system. Bioresour. Technol. 2016, 208, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Xie, Q.; Zhao, H.; Zhang, Y.; Chen, S.; Tao, L.; Quan, W. Accelerated startup of moving bed biofilm process with novel electrophilic suspended biofilm carriers. Chem. Eng. J. 2017, 315, 364–372. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, X.; Ngo, H.H.; Guo, W.; Song, P.; Zhang, Y.; Wen, H.; Guo, J. Zeolite powder based polyurethane sponges as biocarriers in moving bed biofilm reactor for improving nitrogen removal of municipal wastewater. Sci. Total Environ. 2019, 651, 1078–1086. [Google Scholar] [CrossRef] [PubMed]

- Ødegaard, H.; Gisvold, B.; Strickland, J. The influence of carrier size and shape in the moving bed biofilm process. Water Sci. Technol. 2000, 4, 383–391. [Google Scholar] [CrossRef]

- Shen, Z.; Hu, J.; Wang, J.; Zhou, Y. Biological denitrification using starch/polycaprolactone blends as carbon source and biofilm support. Desalin. Water Treat. 2015, 54, 609–615. [Google Scholar] [CrossRef]

- Dupla, M.; Comeau, Y.; Parent, S.; Villemur, R.; Jolicoeur, M. Design optimization of a self-cleaning moving-bed bioreactor for seawater denitrification. Water Res. 2006, 40, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Ferrai, M.; Guglielmi, G.; Andreottola, G. Modelling respirometric tests for the assessment of kinetic and stoichiometric parameters on MBBR biofilm for municipal wastewater treatment. Environ. Model. Softw. 2010, 25, 626–632. [Google Scholar] [CrossRef]

- Stinson, B.; Peric, M.; Neupane, D.; Laquidara, M.; Locke, E.; Murthy, S.; Bailey, W.; Kharkar, S.; Passarelli, N.; Derminassian, R.; et al. Design and operating considerations for a post denitrification MBBR to achieve limit of technology effluent NOx <1 mg/L and effluent TP <0.18 mg/L. Nutr. Remov. 2009, 4, 1225–1254. [Google Scholar]

- Cheng, Z.; Jiang, Y.; Wang, H.; Li, P.; Hang, Q.; Li, L.; Yang, Y.; Zhong, Z. Study on carrier optimum filling ratio of two-stage MBBR for treatment of reverse osmosis concentrate from high-quality water reclamation of WWTP effluent. J. Environ. Eng. Technol. 2017, 7, 285–292. [Google Scholar]

- Gu, Q.; Sun, T.; Wu, G.; Li, M.; Wei, Q. Influence of carrier filling ratio on the performance of moving bed biofilm reactor in treating coking wastewater. Bioresour. Technol. 2014, 166, 72–78. [Google Scholar] [CrossRef] [PubMed]

- Barwal, A.; Chaudhary, R. Impact of carrier filling ratio on oxygen uptake & transfer rate, volumetric oxygen transfer coefficient and energy saving potential in a lab-scale MBBR. J. Water Process Eng. 2015, 8, 202–208. [Google Scholar]

- Zhang, X.; Song, Z.; Guo, W.; Lu, Y.; Qi, L.; Wen, H.; Ngo, H.H. Behavior of nitrogen removal in an aerobic sponge based moving bed biofilm reactor. Bioresour. Technol. 2017, 245, 1281–1285. [Google Scholar] [CrossRef] [PubMed]

- Quan, F.; Wang, Y.; Wang, T.; Hao, Z.; Chu, L.; Chong, Z.; Chen, H.; Kong, X.; Xing, X.H. Effects of packing rates of cubic-shaped polyurethane foam carriers on the microbial community and the removal of organics and nitrogen in moving bed biofilm reactors. Bioresour. Technol. 2012, 117, 201–207. [Google Scholar]

- Piculell, M.; Suarez, C.; Li, C.; Christensson, M.; Persson, F.; Wagner, M.; Hermansson, M.; Jönsson, K.; Welander, T. The inhibitory effects of reject water on nitrifying populations grown at different biofilm thickness. Water Res. 2016, 104, 292–302. [Google Scholar] [CrossRef]

- APHA; WEF. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Liu, Y. Estimating Minimum Fixed Biomass Concentration and Active Thickness of Nitrifying Biofilm. J. Environ. Eng. 1997, 123, 198–202. [Google Scholar] [CrossRef]

- Vilar-Sanz, A.; Puig, S.; García-Lledó, A.; Trias, R.; Balaguer, M.D.; Colprim, J.; Bañeras, L. Denitrifying bacterial communities affect current production and nitrous oxide accumulation in a microbial fuel cell. PLoS ONE 2013, 8, e63460. [Google Scholar] [CrossRef]

- Scala, D.J.; Kerkhof, L.J. Nitrous oxide reductase (nosZ) gene-specific PCR primers for detection of denitrifiers and three nosZ genes from marine sediments. Fems Microbiol. Lett. 1998, 162, 61–68. [Google Scholar] [CrossRef]

- Spellerberg, I.F. Shannon-Wiener Index. In Encyclopedia of Ecology; Elsevier: Amsterdam, The Netherlands, 2008; pp. 3249–3252. [Google Scholar]

- Kelly, M.G. Use of similarity measures for quality control of benthic diatom samples. Water Res. 2001, 35, 2784–2788. [Google Scholar] [CrossRef]

- Tao, W.; Wen, J.; Han, Y.; Huchzermeier, M.P. Nitrogen Removal in Constructed Wetlands Using Nitritation/Anammox and Nitrification/ Denitrification: Effects of Influent Nitrogen Concentration. Water Environ. Res. 2012, 8, 2099–2105. [Google Scholar] [CrossRef]

- Yang, X.L.; Jiang, Q.; Song, H.L.; Gu, T.T.; Xia, M.Q. Selection and application of agricultural wastes as solid carbon sources and biofilm carriers in MBR. J. Hazard. Mater. 2015, 283, 186–192. [Google Scholar] [CrossRef] [PubMed]

- Nicolella, C.; Loosdrecht, M.C.M.V.; Heijnen, J.J. Wastewater treatment with particulate biofilm reactors. J. Biotechnol. 2000, 80, 1–33. [Google Scholar] [CrossRef]

- Damaraju, S.; Singh, U.K.; Sreekanth, D.; Bhandari, A. Denitrification in biofilm configured horizontal flow woodchip bioreactor: Effect of hydraulic retention time and biomass growth. Ecohydrol. Hydrobiol. 2015, 15, 39–48. [Google Scholar] [CrossRef]

- Wang, R.C.; Wen, X.H.; Qian, Y. Influence of carrier concentration on the performance and microbial characteristics of a suspended carrier biofilm reactor. Process Biochem. 2005, 40, 2992–3001. [Google Scholar] [CrossRef]

- Hansson, B.; Gunnarson, L. The Use of Industrial By-Products as a Carbon Source for Denitrification. In Chemical Water and Wastewater Treatment; Springer: Berlin/Heidelberg, German, 1990. [Google Scholar]

- Shen, Z.; Zhou, Y.; Hu, J.; Wang, J. Denitrification performance and microbial diversity in a packed-bed bioreactor using biodegradable polymer as carbon source and biofilm support. J. Hazard. Mater. 2013, 250–251, 431–438. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Hou, H.J.; Qin, H.L.; Zhu, Y.J.; Wei, W.X. Effect of N application on the abundance of denitrifying genes(narG/nosZ) and N2O emission in paddy soil. Acta Ecol. Sin. 2012, 32, 3386–3393. [Google Scholar] [CrossRef]

- Henderson, S.L.; Dandie, C.E.; Patten, C.L.; Zebarth, B.J.; Burton, D.L.; Trevors, J.T.; Goyer, C. Changes in Denitrifier Abundance, Denitrification Gene mRNA Levels, Nitrous Oxide Emissions, and Denitrification in Anoxic Soil Microcosms Amended with Glucose and Plant Residues. Appl. Environ. Microbiol. 2010, 76, 2155–2164. [Google Scholar] [CrossRef] [Green Version]

- Kitts, C.L. Terminal restriction fragment patterns: A tool for comparing microbial communities and assessing community dynamics. Curr. Issues Intest. Microbiol. 2001, 2, 17–25. [Google Scholar]

- Tiedje, J.M.; Asuming-Brempong, S.; Nüsslein, K.; Marsh, T.L.; Flynn, S.J. Opening the black box of soil microbial diversity. Appl. Soil Ecol. 1999, 13, 109–122. [Google Scholar] [CrossRef]

| Phase | Operational Day (d) | pH | NO3-N (mg/L) | NO2-N (mg/L) | NH4+-N (mg/L) | TN (mg/L) | COD * (mg/L) |

|---|---|---|---|---|---|---|---|

| I | 0–30 | 7.2–7.9 | 4.7 ± 2.6 | 0.6 ± 0.2 | 0.7 ± 0.2 | 8.7 ± 5.2 | 52.2 ± 25.3 |

| II | 31–50 | 7.1–7.8 | 6.4 ± 2.5 | 0.8 ± 0.4 | 1.4 ± 0.5 | 11.0 ± 3.0 | 68.9 ± 9.0 |

| III | 51–70 | 7.1–7.8 | 6.4 ± 2.5 | 0.8 ± 0.4 | 1.4 ± 0.5 | 11.0 ± 3.0 | 68.9 ± 9.0 |

| IV | 71–90 | 7.2–7.9 | 5.1 ± 2.4 | 0.7 ± 0.2 | 0.9 ± 0.6 | 8.9 ± 4.8 | 52.2 ± 25.3 |

| FR(%) | NH4+-N (mg/L) | NO2-N (mg/L) | TN (mg/L) | Biofilm mass (mg/g-carriers) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Influent | Effluent | Removal rate (%) | Influent | Effluent | Removal rate (%) | Influent | Effluent | Removal rate (%) | ||

| 20 | 0.7 ± 0.2 | 0.5 ± 0.3 | 27.9 ± 39.1 | 0.6 ± 0.2 | 0.8 ± 0.5 | −21.1 ± 61.9 | 8.7 ± 5.2 | 2.6 ± 3.2 | 74.5 ± 16.0 | 4.86 |

| 30 | 1.4 ± 0.5 | 0.8 ± 0.4 | 38.5 ± 28.0 | 0.8 ± 0.4 | 0.9 ± 0.4 | −29.6 ± 65.7 | 11.0 ± 3.0 | 6.2 ± 2.2 | 42.1 ± 16.2 | 3.29 |

| 40 | 1.4 ± 0.5 | 0.9 ± 0.5 | 35.0 ± 31.9 | 0.8 ± 0.4 | 1.0 ± 0.6 | −27.3 ± 54.6 | 11.0 ± 3.0 | 6.2 ± 2.6 | 42.8 ± 20.0 | 2.51 |

| 50 | 0.9 ± 0.6 | 0.6 ± 0.2 | 19.4 ± 39.6 | 0.7 ± 0.2 | 0.7 ± 0.3 | −4.9 ± 26.7 | 8.9 ± 4.8 | 1.9 ± 2.0 | 80.4 ± 11.4 | 2.17 |

| Filling rate | 20% | 30% | 40% | 50% |

|---|---|---|---|---|

| narG abundance (copies/g-SS) | 2.76 × 107 | 1.00 × 108 | 2.78 × 108 | 2.89 × 108 |

| nosZ abundance (copies/g-SS) | 7.66 × 104 | 1.74 × 107 | 2.15 × 107 | 2.42 × 107 |

| Shannon-Wiener index (H′) | 0.4 | 1.9 | 1.3 | 1.6 |

| Evenness (E′) | 0.6 | 0.9 | 0.9 | 1.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Yuan, Q.; He, Z.; Wang, H.; Yan, G.; Chang, Y.; Chu, Z.; Ling, Y.; Wang, H. Influence of Carrier Filling Ratio on the Advanced Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrifying MBBR. Int. J. Environ. Res. Public Health 2019, 16, 3244. https://doi.org/10.3390/ijerph16183244

Zhao Y, Yuan Q, He Z, Wang H, Yan G, Chang Y, Chu Z, Ling Y, Wang H. Influence of Carrier Filling Ratio on the Advanced Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrifying MBBR. International Journal of Environmental Research and Public Health. 2019; 16(18):3244. https://doi.org/10.3390/ijerph16183244

Chicago/Turabian StyleZhao, Yuanzhe, Quan Yuan, Zan He, Haiyan Wang, Guokai Yan, Yang Chang, Zhaosheng Chu, Yu Ling, and Huan Wang. 2019. "Influence of Carrier Filling Ratio on the Advanced Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrifying MBBR" International Journal of Environmental Research and Public Health 16, no. 18: 3244. https://doi.org/10.3390/ijerph16183244

APA StyleZhao, Y., Yuan, Q., He, Z., Wang, H., Yan, G., Chang, Y., Chu, Z., Ling, Y., & Wang, H. (2019). Influence of Carrier Filling Ratio on the Advanced Nitrogen Removal from Wastewater Treatment Plant Effluent by Denitrifying MBBR. International Journal of Environmental Research and Public Health, 16(18), 3244. https://doi.org/10.3390/ijerph16183244