Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composting Experiments

2.2. Compost Sampling and Chemical Analysis

2.3. N2O and NH3 Emission Measurements

2.4. Germination Index (GI) Measurement

2.5. N Loss Calculation

2.6. Statistical Analysis

3. Results

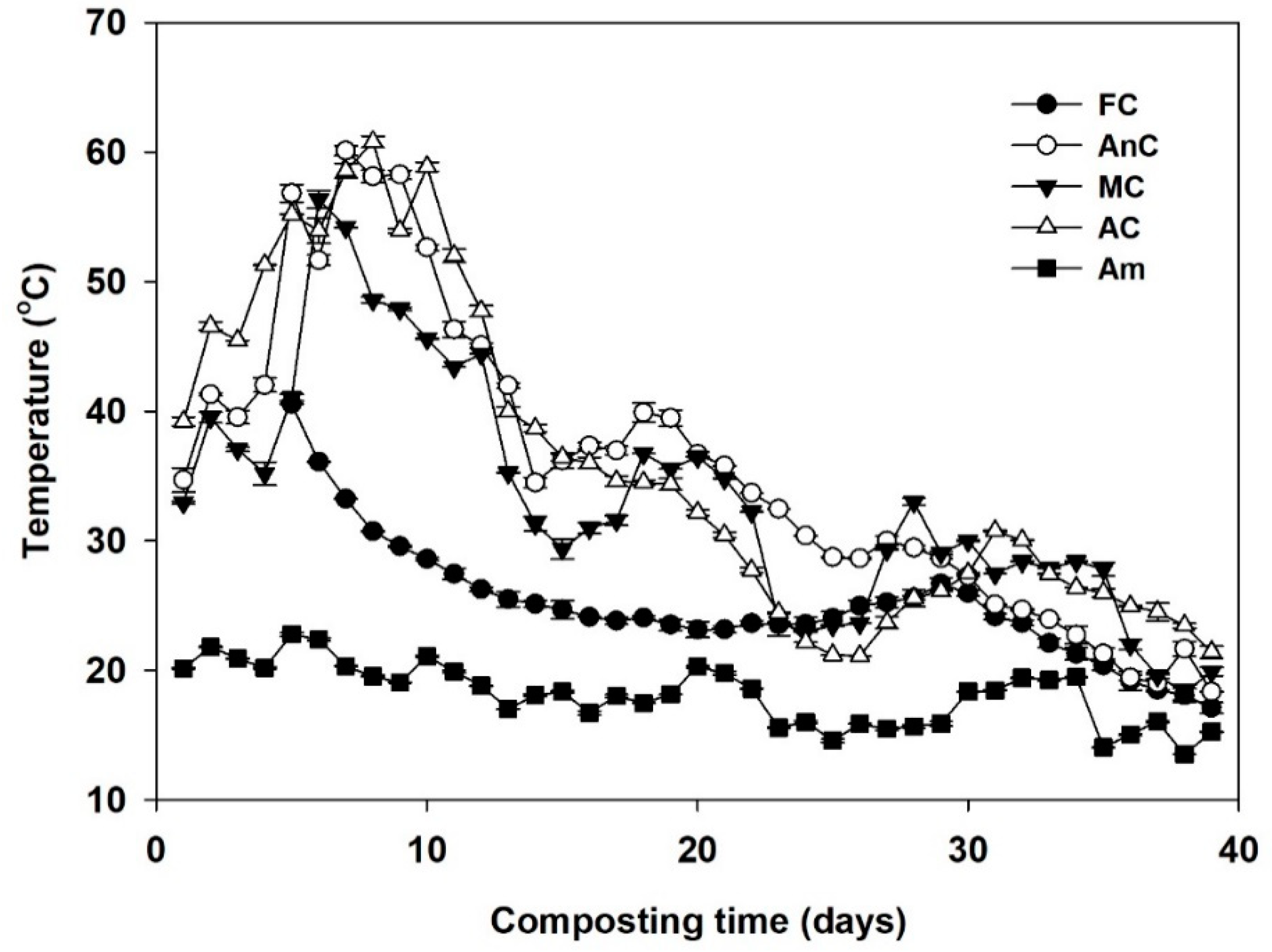

3.1. Compost Temperature and Moisture Content

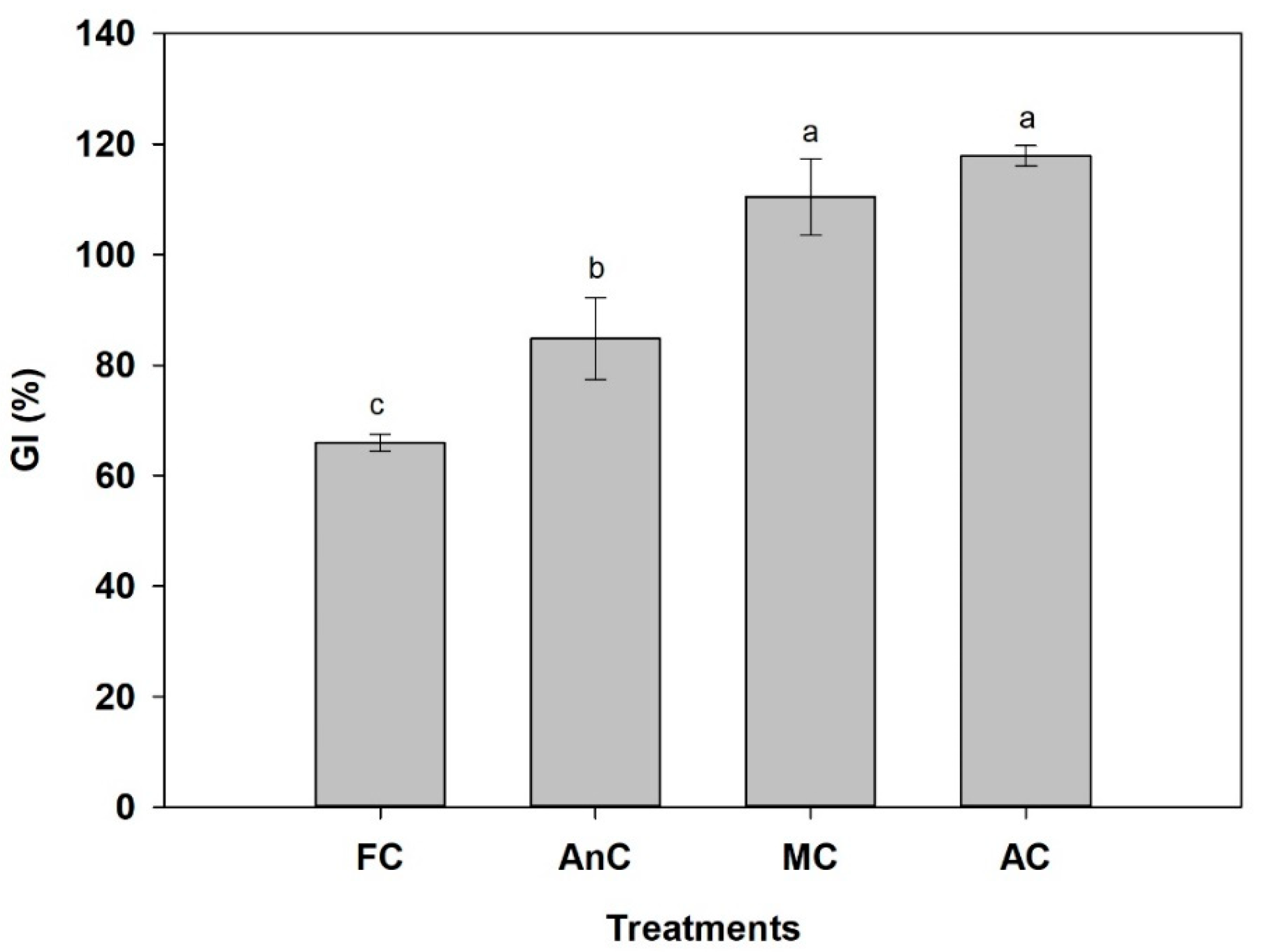

3.2. Germination Index

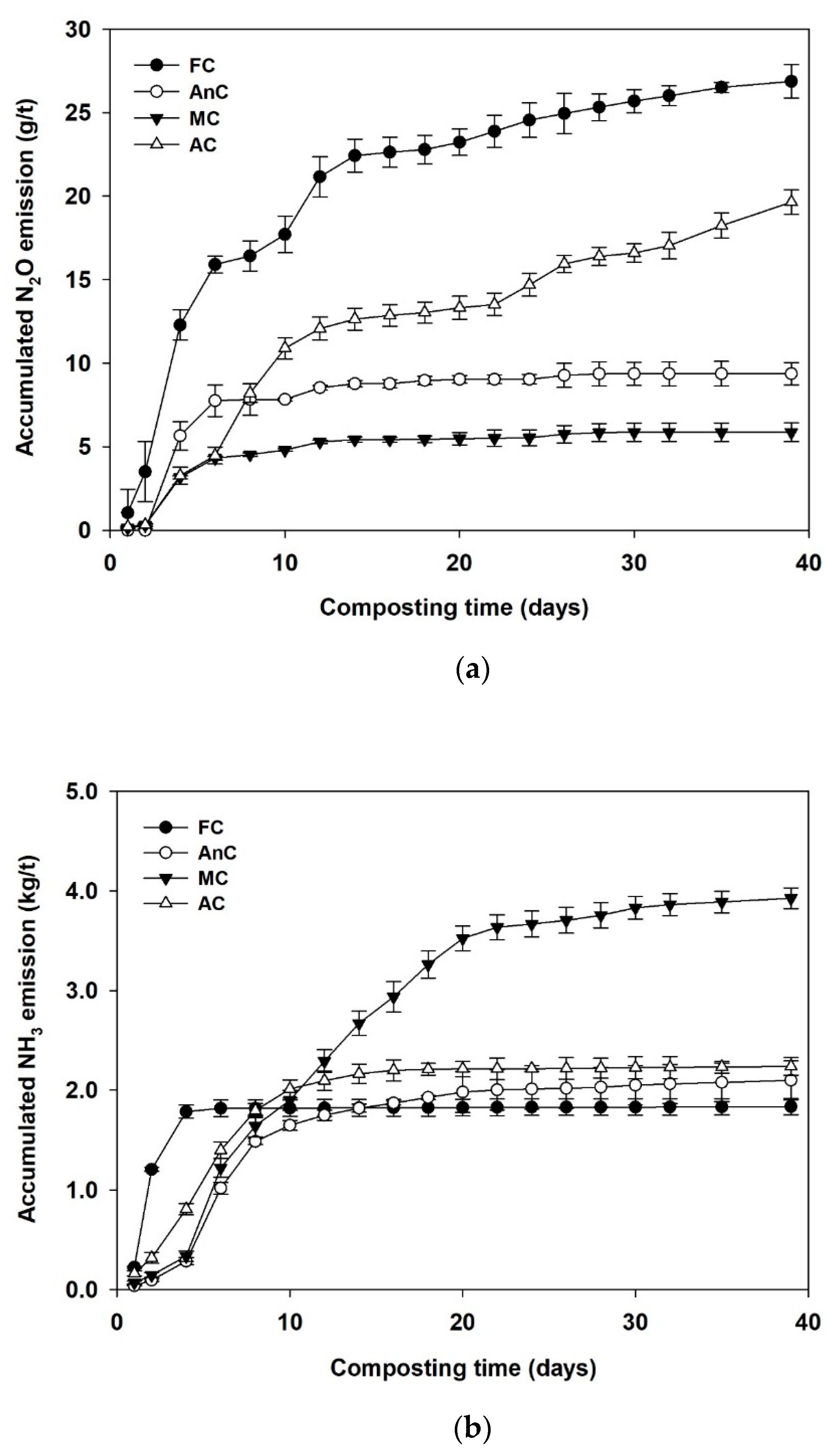

3.3. Nitrogen Gas Emissions

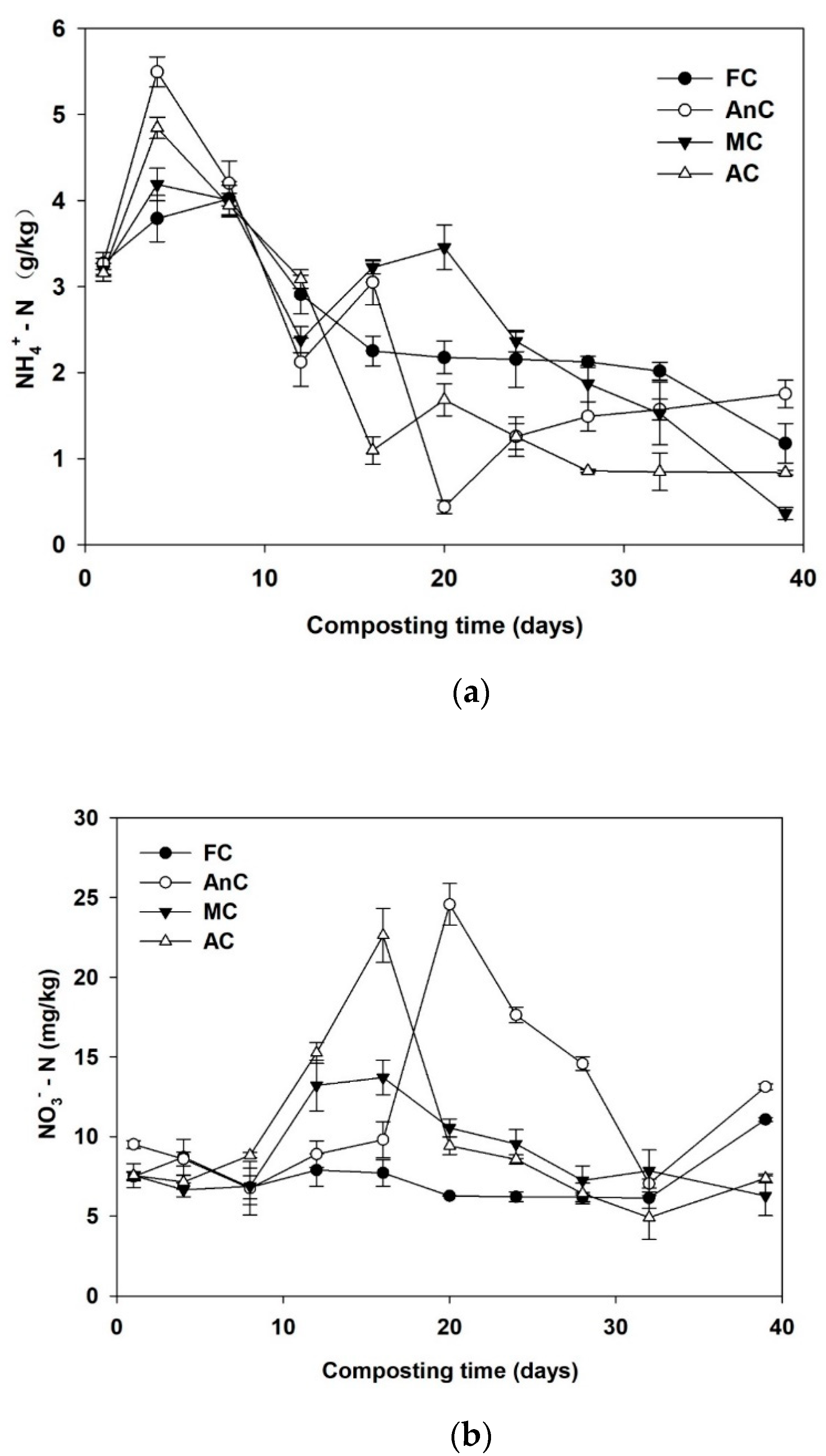

3.4. Nitrogen Variations in the Composts

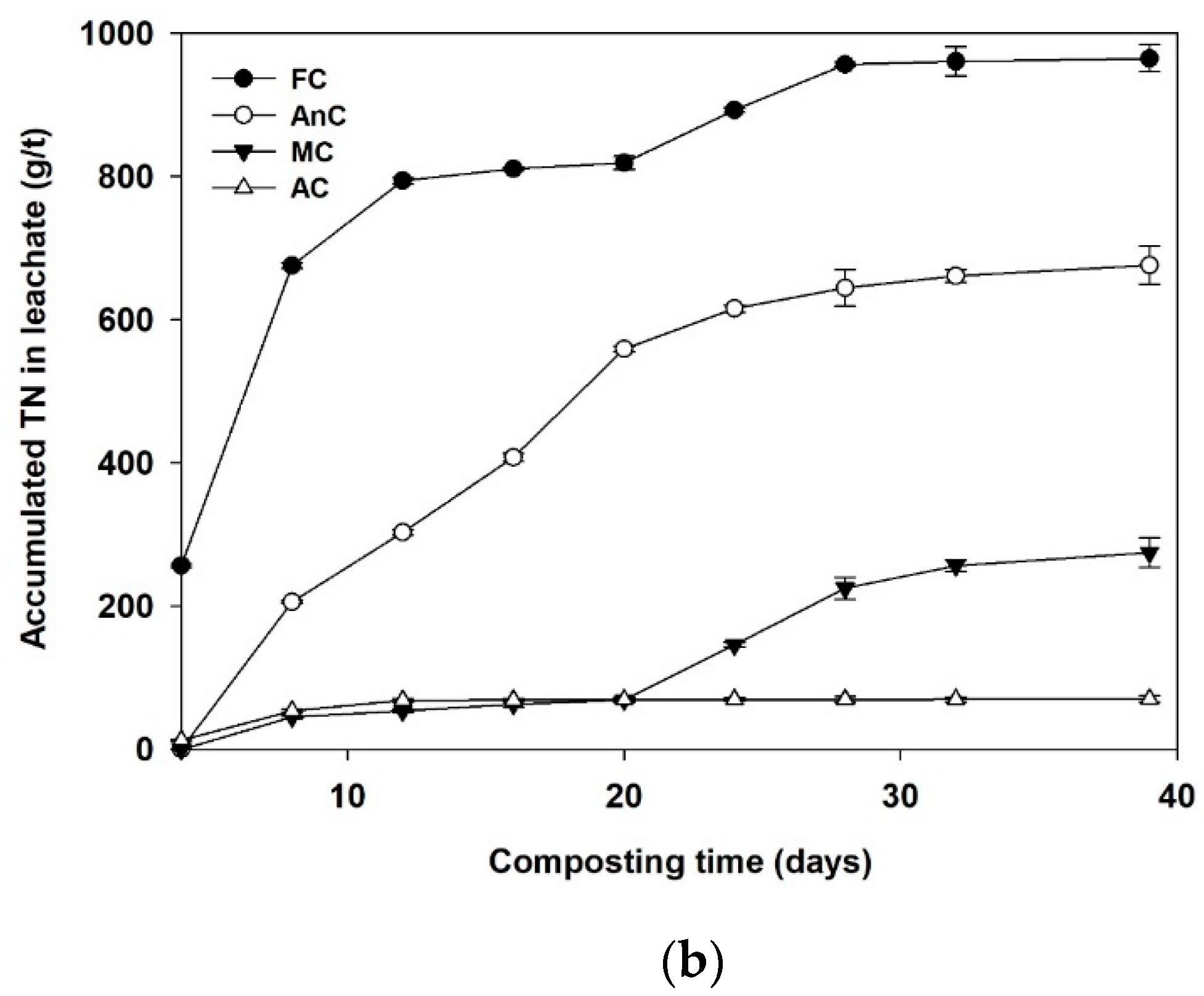

3.5. Volume and TN Variations in the Leachate

3.6. TN Losses

4. Discussion

4.1. Effects of Different Composting Treatments on Compost Temperature, Moisture Content, and GI

4.2. Effects of Different Composting Treatments on Nitrogen Retention

4.3. Effects of Different Composting Treatments on Nitrogen Losses

4.4. Effects of Different Composting Treatments on N Balances

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, J.S.; Liu, X.L.; Huang, Y.M.; Huang, H. Inoculation with nitrogen turnover bacterial agent appropriately increasing nitrogen and promoting maturity in pig manure composting. Waste Manag. 2015, 39, 78–85. [Google Scholar] [CrossRef]

- Shi, M.; Wei, Z.; Wang, L.; Wu, J.; Zhang, D.; Wei, D.; Tang, Y.; Zhao, Y. Response of humic acid formation to elevated nitrate during chicken manure composting. Bioresour. Technol. 2018, 258, 390–394. [Google Scholar] [CrossRef]

- Cang, L.; Wang, Y.J.; Zhou, D.M.; Dong, Y.H. Heavy metals pollution in poultry and livestock feeds and manures under intensive farming in Jiangsu Province. J. Environ. Sci. 2004, 16, 371–374. [Google Scholar] [CrossRef]

- LÜ, D.; Yan, B.; Wang, L.; Deng, Z.; Zhang, Y. Changes in Phosphorus Fractions and Nitrogen Forms During Composting of Pig Manure with Rice Straw. J. Integr. Agric. 2013, 12, 1855–1864. [Google Scholar] [CrossRef]

- Chen, Y.X.; Huang, X.D.; Han, Z.Y.; Huang, X.; Hu, B.; Shi, D.Z.; Wu, W.X. Effects of bamboo charcoal and bamboo vinegar on nitrogen conservation and heavy metals immobility during pig manure composting. Chemosphere 2010, 78, 1177–1181. [Google Scholar] [CrossRef]

- Thiyageshwari, S.; Gayathri, P.; Krishnamoorthy, R.; Anandham, R.; Paul, D. Exploration of Rice Husk Compost as an Alternate Organic Manure to Enhance the Productivity of Blackgram in Typic Haplustalf and Typic Rhodustalf. Int. J. Environ. Res. Public Health 2018, 15, 358. [Google Scholar] [CrossRef]

- Matson, P.A.; Parton, W.J.; Power, A.G.; Swift, M.J. Agricultural intensification and ecosystem properties. Science 1997, 277, 504–509. [Google Scholar] [CrossRef]

- De Guardia, A.; Mallard, P.; Teglia, C.; Marin, A.; Le Pape, C.; Launay, M.; Benoist, J.C.; Petiot, C. Comparison of five organic wastes regarding their behaviour during composting: Part 2, nitrogen dynamic. Waste Manag. 2010, 30, 415–425. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Li, G.X.; Yang, Q.Y.; Luo, W.H. Effect of bulking agents on maturity and gaseous emissions during kitchen waste composting. Chemosphere 2013, 93, 1393–1399. [Google Scholar] [CrossRef]

- Zeng, Y.; De Guardia, A.; Daumoin, M.; Benoist, J.C. Characterizing the transformation and transfer of nitrogen during the aerobic treatment of organic wastes and digestates. Waste Manag. 2012, 32, 2239–2247. [Google Scholar] [CrossRef]

- Han, Z.; Qi, F.; Wang, H.; Li, R.; Sun, D. Odor assessment of NH3 and volatile sulfide compounds in a full-scale municipal sludge aerobic composting plant. Bioresour. Technol. 2019, 282, 447–455. [Google Scholar] [CrossRef]

- Paoli, L.; Pirintsos, S.A.; Kotzabasis, K.; Pisani, T.; Navakoudis, E.; Loppi, S. Effects of ammonia from livestock farming on lichen photosynthesis. Environ. Pollut. 2010, 158, 2258–2265. [Google Scholar] [CrossRef]

- Hashemi, H.; Pourzamani, H.; Amin, M.; Bina, B.; Ebrahimi, A.; Ebrahimi, A. Environmental pollutants removal from composting leachate using anaerobic biological treatment process. Int. J. Health Syst. Disaster Manag. 2014, 2, 216–219. [Google Scholar] [CrossRef]

- Chen, H.; Awasthi, M.K.; Liu, T.; Zhao, J.; Ren, X.; Wang, M.; Duan, Y.; Awasthi, S.K.; Zhang, Z. Influence of clay as additive on greenhouse gases emission and maturity evaluation during chicken manure composting. Bioresour. Technol. 2018, 266, 82–88. [Google Scholar] [CrossRef]

- Jiang, T.; Schuchardt, F.; Li, G.X.; Guo, R.; Luo, Y.M. Gaseous emission during the composting of pig feces from Chinese Ganqinfen system. Chemosphere 2013, 90, 1545–1551. [Google Scholar] [CrossRef]

- Mulbry, W.; Ahn, H. Greenhouse gas emissions during composting of dairy manure: Influence of the timing of pile mixing on total emissions. Biosyst. Eng. 2014, 126, 117–122. [Google Scholar] [CrossRef]

- Sommer, S.G. Effect of composting on nutrient loss and nitrogen availability of cattle deep litter. Eur. J. Agron. 2001, 14, 123–133. [Google Scholar] [CrossRef]

- Parkinson, R.; Gibbs, P.; Burchett, S.; Misselbrook, T. Effect of turning regime and seasonal weather conditions on nitrogen and phosphorus losses during aerobic composting of cattle manure. Bioresour. Technol. 2004, 91, 171–178. [Google Scholar] [CrossRef]

- Gabhane, J.; William, S.P.M.P.; Bidyadhar, R.; Bhilawe, P.; Anand, D.; Vaidya, A.N.; Wate, S.R. Additives aided composting of green waste: Effects on organic matter degradation, compost maturity, and quality of the finished compost. Bioresour. Technol. 2012, 114, 382–388. [Google Scholar] [CrossRef]

- Mao, H.; Lv, Z.; Sun, H.; Li, R.; Zhai, B.; Wang, Z.; Awasthi, M.K.; Wang, Q.; Zhou, L. Improvement of biochar and bacterial powder addition on gaseous emission and bacterial community in pig manure compost. Bioresour. Technol. 2018, 258, 195–202. [Google Scholar] [CrossRef]

- Ahn, H.K.; Mulbry, W.; White, J.W.; Kondrad, S.L. Pile mixing increases greenhouse gas emissions during composting of dairy manure. Bioresour. Technol. 2011, 102, 2904–2909. [Google Scholar] [CrossRef]

- Szanto, G.L.; Hamelers, H.M.; Rulkens, W.H.; Veeken, A.H.M. NH3, N2O and CH4 emissions during passively aerated composting of straw-rich pig manure. Bioresour. Technol. 2007, 98, 2659–2670. [Google Scholar] [CrossRef]

- Kirchmann, H. Losses, plant uptake and utilisation of manure nitrogen during a production cycle. Acta Agric. Scand. Suppl. 1985, 24, 1–77. [Google Scholar]

- Sagoo, E.; Williams, J.R.; Chambers, B.J.; Boyles, L.O.; Matthews, R.; Chadwick, D.R. Integrated management practices to minimise losses and maximise the crop nitrogen value of broiler litter. Biosyst. Eng. 2007, 97, 512–519. [Google Scholar] [CrossRef]

- Shah, G.M.; Groot, J.C.J.; Oenema, O.; Lantinga, E.A. Covered storage reduces losses and improves crop utilisation of nitrogen from solid cattle manure. Nutr. Cycl. Agroecosyst. 2012, 94, 299–312. [Google Scholar] [CrossRef]

- Shah, G.M.; Shah, G.A.; Groot, J.C.J.; Oenema, O.; Raza, A.S.; Lantinga, E.A. Effect of storage conditions on losses and crop utilization of nitrogen from solid cattle manure. J. Agric. Sci. 2016, 154, 58–71. [Google Scholar] [CrossRef]

- Mahimairaja, S.; Bolan, N.S.; Hedley, M.J.; Macgregor, A.N. Losses and transformation of nitrogen during composting of poultry manure with different amendments: An incubation experiment. Bioresour. Technol. 1994, 47, 265–273. [Google Scholar] [CrossRef]

- Witter, E.; Lopez-Real, J. Nitrogen losses during the composting of sewage sludge, and the effectiveness of clay soil, zeolite, and compost in adsorbing the volatilized ammonia. Biol. Wastes 1988, 23, 279–294. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; De Neergaard, A.; Jensen, L.S. Potential of aeration flow rate and bio-char addition to reduce greenhouse gas and ammonia emissions during manure composting. Chemosphere 2014, 97, 16–25. [Google Scholar] [CrossRef]

- Hagemann, N.; Subdiaga, E.; Orsetti, S.; De la Rosa, J.M.; Knicker, H.; Schmidt, H.P.; Kappler, A.; Behrens, S. Effect of biochar amendment on compost organic matter composition following aerobic composting of manure. Sci. Total Environ. 2018, 613, 20–29. [Google Scholar] [CrossRef]

- Li, R.H.; Zhang, G.J.; Zhang, Z.Q.; Wang, Q.; Sun, X.N. Improving pig manure and rice husk compost technology and quality by wood charcoal addition. Trans. Chin. Soc. Agric. Eng. 2014, 30, 230–238. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M.K.; Ren, X.; Zhao, J.; Li, R.; Wang, Z.; Chen, H.; Wang, M.; Zhang, Z. Comparison of biochar, zeolite and their mixture amendment for aiding organic matter transformation and nitrogen conservation during pig manure composting. Bioresour. Technol. 2017, 245, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Li, H.; Wei, Y.; Zhong, J.; Zheng, J.; Han, S.; Wan, H. Effects of Turning Frequency on Emission of Greenhouse Gas and Ammonia During Swine Manure Windrow Composting. Environ. Sci. 2014, 35, 533–540. [Google Scholar]

- Wang, Z.; Liu, X.; Ju, X.; Zhang, F. Field in situ determination of ammonia volatilization from soil: Venting method. Plant Nutr. Fertil. Sci. 2002, 8, 205–209. [Google Scholar] [CrossRef]

- Yang, F.; Li, G.X.; Shi, H.; Wang, Y.M. Effects of phosphogypsum and superphosphate on compost maturity and gaseous emissions during kitchen waste composting. Waste Manag. 2015, 36, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Sellami, F.; Hachicha, S.; Chtourou, M.; Medhioub, K.; Ammar, E. Maturity assessment of composted olive mill wastes using UV spectra and humification parameters. Bioresour. Technol. 2008, 99, 6900–6907. [Google Scholar] [CrossRef] [PubMed]

- Zucconi, F.; Pera, A.; Forte, M.; De Bertoldi, M. Evaluating toxicity of immature compost. BioCycle 1981, 22, 54–57. [Google Scholar]

- Liu, E.; Yan, C.; Mei, X.; He, W.; Bing, S.H.; Ding, L.; Liu, Q.; Liu, S.; Fan, T. Long-term effect of chemical fertilizer, straw, and manure on soil chemical and biological properties in northwest China. Geoderma 2010, 158, 173–180. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Richard, T.L.; Honeyman, M.S. Carbon, nutrient, and mass loss during composting. Nutr. Cycl. Agroecosyst. 2002, 62, 15–24. [Google Scholar] [CrossRef]

- Ren, L.M.; Schuchardt, F.; Shen, Y.J.; Li, G.X.; Li, C.P. Impact of struvite crystallization on nitrogen losses during composting of pig manure and cornstalk. Waste Manag. 2010, 30, 885–892. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Microbial activities during composting of spent pig-manure sawdust litter at different moisture contents. Bioresour. Technol. 1996, 55, 201–206. [Google Scholar] [CrossRef]

- Villar, I.; Alves, D.; Garrido, J.; Mato, S. Evolution of microbial dynamics during the maturation phase of the composting of different types of waste. Waste Manag. 2016, 54, 83–92. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chan, M.T.; Selvam, A.; Wong, J.W.C. Reducing nitrogen loss and salinity during ‘struvite’ food waste composting by zeolite amendment. Bioresour. Technol. 2016, 200, 838–844. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Li, B.; Ni, J.; Xie, D. Effect of four crop straws on transformation of organic matter during sewage sludge composting. J. Integr. Agric. 2016, 15, 232–240. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of composting on phytotoxicity of spent pig-manure sawdust litter. Environ. Pollut. 1996, 93, 249–256. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Liu, J.; LÜ, Y.; Wang, X.; Cui, Z. Microbial Community Dynamics During Biogas Slurry and Cow Manure Compost. J. Integr. Agric. 2013, 12, 1087–1097. [Google Scholar] [CrossRef]

- Li, M.C. Effects of Different Composting Materials on Carbon Transformation Characteristics and the Content of Humus and Its Components in Composting Process. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2018. [Google Scholar]

- Li, X.; Zhang, R.; Pang, Y. Characteristics of dairy manure composting with rice straw. Bioresour. Technol. 2008, 99, 359–367. [Google Scholar] [CrossRef]

- Li, R.H.; Wang, J.J.; Zhang, Z.Q.; Shen, F.; Zhang, G.J.; Qin, R.; Li, X.L.; Xiao, R. Nutrient transformations during composting of pig manure with bentonite. Bioresour. Technol. 2012, 121, 362–368. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y. Elimination of phytotoxicity during co-composting of spent pig-manure sawdust litter and pig sludge. Bioresour. Technol. 1998, 65, 43–49. [Google Scholar] [CrossRef]

- Guo, R.; Li, G.; Jiang, T.; Schuchardt, F.; Chen, T.; Zhao, Y.; Shen, Y. Effect of aeration rate, C/N ratio and moisture content on the stability and maturity of compost. Bioresour. Technol. 2012, 112, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, M.K.; Wang, Q.; Ren, X.N.; Zhao, J.C.; Huang, H.; Awasthi, S.K.; Lahori, A.H.; Li, R.H.; Zhou, L.N.; Zhang, Z.Q. Role of biochar amendment in mitigation of nitrogen loss and greenhouse gas emission during sewage sludge composting. Bioresour. Technol. 2016, 219, 270–280. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Monedero, M.A.; Roig, A.; Cegarra, J.; Bernal, M.P. Relationships between water-soluble carbohydrate and phenol fractions and the humification indices of different organic wastes during composting. Bioresour. Technol. 1999, 70, 193–201. [Google Scholar] [CrossRef]

- Lu, Y.J.; Wu, X.W.; Guo, J.F. Characteristics of municipal solid waste and sewage sludge co-composting. Waste Manag. 2009, 29, 1152–1157. [Google Scholar] [CrossRef] [PubMed]

- Koenig, R.T.; Palmer, M.D.; Miner, F.D.; Miller, B.E.; Harrison, J.D. Chemical amendments and process controls to reduce ammonia volatilization during in-house composting. Compost Sci. Util. 2005, 13, 141–149. [Google Scholar] [CrossRef]

- Sanchez-Monedero, M.A.; Roig, A.; Paredes, C.; Bernal, M.P. Nitrogen transformation during organic waste composting by the Rutgers system and its effects on pH, EC and maturity of the composting mixtures. Bioresour. Technol. 2001, 78, 301–308. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.; Alburquerque, J.A.; Sanchez-Monedero, M.A.; Roig, A.; Cayuela, M.L. Biochar accelerates organic matter degradation and enhances N mineralisation during composting of poultry manure without a relevant impact on gas emissions. Bioresour. Technol. 2015, 192, 272–279. [Google Scholar] [CrossRef] [PubMed]

- Li, D.Y.; Li, S.Y.; Li, G.X.; Wang, K. Effects of additive on nitrogen loss during composting of pig manure and corn straw. Trans. Chin. Soc. Agric. Eng. 2016, 32, 260–267. [Google Scholar] [CrossRef]

- He, Q.; Li, G.X.; Zhang, Y.N.; Lin, X.F. N loss and its characteristics during high temperature composting. J. Agro-Environ. Sci. 2005, 24, 169–173. [Google Scholar] [CrossRef]

- Sanchez-Monedero, M.A.; Serramia, N.; Civantos, C.G.O.; Fernandez-Hernandez, A.; Roig, A. Greenhouse gas emissions during composting of two-phase olive mill wastes with different agroindustrial by-products. Chemosphere 2010, 81, 18–25. [Google Scholar] [CrossRef]

- Wang, X.; Selvam, A.; Chan, M.T.; Wong, J.W.C. Nitrogen conservation and acidity control during food wastes composting through struvite formation. Bioresour. Technol. 2013, 147, 17–22. [Google Scholar] [CrossRef] [PubMed]

- Malinska, K.; Zabochnicka-Swiatek, M.; Dach, J. Effects of biochar amendment on ammonia emission during composting of sewage sludge. Ecol. Eng. 2014, 71, 474–478. [Google Scholar] [CrossRef]

- Ibezute, A.; Tawari-Fufeyin, P.; Oghama, O.E. Analysis of Pollution Removal from Compost Leachate by Vetiver grass (L.) Nash Plant (Vetiveria zizanioides). Resour. Environ. 2014, 4, 268–273. [Google Scholar] [CrossRef]

- Tyrrel, S.F.; Seymour, I.; Harris, J.A. Bioremediation of leachate from a green waste composting facility using waste-derived filter media. Bioresour. Technol. 2008, 99, 7657–7664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goyal, S.; Dhull, S.K.; Kapoor, K.K. Chemical and biological changes during composting of different organic wastes and assessment of compost maturity. Bioresour. Technol. 2005, 96, 1584–1591. [Google Scholar] [CrossRef]

- Martins, O.; Dewes, T. Loss of nitrogenous compounds during composting of animal wastes. Bioresour. Technol. 1992, 42, 103–111. [Google Scholar] [CrossRef]

- Brown, S.; Kruger, C.; Subler, S. Greenhouse gas balance for composting operations. J. Environ. Qual. 2008, 37, 1396–1410. [Google Scholar] [CrossRef]

- Beck-Friis, B.; Smars, S.; Jonsson, H.; Kirchmann, H. Gaseous emissions of carbon dioxide, ammonia and nitrous oxide from organic household waste in a compost reactor under different temperature regimes. J. Agric. Eng. Res. 2001, 78, 423–430. [Google Scholar] [CrossRef]

- Jarvis, A.; Sundberg, C.; Milenkovski, S.; Pell, M.; Smars, S.; Lindgren, P.E.; Hallin, S. Activity and composition of ammonia oxidizing bacterial communities and emission dynamics of NH3 and N2O in a compost reactor treating organic household waste. J. Appl. Microbiol. 2009, 106, 1502–1511. [Google Scholar] [CrossRef]

- Shah, G.M.; Tufail, N.; Bakhat, H.F.; Imran, M.; Murtaza, B.; Farooq, A.U.; Saeed, F.; Waqar, A.; Rashid, M.I. Anaerobic degradation of municipal organic waste among others composting techniques improves N cycling through waste-soil-plant continuum. J. Soil Sci. Plant Nutr. 2017, 17, 529–542. [Google Scholar] [CrossRef]

| Treatment | Specific Measures |

|---|---|

| FC | The famer’s method of composting was adopted, and the compost pile was not turned, ventilated, or covered with plastic film. |

| AnC | During the whole composting process, the compost pile was not turned or ventilated but was covered with plastic film. |

| MC | During the composting process, the compost pile was turned manually every 5 days and covered with plastic film but was not ventilated. |

| AC | Fans (120 W) actively pumped fresh air through perforated tubes at the bottoms of the reactors for 30 min daily, and the applied aeration rate was 2.5 m3/min. Moreover, the compost pile was thoroughly manually turned every 5 days and covered with plastic film. |

| Treatment | N Losses (%) | ||||

|---|---|---|---|---|---|

| N Losses Via N2O | N Losses Via NH3 | N Losses Via Leachate | N Unaccounted for 1 | TN Losses | |

| FC | 0.09 ± 0.008a | 8.10 ± 1.35b | 5.17 ± 1.17a | 2.62 ± 0.43a | 15.98 ± 1.99b |

| AnC | 0.03 ± 0.009c | 9.27 ± 0.98b | 3.62 ± 0.38b | 2.15 ± 0.75a | 15.08 ± 1.66bc |

| MC | 0.02 ± 0.007c | 17.33 ± 0.61a | 1.49 ± 0.10c | 0.91 ± 0.26b | 19.75 ± 0.57a |

| AC | 0.07 ± 0.013b | 9.88 ± 0.55b | 0.38 ± 0.08c | 2.81 ± 0.83a | 13.13 ± 1.43c |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Liu, E.; Zhu, X.; Wang, H.; Liu, H.; Liu, X.; Dong, W. Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting. Int. J. Environ. Res. Public Health 2019, 16, 3324. https://doi.org/10.3390/ijerph16183324

Yang X, Liu E, Zhu X, Wang H, Liu H, Liu X, Dong W. Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting. International Journal of Environmental Research and Public Health. 2019; 16(18):3324. https://doi.org/10.3390/ijerph16183324

Chicago/Turabian StyleYang, Xiao, Enke Liu, Xinmeng Zhu, Hongyuan Wang, Hongbin Liu, Xiu Liu, and Wenyi Dong. 2019. "Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting" International Journal of Environmental Research and Public Health 16, no. 18: 3324. https://doi.org/10.3390/ijerph16183324

APA StyleYang, X., Liu, E., Zhu, X., Wang, H., Liu, H., Liu, X., & Dong, W. (2019). Impact of Composting Methods on Nitrogen Retention and Losses during Dairy Manure Composting. International Journal of Environmental Research and Public Health, 16(18), 3324. https://doi.org/10.3390/ijerph16183324