Development and Verification of a Risk Index for Evaluating the Chemical Accident Risk of Korean Chemical Enterprises

Abstract

:1. Introduction

2. Materials and Methods

2.1. Proposal of the Chemical Accident Risk Index Model

2.2. Calculation of Risk Index and Model Validation

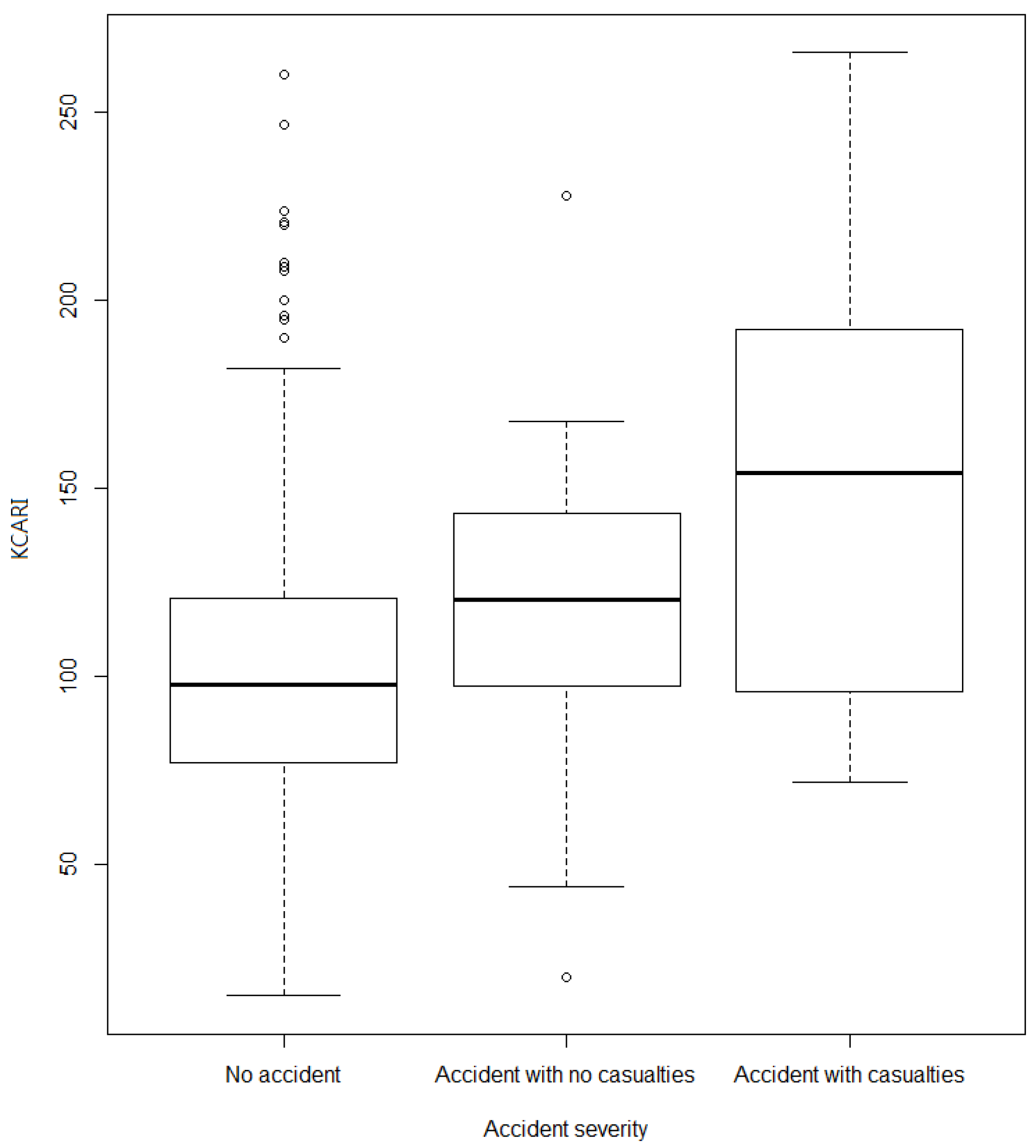

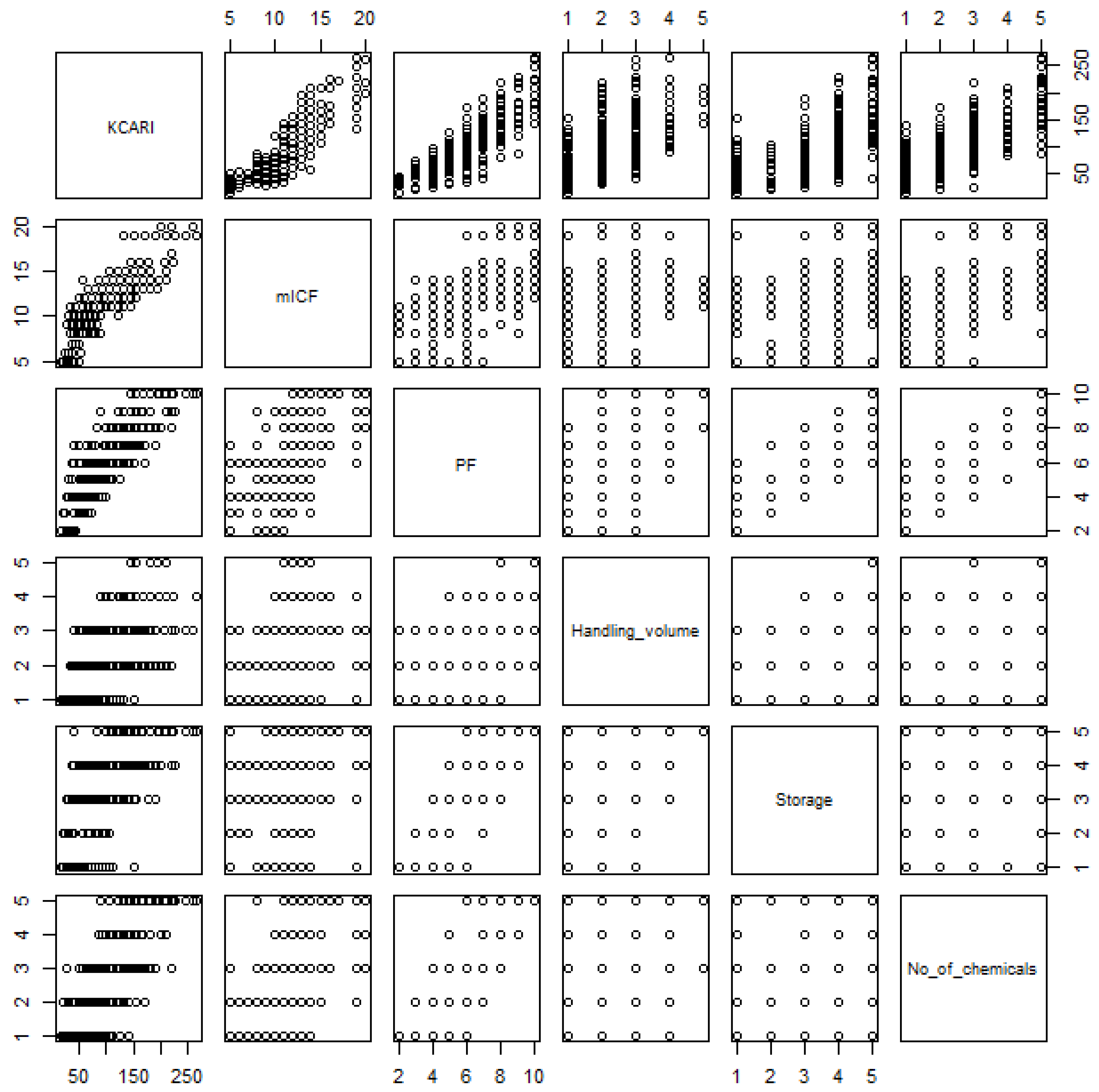

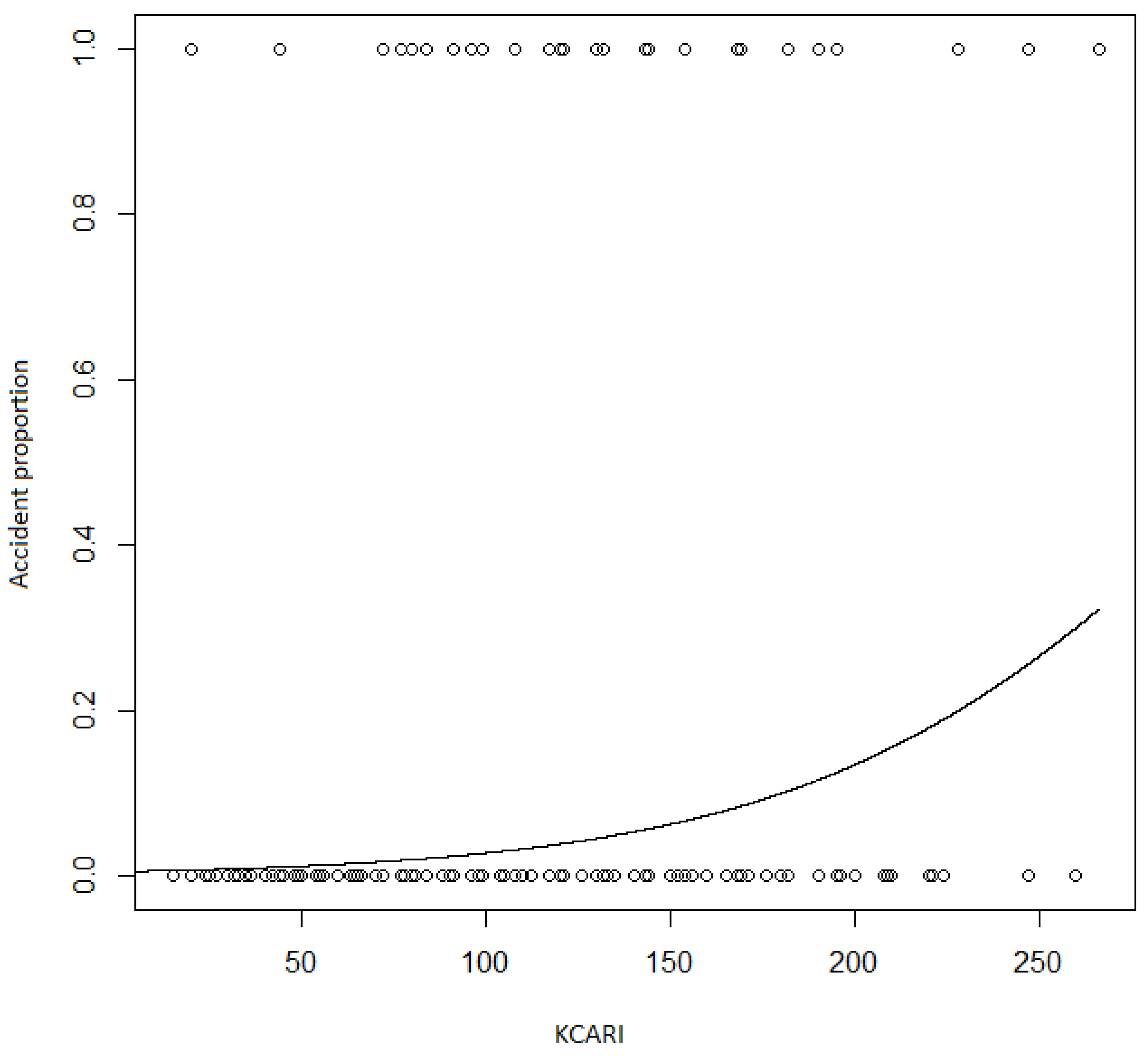

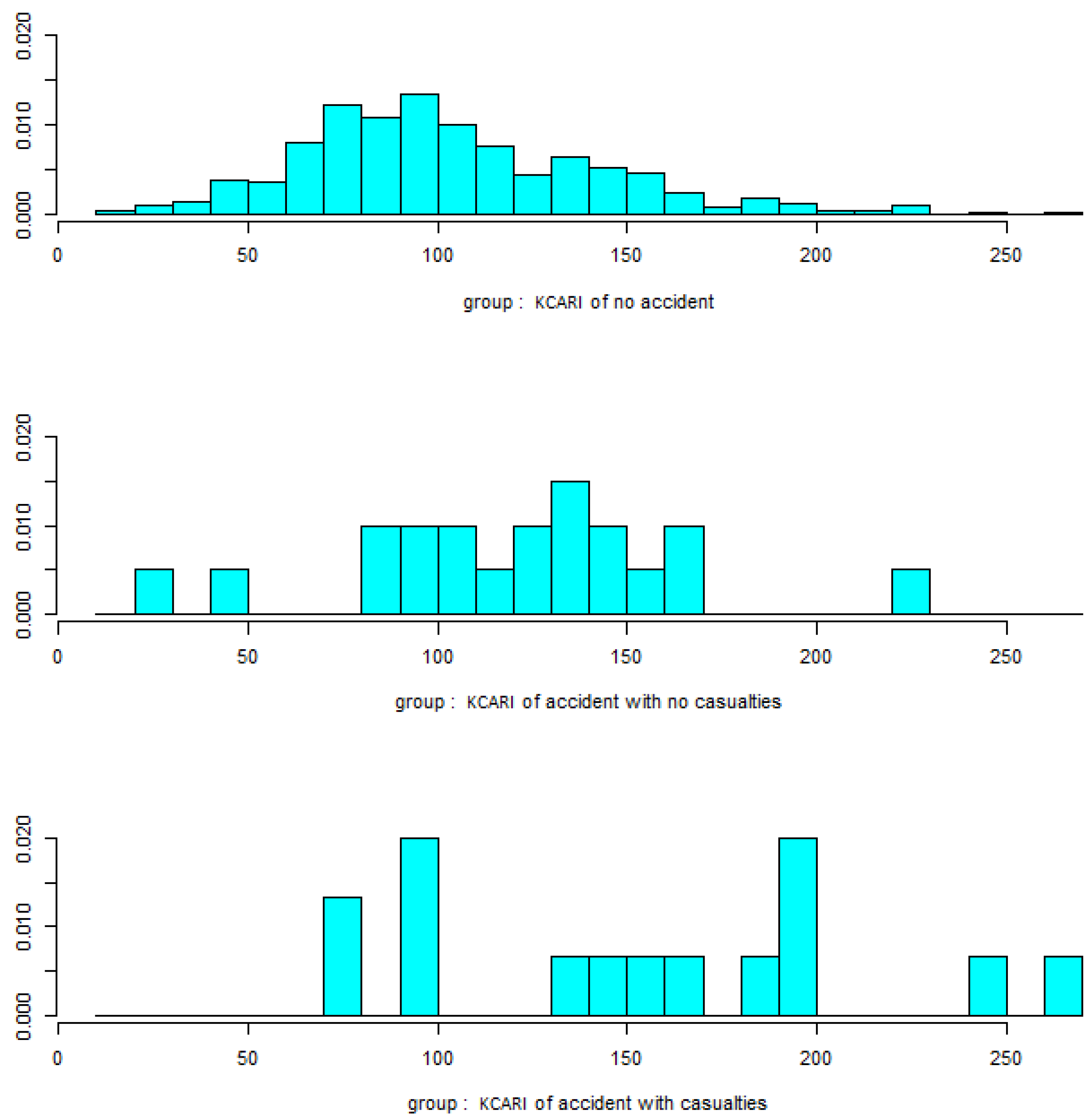

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Sub-index | Criteria | Score |

|---|---|---|

| Flammability | NFPA 704 Flammability rating = 0 | 1 |

| NFPA 704 Flammability rating = 1 | 2 | |

| NFPA 704 Flammability rating = 2 | 3 | |

| NFPA 704 Flammability rating = 3 | 4 | |

| NFPA 704 Flammability rating = 4 | 5 | |

| Reactivity | NFPA 704 Reactivity rating = 0 | 1 |

| NFPA 704 Reactivity rating = 1 | 2 | |

| NFPA 704 Reactivity rating = 2 | 3 | |

| NFPA 704 Reactivity rating = 3 | 4 | |

| NFPA 704 Reactivity rating = 4 | 5 | |

| Explosiveness | Not explosive | 1 |

| 0 ≤ Difference of Upper and Lower Explosive Limits < 20 | 2 | |

| 20 ≤ Difference of Upper and Lower Explosive Limits < 45 | 3 | |

| 45 ≤ Difference of Upper and Lower Explosive Limits < 70 | 4 | |

| 70 ≤ Difference of Upper and Lower Explosive Limits | 5 | |

| GHS Hazard Classification | ||

| Corrosiveness | Substances corrosive to metal—No category | 1 |

| Substances corrosive to metal—Category 1 | 2 | |

| GHS Hazard Classification | ||

| Toxicity | Other or no health hazard category | 1 |

| Skin Irritation—Category 2; Eye Irritation—Category 2; Target organ systemic toxicity: single—Category 3 | 2 | |

| Acute toxicity (dermal, inhalation)—Category 4; Aspiration Toxicity—Category 1–2 | 3 | |

| Acute toxicity (dermal, inhalation)—Category 3; Serious Eye Damage—Category 1; Skin Sensitization—Category 1; Respiratory Sensitization—Category 1 | 4 | |

| Acute toxicity (dermal, inhalation)—Category 1–2; Skin Corrosion—Category 1 | 5 | |

| Sub-index | Criteria | Score |

|---|---|---|

| Handling volume | <100 ton | 1 |

| 100 ton ≤, <1000 ton | 2 | |

| 1000 ton ≤, <10,000 ton | 3 | |

| 10,000 ton ≤, <100,000 ton | 4 | |

| 100,000 ton≤ | 5 | |

| Storage | <0.5 ton | 1 |

| 0.5 ton ≤, <5 ton | 2 | |

| 5 ton ≤, <50 ton | 3 | |

| 50 ton ≤, <500 ton | 4 | |

| 500 ton≤ | 5 | |

| No. of chemicals | 1 | 1 |

| 2–3 | 2 | |

| 4–9 | 3 | |

| 10–15 | 4 | |

| 16– | 5 |

References

- Kim, K.W.; Park, J.W.; Jeong, M.S. Association Between Communication for Chemical Hazards Information and Characteristics of Occupational Safety and Health Manager. J. Korean Soc. Occup. Environ. Hyg. 2012, 22, 156–163. [Google Scholar]

- Kim, K.-R.; Hwang, S.Y.; Kim, B.H. A Study on the Safety Management of the Petrochemical Complex Area. Fire Sci. Eng. 2012, 26, 38–42. [Google Scholar]

- You, J.; Chung, Y.-J. Case Analysis of the Harmful Chemical Substances′ Spill. Fire Sci. Eng. 2014, 28, 90–98. [Google Scholar] [CrossRef]

- Kim, J.C. A Study on the Full Amendment of “Toxic Chemicals Control Act” into “Chemicals Control Act”. Environ. Law Rev. 2014, 36, 3–42. [Google Scholar]

- Lee, T.-H.; Park, J.D.; Bang, B.S.; Kim, K.P.; Kim, M.S. Characteristics of chemical substance accident in Korea. Korean J. Hazard. Mater. 2015, 3, 37–41. [Google Scholar]

- Kim, C.-H.; Park, C.J.; Park, J.H.; Im, C.S.; Kim, M.S. Chemical Accidents Response Information System(CARIS) for the Response of Atmospheric Dispersion Accidents in association with Hazardous Chemicals. J. Environ. Impact Assess. 2003, 12, 23–34. [Google Scholar]

- Lee, D.J.; Lyu, S.W.; Song, C.G. Improvement Strategy for Management of Accident Preparedness Substances Causing Chemical Accidents. Korean Soc. Saf. 2017, 32, 47–52. [Google Scholar]

- Kim, K.-H.; Chun, Y.-W.; Hwang, Y.-W.; Lee, I.-M. Establishment of the Appropriate Risk Standard through the Risk Assessment of Accident Scenario. J. Korean Soc. Environ. Eng. 2017, 39, 74–81. [Google Scholar] [CrossRef]

- Tyler, B. Using the Mond Index to measure inherent hazards. Plant Oper. Prog. 1985, 4, 172–175. [Google Scholar] [CrossRef]

- Tyler, B.; Thomas, A.R.; Doran, P.; Greig, T.R. A Toxicity Hazard Index: Institution of Chemical Engineers Symposium Series; Hemisphere: Arizona, AZ, USA, 1994. [Google Scholar]

- Heikkilä, A.-M.; Hurme, M.; Järveläinen, M. Safety considerations in process synthesis. Comput. Chem. Eng. 1996, 20, S115–S120. [Google Scholar] [CrossRef]

- Khan, F.I.; Husain, T.; Abbasi, S.A. Safety weighted hazard index (SWeHI): A new, user-friendly tool for swift yet comprehensive hazard identification and safety evaluation in chemical process industries. Process Saf. Environ. Prot. 2001, 79, 65–80. [Google Scholar] [CrossRef]

- Suardin, J.A.; Mannan, M.S.; El-Halwagi, M.M. The integration of Dow′s fire and explosion index (F&EI) into process design and optimization to achieve inherently safer design. J. Loss Prev. Process Ind. 2007, 20, 79–90. [Google Scholar]

- Kletz, T.A. Cheaper, Safer Plants or Wealth and Safety at Work: Notes on Inherently Safer and Simpler Plants; Institution Chemical Engineers: Coventry, UK, 1985. [Google Scholar]

- Heikkilä, A.-M. Inherent Safety in Process Plant Design: An Index-Based Approach; VTT Technical Research Centre of Finland: Espoo, Finland, 1999. [Google Scholar]

- Edwards, D.W.; Lawrence, D. Assessing the inherent safety of chemical process routes: Is there a relation between plant costs and inherent safety? Process Saf. Environ. Prot. 1993, 71, 252–258. [Google Scholar]

- Jafari, M.J.; Mohammadi, H.; Reniers, G.; Pouyakian, M.; Nourai, F.; Torabi, S.A.; Miandashti, M.R. Exploring inherent process safety indicators and approaches for their estimation: A systematic review. J. Loss Prev. Process Ind. 2018, 52, 66–80. [Google Scholar] [CrossRef]

- Woodruff, J.M. Consequence and likelihood in risk estimation: A matter of balance in UK health and safety risk assessment practice. Saf. Sci. 2005, 43, 345–353. [Google Scholar] [CrossRef]

- NFPA. NFPA 704: Standard System for the Identification of the Hazards of Materials for Emergency Response; NFPA: Massachusetts, MA, USA, 2001. [Google Scholar]

- Hinkle, D.E. Applied Statistics for the Behavioral Sciences; Houghton Mifflin Co.: Boston, MA, USA, 1998. [Google Scholar]

- Palaniappan, C.; Srinivasan, R.; Tan, R. Expert system for the design of inherently safer processes 1. Route selection stage. Ind. Eng. Chem. Res. 2002, 41, 6698–6722. [Google Scholar] [CrossRef]

- Li, X.; Zanwar, A.; Jayswal, A.; Lou, H.H.; Huang, Y. Incorporating exergy analysis and inherent safety analysis for sustainability assessment of biofuels. Ind. Eng. Chem. Res. 2011, 50, 2981–2993. [Google Scholar] [CrossRef]

- Zheng, K.; Lou, H.H. Incorporating sustainability into the conceptual design of chemical process-reaction routes selection. Ind. Eng. Chem. Res. 2012, 51, 9300–9309. [Google Scholar] [CrossRef]

- Gangadharan, P.; Singh, R.; Cheng, F.; Lou, H.H. Novel methodology for inherent safety assessment in the process design stage. Ind. Eng. Chem. Res. 2013, 52, 5921–5933. [Google Scholar] [CrossRef]

- Palaniappan, C.; Srinivasan, R.; Tan, R. Selection of inherently safer process routes: A case study. Chem. Eng. Process. Process Intensif. 2004, 43, 641–647. [Google Scholar] [CrossRef]

- Hassim, M.; Edwards, D. Development of a methodology for assessing inherent occupational health hazards. Process Saf. Environ. Prot. 2006, 84, 378–390. [Google Scholar] [CrossRef]

- Hassim, M.; Hurme, M. Inherent occupational health assessment during process research and development stage. J. Loss Prev. Process Ind. 2010, 23, 127–138. [Google Scholar] [CrossRef]

- Hassim, M.H.; Hurme, M. Occupational chemical exposure and risk estimation in process development and design. Process Saf. Environ. Prot. 2010, 88, 225–235. [Google Scholar] [CrossRef]

- Jia, X.; Li, Z.; Wang, F.; Qian, Y. Integrated sustainability assessment for chemical processes. Clean Technol. Environ. Policy 2016, 18, 1295–1306. [Google Scholar] [CrossRef]

- Cross, H.J.; Faux, S.P.; Levy, L.S. Establishing an occupational exposure limit for hexavalent chromium in the European Union. Regul. Toxicol. Pharmacol. 1997, 26, S72–S76. [Google Scholar] [CrossRef] [PubMed]

- Lahiri, S.; Levenstein, C.; Nelson, D.I.; Rosenberg, B.J. The cost effectiveness of occupational health interventions: Prevention of silicosis. Am. J. Ind. Med. 2005, 48, 503–514. [Google Scholar] [CrossRef] [PubMed]

- Cordella, M.; Tugnoli, A.; Barontini, F.; Spadoni, G.; Cozzani, V. Inherent safety of substances: Identification of accidental scenarios due to decomposition products. J. Loss Prev. Process Ind. 2009, 22, 455–462. [Google Scholar] [CrossRef]

- Ribeiro, M.G.T.; Machado, A.A. Holistic metrics for assessment of the greenness of chemical reactions in the context of Chemical Education. J. Chem. Educ. 2013, 90, 432–439. [Google Scholar] [CrossRef]

- Pandian, S.; Hassim, M.H.; Ng, R.T.M.; Hurme, M. Designing an inherently healthier process based on inherently safer design (ISD) concept: Research and development stage. Clean Technol. Environ. Policy 2015, 17, 1247–1259. [Google Scholar] [CrossRef]

- Khan, F.I.; Abbasi, S. Multivariate hazard identification and ranking system. Process Saf. Progress 1998, 17, 157–170. [Google Scholar] [CrossRef]

- Khan, F.I.; Amyotte, P.R. Integrated inherent safety index (I2SI): A tool for inherent safety evaluation. Process Saf. Progress 2004, 23, 136–148. [Google Scholar] [CrossRef]

- Nadal, M.; Kumar, V.; Schuhmacher, M.; Domingo, J.L. Definition and GIS-based characterization of an integral risk index applied to a chemical/petrochemical area. Chemosphere 2006, 64, 1526–1535. [Google Scholar] [CrossRef] [PubMed]

- López-Atamoros, L.G.; Fernández-Villagómez, G.; Cruz-Gómez, M.J.; Durán-de-Bazúa, C. Development of a relative ranking risk index for risk assessment in the transportation of liquefied petroleum gas in Mexico City′s metropolitan area. Hum. Ecol. Risk Assess. Int. J. 2011, 17, 1193–1209. [Google Scholar] [CrossRef]

- Zhu, H.-N.; Yuan, X.-Z.; Zeng, G.-M.; Jiang, M.; Liang, J.; Zhang, C.; Yin, J.; Huang, H.-J.; Liu, Z.-F.; Jiang, H.-W. Ecological risk assessment of heavy metals in sediments of Xiawan Port based on modified potential ecological risk index. Trans. Nonferrous Met. Soc. China 2012, 22, 1470–1477. [Google Scholar] [CrossRef]

| The Name of Enterprise | Industry | The Storage Volume of Plant (ton) | Chemical (CASRN) | The Handling Volume of Chemical (ton) |

|---|---|---|---|---|

| Plant A | Using | 657.8 | Nitric acid (7697-37-2) | 148.5 |

| Hydrogen peroxide (7722-84-1) | 565.75 | |||

| Hydrofluoric acid (7664-39-3) | 240.9 | |||

| Sodium hydroxide (1310-73-2) | 167.9 | |||

| Potassium hydroxide (1310-58-3) | 1.8 | |||

| Antimony (III) oxide (1309-64-4) | 0.001 | |||

| Ammonium hydroxide (1336-21-6) | 480.8 | |||

| Hydrochloric Acid (7647-01-0) | 98.5 | |||

| Phosphorus (V) oxychloride (10025-87-3) | 0.09 | |||

| Ammonium fluoride (12125-01-8) | 70.4 | |||

| Sulfuric acid (7664-93-9) | 861.5 |

| Chemical | Flammability | Reactivity | Explosiveness | Corrosiveness | Toxicity (Highest Score Characteristic) | ICF | m-ICF | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NFPA F | Score | NFPA R | Score | UEL–LEL | Score | GHS * | Score | GHS * | Score | |||

| Nitric acid | 1 | 2 | 0 | 1 | - | 1 | - | 1 | SC | 5 | 10 | 12 |

| Hydrogen peroxide | 1 | 2 | 0 | 1 | - | 1 | - | 1 | SC | 5 | 10 | |

| Hydrofluoric acid | 1 | 2 | 0 | 1 | - | 1 | C-1 | 2 | AT-1, SC | 5 | 11 | |

| Sodium hydroxide | 1 | 2 | 0 | 1 | - | 1 | C-1 | 2 | SC | 5 | 11 | |

| Potassium hydroxide | 1 | 2 | 0 | 1 | - | 1 | C-1 | 2 | SC | 5 | 11 | |

| Antimony (III) oxide | 0 | 1 | 0 | 1 | - | 1 | - | 1 | - | 1 | 5 | |

| Ammonium hydroxide | 0 | 1 | 0 | 1 | - | 1 | - | 2 | SC | 5 | 10 | |

| Hydrochloric Acid | 1 | 2 | 0 | 1 | - | 1 | - | 1 | SC | 5 | 10 | |

| Phosphorus (V) oxychloride | 2 | 3 | 0 | 1 | - | 1 | - | 1 | AT-1, SC | 5 | 11 | |

| Ammonium fluoride | 0 | 1 | 0 | 1 | - | 1 | - | 1 | AT-3 | 4 | 8 | |

| Sulfuric acid | 2 | 3 | 0 | 1 | - | 1 | C-1 | 2 | AT-2, SC | 5 | 12 | |

| Handling Volume | Storage | The Number of Chemicals | PF | |||

|---|---|---|---|---|---|---|

| Total Handling Volume of Chemicals (ton) | Score | The Storage Volume of Plant (ton) | Score | The Number of Chemicals | Score | |

| 2636.141 | 3 | 657.8 | 5 | 11 | 5 | 13 |

| KCARI | mICF | PF | Handling Volume | Storage | No. of Chemical | |

|---|---|---|---|---|---|---|

| KCARI | 1 | - | - | - | - | - |

| mICF | 0.77 | 1 | - | - | - | - |

| PF | 0.90 | 0.56 | 1 | - | - | - |

| Handling volume | 0.58 | 0.27 | 0.40 | 1 | - | - |

| Storage | 0.74 | 0.35 | 0.83 | 0.47 | 1 | - |

| No. of chemical | 0.79 | 0.61 | 0.85 | 0.26 | 0.46 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, S.; Byeon, S.-H.; Sohn, J.-R.; Moon, K.W. Development and Verification of a Risk Index for Evaluating the Chemical Accident Risk of Korean Chemical Enterprises. Int. J. Environ. Res. Public Health 2019, 16, 4409. https://doi.org/10.3390/ijerph16224409

Shin S, Byeon S-H, Sohn J-R, Moon KW. Development and Verification of a Risk Index for Evaluating the Chemical Accident Risk of Korean Chemical Enterprises. International Journal of Environmental Research and Public Health. 2019; 16(22):4409. https://doi.org/10.3390/ijerph16224409

Chicago/Turabian StyleShin, Saemi, Sang-Hoon Byeon, Jong-Ryeul Sohn, and Kyong Whan Moon. 2019. "Development and Verification of a Risk Index for Evaluating the Chemical Accident Risk of Korean Chemical Enterprises" International Journal of Environmental Research and Public Health 16, no. 22: 4409. https://doi.org/10.3390/ijerph16224409

APA StyleShin, S., Byeon, S.-H., Sohn, J.-R., & Moon, K. W. (2019). Development and Verification of a Risk Index for Evaluating the Chemical Accident Risk of Korean Chemical Enterprises. International Journal of Environmental Research and Public Health, 16(22), 4409. https://doi.org/10.3390/ijerph16224409