Risk Profiling from the European Statistics on Accidents at Work (ESAW) Accidents′ Databases: A Case Study in Construction Sites

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Infor.MO Database

- Type of accident: e.g., fatality, serious injury, or disabling accident.

- Data related to the event: e.g., date, hour, no. of people involved, type of working activity carried out when the accident occurred, type of company, economic sector of the company, etc.

- Description of the accident: a synthetic description of the accident is provided based on the reports of the authorities.

- Type of energy transfer: energy exchange, energy release, and improper use of energy.

- ESAW variables: following the ESAW rules, data such as deviation, material agent, contact type, etc. are codified.

- Information on the victim: age, sex, nationality, working experience, type of lesion/injury, part of the body injured, etc.

2.2. Cluster Analysis for Occupational Safety

2.3. Systemic Approach

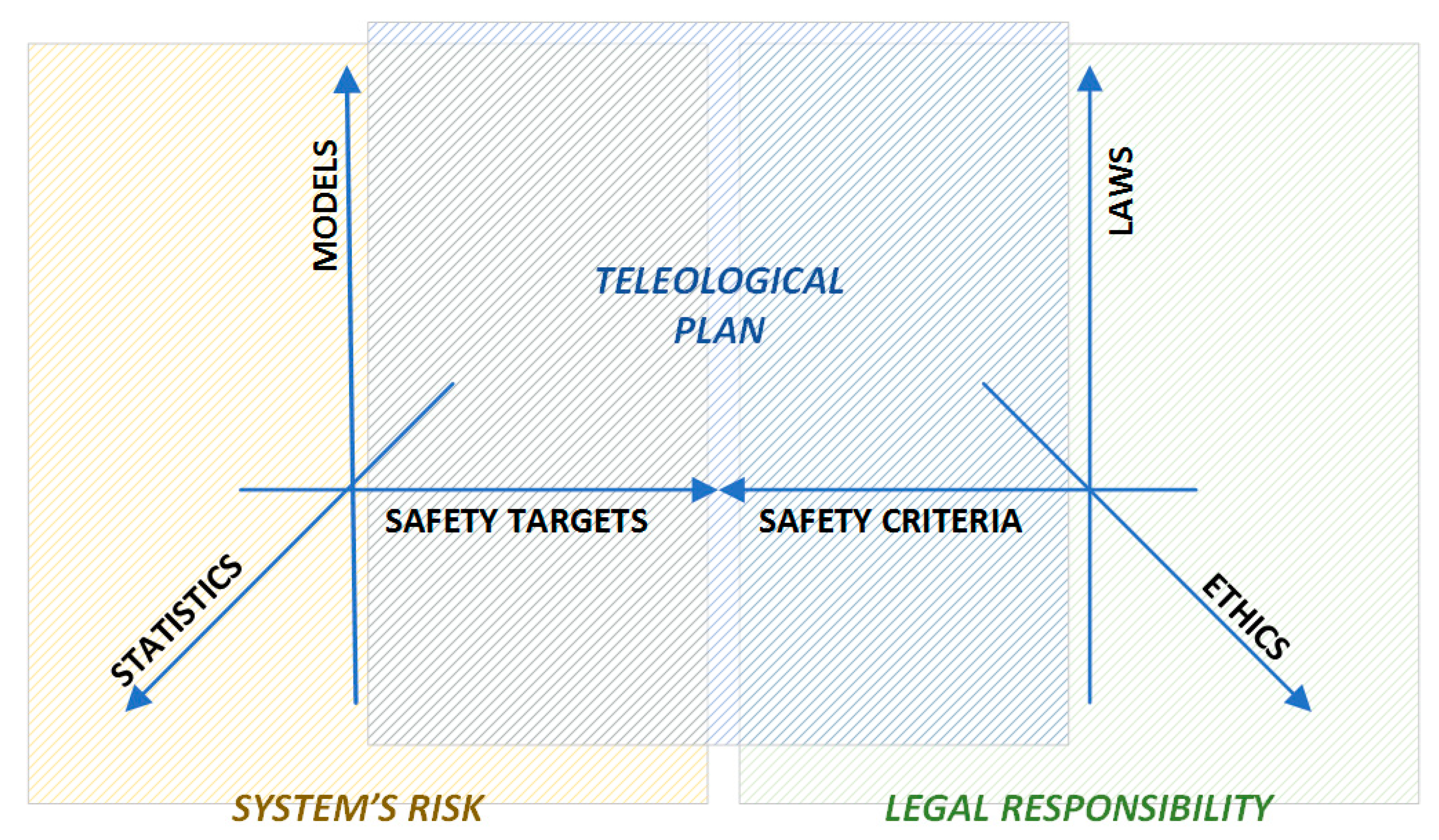

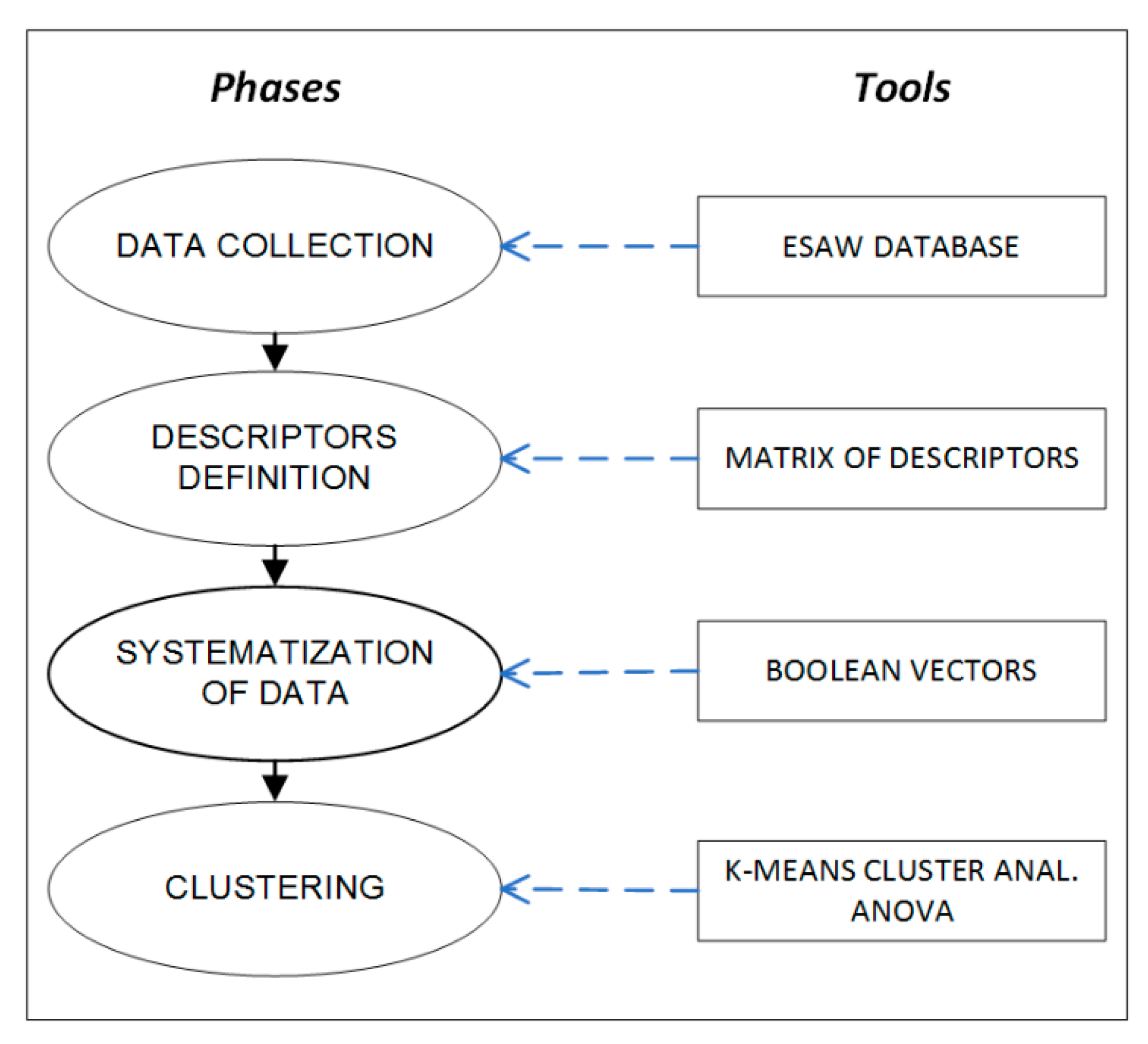

2.4. Research Approach

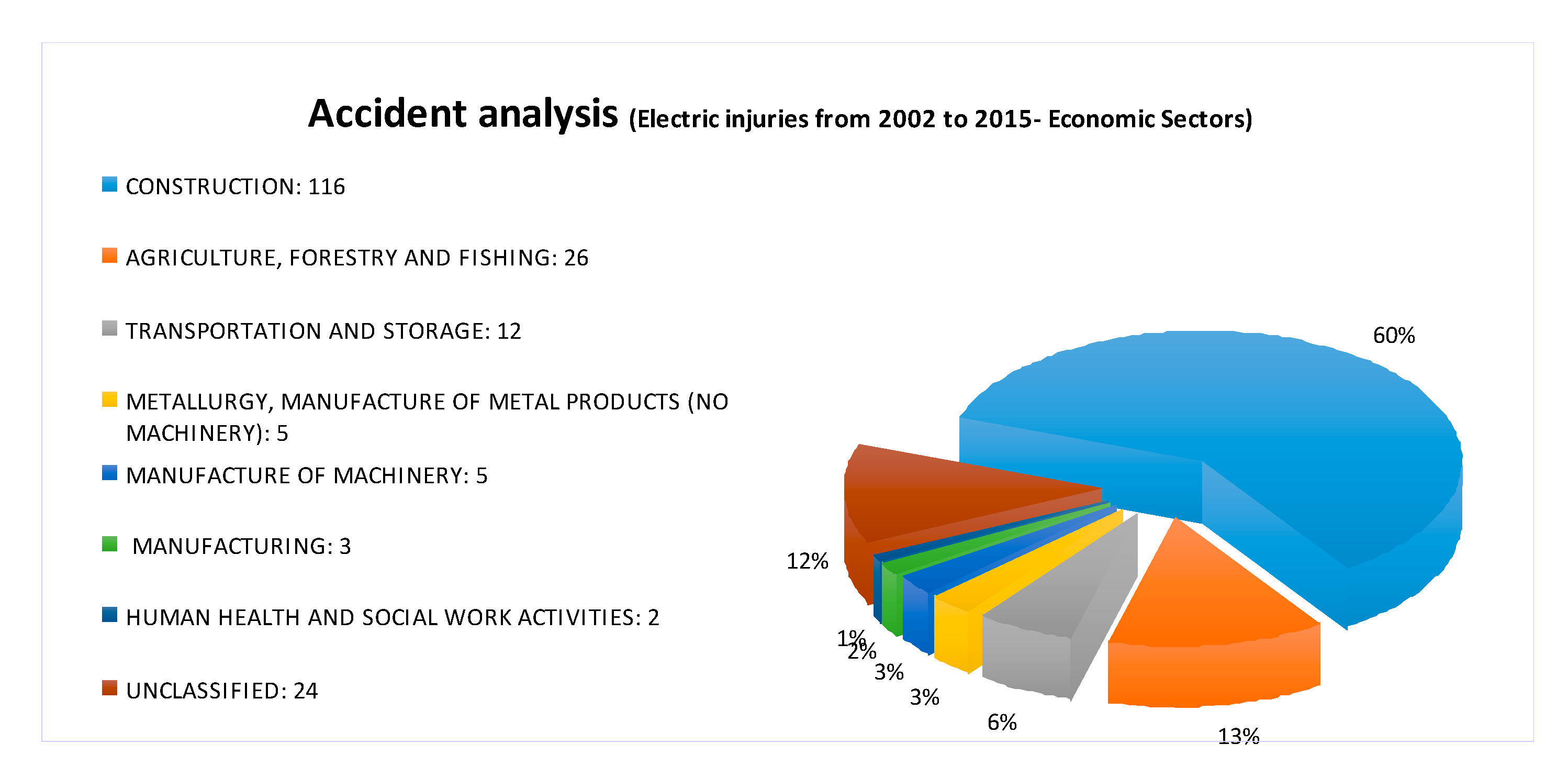

- Data collection: data related to a specific type of accidents (e.g., accidents due to electric shock in the construction sector) are extracted from the Infor.MO database.

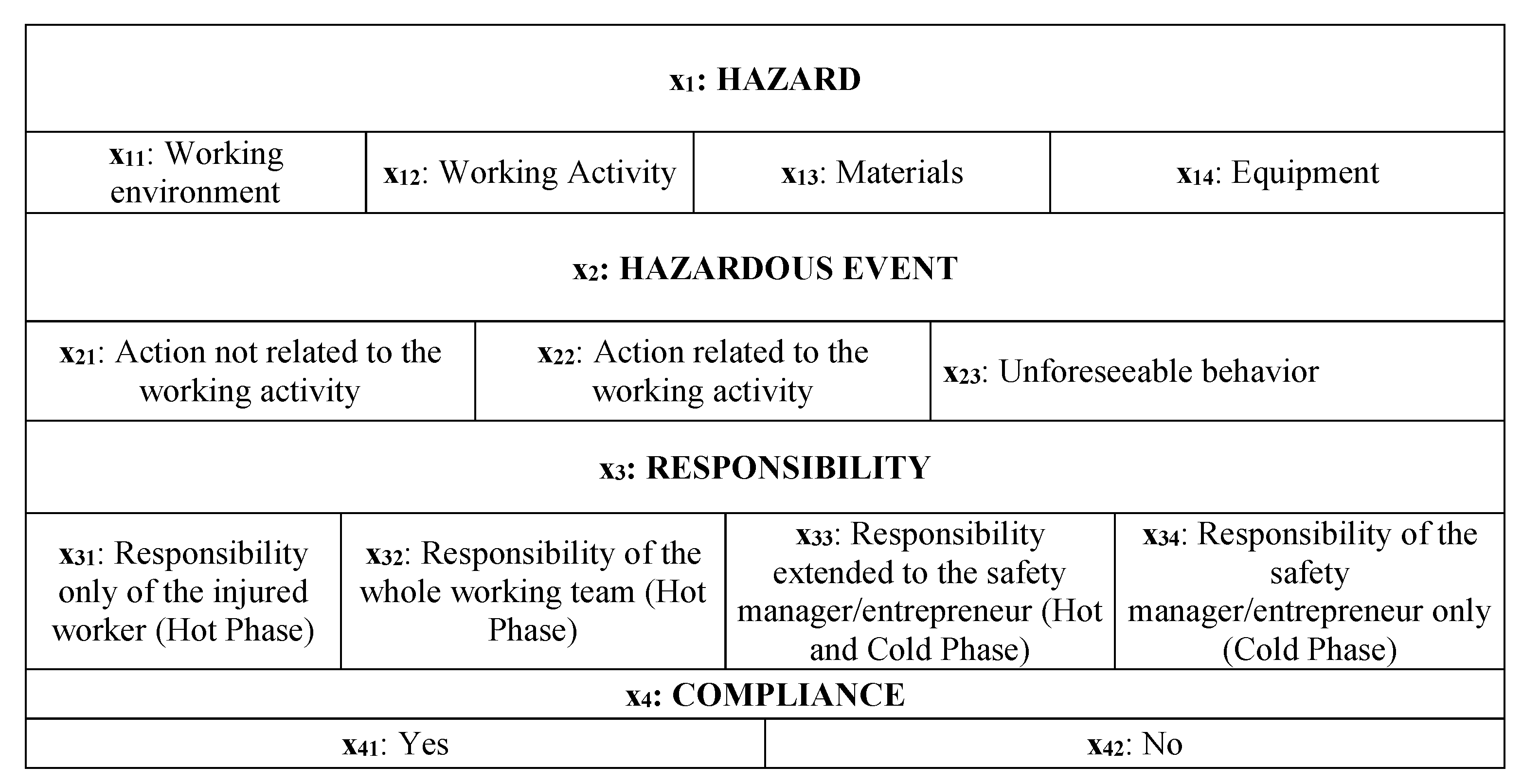

- Identification of the descriptive variables of accidents: information provided in each accident report is analyzed in order to depict the sub-descriptors of the system, which are translated into the n variables into the related k types of the reference areas (i.e., the descriptors). In practice, the general scheme of such a classification consists in relating the four different types of descriptors (hazard, hazardous event, responsibility, and compliance) with the xi variables, where i = 1, … 4 (maximum number of areas of relevance) indicates the number of the descriptors, while j = 1, … m represents the number of the different sub-descriptors for each descriptor. The output of such a process consists in the definition of the “Matrix of Descriptors” (MoD) depicted in Figure 4, where each descriptor is composed by different sub-descriptors, representing the descriptive variables of the system that can be extracted from the ESAW accident reports. It has to be noted that in this way the logical disjunction of the xij variables is guaranteed. In total, 13 variables were identified (n = 13).The Matrix of Descriptors allows us to merge the characteristics of the epistemic-mnesic and ethical-axiological spaces of the cindynic approach, representing a tool aimed at “filtering” accidents data in order to elicit their main features in terms of safety targets and safety criteria. Accordingly, the selection of descriptors and sub-descriptors was made taking into account both the system′s risk features and legal responsibilities issues related to an accident, consistently with the variables suggested by the ESAW system and the ILO guidelines [70].

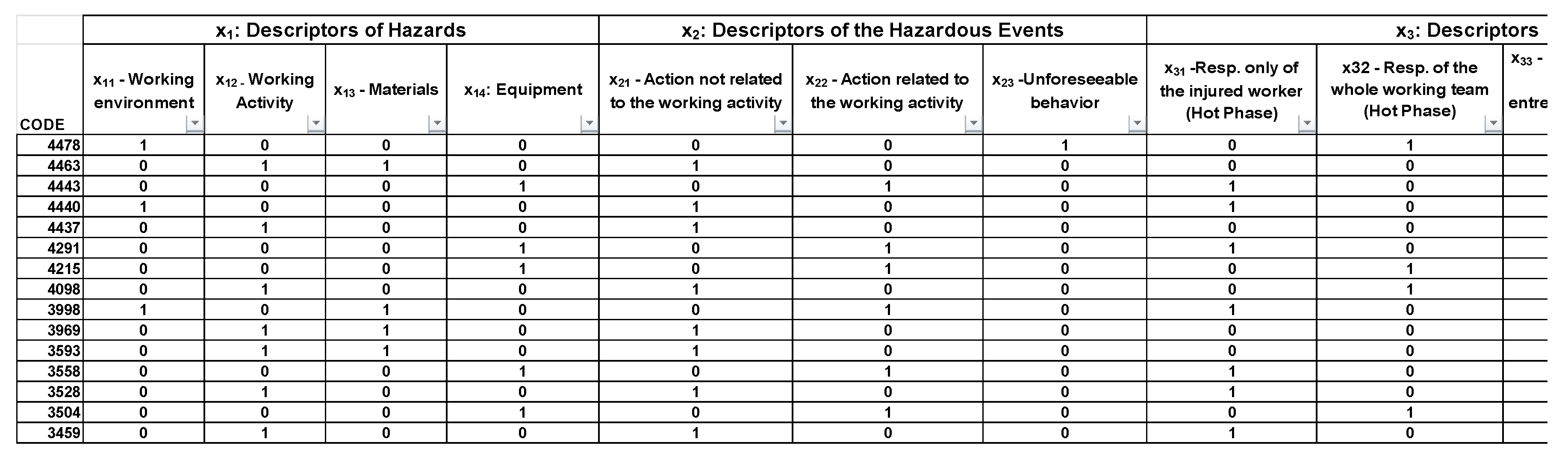

- Systematization of data extracted from the accidents database by means of Boolean coordinates: categorical information is translated into dichotomous variables. In other words, the xij variables that describe an accident are translated into an algebraic vector by means of the Boolean n-tuple of coordinates in the space Rn. For this purpose the MoD is used, filling it with Boolean values (i.e., “0” when the accident is not affected by a certain variable; or “1” when the accident is affected by a certain variable). In Figure 5 an example of the MoD application is shown (the code number used is the one reported in the Infor.MO database).

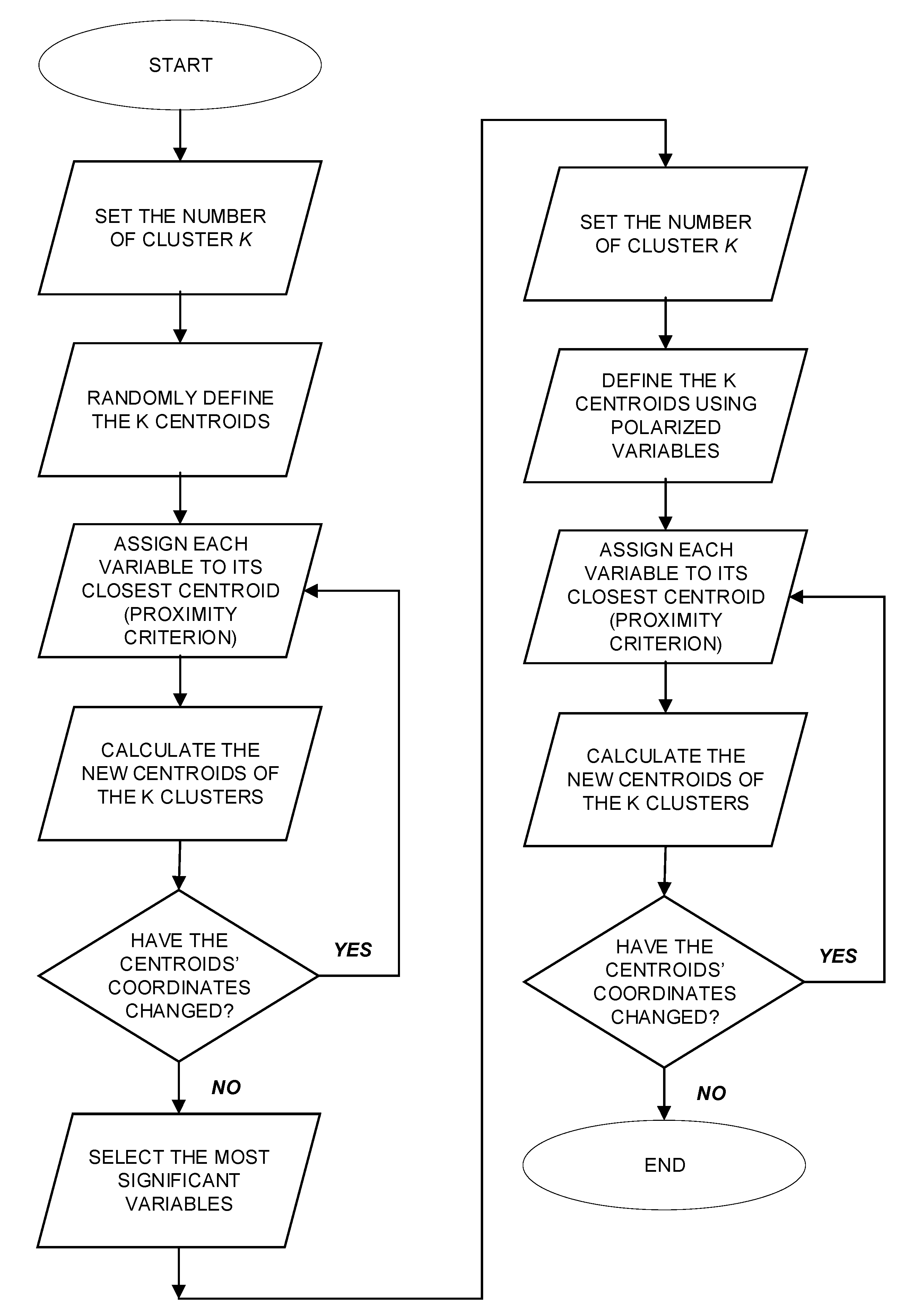

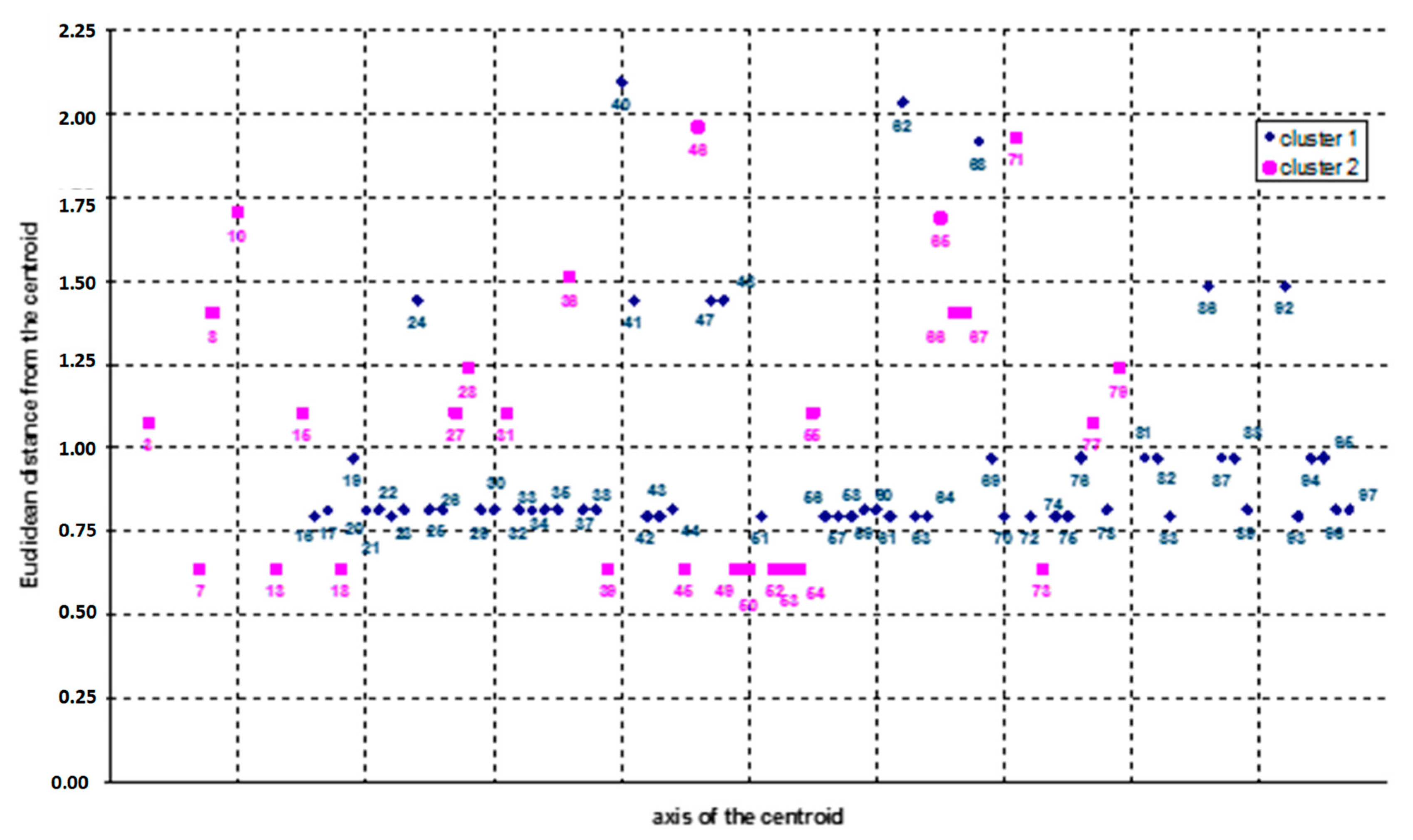

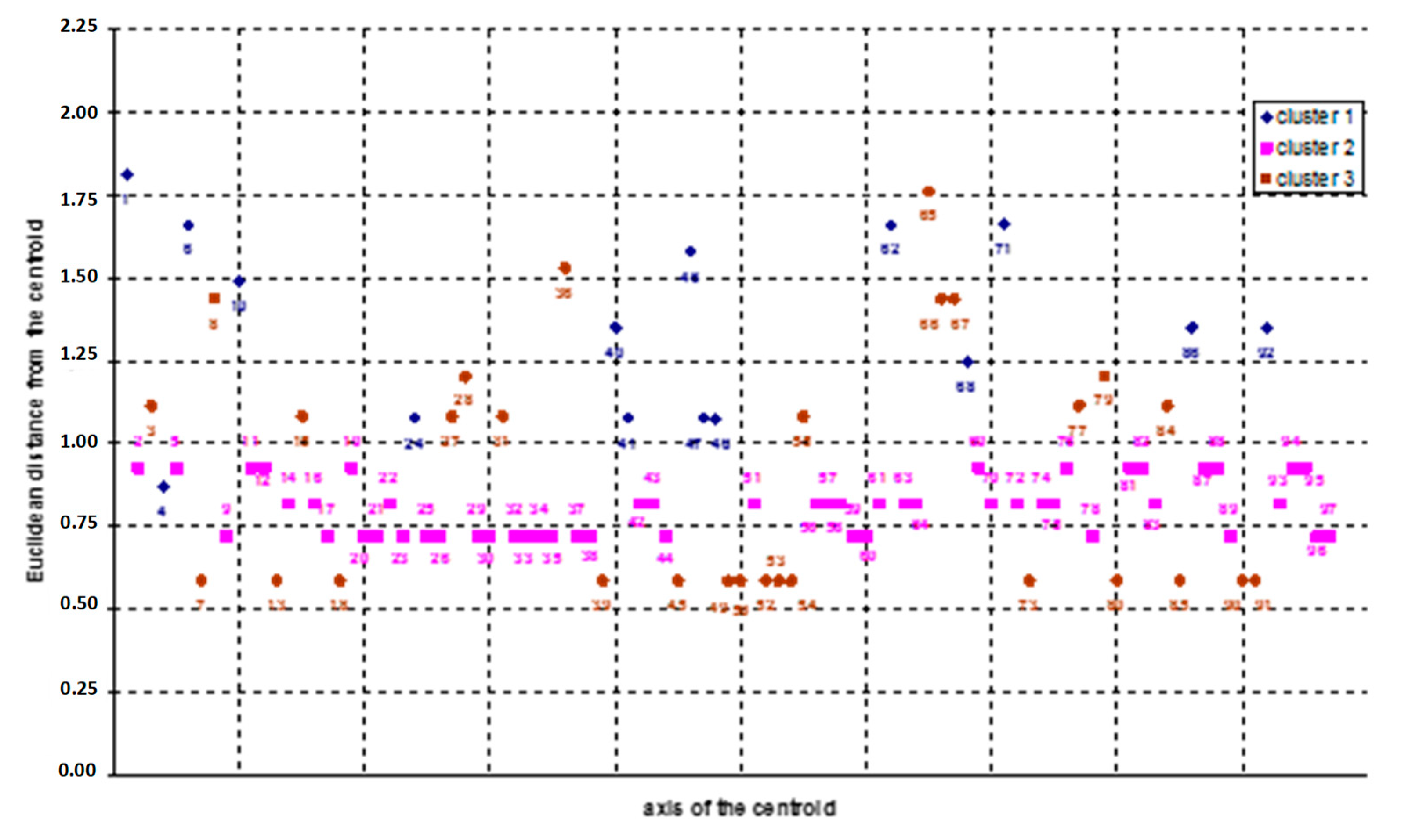

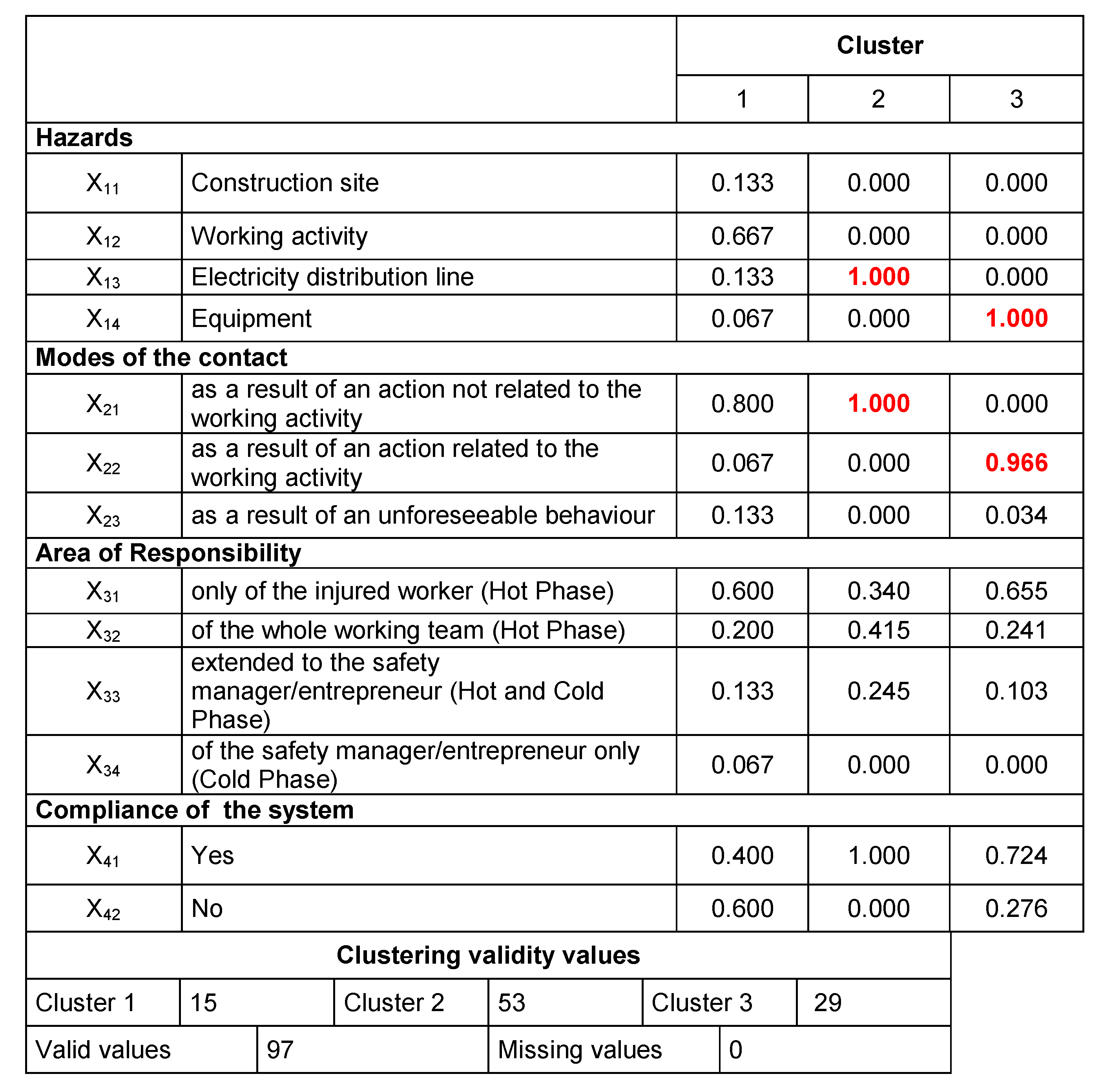

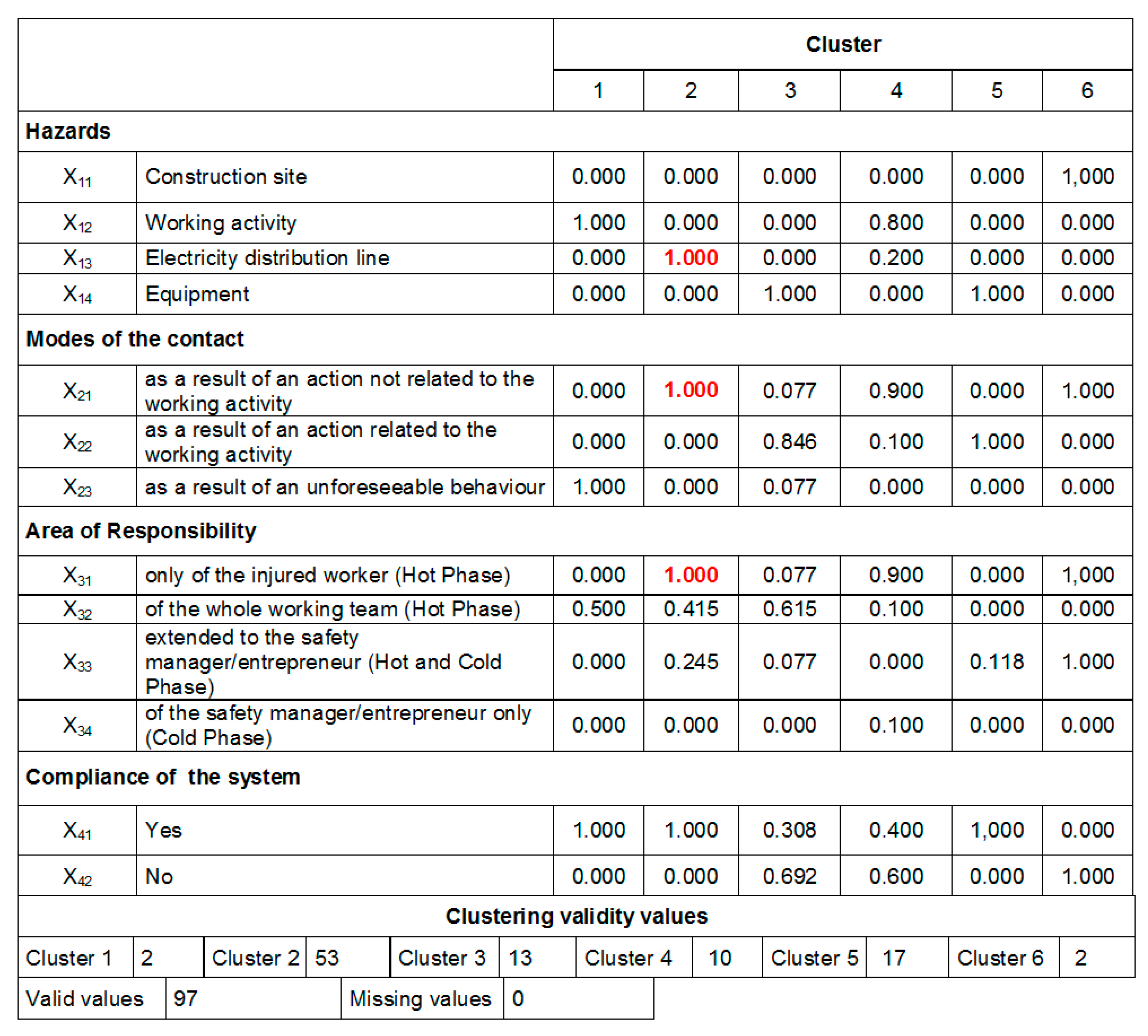

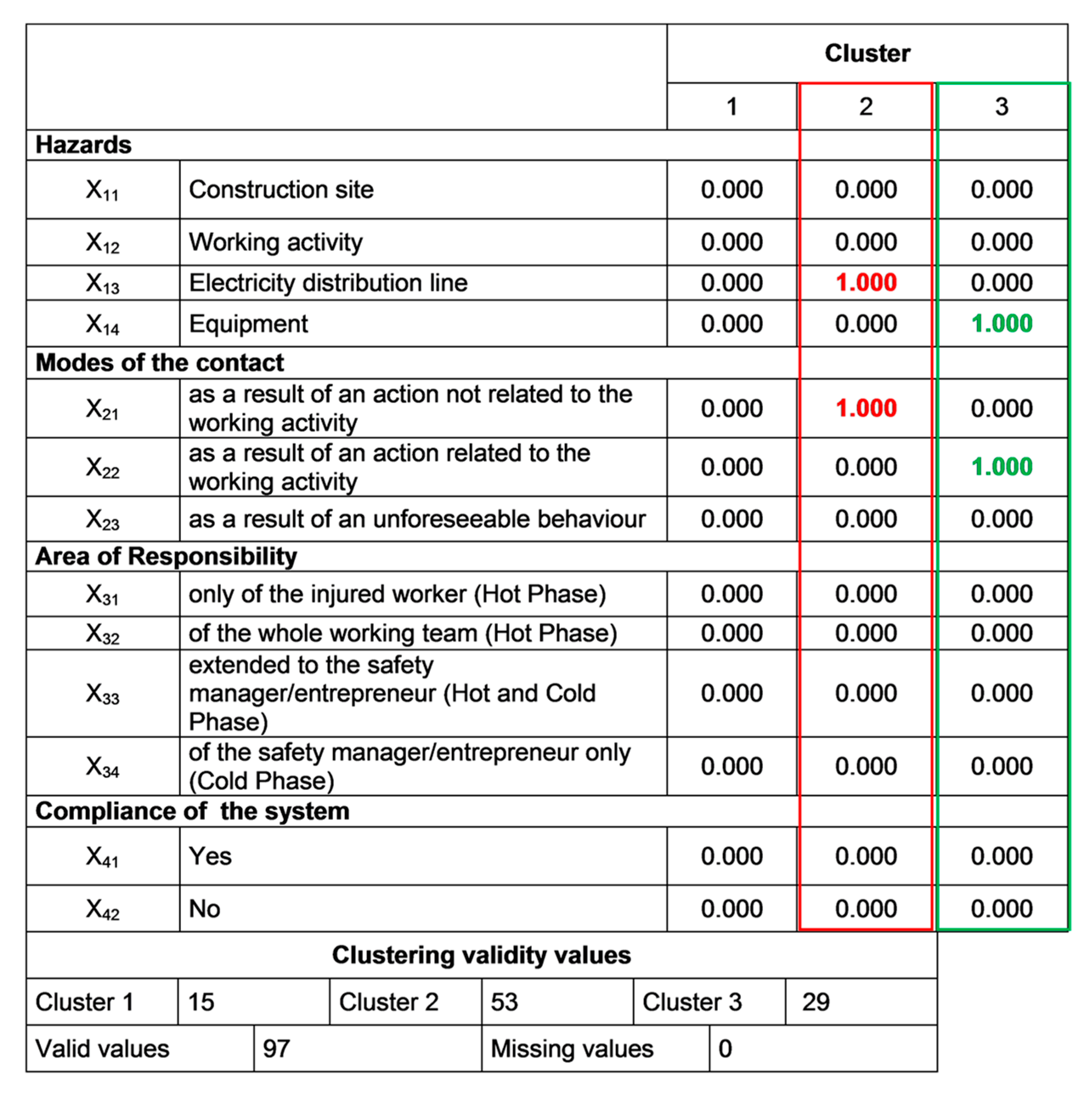

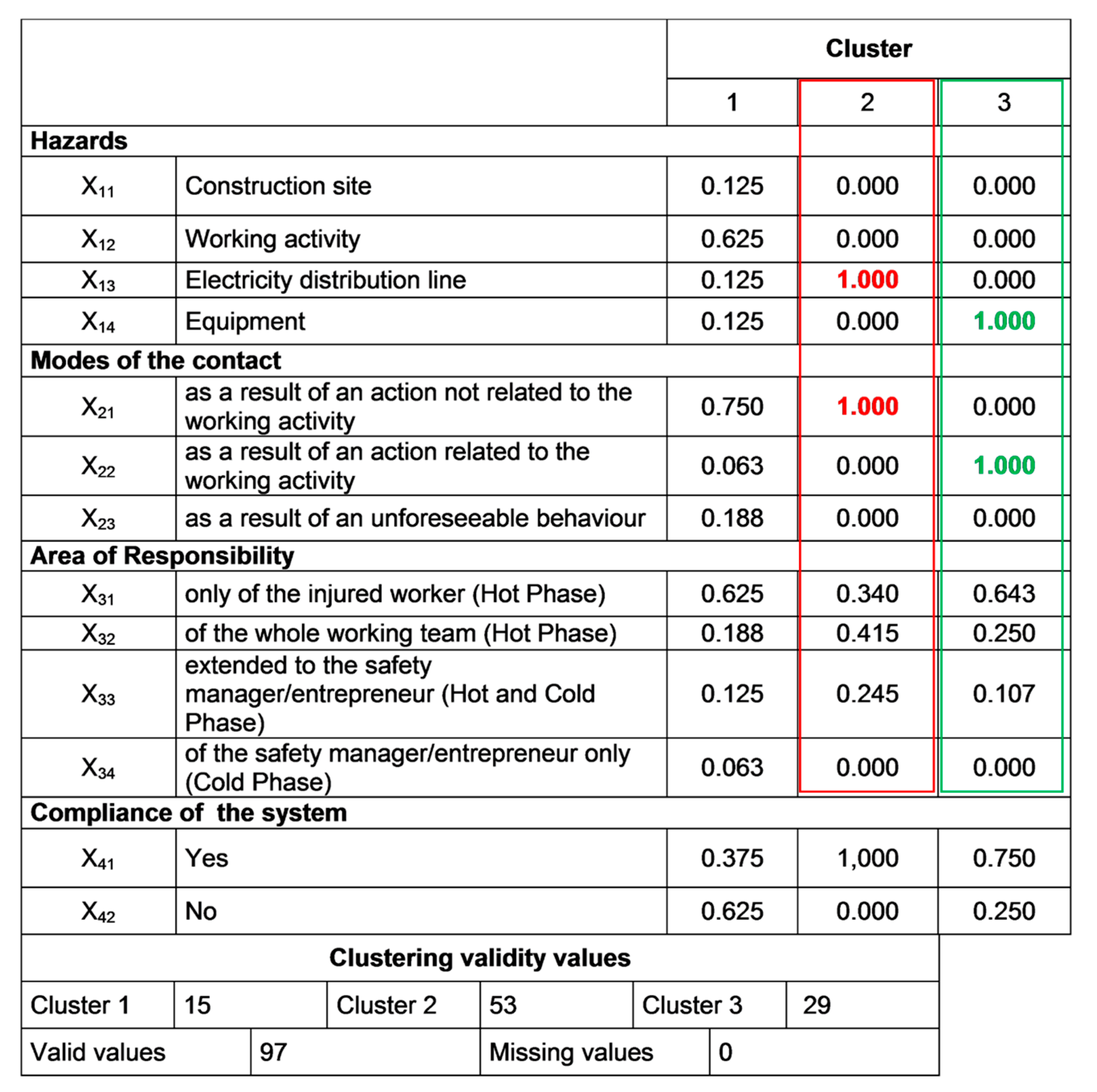

- Cluster analysis application aimed at identifying homogenous groups of accident cases based on the xij variables systematized in the previous phase. In other words, the set of observations is represented by the algebraic vectors defined above (corresponding to the n variables) with the goal of partitioning them into k (≤ n) sets (i.e., the clusters), where the algebraic vectors are assigned to a specific cluster following the criterion of “proximity” to the initial centroid. Based on this, in our context the use of the k-means clustering approach [59,60] is foreseen twice (Figure 6): the first time the application is aimed at defining the most relevant variables characterizing the type of accidents analyzed (which we called “polarized” variables), while the second application is focused on verifying the significance of this output, refining the mutual relationships among the variables to better understand the accident scenario. More in detail, the first series of iterations is carried without assigning the centroids in advance: the coordinates of centroids are randomly assigned by the software (in this study the IBM SPSS® version 5.0 software (Armonk, NY, USA) [71] was used). The results obtained allows the definition of most relevant cluster solutions and the related coordinates of the centroids. These coordinates are used for further iterations, which end when the new centroids′ coordinates do not change [53]. The validation of the results is carried out by means of the Analysis of Variance (ANOVA) test [72]. The result of this first clustering process consists in the individuation of the most relevant variables, i.e., those representing the most impacting accidents′ determinants (the “polarized” variables). Afterwards, as illustrated in Figure 6, the whole procedure is repeated using these “polarized” variables as the input coordinates of initial k centroids. For this purpose, a new transformation into dichotomous variables (the value “1” is assigned to the “polarized” variables, while “0” is assigned to the other variables) was carried out to initialize the second clustering process.

3. Case Study

4. Discussion

4.1. Case Study Results

- Cluster 2, populated by 53 cases, which are characterized by direct contact with the electrical line during construction activities not related to electrical works. Namely, 42% of these accidents are due to a failure of the working team and/or the safety manager.

- Cluster 3, populated by 29 cases, determined by a failure of the worker (65%) when using a working equipment (e.g., a crane or a scaffold).

4.2. Research Implications

4.3. Limitations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Health and Safety Executive (HSE). Construction Statistics in Great Britain. 2019. Available online: http://www.hse.gov.uk/statistics/industry/construction.pdf (accessed on 19 November 2019).

- Japan Industrial Safety and Health Association (JISHA). OSH Statistics in Japan—2018. Available online: https://www.jisha.or.jp/english/statistics/accidents_in_detail_2018.html (accessed on 19 November 2019).

- Eurostat. Accidents at Work—Statistics by Economic Activity. Available online: https://ec.europa.eu/ eurostat/statistics-explained/index.php?title=Accidents_at_work_-_statistics_by_economic_activity (accessed on 19 November 2019).

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Khan, R.M.A. Trend analysis of construction industrial accidents in Korea from 2011 to 2015. Sustainability 2017, 9, 1297. [Google Scholar] [CrossRef]

- Gürcanli, G.E.; Müngen, U. Analysis of construction accidents in Turkey and responsible parties. Ind. Health 2013, 52, 581–595. [Google Scholar] [CrossRef] [PubMed]

- Shafique, M.; Rafiq, M. An Overview of Construction Occupational Accidents in Hong Kong: A Recent Trend and Future Perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef]

- Zhou, X.-H.; Shen, S.-L.; Xu, Y.-S.; Zhou, A.-N. Analysis of Production Safety in the Construction Industry of China in 2018. Sustainability 2019, 11, 4537. [Google Scholar] [CrossRef]

- Sunindijo, R.Y.; Zou, P.X.W. Political Skill for Developing Construction Safety Climate. J. Constr. Eng. Manag. 2011, 138, 605–612. [Google Scholar] [CrossRef]

- Liaudanskiene, R.; Varnas, N.; Ustinovichius, L. Modelling the application of workplace safety and health act in Lithuanian construction sector. Technol. Econ. Dev. Econ. 2010, 16, 233–253. [Google Scholar] [CrossRef]

- Sherratt, F.; Farrell, P.; Noble, R. UK construction site safety: Discourses of enforcement and engagement. Constr. Manag. Econ. 2013, 31, 623–635. [Google Scholar] [CrossRef]

- Fargnoli, M.; De Minicis, M.; Di Gravio, G. Knowledge Management integration in Occupational Health and Safety systems in the construction industry. Int. J. Prod. Dev. 2011, 14, 165–185. [Google Scholar] [CrossRef]

- Loosemore, M.; Andonakis, N. Barriers to implementing OHS reforms—The experiences of small subcontractors in the Australian Construction Industry. Int. J. Proj. Manag. 2007, 25, 579–588. [Google Scholar] [CrossRef]

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational risk assessment in construction industry—Overview and reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Aires, M.D.M.; Gámez, M.C.R.; Gibb, A. Prevention through design: The effect of European Directives on construction workplace accidents. Saf. Sci. 2010, 48, 248–258. [Google Scholar] [CrossRef]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Guadagno, F. Hazard Function Deployment: A QFD based tool for the assessment of working tasks—A practical study in the construction industry. Int. J. Occup. Saf. Ergon. 2018, 1–53. [Google Scholar] [CrossRef]

- Sousa, V.; Almeida, N.M.; Dias, L.A. Risk-based management of occupational safety and health in the construction industry—Part 1: Background knowledge. Saf. Sci. 2014, 66, 75–86. [Google Scholar] [CrossRef]

- Bas, E. An integrated quality function deployment and capital budgeting methodology for occupational safety and health as a systems thinking approach: The case of the construction industry. Accid. Anal. Prev. 2014, 68, 42–56. [Google Scholar] [CrossRef]

- Gunduz, M.; Laitinen, H. A 10-step safety management framework for construction small and medium-sized enterprises. Int. J. Occup. Saf. Ergon. 2017, 23, 353–359. [Google Scholar] [CrossRef]

- Underwood, P.; Waterson, P. Systems thinking, the Swiss Cheese Model and accident analysis: A comparative systemic analysis of the Grayrigg train derailment using the ATSB, AcciMap and STAMP models. Accid. Anal. Prev. 2014, 68, 75–94. [Google Scholar] [CrossRef]

- Aneziris, O.N.; Topali, E.; Papazoglou, I.A. Occupational risk of building construction. Reliab. Eng. Sys. Saf. 2012, 105, 36–46. [Google Scholar] [CrossRef]

- Jacinto, C.; Soares, C. The added value of the new ESAW/Eurostat variables in accident analysis in the mining and quarrying industry. J. Saf. Res. 2008, 39, 631–644. [Google Scholar] [CrossRef]

- Lundberg, J.; Rollenhagen, C.; Hollnagel, E. What you look for is what you find—The consequences of underlying accident models in eight accident investigation manuals. Saf. Sci. 2009, 47, 1297–1311. [Google Scholar] [CrossRef]

- Lindberg, A.; Ove Hansson, S.; Rollenhagen, C. Learning from accidents—What more do we need to know. Saf. Sci. 2010, 48, 714–721. [Google Scholar] [CrossRef]

- Gibb, A.; Lingard, H.; Behm, M.; Cooke, T. Construction accident causality: Learning from different countries and differing consequences. Constr. Manag. Econ. 2014, 32, 446–459. [Google Scholar] [CrossRef]

- Chong, H.Y.; Low, T.S. Accidents in Malaysian construction industry: Statistical data and court cases. Int. J. Occup. Saf. Ergon. 2014, 20, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Molinero-Ruiz, E.; Pitarque, S.; Fondevila-McDonald, Y.; Martin-Bustamante, M. How reliable and valid is the coding of the variables of the European Statistics on Accidents at Work (ESAW)? A need to improve preventive public policies. Saf. Sci. 2015, 79, 72–79. [Google Scholar] [CrossRef]

- Salguero-Caparros, F.; Suarez-Cebador, M.; Rubio-Romero, J.C. Analysis of investigation reports on occupational accidents. Saf. Sci. 2015, 72, 329–336. [Google Scholar] [CrossRef]

- Schenk, L.; Öberg, M. Comparing data from the Poisons Information Centre with employers′ accident reports reveal under-recognized hazards at the workplace. Ann. Work Expo. Health 2018, 62, 517–529. [Google Scholar] [CrossRef]

- Kogler, R.; Quendler, E.; Boxberger, J. Analysis of occupational accidents with agricultural machinery in the period 2008–2010 in Austria. Saf. Sci. 2015, 72, 319–328. [Google Scholar] [CrossRef]

- Rondelli, V.; Casazza, C.; Martelli, R. Tractor rollover fatalities, analyzing accident scenario. J. Saf. Res. 2018, 67, 99–106. [Google Scholar] [CrossRef]

- Palamara, F.; Piglione, F.; Piccinini, N. Self-Organizing Map and clustering algorithms for the analysis of occupational accident databases. Saf. Sci. 2011, 49, 1215–1230. [Google Scholar] [CrossRef]

- Comberti, L.; Demichela, M.; Baldissone, G.; Fois, G.; Luzzi, R. Large Occupational Accidents Data Analysis with a Coupled Unsupervised Algorithm: The S.O.M. K-Means Method. An Application to the Wood Industry. Safety 2018, 4, 51. [Google Scholar] [CrossRef]

- Carrillo-Castrillo, J.A.; Trillo-Cabello, A.F.; Rubio-Romero, J.C. Construction accidents: Identification of the main associations between causes, mechanisms and stages of the construction process. Int. J. Occup. Saf. Ergon. 2017, 23, 240–250. [Google Scholar] [CrossRef]

- Jacinto, C.; Santos, F.P.; Soares, C.G.; Silva, S.A. Assessing the coding reliability of work accidents statistical data: How coders make a difference. J. Saf. Res. 2016, 59, 9–21. [Google Scholar] [CrossRef] [PubMed]

- Bilir, S.; Gurcanli, G.E. A Method to Calculate the Accident Probabilities in Construction Industry Using a Poisson Distribution Model. In Advances in Safety Management and Human Factors; Arezes, P., Ed.; Springer: Cham, Switzerland, 2016; pp. 513–523. [Google Scholar] [CrossRef]

- Dien, Y.; Dechy, N.; Guillaume, E. Accident investigation: From searching direct causes to finding in-depth causes—Problem of analysis or/and of analyst? Saf. Sci. 2012, 50, 1398–1407. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, W.; Xu, P.; Chen, N. Applicability of accident analysis methods to Chinese construction accidents. J. Saf. Res. 2019, 68, 187–196. [Google Scholar] [CrossRef] [PubMed]

- Hola, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. [Google Scholar] [CrossRef] [Green Version]

- Bellamy, L.J.; Ale, B.J.; Geyer, T.A.W.; Goossens, L.H.; Hale, A.R.; Oh, J.; Mud, M.; Bloemhof, A.; Papazoglou, I.A.; Whiston, J.Y. Storybuilder—A tool for the analysis of accident reports. Reliab. Eng. Sys. Saf. 2007, 92, 735–744. [Google Scholar] [CrossRef]

- Kvaloy, J.T.; Aven, T. An alternative approach to trend analysis in accident data. Reliab. Eng. Syst. Saf. 2005, 90, 75–82. [Google Scholar] [CrossRef]

- Lombardi, M.; Fargnoli, M. Prioritization of hazards by means of a QFD-based procedure. Int. J. Saf. Secur. Eng. 2018, 8, 342–353. [Google Scholar] [CrossRef] [Green Version]

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2019, 111, 253–263. [Google Scholar] [CrossRef]

- Raviv, G.; Shapira, A.; Fishbain, B. AHP-based analysis of the risk potential of safety incidents: Case study of cranes in the construction industry. Saf. Sci. 2017, 91, 298–309. [Google Scholar] [CrossRef]

- Ayhan, B.U.; Tokdemir, O.B. Predicting the outcome of construction incidents. Saf. Sci. 2019, 113, 91–104. [Google Scholar] [CrossRef]

- Biggs, H.C.; Dinsdag, D.; Kirk, P.J.; Cipolla, D. Safety culture research, lead indicators, and the development of safety effectiveness indicators in the construction sector. Int. J. Technol. Knowl. Soc. 2010, 6, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Hola, B.; Szóstak, M. Methodology of analysing the accident rate in the construction industry. Procedia Eng. 2017, 172, 355–362. [Google Scholar] [CrossRef]

- Ale, B.J.; Bellamy, L.J.; Baksteen, H.; Damen, M.; Goossens, L.H.; Hale, A.R.; Mud, M.; Oh, J.; Papazoglou, I.A.; Whiston, J.Y. Accidents in the construction industry in the Netherlands: An analysis of accident reports using Storybuilder. Reliab. Eng. Sys. Saf. 2008, 93, 1523–1533. [Google Scholar] [CrossRef]

- Love, P.E.D.; Teo, P.; Smith, J.; Ackermann, F.; Zhou, Y. The nature and severity of workplace injuries in construction: Engendering operational benchmarking. Ergonomics 2019, 62. [Google Scholar] [CrossRef] [PubMed]

- Cross, J. ISO 31010 Risk assessment techniques and open systems. In Proceedings of the Sixth Workshop on Open Systems Dependability (WOSD), Tokyo, Japan, 21 October 2017; pp. 15–18. [Google Scholar]

- Abdi, H.; Williams, L.J. Principal component analysis. Wiley Interdiscip. Rev. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Dillon, W.R.; Goldstein, M. Multivariate Analysis Methods and Applications; Wiley: New York, NY, USA, 1984. [Google Scholar]

- Celebi, M.E.; Kingravi, H.A.; Vela, P.A. A comparative study of efficient initialization methods for the k-means clustering algorithm. Exp. Sys. Appl. 2013, 40, 200–210. [Google Scholar] [CrossRef] [Green Version]

- Brodny, J.; Tutak, M. Analysis of the diversity in emissions of selected gaseous and particulate pollutants in the European Union countries. J. Environ. Manag. 2019, 231, 582–595. [Google Scholar] [CrossRef]

- INAIL (Italian Workers′ Compensation Authority). INFORMO Database on Serious and Fatal Accidents. Available online: https://appsricercascientifica.inail.it/getinf/informo/home_informo.asp (accessed on 25 September 2019).

- Proto, A.R.; Mazzocchi, F.; Cossio, F.; Bortolini, L.; Pascuzzi, S.; Caruso, L.; Diano, M.; Zimbalatti, G. A survey on occupational injuries in works on trees in Italy. Procedia Soc. Behav. Sci. 2016, 223, 435–441. [Google Scholar] [CrossRef]

- Lombardi, M.; Rossi, G. Cluster Analysis of Fatal Accidents Series in the Infor.Mo Database: Analysis, Evidence and Research Perspectives. Int. J. Saf. Secur. Eng. 2013, 3, 317–331. [Google Scholar] [CrossRef]

- Oltedal, S.; Rundmo, T. Using cluster analysis to test the cultural theory of risk perception. Transp. Res. Part F Traffic Psychol. Behav. 2007, 10, 254–262. [Google Scholar] [CrossRef]

- INAIL (Italian Workers′ Compensation Authority). INFORMO Database on Serious and Fatal Accidents. Details of Information Related to Fatal Accident 8164. Available online: https://appsricercascientifica.inail.it/ getinf_u/v iewCase.asp?id=8164&v (accessed on 25 September 2019).

- Punj, G.; Stewart, D.W. Cluster analysis in marketing research: Review and suggestions for application. J. Mark. Res. 1983, 20, 134–148. [Google Scholar] [CrossRef]

- Everitt, B.S.; Landau, S.; Leese, M. Cluster Analysis, 4th ed.; Arnold: London, UK, 2001. [Google Scholar]

- Alper, S.J.; Karsh, B.T. A systematic review of safety violations in industry. Accid. Anal. Prev. 2009, 41, 739–754. [Google Scholar] [CrossRef] [PubMed]

- Arocena, P.; Núñez, I. An empirical analysis of the effectiveness of occupational health and safety management systems in SMEs. Int. Small Bus. J. 2010, 28, 398–419. [Google Scholar] [CrossRef]

- Champoux, D.; Brun, J.P. Occupational health and safety management in small size enterprises: An overview of the situation and avenues for intervention and research. Saf. Sci. 2003, 41, 301–318. [Google Scholar] [CrossRef]

- Engkvist, I.L.; Kjellberg, A.; Wigaeus, H.E.; Hagberg, M.; Menckel, E.; Ekenvall, L. Back injuries among nursing personnel—Identification of work conditions with cluster analysis. Saf. Sci. 2001, 37, 1–18. [Google Scholar] [CrossRef]

- Raviv, G.; Fishbain, B.; Shapira, A. Analyzing risk factors in crane-related nearmiss and accident reports. Saf. Sci. 2017, 91, 192–205. [Google Scholar] [CrossRef]

- Kervern, G.Y. Cindynics: The science of danger. Risk Manag. 1995, 42, 34. [Google Scholar]

- Chantelauve, G. An overview of maritime safety assessment trends in a stakeholder perspective. In Proceedings of the European Safety and Reliability Conference 2003, Maastricht, The Netherlands, 15–18 June 2003; Bedford, T., van Gelder, P.H.A.J.M., Eds.; CRC Press Book: Maastricht, The Netherlands, 2003; pp. 387–395. [Google Scholar]

- Guo, B.H.; Yiu, T.W.; González, V.A. Identifying behaviour patterns of construction safety using system archetypes. Accid. Anal. Prev. 2015, 80, 125–141. [Google Scholar] [CrossRef]

- Wiegmann, D.A.; Shappell, S.A. Human error analysis of commercial aviation accidents: Application of the Human Factors Analysis and Classification System (HFACS). Aviat. Space Environ. Med. 2001, 72, 1006–1016. [Google Scholar]

- International Labour Office (ILO). Improvement of National Reporting, Data Collection and Analysis of Occupational Accidents and Diseases; ILO Publications: Geneva, Switzerland, 2012; ISBN 978-92-2-126817-8. [Google Scholar]

- IBM. Statistical Package for Social Science (SPSS), Version 5.0. Available online: https://www.ibm.com/it-it/products/spss-statistics/details (accessed on 25 September 2019).

- Harb, H.; Makhoul, A.; Couturier, R. An enhanced K-means and ANOVA-based clustering approach for similarity aggregation in underwater wireless sensor networks. IEEE Sens. J. 2015, 15, 5483–5493. [Google Scholar] [CrossRef] [Green Version]

- Szüle, B. Introduction to Data Analysis; Faculty of Economics, Corvinus University of Budapest: Budapest, Hungary, 2016; ISBN 978-963-503-619-6. [Google Scholar]

- Fargnoli, M.; Lombardi, M. Preliminary Human Safety Assessment (PHSA) for the Improvement of the Behavioral Aspects of Safety Climate in the Construction Industry. Buildings 2019, 9, 69. [Google Scholar] [CrossRef] [Green Version]

- Zhao, D.; Thabet, W.; McCoy, A.; Kleiner, B. Electrical deaths in the US construction: An analysis of fatality investigations. Int. J. Inj. Control. Saf. Prev. 2014, 21, 278–288. [Google Scholar] [CrossRef] [PubMed]

- Suarez Sanchez, F.A.; Carvajal Pelaez, G.I.; Catala Alis, J. Occupational safety and health in construction: A review of applications and trends. Ind. Health 2017, 55, 210–218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suárez-Cebador, M.; Rubio-Romero, J.C.; López-Arquillos, A. Severity of electrical accidents in the construction industry in Spain. J. Saf. Res. 2014, 48, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Castillo-Rosa, J.; Suárez-Cebador, M.; Rubio-Romero, J.C.; Aguado, J.A. Personal factors and consequences of electrical occupational accidents in the primary, secondary and tertiary sectors. Saf. Sci. 2017, 91, 286–297. [Google Scholar] [CrossRef]

- Wang, J.; Yan, M. Application of an Improved Model for Accident Analysis: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 2756. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Fleyeh, H.; Wang, X.; Lu, M. Construction site accident analysis using text mining and natural language processing techniques. Autom. Constr. 2019, 99, 238–248. [Google Scholar] [CrossRef]

- Ning, X.; Qi, J.; Wu, C. A quantitative safety risk assessment model for construction site layout planning. Saf. Sci. 2018, 104, 246–259. [Google Scholar] [CrossRef]

- Raviv, G.; Shapira, A. Systematic approach to crane-related near-miss analysis in the construction industry. Int. J. Constr. Manag. 2018, 18, 310–320. [Google Scholar] [CrossRef]

- Rubio-Romero, J.C.; Suárez-Cebador, M.; Pardo-Ferreira, M.C.; De la Varga-Salto, J.M.; Carrillo-Castrillo, J.A. Does Europe Need an EU Product Safety Directive for Access Scaffolding? Int. J. Environ. Res. Public Health 2019, 16, 103. [Google Scholar] [CrossRef] [Green Version]

- Fargnoli, M.; Lombardi, M.; Haber, N. A fuzzy-QFD approach for the enhancement of work equipment safety: A case study in the agriculture sector. Int. J. Reliab. Saf. 2018, 12, 306–326. [Google Scholar] [CrossRef]

- Alrifaey, M.; Sai Hong, T.; Supeni, E.E.; As′arry, A.; Ang, C.K. Identification and Prioritization of Risk Factors in an Electrical Generator Based on the Hybrid FMEA Framework. Energies 2019, 12, 649. [Google Scholar] [CrossRef] [Green Version]

- Pinto, A. QRAM a Qualitative Occupational Safety Risk Assessment Model for the construction industry that incorporate uncertainties by the use of fuzzy sets. Saf. Sci. 2014, 63, 57–76. [Google Scholar] [CrossRef]

- Li, R.Y.M.; Chau, K.W.; Zeng, F.F. Ranking of Risks for Existing and New Building Works. Sustainability 2019, 11, 2863. [Google Scholar] [CrossRef] [Green Version]

- Suraji, A.; Duff, A.R.; Peckitt, S.J. Development of causal model of construction accident causation. J. Constr. Eng. Manag. 2001, 127, 337–344. [Google Scholar] [CrossRef]

- Ammon, B.V.; Bowman, J.; Mourad, R. Who are our students? Cluster analysis as a tool for understanding community college student populations. J. Appl. Res. Community Coll. 2008, 16, 29–41. [Google Scholar]

- Armstrong, J.J.; Zhu, M.; Hirdes, J.P.; Stolee, P. K-means cluster analysis of rehabilitation service users in the home health care system of Ontario: Examining the heterogeneity of a complex geriatric population. Arch. Phys. Med. Rehabil. 2012, 93, 2198–2205. [Google Scholar] [CrossRef]

- Gillman, M.; Pillay, M. An Integrative Literature Review: What Are the Barriers that Stop Organisations from Learning the Lessons Highlighted in Serious Incident Investigations? In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Los Angeles, CA, USA, 17–21 July 2017; Springer: Cham, Switzerland; pp. 627–634. [Google Scholar] [CrossRef]

- Margaryan, A.; Littlejohn, A.; Stanton, N.A. Research and development agenda for Learning from Incidents. Saf. Sci. 2017, 99, 5–13. [Google Scholar] [CrossRef] [Green Version]

- Swuste, P.; Frijters, A.; Guldenmund, F. Is it possible to influence safety in the building sector?: A literature review extending from 1980 until the present. Saf. Sci. 2012, 50, 1333–1343. [Google Scholar] [CrossRef]

- Guarascio, M.; Lombardi, M.; Rossi, G.; Sciarra, G. Risk analysis and acceptability criteria. WIT Trans. Built Environ. 2007, 94, 131–138. [Google Scholar] [CrossRef] [Green Version]

- Mazaheri, A.; Montewka, J.; Nisula, J.; Kujala, P. Usability of accident and incident reports for evidence-based risk modeling—A case study on ship grounding reports. Saf. Sci. 2015, 76, 202–214. [Google Scholar] [CrossRef]

- Awal, Z.I.; Hasegawa, K. A study on accident theories and application to maritime accidents. Procedia Eng. 2017, 194, 298–306. [Google Scholar] [CrossRef]

- Hoła, B.; Szóstak, M. Modeling of the Accidentality Phenomenon in the Construction Industry. Appl. Sci. 2019, 9, 1878. [Google Scholar] [CrossRef] [Green Version]

- Drupsteen, L.; Groeneweg, J.; Zwetsloot, G.I. Critical steps in learning from incidents: Using learning potential in the process from reporting an incident to accident prevention. Int. J. Occup. Saf. Ergon. 2013, 19, 63–77. [Google Scholar] [CrossRef] [Green Version]

| Variables | N | Minimum | Maximum | Mean | Deviat. | Variance | |

|---|---|---|---|---|---|---|---|

| Statistics | Statistics | Statistics | Statistics | Stand. Error | Statistics | Statistics | |

| x11 | 97 | 0.000 | 1.000 | 0.02062 | 0.014503 | 0.142842 | 0.20 |

| x12 | 97 | 0.000 | 1.000 | 0.10309 | 0.031035 | 0.305660 | 0.093 |

| x13 | 97 | 0.000 | 1.000 | 0.56701 | 0.050571 | 0.498063 | 0.248 |

| x14 | 97 | 0.000 | 1.000 | 0.30928 | 0.047173 | 0.464597 | 0.216 |

| x21 | 97 | 0.000 | 1.000 | 0.67010 | 0.047987 | 0.472618 | 0.223 |

| x22 | 97 | 0.000 | 1.000 | 0.29897 | 0.046725 | 0.460184 | 0.212 |

| x23 | 97 | 0.000 | 1.000 | 0.03093 | 0.017669 | 0.174022 | 0.030 |

| x31 | 97 | 0.000 | 1.000 | 0.47423 | 0.050963 | 0.501929 | 0.252 |

| x32 | 97 | 0.000 | 1.000 | 0.32990 | 0.047987 | 0.472618 | 0.223 |

| x33 | 97 | 0.000 | 1.000 | 0.18557 | 0.039677 | 0.390776 | 0.153 |

| x34 | 97 | 0.000 | 1.000 | 0.01031 | 0.010309 | 0.101535 | 0.010 |

| x41 | 97 | 0.000 | 1.000 | 0.82474 | 0.038803 | 0.382162 | 0.146 |

| x42 | 97 | 0.000 | 1.000 | 0.17526 | 0.038803 | 0.382162 | 0.146 |

| Valid (listwise) | 97 | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lombardi, M.; Fargnoli, M.; Parise, G. Risk Profiling from the European Statistics on Accidents at Work (ESAW) Accidents′ Databases: A Case Study in Construction Sites. Int. J. Environ. Res. Public Health 2019, 16, 4748. https://doi.org/10.3390/ijerph16234748

Lombardi M, Fargnoli M, Parise G. Risk Profiling from the European Statistics on Accidents at Work (ESAW) Accidents′ Databases: A Case Study in Construction Sites. International Journal of Environmental Research and Public Health. 2019; 16(23):4748. https://doi.org/10.3390/ijerph16234748

Chicago/Turabian StyleLombardi, Mara, Mario Fargnoli, and Giuseppe Parise. 2019. "Risk Profiling from the European Statistics on Accidents at Work (ESAW) Accidents′ Databases: A Case Study in Construction Sites" International Journal of Environmental Research and Public Health 16, no. 23: 4748. https://doi.org/10.3390/ijerph16234748