Installation Planning in Regional Thermal Power Industry for Emissions Reduction Based on an Emissions Inventory

Abstract

:1. Introduction

2. Methods

2.1. Data Collection

2.2. Establishment and Verification of Emissions Inventory

2.3. Establishment of Unequal Relations

2.4. Installed Efficiency

2.5. K-Means Clustering Analysis

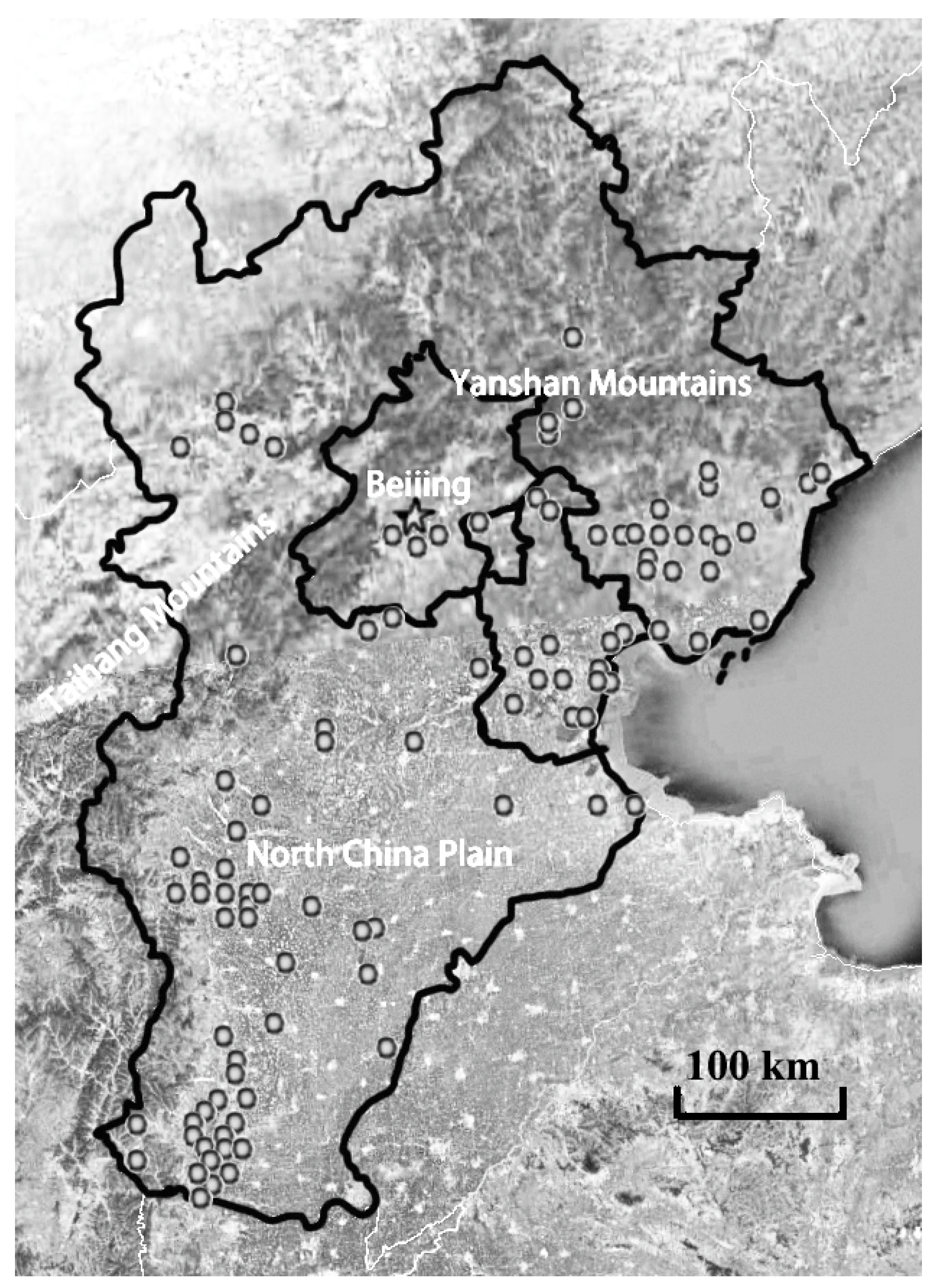

2.6. Case Study

3. Results and Discussion

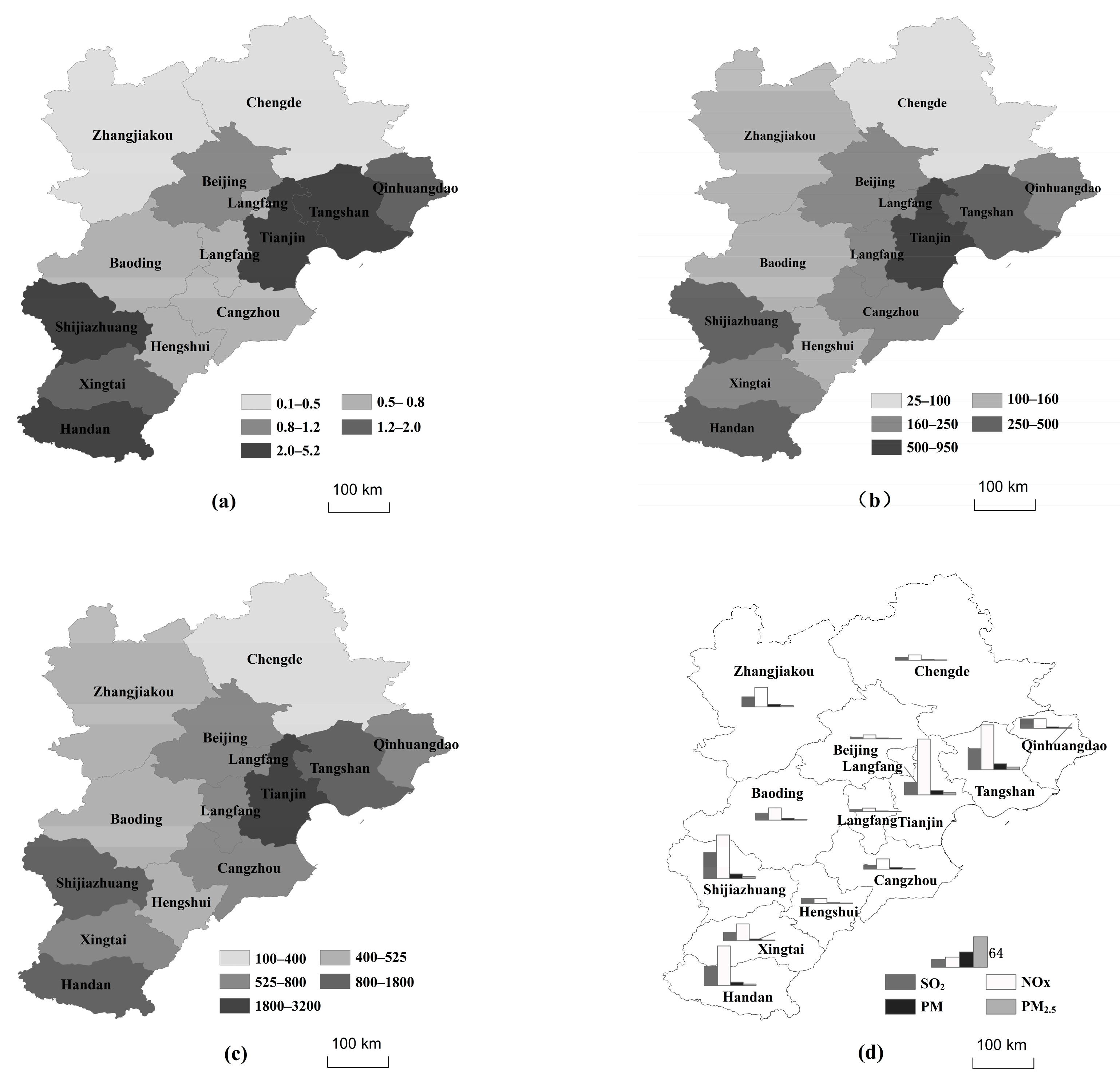

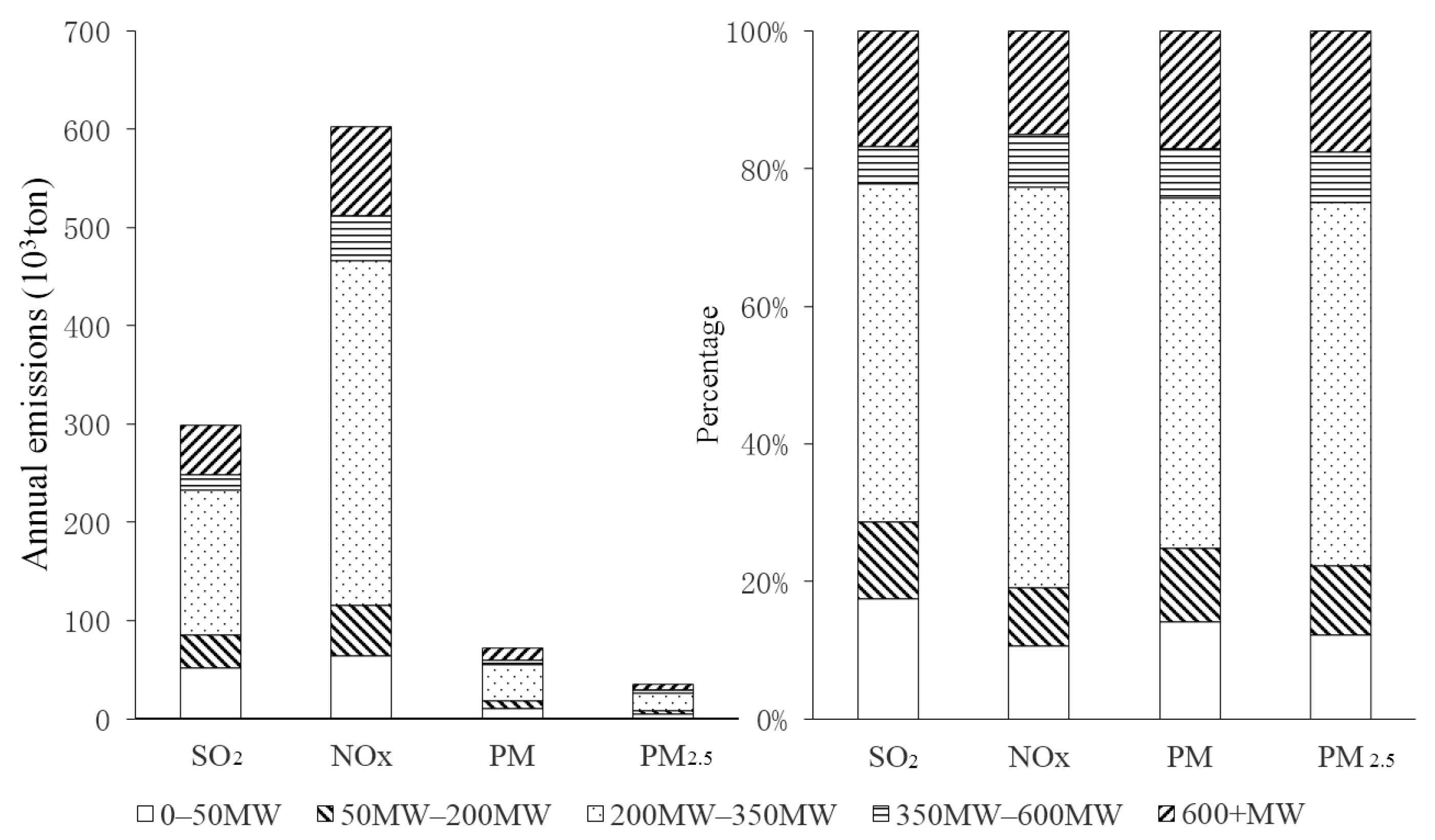

3.1. Production Scale and Emissions Data

3.2. Unit Classification

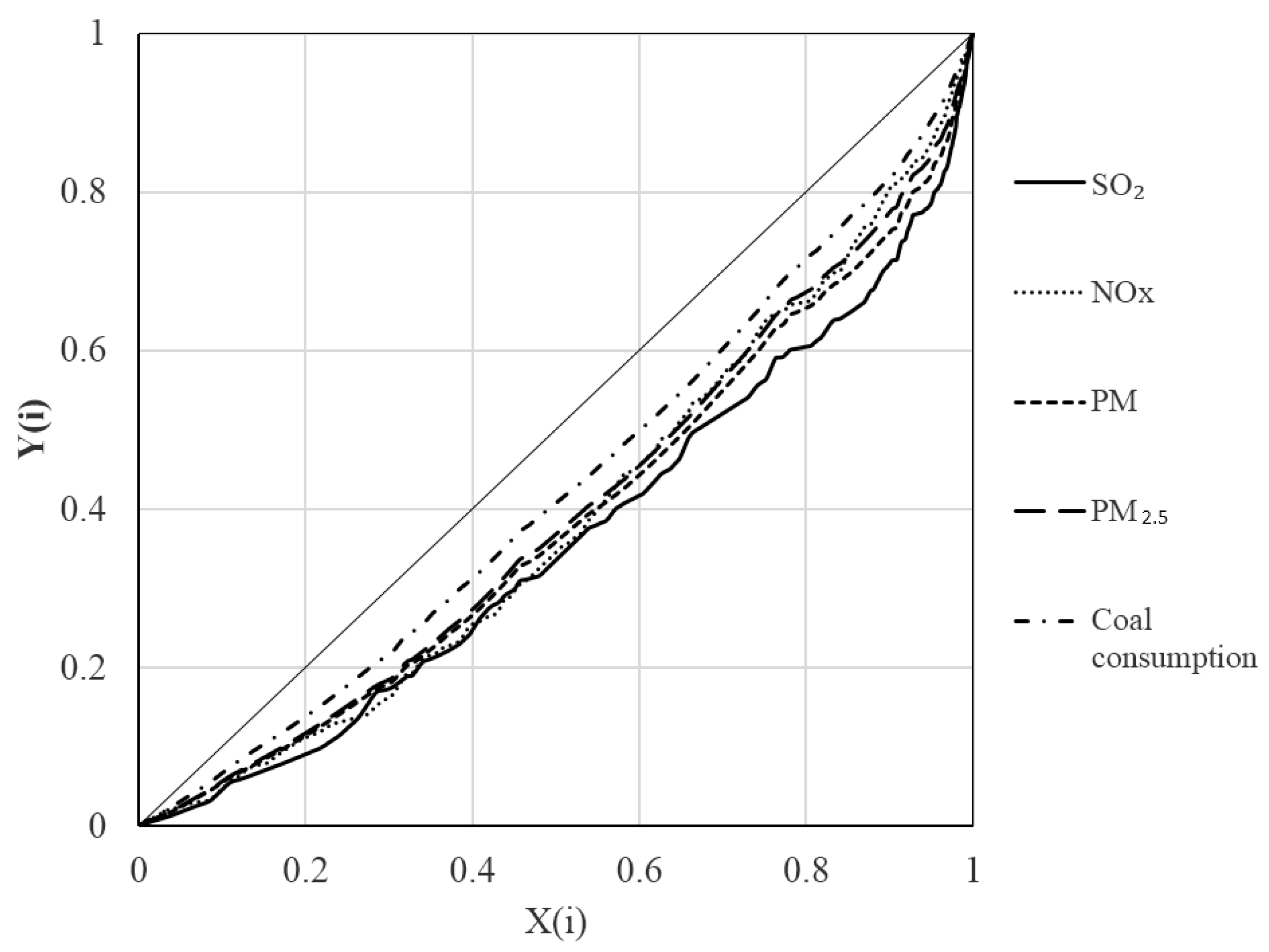

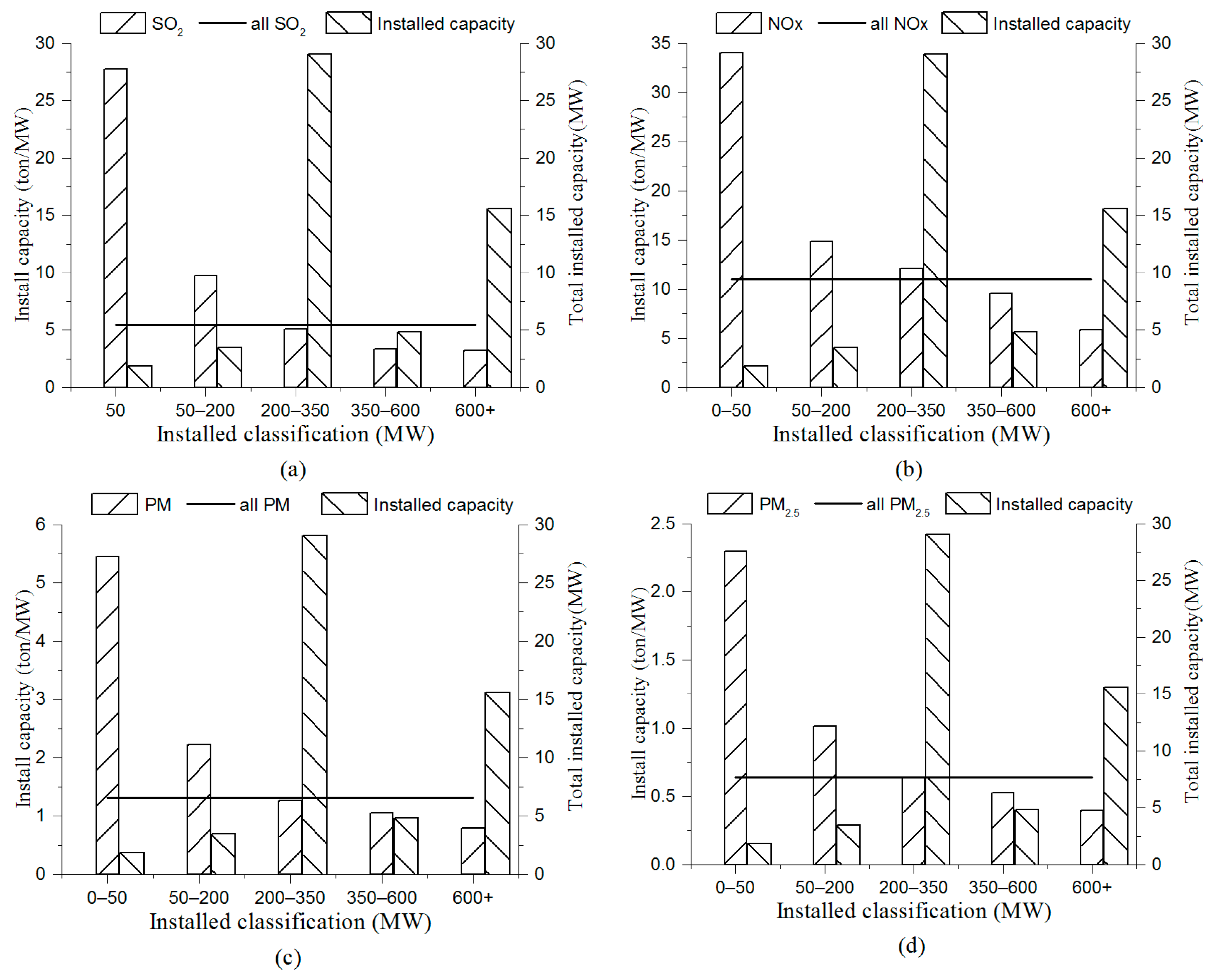

3.3. Emission Characteristics

3.4. Installed Efficiency

3.5. Energy Conservation and Emissions Reduction Scenario

- (1)

- All <50 MW units were shut down.

- (2)

- The 50–200 MW units met special emission standards (with emission concentrations no greater than 50 (SO2), 100 (NOx), and 20 (PM) mg/m3), with a standard coal consumption for power generation that was no greater than 293 g/kWh.

- (3)

- The 200–350 MW thermal power units met ultra-low emission standards (with emission concentrations no greater than 35 (SO2), 50 (NOx), and 10 (PM) mg/m3), with a standard coal consumption for power generation that was no greater than 293 g/kWh.

- (4)

- The existing 350–600 MW and 600+ MW thermal power units met ultra-low emission standards (as given in item 3), with a standard coal consumption for power generation no greater than 293 and 284 g/kWh when installed capacity was increased by 5% and 10%, respectively. The newly installed units met ultra-low emission standards and the standard coal consumption for power generation by the new thermal power units was no greater than 287 and 270 g/kWh, respectively.

- (1)

- Shutting down the 0–50 MW thermal power units reduced the installed capacity, power generation, and coal consumption by 3.4%, 3.7%, and 8.3%, respectively; the total emissions were reduced by 17.4% (SO2), 10.6% (NOx), 14.2% (PM) and 12.3% (PM2.5).

- (2)

- For the 50–200 MW units, the EE scenario with constant installed capacity and power generation reduced coal consumption by 0.9%; the total emissions by 8.6% (SO2), 5.8% (NOx), 5.9% (PM), and 5.1% (PM2.5).

- (3)

- For the 200–350 MW units, the EE scenario with constant installed capacity and power generation reduced coal consumption by 1.9%; the total emissions were reduced by 38.1% (SO2), 50.4% (NOx), 24.7% (PM), and 25.9% (PM2.5).

- (4)

- For the 350–600 MW units, the EE scenario increased the installed capacity, power generation, and coal consumption by 0.4%, 0.4%, and 0.4%, respectively; the total emissions were reduced by 3.6% (SO2), 6.4% (NOx), 5.0% (PM), and 5.1% (PM2.5).

- (5)

- For the 600+ MW units, the EE scenario increased the installed capacity, power generation, and coal consumption by 2.8%, 2.8%, and 2.1%, respectively; the total emissions were reduced by 12.1% (SO2), 11.7% (NOx), 11.1% (PM), and 11.4% (PM2.5).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Energy Information Administration. International Energy Outlook 2017. Available online: http://cn.knoema.com/EIAIEO2017/international-energy-outlook-2017 (accessed on 16 February 2019).

- Jin, Q.; Fang, X.; Wen, B.; Shan, A. Spatio-temporal variations of PM2.5 emissions in china from 2005 to 2014. Chemosphere 2017, 183, 429–436. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Bing, Z. Air pollution and healthcare expenditure: Implication for the benefit of air pollution control in China. Environ. Int. 2018, 120, 443–455. [Google Scholar] [CrossRef]

- Liu, W.; Xu, Z.; Yang, T. Health Effects of Air Pollution in China. Int. J. Environ. Res. Pub. Health 2018, 15, 1471. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.; Andersson, H.; Zhang, S.; Tian, W.L.; Zhang, Q.Y.; Jiao, L. Air Pollution Control Policies in China: A Retrospective and Prospects. Int. J. Environ. Res. Pub. Health 2016, 13, 1219. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Sun, G.; Wang, X.; Tian, W.L.; Zhang, Q.Y.; Jiao, L. Vehicle exhausts emission characteristics and contributions in Hangzhou district. China Environ. Sci. 2013, 33, 1684–1689. (In Chinese) [Google Scholar]

- Shen, J.; Zheng, C.; Yang, L.; Xu, L.; Zhang, Y.; Liu, S.; Gao, X. Atmospheric emission inventory of SO3 from coal-fired power plants in China in the period 2009–2014. Atmos. Environ. 2019, 197, 14–21. [Google Scholar] [CrossRef]

- Liang, X.; Chen, X.; Zhang, J.; Shi, T.; Sun, X.; Fan, L.; Ye, D. Reactivity-based industrial volatile organic compounds emission inventory and its implications for ozone control strategies in China. Atmos. Environ. 2017, 162, 115–126. [Google Scholar] [CrossRef]

- Gao, C.; Gao, W.; Song, K.; Na, H.; Tian, F.; Zhang, S. Spatial and temporal dynamics of air-pollutant emission inventory of steel industry in China: A bottom-up approach. Resour. Conserv. Recycl. 2019, 143, 184–200. [Google Scholar] [CrossRef]

- Chen, L.; Li, L.; Yang, X.; Zhang, Y.; Chen, L.; Ma, X. Assessing the Impact of Land-Use Planning on the Atmospheric Environment through Predicting the Spatial Variability of Airborne Pollutants. Int. J. Environ. Res. Pub. Health 2019, 16, 172. [Google Scholar] [CrossRef] [PubMed]

- Gastwirth, J.L. A general definition of the Lorenz curve. Econometrica 1971, 39, 1037–1039. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H. Spatial analysis on China’s regional air pollutants and CO2, emissions: Emission pattern and regional disparity. Atmos. Environ. 2014, 92, 280–291. [Google Scholar] [CrossRef]

- Dong, L.; Liang, H.; Luo, X.; Ren, J.; Zhang, N.; Gao, Z.; Dou, Y. Balancing regional industrial development: Analysis on regional disparity of China’s industrial emissions and policy implications. J. Clean. Prod. 2016, 126, 223–235. [Google Scholar] [CrossRef]

- Saha, D.; Kemanian, A.R.; Montes, F.; Gall, H.; Adler, P.R.; Rau, B.M. Lorenz curve and gini coefficient reveal hot spots and hot moments for nitrous oxide emissions. J. Geophys. Res. 2018, 123, 193–206. [Google Scholar] [CrossRef]

- Kingsy, G.R.; Manimegalai, R.; Geetha, D.M.; Rajathi, S.; Usha, K.; Raabiathul, B.N. Air pollution analysis using enhanced K-Means clustering algorithm for real time sensor data. In Proceedings of the 2016 IEEE Region 10 Conference, Singapore, 22–25 November 2016; pp. 1945–1949. [Google Scholar]

- Keller, J.P.; Drton, M.; Larson, T.; Kaufman, J.D.; Sandler, D.P.; Szpiro, A.A. Covariate-adaptive clustering of exposures for air pollution epidemiology cohorts. Ann. Appl. Stat. 2017, 11, 93–113. [Google Scholar] [CrossRef] [PubMed]

- Min, K.D.; Kwon, H.J.; Kim, K.; Kim, S.Y. Air Pollution Monitoring Design for Application in a Densely Populated City. Int. J. Environ. Res. Public Health 2017, 14, 686. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Ecology and Environmental of the People’s Republic of China. Annual Statistic Report on Environment in China, 2014; China Environmental Press: Beijing, China, 2014; pp. 77–82.

- Huang, R.J.; Zhang, Y.; Bozzetti, C.; Ho, K.F.; Cao, J.J.; Han, Y.; Zotter, P. High secondary aerosol contribution to particulate pollution during haze events in china. Nature 2014, 514, 218–222. [Google Scholar] [CrossRef] [PubMed]

- Ministry of Ecology and Environmental of the People’s Republic of China. China Environmental Status Bulletin. 2013. Available online: http://www.mee.gov.cn/hjzl/zghjzkgb/lnzghjzkgb/201605/P020160526564151497131.pdf (accessed on 16 February 2019).

- China Electricity Council. Annual Development Report of Electric Power Industry in China, 2014. Guangming; Daily News Agency: Beijing, China, 2014; pp. 12–14. [Google Scholar]

- Xin, B.; Wang, G.; Wen, R.; He, Y.; Ding, F.; Wu, Z.; Meng, F. Air pollution effect of the thermal power plants in Beijing-Tianjin-Hebei region. China Environ. Sci. 2015, 35, 364–373. (In Chinese) [Google Scholar]

- Beijing Municipal Environmental Protection Bureau. Beijing Environmental Statement. 2013. Available online: http://www.bjepb.gov.cn/bjhrb/resource/cms/2018/04/2018042409561997085.pdf (accessed on 16 February 2019).

- Tianjin Ecology and Environment Bureau. Tianjin Environmental Statement. 2013. Available online: http://hjbh.tj.gov.cn/env/env-quality/the-state-of-the-environment-bulletin/tianjin/201410/t20141024–2196.html (accessed on 16 February 2019).

- Hebei Provincial Department of Ecology and Environment. Hebei Environmental Statement. 2013. Available online: http://www.hebhb.gov.cn/hjzlzkgb/201406/P020140606552933555911.pdf (accessed on 16 February 2019).

- Emission Standards of Air Pollutants for Thermal Power Plants GB 13223–2011; China Environmental Press: Beijing, China, 2011.

- Ministry of Ecology and Environmental of the People’s Republic of China. Announcement on the Implementation of Special Emission Limits for Air Pollutants. 2013. Available online: http://dqhj.mee.gov.cn/zcfg/201303/t20130305–343569.shtml (accessed on 16 February 2019).

- National Development and Reform Commission. Action Plan for Energy Saving, Emission Reduction, Upgrading Coal-Fired Power Plants (2014–2020). 2014. Available online: http://bgt.ndrc.gov.cn/zcfb/201409/t20140919–626242.html (accessed on 16 February 2019).

- Ministry of Ecology and Environmental of the People’s Republic of China. Air Pollution Control Work Program in Jing-Jin-Ji Region and Surrounding Areas for 2017. 2017. Available online: http://dqhj.mep.gov.cn/dtxx/201703/t20170323–408663.shtml (accessed on 16 February 2019).

- Wu, J.; Zhou, C.; Xu, H.; Huang, R.; Mo, H.; Zhu, J.; Zhang, Q. Study on spatial-temporal variabilities of air pollution emission from coal-fired power generation industry in Beijing-Tianjing-Hebei region. Environ. Eng. 2017, 8, 141–145. (In Chinese) [Google Scholar]

| Information Category | Specific Description |

|---|---|

| Geographic location | City, province and longitude, latitude (°/′/′′) |

| Unit information | Unit number, installation thermal capacity, boiler tonnage, construction conditions, construction property, and power generation hours |

| Coal consumption construction | Standard coal consumption for power generation, coal consumption, coal quality information (ash content, sulfur content, nitrogen content, mercury content, coal source, and calorific value) |

| Flue gas emissions | Flue gas volume, SO2 concentration, SO2 emission rate, NOx concentration, NOx emission rate, PM concentration, and PM emission rate |

| Pollutant control | Treatment process, treatment efficiency, emission concentration, and emission load |

| Chimney parameters | Height, outlet diameter, outlet temperature, flow rate, and emission pattern |

| Installed Capacity | Coal Consumption (103 ton/MW) | SO2 (ton/MW) | NOx (ton/MW) | PM (ton/MW) | PM2.5 (ton/MW) | Cluster |

|---|---|---|---|---|---|---|

| 0–50 | 0.87 | 27.76 | 34.04 | 5.45 | 2.3 | 1 |

| 50–100 | 0.58 | 10.3 | 15.07 | 2.63 | 1.18 | 2 |

| 100–150 | 0.54 | 9.92 | 13.1 | 1.78 | 0.87 | 2 |

| 150–200 | 0.53 | 10.05 | 14.69 | 2.45 | 1.06 | 2 |

| 200–250 | 0.46 | 4.94 | 13.8 | 1.16 | 0.6 | 5 |

| 250–300 | 0.4 | 4.84 | 12.33 | 1.17 | 0.62 | 5 |

| 300–350 | 0.36 | 5.13 | 11.82 | 1.29 | 0.65 | 5 |

| 350–400 | 0.31 | 3.58 | 11.71 | 1.05 | 0.53 | 4 |

| 400–450 * | - | - | - | - | - | - |

| 450–500 * | - | - | - | - | - | - |

| 500–550 | 0.35 | 2.93 | 12.08 | 1.05 | 0.52 | 4 |

| 550–600 * | - | - | - | - | - | - |

| 600–650 | 0.27 | 3.54 | 6 | 0.83 | 0.42 | 3 |

| 650–700 | 0.26 | 3.18 | 5.28 | 0.81 | 0.4 | 3 |

| 1000+ | 0.21 | 1.71 | 6.09 | 0.57 | 0.29 | 3 |

| Installed Classification (MW) | Scenario | Number of Installed Units | Installed Capacity (MW) | Power Generation (106 MWh) | Coal Consumption (106 ton/a) | SO2 (103 ton/a) | NOx (103 ton/a) | PM (103 ton/a) | PM2.5 (103 ton/a) |

|---|---|---|---|---|---|---|---|---|---|

| 0–50 | BAU | 156 | 1875.5 | 12.2 | 16.4 | 52.1 | 63.8 | 10.2 | 4.3 |

| EE | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50–200 | BAU | 41 | 3453.0 | 21.6 | 19.0 | 33.6 | 51.3 | 7.7 | 3.5 |

| EE | 41 | 3453.0 | 21.6 | 17.2 | 7.9 | 16.3 | 3.4 | 1.7 | |

| 200–350 | BAU | 105 | 29,082.0 | 174.3 | 105.0 | 146.8 | 351.3 | 36.7 | 18.6 |

| EE | 105 | 29,082.0 | 174.3 | 101.2 | 33.1 | 47.3 | 18.9 | 9.5 | |

| 350–600 | BAU | 12 | 4830.0 | 27.9 | 15.7 | 16.0 | 46.1 | 5.1 | 2.5 |

| EE | 12 | 5071.5 | 29.3 | 16.5 | 5.2 | 7.4 | 1.5 | 0.7 | |

| 600+ | BAU | 24 | 15,560.0 | 94.0 | 40.3 | 50.0 | 90.7 | 12.4 | 6.2 |

| EE | 25 | 17,116.0 | 103.4 | 44.3 | 14.0 | 19.9 | 4.3 | 2.2 |

| Scenario Comparison | Installed Capacity (MW) | Power Generation (106 MWh) | Coal Consumption (106 ton/a) | SO2 (103 ton/a) | NOx (103 ton/a) | PM (103 ton/a) | PM2.5 (103 ton/a) |

|---|---|---|---|---|---|---|---|

| BAU | 54,800.5 | 330.1 | 196.4 | 298.4 | 603.2 | 72.0 | 35.1 |

| EE | 54,722.5 | 328.7 | 179.3 | 60.2 | 90.9 | 28.1 | 14.1 |

| Ratio | −0.1% | −0.4% | −8.7% | −79.8% | −84.9% | −60.9% | −59.9% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wu, J.; Zhou, C.; Zhang, Q. Installation Planning in Regional Thermal Power Industry for Emissions Reduction Based on an Emissions Inventory. Int. J. Environ. Res. Public Health 2019, 16, 938. https://doi.org/10.3390/ijerph16060938

Zhang Y, Wu J, Zhou C, Zhang Q. Installation Planning in Regional Thermal Power Industry for Emissions Reduction Based on an Emissions Inventory. International Journal of Environmental Research and Public Health. 2019; 16(6):938. https://doi.org/10.3390/ijerph16060938

Chicago/Turabian StyleZhang, Yu, Jiayu Wu, Chunyao Zhou, and Qingyu Zhang. 2019. "Installation Planning in Regional Thermal Power Industry for Emissions Reduction Based on an Emissions Inventory" International Journal of Environmental Research and Public Health 16, no. 6: 938. https://doi.org/10.3390/ijerph16060938

APA StyleZhang, Y., Wu, J., Zhou, C., & Zhang, Q. (2019). Installation Planning in Regional Thermal Power Industry for Emissions Reduction Based on an Emissions Inventory. International Journal of Environmental Research and Public Health, 16(6), 938. https://doi.org/10.3390/ijerph16060938