Antimicrobial Air Filters Using Natural Sea Salt Particles for Deactivating Airborne Bacterial Particles

Abstract

:1. Introduction

2. Methods

2.1. Preparation of Ethanolic NSS Solution for Aerosol Process

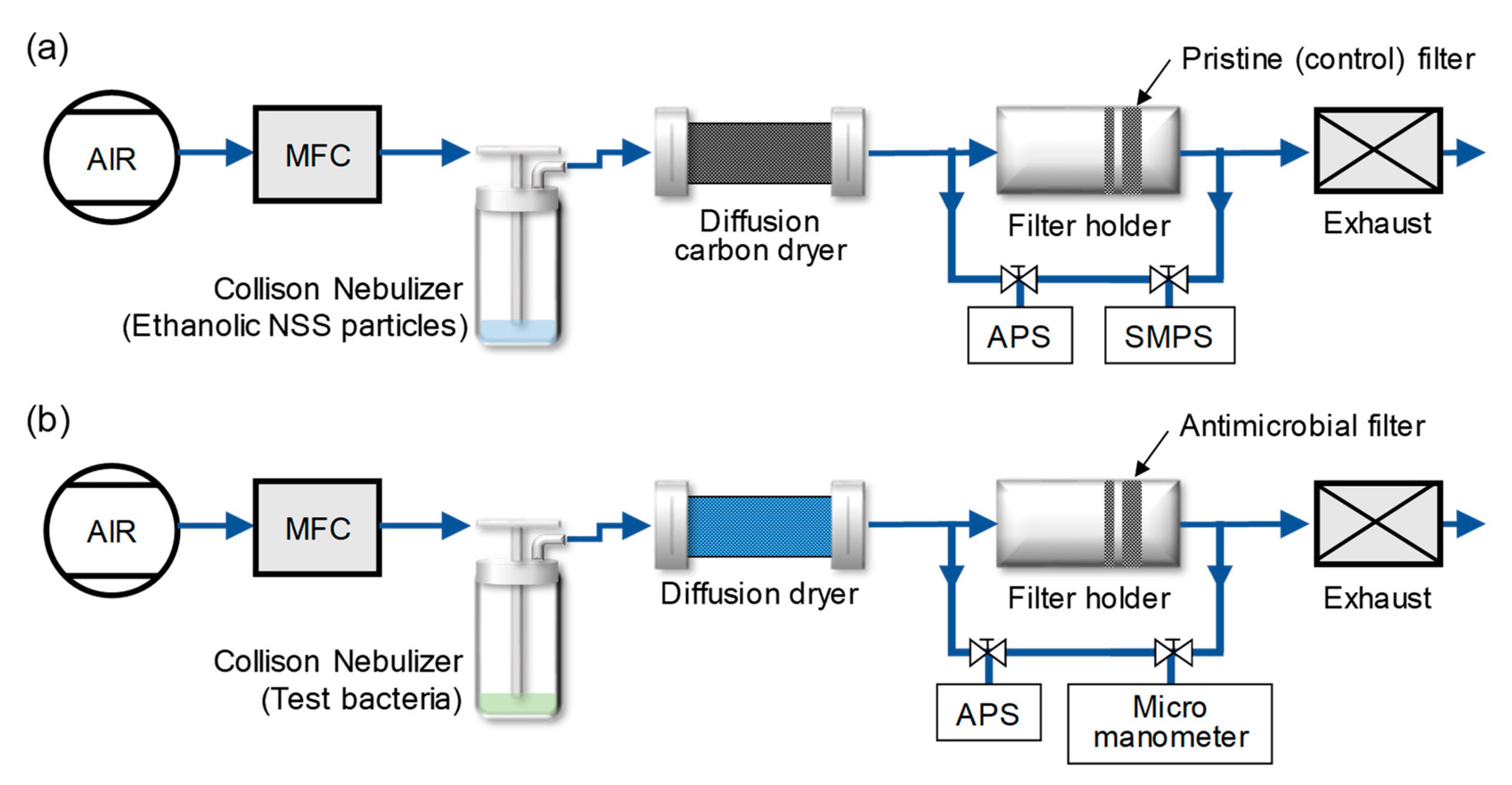

2.2. Preparation of Antimicrobial Air Filters

2.3. Preparation of Tested Bacterial Bioaerosols

2.4. Filtration Tests

2.5. Antimicrobial Tests

2.6. Statistical Analyses

3. Results and Discussion

3.1. Characteristics of Aerosolized NSS Particles

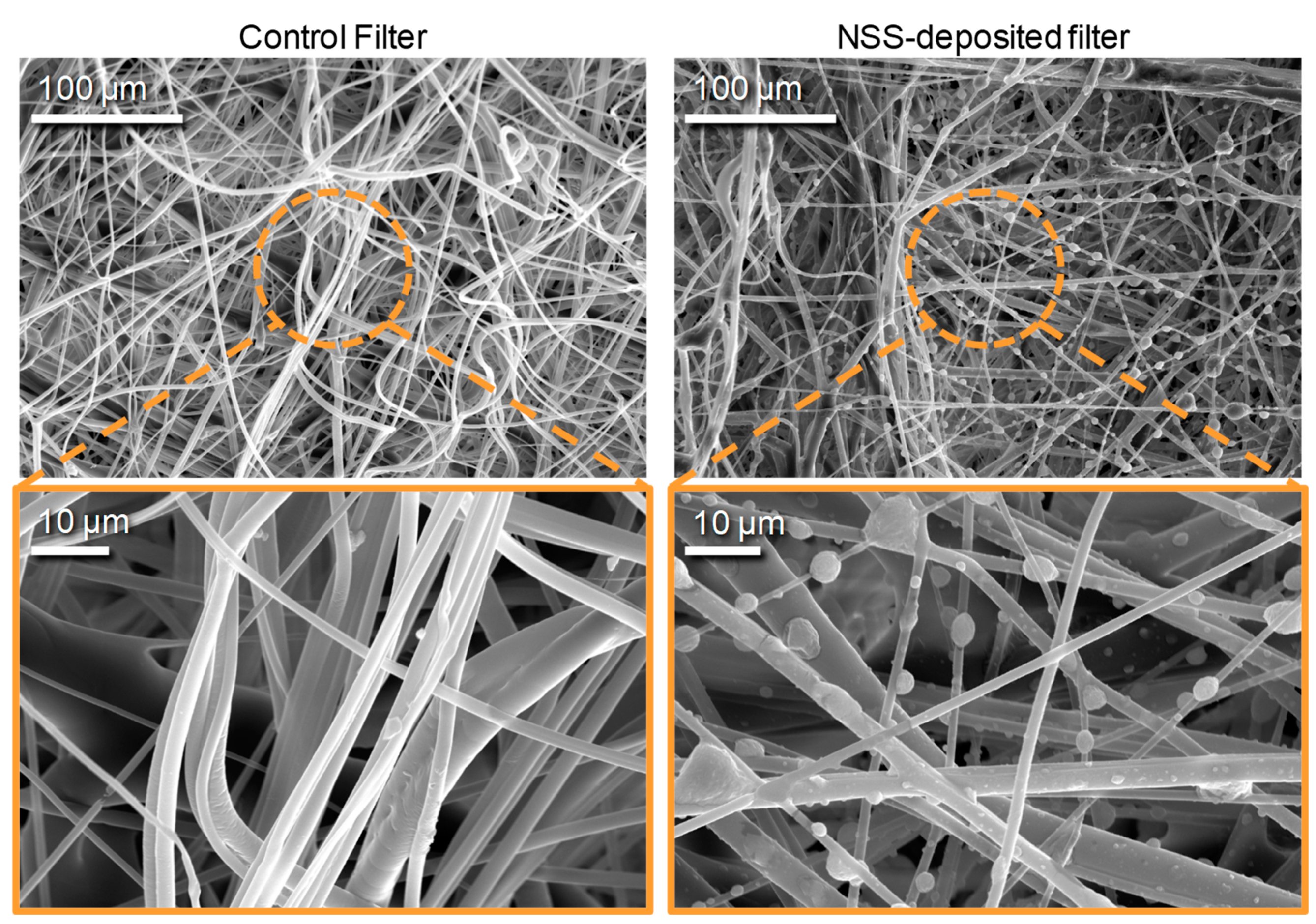

3.2. Preparation of Filters Coated by NSS Particles

3.3. Filtration Test of NSS-Deposited Filters Using Bacterial Aerosols

3.4. Antimicrobial Tests of NSS-Deposited Filters Using Bacterial Aerosols

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Douwes, J.; Thorne, P.; Pearce, N.; Heederik, D. Bioaerosol health effects and exposure assessment: Progress and prospects. Ann. Occup. Hyg. 2003, 47, 187–200. [Google Scholar] [PubMed] [Green Version]

- Hinds, W.C. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles; John Wiley Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Lee, B.U. Life comes from the air: A short review on bioaerosol control. Aerosol Air Qual. Res. 2011, 11, 921–927. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Environment, Republic of Korea. 2019. Available online: http://www.me.go.kr (accessed on 20 December 2019).

- Awad, A.H.A.; Farag, S.A. An indoor bio-contaminants air quality. Int. J. Environ. Health Res. 1999, 9, 313–319. [Google Scholar] [CrossRef]

- Indoor Air Quality Association (IAQA). Indoor Air Quality Standard 95-1 Recommended for Florida; Indoor Air Quality Association: Mt Laurel, NJ, USA, 1995. [Google Scholar]

- World Health Organization. Indoor Air Quality: Biological Contaminants: Report on a WHO Meeting, Rautavaara, 29 August–2 September 1988; World Health Organization, Regional Office for Europe: Copenhagen, Denmark, 1990. [Google Scholar]

- Kim, K.H.; Kabir, E.; Jahan, S.A. Airborne bioaerosols and their impact on human health. J. Environ. Sci. 2018, 67, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Nazaroff, W.W. Indoor bioaerosol dynamics. Indoor Air 2016, 26, 61–78. [Google Scholar] [CrossRef] [PubMed]

- Peccia, J.; Milton, D.K.; Reponen, T.; Hill, A.J. A role for environmental engineering and science in preventing bioaerosol-related disease. Environ. Sci. Technol. 2008, 42, 4631–4637. [Google Scholar] [CrossRef]

- Grinshpun, S.A.; Adhikari, A.; Li, C.; Reponen, T.; Yermakov, M.; Schoenitz, M.; Dreizin, E.; Trunov., M.; Mohan, S. Thermal inactivation of airborne viable Bacillus subtilis spores by short-term exposure in axially heated air flow. J. Aerosol Sci. 2010, 41, 352–363. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lee, B.U. Inactivation of airborne E. coli and B. subtilis bioaerosols utilizing thermal energy. J. Microbiol. Biotechnol. 2006, 16, 1684–1689. [Google Scholar]

- Brickner, P.W.; Vincent, R.L.; First, M.; Nardell, E.; Murray, M.; Kaufman, W. The application of ultraviolet germicidal irradiation to control transmission of airborne disease: Bioterrorism countermeasure. Public Health Rep. 2003, 118, 99. [Google Scholar] [CrossRef]

- Xu, P.; Peccia, J.; Fabian, P.; Martyny, J.W.; Fennelly, K.P.; Hernandez, M.; Miller, S.L. Efficacy of ultraviolet germicidal irradiation of upper-room air in inactivating airborne bacterial spores and mycobacteria in full-scale studies. Atmos. Environ. 2003, 36, 405–419. [Google Scholar] [CrossRef]

- Huang, R.; Agranovski, I.; Pyankov, O.; Grinshpun, S. Removal of viable bioaerosol particles with a low-efficiency HVAC filter enhanced by continuous emission of unipolar air ions. Indoor Air 2008, 18, 106–112. [Google Scholar] [CrossRef] [PubMed]

- Fisk, W.J. Health benefits of particle filtration. Indoor Air 2013, 23, 357–368. [Google Scholar] [CrossRef] [PubMed]

- Kulmala, M.; Asmi, A.; Pirjola, L. Indoor air aerosol model: The effect of outdoor air, filtration and ventilation on indoor concentrations. Atmos. Environ. 1999, 33, 2133–2144. [Google Scholar] [CrossRef]

- Simmons, R.B.; Crow, S.A. Fungal colonization of air filters for use in heating, ventilating, and air conditioning (HVAC) systems. J. Ind. Microbiol. 1995, 14, 41–45. [Google Scholar] [CrossRef]

- Jeong, S.B.; Ko, H.S.; Seo, S.C.; Jung, J.H. Evaluation of filtration characteristics and microbial recovery rates of commercial filtering facepiece respirators against airborne bacterial particles. Sci. Total Environ. 2019, 682, 729–736. [Google Scholar] [CrossRef]

- Majchrzycka, K.; Okrasa, M.; Skóra, J.; Gutarowska, B. Evaluation of the survivability of microorganisms deposited on filtering respiratory protective devices under varying conditions of humidity. Int. J. Environ. Res. Public Health. 2016, 13, 98. [Google Scholar] [CrossRef] [Green Version]

- Chuaybamroong, P.; Chotigawin, R.; Supothina, S.; Sribenjalux, P.; Larpkiattaworn, S.; Wu, C.Y. Efficacy of photocatalytic HEPA filter on microorganism removal. Indoor Air 2010, 20, 246–254. [Google Scholar] [CrossRef]

- Zacarías, S.M.; Satuf, M.L.; Vaccari, M.C.; Alfano, O.M. Efficiency evaluation of different TiO2 coatings on the photocatalytic inactivation of airborne bacterial spores. Ind. Eng. Chem. Res. 2012, 51, 13599–13608. [Google Scholar] [CrossRef]

- Li, P.; Li, J.; Feng, X.; Li, J.; Hao, Y.; Zhang, J.; Wang, H.; Yin, A.; Zhou, J.; Ma, X.; et al. Metal-organic frameworks with photocatalytic bactericidal activity for integrated air cleaning. Nat. Commun. 2019, 10, 2177. [Google Scholar] [CrossRef]

- Jeong, S.B. A Study on Antimicrobial Air Filter Using Natural Product and Enhancing the Antimicrobial Activity via Electrospray System. Master’s Thesis, Konkuk University, Gwangjin-gu, Seoul, 2018. [Google Scholar]

- Ma, C.; White, J.C.; Dhankher, O.P.; Xing, B. Metal-based nanotoxicity and detoxification pathways in higher plants. Environ. Sci. Technol. 2015, 49, 7109–7122. [Google Scholar] [CrossRef]

- Panyala, N.R.; Peña-Méndez, E.M.; Havel, J. Silver or silver nanoparticles: A hazardous threat to the environment and human health? J. Appl. Biomed. 2008, 6, 117–129. [Google Scholar] [CrossRef] [Green Version]

- Pulskamp, K.; Diabaté, S.; Krug, H.F. Carbon nanotubes show no sign of acute toxicity but induce intracellular reactive oxygen species in dependence on contaminants. Toxicol. Lett. 2007, 168, 58–74. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Pyankov, O.V.; Yu, B.; Agranovski, I.E. Inactivation of fungal spores collected on fibrous filters by Melaleuca alternifolia (tea tree oil). Aerosol Sci. Technol. 2010, 44, 262–268. [Google Scholar] [CrossRef]

- Hwang, G.B.; Heo, K.J.; Yun, J.H.; Lee, J.E.; Lee, H.J.; Nho, C.W.; Bae, G.N.; Jung, J.H. Antimicrobial air filters using natural Euscaphis japonica nanoparticles. PLoS ONE 2015, 10, e0126481. [Google Scholar] [CrossRef]

- Jung, J.H.; Hwang, G.B.; Park, S.Y.; Lee, J.E.; Nho, C.W.; Lee, B.U.; Bae, G.N. Antimicrobial air filtration using airborne Sophora flavescens natural-product nanoparticles. Aerosol Sci. Technol. 2011, 45, 1510–1518. [Google Scholar] [CrossRef] [Green Version]

- Woo, C.G.; Kang, J.S.; Kim, H.J.; Kim, Y.J.; Han, B. Treatment of air filters using the antimicrobial natural products propolis and grapefruit seed extract for deactivation of bioaerosols. Aerosol Sci. Technol. 2015, 49, 611–619. [Google Scholar] [CrossRef] [Green Version]

- Han, G.J.; Son, A.; Lee, S.M.; Jung, J.K.; Kim, S.H.; Park, K.Y. Improved quality and increased in vitro anticancer effect of Kimchi by using natural sea salt without bittern and baked (Guwun) salt. J. Korean Soc. Food Sci. Nutr. 2009, 38, 996–1002. [Google Scholar] [CrossRef]

- Gutierrez, C.; Abee, T.; Booth, I.R. Physiology of the osmotic stress response in microorganisms. Int. J. Food Microbiol. 1995, 28, 233–244. [Google Scholar] [CrossRef]

- Wijnker, J.J.; Koop, G.; Lipman, L.J.A. Antimicrobial properties of salt (NaCl) used for the preservation of natural casings. Food Microbiol. 2006, 23, 657–662. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, S.J.; Kim, S.H.; Kim, B.H.; Kang, S.G.; Nam, S.H.; Jung, S.T. Determination of mineral and heavy metal contents of various salts. Korean J. Food Sci. Technol. 2000, 32, 1442–1445. [Google Scholar]

- Shin, T.S.; Park, C.K.; Lee, S.H.; Han, K.H. Effects of age on chemical composition in sun-dried salts. Korean J. Food Sci. Technol. 2005, 37, 312–317. [Google Scholar]

- Han, B.; Kang, J.S.; Kim, H.J.; Woo, C.G.; Kim, Y.J. Investigation of antimicrobial activity of grapefruit seed extract and its application to air filters with comparison to propolis and shiitake. Aerosol Air Qual. Res. 2015, 15, 1035–1044. [Google Scholar] [CrossRef] [Green Version]

- Jung, J.H.; Hwang, G.B.; Lee, J.E.; Bae, G.N. Preparation of airborne Ag/CNT hybrid nanoparticles using an aerosol process and their application to antimicrobial air filtration. Langmuir 2011, 27, 10256–10264. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Jung, J.H.; Lee, B.U. Effect of Treatment with a Natural Extract of Mukdenia Rossii (Oliv) Koidz and Unipolar Ion Emission on the Antibacterial Performance of Air Filters. Aerosol Air Qual. Res. 2013, 13, 771–776. [Google Scholar] [CrossRef] [Green Version]

- Burton, N.C.; Grinshpun, S.A.; Reponen, T. Physical collection efficiency of filter materials for bacteria and viruses. Ann. Occup. Hyg. 2006, 51, 143–151. [Google Scholar]

- Podgórski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Thomas, D.; Penicot, P.; Contal, P.; Leclerc, D.; Vendel, J. Clogging of fibrous filters by solid aerosol particles experimental and modelling study. Chem. Eng. Sci. 2001, 56, 3549–3561. [Google Scholar] [CrossRef]

- Papo, N.; Shai, Y. A molecular mechanism for lipopolysaccharide protection of Gram-negative bacteria from antimicrobial peptides. J. Biol. Chem. 2005, 280, 10378–10387. [Google Scholar] [CrossRef] [Green Version]

- Baldwin, R.L. How Hofmeister ion interactions affect protein stability. Biophys. J. 1996, 71, 2056–2063. [Google Scholar] [CrossRef] [Green Version]

- Quan, F.S.; Rubino, I.; Lee, S.H.; Koch, B.; Choi, H.J. Universal and reusable virus deactivation system for respiratory protection. Sci. Rep. 2017, 7, 39956. [Google Scholar] [CrossRef] [Green Version]

| Type of Bacteria | Particle Concentration (×102 Particles/cm3air) | Peak Diameter (μm) | GMD (μm) | GSD |

|---|---|---|---|---|

| Staphylococcus epidermidis | 5.71 ± 0.352 | 0.77 ± 0.01 | 0.78 ± 0.014 | 1.22 ± 0.014 |

| Escherichia coli | 5.88 ± 0.493 | 0.84 ± 0.01 | 0.81 ± 0.007 | 1.18 ± 0.011 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, S.B.; Heo, K.J.; Lee, B.U. Antimicrobial Air Filters Using Natural Sea Salt Particles for Deactivating Airborne Bacterial Particles. Int. J. Environ. Res. Public Health 2020, 17, 190. https://doi.org/10.3390/ijerph17010190

Jeong SB, Heo KJ, Lee BU. Antimicrobial Air Filters Using Natural Sea Salt Particles for Deactivating Airborne Bacterial Particles. International Journal of Environmental Research and Public Health. 2020; 17(1):190. https://doi.org/10.3390/ijerph17010190

Chicago/Turabian StyleJeong, Sang Bin, Ki Joon Heo, and Byung Uk Lee. 2020. "Antimicrobial Air Filters Using Natural Sea Salt Particles for Deactivating Airborne Bacterial Particles" International Journal of Environmental Research and Public Health 17, no. 1: 190. https://doi.org/10.3390/ijerph17010190

APA StyleJeong, S. B., Heo, K. J., & Lee, B. U. (2020). Antimicrobial Air Filters Using Natural Sea Salt Particles for Deactivating Airborne Bacterial Particles. International Journal of Environmental Research and Public Health, 17(1), 190. https://doi.org/10.3390/ijerph17010190