Application of Spatiotemporal Hybrid Model of Deformation in Safety Monitoring of High Arch Dams: A Case Study

Abstract

1. Introduction

- (1)

- Taking Jinping-I arch dam as the object, this paper explores the data representation methods, which are suitable for monitoring deformation spatiotemporal data analysis, analyzes the category and source of monitoring deformation spatiotemporal data pollution, and studies the processing method of data missing [27], so as to improve the data quality.

- (2)

- Combined with the actual working behavior of the dam and dam foundation, aiming at the clear relationship between the water depth and the dam deformation, the finite element method is used to calculate the effect field (such as displacement field and stress field) under the action of water pressure load [28], and the deterministic relationship between the water depth and dam deformation is established. Then, other components are still obtained by a statistical model [29]. The model is optimized and fitted with the measured data to obtain the adjustment parameters so as to establish the dam deformation safety monitoring hybrid prediction model [30,31,32,33,34].

- (3)

- The hybrid model of single measuring point does not consider the relationship among measuring points, which cannot fully reflect the overall situation. Also, there will be too many hybrid models for each measuring point. It is difficult to predict the deformation of dam position without measuring points. Therefore, this paper establishes the deformation spatiotemporal hybrid model [35,36], in which the multiple measuring points in space are used and the spatial coordinate variables of points are introduced. One spatiotemporal hybrid model is used to estimate the deformation of the dam at any position by including the measured values of all typical measuring points.

2. Deformation Data Analysis of Jinping–I Arch Dam

2.1. Deformation Data Representation Methods

- (1)

- Time series representation

- (2)

- Cross-section data representation

- (3)

- Panel data representation

- (4)

- Spatial panel data representation

2.2. Preprocessing of Spatiotemporal Deformation Data

- (1)

- During the dam operation, it is necessary to ensure the instruments maintenance to prevent the loss or error of deformation data. For the key monitoring location, the combination of manual monitoring and instrument monitoring is supposed to be adopted to ensure the authenticity and integrity of the data. For the newly found abnormal deformation location, deformation monitoring instruments is necessary to be added to track the deformation data in time.

- (2)

- In the analysis stage of deformation data, only by fully extracting the influencing factors of dam deformation and establishing a relatively complete and reasonable deformation analysis model can the deformation state of dam be truly reflected to a greater extent.

- (1)

- Neglect method. In general, the real deformation data cannot be recovered completely, the unreasonable estimation of the missing value may lead to errors in the analysis model, so the missing data is neglected and not processed. To some extent, this method is reasonable and common.

- (2)

- Likelihood method. In some specific cases, if it is necessary to study the spatial distribution of cross-section data at a certain time, it is still necessary to estimate the missing data and replace the missing value with the most likely likelihood value at that time.

- (1)

- Interpolation of spatial neighboring points

- (2)

- Space inverse distance weighted interpolation

3. Spatiotemporal Hybrid Security Monitoring Model

3.1. Principle of Hybrid Model

- (1)

- Hydraulic component

- (2)

- Temperature component

- (3)

- Time effect component

3.2. Spatiotemporal Hybrid Model

- (1)

- Calculation principle and formula of each component

- (2)

- Estimation of parameters in the model

4. Case Study

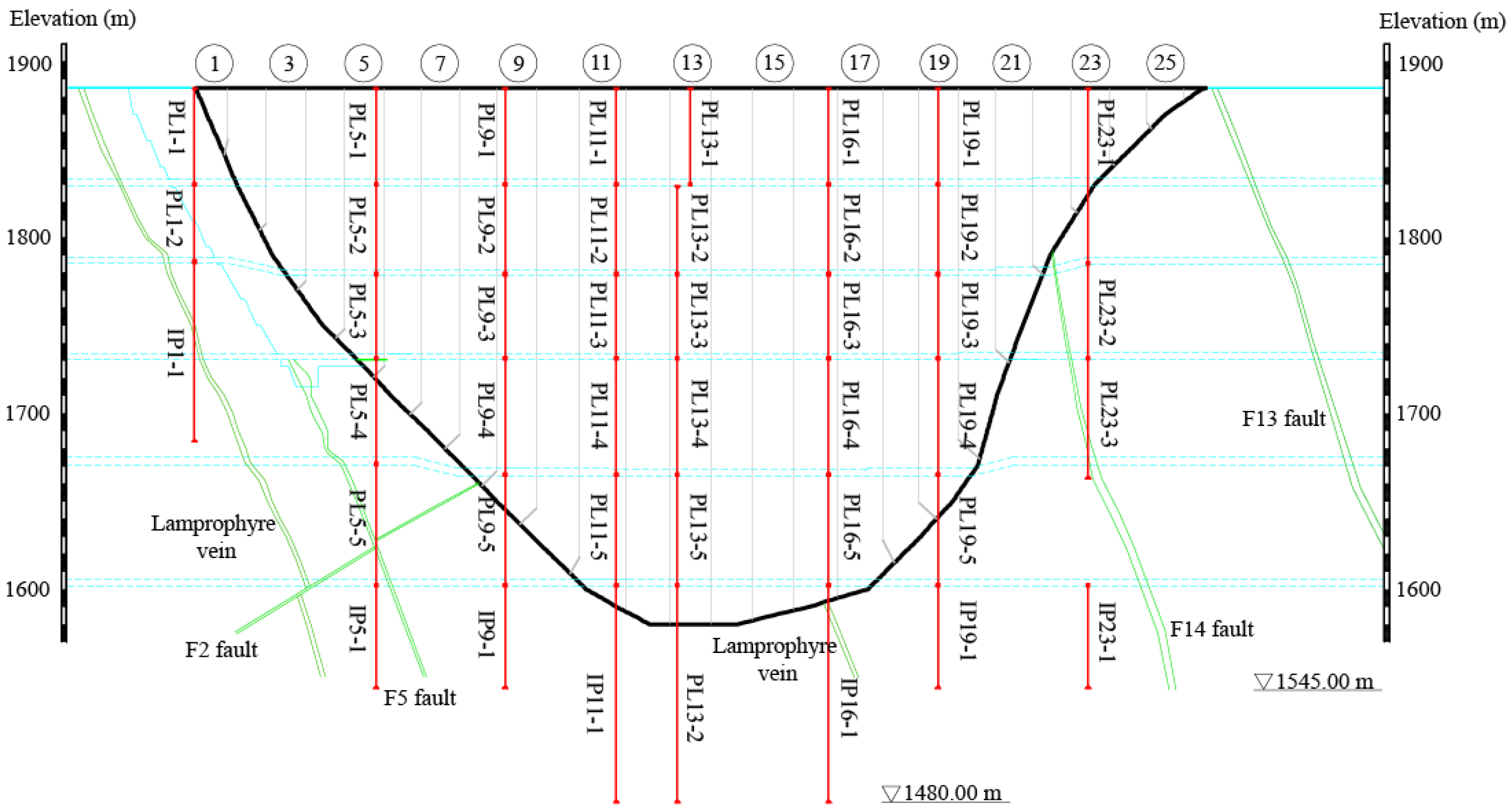

4.1. Project Overview

4.2. Deformation Data Representation

4.3. Hybrid Model Analysis

4.3.1. Finite Element Model of Jinping-I Arch Dam

4.3.2. Calculation Results of the Hybrid Model

4.4. Spatiotemporal Hybrid Model Results

5. Conclusions

- (1)

- This paper studies the representation methods of monitoring deformation data, and analyzes the characteristics of various methods. We should choose the spatial panel data representation if possible, which is more suitable on deformation data analysis. Aiming at data pollution, this paper puts forward the regressions of interpolation of spatial neighboring points and the spatial inverse distance weighted interpolation methods, both of which are applicable. We can choose the methods when the missing data is important;

- (2)

- Combined with the actual working behavior of Jinping-I arch dam, a hybrid model is established. The FEM is used to calculate the displacement field of the dam and its foundation under the action of hydraulic pressure. The statistical model is still used for the other components. The results show that the established hybrid model is feasible with high accuracy. During the dam operation, a hybrid model is necessary to be established to monitor the dam deformation at the measured points.

- (3)

- Considering the lack of space influence in the single measuring point hybrid model, the spatiotemporal hybrid model of radial displacement is established by using multiple measuring points in space and introducing the spatial coordinate variables. The specific spatiotemporal hybrid model includes the measured values of all the typical measuring points of pendulums of the dam body. The spatiotemporal hybrid model is much easier after it is built. The model can be basically applied to the calculation of radial displacement at any position on the dam body. It can be proved that the established model is feasible, accurate, and applicable for the Jinping-I arch dam.

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Alcay, S.; Yigit, C.O.; Inal, C.; Ceylan, A. Analysis of Displacement Response of the Ermenek Dam Monitored by an Integrated Geodetic and Pendulum System. Int. J. Civil Eng. 2018, 16, 1279–1291. [Google Scholar] [CrossRef]

- Ribeiro, L.S.; Wilhelm, V.E.; Faria, E.F.; Correa, J.M.; dos Santos, A.C.P. A comparative analysis of long-term concrete deformation models of a buttress dam. Eng. Struct. 2019, 193, 301–307. [Google Scholar] [CrossRef]

- Fu, X.; Gu, C.; Qin, D. Deformation features of a super-high arch dam structural system. Optik 2017, 130, 681–695. [Google Scholar] [CrossRef]

- Mujahid, M.S.; Sohn, E.K.; Izenberg, J.; Gao, X.; Tulier, M.E.; Lee, M.M.; Yen, I.H. Gentrification and Displacement in the San Francisco Bay Area: A Comparison of Measurement Approaches. Int. J. Environ. Res. Public Health 2019, 16, 2246. [Google Scholar] [CrossRef]

- Kang, F.; Li, J.; Zhao, S.; Wang, Y. Structural health monitoring of concrete dams using long-term air temperature for thermal effect simulation. Eng. Struct. 2019, 180, 642–653. [Google Scholar] [CrossRef]

- Laxman, S.; Sastry, P.S. A survey of temporal data mining. Sadhana-Acad. Proc. Eng. Sci. 2006, 31, 173–198. [Google Scholar] [CrossRef]

- Lin, P.; Zhu, X.; Li, Q.; Liu, H.; Yu, Y. Study on Optimal Grouting Timing for Controlling Uplift Deformation of a Super High Arch Dam. Rock Mech. Rock Eng. 2016, 49, 115–142. [Google Scholar] [CrossRef]

- Li, M.; Shen, Y.; Ren, Q.; Li, H. A new distributed time series evolution prediction model for dam deformation based on constituent elements. Adv. Eng. Inform. 2019, 39, 41–52. [Google Scholar] [CrossRef]

- Croissant, Y.; Millo, G. Panel data econometrics in R: The plum package. J. Stat. Softw. 2008, 27, 1–43. [Google Scholar] [CrossRef]

- Badinger, H.; Egger, P. Fixed Effects and Random Effects Estimation of Higher-order Spatial Autoregressive Models with Spatial Autoregressive and Heteroscedastic Disturbances. Spat. Econ. Anal. 2015, 10, 11–35. [Google Scholar] [CrossRef]

- Lambert, R.S.C.; Lemke, F.; Kucherenko, S.S.; Song, S.; Shah, N. Global sensitivity analysis using sparse high dimensional model representations generated by the group method of data handling. Math. Comput. Simul. 2016, 128, 42–54. [Google Scholar] [CrossRef]

- Lee, L.-F.; Yu, J. Estimation of spatial autoregressive panel data models with fixed effects. J. Econom. 2010, 154, 165–185. [Google Scholar] [CrossRef]

- Saalfeld, B.; Tute, E.; Wolf, K.-H.; Marschollek, M. Introducing a Method for Transformation of Paper-Based Research Data into Concept-Based Representation with openEHR. Stud. Health Technol. Inform. 2017, 235, 151–155. [Google Scholar] [PubMed]

- Zouabi, O.; Peridy, N. Direct and indirect effects of climate on agriculture: An application of a spatial panel data analysis to Tunisia. Clim. Chang. 2015, 133, 301–320. [Google Scholar] [CrossRef]

- Wang, X.; He, S.; Chen, S.; Zhang, Y.; Wang, A.; Luo, J.; Ye, X.; Mo, Z.; Wu, L.; Xu, P.; et al. Spatiotemporal Characteristics and Health Risk Assessment of Heavy Metals in PM2.5 in Zhejiang Province. Int. J. Environ. Res. Public Health 2018, 15, 583. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Pan, P.; Li, L.; Jin, Y. A survey of data mining on spatial-temporal user behavior data for public safety. J. Chongqing Univ. Posts Telecommun. Nat. Sci. Ed. 2018, 30, 40–52. [Google Scholar]

- Wei, B.; Yuan, D.; Xu, Z.; Li, L. Modified hybrid forecast model considering chaotic residual errors for dam deformation. Struct. Control Health Monit. 2018, 25, e2188. [Google Scholar] [CrossRef]

- Chen, B.; Hu, T.; Huang, Z.; Fang, C. A spatio-temporal clustering and diagnosis method for concrete arch dams using deformation monitoring data. Struct. Health Monit. Int. J. 2019, 18, 1355–1371. [Google Scholar] [CrossRef]

- Liu, J.; Yang, J. Action recognition using spatiotemporal features and hybrid generative/discriminative models. J. Electron. Imaging 2012, 21, 023010. [Google Scholar] [CrossRef]

- Rosà, R.; Andreo, V.; Tagliapietra, V.; Baráková, I.; Arnoldi, D.; Hauffe, C.H.; Manica, M.; Rosso, F.; Blaňarová, L.; Bona, M.; et al. Effect of Climate and Land Use on the Spatio-Temporal Variability of Tick-Borne Bacteria in Europe. Int. J. Environ. Res. Public Health 2018, 15, 732. [Google Scholar] [CrossRef]

- Salazar, F.; Moran, R.; Toledo, M.A.; Onate, E. Data-Based Models for the Prediction of Dam Behaviour: A Review and Some Methodological Considerations. Arch. Comput. Methods Eng. 2017, 24, 1–21. [Google Scholar] [CrossRef]

- De Sortis, A.; Paoliani, P. Statistical analysis and structural identification in concrete dam monitoring. Eng. Struct. 2007, 29, 110–120. [Google Scholar] [CrossRef]

- Mata, J.; de Castro, A.T.; da Costa, J.S. Constructing statistical models for arch dam deformation. Struct. Control Health Monit. 2014, 21, 423–437. [Google Scholar] [CrossRef]

- Swanepoel, A.; Barnard, S.; Recknagel, F.; Cao, H. Evaluation of models generated via hybrid evolutionary algorithms for the prediction of Microcystis concentrations in the Vaal Dam, South Africa. Water SA 2016, 42, 243–252. [Google Scholar] [CrossRef][Green Version]

- Tatin, M.; Briffaut, M.; Dufour, F.; Simon, A.; Fabre, J.P. Statistical modelling of thermal displacements for concrete dams: Influence of water temperature profile and dam thickness profile. Eng. Struct. 2018, 165, 63–75. [Google Scholar] [CrossRef]

- Morshedy, A.H.; Torabi, S.A.; Memarian, H. A hybrid fuzzy zoning approach for 3-dimensional exploration geotechnical modeling: A case study at Semilan dam, southern Iran. Bull. Eng. Geol. Environ. 2019, 78, 691–708. [Google Scholar] [CrossRef]

- Wang, W.; Lee, L.-F. Estimation of spatial autoregressive models with randomly missing data in the dependent variable. Econom. J. 2013, 16, 73–102. [Google Scholar] [CrossRef]

- Zheng, D.; Huo, Z.; Li, B. Arch-dam crack deformation monitoring hybrid model based on XFEM. Sci. China-Technol. Sci. 2011, 54, 2611. [Google Scholar] [CrossRef]

- Yigit, C.O.; Alcay, S.; Ceylan, A. Displacement response of a concrete arch dam to seasonal temperature fluctuations and reservoir level rise during the first filling period: Evidence from geodetic data. Geomat. Nat. Hazards Risk 2016, 7, 1489–1505. [Google Scholar] [CrossRef]

- Kahsay, T.N.; Arjoon, D.; Kuik, O.; Brouwer, R.; Tilmant, A.; van der Zaag, P. A hybrid partial and general equilibrium modeling approach to assess the hydro-economic impacts of large dams—The case of the Grand Ethiopian Renaissance Dam in the Eastern Nile River basin. Environ. Model. Softw. 2019, 117, 76–88. [Google Scholar] [CrossRef]

- Kien-Trinh Thi, B.; Dieu Tien, B.; Zou, J.; Chinh Van, D.; Revhaug, I. A novel hybrid artificial intelligent approach based on neural fuzzy inference model and particle swarm optimization for horizontal displacement modeling of hydropower dam. Neural Comput. Appl. 2018, 29, 1495–1506. [Google Scholar]

- Kim, Y.-S.; Kim, B.-T. Prediction of relative crest settlement of concrete-faced rockfill dams analyzed using an artificial neural network model. Comput. Geotech. 2008, 35, 313–322. [Google Scholar] [CrossRef]

- Zhou, L.; Xia, J.; Yu, L.; Wang, Y.; Shi, Y.; Cai, S.; Nie, S. Using a Hybrid Model to Forecast the Prevalence of Schistosomiasis in Humans. Int. J. Environ. Res. Public Health 2016, 13, 355. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wu, P.; Chen, H.; Zhou, L.; Tao, Z. A Hybrid Forecasting Approach to Air Quality Time Series Based on Endpoint Condition and Combined Forecasting Model. Int. J. Environ. Res. Public Health 2018, 15, 1941. [Google Scholar] [CrossRef] [PubMed]

- Nourani, V.; Ejlali, R.G.; Alami, M.T. Spatiotemporal Groundwater Level Forecasting in Coastal Aquifers by Hybrid Artificial Neural Network-Geostatistics Model: A Case Study. Environ. Eng. Sci. 2011, 28, 217–228. [Google Scholar] [CrossRef]

- Tine, M.; Perez, L.; Molowny-Horas, R. Hybrid spatiotemporal simulation of future changes in open wetlands: A study of the Abitibi-Temiscamingue region, Quebec, Canada. Int. J. Appl. Earth Obs. Geoinf. 2019, 74, 302–313. [Google Scholar] [CrossRef]

- Kohler, R.; Zenz, G.; Steyrer, P. Tsankov Kamak dam—Design, construction and impounding. In Proceedings of the 8th ICOLD European Club Symposium, Dam Safety, Innsbruck, Austria, 22–23 September 2010. [Google Scholar]

- Obernhuber, P.; Perner, F. Displacements in concrete dams caused by temperature variation. Int. J. Hydropower Dams 2005, 12, 80–86. [Google Scholar]

- Perner, F.; Obernhuber, P. Analysis of arch dam deformations. In Proceedings of the 8th ICOLD European Club Symposium, Dam Safety, Innsbruck, Austria, 22–23 September 2010. [Google Scholar]

- Marence, A.; Mihaylova, A.; Hristova, J.C. Chacon-Hurtado, Arch dam deformation prediction using computational intelligence techniques. In Proceedings of the 85th Annual Meeting of International Commission on Large Dams (ICOLD), Prague, Czech Republic, 3–7 July 2017. [Google Scholar]

| Time | 1 | 2 | 3 | … | t |

|---|---|---|---|---|---|

| Deformation |

| Points | 1 | 2 | 3 | … | n |

|---|---|---|---|---|---|

| Deformation |

| Points | 1 | 2 | 3 | t | |

|---|---|---|---|---|---|

| 1 | |||||

| 2 | |||||

| 3 | |||||

| n |

| Points | Space Coordinates | 1 | 2 | 3 | t | |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | ||||||

| 3 | ||||||

| n |

| Method | Spatial Proximal Point Interpolation | Spatial Inverse Distance Interpolation |

|---|---|---|

| Coefficient of determination | 0.998 | 0.987 |

| Standard estimation error (mm) | 0.046 | 0.053 |

| Locations | Volume (m3) | Modulus (GPa) |

|---|---|---|

| Zone A | 2.23 ✕ 106 | 30.7 |

| Zone B | 2.10 ✕ 106 | 30.5 |

| Zone C | 5.97 ✕ 105 | 28.0 |

| Dam foundation | 1.54 ✕ 109 | 27.0 |

| Dam Section | Points | R | S (mm) | Dam Section | Points | R | S (mm) |

|---|---|---|---|---|---|---|---|

| 1# | PL1-1 | 0.987 | 0.217 | 13# | PL13-2 | 0.997 | 0.912 |

| PL1-2 | 0.974 | 0.360 | PL13-3 | 0.999 | 0.573 | ||

| IP1-1 | 0.953 | 0.360 | PL13-4 | 0.996 | 0.787 | ||

| 5# | PL5-1 | 0.997 | 0.599 | PL13-5 | 0.990 | 0.765 | |

| PL5-2 | 0.998 | 0.423 | IP13-2 | 0.984 | 0.364 | ||

| PL5-3 | 0.997 | 0.395 | 16# | PL16-1 | 0.993 | 1.014 | |

| PL5-4 | 0.980 | 0.623 | PL16-2 | 0.996 | 0.871 | ||

| IP5-1 | 0.910 | 0.091 | PL16-3 | 0.997 | 0.707 | ||

| 9# | PL9-1 | 0.995 | 1.268 | PL16-4 | 0.994 | 0.837 | |

| PL9-2 | 0.997 | 0.931 | PL16-5 | 0.990 | 0.703 | ||

| PL9-3 | 0.998 | 0.507 | IP16-1 | 0.980 | 0.477 | ||

| PL9-4 | 0.999 | 0.290 | 19# | PL19-1 | 0.992 | 0.629 | |

| PL9-5 | 0.986 | 0.275 | PL19-2 | 0.996 | 0.511 | ||

| IP9-1 | 0.935 | 0.130 | PL19-3 | 0.994 | 0.583 | ||

| 11# | PL11-1 | 0.998 | 0.964 | PL19-4 | 0.988 | 0.691 | |

| PL11-2 | 0.998 | 0.840 | PL19-5 | 0.983 | 0.509 | ||

| PL11-3 | 0.998 | 0.674 | IP19-1 | 0.988 | 0.183 | ||

| PL11-4 | 0.997 | 0.667 | 23# | PL23-1 | 0.955 | 0.339 | |

| PL11-5 | 0.985 | 0.966 | PL23-2 | 0.954 | 0.276 | ||

| IP11-1 | 0.969 | 0.573 | PL23-3 | 0.954 | 0.261 | ||

| 13# | PL13-1 | 0.998 | 0.764 | IP23-1 | 0.957 | 0.148 |

| Points | ||||||||

|---|---|---|---|---|---|---|---|---|

| PL1-1 | 4.392 | 4.196 | 0.904 | −0.065 | −0.250 | 0.033 | 0.046 | 0.867 |

| PL1-2 | 4.463 | 17.707 | −0.330 | −0.494 | 0.267 | 0.076 | 0.018 | 1.198 |

| IP1-1 | −0.278 | −18.696 | −0.249 | −0.244 | 0.000 | 0.000 | 0.057 | 0.641 |

| PL5-1 | 0.863 | 0.835 | 3.137 | −1.786 | −0.288 | 0.000 | 0.247 | −1.770 |

| PL5-2 | 1.135 | 0.880 | −1.275 | −1.746 | 0.236 | −0.165 | 0.167 | 0.123 |

| PL5-3 | 0.505 | 1.081 | 1.460 | −0.189 | −0.323 | −0.045 | 0.152 | 0.506 |

| PL5-4 | 0.780 | 2.074 | 1.295 | −0.846 | −0.466 | 0.061 | 0.179 | 0.792 |

| IP5-1 | 0.099 | −1.148 | 0.021 | 0.015 | 0.000 | −0.022 | 0.030 | 0.000 |

| PL9-1 | −8.326 | 0.771 | 3.731 | −3.361 | 0.000 | −0.172 | 0.124 | −4.058 |

| PL9-2 | −5.862 | 0.726 | −1.491 | −2.966 | 0.374 | −0.096 | 0.052 | −2.212 |

| PL9-3 | −2.818 | 0.755 | 1.653 | 0.690 | 0.000 | −0.165 | 0.020 | −1.022 |

| PL9-4 | −0.753 | 0.859 | 1.197 | −0.177 | −0.169 | −0.085 | 0.055 | −0.098 |

| PL9-5 | 0.979 | 1.197 | 0.392 | −0.246 | −0.141 | 0.000 | −0.025 | 0.383 |

| IP9-1 | 0.409 | 14.357 | −0.045 | 0.185 | 0.000 | −0.020 | 0.000 | 0.230 |

| PL11-1 | −8.068 | 0.712 | 4.164 | −2.939 | −0.313 | −0.137 | 0.231 | −3.201 |

| PL11-2 | −5.984 | 0.692 | −2.058 | −3.465 | 0.614 | −0.188 | 0.255 | −1.764 |

| PL11-3 | −3.720 | 0.737 | −2.389 | −1.823 | 0.189 | −0.264 | 0.167 | 0.233 |

| PL11-4 | 0.074 | 0.778 | −1.948 | −0.747 | 0.000 | −0.221 | 0.124 | 1.347 |

| PL11-5 | −1.694 | 0.984 | 1.586 | −0.735 | −0.412 | 0.000 | 0.244 | 0.897 |

| IP11-1 | −1.611 | 1.777 | 0.585 | −0.336 | −0.233 | 0.000 | 0.151 | 0.751 |

| PL13-1 | −11.022 | 0.772 | 3.021 | 3.952 | 0.000 | 0.000 | 0.000 | −3.316 |

| PL13-2 | −4.555 | 0.659 | −1.619 | −3.565 | 0.537 | −0.204 | 0.000 | −2.540 |

| PL13-3 | −3.820 | 0.727 | 3.034 | 0.528 | −0.271 | −0.271 | 0.068 | −1.117 |

| PL13-4 | −2.553 | 0.814 | 2.800 | −0.781 | −0.600 | −0.076 | 0.095 | −0.282 |

| PL13-5 | −0.619 | 0.905 | 1.736 | −0.895 | −0.597 | 0.000 | 0.070 | 0.564 |

| IP13-2 | −0.325 | 1.310 | 0.721 | −0.373 | −0.342 | 0.000 | 0.066 | 0.376 |

| PL16-1 | −2.132 | 0.811 | 3.428 | 2.279 | 0.505 | 0.132 | 0.111 | −0.386 |

| PL16-2 | −2.338 | 0.719 | −1.945 | −2.472 | 0.634 | −0.299 | 0.364 | −1.083 |

| PL16-3 | −1.833 | 0.817 | 2.780 | −0.268 | −0.382 | −0.237 | 0.254 | −0.309 |

| PL16-4 | −1.494 | 0.960 | 2.676 | −1.275 | −0.681 | 0.000 | 0.295 | 0.201 |

| PL16-5 | 0.442 | 1.078 | 1.614 | −1.089 | −0.539 | 0.100 | 0.136 | 1.103 |

| IP16-1 | −0.790 | 2.520 | 0.980 | −0.784 | −0.371 | 0.092 | 0.140 | 0.628 |

| PL19-1 | 3.249 | 0.931 | 2.142 | −1.333 | −0.133 | 0.000 | 0.330 | −1.575 |

| PL19-2 | 0.632 | 0.873 | −0.898 | −1.296 | 0.183 | −0.228 | 0.321 | −0.102 |

| PL19-3 | −0.160 | 1.052 | 1.460 | −0.413 | −0.475 | −0.098 | 0.363 | 0.429 |

| PL19-4 | −0.071 | 1.434 | 1.373 | −1.010 | −0.537 | 0.000 | 0.232 | 0.946 |

| PL19-5 | −0.496 | 2.272 | 0.829 | −0.607 | −0.369 | 0.000 | 0.229 | 0.549 |

| IP19-1 | −1.162 | 8.240 | 0.266 | −0.152 | −0.127 | 0.030 | 0.159 | 0.052 |

| PL23-1 | 5.279 | 1.038 | −0.937 | −0.751 | −0.200 | −0.269 | −0.115 | 0.585 |

| PL23-2 | −2.116 | −9.697 | 0.180 | 0.235 | −0.104 | 0.060 | −0.082 | 0.865 |

| PL23-3 | 1.108 | −5.721 | 0.111 | 0.000 | −0.125 | 0.041 | −0.030 | 0.707 |

| IP23-1 | 0.272 | −7.884 | 0.266 | −0.225 | −0.122 | 0.000 | 0.008 | 0.294 |

| Dam Section | Points | X (m) | Z (m) |

|---|---|---|---|

| 1# | PL1-1 | 792.00 | 1885.00 |

| PL1-2 | 792.83 | 1830.00 | |

| IP1-1 | 791.89 | 1778.00 | |

| 5# | PL5-1 | 867.72 | 1885.00 |

| PL5-2 | 873.42 | 1830.00 | |

| PL5-3 | 874.09 | 1778.00 | |

| PL5-4 | 875.63 | 1730.00 | |

| IP5-1 | 873.86 | 1601.00 | |

| 9# | PL9-1 | 931.02 | 1885.00 |

| PL9-2 | 930.05 | 1830.00 | |

| PL9-3 | 929.17 | 1778.00 | |

| PL9-4 | 936.48 | 1730.00 | |

| PL9-5 | 935.37 | 1664.25 | |

| IP9-1 | 934.83 | 1601.00 | |

| 11# | PL11-1 | 991.16 | 1885.00 |

| PL11-2 | 990.45 | 1830.00 | |

| PL11-3 | 990.02 | 1778.00 | |

| PL11-4 | 989.09 | 1730.00 | |

| PL11-5 | 989.53 | 1664.25 | |

| IP11-1 | 990.06 | 1601.00 | |

| 13# | PL13-1 | 1030.26 | 1885.00 |

| PL13-2 | 1022.98 | 1830.00 | |

| PL13-3 | 1022.92 | 1778.00 | |

| PL13-4 | 1022.66 | 1730.00 | |

| PL13-5 | 1022.49 | 1664.25 | |

| IP13-2 | 1022.49 | 1601.00 | |

| 16# | PL16-1 | 1104.84 | 1885.00 |

| PL16-2 | 1105.03 | 1830.00 | |

| PL16-3 | 1105.42 | 1778.00 | |

| PL16-4 | 1106.21 | 1730.00 | |

| PL16-5 | 1105.78 | 1664.25 | |

| IP16-1 | 1105.46 | 1601.00 | |

| 19# | PL19-1 | 1162.66 | 1885.00 |

| PL19-2 | 1163.91 | 1830.00 | |

| PL19-3 | 1162.97 | 1778.00 | |

| PL19-4 | 1162.41 | 1730.00 | |

| PL19-5 | 1161.26 | 1664.25 | |

| IP19-1 | 1160.83 | 1601.00 | |

| 23# | PL23-1 | 1224.58 | 1885.00 |

| PL23-2 | 1224.81 | 1778.00 | |

| PL23-3 | 1224.87 | 1730.00 | |

| IP23-1 | 1224.18 | 1601.00 |

| Points | ||

|---|---|---|

| PL1-1~IP23-1 | 0.981 | 2.305 |

| A00 | A10 | A20 | A30 | B2002 | B2012 | B2022 | B2032 | ||

| −30.28 | 78.24 | −65.37 | 18.70 | 3.40 | −188.27 | 175.15 | 0.00 | ||

| A01 | A11 | A21 | A31 | B2003 | B2013 | B2023 | B2033 | ||

| 182.18 | −453.85 | 354.67 | −86.87 | −3.46 | 143.39 | −160.98 | 24.75 | ||

| A02 | A12 | A22 | A32 | B0200 | B0210 | B0220 | B0230 | ||

| −348.74 | 873.52 | −685.64 | 166.01 | 0.69 | 0.00 | −2.86 | 2.14 | ||

| A03 | A13 | A23 | A33 | B0201 | B0211 | B0221 | B0231 | ||

| 219.08 | −550.23 | 440.76 | −110.75 | −4.47 | 0.00 | −64.79 | 64.27 | ||

| B1000 | B1010 | B1020 | B1030 | B0202 | B0212 | B0222 | B0232 | ||

| 0.62 | 0.00 | −2.80 | 3.03 | 3.84 | 80.97 | 0.00 | −75.78 | ||

| B1001 | B1011 | B1021 | B1031 | B0203 | B0213 | B0223 | B0133 | ||

| −4.91 | 0.00 | −132.14 | 140.08 | 0.00 | −86.86 | 82.62 | 0.00 | ||

| B1002 | B1012 | B1022 | B1032 | C1000 | C1010 | C1020 | C1030 | ||

| 4.10 | 137.32 | 150.19 | −286.18 | 0.69 | −1.09 | 0.00 | 0.32 | ||

| B1003 | B1013 | B1023 | B1033 | C1001 | C1011 | C1021 | C1031 | ||

| 0.00 | −144.29 | 0.00 | 135.92 | −3.50 | −20.63 | 42.23 | −18.09 | ||

| B0100 | B0110 | B0120 | B0130 | C1002 | C1012 | C1022 | C1032 | ||

| −3.51 | −6.75 | 31.99 | −21.86 | 4.71 | 82.35 | −146.21 | 60.40 | ||

| B0101 | B0111 | B0121 | B0131 | C1003 | C1013 | C1023 | C1033 | ||

| 26.84 | 0.00 | 245.33 | −230.63 | −2.02 | −62.25 | 108.21 | −45.47 | ||

| B0102 | B0112 | B0122 | B0132 | C0100 | C0110 | C0120 | C0130 | ||

| −36.36 | −271.01 | −190.06 | 417.36 | −11.10 | 42.54 | −46.72 | 18.96 | ||

| B0103 | B0113 | B0123 | B0133 | C0101 | C0111 | C0121 | C0131 | ||

| 13.24 | 299.10 | −142.85 | −130.61 | 56.73 | 86.55 | −38.55 | −132.84 | ||

| B2000 | B2010 | B2020 | B2030 | C0102 | C0112 | C0122 | C0132 | ||

| 0.000 | −10.13 | 24.36 | −14.40 | −64.47 | −755.24 | 856.22 | 0.00 | ||

| B2001 | B2011 | B2021 | B2031 | C0103 | C0113 | C0123 | C0133 | ||

| 0.00 | 61.48 | −55.41 | 0.00 | 22.08 | 635.42 | −792.72 | 127.82 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, C.; Fu, X.; Shao, C.; Shi, Z.; Su, H. Application of Spatiotemporal Hybrid Model of Deformation in Safety Monitoring of High Arch Dams: A Case Study. Int. J. Environ. Res. Public Health 2020, 17, 319. https://doi.org/10.3390/ijerph17010319

Gu C, Fu X, Shao C, Shi Z, Su H. Application of Spatiotemporal Hybrid Model of Deformation in Safety Monitoring of High Arch Dams: A Case Study. International Journal of Environmental Research and Public Health. 2020; 17(1):319. https://doi.org/10.3390/ijerph17010319

Chicago/Turabian StyleGu, Chongshi, Xiao Fu, Chenfei Shao, Zhongwen Shi, and Huaizhi Su. 2020. "Application of Spatiotemporal Hybrid Model of Deformation in Safety Monitoring of High Arch Dams: A Case Study" International Journal of Environmental Research and Public Health 17, no. 1: 319. https://doi.org/10.3390/ijerph17010319

APA StyleGu, C., Fu, X., Shao, C., Shi, Z., & Su, H. (2020). Application of Spatiotemporal Hybrid Model of Deformation in Safety Monitoring of High Arch Dams: A Case Study. International Journal of Environmental Research and Public Health, 17(1), 319. https://doi.org/10.3390/ijerph17010319