Evaluation of Stoffenmanager and a New Exposure Model for Estimating Occupational Exposure to Styrene in the Fiberglass Reinforced Plastics Lamination Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Collection

2.2. Development of a New Semi-Quantitative Exposure Model

2.3. Data Input and Parameter Translation

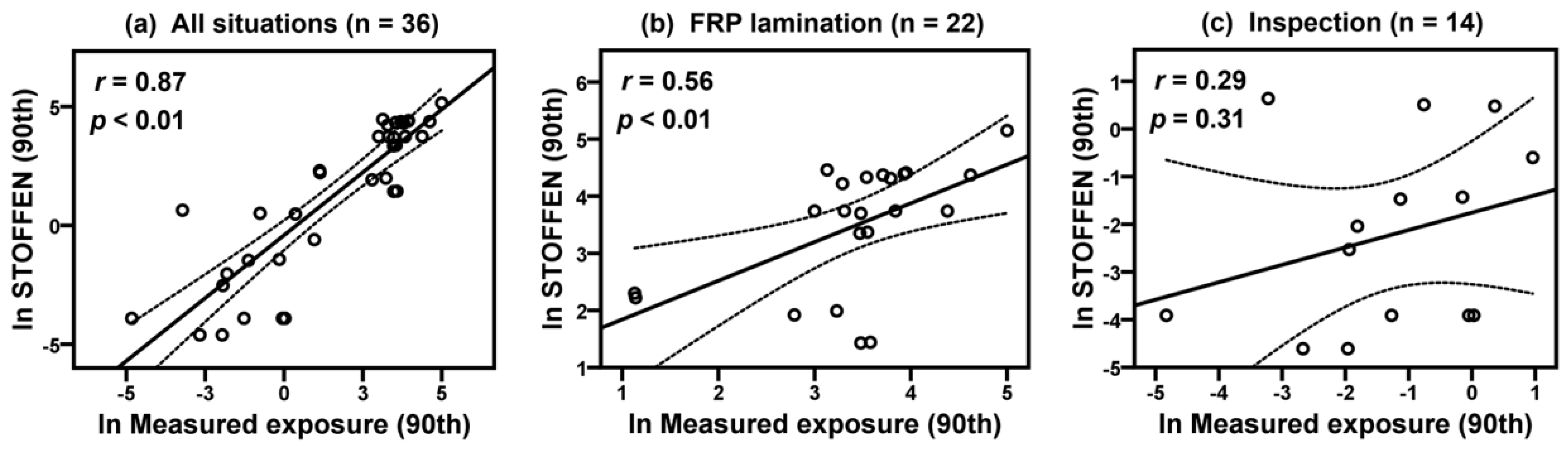

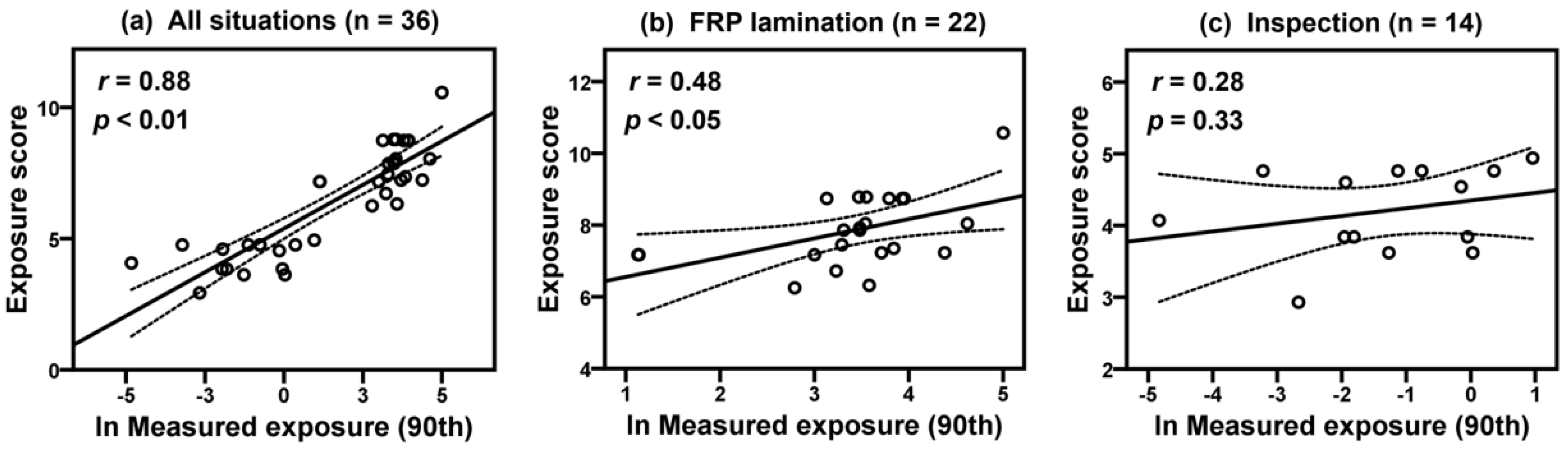

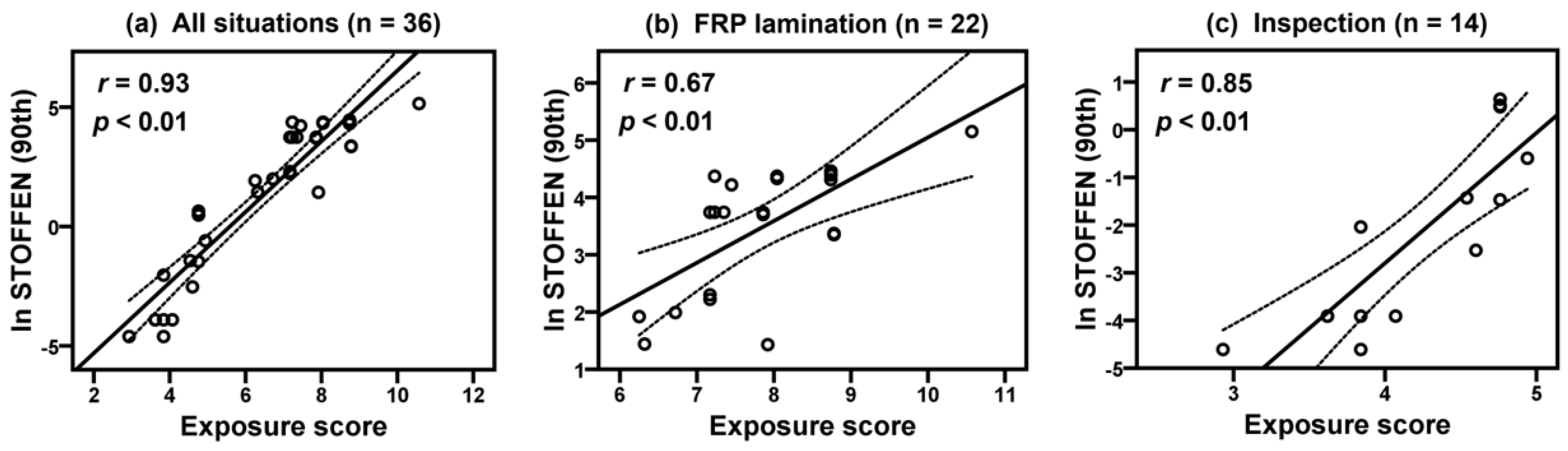

2.4. Evaluation of Stoffenmanager and the New Model

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- European Comission. Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH); EU CEC: Brussels, Belgium, 2006. [Google Scholar]

- European Comission. Commission Regulation (EU) 2017/1000 of 13 June 2017: Amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as Regard. Off. J. Eur. Union 2017, 50, 1–527. [Google Scholar]

- Ministry of Environment. Act on the Registration and Evaluation, etc. of Chemical Substances (ARECS). Available online: http://www.law.go.kr/LSW/eng/engMain.do (accessed on 1 May 2020).

- Ha, S.; Seidle, T.; Lim, K.-M. Act on the Registration and Evaluation of Chemicals (K-REACH) and replacement, reduction or refinement best practices. Environ. Health Toxicol. 2016, 31, e2016026. [Google Scholar] [CrossRef] [PubMed]

- Lee, N.; Cho, B.; Lee, I. Research on regulatory policy in governments and management scheme in company of chemicals to protect workers from hazardous chemicals. In Institute; KOSHA: Ulsan, Korea, 2019. [Google Scholar]

- ECHA. Guidance on Information Requirements and Chemical Safety Assessment. Chapter R. 14: Occupational Exposure Assessment; European Chemical Agency: Helsinki, Finland, 2016. [Google Scholar]

- Lee, J.H.; Lee, K.S.; Hong, M.K. Evaluation of the application of a European chemical risk assessment tool in Korea. J. Korean Soc. Occup. Environ. Hyg. 2012, 22, 191–199. [Google Scholar]

- Kim, S.W.; Jang, J.; Kim, G.B. Development and Validation of Exposure Models for Construction Industry: Tier 2 Model. J. Korean Soc. Occup. Environ. Hyg. 2014, 24, 219–228. [Google Scholar] [CrossRef]

- Moon, J.; Ock, J.; Jung, U.-H.; Ra, J.-S.; Kim, K.-T. Occupational Exposure Assessment for Benzene Using Exposure Models (ECETOC TRA and Stoffenmanager) and Applicability Evaluation of Exposure Models in K-REACH. Korean J. Environ. Health Sci. 2018, 44, 460–467. [Google Scholar]

- Kim, K.-E.; Kim, J.; Jeon, H.; Kim, S.; Cheong, Y. Enhancement of Occupational Exposure Assessment in Korea through the Evaluation of ECETOC TRA according to PROCs. Korean J. Environ. Health Sci. 2019, 45, 173–185. [Google Scholar]

- Lee, S.; Lee, K.; Kim, H. Comparison of Quantitative Exposure Models for Occupational Exposure to Organic Solvents in Korea. Ann. Work Expo. Health 2019, 63, 197–217. [Google Scholar] [CrossRef]

- Hewett, P.; Ganser, G.H. Models for nearly every occasion: Part I—One box models. J. Occup. Environ. Hyg. 2017, 14, 49–57. [Google Scholar] [CrossRef]

- Ganser, G.H.; Hewett, P. Models for nearly every occasion: Part II—Two box models. J. Occup. Environ. Hyg. 2017, 14, 58–71. [Google Scholar] [CrossRef]

- Clerc, F.; Bertrand, N.; Vincent, R. TEXAS: A Tool for EXposure ASsessment—Statistical models for estimating occupational exposure to chemical agents. Ann. Occup. Hyg. 2015, 59, 277–291. [Google Scholar]

- Goede, H.A.; McNally, K.; Gorce, J.-P.; Marquart, H.; Warren, N.D.; Fransman, W.; Tischer, M.; Schinkel, J. Dermal Advanced REACH Tool (dART)—Development of a Dermal Exposure Model for Low-Volatile Liquids. Ann. Work Expo. Health 2019, 63, 624–636. [Google Scholar] [CrossRef] [PubMed]

- Sailabaht, A.; Wang, F.; Cherrie, J. Extension of the Advanced REACH Tool (ART) to Include Welding Fume Exposure. Int. J. Environ. Res. Public Health 2018, 15, 2199. [Google Scholar] [CrossRef] [PubMed]

- Savic, N.; Racordon, D.; Buchs, D.; Gasic, B.; Vernez, D. TREXMO: A translation tool to support the use of regulatory occupational exposure models. Ann. Occup. Hyg. 2016, 60, 991–1008. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Savic, N.; Lee, E.G.; Gasic, B.; Vernez, D. TREXMO plus: An advanced self-learning model for occupational exposure assessment. J. Expo. Sci. Environ. Epidemiol. 2020, 30, 554–566. [Google Scholar] [CrossRef]

- Persoons, R.; Richard, J.; Herve, C.; Montlevier, S.; Marques, M.; Maitre, A. Biomonitoring of styrene occupational exposures: Biomarkers and determinants. Toxicol. Lett. 2018, 298, 99–105. [Google Scholar] [CrossRef]

- IARC Monograph Working Group. Styrene, Styrene-7, 8-oxide, and Quinoline. In IARC Working Group on the Evaluation of Carcinogenic Risks to Humans; International Agency for Research on Cancer: Lyon, France, 2019; Volume 121, pp. 1–355. [Google Scholar]

- ATSDR. Toxicological Profile for Styrene; US Public Health Service; US Department of Health and Human Services: Atlanta, GA, USA, 2010; pp. 1–283.

- Banton, M.; Bus, J.; Collins, J.; Delzell, E.; Gelbke, H.-P.; Kester, J.; Moore, M.; Waites, R.; Sarang, S. Evaluation of potential health effects associated with occupational and environmental exposure to styrene–an update. J. Toxicol. Environ. Health Part B 2019, 22, 1–130. [Google Scholar] [CrossRef]

- NTP. Report on Carcinogens, 14th ed.; Department of Health and Human Services, Public Health Service: Research Triangle Park, NC, USA, 2016. Available online: http://ntp.niehs.nih.gov/go/roc14 (accessed on 21 June 2020).

- Cho, H.-Y.; Cho, S.-H.; Kim, E.-A.; Kim, B.-G.; Park, S.-H.; Kang, S.-K. A survey on the status of using styrene in Korea. J. Korean Soc. Occup. Environ. Hyg. 2008, 18, 310–317. [Google Scholar]

- Hahm, M.; Lee, J.; Lee, M.-y.; Byeon, S.-H. Health risk assessment of occupational exposure to styrene depending on the type of industry: Data from the Workplace Environmental Monitoring Program in Korea. Hum. Ecol. Risk Assess. Int. J. 2016, 22, 1312–1322. [Google Scholar] [CrossRef]

- Park, J.-J.; Choi, S. Characteristics of Workers’ Exposure to Styrene in Fiberglass-Reinforced Plastics Laminating Process. Master’s Thesis, Daegu Catholic University, Daegu, Korea, 2012. [Google Scholar]

- Choi, S.; Jeong, Y. Exposure to Styrene in the Lamination Processes with Fiberglass-Reinforced Plastics: Health Diagnosis Case Report. J. Korean Soc. Occup. Environ. Hyg. 2015, 25, 126–133. [Google Scholar] [CrossRef]

- Shin, Y.; Kim, J.; Kang, D.; Kim, J.; Lee, H.; Kim, B. A Study on Revision of KOREAN Occupational Exposure Limits (Styrene); Ministry of Employment and Labour (MoEL): Sejong, Korea, 2005.

- Cherrie, J.W.; Schneider, T. Validation of a new method for structured subjective assessment of past concentrations. Ann. Occup. Hyg. 1999, 43, 235–245. [Google Scholar] [CrossRef]

- Dosemeci, M.; Alavanja, M.C.; Rowland, A.S.; Mage, D.; Zahm, S.H.; Rothman, N.; Lubin, J.H.; Hoppin, J.A.; Sandler, D.P.; Blair, A. A quantitative approach for estimating exposure to pesticides in the Agricultural Health Study. Ann. Occup. Hyg. 2002, 46, 245–260. [Google Scholar] [PubMed]

- ECETOC. Technical Report No. 93; European Centre for Ecotoxicology and Toxicology of Chemicals: Brussels, Belgium, 2004. [Google Scholar]

- ECETOC. ECETOC TRA Version 3: Background and Rationale for the Improvements; European Centre for Ecotoxicology and Toxicology of Chemicals: Brussels, Belgium, 2012. [Google Scholar]

- Marquart, H.; Heussen, H.; Le Feber, M.; Noy, D.; Tielemans, E.; Schinkel, J.; West, J.; Van Der Schaaf, D. ‘Stoffenmanager’, a web-based control banding tool using an exposure process model. Ann. Occup. Hyg. 2008, 52, 429–441. [Google Scholar] [PubMed]

- Tielemans, E.; Noy, D.; Schinkel, J.; Heussen, H.; Van Der Schaaf, D.; West, J.; Fransman, W. Stoffenmanager exposure model: Development of a quantitative algorithm. Ann. Occup. Hyg. 2008, 52, 443–454. [Google Scholar] [PubMed]

- Fransman, W.; Van Tongeren, M.; Cherrie, J.W.; Tischer, M.; Schneider, T.; Schinkel, J.; Kromhout, H.; Warren, N.; Goede, H.; Tielemans, E. Advanced Reach Tool (ART): Development of the mechanistic model. Ann. Occup. Hyg. 2011, 55, 957–979. [Google Scholar] [PubMed]

- Tielemans, E.; Warren, N.; Fransman, W.; Van Tongeren, M.; Mcnally, K.; Tischer, M.; Ritchie, P.; Kromhout, H.; Schinkel, J.; Schneider, T. Advanced REACH Tool (ART): Overview of version 1.0 and research needs. Ann. Occup. Hyg. 2011, 55, 949–956. [Google Scholar] [PubMed]

- Van Tongeren, M.; Fransman, W.; Spankie, S.; Tischer, M.; Brouwer, D.; Schinkel, J.; Cherrie, J.W.; Tielemans, E. Advanced REACH Tool: Development and application of the substance emission potential modifying factor. Ann. Occup. Hyg. 2011, 55, 980–988. [Google Scholar]

- Jeong, J.Y.; Kang, T.S.; Lee, S.G.; Park, H.D.; Kim, K.Y. An improvement plan for a workplace monitoring system through random selection of workplaces and unnoticed measurement inspection. J. Korean Soc. Occup. Environ. Hyg. 2017, 27, 105–114. [Google Scholar]

- Fleming, D.A.; Woskie, S.R.; Jones, J.H.; Silver, S.R.; Luo, L.; Bertke, S.J. Retrospective assessment of exposure to chemicals for a microelectronics and business machine manufacturing facility. J. Occup. Environ. Hyg. 2014, 11, 292–305. [Google Scholar] [CrossRef]

- American Industrial Hygiene Association (AIHA). Guidance for Conducting Control Banding Analyses; AIHA: Fairfax, VA, USA, 2007. [Google Scholar]

- Elliott, L.J.; Oestenstad, R.K. Evaluation of the predictive abilities of a qualitative exposure assessment model. J. Occup. Environ. Hyg. 2007, 4, 440–447. [Google Scholar] [CrossRef]

- KOSHA. Chemical Hazard Risk Management (CHARM) Guideline; Korea Occupational Safety and Health Agency (KOSHA): Ulsan, Korea, 2012. [Google Scholar]

- HSE. COSHH Essentials; HSE: London, UK, 1999.

- United Nations. Globally Harmonized System of Classification and Labelling of Chemicals (GHS, Rev. 8); United Nations: New York, NY, USA; Geneva, Switzerland, 2019; pp. 283–384. [Google Scholar]

- Schinkel, J.; Fransman, W.; Heussen, H.; Kromhout, H.; Marquart, H.; Tielemans, E. Cross-validation and refinement of the Stoffenmanager as a first tier exposure assessment tool for REACH. Occup. Environ. Med. 2010, 67, 125–132. [Google Scholar] [CrossRef]

- Koppisch, D.; Schinkel, J.; Gabriel, S.; Fransman, W.; Tielemans, E. Use of the MEGA exposure database for the validation of the Stoffenmanager model. Ann. Occup. Hyg. 2012, 56, 426–439. [Google Scholar] [PubMed]

- Riedmann, R.; Gasic, B.; Vernez, D. Sensitivity analysis, dominant factors, and robustness of the ECETOC TRA v3, Stoffenmanager 4.5, and ART 1.5 occupational exposure models. Risk Anal. 2015, 35, 211–225. [Google Scholar] [CrossRef]

- Landberg, H.E.; Axmon, A.; Westberg, H.; Tinnerberg, H. A study of the validity of two exposure assessment tools: Stoffenmanager and the Advanced REACH Tool. Ann. Work Expo. Health 2017, 61, 575–588. [Google Scholar] [CrossRef] [PubMed]

- Spinazzè, A.; Lunghini, F.; Campagnolo, D.; Rovelli, S.; Locatelli, M.; Cattaneo, A.; Cavallo, D.M. Accuracy evaluation of three modelling tools for occupational exposure assessment. Ann. Work Expo. Health 2017, 61, 284–298. [Google Scholar] [CrossRef] [PubMed]

- Van Tongeren, M.; Lamb, J.; Cherrie, J.W.; MacCalman, L.; Basinas, I.; Hesse, S. Validation of lower tier exposure tools used for REACH: Comparison of tools estimates with available exposure measurements. Ann. Work Expo. Health 2017, 61, 921–938. [Google Scholar] [CrossRef] [PubMed]

- Lee, E.G.; Lamb, J.; Savic, N.; Basinas, I.; Gasic, B.; Jung, C.; Kashon, M.L.; Kim, J.; Tischer, M.; Van Tongeren, M.; et al. Evaluation of Exposure Assessment Tools under REACH: Part II—Higher Tier Tools. Ann. Work Expo. Health 2018, 63, 230–241. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.; Choi, S. Comparison of the Styrene Exposure Risk at Fiberglass Reinforced Plastic Laminating Process Using the COSHH Essentials, CHARM and Field Measurements; Daegu Catholic University: Daegu, Korea, 2014; pp. 1–56. [Google Scholar]

- Schinkel, J.; Warren, N.; Fransman, W.; Van Tongeren, M.; McDonnell, P.; Voogd, E.; Cherrie, J.W.; Tischer, M.; Kromhout, H.; Tielemans, E. Advanced REACH Tool (ART): Calibration of the mechanistic model. J. Environ. Monit. 2011, 13, 1374–1382. [Google Scholar] [CrossRef]

- Schinkel, J.; Ritchie, P.; Goede, H.; Fransman, W.; Van Tongeren, M.; Cherrie, J.W.; Tielemans, E.; Kromhout, H.; Warren, N. The Advanced REACH Tool (ART): Incorporation of an Exposure Measurement Database. Ann. Occup. Hyg. 2013, 57, 717–727. [Google Scholar]

- Mc Donnell, P.E.; Schinkel, J.M.; Coggins, M.A.; Fransman, W.; Kromhout, H.; Cherrie, J.W.; Tielemans, E.L. Validation of the inhalable dust algorithm of the Advanced REACH Tool using a dataset from the pharmaceutical industry. J. Environ. Monit. 2011, 13, 1597–1606. [Google Scholar] [CrossRef]

- Savic, N.; Gasic, B.; Vernez, D. ART, Stoffenmanager, and TRA: A Systematic Comparison of Exposure Estimates Using the TREXMO Translation System. Ann. Work Expo. Health 2017, 62, 72–87. [Google Scholar] [CrossRef]

- Van Duuren-Stuurman, B.; Vink, S.R.; Verbist, K.J.; Heussen, H.G.; Brouwer, D.H.; Kroese, D.E.; Van Niftrik, M.F.; Tielemans, E.; Fransman, W. Stoffenmanager nano version 1.0: A web-based tool for risk prioritization of airborne manufactured nano objects. Ann. Occup. Hyg. 2012, 56, 525–541. [Google Scholar] [PubMed]

- Bekker, C.; Voogd, E.; Fransman, W.; Vermeulen, R. The validity and applicability of using a generic exposure assessment model for occupational exposure to nano-objects and their aggregates and agglomerates. Ann. Occup. Hyg. 2016, 60, 1039–1048. [Google Scholar] [CrossRef] [PubMed]

- Sailabaht, A.; Wang, F.; Cherrie, J.W. Calibration of the Welding Advanced REACH Tool (weldART). Int. J. Environ. Res. Public Health 2020, 227, 113519. [Google Scholar]

- McNally, K.; Gorce, J.-P.; Goede, H.A.; Schinkel, J.; Warren, N. Calibration of the Dermal Advanced REACH Tool (dART) Mechanistic Model. Ann. Work Expo. Health 2019, 63, 637–650. [Google Scholar] [CrossRef]

| Parameter | Modifying Factor | Classification | Score | Reference | |

|---|---|---|---|---|---|

| Job classification (= Pf) | Position factor (Pf) | Office worker | 1.0 | Fleming et al. (2014) [39] | |

| Utility engineer, EHS manager, field inspector, engineer/scientist, supervisor, etc. | 1.2 | ||||

| General worker (e.g., manufacturing, assembly, quality controls, process operation, etc.) | 2.0 | ||||

| Maintenance engineer (e.g., solvent cleaning, maintenance of equipment tools, etc.) | 3.0 | ||||

| Exposure potential (= EP × Eh × Em) | Potential emission and handling of products (Ep) (either liquid or solid) | Liquid | Neither potential emission nor handling | 1.0 | Cherrie and Schneider (1999) [29] Marquart et al. (2008) [33] Fransman et al. (2011) [35] Van Tongeren et al. (2011) [37] |

| Small amount of chemicals (in grams) is used and may be released | 1.5 | ||||

| Medium amount of chemicals (in kilograms) is used with low pressure and speed on medium-sized surfaces and workplaces | 2.0 | ||||

| Large amount of chemicals (in tons) is used with high pressure and speed resulting in generation of mist or spray/haze on large surfaces and workplaces | 3.0 | ||||

| Extremely large amount of chemicals is used with extremely high pressure and speed resulting in highly substantial generation of mist or spray/haze in workplaces | 5.0 | ||||

| Solid | Neither potential emission nor handling | 1.0 | |||

| Small amount of chemicals (in grams) is used and may be released (little dusty) | 1.5 | ||||

| Medium amount of chemicals (in kilograms) is used with low pressure and speed on medium or large surfaces or workplaces (some dusty) | 2.0 | ||||

| Large amount of chemicals (in tons) is used with high pressure and speed resulting in large quantities of dusts generated and dispersed at workplaces (dusty) | 3.0 | ||||

| Extremely large amount of chemicals is used with extremely high pressure and speed resulting in extremely high quantities of dusts generated and dispersed (very dusty) | 5.0 | ||||

| Historical exposure (Eh) 1 | With IH data | No exposure (either ‘non-detectable’ or ‘below detection limits’) | 1.0 | AIHA (2007) [40] Elliott et al. (2007) [41] KOSHA (2012) [42] | |

| Samples were < 10% of exposure limits (e.g., 8h-TWA, STEL, etc.) | 1.2 | ||||

| Samples were 10–50% of exposure limits | 2.0 | ||||

| Samples were 50–100% of exposure limits (under the exposure limits) | 3.0 | ||||

| Samples exceeded the exposure limits (>100%) | 5.0 | ||||

| No IH data | No exposure | 1.0 | |||

| Low level of exposure (fully enclosed and highly controlled) | 1.2 | ||||

| Medium level of exposure (partially enclosed and well controlled) | 2.0 | ||||

| High level of exposure (trivially enclosed and slightly controlled) | 3.0 | ||||

| Extremely high level of exposure (neither enclosed nor controlled) | 5.0 | ||||

| Type of process with tool cleaning, inspection and maintenance (Em) | No exposure | 1.0 | Marquart et al. (2008) [33] Fransman et al. (2011) [35] | ||

| Full automation of process with daily cleaning, inspection, and maintenance | 1.2 | ||||

| Semi-automation of process with weekly cleaning, inspection, and maintenance | 1.5 | ||||

| Manual handling in process with no cleaning, inspection, and maintenance | 2.0 | ||||

| Engineering controls (= ηgv × Lc × PPE) | Ventilation and containment (ηgv) | No exposure | 1.0 | Marquart et al. (2008) [33] Elliott et al. (2007) [41] | |

| Fully ventilated with high-level containment at the source | 1.2 | ||||

| Partially ventilated with medium-level containment at the source | 1.5 | ||||

| General ventilation with low-level containment at the source | 2.0 | ||||

| Neither ventilation nor containment is used at the source | 3.0 | ||||

| Localized control measure (Lc) | No exposure | 1.0 | Marquart et al. (2008) [33] Fransman et al. (2011) [35] Elliott et al. (2007) [41] | ||

| Local exhaust ventilation (LEV) is used, and all contaminants are fully removed | 1.5 | ||||

| LEV is used, but some contaminants are not removed and remain | 2.0 | ||||

| No LEV is used (in the open process) thus no removal of contaminants | 3.0 | ||||

| Personal protective equipment (PPE) | No exposure | 1.0 | Dosemeci et al. (2002) [30] | ||

| 90% protection using PPE-1 2 and PPE-2 3 and PPE-3 4 | 1.2 | ||||

| 70% protection using PPE-2 and PPE-3 | 1.5 | ||||

| 50% protection using PPE-1 and PPE-2 | 2.0 | ||||

| 40% protection using PPE-3 | 2.5 | ||||

| 30% protection using PPE-2 | 3.0 | ||||

| 20% protection using PPE-1 | 4.0 | ||||

| 0% protection (no use of PPE) | 5.0 | ||||

| Chemical hazard (= H) | Health hazard category (H) 5 | No exposure | 1.0 | AIHA (2007) [40] KOSHA (2012) [42] HSE (1999) [43] United Nations (2019) [44] | |

| Hazard category 4 or 5 (e.g., H302, H303, H312, H332, H333, etc.) | 2.0 | ||||

| Hazard category 3 (e.g., H301, H311, H316, H331, H335, H336, etc.) | 3.0 | ||||

| Hazard category 2 (e.g., H305, H315, H319, H320, H371, H373, etc.) | 4.0 | ||||

| Hazard category 1 or CMR (carcinogenicity, reproductive, or mutagenicity) (e.g., H300, H330, H334, H340, H341, H350, H351, H360, H361, H370, etc.) | 6.0 | ||||

| Exposure probability (= Th × Tf × D) | Task duration (Th) | No exposure | 1.0 | Marquart et al. (2008) [33] | |

| <1 h | 1.5 | ||||

| 1–4 h | 2.0 | ||||

| 4–8 h | 3.0 | ||||

| Task frequency (Tf) | No exposure | 1.0 | Marquart et al. (2008) [33] | ||

| 1 day a year | 1.2 | ||||

| 1 day a month | 1.5 | ||||

| 2–3 days a week | 2.0 | ||||

| 4–5 days a week | 3.0 | ||||

| All-time | 5.0 | ||||

| Distance from the source (D) | No exposure | 1.0 | Cherrie and Schneider (1999) [29] Fransman et al. (2011) [35] | ||

| >1 m | 1.5 | ||||

| ≤1 m | 2.0 | ||||

| Workplace size (= V) | Room volume (V) | No exposure | 1.0 | Marquart et al. (2008) [33] | |

| <100 m3 | 1.0 | ||||

| 100–1000 m3 | 5.0 | ||||

| >1000 m3 | 10.0 | ||||

| Exposure Category 1 | Description | Range of Exposure Score | Percentage of Exposure Score |

|---|---|---|---|

| 1 | No exposure (e.g., office worker) | 1.00 | - |

| 2 | Low level of exposure (fully enclosed and highly controlled) | 1.01–4.76 | <34% |

| 3 | Medium level of exposure (partially enclosed and well controlled) | 4.77–9.38 | 34–67% |

| 4 | High level of exposure (little enclosed and poorly controlled) | 9.39–14.01 | 67–100% |

| Modifying Factor | Stoffenmanager | New Exposure Model | Level of Translation | |

|---|---|---|---|---|

| Exposure Situation (Task) | FRP Lamination for Ship Manufacturing | FRP Lamination for Ship Manufacturing | (Score) | |

| Intrinsic emission source | ||||

| Name of agent | Styrene | Styrene | - | Direct translation (Korean → English) |

| Type of agent | Liquid | Liquid | - | Direct translation |

| Process temperature | 25 °C | - | - | Direct coding |

| Molecular weight | 104.15 g/mol | - | - | Direct coding (Reference.: PubChem) |

| Vapor pressure | 853 Pa | - | - | Direct coding (Reference.: PubChem) |

| Percentage in product | 33–44% | - | - | Direct coding |

| Job classification | ||||

| Position factor | - | General worker (manufacturing, assembly, etc.) | (2.0) | Direct translation with expert judgment |

| Process | ||||

| Type of task (Activity) | Handling of liquids on large surfaces or large workpieces | Large amount of chemicals (in tons) is used with high pressure and speed resulting in generation of mist or spray/haze on large surfaces and workplaces | (3.0) | Direct translation with expert judgment (used the information on type of process, task description, quantity of chemical, etc.) |

| Historical exposure | - | Samples were 10–50% of exposure limits | (2.0) | Direct translation |

| Process category (PROC) | PROC7: Industrial spraying | - | - | Direct translation with expert judgment |

| Task duration | 180 min | 1–4 h | (2.0) | Direct coding |

| Task frequency | 4–5 days a week | 4–5 days a week | (3.0) | Direct coding |

| Distance from the source | Yes (≤1 m, in breathing zone) | ≤1 m | (2.0) | Direct coding |

| Coworker carrying out the same task | Yes | - | - | Direct coding |

| Evaporation, drying, or curing | Yes | - | - | Direct translation |

| RPE | Reusable half mask respirator-gas/vapour filter | 50% protection using PPE-1 and PPE-2 | (2.0) | Direct translation with expert judgment |

| Chemical hazard | ||||

| Health hazard category | - | Hazard category 2 (e.g., H305, H315, H319, etc.) | (4.0) | Direct coding (Reference.: PubChem) |

| Workplace | ||||

| Room volume | >1000 m3 | >1000 m3 | (10.0) | Direct coding |

| General ventilation | Good ventilation (open windows and doors) | Fully ventilated with high-level containment | (1.2) | Direct translation with expert judgment |

| Control measure | Local exhaust ventilation (LEV) | LEV is used, but some contaminants are not removed and remain | (2.0) | Direct translation with expert judgment |

| Inspections and maintenance of equipment | Yes | Manual handling with low-level cleaning | (2.0) | Direct translation with expert judgment |

| General house cleaning | Yes | - | - | Direct translation |

| Protection of employee | Not work in a cabin | - | - | Direct translation |

| Exposure Situation (Task) | Company | Product | Task Duration (min) | n | AM (ppm) | GM (ppm) | GSD | Min–Max (ppm) | KOEL 1 (8 h-TWA) | Analytical Method |

|---|---|---|---|---|---|---|---|---|---|---|

| FRP lamination (spraying and coating) | A | Ship | 180 | 8 | 16.49 | 11.78 | 2.39 | 3.77–40.04 | 20 ppm | NIOSH 1501 |

| B | Ship | 120 | 2 | 25.29 | 19.07 | 3.06 | 8.68–41.89 | |||

| C | Ship | 60 | 1 | 3.10 | 3.10 | - | 3.10 | |||

| D | Ship | 180 | 2 | 25.66 | 25.64 | 1.05 | 24.86–26.45 | |||

| E | Ship | 60 | 4 | 9.08 | 8.02 | 1.74 | 4.88–17.38 | |||

| F | Ship | 180 | 15 | 16.44 | 11.81 | 2.30 | 4.25–53.60 | |||

| G | Ship | 180 | 3 | 10.85 | 9.67 | 1.77 | 6.14–18.41 | |||

| H | Ship | 180 | 1 | 32.19 | 32.19 | - | 32.19 | |||

| I | Ship | 180 | 5 | 27.27 | 15.74 | 4.29 | 1.67–45.15 | |||

| J | Ship | 180 | 16 | 19.68 | 14.77 | 2.45 | 1.82–43.67 | |||

| K | Automotive products and repair parts | 120 | 9 | 19.07 | 11.97 | 3.09 | 2.28–46.45 | |||

| L | Automotive products and repair parts | 180 | 20 | 49.72 | 26.06 | 3.89 | 1.07–186.34 | |||

| M | Automotive products and repair parts | 180 | 6 | 13.02 | 9.27 | 2.65 | 2.11–30.21 | |||

| N | Double-walled underground storage tank (UST) | 180 | 1 | 34.88 | 34.88 | - | 34.88 | |||

| O | Double-walled underground storage tank (UST) | 180 | 4 | 17.93 | 10.27 | 3.54 | 3.52–45.90 | |||

| P | Double-walled underground storage tank (UST) | 180 | 14 | 17.21 | 11.04 | 2.95 | 1.68–36.60 | |||

| Q | Double-walled underground storage tank (UST) | 180 | 3 | 12.56 | 11.51 | 1.71 | 6.36–17.95 | |||

| R | Double-walled underground storage tank (UST) | 120 | 4 | 9.89 | 7.66 | 2.66 | 1.80–15.00 | |||

| S | Sluice | 120 | 10 | 11.16 | 7.59 | 2.56 | 2.31–37.51 | |||

| T | Sluice | 120 | 4 | 15.98 | 9.76 | 3.06 | 4.10–43.52 | |||

| U | Sluice | 60 | 1 | 3.12 | 3.12 | - | 3.12 | |||

| V | Double-walled underground storage tank (UST) | 180 | 4 | 25.85 | 25.54 | 1.20 | 19.52–28.99 | |||

| Total | 137 | 21.80 | 13.07 | 2.86 | 1.07–186.34 | |||||

| Inspection | A | Ship | 60 | 1 | 0.07 | 0.07 | - | 0.07 | ||

| B | Ship | 60 | 1 | 0.14 | 0.14 | - | 0.14 | |||

| E | Ship | 60 | 1 | 0.95 | 0.95 | - | 0.95 | |||

| G | Ship | 60 | 1 | 0.01 | 0.01 | - | 0.01 | |||

| H | Ship | 60 | 1 | 0.32 | 0.32 | - | 0.32 | |||

| J | Ship | 60 | 1 | 0.16 | 0.16 | - | 0.16 | |||

| L | Automotive products and repair parts | 60 | 6 | 0.58 | 0.27 | 5.84 | 0.02–1.43 | |||

| M | Automotive products and repair parts | 60 | 3 | 0.64 | 0.54 | 2.14 | 0.23–0.99 | |||

| N | Double-walled underground storage tank (UST) | 60 | 2 | 0.04 | 0.03 | 1.12 | 0.03–0.04 | |||

| O | Double-walled underground storage tank (UST) | 120 | 1 | 0.14 | 0.14 | - | 0.14 | |||

| R | Double-walled underground storage tank (UST) | 60 | 2 | 0.46 | 0.46 | 1.02 | 0.45–0.46 | |||

| S | Sluice | 60 | 1 | 1.03 | 1.03 | - | 1.03 | |||

| T | Sluice | 60 | 1 | 0.86 | 0.86 | - | 0.86 | |||

| V | Double-walled underground storage tank (UST) | 60 | 1 | 0.28 | 0.28 | - | 0.28 | |||

| Total | 23 | 0.45 | 0.23 | 4.25 | 0.01–1.43 | |||||

| Exposure Situation (Task) | Company | Product | n | Exposure Measurement | Model Estimation | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| GM (ppm) | 90th 1 (ppm) | Stoffenmanager | New Model | |||||||

| Daily Average (ppm) | 50th (ppm) | 90th (ppm) | Score 2 | Exposure Category | ||||||

| FRP lamination (spraying and coating) | A | Ship | 8 | 11.78 | 36.02 | 1.57 | 0.46 | 4.20 | 6.32 | 3 |

| B | Ship | 2 | 19.07 | 79.86 | 10.49 | 4.65 | 42.02 | 7.23 | 3 | |

| C | Ship | 1 | 3.10 | - | 9.93 | 8.80 | 79.35 | 7.17 | 3 | |

| D | Ship | 2 | 25.64 | 27.32 | 15.73 | 4.65 | 42.02 | 7.86 | 3 | |

| E | Ship | 4 | 8.02 | 16.25 | 0.85 | 0.76 | 6.82 | 6.25 | 3 | |

| F | Ship | 15 | 11.81 | 34.39 | 28.41 | 8.37 | 75.59 | 8.04 | 3 | |

| G | Ship | 3 | 9.67 | 20.07 | 15.73 | 4.65 | 42.02 | 7.17 | 3 | |

| H | Ship | 1 | 32.19 | - | 28.64 | 8.48 | 76.53 | 8.78 | 3 | |

| I | Ship | 5 | 15.74 | 101.93 | 29.81 | 8.80 | 79.35 | 8.04 | 3 | |

| J | Ship | 16 | 14.77 | 46.55 | 15.73 | 4.65 | 42.02 | 7.35 | 3 | |

| K | Automotive products and repair parts | 9 | 11.97 | 50.93 | 20.08 | 8.90 | 80.29 | 8.74 | 3 | |

| L | Automotive products and repair parts | 20 | 26.06 | 148.93 | 65.03 | 19.17 | 173.02 | 10.57 | 4 | |

| M | Automotive products and repair parts | 6 | 9.27 | 32.32 | 15.22 | 4.50 | 40.61 | 7.86 | 3 | |

| N | Double-walled underground storage tank (UST) | 1 | 34.88 | - | 29.11 | 8.59 | 77.47 | 8.78 | 3 | |

| O | Double-walled underground storage tank (UST) | 4 | 10.27 | 51.82 | 30.99 | 9.14 | 82.63 | 8.74 | 3 | |

| P | Double-walled underground storage tank (UST) | 14 | 11.04 | 44.20 | 27.94 | 8.26 | 74.42 | 8.74 | 3 | |

| Q | Double-walled underground storage tank (UST) | 3 | 11.51 | 22.87 | 32.63 | 9.62 | 86.86 | 8.74 | 3 | |

| R | Double-walled underground storage tank (UST) | 4 | 7.66 | 26.88 | 17.05 | 7.55 | 68.31 | 7.45 | 3 | |

| S | Sluice | 10 | 7.59 | 25.31 | 1.84 | 0.81 | 7.35 | 6.72 | 3 | |

| T | Sluice | 4 | 9.76 | 40.85 | 19.86 | 8.80 | 79.35 | 7.23 | 3 | |

| U | Sluice | 1 | 3.12 | - | 9.19 | 8.14 | 73.48 | 7.17 | 3 | |

| V | Double-walled underground storage tank (UST) | 4 | 25.54 | 32.36 | 1.57 | 0.46 | 4.18 | 7.92 | 3 | |

| Inspection | A | Ship | 1 | 0.07 | - | 0.01 | 0.01 | 0.10 | 2.93 | 2 |

| B | Ship | 1 | 0.14 | - | 0.01 | 0.01 | 0.10 | 3.84 | 2 | |

| E | Ship | 1 | 0.95 | - | 0.02 | 0.02 | 0.17 | 3.84 | 2 | |

| G | Ship | 1 | 0.01 | - | 0.02 | 0.02 | 0.17 | 4.07 | 2 | |

| H | Ship | 1 | 0.32 | - | 0.23 | 0.21 | 1.86 | 4.76 | 2 | |

| J | Ship | 1 | 0.16 | - | 0.13 | 0.11 | 1.02 | 3.84 | 2 | |

| L | Automotive products and repair parts | 6 | 0.27 | 2.61 | 0.07 | 0.06 | 0.55 | 4.94 | 3 | |

| M | Automotive products and repair parts | 3 | 0.54 | 1.43 | 0.20 | 0.18 | 1.62 | 4.76 | 2 | |

| N | Double-walled underground storage tank (UST) | 2 | 0.03 | 0.04 | 0.23 | 0.21 | 1.89 | 4.76 | 2 | |

| O | Double-walled underground storage tank (UST) | 1 | 0.14 | - | 0.08 | 0.04 | 0.33 | 4.60 | 2 | |

| R | Double-walled underground storage tank (UST) | 2 | 0.46 | 0.47 | 0.21 | 0.18 | 1.66 | 4.76 | 2 | |

| S | Sluice | 1 | 1.03 | - | 0.02 | 0.02 | 0.18 | 3.62 | 2 | |

| T | Sluice | 1 | 0.86 | - | 0.24 | 0.21 | 1.93 | 4.54 | 2 | |

| V | Double-walled underground storage tank (UST) | 1 | 0.28 | - | 0.02 | 0.02 | 0.17 | 3.62 | 2 | |

| Exposure Situation (Task) | n | Stoffenmanager | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 50th | 90th | ||||||||

| Bias | Relative Bias (%) | Precision | Accuracy | Bias | Relative Bias (%) | Precision | Accuracy | ||

| Overall | 160 | −1.00 | −63.32 | 2.07 | 1.28 | −0.32 | −27.30 | 2.32 | 1.16 |

| FRP lamination | 137 | −0.81 | −55.60 | 1.26 | 1.02 | 0.06 | 6.38 | 0.96 | 0.75 |

| Inspection | 23 | −1.30 | −72.82 | 1.64 | 1.69 | −0.92 | −60.03 | 2.12 | 1.80 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Choi, S.; Lee, K. Evaluation of Stoffenmanager and a New Exposure Model for Estimating Occupational Exposure to Styrene in the Fiberglass Reinforced Plastics Lamination Process. Int. J. Environ. Res. Public Health 2020, 17, 4486. https://doi.org/10.3390/ijerph17124486

Lee S, Choi S, Lee K. Evaluation of Stoffenmanager and a New Exposure Model for Estimating Occupational Exposure to Styrene in the Fiberglass Reinforced Plastics Lamination Process. International Journal of Environmental Research and Public Health. 2020; 17(12):4486. https://doi.org/10.3390/ijerph17124486

Chicago/Turabian StyleLee, Seokwon, Sangjun Choi, and Kyoungho Lee. 2020. "Evaluation of Stoffenmanager and a New Exposure Model for Estimating Occupational Exposure to Styrene in the Fiberglass Reinforced Plastics Lamination Process" International Journal of Environmental Research and Public Health 17, no. 12: 4486. https://doi.org/10.3390/ijerph17124486

APA StyleLee, S., Choi, S., & Lee, K. (2020). Evaluation of Stoffenmanager and a New Exposure Model for Estimating Occupational Exposure to Styrene in the Fiberglass Reinforced Plastics Lamination Process. International Journal of Environmental Research and Public Health, 17(12), 4486. https://doi.org/10.3390/ijerph17124486