A Design Strategy for Energy-Efficient Rural Houses in Severe Cold Regions

Abstract

:1. Introduction

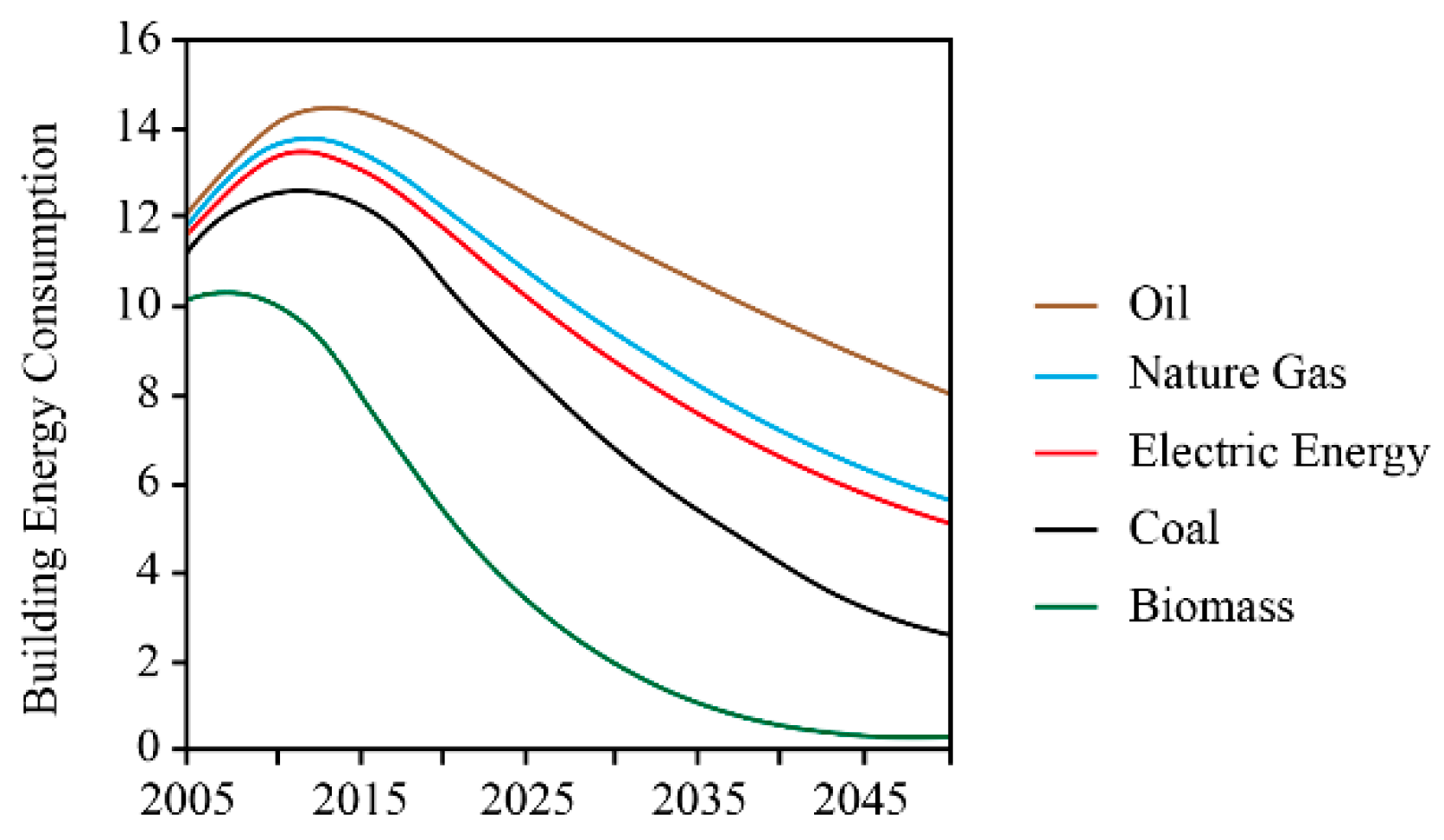

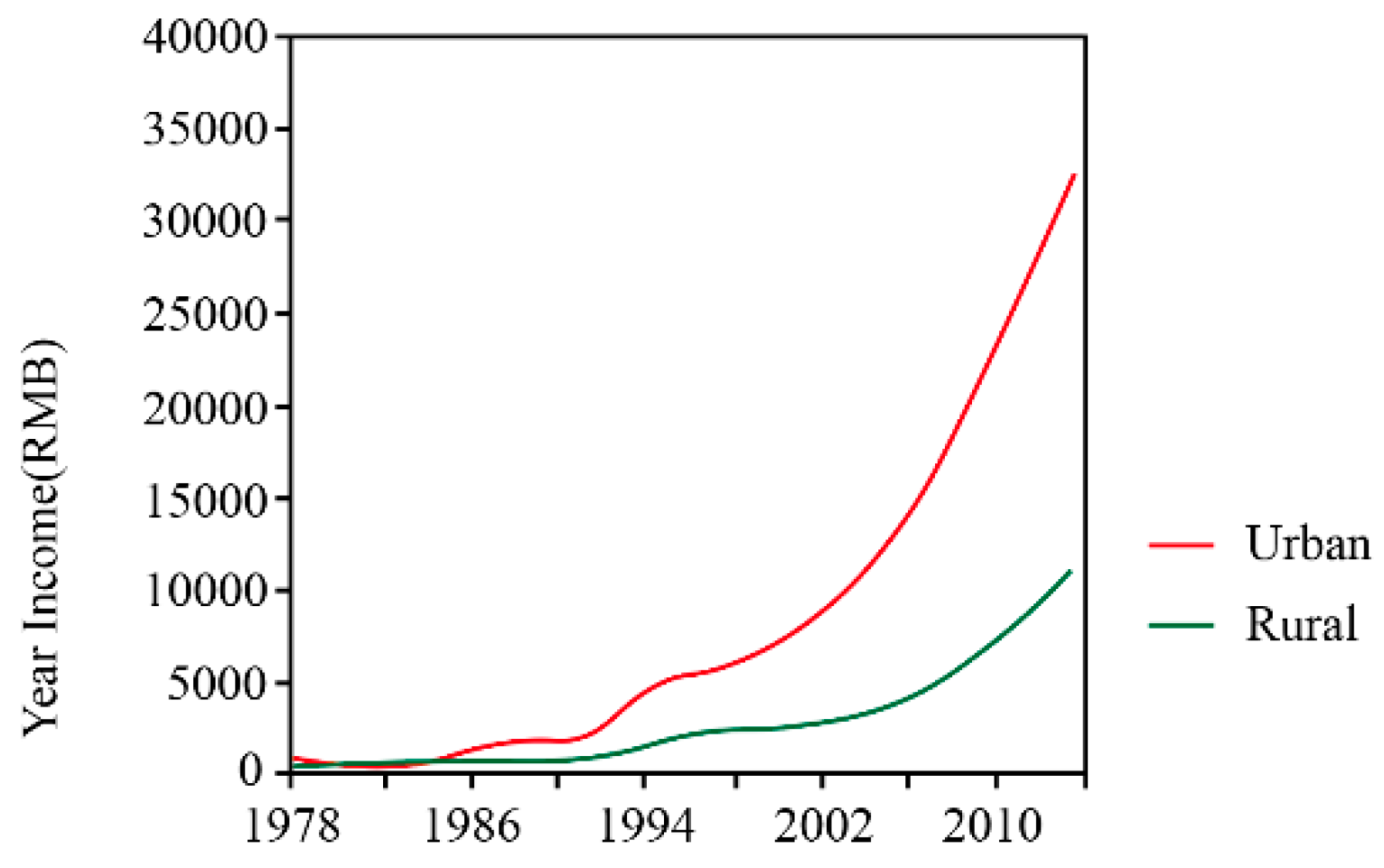

1.1. Current Status of Rural Residential Energy Consumption in Severe Cold Regions

1.2. Existing Energy-Saving Design Method for Rural Houses in Severe Cold Regions

2. Design Strategy for Rural Houses in Severe Cold Regions

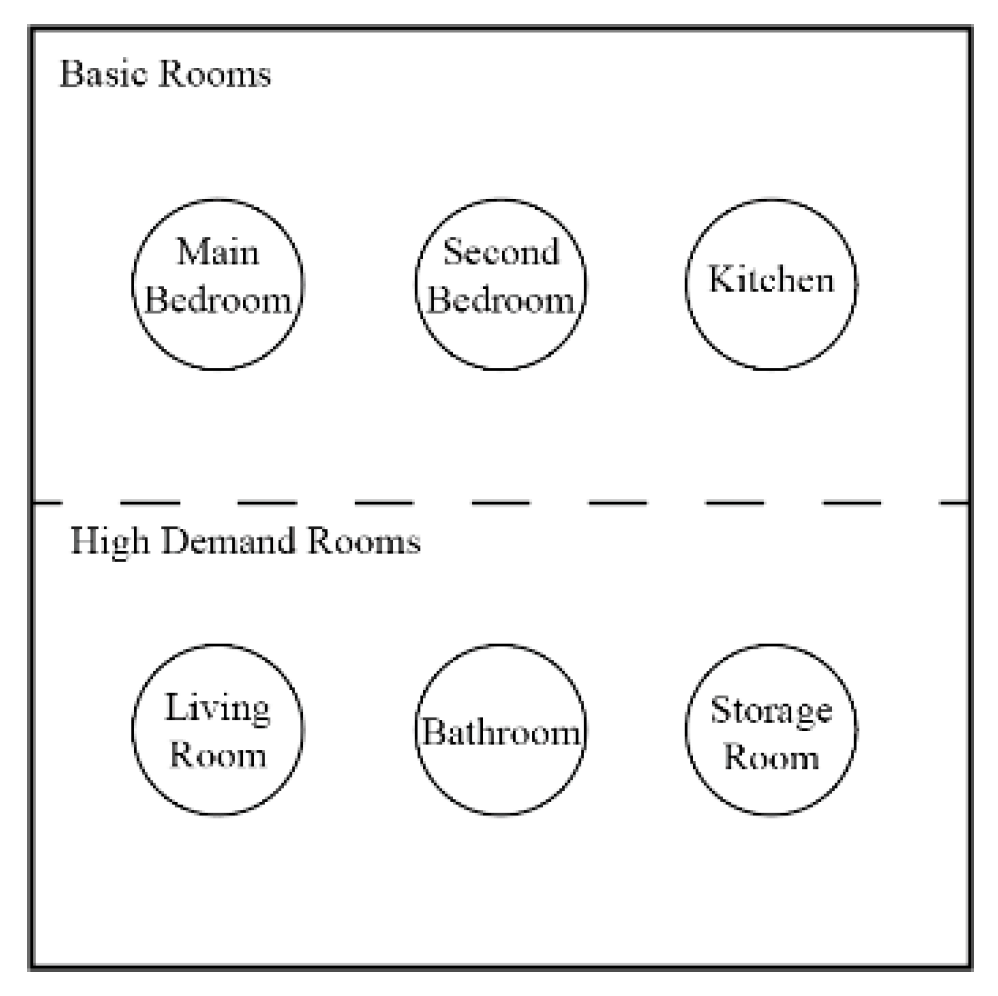

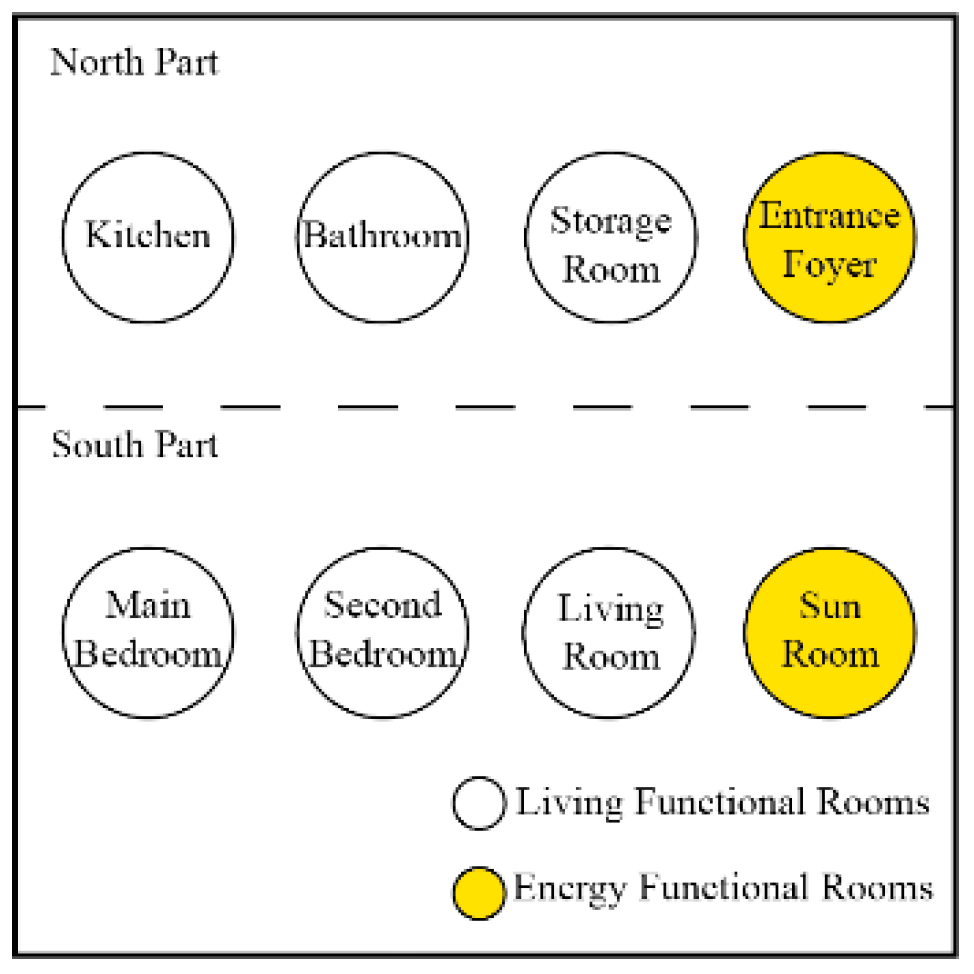

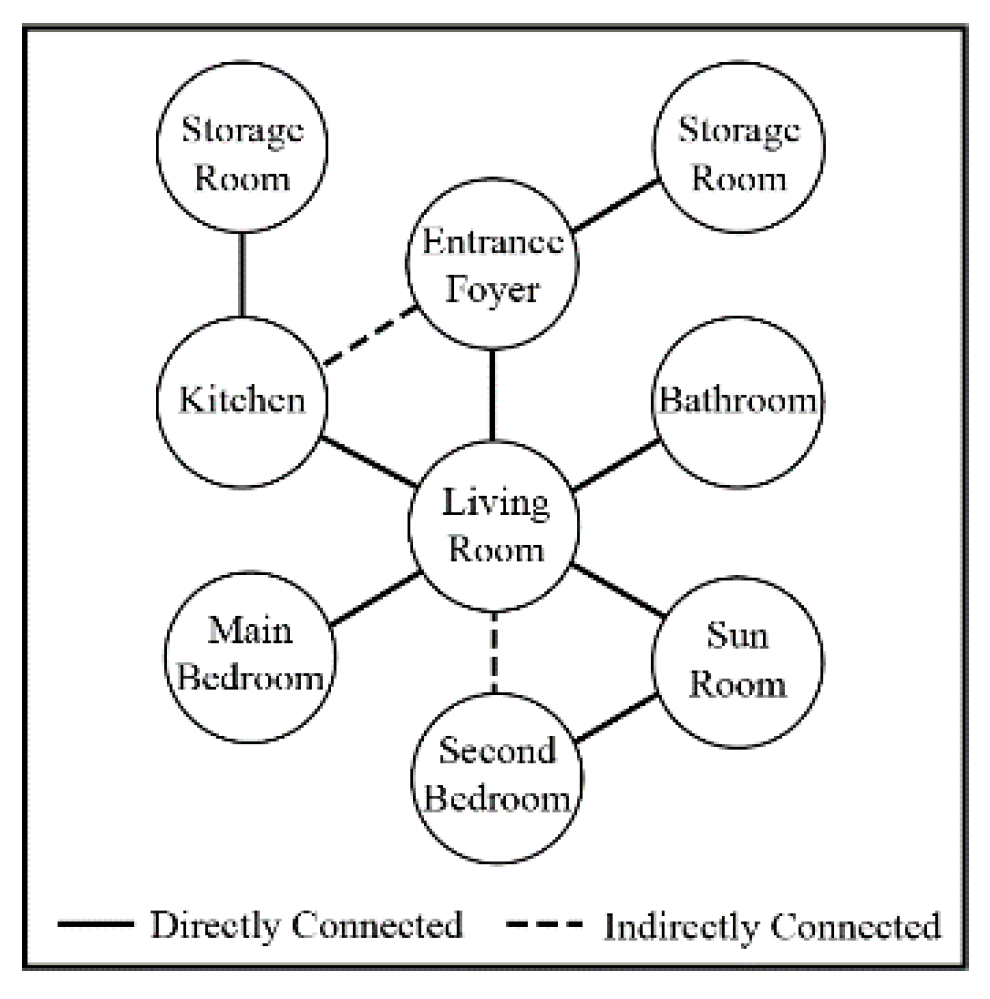

2.1. Spatial Layout

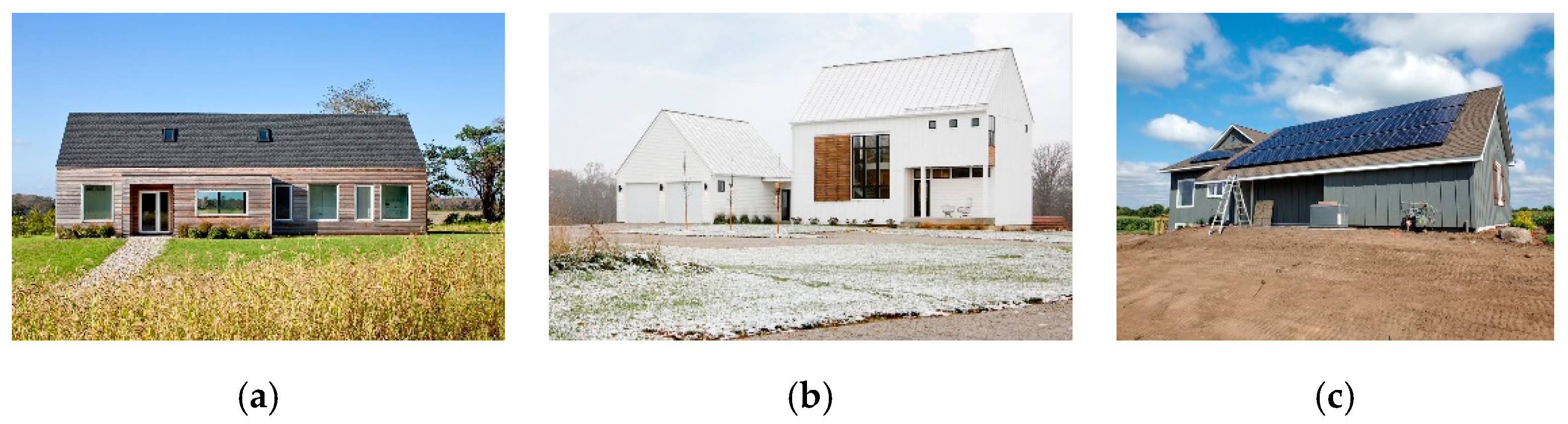

2.2. Building Type

2.3. Enclosure System

2.3.1. Walls

2.3.2. Windows

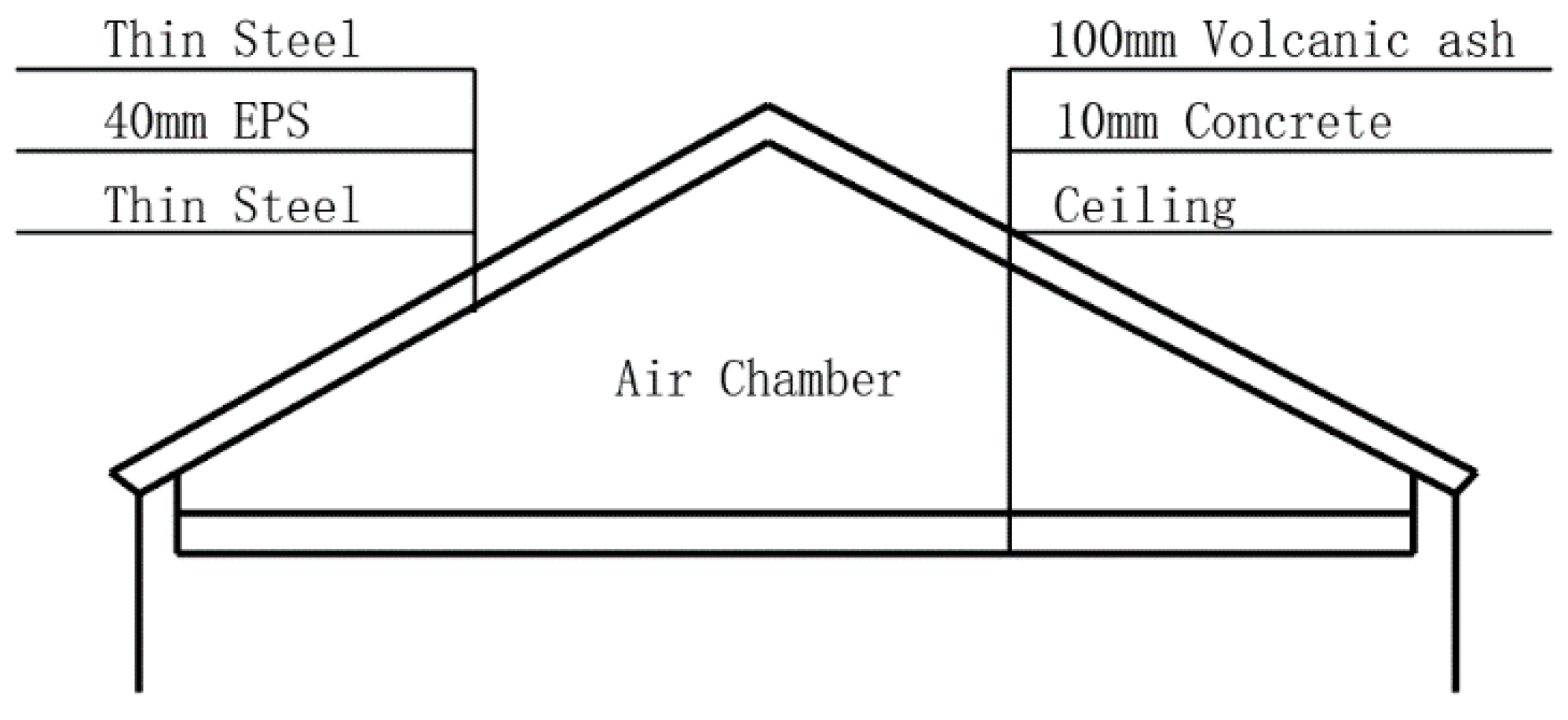

2.3.3. Roof

2.4. Heating System

2.4.1. Water Heating System Combined with the Traditional Kang and Firewall

2.4.2. Phase Change Heat Storage Device

3. Performance Comparison Test and Simulation Analysis of the Demonstration House

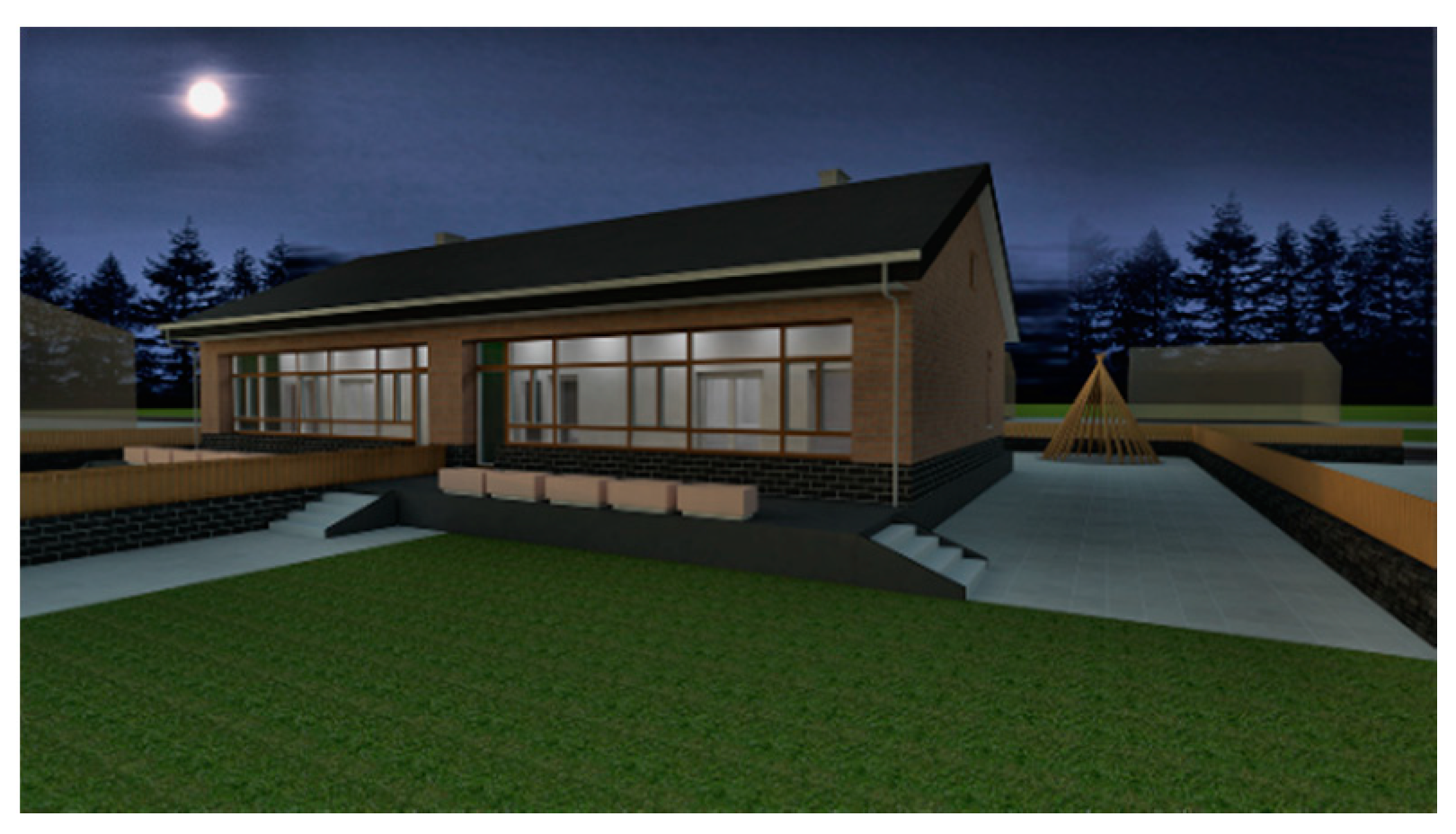

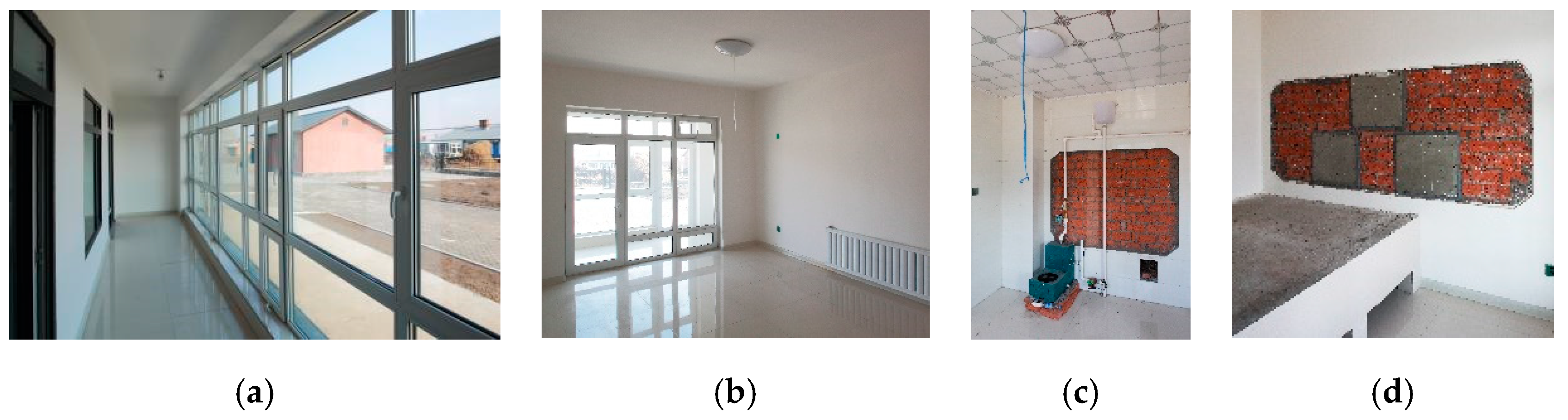

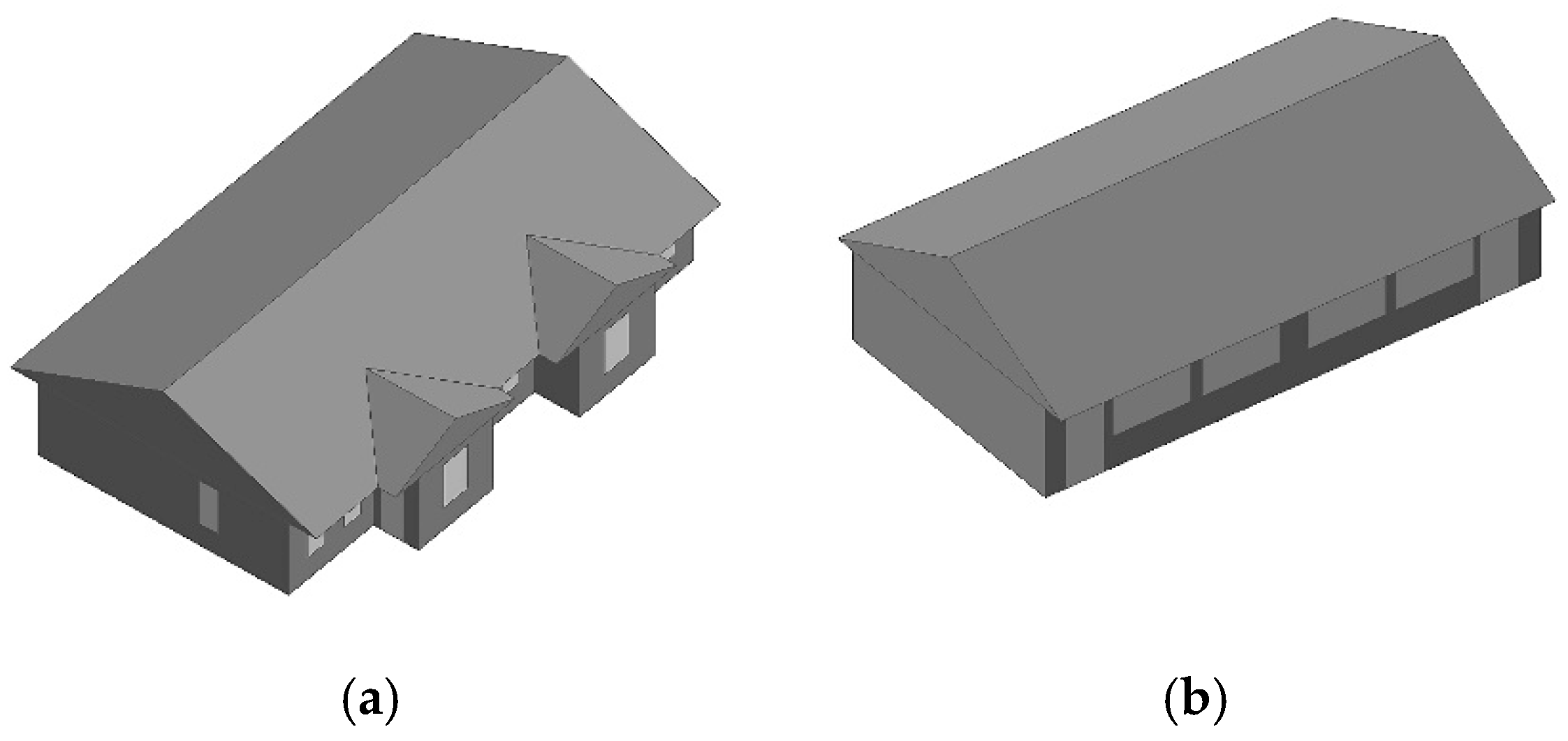

3.1. Demonstration House and Comparative House

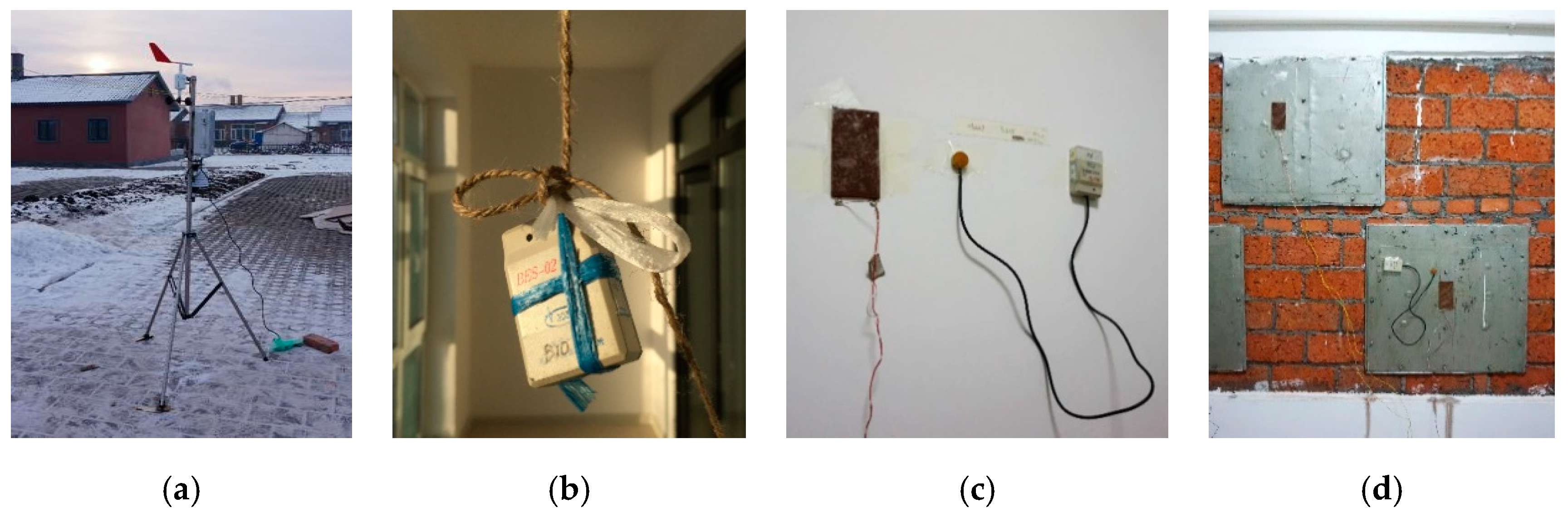

3.2. Test Methods

3.3. Test Results

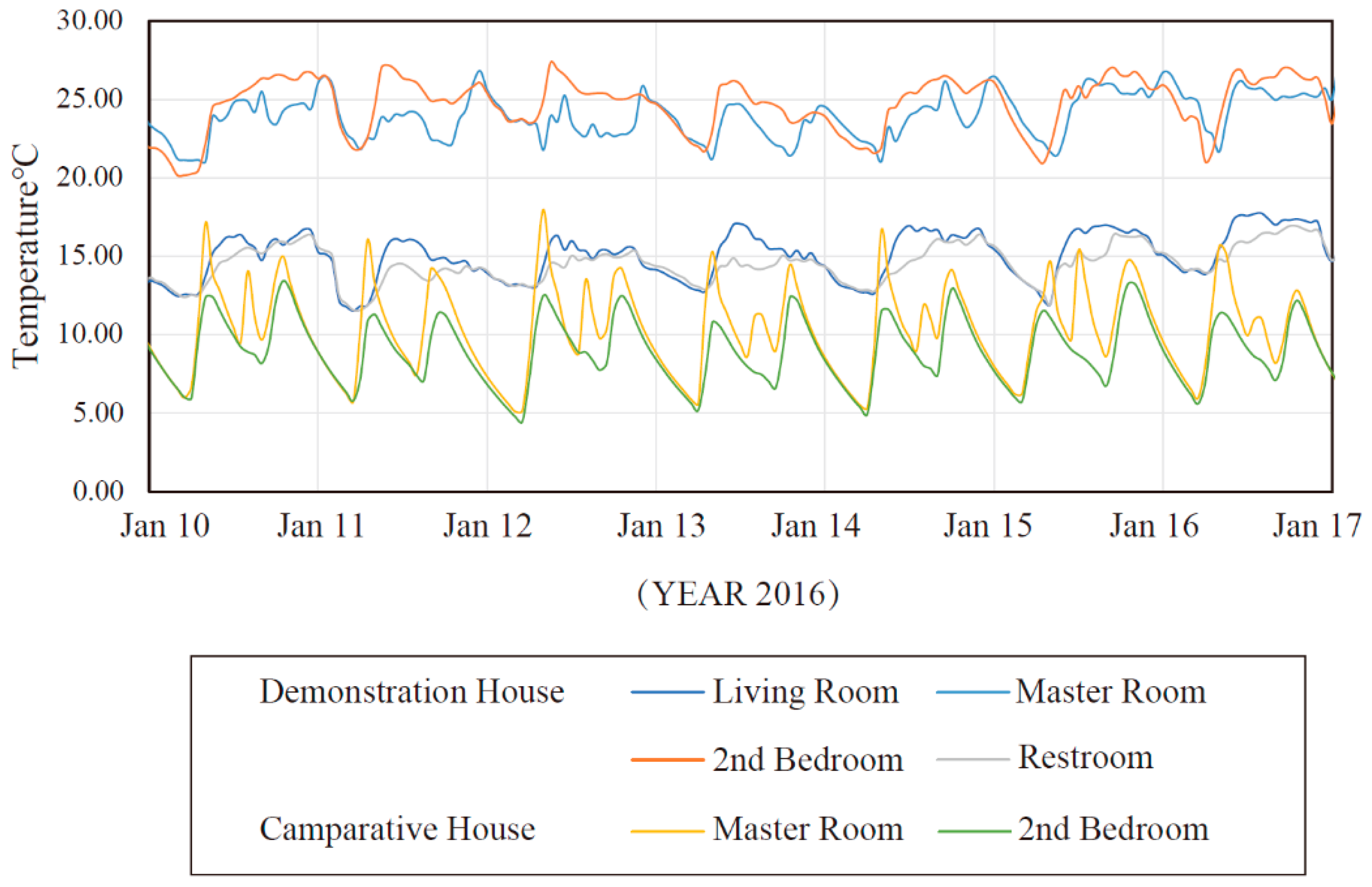

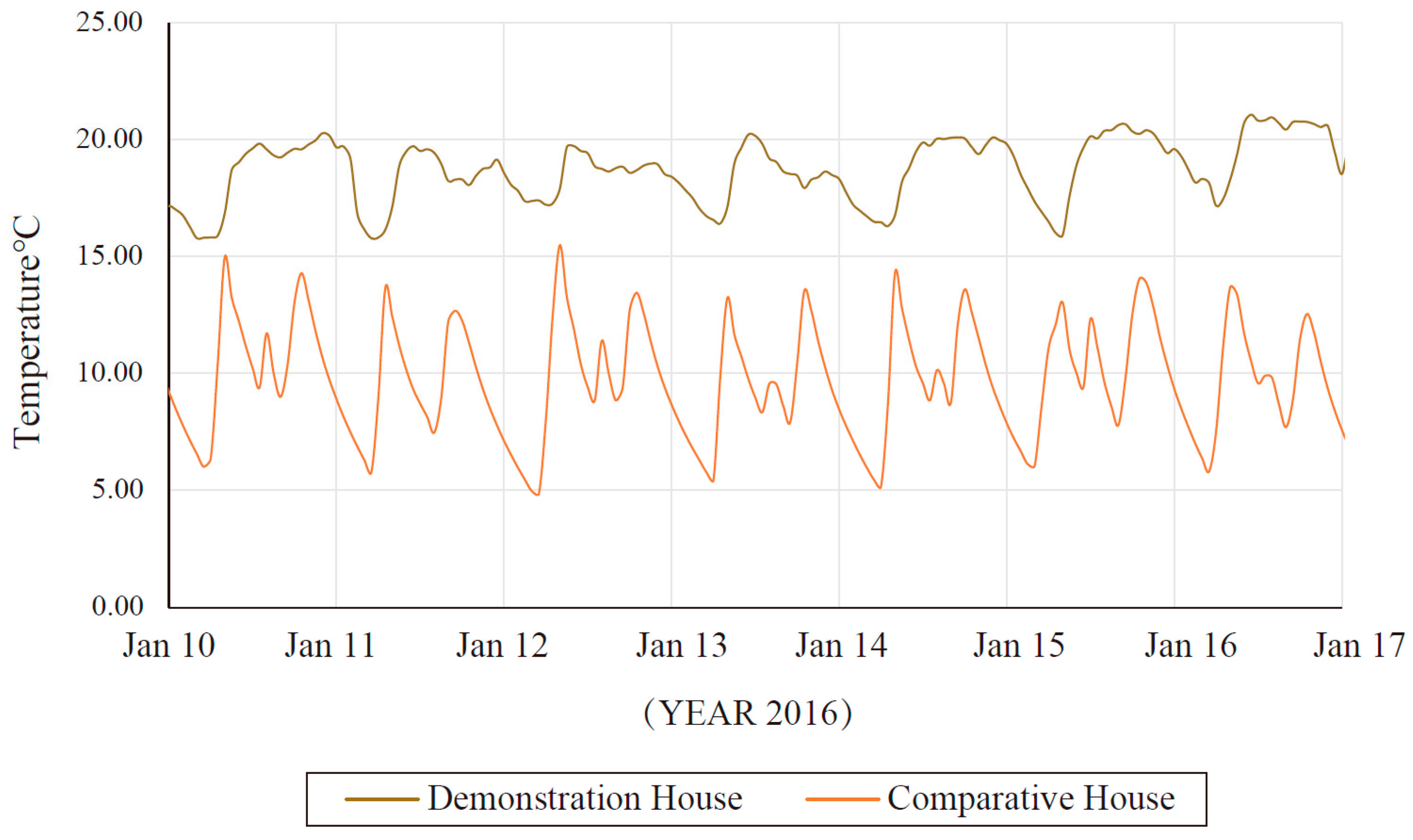

3.3.1. Room Temperature

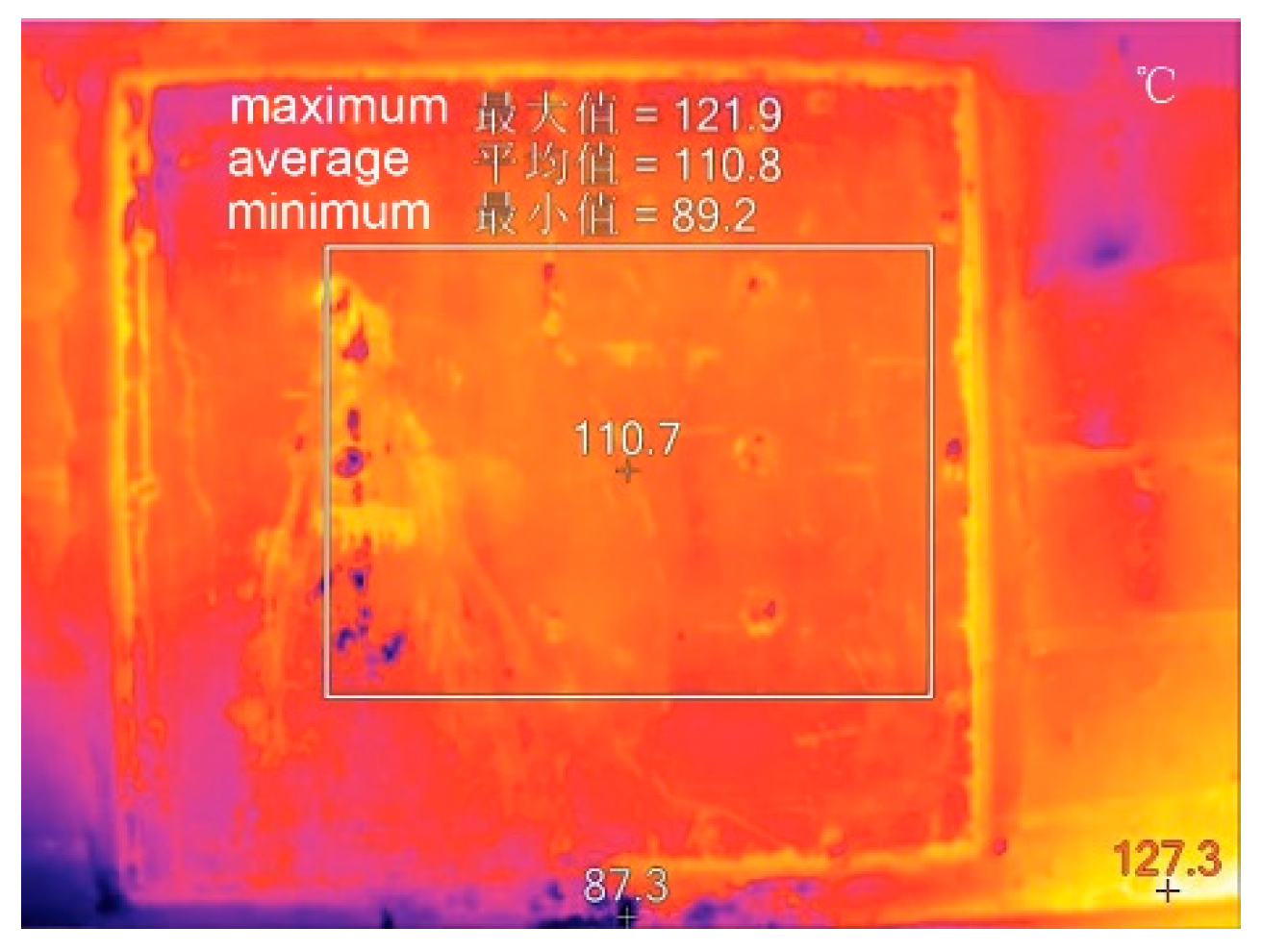

3.3.2. Heat Transfer Coefficient of the Building Envelope

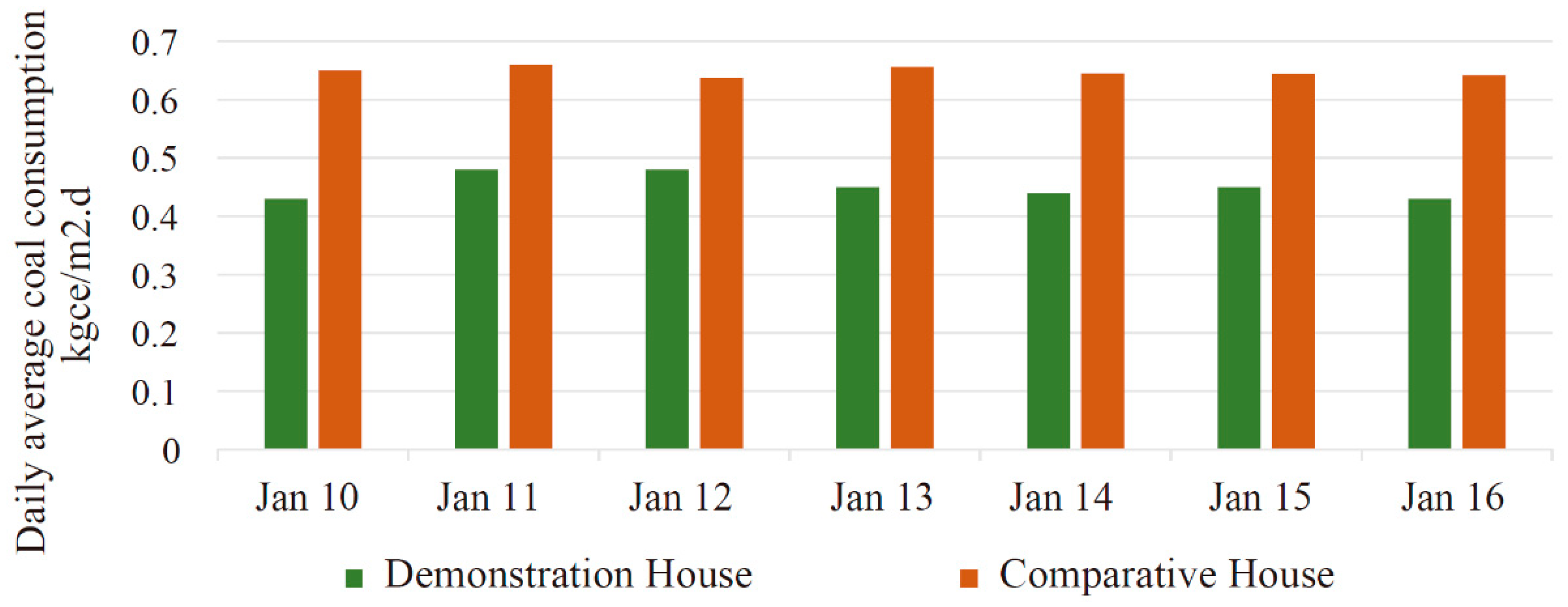

3.3.3. Building Energy Consumption

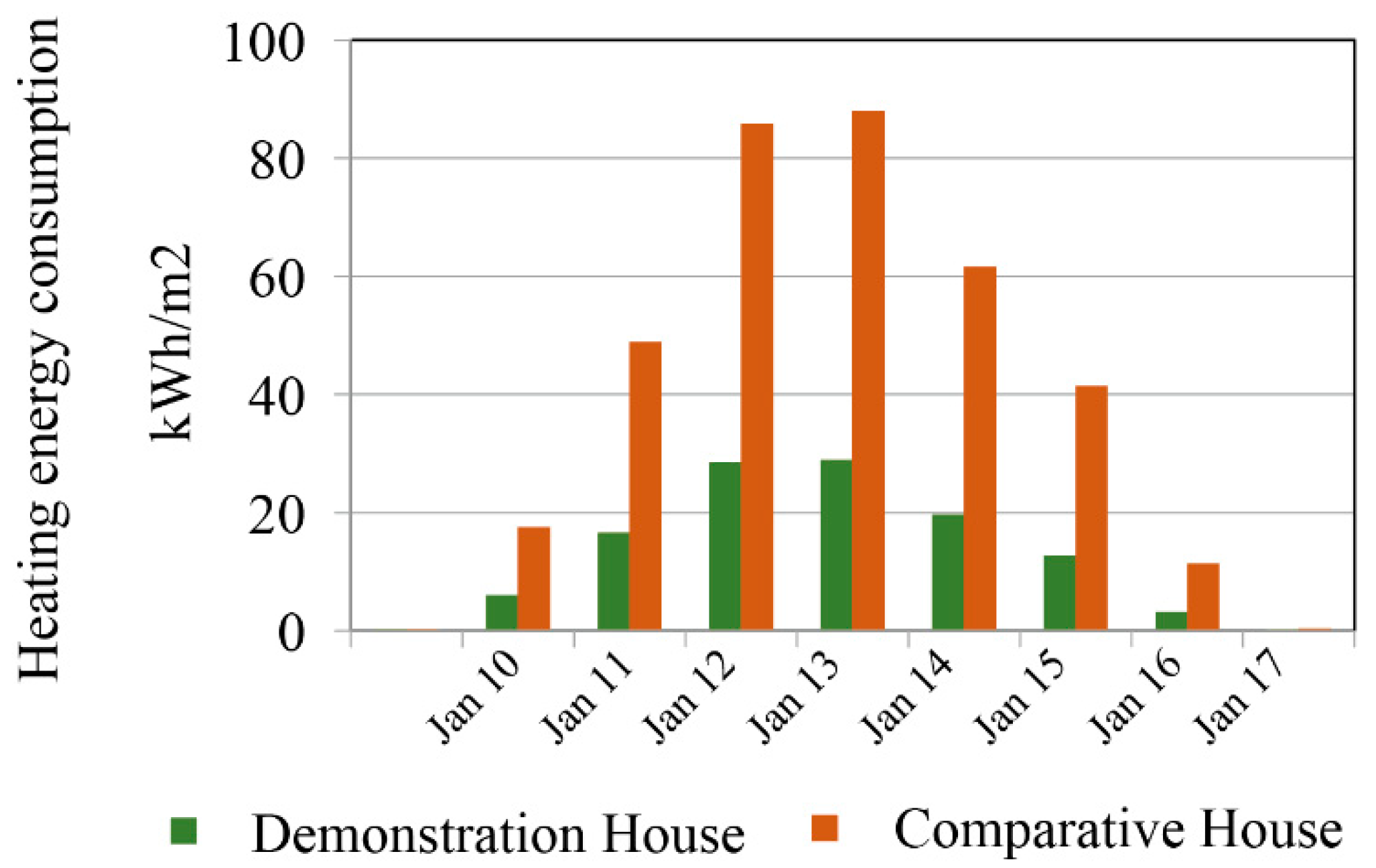

3.4. Simulation of the Annual Heating Energy Consumption of Model Buildings and a Comparison with Measured Data

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Item | Sub-Item | House 1 | House 2 | House 3 | House 4 | House 5 | House 6 | House 7 | House 8 | House 9 | House 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Homeowner age | 33 | 59 | 37 | 40 | 57 | 67 | 67 | 55 | 43 | 57 | |

| Family members | 6 | 6 | 3 | 3 | 4 | 6 | 5 | 4 | 5 | 4 | |

| Residents | 6 | 6 | 3 | 3 | 4 | 2 | 3 | 2 | 5 | 4 | |

| Annual income | 50,000 | 25,000 | 15,000 | 20,000 | 10,000 | 10,000 | 7000 | 10,000 | 15,000 | 20,000 | |

| Generations | 3 | 3 | 2 | 2 | 3 | 1 | 2 | 2 | 2 | 3 | |

| Energy cost | 2600 | 2500 | 2000 | 3000 | 6000 | 2000 | 1500 | 3000 | 3000 | 1000 | |

| Structure type | Brick | Brick | Brick | Brick | Brick | Brick | Brick | Brick | Brick | Brick | |

| Year | 2008 | 1994 | 2008 | 1980 | 1996 | 1989 | 1996 | 1995 | 1992 | 1994 | |

| Cost | 100 K | 25 K | 60 K | 60 K | 6 K | 30 K | 40 K | 60 K | 50 K | 24 K | |

| Floor | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | |

| Indoor height | 2.7 m | 2.7 m | 2.5 m | 2.7 m | 2.6 m | 2.6 m | 4 m | 2.5 m | 2.5 | 2.5 m | |

| Roof height | 1.8 m | 1.5 m | 4 m | 4 m | 1.25 m | 4 m | 4 m | ||||

| Total height | 5 m | 4 m | 5 m | 4 m | 5 m | 4 m | 4.5 m | 4 m | 4.5 m | 4.5 m | |

| Building length | 14 m | 20 m | 13 m | 8.6 m | 13.5 m | 8.6 m | 14 m | 15.8 m | 14 m | ||

| Building depth | 7.6 m | 8 m | 8.3 m | 7.5 m | 8.5 m | 7.8 m | 8.25 m | 8.5 m | 8 m | ||

| Main bedroom | Area | 18.4 | 24 | 9.43 | 30.4 | 8.37 | 12.4 | 19 | 20 | 15.48 | 26.8 |

| Length | 4.8 | 4 | 4.1 | 7.6 | 2.7 | 3.1 | 5 | 5 | 4.3 | 6.7 | |

| Depth | 4 | 6 | 3.3 | 4 | 3.1 | 4 | 3.8 | 4 | 3.6 | 4 | |

| Second bedroom | Area | 16.72 | 12.8 | 8.64 | 22 | 12.8 | 7.2 | 7.5 | 7.8 | 8.6 | |

| Length | 2.2 | 3.2 | 3.6 | 5.8 | 3.2 | 2.4 | 2.5 | 2.6 | 3.2 | ||

| Depth | 7.6 | 4 | 2.4 | 3.1 | 4 | 3 | 3 | 6 | 2.7 | ||

| Living room | √ | √ | |||||||||

| Dining room | √ | √ | √ | ||||||||

| Restroom | |||||||||||

| Storage | √ | √ | √ | ||||||||

| Balcony | √ | ||||||||||

| Fuel type | Summer | None | Wood | None | None | None | None | None | None | None | Wood |

| Winter | Coal | Wood | Coal | Coal | Coal | Coal | Wood | Wood | Wood | Wood | |

| Other fuel | CNG | CNG | CNG | CNG | Straw | CNG | CNG | CNG | CNG |

References

- CNBS. China Statistical Yearbook 2011; China National Bureau of Statistics: Beijing, China, 2011.

- UN. World Urbanization Prospects: The 2010 Revision; Population Division of the Department of Economic and Social Affairs of the United Nations Secretariat: New York, NY, USA, 2010; Available online: http://esa.un.org/unpd/wpp/index.htm (accessed on 13 May 2020).

- Thermal Design Code for Civil Buildings; GB 50176–51993; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 1993.

- Design Code for Heating Ventilation and Air Conditioning of Civil Buildings; GB 50736-2012; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012.

- CNBS. China Energy Statistical Yearbook 2006; China National Bureau of Statistics: Beijing, China, 2007.

- Zhu, L.; Wang, B.; Sun, Y. Multi-objective optimization for energy consumption, daylighting and thermal comfort performance of rural tourism buildings in north China. Build. Environ. 2020, 176, 106841. [Google Scholar] [CrossRef]

- Evans, M.; Yu, S.; Song, B.; Deng, Q.; Liu, J.; Delgado, A. Building energy efficiency in rural China. Energy Policy 2014, 64, 243–251. [Google Scholar] [CrossRef]

- NBS. China Yearbook of Household Survey 2017; China Statistics Press: Beijing, China, 2017.

- Shao, T.; Jin, H. A field investigation on the winter thermal comfort of residents in rural houses at different latitudes of northeast severe cold regions, China. J. Build. Eng. 2020, 101476. [Google Scholar] [CrossRef]

- Wang, X.; Tan, Y.; Zhang, T.; Lu, X.; Yu, K. Experimental and numerical research on the performance of an energy-saving elevated kang in rural buildings of northeast China. Energy Build. 2018, 177, 47–63. [Google Scholar] [CrossRef]

- Jin, H.; Ling, W. External wall structure of green rural houses in Daqing, China, based on life cycle and ecological footprint theories. Front. Arch. Res. 2015, 4, 212–219. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Wu, D.; He, B.-J.; Wang, Q.; Yu, H.; Ma, W.; Jin, G. Evaluating potentials of passive solar heating renovation for the energy poverty alleviation of plateau areas in developing countries: A case study in rural Qinghai-Tibet Plateau, China. Sol. Energy 2019, 187, 95–107. [Google Scholar] [CrossRef]

- Wang, W.; Yuan, M.; Li, Y.-Z.; Li, C. Numerical investigation on the impact of an on-top sunspace passive heating approach for typical rural buildings in northern China. Sol. Energy 2019, 186, 300–310. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- ZeroEnergy Design. Passive House Retreat—New England Zero Energy Design. Available online: https://zeroenergy.com/passive-house-retreat (accessed on 10 May 2020).

- Hills, S.W. Energy-Efficient Design Can Be Simple. 2020. Available online: https://www.curbed.com/2018/12/10/18128862/home-tour-indiana-passive-house-cedar-street-builders-david-rausch (accessed on 5 May 2020).

- Jossi, F. Net-Zero Home Highlights Builders’ Growing Interest in Energy Efficiency. 2020. Available online: https://energynews.us/2019/09/20/midwest/net-zero-home-highlights-builders-growing-interest-in-energy-efficiency/ (accessed on 19 September 2019).

- Mongibello, L.; Capezzuto, M.; Graditi, G. Technical and cost analyses of two different heat storage systems for residential micro-CHP plants. Appl. Therm. Eng. 2014, 71, 636–642. [Google Scholar] [CrossRef]

- Liu, Y.; Yu, K.; Gao, X.; Ren, M.; Jia, M.; Yang, Y. Enhanced thermal properties of hydrate salt/poly (acrylate sodium) copolymer hydrogel as form-stable phase change material via incorporation of hydroxyl carbon nanotubes. Sol. Energy Mater. Sol. Cells 2020, 208, 110387. [Google Scholar] [CrossRef]

- Energy-Saving Design Standards for Residential Buildings in Severe Cold and Cold Areas; JCJ 26-2010; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010.

- Energy-Saving Design Standards for Rural Residential Buildings; GB/T 50824-2013; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2013.

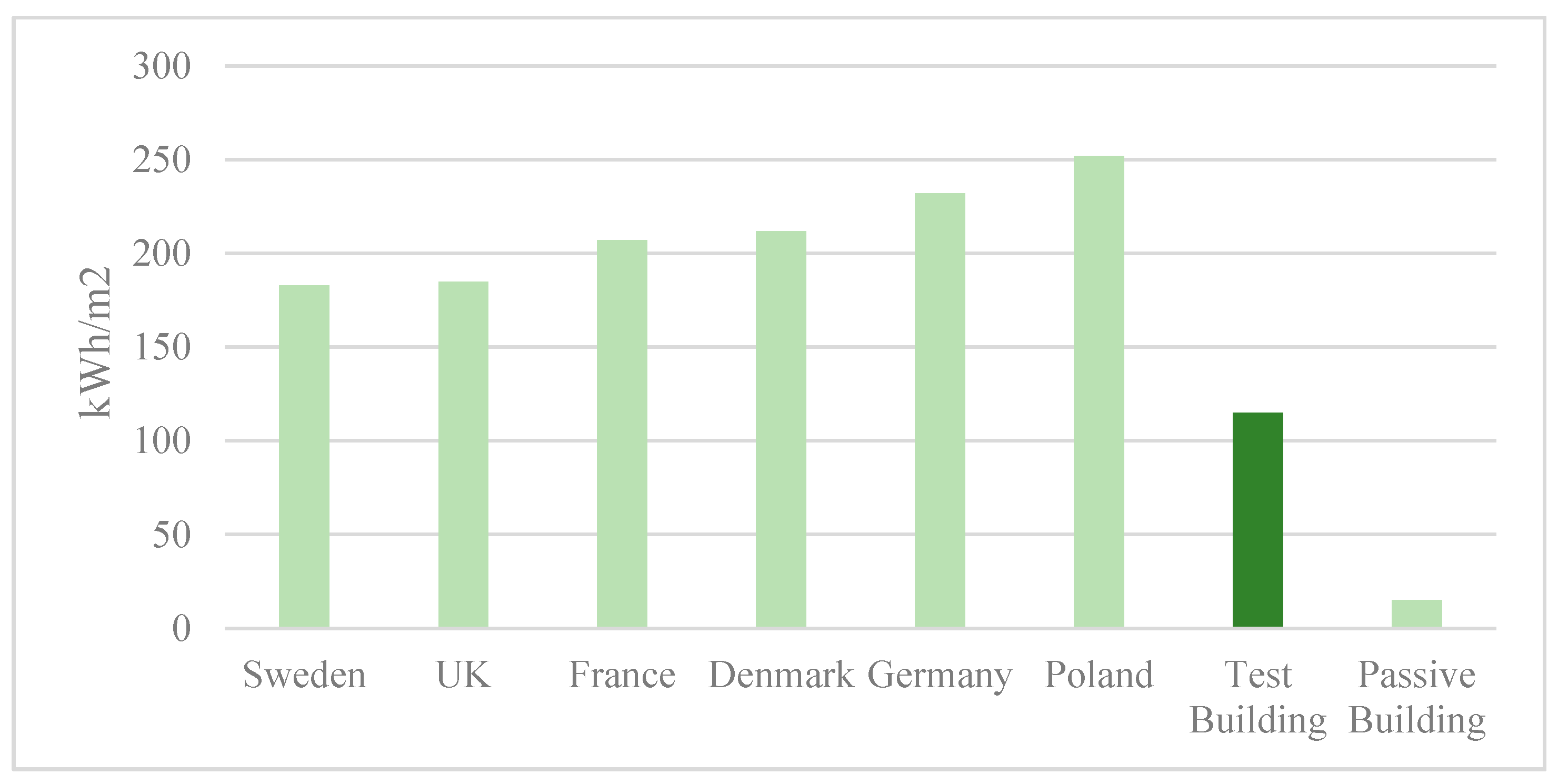

- Consumption of Household per m2 for Space Heating [Chart]. Available online: https://www.indicators.odyssee-mure.eu/online-indicators.html (accessed on 14 May 2020).

- Lu, Y. Practical Heating Design Manual; China Building Industry Press: Beijing, China, 2008. [Google Scholar]

| Type of Wall | Layers (from Internal to External) | d mm | Thermal Transmittance W/(m2 K) | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Internal Insulation | Lime and cement plaster 10 mm EPS board 100 mm Brick 240 mm Lime and cement plaster 10 mm | 320 | 0.72 | Indoor temperature is easy to adjust | Poor heat storage, condensation can occur |

| Middle Insulation | Lime and cement plaster 10 mm Brick 120 mm Lime and cement plaster 10 mm EPS board 100 mm Lime and cement plaster 10 mm Brick 120 mm Lime and cement plaster 10 mm | 340 | 0.86 | Good protection of the thermal insulation layer; good heat storage performance | High cost |

| External Insulation | Lime and cement plaster 10 mm Brick 240 mm EPS board 100 mm Lime and cement plaster 10 mm | 320 | 0.72 | Good heat storage and low cost | Lack of protection for building insulation |

| Type of Window | Advantages | Heat Transfer Coefficient W/(m2 K) | Cost Per sq m RMB |

|---|---|---|---|

| Energy-savings plastic steel window | Low cost and middle level of thermal insulation | 2.0–3.4 | 180–300 |

| Aluminum window | High strength and various opening methods | 2.2–6.4 | 120–220 |

| Broken bridge aluminum window | Good thermal insulation performance, lightweight and high strength | 1.8–2.2 | 400–600 |

| Aluminum-clad wood window | Thermal insulation, durable | 0.8–1.5 | 1000–2500 |

| Item | Demonstration House | Comparative House |

|---|---|---|

| Photo |  |  |

| Year of completion | 2015 | 2008 |

| Floor area | 101.48 m2 | 60 m2 |

| Exterior wall structure | 100 cm thick polystyrene board + 200 cm thick hollow concrete block wall | 50 cm thick brick wall |

| Exterior windows | Three-layer glass-plastic steel windows | Aluminum window |

| Roof structure | Concrete board + 10 cm layer of volcanic ash + wooden roof frame + steel plate with 40 cm thick EPS boards | Wooden structure |

| Heating method | Water heating system + hanging Kang + phase change firewall | Water heating system + Kang + firewall |

| Heating fuel | Coal + wood | Coal + wood |

| Device Model/Name | Usage | Location |

|---|---|---|

| Small outdoor weather station | Outdoor weather parameters | Outdoors in a non-shaded area |

| Bes temperature probe | Room and wall temperature | Indoors at the center of the room |

| Heat flow meter | Heat flux | Inside the building on the exterior wall and the interior wall |

| T-scale electronic scale | Coal/biomass weight | |

| FLUKE infrared thermal imager FLK-TiS60 | Temperature |

| Demonstration House | Comparative House | Standard Limit | |||

|---|---|---|---|---|---|

| Wall | Roof | Wall | Roof | Wall | Roof |

| 0.33 | 0.32 | 0.73 | 0.69 | 0.5 | 0.45 |

| Material | Concrete | Polystyrene Board | Steel |

|---|---|---|---|

| Thermal conductivity (W/m.K) | 1.740 | 0.030 | 58.200 |

| Specific heat capacity (J/kg.K) | 920.0000 | 5346.4000 | 480.0000 |

| Dry density (kg/m3) | 2500.00 | 25.00 | 7850.00 |

| Time | Bedroom | Living Room, Kitchen, Rest Room | Foyer, Sunroom |

|---|---|---|---|

| 6:00 to 21:00 | 18 °C | 18 °C | No control |

| 21:00 to 6:00 | No control | No control | No control |

| Project | Mohe | Keshan | Shenyang |

|---|---|---|---|

| Demonstration House | 146.6 | 116.1 | 67.9 |

| Comparative House | 470.2 | 355.2 | 201.0 |

| Energy savings rate (%) | 68.8 | 67.3 | 66.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, W.; Mei, H. A Design Strategy for Energy-Efficient Rural Houses in Severe Cold Regions. Int. J. Environ. Res. Public Health 2020, 17, 6481. https://doi.org/10.3390/ijerph17186481

Pan W, Mei H. A Design Strategy for Energy-Efficient Rural Houses in Severe Cold Regions. International Journal of Environmental Research and Public Health. 2020; 17(18):6481. https://doi.org/10.3390/ijerph17186481

Chicago/Turabian StylePan, Wente, and Hongyuan Mei. 2020. "A Design Strategy for Energy-Efficient Rural Houses in Severe Cold Regions" International Journal of Environmental Research and Public Health 17, no. 18: 6481. https://doi.org/10.3390/ijerph17186481