Sustainable Development of Industry–Environmental System Based on Resilience Perspective

Abstract

:1. Introduction

- (1)

- Evaluate environmental pollution, resource consuming, and industrial adjustment in a quantitative way, and give the pressure levels of different indexes in industrial–environment system. Identify resilience changing curve of industrial activities sub-system and environment subsystem by using resilience quantitative and analyze the coupled system adaptive ability.

- (2)

- The validity of the evaluation model is verified by an empirical case. The results of the study provide guidance for the sustainable development of Chengdu and provide decision-making basis for promoting industrial development and maintaining economic and ecological balance.

- (3)

- Master the resilient change law of the industry–environmental system, discuss and understand the characteristics of different stages, and explore the appropriate implementation cycle and feedback effects of various key indicators. In the period of industrial transformation and development of various cities, it contributes to policy changes, industrial adjustment, and strategy formulation.

2. Background

2.1. Literature Review

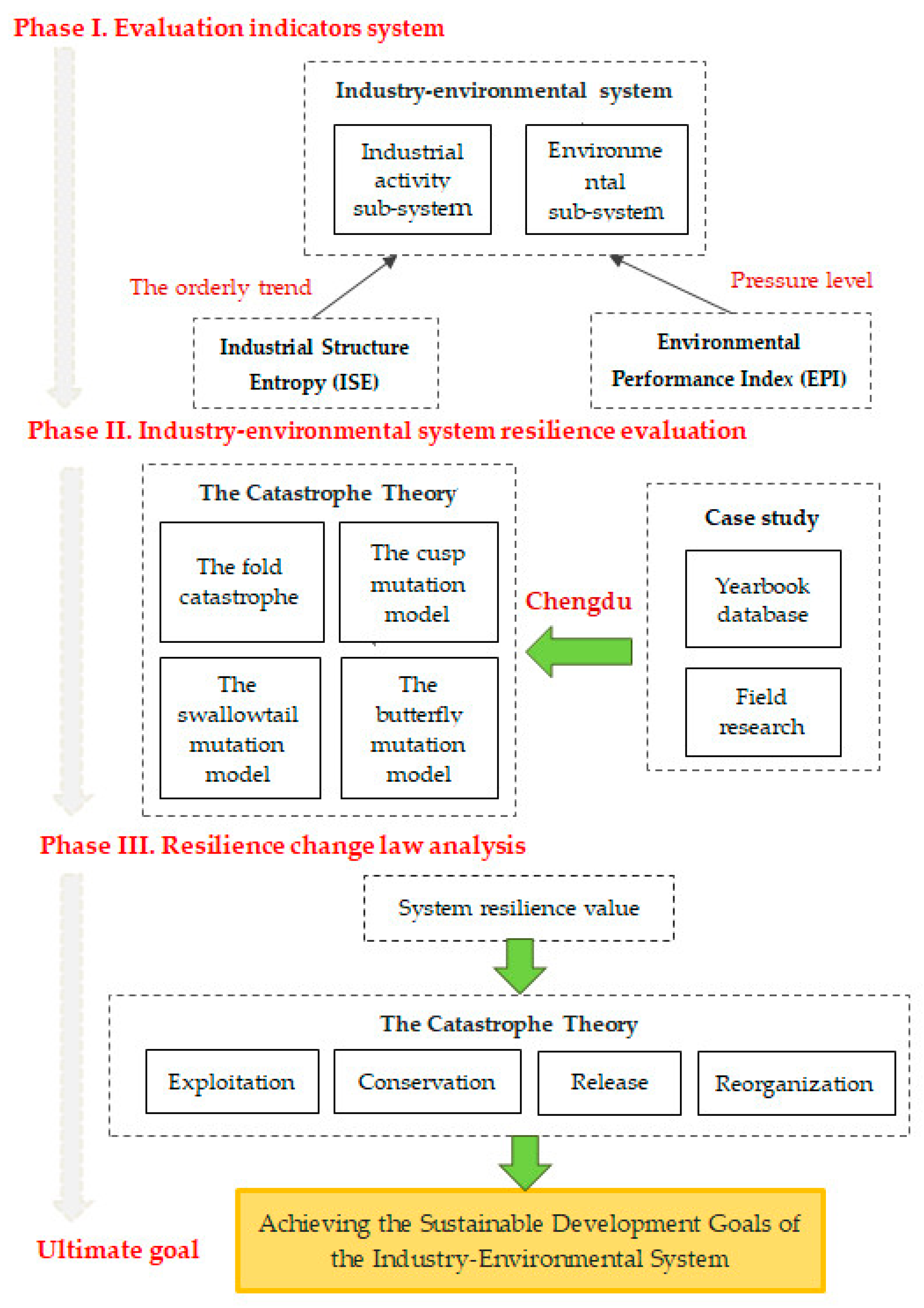

2.2. Research Framework

3. Materials and Methods

3.1. Evaluation Index System

Data Standardization

3.2. Environmental Performance Index

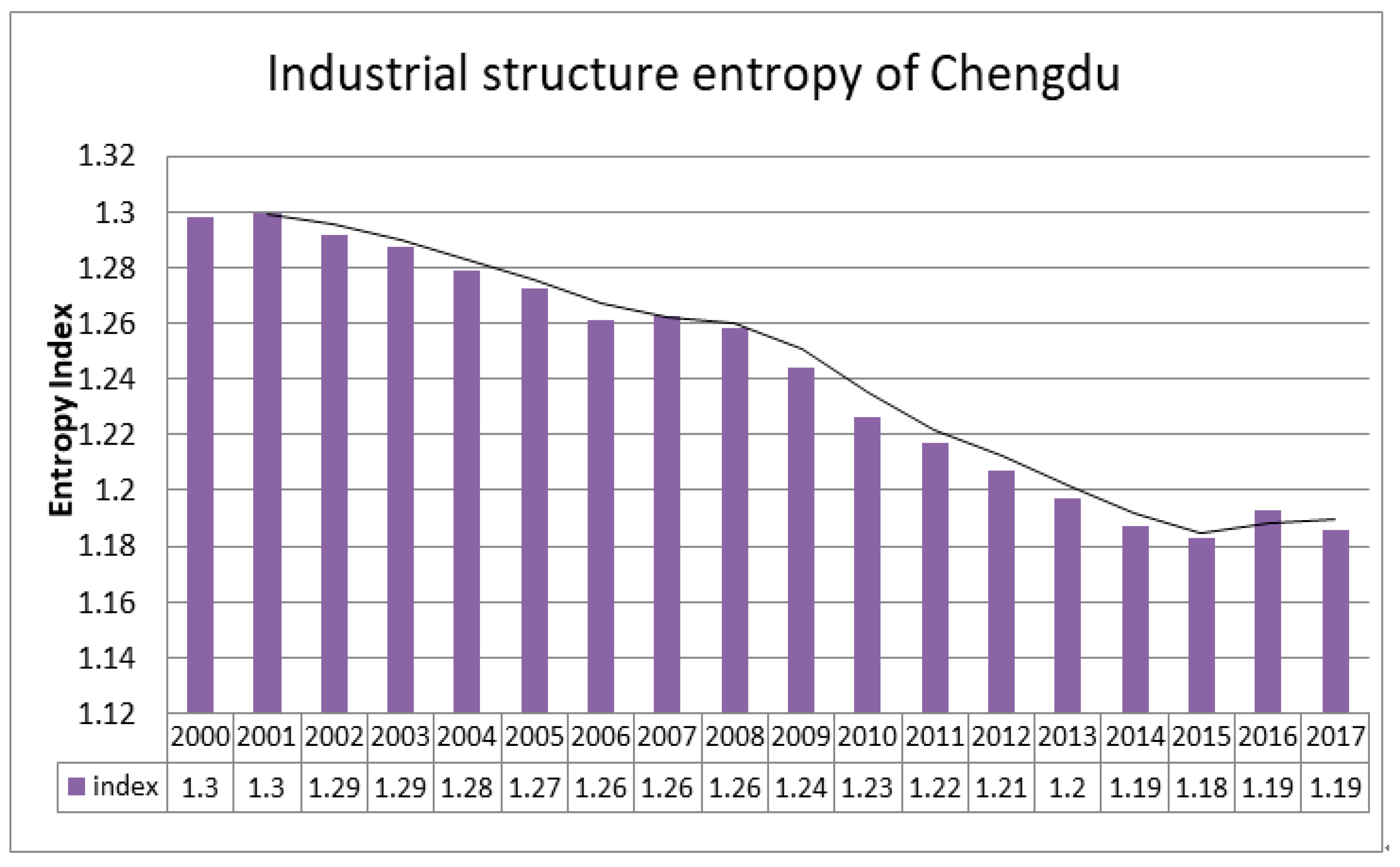

3.3. Industrial Structure Entropy

3.4. Catastrophe Theory

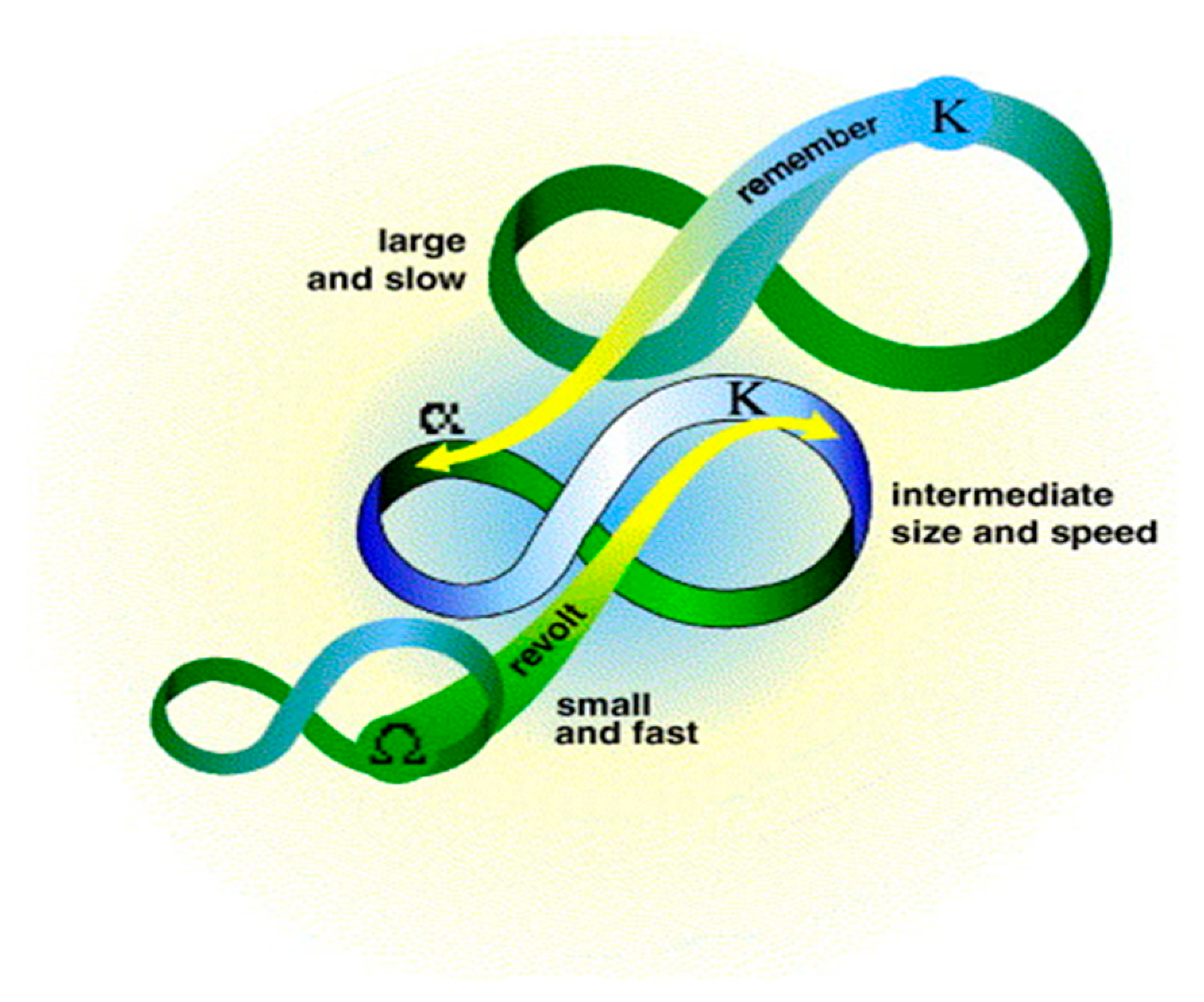

3.5. Adaptive Cycle Model

4. Case Study

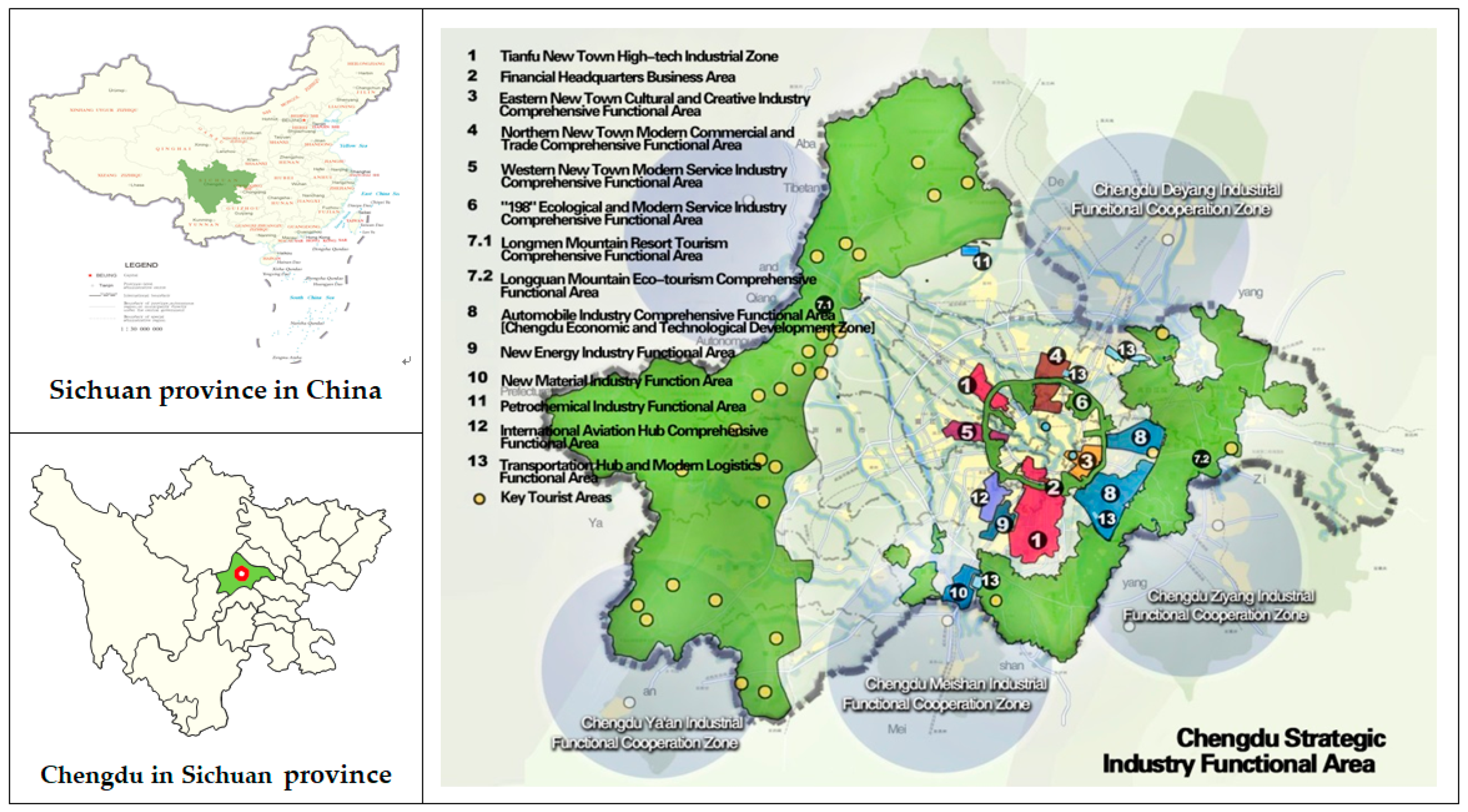

4.1. Research Case Area

4.2. Data Acquisition and Processing

4.2.1. Data Processing Results Analysis of EPI

4.2.2. Data Processing Results Analysis of ISE

4.3. Analytic Results

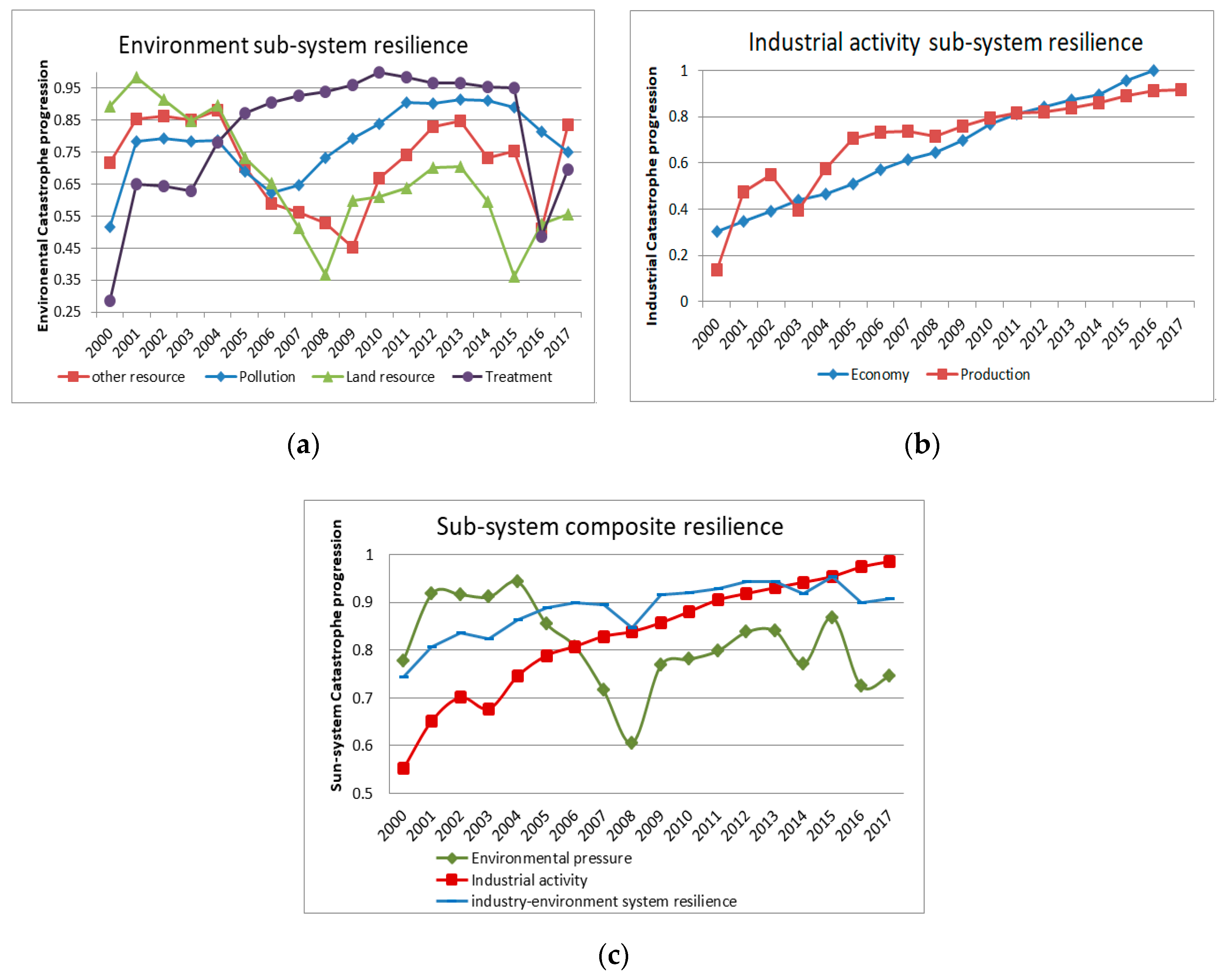

4.3.1. Environmental Sub-System

4.3.2. Industrial Activity Sub-System

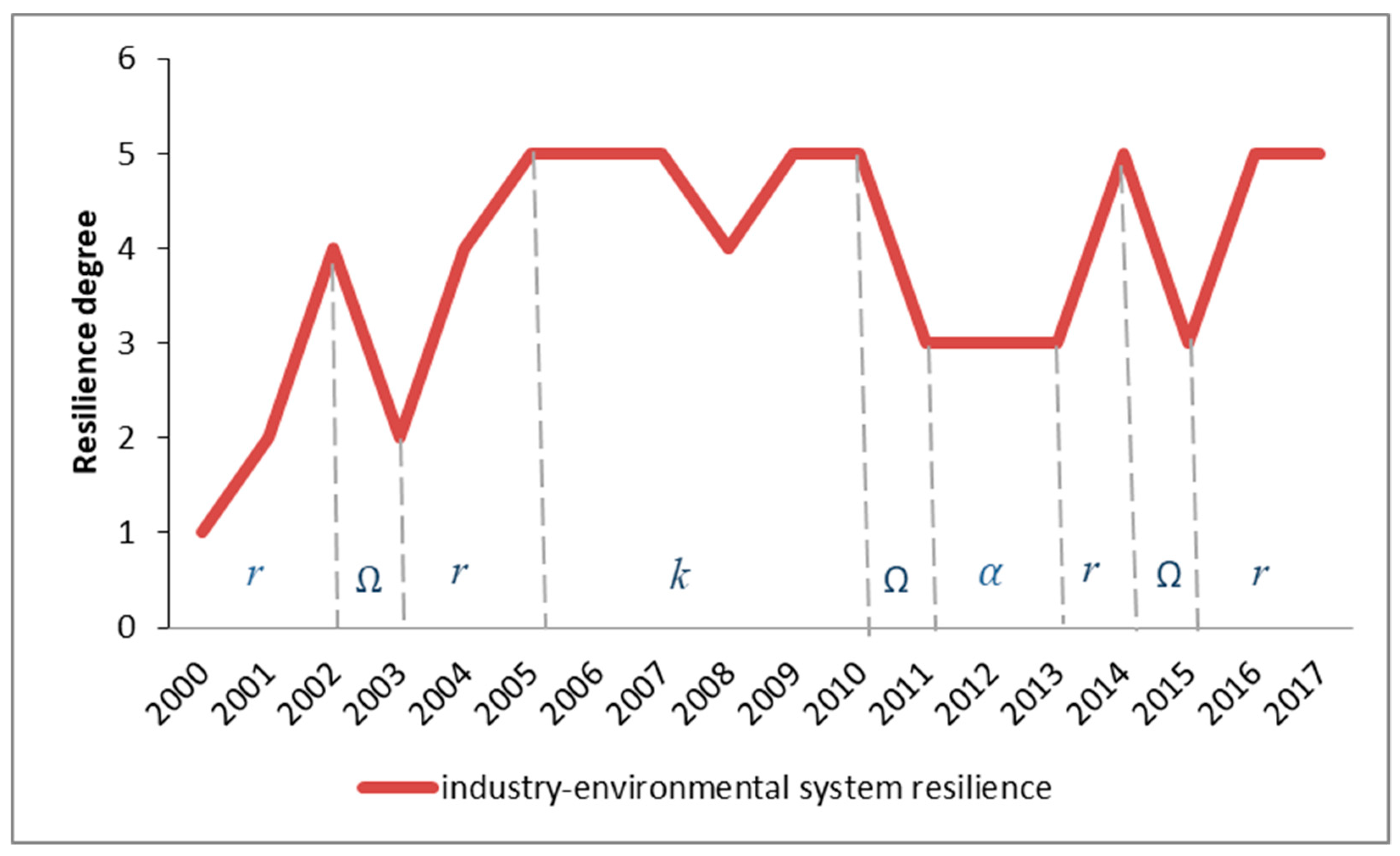

4.3.3. Resilience Change in the Industry–Environmental Systems

4.4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Erkman, S. Industrial ecology: An historical view. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Cmtzen, P.J. Geology of mankind. Nature 2002, 415, 23. [Google Scholar]

- Grabara, J. Sustainable development—Never fulfilled dream. Calitatea 2019, 20, 565–570. [Google Scholar]

- Grabara, J. The another point of view on sustainable management. Qual. Access Success 2017, 18, 344–349. [Google Scholar]

- Li, Y.; Shi, L. The resilience of interdependent industrial symbiosis networks: A case of Yixing economic and technological development zone. J. Ind. Ecol. 2015, 19, 264–273. [Google Scholar] [CrossRef]

- Jia, X.; Foo, D.; Tan, R.; Li, Z. Sustainable development paths for resource-constrained process industries. Resour. Conserv. Recycl. 2017, 119, 1–3. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, J.; Zhang, N. Industrial eco-efficiency, regional disparity, and spatial convergence of China’s regions. J. Clean. Prod. 2018, 204, 872–887. [Google Scholar] [CrossRef]

- Wu, M.; Ma, J. Measurement on regional ecological efficiency in China and analysis on its influencing factors: Based on DEA-Tobit Two-stage Method. Technol. Econ. Dev. Econ. 2016, 35, 75–80. [Google Scholar]

- Auty, R.M. Sustaining Development in Mineral Economies: The Resource Curse Thesis; Routledge: London, UK, 1993. [Google Scholar]

- Panayotou, T. Empirical Tests and Policy Analysis of Environmental Degradation at Different Stages of Economic Development; International Labour Office: Geneva, Switzerland, 1993. [Google Scholar]

- Hollings, C.S. Resilience and stability of ecological systems. Annu. Rev. Ecol. Evol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Fraccascia, L.; Giannoccaro, I.; Albino, V. Rethinking Resilience in Industrial Symbiosis: Conceptualization and Measurements. Ecol. Econ. 2017, 137, 148–162. [Google Scholar] [CrossRef]

- Sun, L.; Li, H.; Dong, L.; Fang, K.; Ren, J.; Geng, Y.; Fujii, M.; Zhang, W.; Zhang, N.; Liu, Z. Eco-benefits assessment on urban industrial symbiosis based on material flows analysis and emergy evaluation approach: A case of Liuzhou city, China. Resour. Conserv. Recycl. 2017, 119, 78–88. [Google Scholar] [CrossRef] [Green Version]

- Ashton, W.S.; Chopra, S.S.; Kashyap, A.R. Life and Death of Industrial Ecosystems. Sustainability 2017, 9, 605. [Google Scholar] [CrossRef] [Green Version]

- Valenzuela-Venegas, G.; Henríquez-Henríquez, F.; Boix, M.; Díaz-Alvarado, F.A. Resilience Study Applied in Eco-Industrial Parks. Comput. Aided Chem. Eng. 2017, 40, 1957–1962. [Google Scholar]

- Valenzuela-Venegas, G.; Henríquez-Henríquez, F.; Boix, M.; Montastruc, L.; Arenas-Araya, F.; Miranda-Pérez, J.; Díaz-Alvarado, F.A. A resilience indicator for Eco-Industrial Parks. J. Clean. Prod. 2018, 174, 807–820. [Google Scholar] [CrossRef] [Green Version]

- Adger, W.N. Social and ecological resilience: Are they related. Prog. Hum. Geogr. 2000, 24, 347–364. [Google Scholar] [CrossRef]

- Folke, C. Resilience: The emergence of a perspective for social-ecological systems analyses. Glob. Environ. Chang. 2006, 16, 253–267. [Google Scholar] [CrossRef]

- Hu, M.C.; Fan, C.; Huang, T.; Wang, C.F.; Chen, Y.H. Urban metabolic analysis of a food-water-energy system for sustainable resources management. Int. J. Environ. Res. Public Health 2019, 16, 90. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Ruth, M. Exploring the resilience of industrial ecosystems. J. Environ. Manag. 2013, 122, 65–75. [Google Scholar] [CrossRef]

- Carpenter, S.; Walker, B.; Anderies, J.M.; Abel, N. From metaphor to measurement: Resilience of what to what. Ecosystems 2001, 4, 765–781. [Google Scholar] [CrossRef]

- Li, Y.; Degener, J.; Gaudreau, M.; Li, Y.; Kappas, M. Adaptive capacity based water quality resilience transformation and policy implications in rapidly urbanizing landscapes. Sci. Total Environ. 2016, 569, 168–178. [Google Scholar] [CrossRef]

- Terao, T. Industrial Policy, Industrial Development and Pollution Control in Post-War Japan: Implications for Developing Countries; Institute of Developing Economies: London, UK, 2007. [Google Scholar]

- Liu, Q.; Li, L. Spatial heterogeneity of government regulation, spatial distance and enterprise carbon information disclosure: An analysis based on the heavy pollution industry in China. Int. J. Environ. Res. Public Health 2019, 16, 4777. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Staniški, H.J.K. Green industry—A new concept. Environ. Res. Eng. Manag. 2011, 56, 3–15. [Google Scholar] [CrossRef]

- Yin, Q.; Piao, H.; Liu, B. Ecological Industry Chain Designing of Making Paper Industry: Turning Pollution Industry into Ecological Industry. Chin. J. Environ. Sci. 2003, 24, 140–144. [Google Scholar]

- Fazey, I.; Fazey, J.A.; Fischer, J.; Sherren, K.; Warren, J.; Noss, R.F.; Dovers, S.R. Adaptive capacity and learning to learn as leverage for social–ecological resilience. Front. Ecol. Environ. 2007, 5, 375–380. [Google Scholar] [CrossRef]

- Liu, G.; Hao, Y.; Zhou, Y.; Yang, Z.; Zhang, Y.; Su, M. China’s low-carbon industrial transformation assessment based on Logarithmic Mean Divisia Index model. Resour. Conserv. Recycl. 2016, 108, 156–170. [Google Scholar] [CrossRef]

- Yang, D.; Liu, B.; Ma, W.; Guo, Q.; Li, F.; Yang, D. Sectoral energy-carbon nexus and low-carbon policy alternatives: A case study of Ningbo, China. J. Clean. Prod. 2017, 156, 480–490. [Google Scholar] [CrossRef]

- Miao, C.; Fang, D.; Sun, L.; Luo, Q. Natural resources utilization efficiency under the influence of green technological innovation. Resour. Conserv. Recycl. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Ho, H.H.; Yong, Y. Eco-health evaluation for the Shanghai metropolitan area during the recent industrial transformation (1990–2003). J. Environ. Manag. 2008, 88, 1047–1055. [Google Scholar] [CrossRef]

- Xie, L.; Chen, C.; Yu, Y. Dynamic Assessment of Environmental Efficiency in Chinese Industry: A Multiple DEA Model with a Gini Criterion Approach. Sustainability 2019, 11, 2294. [Google Scholar] [CrossRef] [Green Version]

- Yang, D.; Gao, X.; Xu, L.; Gou, Q. Constraint-adaptation challenges and resilience transitions of the industry–environmental system in a resource-dependent city. Resour. Conserv. Recycl. 2018, 134, 196–205. [Google Scholar] [CrossRef]

- Kuai, P.; Li, W.; Cheng, R.; Cheng, G. An application of system dynamics for evaluating planning alternatives to guide a green industrial transformation in a resource-based city. J. Clean. Prod. 2015, 104, 403–412. [Google Scholar] [CrossRef]

- Zeng, X.; Zhu, Y.; Chen, C.; Tong, Y.; Li, Y.; Huang, G.; Nie, S.; Wang, X. A production-emission nexus based stochastic-fuzzy model for identification of urban industry-environment policy under uncertainty. J. Clean. Prod. 2017, 154, 61–82. [Google Scholar] [CrossRef]

- Pyka, R. Minimizing the side effects of the metropolization as a condition for maintenance of transition and resilience in post-industrial agglomerations. J. Econ. Manag. 2013, 10, 121–136. [Google Scholar]

- Ribeiro, P.J.G.; Gonçalves, L. Urban Resilience: A conceptual framework. Sustain. Cities Soc. 2019, 50, 101625. [Google Scholar] [CrossRef]

- Li, Y.; Kappas, M.; Li, Y. Exploring the coastal urban resilience and transformation of coupled human-environment systems. J. Clean. Prod. 2018, 195, 1505–1511. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Kappas, M.; Pavao-Zuckerman, M. Identifying the key catastrophic variables of urban social-environmental resilience and early warning signal. Environ. Int. 2018, 113, 184–190. [Google Scholar] [CrossRef]

- Liu, H.; Wang, H.; Zhou, X.; Fan, J.; Liu, Y.; Yang, Y. A comprehensive index for evaluating and enhancing effective wastewater treatment in two industrial parks in China. J. Clean. Prod. 2019, 230, 854–861. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Q.; Chang, Y.T. China’s regional industrial two-stage system—Efficiencies and their influencing factors. J. Clean. Prod. 2019. [Google Scholar] [CrossRef]

- Huang, J.; Xia, J.; Yu, Y.; Zhang, N. Composite eco-efficiency indicators for China based on data envelopment analysis. Ecol. Indic. 2018, 85, 674–697. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, Y.; Chang, Y.; Zhang, L. Industrial eco-efficiency in China: A provincial quantification using three-stage data envelopment analysis. J. Clean. Prod. 2017, 143, 61–82. [Google Scholar] [CrossRef]

- Chang, Y.; Hou, K.; Wu, Y.; Li, X.; Zhang, J. A conceptual framework for establishing the index system of ecological environment evaluation—A case study of the upper Hanjiang River, China. Ecol. Indic. 2019, 107, 105568. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, L.; Zhang, R.; Deng, S.; Zhang, Y.; Wu, J.; Li, Y.; Lin, L.; Li, L.; Wang, Y.; et al. Evaluating the relationships among economic growth, energy consumption, air emissions and air environmental protection investment in China. Renew. Sustain. Energy Rev. 2013, 18, 259–270. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, L. Exploring the relation between the industrial structure and the eco-environment based on an integrated approach: A case study of Beijing, China. Ecol. Indic. 2019, 103, 83–93. [Google Scholar] [CrossRef]

- Zhou, Y.; Kong, Y.; Sha, J.; Wang, H. The role of industrial structure upgrades in eco-efficiency evolution: Spatial correlation and spillover effects. Sci. Total Environ. 2019, 687, 1327–1336. [Google Scholar] [CrossRef]

- Xiong, S.; Ma, X.; Ji, J. The impact of industrial structure efficiency on provincial industrial energy efficiency in China. J. Clean. Prod. 2019, 215, 952–962. [Google Scholar] [CrossRef]

- Wang, D.; Wan, K.; Yang, J. Measurement and evolution of eco-efficiency of coal industry ecosystem in China. J. Clean. Prod. 2019, 209, 803–818. [Google Scholar] [CrossRef]

- Chaim, O.; Muschard, B.; Cazarini, E.; Rozenfeld, H. Insertion of sustainability performance indicators in an industry 4.0 virtual learning environment. Procedia Manuf. 2018, 21, 446–453. [Google Scholar] [CrossRef]

- García-Sánchez, I.M.; Almeida, T.A.N.; Camara, R.P.B. A proposal for a composite index of environmental performance (CIEP) for countries. Ecol. Indic. 2015, 48, 171–188. [Google Scholar] [CrossRef]

- Hsu, A.; Emerson, J.; Levy, M.; Sherbinin, A.; Johnson, L.; Malik, O.; Schwartz, J.; Jaiteh, M. The 2014 Environmental Performance Index; Yale Center for Environmental Law & Policy: New Haven, CT, USA, 2014. [Google Scholar]

- Ravichandran, R. Management of Radioactive Wastes in a Hospital Environment. In Modelling Trends in Solid and Hazardous Waste Management; Springer: Singapore; Muscat, Oman, 2017; pp. 1–14. [Google Scholar]

- Das Neves Almeida, T.A.; García-Sánchez, I.M. A comparative analysis between composite indexes of environmental performance: An analysis on the CIEP and EPI. Environ. Sci. Policy 2016, 64, 59–74. [Google Scholar] [CrossRef]

- Liu, G.; Shen, L. Characteristics and mechanism of Tibet’s industrial structure evolution from 1951–2004. Acta Geogr. Sin. 2007, 62, 364–376. [Google Scholar]

- Shannon, C.E. A mathematical theory of communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Lin, M.; Yuna, H. Study on the Evolution of Industrial Structure in the Process of Transformation of Resource-based Cities in Northeast China. Arid Area Resour. Environ. 2016, 30, 20–27. [Google Scholar]

- Yang, Z.F.; Zhao, W. Analysis on Evolution of Urban Energy System Structure Based on Information Entropy, Energy Sources Part A—Recovery Util. Environ. Eff. 2008, 30, 1400–1412. [Google Scholar]

- FAO. Self-Evaluation and Holistic Assessment of Climate Resilience of Farmers and Pastoralists; FAO: Rome, Italy, 2015. [Google Scholar]

- Resilience Alliance, 2010. Assessing Resilience in Social-Ecological Systems: Workbook for Practitioners. Available online: http://www.resalliance.org/3871.php (accessed on 1 January 2010).

- Chen, Y.; Song, G.; Yang, F.; Zhang, S.; Zhang, Y.; Liu, Z. Risk Assessment and Hierarchical Risk Management of Enterprises in Chemical Industrial Parks Based on Catastrophe Theory. Int. J. Environ. Res. Public Health 2012, 9, 4386–4402. [Google Scholar] [CrossRef] [Green Version]

- Youn, B.D.; Hu, C.; Wang, P. Resilience-driven system design of complex engineered systems. J. Mech. Des. 2011, 133, 101011. [Google Scholar] [CrossRef]

- Rose, A. Economic resilience to natural and man-made disasters: Multidisciplinary origins and contextual dimensions. Environ. Hazards 2007, 7, 383–398. [Google Scholar] [CrossRef]

- Fenton, N.; Neil, M. Risk Assessment and Decision Analysis with Bayesian Networks; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Wang, W.; Liu, S.; Zhang, S.; Chen, J. Assessment of a model of pollution disaster in near-shore coastal waters based on catastrophe theory. Ecol. Model. 2011, 222, 307–312. [Google Scholar] [CrossRef]

- Ahammed, S.; Chung, E.S.; Shahid, S. Parametric assessment of pre-monsoon agricultural water scarcity in bangladesh. Sustainability 2018, 10, 819. [Google Scholar] [CrossRef] [Green Version]

- Bănică, A.; Istrate, M.; Muntele, I. Challenges for the Resilience Capacity of Romanian Shrinking Cities. Sustainability 2017, 9, 2289. [Google Scholar] [CrossRef] [Green Version]

- Gunderson, L.H.; Holling, C.S. Panarchy. In Understanding Transformations in Human and Natural Systems; Island Press: Washington, DC, USA, 2002. [Google Scholar]

- Walker, B.; Salt, D. Resilience Practice: Building Capacity to Absorb Disturbance and Maintain Function; Island Press: Washington, DC, USA, 2012. [Google Scholar]

- Haseeb, M.; Hussain, H.I.; Kot, S.; Androniceanu, A.; Jermsittiparsert, K. Role of Social and Technological Challenges in Achieving a Sustainable Competitive Advantage and Sustainable Business Performance. Sustainability 2019, 11, 3811. [Google Scholar] [CrossRef] [Green Version]

- Sutopo, B.; Kot, S.; Adiati, A.K.; Ardila, L.N. Sustainability Reporting and Value Relevance of Financial Statements. Sustainability 2018, 10, 678. [Google Scholar] [CrossRef] [Green Version]

- Poston, T.; Stewart, I. Catastrophe Theory and Its Application; Dover Publications Inc.: New York, NY, USA, 2012. [Google Scholar]

| Authors | Environment Sub-System | ||||||

|---|---|---|---|---|---|---|---|

| Economy | Production | Industrial Structure | Land Use | Pollution | Treatment | Resource Consumption | |

| Yang et al. [33] | √ | √ | √ | √ | |||

| Li et al. [38] | √ | √ | √ | √ | √ | √ | |

| Chen and Zhao [46] | √ | √ | √ | √ | √ | ||

| Zhou et al. [47] | √ | √ | √ | √ | |||

| Xiong et al. [48] | √ | √ | √ | ||||

| Wang et al. [49] | √ | √ | √ | √ | √ | ||

| Huang et al. [42] | √ | √ | √ | √ | |||

| Chang et al. [44] | √ | √ | √ | √ | |||

| Chaim et al. [50] | √ | √ | √ | ||||

| Zhang et al. [43] | √ | √ | √ | √ | |||

| Li et al. [39] | √ | √ | √ | √ | √ | √ | |

| Sub-Systems | Criteria Layer | Indicators | Direction |

|---|---|---|---|

| Industrial activity (A1) | Economy (B1) | Output value of the primary industry (C11) + | ↓ |

| Output value of the secondary industry (C12) + | ↓ | ||

| Output value of the tertiary industry (C13) ++ | ↑ | ||

| Production (B2) | Proportion of industry (C24) ++ | ↑ | |

| industrial structure (C25) + | ↑ | ||

| Output value of agriculture, Forest, Animal husbandry and fishery (C26) + | ↓ | ||

| Environment (A2) | Land resource (B3) | Construction land area (C37) * | ↑ |

| cultivated field (C38) ++ | ↑ | ||

| Other resources (B4) | Energy consumption (C49) ++ | ↑ | |

| Water consumption (C410) ++ | ↑ | ||

| Power consumption (C411) ++ | ↑ | ||

| Pollution (B5) | Wastewater discharge (C512) ++ | ↑ | |

| Industry Waste gas (C513) ++ | ↑ | ||

| Industrial Smoke dust (C514) ++ | ↑ | ||

| Industrial Solid waste (C515) ++ | ↑ | ||

| Treatment (B6) | Industrial solid wastes utilization (C616) + | ↓ | |

| Wastewater treatment capacity (C617) ++ | ↑ |

| Approaches | Measure | References | Description |

|---|---|---|---|

| Passive survival rate and proactive survival rate | Resilience (Ψ) = Reliability (R) + Restoration (ρ) | Youn, Hu and Wang [62] | Passive survival refers to the reliability of the system, and active survival represents the resilience of the system. Although this method is most suitable for earthquakes, it can still be used to quantify the resiliency of other systems. |

| Dynamic resilience (DR) | DR = | Rose [63] | Dynamic resilience calculation based on hastened recovery (SOHR) and without hastened recovery (SOWR) |

| The Bayesian network | P(Y1,Y2,Y3,…,Yn) = P(Y1/Y2,Y3,…,Yn)P(Y2, /Y3,…,Yn)…P(Yn-1/Pn)P(Yn) | Fenton and Neil [64] | The BN is a powerful tool for risk evaluation, reliability prediction, and decision making under the stochastic conditions of a complex system. It makes statistical inference in a reasonable way by updating the prior beliefs of an elementary event |

| The catastrophe theory | Fold: V = x3 + ax; Xa1 = ; Cusp: V = x4 + ax2 + bx; Xa1 = , Xa2 = ; Swallowtail: V = x5 + ax3 + bx2 + cx; Xa1 = , Xa2 = , Xa3 = ; Butterfly: V = x6 + ax4 + bx3 + cx2 + dx; Xa1 = , Xa2 = , Xa3 = , Xa4 = | Y. Li, Y.F. Li and M. Kappas [39] | The catastrophe theory contains four models with different equilibrium surfaces: Fold, Cusp, Swallowtail, and Butterfly. The dimension of control variables in a sub-system dictates the calculation model, which means the number of indicator in sub-system determines the model. Since catastrophe theory follows a hierarchical process, the resilience value is calculated by indicator to sub-system. |

| Year | Power Consumption | Water Consumption | Energy Consumption | Construction Land Area | Wastewater Discharge | Industry Waste Gas | Industrial Smoke Dust | Industrial Solid Waste |

|---|---|---|---|---|---|---|---|---|

| 2000 | 0.471 | 0.066 | 0.233 | 0.716 | 0.694 | 0.402 | 0.95 | 0.274 |

| 2001 | 0.3973 | 0.0492 | 0.2133 | 0.6007 | 0.5325 | 0.3492 | 0.7736 | 0.2511 |

| 2002 | 0.3728 | 0.0536 | 0.2094 | 0.6587 | 0.5496 | 0.3363 | 0.7733 | 0.2299 |

| 2003 | 0.3873 | 0.0573 | 0.2105 | 0.681 | 0.5685 | 0.3301 | 0.7943 | 0.2231 |

| 2004 | 0.3748 | 0.06 | 0.1984 | 0.6098 | 0.5561 | 0.3031 | 0.8288 | 0.2145 |

| 2005 | 0.4644 | 0.0782 | 0.2305 | 0.7668 | 0.7103 | 0.3786 | 0.8045 | 0.2492 |

| 2006 | 0.4628 | 0.0699 | 0.2462 | 0.8122 | 0.5737 | 0.3838 | 0.3881 | 0.3265 |

| 2007 | 0.5887 | 0.0719 | 0.2409 | 0.8787 | 0.4723 | 0.5873 | 0.3146 | 0.2898 |

| 2008 | 0.6117 | 0.0815 | 0.2319 | 0.9023 | 0.6717 | 0.3943 | 0.2591 | 0.3086 |

| 2009 | 0.6189 | 0.0793 | 0.2169 | 0.8359 | 0.6916 | 0.3547 | 0.2862 | 0.2186 |

| 2010 | 0.6042 | 0.0811 | 0.1971 | 0.825 | 0.6663 | 0.3182 | 0.2428 | 0.1581 |

| 2011 | 0.5763 | 0.0813 | 0.1859 | 0.7925 | 0.6036 | 0.2463 | 0.1219 | 0.1127 |

| 2012 | 0.5476 | 0.082 | 0.1554 | 0.7326 | 0.6058 | 0.2489 | 0.1323 | 0.1176 |

| 2013 | 0.5343 | 0.0836 | 0.1492 | 0.7175 | 0.6323 | 0.147 | 0.1095 | 0.1059 |

| 2014 | 0.5406 | 0.0974 | 0.1806 | 0.7022 | 0.6454 | 0.1511 | 0.0938 | 0.0885 |

| 2015 | 0.5324 | 0.0904 | 0.187 | 0.7437 | 0.7108 | 0.1207 | 0.0855 | 0.0571 |

| 2016 | 0.545 | 0.1131 | 0.1822 | 0.8926 | 0.8141 | 0.1024 | 0.0756 | 0.0585 |

| 2017 | 0.1094 | 0.1748 | 0.8747 | 0.8405 | 0.0928 | 0.0743 | 0.0468 |

| Grades | Resilience Interval |

|---|---|

| 1. Non-resilience | <0.81 |

| 2. Low-resilience | 0.81–0.82 |

| 3. Resilience | 0.82–0.86 |

| 4. Mid-resilience | 0.86–0.93 |

| 5. High-resilience | >0.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, X.; Yang, X.; Wen, Q.; Gang, J.; Gan, L. Sustainable Development of Industry–Environmental System Based on Resilience Perspective. Int. J. Environ. Res. Public Health 2020, 17, 645. https://doi.org/10.3390/ijerph17020645

Wan X, Yang X, Wen Q, Gang J, Gan L. Sustainable Development of Industry–Environmental System Based on Resilience Perspective. International Journal of Environmental Research and Public Health. 2020; 17(2):645. https://doi.org/10.3390/ijerph17020645

Chicago/Turabian StyleWan, Xue, Xiaoning Yang, Quaner Wen, Jun Gang, and Lu Gan. 2020. "Sustainable Development of Industry–Environmental System Based on Resilience Perspective" International Journal of Environmental Research and Public Health 17, no. 2: 645. https://doi.org/10.3390/ijerph17020645