CFD Simulation Analysis on Make-up Air Supply by Distance from Cookstove for Cooking-Generated Particle

Abstract

1. Introduction

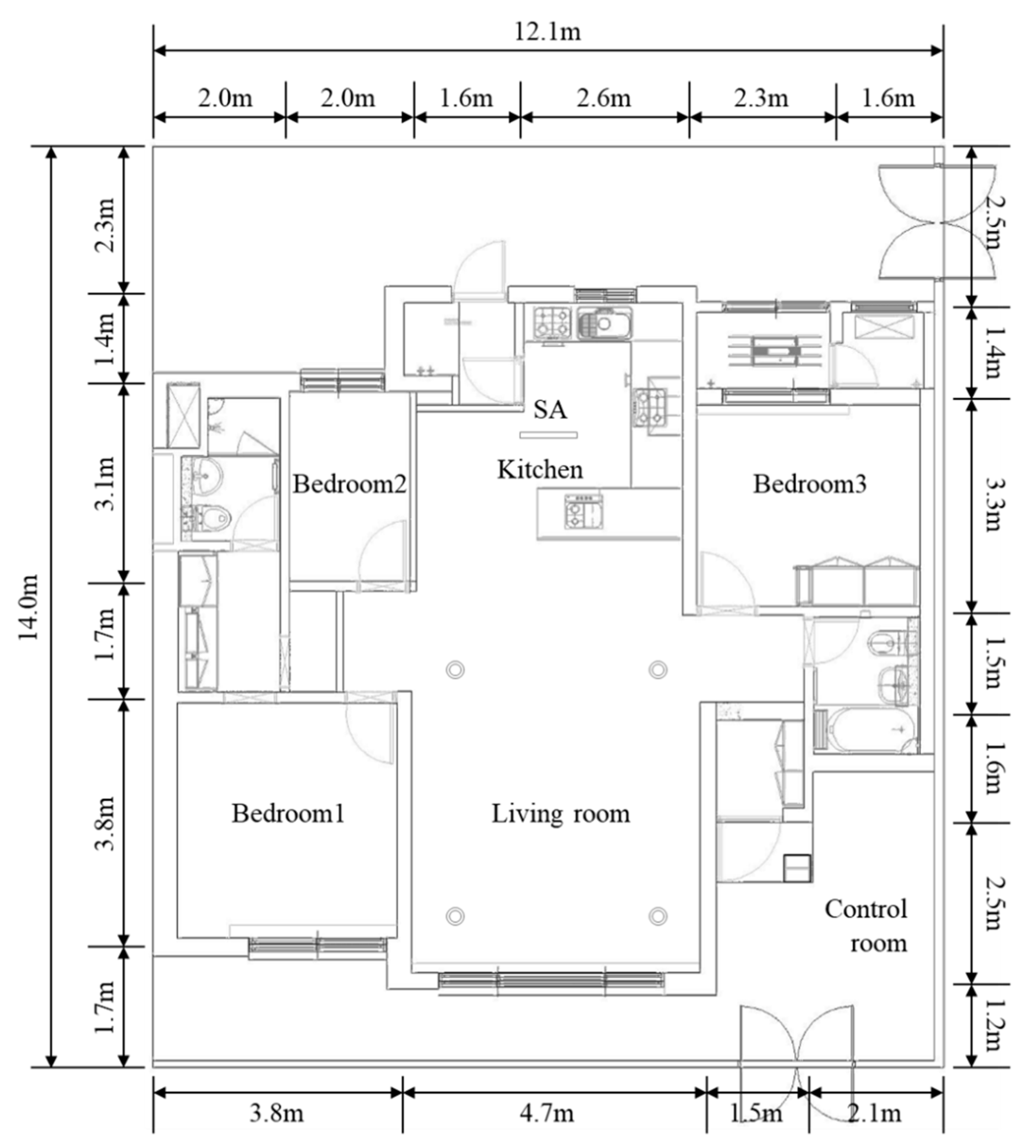

2. Building Description and Field Measurement

2.1. Building Description

2.2. Field Measurement for Validation of CFD Model

3. Description for CFD Simulation

3.1. Numerical Methods

3.2. Boundary Conditions

4. Measurement and Validation of CFD Simulation

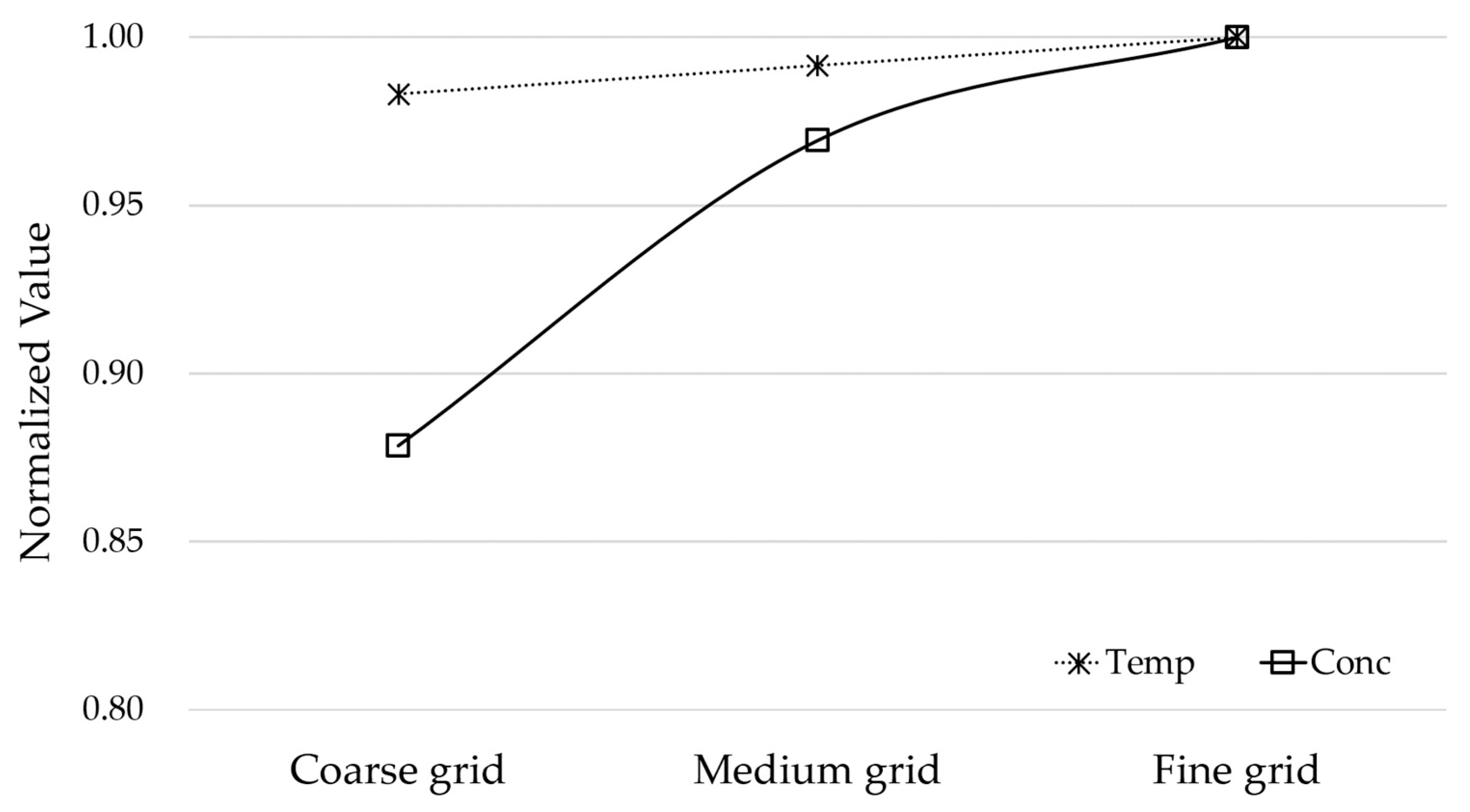

4.1. Grid Sensitivity Analysis

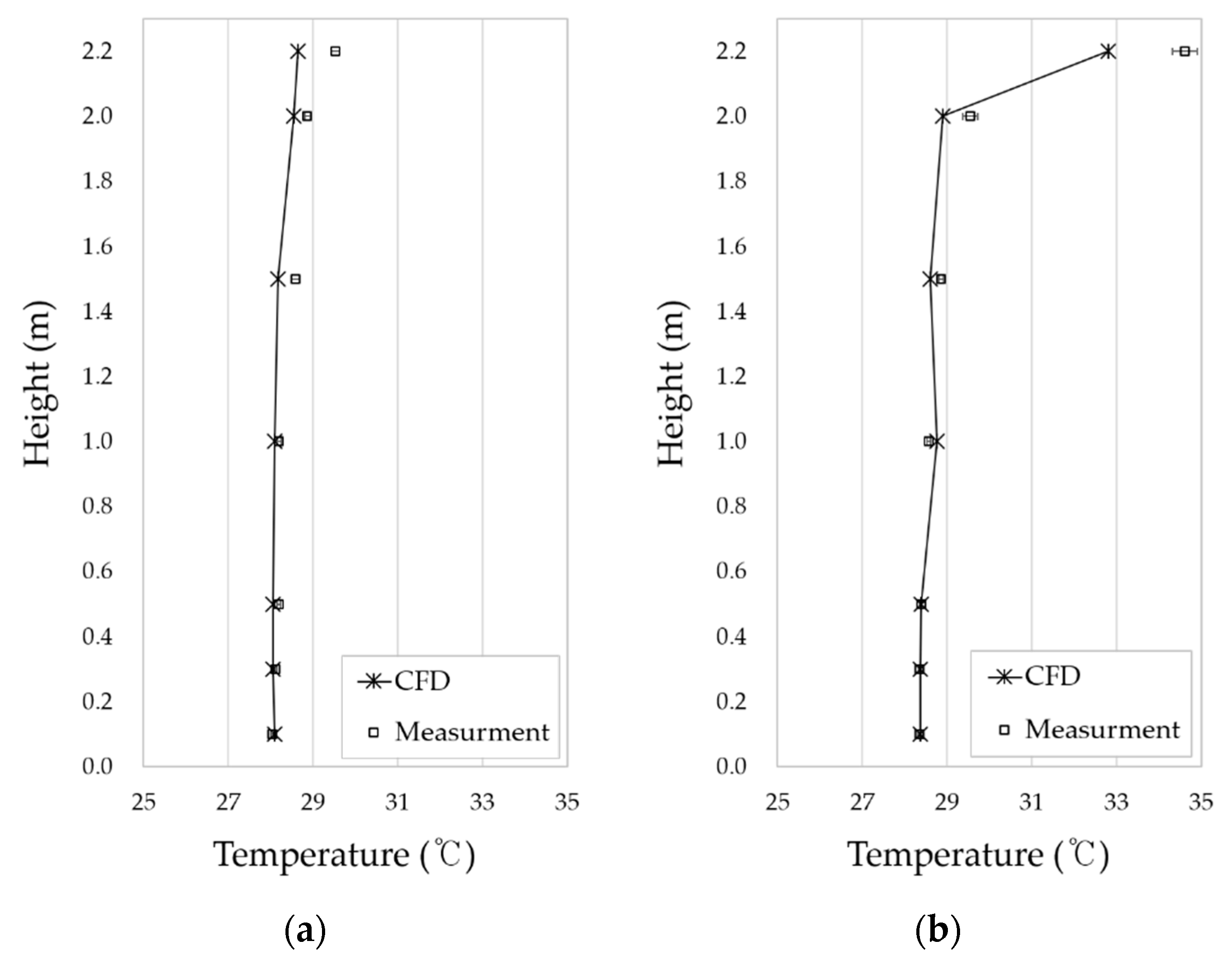

4.2. Measurement Result and Validation of CFD Model

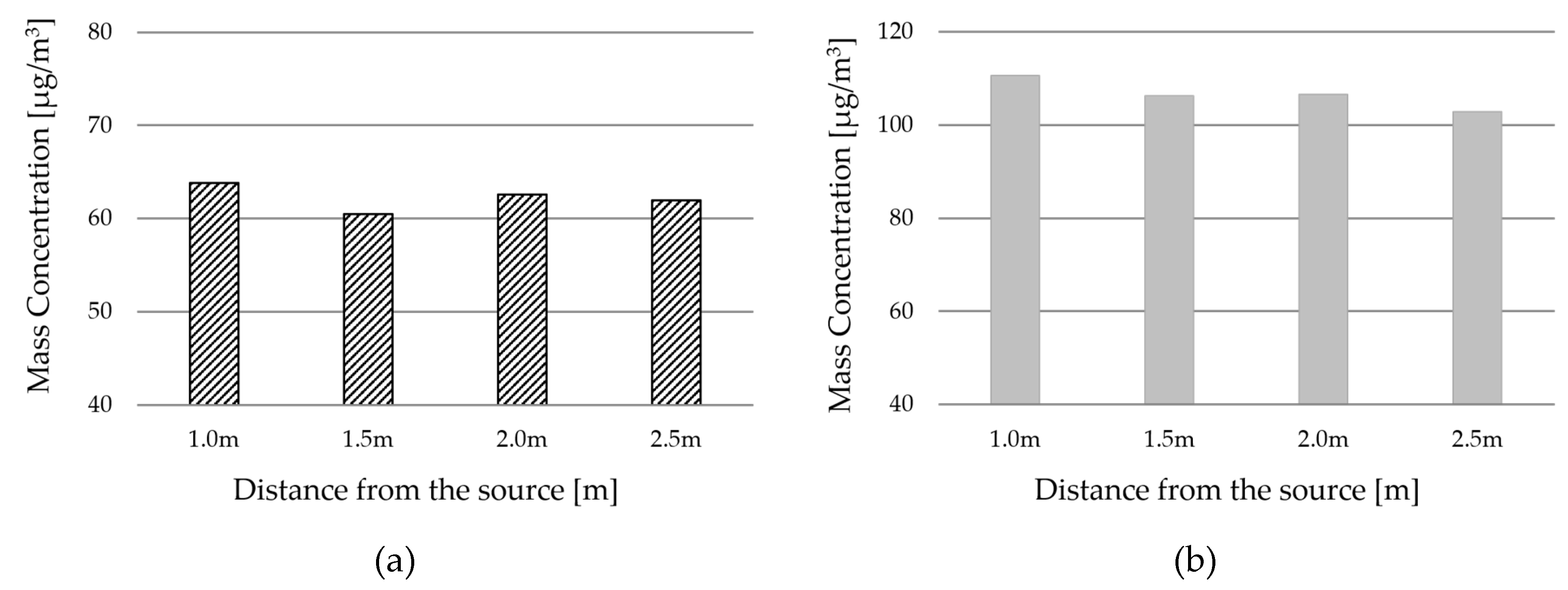

5. Result and Discussion

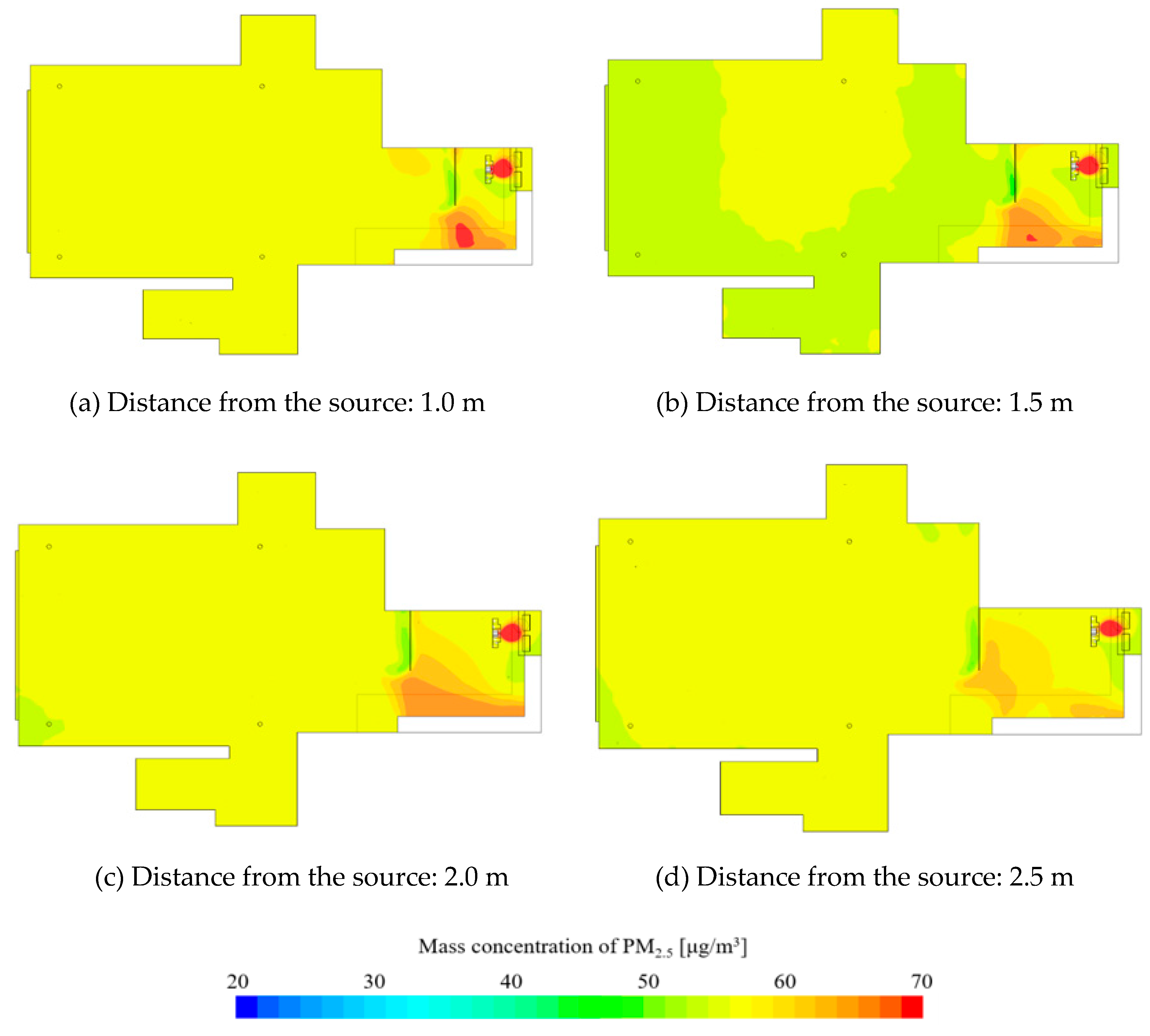

5.1. Result of CFD Simulation

5.2. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Klepeis, N.E.; Nelson, W.C.; Ott, W.R.; Robinson, J.P.; Tsang, A.M.; Switzer, P.; Behar, J.V.; Hern, S.C.; Engelmann, W.H. The National Human Activity Pattern Survey (NHAPS): A resource for assessing exposure to environmental pollutants. J. Expo. Anal. Environ. Epidemiol. 2001, 11, 231. [Google Scholar] [CrossRef]

- Jonathan, M.; Samet, M.D. Indoor Air Pollution: A Public Health Perspective. Indoor Air 1993, 3, 219–226. [Google Scholar]

- World Health Organization. WHO Air Quality Guidelines for Particulate Matter, Ozone, Nitrogen Dioxide and Sulfur Dioxide, Global Update 2005; WHO: Geveva, Switzerland, 2006. [Google Scholar]

- Jones, A.P. Indoor air quality and health. Atmos. Environ. 1999, 33, 4535–4564. [Google Scholar] [CrossRef]

- Janssen, N.A.H.; Hoek, G.; Brunekreef, B.; Harssema, H.; Mensink, I.; Zuidhof, A. Personal sampling of particles in adults: Relation among personal, indoor, and outdoor air concentrations. Am. J. Epidemiol. 1998, 147, 537–547. [Google Scholar] [CrossRef] [PubMed]

- Morawska, L.; He, C.; Hitchins, J.; Mengersen, K.; Gilbert, D. Characteristics of particle number and mass concentrations in residential houses in Brisbane, Australia. Atmos. Environ. 2003, 37, 4195–4203. [Google Scholar] [CrossRef]

- He, C.; Morawska, L.; Hitchins, J.; Gilbert, D. Contribution from indoor sources to particle number and mass concentrations in residential houses. Atmos. Environ. 2004, 38, 3405–3415. [Google Scholar] [CrossRef]

- Gao, J.; Jian, Y.; Cao, C.; Chen, L.; Zhang, X. Indoor emission, dispersion and exposure of total particle-bound polycyclic aromatic hydrocarbons during cooking. Atmos. Environ. 2015, 120, 191–199. [Google Scholar] [CrossRef]

- Ai, Z.T.; Mak, C.M.; Cui, D.J. On-site measurements of ventilation performance and indoor air quality in naturally ventilated high-rise residential buildings in Hong Kong. Indoor Built Environ. 2015, 24, 214–224. [Google Scholar] [CrossRef]

- Stratton, J.C.; Singer, B.C. Addressing Kitchen Contaminants for Healthy, Low-Energy Homes; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2014. [Google Scholar]

- Cao, C.; Gao, J.; Wu, L.; Ding, X.; Zhang, X. Ventilation improvement for reducing individual exposure to cooking-generated particles in Chinese residential kitchen. Indoor Built Environ. 2017, 26, 226–237. [Google Scholar] [CrossRef]

- Swierczyna, R.T.; Sobiski, P.A. The effect of makeup air on kitchen hoods. Ashrae J. 2003, 45, K18–K22. [Google Scholar]

- Han, O.; Li, A.; Kosonen, R. Hood performance and capture efficiency of kitchens: A review. Build. Environ. 2019, 161, 106221. [Google Scholar] [CrossRef]

- Kim, T.; Park, B.Y.; Cheong, C.H. Ventilation systems to prevent food odour spread in high-rise residential buildings. Indoor Built Environ. 2012, 21, 304–316. [Google Scholar] [CrossRef]

- Heiselberg, P.; Li, Y.; Andersen, A.; Bjerre, M.; Chen, Z. Experimental and CFD evidence of multiple solutions in a naturally ventilated building. Indoor Air 2003, 14, 43–54. [Google Scholar] [CrossRef]

- Sørensen, D.N.; Nielsen, P.V. Quality control of computational fluid dynamics in indoor environments. Indoor Air 2003, 13, 2–17. [Google Scholar] [CrossRef] [PubMed]

- Lawson, T. Building Aerodynamics; Imperial College Press: London, UK, 2001. [Google Scholar]

- Zhai, Z. Application of Computational Fluid Dynamics in Building Design: Aspects and Trends. Indoor Built Environ. 2006, 15, 305–313. [Google Scholar] [CrossRef]

- Liu, X.; Zhai, Z. Inverse modeling methods for indoor airborne pollutant tracking: Literature review and fundamentals. Indoor Air 2007, 17, 419–438. [Google Scholar] [CrossRef] [PubMed]

- Kong, M.; Zhang, J.; Wang, J. Air and air contaminant flows in office cubicles with and without personal ventilation: A CFD modeling and simulation study. Build. Simul-China 2015, 8, 381–392. [Google Scholar] [CrossRef]

- Oh, W.; Kato, S. The effect of airspeed and wind direction on human’s thermal conditions and air distribution around the body. Build. Environ. 2018, 141, 103–116. [Google Scholar] [CrossRef]

- Ardkapan, S.R.; Nielsen, P.V.; Afshari, A. Studying passive ultrafine particle dispersion in a room with a heat source. Build. Environ. 2014, 71, 1–6. [Google Scholar] [CrossRef]

- Sugahara, A.; Kotani, H.; Momoi, Y.; Yamanaka, T.; Sagara, K.; Fujiwara, R. PIV measurement and CFD analysis of airflow around building roof with various building installations. Int. J. Vent. 2017, 16, 163–173. [Google Scholar] [CrossRef]

- Afshari, A.; Matson, U.; Ekberg, L.E. Characterization of indoor sources of fine and ultrafine particles: A study conducted in a full-scale chamber. Indoor Air 2005, 15, 141–150. [Google Scholar] [CrossRef] [PubMed]

- Nazaroff, W.W. Indoor particle dynamics. Indoor Air 2004, 14, 175–183. [Google Scholar] [CrossRef]

- Holmberg, S. Modelling of the indoor environment—Particle dispersion and deposition. Indoor Air 1998, 8, 113–122. [Google Scholar] [CrossRef]

- Gao, N.P.; Niu, J.L. Modeling particle dispersion and deposition in indoor environments. Atmos. Environ. 2007, 41, 3862–3876. [Google Scholar] [CrossRef] [PubMed]

- Bredberg, J.; Davidson, L. Low-Reynolds Number Turbulence Models: An Approach for Reducing Mesh Sensitivity. J. Fluids Eng. 2004, 126, 14–21. [Google Scholar] [CrossRef]

- Sideroff, C.N.; Dang, T.Q. Verification and Validation of CFD for the Personal Micro-Environment. Ashrae Trans. 2008, 114, 45–56. [Google Scholar]

- Lai, A.C.K.; Ho, Y.W. Spatial concentration variation of cooking-emitted particles in a residential kitchen. Build. Environ. 2008, 43, 871–876. [Google Scholar] [CrossRef]

- Dobbin, N.A.; Sun, L.; Wallace, L.; Kulka, R.; You, H.; Shin, T.; Aubin, D.; St-Jean, M.; Singer, B.C. The benefit of kitchen exhaust fan use after cooking—An experimental assessment. Build. Environ. 2018, 135, 286–296. [Google Scholar] [CrossRef]

| Boundary | Boundary Condition | Value |

|---|---|---|

| Auxiliary supply diffuser | Velocity inlet | Surface temperature: 27.5 °C Velocity: 1.929 m/s (150 CMH) |

| Range hood outlet | Pressure outlet | Pressure: −10 Pa |

| Frying pan (surface) | Wall (heat, emission source) | Surface temperature: 163 °C Emission rate of PM2.5: 3.068 mg/s |

| Wall | Wall (Temperature) | Surface temperature (floor, sink, walls of kitchen and living room): measurement data Other surfaces: adiabatic |

| Occupant | Wall (heat source) | Heat: 76 W |

| Coarse Grid | Medium Grid | Fine Grid | |

|---|---|---|---|

| Minimum size (mm) | 2 | 1 | 1 |

| Target size (mm) | 200 | 100 | 80 |

| Cells | 393,515 | 583,371 | 1,109,294 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.; Kang, K.; Kim, T. CFD Simulation Analysis on Make-up Air Supply by Distance from Cookstove for Cooking-Generated Particle. Int. J. Environ. Res. Public Health 2020, 17, 7799. https://doi.org/10.3390/ijerph17217799

Kim H, Kang K, Kim T. CFD Simulation Analysis on Make-up Air Supply by Distance from Cookstove for Cooking-Generated Particle. International Journal of Environmental Research and Public Health. 2020; 17(21):7799. https://doi.org/10.3390/ijerph17217799

Chicago/Turabian StyleKim, Hyungkeun, Kyungmo Kang, and Taeyeon Kim. 2020. "CFD Simulation Analysis on Make-up Air Supply by Distance from Cookstove for Cooking-Generated Particle" International Journal of Environmental Research and Public Health 17, no. 21: 7799. https://doi.org/10.3390/ijerph17217799

APA StyleKim, H., Kang, K., & Kim, T. (2020). CFD Simulation Analysis on Make-up Air Supply by Distance from Cookstove for Cooking-Generated Particle. International Journal of Environmental Research and Public Health, 17(21), 7799. https://doi.org/10.3390/ijerph17217799