1. Introduction

The purpose of sewer systems is to prevent urban flooding and maintain sanitary conditions. To this end, sewer systems rapidly remove and transport surface rainwater and deliver sewage to treatment plants. Sewer pipes are not visible because they are buried underground, but they are also gradually damaged due to continuous traffic, ground loads, groundwater effects, and aging. Aging sewer pipes crack, and the soil, tree roots, and groundwater that penetrate the cracks disrupt the flow in the pipes. Sewage leaking out of the cracks leads to internal and external problems, such as contaminating soil and causing sink holes [

1]. To prevent or address these problems, repair or replacement is required.

Aging sewer pipes need to be replaced, but general open-cut excavations obstruct traffic and cause long-term inconvenience, thereby incurring social costs. Trenchless sewer rehabilitation, however, necessitates less traffic control [

2], causes fewer complaints and environmental impacts [

3], leads to lower accident risks [

4], and improves productivity [

5] and economic efficiency [

6]. Therefore, it is desirable to extend the service lives of sewer pipes by rehabilitating them if possible.

Trenchless sewer rehabilitation includes various methods, such as pipe bursting, slip lining, and modified cross-section liners [

7], but cured-in-place pipe (CIPP) has been most widely used. CIPP is a method in which a liner impregnated with thermosetting resin is placed into an existing sewer pipe, expanded by hydrostatic or air pressure, attached to the inner surface of the pipe, and cured on-site by applying heat [

8,

9]. The CIPP construction method can be largely divided into the manufacturing and site installation processes (

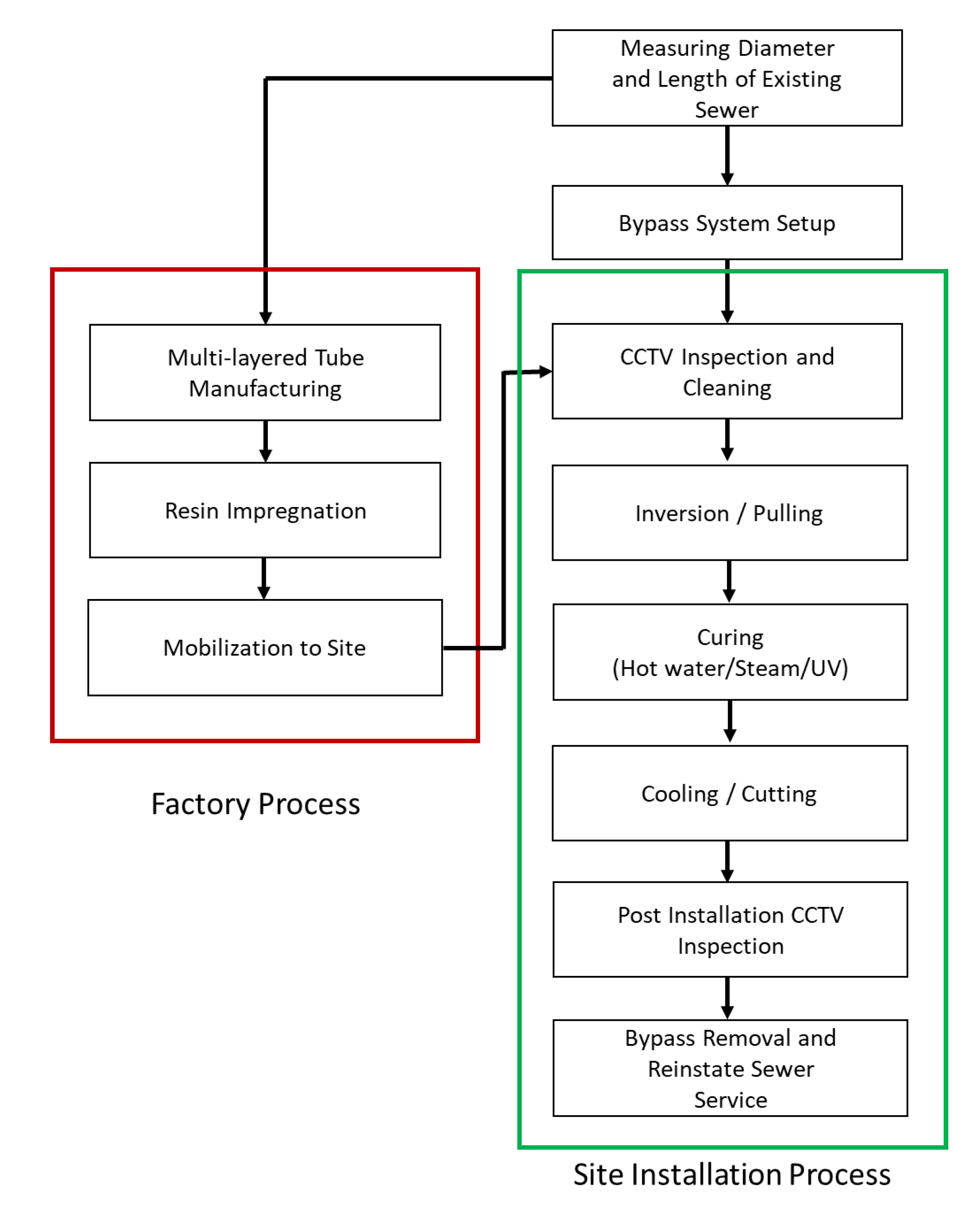

Figure 1). In a factory, a liner is manufactured to fit the size of the existing sewer pipe. At the site, the condition of the pipe is inspected using closed-circuit television (CCTV). After cleaning the pipe, the liner is inserted, cured, cooled, and finished. When the construction is completed, only the cured liner is left inside the pipe for its structural rehabilitation. In terms of work hours, liner manufacturing takes a few days from material preparation to manufacturing, but a team can install and finish a length of approximately 100 m on-site in a single day. Although the field production rate may significantly vary depending on the site conditions, construction method, and workmanship, CIPP is a useful technology for urban sewer rehabilitation because it can significantly reduce traffic obstruction during the construction period and excavation, as compared to traditional excavation work.

A combination of various technologies is required from the start of CIPP to the completion of construction, but the key technology lies in manufacturing the CIPP liner itself. Traditional CIPP liner is made by impregnating nonwoven repair cloth with unsaturated polyester resin. As unsaturated polyester resin in the liquid state cannot maintain its shape, it is impregnated into fabrics, such as repair polyester felt, to maintain cylindrical shapes like those of sewer pipes. Unsaturated polyester resin is a thermosetting resin. It is made by adding diluents such as styrene to unsaturated polyester resin for free molding and by adding polymerization inhibitors to prevent polymerization during transportation. The resin hardens when an appropriate temperature is applied after adding an initiator and a catalyst [

10]. Unsaturated polyester resin has high moldability, and is therefore used in various fields. The unsaturated polyester resin used in CIPP must have a high cure initiation temperature because it needs to stay outside for a long time, even in summer. CIPP resin must be sufficiently impregnated in the cylinder-shaped liner along the pipe wall, and the resin must be able to move inside the liner once it is installed inside the pipe. As the impregnation amount of the resin inside the liner must be maintained before and after curing, and handling must be easy, it is important for the resin to have an appropriate viscosity. In addition, conventional polyester resin for CIPP application needs to comply with the minimum requirement for the chemical resistance properties in standard domestic wastewater, as shown in

Table 1.

The economic efficiency of CIPP is determined by various elements, such as materials, tube manufacturing methods, and construction methods. Among these elements, the flexural structural property is the most important for determining the thickness of a CIPP liner. As the strength of CIPP increases, its design can be performed with a smaller thickness and fewer materials. A liner with a small amount of resin and a small thickness reduces on-site work hours due to the fast curing speed, and is economical because of the low cost for maintaining the heat required for curing decreases.

Traditional CIPPs usually have a large liner thickness because the minimum requirement for the flexural property is not high. Hot water or steam is used for curing, and a large amount of energy is consumed via the transportation of hot water and heating the liner to a curable temperature. On the other hand, CIPPs that use ultraviolet (UV) rays and glass fibers have high structural strength [

12] and can save energy because they do not use hot water. In addition, the combination of epoxy and glass fibers [

13], or epoxy and carbon fibers [

14], can improve the flexural properties. However, epoxy and carbon fibers are relatively costly. Moreover, various resins have been developed and used, including vinyl ester resins with higher chemical resistance than polyester resin [

15], and nonstyrene-based resin and silicate resin without styrene odor [

13]. General unsaturated polyester resin is competitive in price compared to other resins, and thus, has been most widely used in CIPP liners for sewer rehabilitation worldwide.

The new trend of CIPP research and development has focused on environmental implications and high strength CIPP liners. Researchers have shown concern about styrene-based resin and its levels in drinking water sources after the application of a CIPP. Donaldson [

16] revealed that several water sources after the application of CIPPs exceeded the Environmental Protection Agency’s maximum containment level for drinking water of 0.1 mg/L. Ra et al. [

17] and other researchers reported that volatile and semivolatile organic compound (VOC/SVOC) emissions were detected during the sewer CIPP installation process. Environmental implications and other hazardous material emissions during the application of CIPP and their impact on humans are still the subject of debate, and need further research. Polyester resin manufactures developed nonstyrene resin systems for the application CIPPs, but the cost-benefit of using conventional resin systems has not been overcome.

CIPP liner manufacturers have introduced high strength liner materials. However, no similar academic research about the development of these materials, nor any details of their short- and long-term mechanical properties, has been published. Most previous research has focused on retrospective evaluations of existing CIPP liners for long-term quality control and assurance [

18,

19].

Hot water or steam curing, which is the traditional curing method, can transfer temperature and pressure evenly and in a stable manner, thereby enabling the construction of consistently good quality materials. In addition, this curing method does not require special curing equipment, except boilers, and exhibits excellent heat transfer characteristics. Therefore, the development of a high-strength liner that uses ordinary hot water and steam has the benefits of improving strength and quality and reducing costs.

In this study, the long- and short-term structural characteristics of a composite liner, made by adding glass fibers to unsaturated polyester resin and felt, were compared with those of a CIPP composite material liner that uses glass fibers for the development of an economical high-strength CIPP liner. To this end, composite material samples were fabricated by combining liner materials using various methods, and the structural characteristics of the liners were compared and analyzed through short- and long-term flexural strength tests.

2. Experimental Materials and Methods

The CIPP liner samples used in this study were fabricated by combining the liner materials presented in

Table 2 with isophthalic unsaturated polyester resin and through lamination and impregnation. A conventional unsaturated isophthalic polyester resin was diluted with styrene, providing low viscosity to facilitate resin impregnation through liner materials. Styrene was also used as a monomer participating in the free radical polymerization process. A small amount (approximately 1% of the resin weight) of peroxide was added to catalyze the free radicals into the polymerization process. The resin used in this study was produced by a mixture of isophthalic acid, unsaturated dicarboxylic acids, and glycols.

Figure 2 shows a generic structure of isophthalic polyester resin, which is used for the majority of CIPP lining applications in the industry.

The basic thickness of the felt was 2 mm, but this was adjusted by stacking several layers when necessary. The polyester nonwoven felt (F) is polyester-based, as with unsaturated polyester resin. It has excellent material binding and adhesion performance, and the space of the felt structure induces and stores resin impregnation. The felt also secures sufficient tensile strength, thereby preventing excessive stretch or expansion/contraction and maintaining the shape of a CIPP liner during its installation inside a sewer pipe.

A polyester nonwoven felt with coating film (CF) was used on the outer surface of the liner. The impermeable film attached to the felt prevents damage to the tube and improves the liner curing quality by separating sewage from the resin. In addition, it protects the liner against various pollutants contained in the sewage, thereby ensuring appropriate curing and extending the service life of the liner (

Figure 3a). The thickness of the felt and film was approximately 1.5 mm, and that of the film was 0.5 mm.

For the roving cross glass fiber and chopped strand mat (G), which is the main material of this study, one layer of 0.5 mm-thick glass fibers woven into a lattice was bonded to one layer of 0.5-mm-thick glass fibers that were finely chopped and attached like a nonwoven fabric. All the fibers were made of E-glass (

Figure 3b). As this glass fiber had two layers, it was relatively thick. The handling was easy because the two layers maintained its shape, and it has various benefits, such as no directivity. The above materials were mixed using various methods, and tests were conducted to find the optimal structural characteristics.

The preparation of CIPP liner samples follows a standard practice used in the industry. The curing process used hot water as a heat source for the resin polymerization, but the potential degradation issue is eliminated by wrapping waterproof film layers. The water effect during the life cycle service of the CIPP liner is not considered, but the materials used in this study are not known to be degradable by aquatic conditions.

Samples for short- and long-term tests were fabricated in accordance with ASTM D790 [

21]. The mold for the samples was a plate-type made of stainless steel with dimensions of 207 × 239 mm (

Figure 4). The samples were prepared by placing the resin and the other materials into the mold and performing impregnation and curing. Each sample had different thicknesses, depending on the material combinations, but they were cut to the same length and width, i.e., 120 mm and 15 mm, respectively. A table saw was used for the cutting, and a diamond wheel blade for concrete, or a steel blade for acrylic resin, was used.

2.1. Short-Term Test

The liner of CIPP is a composite material that combines thermosetting plastics with reinforcing materials. The minimum strength criteria are a flexural strength of 31 MPa and a flexural modulus of 1724 MPa, as provided by the most widely used ASTM F1216 [

11]. The domestic KS M 3550-9 [

22] also specifies the same strength as the minimum value. These properties can be obtained by conducting the three-point bending test, suggested by ASTM D790, and using the following equations:

and

where

σf is flexural stress (MPa). The maximum flexural stress before 5% flexural strain is the flexural strength (MPa).

P is the load (N),

L is the distance between points (mm),

b is the width of the sample (mm),

d is the thickness of the sample (mm),

EB is the flexural modulus, and m is the initial slope of the load-strain curve (N/mm).

The flexural strength and modulus represent the magnitude of force-resisting bending compared to the thickness. In a three-point bending test, the load is increased until the bar-type sample, fabricated in accordance with the specifications suggested by ASTM D790 [

21], ruptures, and the corresponding vertical displacement is measured.

2.2. Long-Term Test

The magnitude of the load that can be supported by a CIPP liner is determined by the thickness of the liner and the strength characteristics of the liner material. The thickness of the liner is determined using equations to obtain the load value for the liner thickness, which are given by ASTM F1216 [

11] based on the theory on liner deformation characteristics under an external load. The equations are given below in Equation (3) for partial repair, which is used when the existing sewer pipe can sufficiently take care of external force, and Equation (4) for complete repair, which is used under the assumption that the existing sewer pipe can no longer maintain its structural performance. These equations originate from ASTM F1216 [

11] expressions derived to obtain the liner thickness:

and

where

t is the thickness of the CIPP liner (mm),

D is the inner diameter of the sewer pipe,

K is the support improvement factor,

EL,50 is the 50-year long-term modulus of elasticity (MPa),

C is the shape reduction factor,

P is the groundwater pressure (MPa),

N is the safety factor,

ν is Poisson’s ratio,

qt is the total external pressure applied to the pipe (MPa),

Rw is the buoyancy factor of water,

B’ is the elastic support coefficient, and

E’s is the soil reaction coefficient (MPa).

EL,50 is the long-term modulus of elasticity (

EL) that remains 50 years after construction.

EL is determined by the ratio of the flexural stress (Equation (1)) to the flexural strain when a certain load is given, as shown by:

In addition, the flexural strain is obtained using:

where

r is the flexural strain (mm/mm), and

Def is the deflection (mm).

In the short-term test, the changing deflection was measured, and the flexural stress was calculated while the load was slowly changed. In the long-term test, however, the changing deflection was measured, and EL was calculated over time under the fixed load condition. The test methods followed the three-point bending test and sample specifications specified in ASTM D2990 [

23] and ASTM D790 [

21]. The weight of the long-term load used in the long-term test was calculated using Equation (7), as suggested by WIS 4-34-04 [

24]:

where

M is the long-term load (kg), and

S is the flexural strength (MPa), which is equal to 0.0025

EB.

EB is the flexural modulus.

It is generally recommended that the long-term test be conducted for 10,000 h [

25]. Based on the test data, the long-term modulus of elasticity at 50 years (438,000 h) is obtained through linear estimation on a log scale, and the value is described as

EL,50. As 10,000 h exceeds one year, the test is sometimes replaced with 1,000 h test. In this study, however, the test was conducted for more than 10,000 h for a more standardized test. The deflection measurement intervals and frequencies were 30 times per minute, 9 times every 30 min, 45 times every hour, 45 times every 10 h, 20 times every 25 h, 80 times every 50 h, and 80 times every 80 h. The total measurement time was 11,400 h. The long-term modulus of elasticity was evaluated by calculating the creep retention factor (CRF,

CL), which is the ratio of the long-term modulus of elasticity to the flexural modulus, shown in Equation (8), and comparing the values.

The typical values presented in the literature are 0.5 (polyester resin in nonwoven felt), 0.2 (epoxy in woven hose), and 0.7 (epoxy in fiberglass matrix) [

11,

13]. As

CL is closer to 1, the material has better structural performance in the long-term because its deformation is small under a long-term load, making it possible to design a smaller thickness.

4. Conclusions

In this study, CIPP liners were fabricated in various combinations using glass fibers, which have been more frequently used in trenchless sewer rehabilitation, and the structural characteristics of each case were analyzed. When only glass fibers and unsaturated polyester resin were used, the flexural strength was 13.3 times higher, and the flexural modulus was 8 times higher compared to the minimum criteria of ASTM F1216 [

11]. In addition, the flexural strength was 6.2 times higher, and the flexural modulus was 3.6 times higher than the general CIPP liner suggested by NASTT [

13]. When the coating felt with impervious film was added to this to allow the use of traditional hot water and steam curing, the flexural strength decreased to 161 MPa and the flexural modulus to 4.59 GPa, but these values were still high compared to the existing liner.

The 50-year modulus of elasticity was approximately 8 GPa when only glass fibers and unsaturated polyester resin were used, and 2.3 GPa when the coating felt was added. The CRF, which represents flexural modulus degradation over time, ranged from 0.51 to 0.64. These values were slightly higher compared to the CRF (0.5) of the traditional liner that used the unsaturated polyester resin and felt suggested by NASTT [

13]. The long-term modulus of elasticity has a direct effect on the design thickness of a CIPP liner, and it is possible to reduce the liner thickness by 30–54%.

Felt and coating felt increase ductility, which is lacking in resins, through curing with unsaturated polyester resin, but they reduce the flexural strength and the flexural modulus. As traditional CIPPs use only resin and felt, strength degradation cannot be prevented. Glass fibers, however, offset the strength degradation of felt by increasing the strength of a CIPP liner. The use of glass fibers with the composition of materials like that was suggested in this study can improve the strength of a liner while maintaining existing CIPP manufacturing and construction practices.