Research on Energy Management of Hybrid Unmanned Aerial Vehicles to Improve Energy-Saving and Emission Reduction Performance

Abstract

:1. Introduction

2. Establishment of UAV Subsystem Model and Simulation Platform

2.1. Flight Dynamics Model

2.1.1. Aerodynamic Force and Aerodynamic Moment

2.1.2. Kinetic and Kinematic Equations

2.2. Hybrid Propulsion System Model

2.2.1. The Model of Internal Combustion Engine and Generator

2.2.2. The Model of Li-Accumulator

2.2.3. The Model of Motor and Propeller

3. Flight Simulation Calculation Flow of UAV

4. Energy Management of UAV Hybrid System

4.1. Energy Management Model of Hybrid Power System

- Ensure that the state of charge and discharge of the Li-accumulator is in a reasonable range, the maximum value of SOC is 0.9; the minimum value of SOC is 0.4, ensuring that the accumulator will not be damaged by excessive discharge.

- Ensure that the engine torque is in a reasonable range;

- Ensure that the accumulator charging and discharging power is in a reasonable range, if the accumulator power is negative, it represents the accumulator charging;

- Ensure that the engine speed is in a reasonable range, where the working point with zero speed represents the engine shutdown, and the torque at this working point is also zero.

4.2. Design of Energy Management Controller

4.2.1. Power Tracking Control

4.2.2. Q-Learning Method

4.3. Results Analysis and Discussion

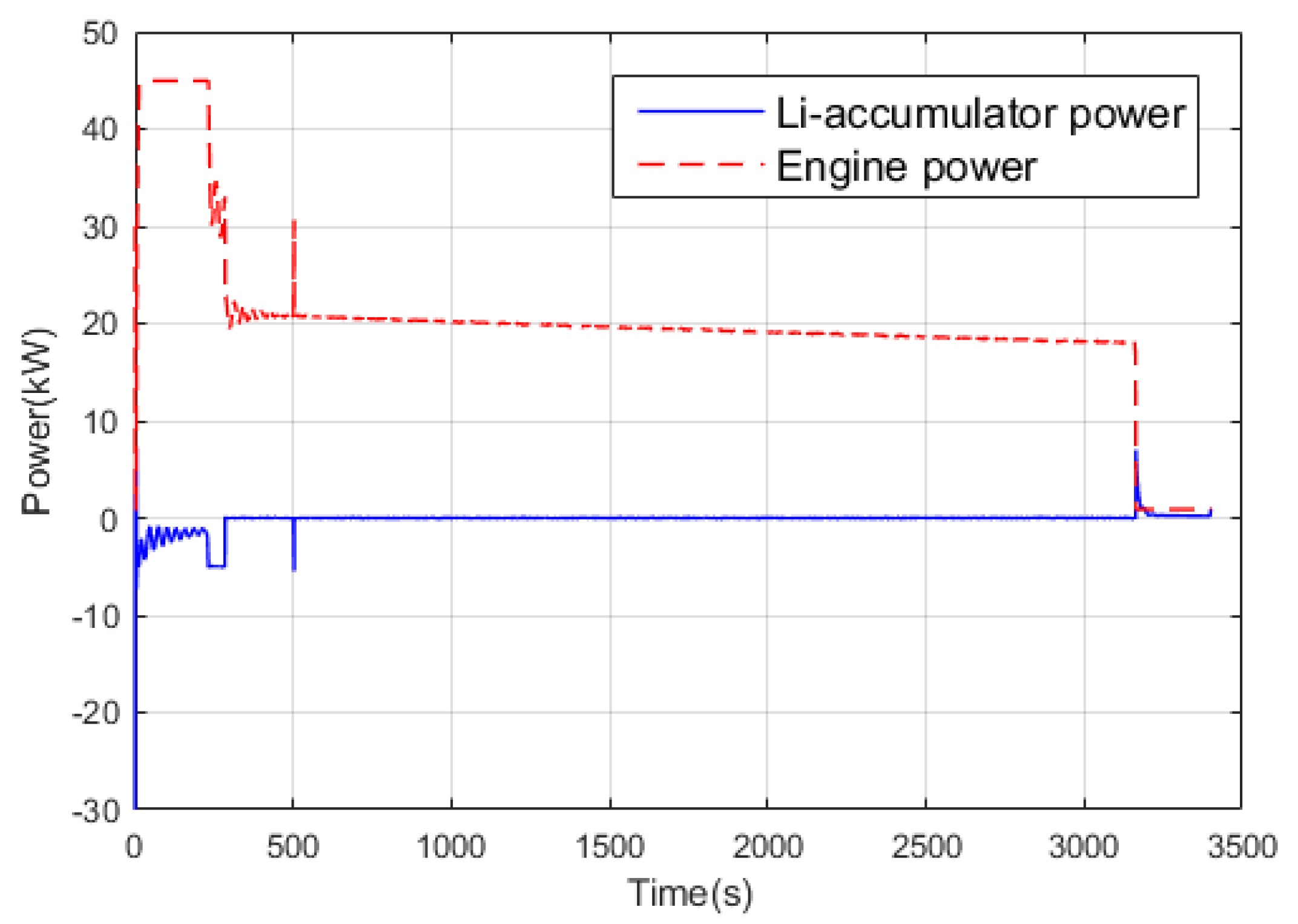

4.3.1. Conventional Cruise Flight Mission

4.3.2. Terrain Tracking Flight Mission

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vedantham, A.; Oppenheimer, M. Long-term scenarios for aviation: Demand and emissions of CO2 and NOx. Energy Policy 1998, 26, 625–641. [Google Scholar] [CrossRef] [Green Version]

- Köhler, J. Globalization and sustainable development: Case study on international transport and sustainable development. J. Environ. Dev. 2014, 23, 66–100. [Google Scholar] [CrossRef]

- Agarwal, R.K. Sustainable (green) aviation: Challenges and opportunities. SAE Int. J. Aerosp. 2009, 2, 1–20. [Google Scholar] [CrossRef]

- Silling, U. Aviation of the Future: What Needs to Change to Get Aviation Fit for the Twenty-First Century; IntechOpen: London, UK, 2019. [Google Scholar]

- Fan, W.; Sun, Y.; Zhu, T.; Wen, Y. Emissions of HC, CO, NOx, CO2, and SO2 from civil aviation in China in 2010. Atmos. Environ. 2012, 56, 52–57. [Google Scholar] [CrossRef]

- Timmis, A.J.; Hodzic, A.; Koh, L.; Bonner, M.; Soutis, C.; Schäfer, A.W.; Dray, L. Environmental impact assessment of aviation emission reduction through the implementation of composite materials. Int. J. Life Cycle Assess. 2015, 20, 233–243. [Google Scholar] [CrossRef] [Green Version]

- Simio, L.D.; Gambino, M.; Iannaccone, S. Gaseous Biofuels from Waste: Low Environmental and Toxicological Impact with Maximum Benefit on the Greenhouse Effect. Int. J. Life Cycle Assess. 2014, 20, 233–243. [Google Scholar]

- Graham, W.R.; Hall, C.A.; Vera Morales, M. The potential of future aircraft technology for noise and pollutant emissions reduction. Transp. Policy 2014, 34, 36–51. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.S. Aviation Greenhouse Gas Emissions. BAN Ki-moon. 2010. Available online: https://www.icao.int/environmental-protection/pages/envreport10.aspx (accessed on 10 April 2020).

- Synylo, K.; Duchene, N. NOx emission model of turbofan engine. Int. J. Sustain. Aviat. 2014, 5, 72–84. [Google Scholar] [CrossRef]

- WHO. Air Quality Guidelines. Global Update 2005; Particulate Matter, Ozone, Nitrogen Dioxide, and Sulfur Dioxide; World Health Organization: Copenhagen, Denmark, 2006; ISBN 9289021926. [Google Scholar]

- Latza, U.; Gerdes, S.; Baur, X. Effects of nitrogen dioxide on human health: Systematic review of experimental and epidemiological studies conducted between 2002 and 2006. Int. J. Hyg. Environ. Health 2009, 212, 271–287. [Google Scholar] [CrossRef]

- Curtis, L.; Rea, W.; Smith-Willis, P.; Fenyves, E.; Pan, Y. Adverse health effects of outdoor air pollutants. Environ. Int. 2006, 32, 815–830. [Google Scholar] [CrossRef]

- Bidoli, E.; Pappagallo, M.; Birri, S.; Frova, L.; Zanier, L.; Serraino, D. Residential proximity to major roadways and lung cancer mortality. Italy, 1990–2010: An observational study. Int. J. Environ. Res. Public Health 2016, 13, 191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brunekreef, B.; Beelen, R.; Hoek, G.; Schouten, L.; Bausch-Goldbohm, S.; Fischer, P.; Armstrong, B.; Hughes, E.; Jerrett, M.; Brandt, P.V.D. Effects of long-term exposure to traffic-related air pollution on respiratory and cardiovascular mortality in the Netherlands: The NLCS-AIR study. Research report. Health Eff. Inst. 2009, 139, 5–71. [Google Scholar]

- Chiarelli, P.S.; Pereira, L.A.A.; Saldiva, P.H.D.N.; Filho, C.F.; Garcia, M.L.B.; Braga, A.; Martins, L.C. The association between air pollution and blood pressure in traffic controllers in Santo André, São Paulo, Brazil. Environ. Res. 2011, 111, 650–655. [Google Scholar] [CrossRef] [PubMed]

- Kubesch, N.; De Nazelle, A.; Guerra, S.; Westerdahl, D.; Martinez, D.; Bouso, L.; Carrasco-Turigas, G.; Hoffmann, B.; Nieuwenhuijsen, M.J. Arterial blood pressure responses to short-term exposure to low and high traffic-related air pollution with and without moderate physical activity. Eur. J. Prev. Cardiol. 2015, 22, 548–557. [Google Scholar] [CrossRef] [PubMed]

- Buregeya, J.M.; Apparicio, P.; Gelb, J. Short-Term Impact of Traffic-Related Particulate Matter and Noise Exposure on Cardiac Function. Int. J. Environ. Res. Public Health 2020, 17, 1220. [Google Scholar] [CrossRef] [Green Version]

- Lee, W.; Kang, M.-Y.; Yoon, J.-H. Cancer Incidence among Air Transportation Industry Workers Using the National Cohort Study of Korea. Int. J. Environ. Res. Public Health 2019, 16, 2906. [Google Scholar] [CrossRef] [Green Version]

- Power, M.C.; Adar, S.D.; Yanosky, J.D.; Weuve, J. Exposure to air pollution as a potential contributor to cognitive function, cognitive decline, brain imaging, and dementia: A systematic review of epidemiologic research. Neurotoxicology 2016, 56, 235–253. [Google Scholar] [CrossRef] [Green Version]

- Renzi, M.; Cerza, F.; Gariazzo, C.; Agabiti, N.; Cascini, S.; Di Domenicantonio, R.; Davoli, M.; Forastiere, F.; Cesaroni, G. Air pollution and occurrence of type 2 diabetes in a large cohort study. Environ. Int. 2018, 112, 68–76. [Google Scholar] [CrossRef]

- Huang, J.; Deng, F.; Wu, S.; Lu, H.; Hao, Y.; Guo, X. The impacts of short-term exposure to noise and traffic-related air pollution on heart rate variability in young healthy adults. J. Expo. Sci. Environ. Epidemiol. 2013, 23, 559–564. [Google Scholar] [CrossRef] [Green Version]

- Anderson, H.; Spix, C.; Medina, S.; Schouten, J.; Castellague, J.; Rossi, G.; Zmirou, D.; Touloumi, G.; Wojtyniak, B.; Pönkä, A.; et al. Air pollution and daily admission for chronic obstructive pulmonary disease in 6 European cities: Results from the APHEA project. Eur. Respir. J. 1997, 10, 1064–1071. [Google Scholar] [CrossRef] [Green Version]

- Colais, P.; Serinelli, M.; Faustini, A.; Stafoggia, M.; Randi, G.; Tessari, R.; Chiusolo, M.; Pacelli, B.; Mallone, S.; Vigotti, M.A.; et al. Air pollution and urgent hospital admissions in nine Italian cities. Results of the EpiAir Project. Epidemiol. Prev. 2009, 33, 77–94. [Google Scholar] [PubMed]

- Goetz, A.R.; Graham, B. Air transport globalization, liberalization and sustainability: Post-2001 policy dynamics in the United States and Europe. J. Transp. Geogr. 2004, 12, 265–276. [Google Scholar] [CrossRef] [PubMed]

- Graham, B.; Guyer, C. Environmental sustainability, airport capacity and European air transport liberalization: Irreconcilable goals? J. Transp. Geogr. 1999, 7, 165–180. [Google Scholar] [CrossRef]

- Hughes, C.; Van Zante, D.; Heidmann, J. Aircraft Engine Technology for Green Aviation to Reduce Fuel Burn. In Proceedings of the 3rd AIAA Atmospheric Space Environments Conference, Honolulu, HI, USA, 27–30 June 2011; p. 3531. [Google Scholar]

- Daggett, D.; Hendricks, R.; Walther, R. Alternative Fuels and Their Potential Impact on Aviation. 2006-214365, ICAS-2006-5.8.2, E-15568.

- Felder, J.L.; Brown, G.V.; DaeKim, H. Turboelectric Distributed Propulsion in a Hybrid Wing Body Aircraft. SABE-2011-1340, E-18064.

- Christian, F.; Paul, A.R. Design of Hybrid-Electric Propulsion Systems for Light Aircraft. In Proceedings of the 14th AIAA Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 16–20 June 2014. [Google Scholar]

- Friedrich, C.; Robertson, P.A. Hybrid-electric propulsion for automotive and aviation applications. CEAS Aeronaut. J. 2014, 6, 279–290. [Google Scholar] [CrossRef] [Green Version]

- Pornet, C. Electric Drives for Propulsion System of Transport Aircraft. In Encyclopedia of Aerospace Engineering; InTech: Rijeka, Croatia, 2015. [Google Scholar]

- Sarlioglu, B.; Morris, C.T. More electric aircraft: Review, challenges, and opportunities for commercial transport aircraft. IEEE Trans. Transp. Electrif. 2015, 1, 54–64. [Google Scholar] [CrossRef]

- Friedrich, C.; Robertson, P.A. Hybrid-electric propulsion for aircraft. J. Aircr. 2014, 52, 176–189. [Google Scholar] [CrossRef]

- Bradley, M.K.; Droney, C.K. Subsonic Ultra Green Aircraft Research; NASA: Hampton, VA, USA, 2011.

- Dever, T.P.; Duffy, K.P.; Provenza, A.J. Assessment of Technologies for Noncryogenic Hybrid Electric Propulsion; NASA: Cleveland, OH, USA, 2015.

- Liu, T.; Zou, Y.; Liu, D.; Sun, F. Reinforcement learning of adaptive energy management with transition probability for a hybrid electric tracked vehicle. IEEE Trans. Ind. Electron. 2015, 62, 7837–7846. [Google Scholar] [CrossRef]

- Opila, D.F.; Wang, X.; McGee, R.; Gillespie, R.B.; Cook, J.A.; Grizzle, J.W. An energy management controller to optimally trade off fuel economy and drivability for hybrid vehicles. IEEE Trans. Control Syst. Technol. 2011, 20, 1490–1505. [Google Scholar] [CrossRef]

- Lave, L.B.; MacLean, H.L. An environmental-economic evaluation of hybrid electric vehicles: Toyota’s Prius vs. its conventional internal combustion engine Corolla. Transp. Res. Part D Transp. Environ. 2002, 7, 155–162. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Wirasingha, S.G.; Emadi, A. Classification and review of control strategies for plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2011, 60, 111–122. [Google Scholar] [CrossRef]

- Liu, T.; Hu, X. A Bi-Level Control for Energy Efficiency Improvement of a Hybrid Tracked Vehicle. IEEE Trans. Ind. Inform. 2018, 14, 1616–1625. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Rathod, D.; Zhang, D.; Yebi, A.; Zhang, X.; Li, X.; Filipi, Z. Parametric study on reinforcement learning optimized energy management strategy for a hybrid electric vehicle. Appl. Energy 2020, 259, 114200. [Google Scholar] [CrossRef]

- Shabbir, W.; Evangelou, S.A. Exclusive operation strategy for the supervisory control of series hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2016, 24, 2190–2198. [Google Scholar] [CrossRef] [Green Version]

- Kong, Z.; Zou, Y.; Liu, T. Implementation of real-time energy management strategy based on reinforcement learning for hybrid electric vehicles and simulation validation. PLoS ONE 2017, 12, e0180491. [Google Scholar] [CrossRef] [Green Version]

- Harmon, F.G.; Frank, A.A.; Chattot, J.-J. Conceptual design and simulation of a small hybrid-electric unmanned aerial vehicle. J. Aircr. 2006, 43, 1490–1498. [Google Scholar] [CrossRef]

- Liu, T.; Zou, Y.; Liu, D.; Sun, F. Reinforcement learning–based energy management strategy for a hybrid electric tracked vehicle. Energies 2015, 8, 7243–7260. [Google Scholar] [CrossRef] [Green Version]

- Lu, P.; Geng, Q. Real-time simulation system for UAV based on Matlab/Simulink. In Proceedings of the IEEE 2nd International Conference on Computing, Control and Industrial Engineering, Wuhan, China, 20–21 August 2011; Volume 1. [Google Scholar]

- Fuller, M.E. A accumulator model for constant-power discharge including rate effects. Energy Convers. Manag. 2014, 88, 199–205. [Google Scholar] [CrossRef]

- Dai, J. Isolated word recognition using Markov chain models. IEEE Trans. Speech Audio Process. 1995, 3, 458–463. [Google Scholar]

- Institute for Global Environmental Strategies. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- Dopelheuer, A.; Lecht, M. Influence of engine performance on emission characteristics. In Proceedings of the Symposium of the Applied Vehicle Technology Pane-Gas Turbine Engine Combustion, Emissions and Alternative Fuels, Lisbon, Portugal, 12–19 October 1998. [Google Scholar]

- Sutkus, D.J., Jr.; Baughcum, S.L.; DuBois, D.P. Scheduled Civil Aircraft Emission Inventories for 1999: Database Development and Analysis; NASA: Hampton, VA, USA, 2001.

- Molina, S.; Guardiola, C.; Martín, J.; García-Sarmiento, D. Development of a control-oriented model to optimise fuel consumption and NOX emissions in a DI Diesel engine. Appl. Energy 2014, 119, 405–416. [Google Scholar] [CrossRef]

| Parameter Name | Parameter Value |

|---|---|

| Wing Area (m2) | 15.24 |

| Aspect Ratio | 16.8 |

| Wingspan (m) | 16 |

| Length (m) | 7.1 |

| Height (m) | 1.7 |

| Maximum Take-Off Mass (kg) | 770 |

| Bare Weight (kg) | 500 |

| Fuel (kg) | 80 |

| Propeller Diameter (cm) | 160 |

| Thrust-Weight Ratio | 0.5 |

| Cruising Speed (m/s) | 50 |

| Peng (kW) | 50 |

| Pm (kW) | 70 |

| Type | Control Strategy | Fuel/kg | % | CO2/kg | % | NOx/kg | % |

|---|---|---|---|---|---|---|---|

| Petrol Powered UAV | - | 11.75 | - | 37.013 | - | 0.518 | - |

| Hybrid UAV | Power Tracking | 9.965 | −15.2 | 31.391 | −15.2 | 0.3806 | −26.52 |

| Hybrid UAV | Q-Learning | 9.708 | −17.38 | 30.58 | −17.38 | 0.352 | −32.05 |

| Type | Control Strategy | Fuel/kg | % | CO2/kg | % | NOx/kg | % |

|---|---|---|---|---|---|---|---|

| Petrol Powered UAV | - | 13.436 | - | 42.323 | - | 0.607 | - |

| Hybrid UAV | Power Tracking | 11.059 | −17.69 | 34.836 | −17.69 | 0.428 | −29.5 |

| Hybrid UAV | Q-Learning | 10.467 | −22.1 | 32.97 | −22.1 | 0.395 | −34.93 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, M.; Yang, W.; Song, D.; Kosuda, M.; Szabo, S.; Lipovsky, P.; Kasaei, A. Research on Energy Management of Hybrid Unmanned Aerial Vehicles to Improve Energy-Saving and Emission Reduction Performance. Int. J. Environ. Res. Public Health 2020, 17, 2917. https://doi.org/10.3390/ijerph17082917

Bai M, Yang W, Song D, Kosuda M, Szabo S, Lipovsky P, Kasaei A. Research on Energy Management of Hybrid Unmanned Aerial Vehicles to Improve Energy-Saving and Emission Reduction Performance. International Journal of Environmental Research and Public Health. 2020; 17(8):2917. https://doi.org/10.3390/ijerph17082917

Chicago/Turabian StyleBai, Mingliang, Wenjiang Yang, Dongbin Song, Marek Kosuda, Stanislav Szabo, Pavol Lipovsky, and Afshar Kasaei. 2020. "Research on Energy Management of Hybrid Unmanned Aerial Vehicles to Improve Energy-Saving and Emission Reduction Performance" International Journal of Environmental Research and Public Health 17, no. 8: 2917. https://doi.org/10.3390/ijerph17082917