Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area

Abstract

1. Introduction

2. Literature Review

2.1. AMI Concept

2.2. Manufacturing Industry Development

2.3. Industry Theory

3. Methodology

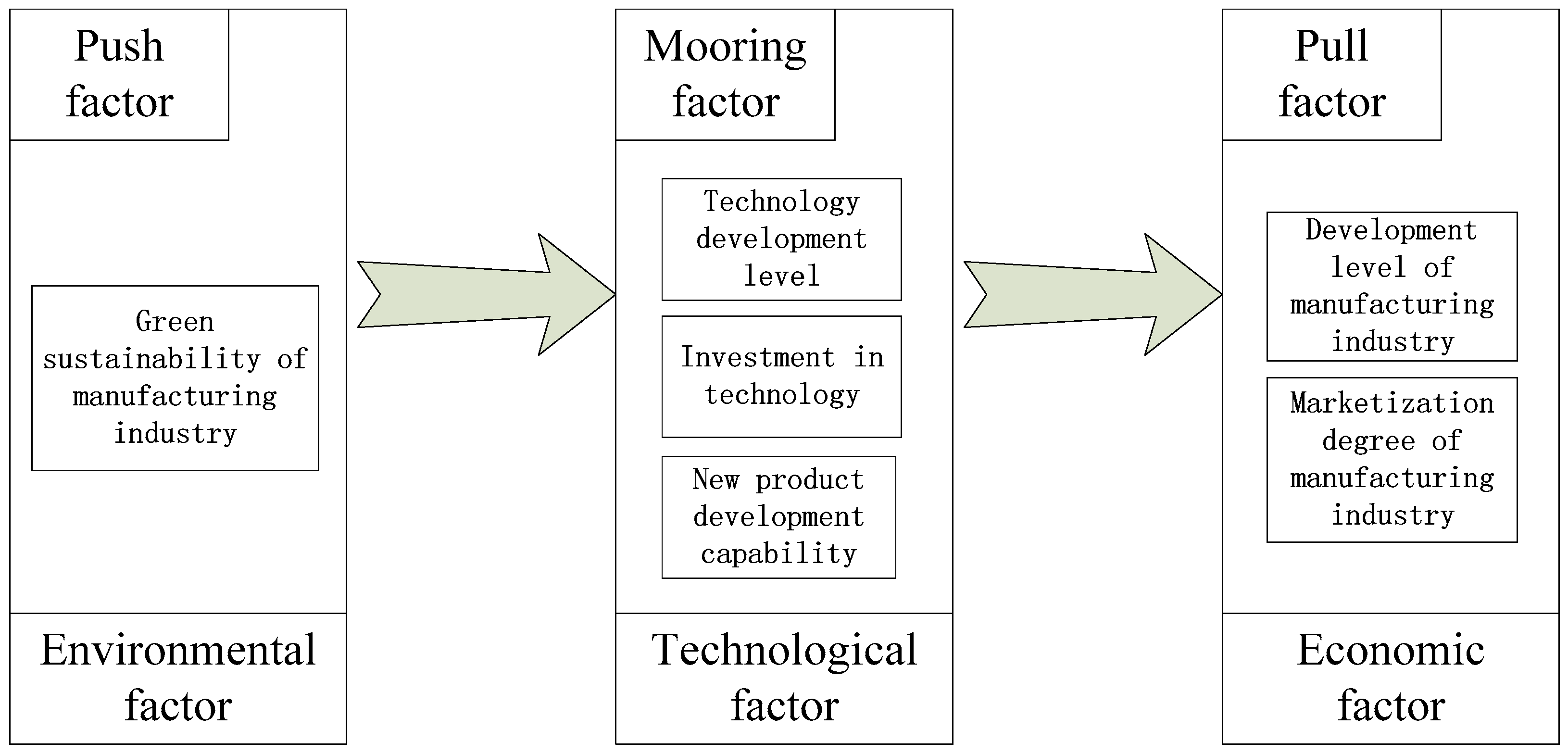

3.1. Research Theory

- (1)

- Push factors, such as bad environments and other negative factors from the source;

- (2)

- Pull factors, such as economic development, rich resources, and other positive factors to the destination;

- (3)

- Mooring factors, such as previous experience and ability.

3.2. Evaluate System

3.3. Research Method

4. Results and Analysis

4.1. Data Sample and Source

4.2. Entropy Results and Analysis

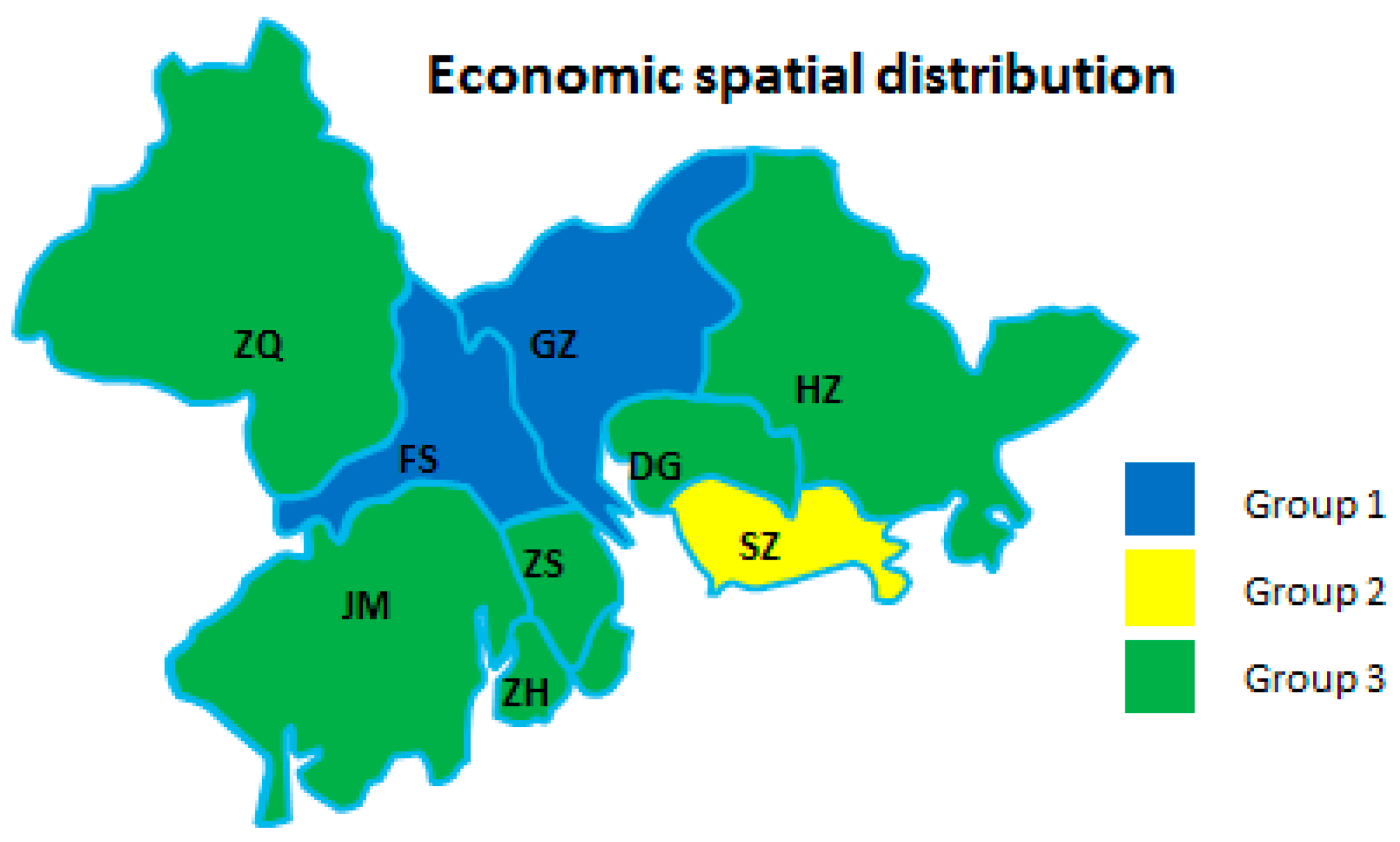

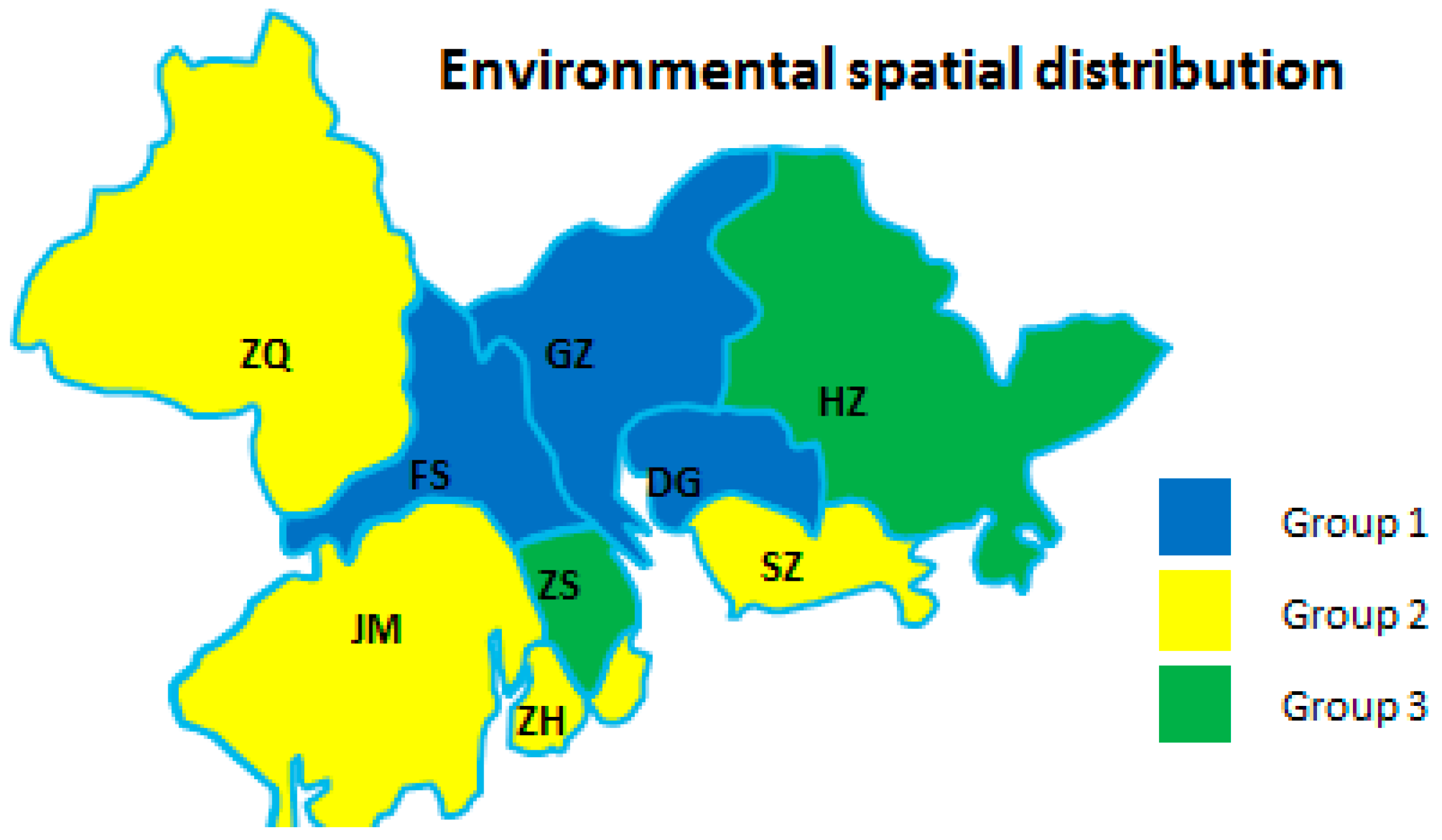

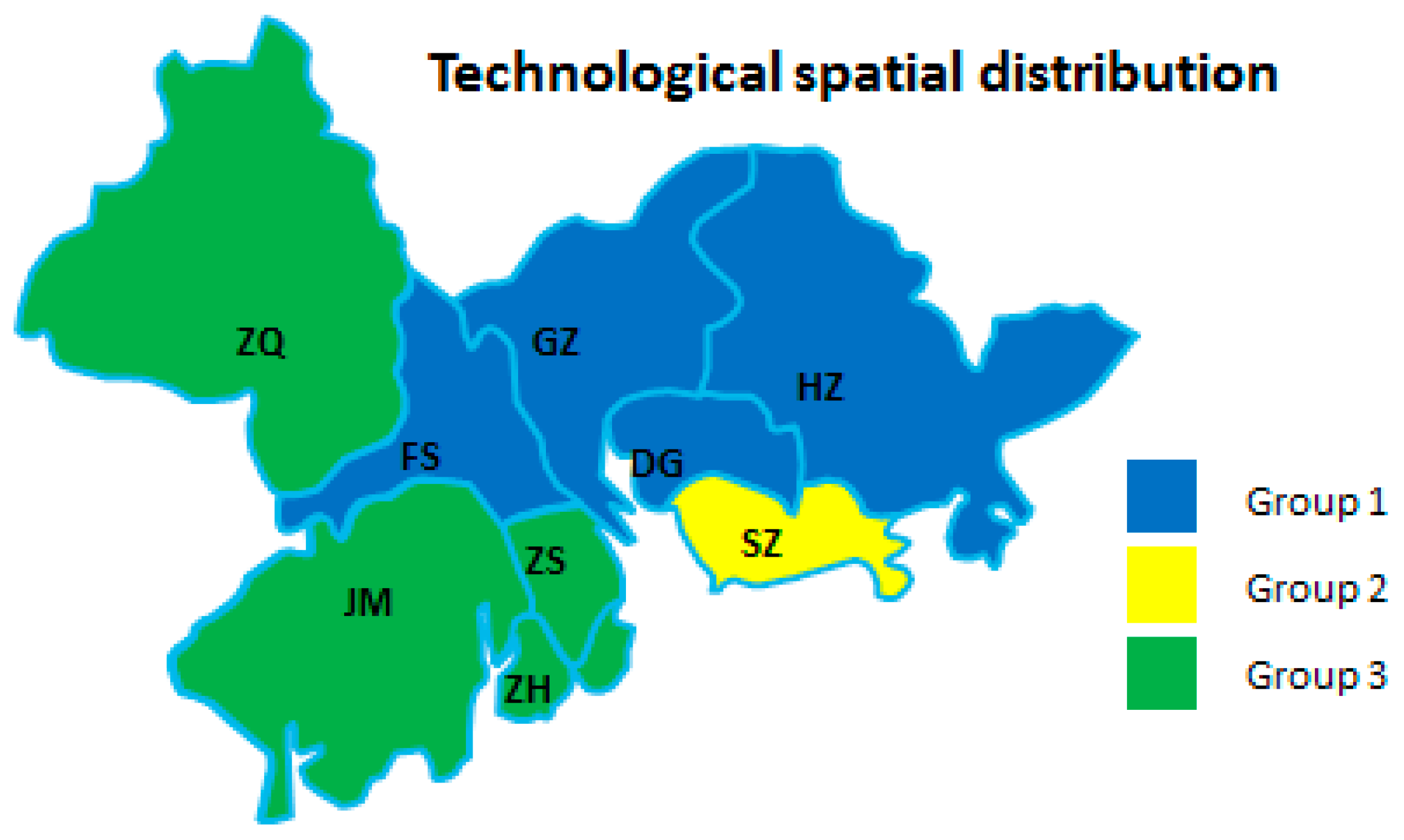

4.3. Cluster Results and Analysis

5. Discussion

5.1. Theoretical Implication

5.2. Practical Implication

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2020. [Google Scholar] [CrossRef]

- Arbia, G.; Espa, G.; Giuliani, D.; Mazzitelli, A. Clusters of firms in an inhomogeneous space: The high-tech industries in Milan. Econ. Model. 2012, 29, 3–11. [Google Scholar] [CrossRef]

- Li, Z. Evaluation Research on Green Degree of Equipment Manufacturing Industry Based on Improved Particle Swarm Optimization Algorithm. Int. J. Reason. Based Intell. Syst. 2020, 12, 1. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Koshy, P.; Alipal, J.; Kadir, M.; Lee, T.C. Challenges of 3D printing technology for manufacturing biomedical products: A case study of Malaysian manufacturing firms. Heliyon 2020, 6, e03734. [Google Scholar] [CrossRef] [PubMed]

- Jia, F.; Ma, X.; Xu, X.; Xie, L. The Differential Role of Manufacturing and Non-manufacturing TFP Growth in Economic Growth. Struct. Chang. Econ. Dyn. 2019, 52, 174–183. [Google Scholar] [CrossRef]

- Chae, J.; Jain, K. Excimer Laser Projection Photoablation Patterning of Metal Thin Films for Fabrication of Microelectronic Devices and Displays. IEEE Photonics Technol. Lett. 2008, 20, 1216–1218. [Google Scholar] [CrossRef]

- Sheridan, T.B. Adaptive Automation, Level of Automation, Allocation Authority, Supervisory Control, and Adaptive Control: Distinctions and Modes of Adaptation. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2011, 41, 662–667. [Google Scholar] [CrossRef]

- Qin, S. Information technology strategy implementation based on differentiated competition on manufacturing enterprises in China. In Proceedings of the 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), Dengleng, China, 8–10 August 2011; pp. 2155–2158. [Google Scholar]

- Lin, Y.C.; Hung, M.H.; Huang, H.C.; Chen, C.C.; Yang, H.C.; Hsieh, Y.S.; Cheng, F.T. Development of Advanced Manufacturing Cloud of Things (AMCoT)—A Smart Manufacturing Platform. IEEE Robot. Autom. Lett. 2017, 2, 1809–1816. [Google Scholar] [CrossRef]

- Johnson, K.; Zemba, M.; Conner, B.; Walker, J.; Burden, E.; Rogers, K.; Cwiok, K.R.; Macdonald, E.; Cortes, P. Digital Manufacturing of Pathologically-Complex 3D Printed Antennas. IEEE Access 2019, 7, 39378–39389. [Google Scholar] [CrossRef]

- Ding, H.; Gao, R.X.; Isaksson, A.J.; Landers, R.G.; Yuan, Y. State of AI-Based Monitoring in Smart Manufacturing and Introduction to Focused Section. IEEE/ASME Trans. Mechatron. 2020, 25, 2143–2154. [Google Scholar] [CrossRef]

- Venkatesh, S.; Davenport, R. A steady-state throughput analysis of cluster tools: Dual-blade versus single-blade robots. IEEE Trans. Semicond. Manuf. 1997, 10, 418–424. [Google Scholar] [CrossRef]

- Thramboulidis, K.; Vachtsevanou, D.C.; Solanos, A. Cyber-Physical Microservices: An IoT-based Framework for Manufacturing Systems. In Proceedings of the 1st IEEE International Conference on Industrial Cyber-Physical Systems (ICPS 2018), Saint Petersburg, Russia, 15–18 May 2018. [Google Scholar]

- Tao, F.; Cheng, Y.; Xu, L.D.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud Computing and Internet of Things-Based Cloud Manufacturing Service System. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442. [Google Scholar]

- Bi, Z.; Xu, L.D.; Wang, C. Internet of Things for Enterprise Systems of Modern Manufacturing. IEEE Trans. Ind. Inform. 2014, 10, 1537–1546. [Google Scholar]

- Small, M.H. Planning, justifying and installing advanced manufacturing technology: A managerial framework. J. Manuf. Technol. Manag. 2007, 18, 513–537. [Google Scholar] [CrossRef]

- Wall, T.D.; Corbett, J.M.; Clegg, C.W.; Martin, J.R. Advanced manufacturing technology and work design: Towards a theoretical framework. J. Organ. Behav. 2010, 11, 201–219. [Google Scholar] [CrossRef]

- Noori, H. Implementing advanced manufacturing technology: The perspective of a newly industrialized country (Malaysia). J. High Technol. Manag. Res. 1997, 8, 1–20. [Google Scholar] [CrossRef]

- Igliński, B.; Iglińska, A.; Cichosz, M.; Kujawski, W.; Buczkowski, R. Renewable energy production in the ódzkie Voivodeship. The PEST analysis of the RES in the voivodeship and in Poland. Renew. Sustain. Energy Rev. 2016, 58, 737–750. [Google Scholar] [CrossRef]

- Healey, N.M. The Transition Economies of Central and Eastern Europe. Columbia J. World Bus. 1994, 29, 62–70. [Google Scholar] [CrossRef]

- Lu, W.; Chen, K.; Xue, F.; Pan, W. Searching for an optimal level of prefabrication in construction: An analytical framework. J. Clean. Prod. 2018, 201, 236–245. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, P. Risk management in distributed wind energy implementing Analytic Hierarchy Process. Renew. Energy 2020, 150, 616–623. [Google Scholar] [CrossRef]

- Charmaine, B.; Dominic, C.; Roberta, P.; Claudia, S.; Antoine, V. The European Insurance Industry: A PEST Analysis. Int. J. Financ. Stud. 2017, 5, 14. [Google Scholar]

- Xiao, B. SWOT Analysis of China’s Port Chemical Industry. Appl. Mech. Mater. 2013, 295–298, 8–11. [Google Scholar] [CrossRef]

- Zima, K.; Plebankiewicz, E.; Wieczorek, D. A SWOT Analysis of the Use of BIM Technology in the Polish Construction Industry. Buildings 2020, 10, 16. [Google Scholar] [CrossRef]

- Zhao, X.; Kang, J.; Bei, L. Focus on the development of shale gas in China—Based on SWOT analysis. Renew. Sustain. Energy Rev. 2013, 21, 603–613. [Google Scholar]

- Narayan, P.K. Fiji’s tourism industry: A SWOT analysis. J. Tour. Stud. 2000, 11, 15–24. [Google Scholar]

- Wu, C.R.; Lin, C.T.; Chen, H.C. Integrated environmental assessment of the location selection with fuzzy analytical network process. Qual. Quant. 2009, 43, 351–380. [Google Scholar] [CrossRef]

- Fang, K.; Zhou, Y.; Wang, S.; Ye, R.; Guo, S. Assessing national renewable energy competitiveness of the G20: A revised Porter’s Diamond Model. Renew. Sustain. Energy Rev. 2018, 93, 719–731. [Google Scholar] [CrossRef]

- Hui, S.; Fan, Z.; Ying, Z.; Ye, S. Empirical research on competitiveness factors: Analysis of real estate industry of Beijing and Tianjin. Engineering 2010, 17, 240–251. [Google Scholar]

- Dou, Z.; Wu, B.B.; Sun, Y.; Wang, T. The Competitiveness of Manufacturing and Its Driving Factors: A Case Study of G20 Participating Countries. Sustainability 2021, 13, 1143. [Google Scholar] [CrossRef]

- Linshan, L.I.; Yanji, M.A.; Geographyagroecology, N.; Sciences, C.; Sciences, U. Spatial-temporal Pattern Evolution of Manufacturing Geographical Agglomeration and Influencing Factors of Old Industrial Base: A Case of Jilin Province, China. Chin. Geogr. Sci. 2015, 25, 486–497. [Google Scholar]

- Nakagawa, M. Which Has Stronger Impacts on Regional Segregation: Industrial Agglomeration or Ethnolinguistic Clustering? Spat. Econ. Anal. 2015, 10, 428–450. [Google Scholar] [CrossRef]

- Martin, R.; Sunley, P. Deconstructing clusters: Chaotic concept or policy panacea? J. Econ. Geogr. 2003, 3, 5–35. [Google Scholar] [CrossRef]

- Nie, X. Green Collaborative Development Model and Innovation of Port Machinery Manufacturing Industry and Service Industry. J. Coast. Res. 2020, 103, 278–283. [Google Scholar] [CrossRef]

- Guo, Y.; Tong, L.; Mei, L. The effect of industrial agglomeration on green development efficiency in Northeast China since the revitalization. J. Clean. Prod. 2020, 258, 120584. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, Y.; Du, K. The impact of industrial agglomeration on industrial pollutant emission: Evidence from China under New Normal. Clean Technol. Environ. Policy 2017, 19, 2327–2334. [Google Scholar] [CrossRef]

- Chen, D.; Chen, S.; Jin, H. Industrial agglomeration and CO2 emissions: Evidence from 187 Chinese prefecture-level cities over 2005–2013. J. Clean. Prod. 2017, 172, 993–1003. [Google Scholar] [CrossRef]

- Li, B.; Huang, L. The Effect of Incremental Innovation and Disruptive Innovation on the Sustainable Development of Manufacturing in China. Sage Open 2019, 9. [Google Scholar] [CrossRef]

- Wang, L.; Xue, Y.; Chang, M.; Xie, C. Macroeconomic determinants of high-tech migration in China: The case of Yangtze River Delta Urban Agglomeration. Cities 2020, 107, 102888. [Google Scholar] [CrossRef]

- Wu, K.; Wang, Y.; Ye, Y.; Zhang, H.; Huang, G. Relationship Between the Built Environment and the Location Choice of High-Tech Firms: Evidence from the Pearl River Delta. Sustainability 2019, 11, 3689. [Google Scholar] [CrossRef]

- Ramadan, M.; Salah, B.; Othman, M.; Ayubali, A.A. Industry 4.0-Based Real-Time Scheduling and Dispatching in Lean Manufacturing Systems. Sustainability 2020, 12, 2272. [Google Scholar] [CrossRef]

- Chang, J.S.; Lee, I.T. An Empirical Study on the Manufacturing Firm’s Strategic Choice for Sustainability in SMEs. Sustainability 2018, 10, 572. [Google Scholar] [CrossRef]

- Lin, C.C.; Yang, J.W. Cost-Efficient Deployment of Fog Computing Systems at Logistics Centers in Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 4603–4611. [Google Scholar] [CrossRef]

- Sasiain, J.; Sanz, A.; Astorga, J.; Jacob, E. Towards Flexible Integration of 5G and IIoT Technologies in Industry 4.0: A Practical Use Case. Appl. Sci. 2020, 10, 7670. [Google Scholar] [CrossRef]

- Marshall, D. IIoT survey results: Realizing the full benefits of the Industrial Internet of Things. Work. Manag. 2016, 69, 21. [Google Scholar]

- Turner, C.; Moreno, M.; Mondini, L.; Salonitis, K.; Charnley, F.; Tiwari, A.; Hutabarat, W. Sustainable Production in a Circular Economy: A Business Model for Re-Distributed Manufacturing. Sustainability 2019, 11, 4291. [Google Scholar] [CrossRef]

- Kuzior, A.; Lobanova, A. Tools of Information and Communication Technologies in Ecological Marketing under Conditions of Sustainable Development in Industrial Regions (Through Examples of Poland and Ukraine). J. Risk Financ. Manag. 2020, 13, 238. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2018, 49, 81–91. [Google Scholar] [CrossRef]

- Leng, J.; Chen, Q.; Ning, M.; Jiang, P. Combining granular computing technique with deep learning for service planning under social manufacturing contexts. Knowl. Based Syst. 2017, 143, 295–306. [Google Scholar] [CrossRef]

- Falck, O.; Heblich, S.; Kipar, S. Industrial innovation: Direct evidence from a cluster-oriented policy. Reg. Sci. Urban Econ. 2010, 40, 574–582. [Google Scholar] [CrossRef]

- Zheng, Q.; Lin, B. Impact of industrial agglomeration on energy efficiency in China’s paper industry. J. Clean. Prod. 2018, 184, 1072–1080. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, W.L.; Wen, J.; Wang, J.S.; Hall, S.; Pauly, P. TFP growth in Chinese cities: The role of factor-intensity and industrial agglomeration. Econ. Model. 2020, 91, 534–549. [Google Scholar] [CrossRef]

- Li, L.; Msaad, H.; Sun, H.; Tan, M.X.; Lu, Y.; Lau, A.K.W. Green Innovation and Business Sustainability: New Evidence from Energy Intensive Industry in China. Int. J. Environ. Res. Public Health 2020, 17, 7826. [Google Scholar] [CrossRef]

- Lee, Z.Y.; Chu, M.T.; Chen, S.S.; Tsai, C.H. Identifying Comprehensive Key Criteria of Sustainable Development for Traditional Manufacturing in Taiwan. Sustainability 2018, 10, 3275. [Google Scholar] [CrossRef]

- Lee, H.S.; Choi, Y. Environmental Performance Evaluation of the Korean Manufacturing Industry Based on Sequential DEA. Sustainability 2019, 11, 874. [Google Scholar] [CrossRef]

- Jung, J.; Han, H.; Oh, M. Travelers’ switching behavior in the airline industry from the perspective of the push-pull-mooring framework. Tour. Manag. 2017, 59, 139–153. [Google Scholar] [CrossRef]

- Bansal, H.S.; Taylor, S.F.; James, Y.S. “Migrating” to new service providers: Toward a unifying framework of consumers’ switching behaviors. J. Acad. Mark. Sci. 2005, 33, 96–115. [Google Scholar] [CrossRef]

- Tang, D.; Yang, Y.; Yan, Y.; Zhou, M. What determines online consumers to migrate from PCs to mobile devices?—An empirical approach on consumers’ internet cross-channel behaviours. Int. J. Serv. Technol. Manag. 2016, 22, 46. [Google Scholar] [CrossRef]

- Leng, P. An Empirical Study on Switching Behavior in Cambodia’s Mobile Telecommunication Service. J. Inf. Commun. Res. 2014, 32, 13–26. [Google Scholar]

- Vu, H.; Tian, G.; Khan, N.; Zada, M.; Zhang, B. Evaluating the International Competitiveness of Vietnam Wood Processing Industry by Combining the Variation Coefficient and the Entropy Method. Forests 2019, 10, 901. [Google Scholar] [CrossRef]

- Sun, Y.; Tong, L.; Liu, D. An Empirical Study of the Measurement of Spatial-Temporal Patterns and Obstacles in the Green Development of Northeast China. Sustainability 2020, 12, 10190. [Google Scholar] [CrossRef]

- Guo, H.; Xu, S.; Pan, C. Measurement of the Spatial Complexity and Its Influencing Factors of Agricultural Green Development in China. Sustainability 2020, 12, 9259. [Google Scholar] [CrossRef]

| Grade 1 | Grade 2 | Grade 3 |

|---|---|---|

| Economic development | Development level of the manufacturing industry | Industrial added value above a designated size (X1) |

| Marketization degree of the manufacturing industry | Total profits of industrial enterprises above a designated size (X2) | |

| Environmental development | Green sustainability of the manufacturing industry | Wastewater discharge of the industrial added value per unit scale (X3) |

| Exhaust emissions of the industrial added value per unit scale (X4) | ||

| Solid production discharge of the industrial added value per unit scale (X5) | ||

| Technological development | Technological development level of the manufacturing industry | Value added of the advanced manufacturing (X6) |

| Value added of the high-tech industry (X7) | ||

| Investment in the manufacturing technology | Internal expenditure on R&D of industrial enterprises above a designated size (X8) | |

| New product development capability | Output value of new products of industrial enterprises above a designated size (X9) |

| Abbreviation | City | Abbreviation | City | Abbreviation | City |

|---|---|---|---|---|---|

| GZ | Guangzhou | FS | Foshan | ZS | Zhongshan |

| SZ | Shenzhen | HZ | Huizhou | JM | Jiangmen |

| ZH | Zhuhai | DG | Dongguan | ZQ | Zhaoqing |

| GZ | SZ | ZH | FS | HZ | DG | ZS | JM | ZQ | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 2011 | Score | 7.70 | 10.00 | 1.09 | 6.96 | 1.64 | 2.66 | 2.34 | 2.10 | 1.00 |

| Rank | 2 | 1 | 8 | 3 | 7 | 4 | 5 | 6 | 9 | |

| 2012 | Score | 7.46 | 10.00 | 1.25 | 8.22 | 2.00 | 3.13 | 2.34 | 1.00 | 1.37 |

| Rank | 3 | 1 | 8 | 2 | 6 | 4 | 5 | 9 | 7 | |

| 2013 | Score | 8.10 | 10.00 | 1.44 | 8.27 | 2.14 | 3.19 | 1.91 | 1.00 | 1.34 |

| Rank | 3 | 1 | 7 | 2 | 5 | 4 | 6 | 9 | 8 | |

| 2014 | Score | 6.99 | 10.00 | 1.42 | 7.70 | 1.99 | 3.08 | 1.70 | 1.00 | 1.21 |

| Rank | 3 | 1 | 7 | 2 | 5 | 4 | 6 | 9 | 8 | |

| 2015 | Score | 6.36 | 10.00 | 1.13 | 7.30 | 1.94 | 2.78 | 1.53 | 1.00 | 1.02 |

| Rank | 3 | 1 | 7 | 2 | 5 | 4 | 6 | 9 | 8 | |

| 2016 | Score | 6.41 | 10.00 | 1.61 | 7.61 | 2.36 | 3.35 | 1.60 | 1.15 | 1.00 |

| Rank | 3 | 1 | 6 | 2 | 5 | 4 | 7 | 8 | 9 | |

| 2017 | Score | 5.88 | 10.00 | 1.90 | 6.49 | 2.54 | 4.14 | 1.44 | 1.42 | 1.00 |

| Rank | 3 | 1 | 6 | 2 | 5 | 4 | 7 | 8 | 9 | |

| 2018 | Score | 5.99 | 10.00 | 1.89 | 6.37 | 2.04 | 3.87 | 1.41 | 1.43 | 1.00 |

| Rank | 3 | 1 | 6 | 2 | 5 | 4 | 8 | 7 | 9 |

| GZ | SZ | ZH | FS | HZ | DG | ZS | JM | ZQ | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 2011 | Score | 3.21 | 4.73 | 1.30 | 8.85 | 1.00 | 10.00 | 1.33 | 8.21 | 4.07 |

| Rank | 6 | 4 | 8 | 2 | 9 | 1 | 7 | 3 | 5 | |

| 2012 | Score | 6.07 | 2.56 | 2.79 | 10.00 | 1.00 | 8.85 | 4.12 | 7.65 | 6.66 |

| Rank | 5 | 8 | 7 | 1 | 9 | 2 | 6 | 3 | 4 | |

| 2013 | Score | 10.00 | 4.85 | 4.64 | 9.35 | 4.95 | 9.92 | 1.00 | 6.93 | 5.27 |

| Rank | 1 | 7 | 8 | 3 | 6 | 2 | 9 | 4 | 5 | |

| 2014 | Score | 9.87 | 4.37 | 5.56 | 8.98 | 2.24 | 10.00 | 1.00 | 7.22 | 5.54 |

| Rank | 2 | 7 | 5 | 3 | 8 | 1 | 9 | 4 | 6 | |

| 2015 | Score | 9.92 | 6.27 | 4.80 | 6.97 | 2.36 | 10.00 | 1.00 | 5.66 | 4.84 |

| Rank | 2 | 4 | 7 | 3 | 8 | 1 | 9 | 5 | 6 | |

| 2016 | Score | 10.00 | 4.03 | 4.85 | 8.90 | 1.00 | 9.56 | 1.29 | 3.54 | 3.94 |

| Rank | 1 | 5 | 4 | 3 | 9 | 2 | 8 | 7 | 6 | |

| 2017 | Score | 9.97 | 4.53 | 4.70 | 7.71 | 4.78 | 10.00 | 1.00 | 4.13 | 4.12 |

| Rank | 2 | 6 | 5 | 3 | 4 | 1 | 9 | 7 | 8 | |

| 2018 | Score | 10.00 | 3.65 | 4.89 | 8.28 | 2.82 | 9.81 | 1.00 | 4.13 | 4.47 |

| Rank | 1 | 7 | 4 | 3 | 8 | 2 | 9 | 6 | 5 |

| GZ | SZ | ZH | FS | HZ | DG | ZS | JM | ZQ | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 2011 | Score | 4.06 | 10.00 | 1.46 | 2.59 | 2.05 | 2.28 | 1.57 | 1.23 | 1.00 |

| Rank | 2 | 1 | 7 | 3 | 5 | 4 | 6 | 8 | 9 | |

| 2012 | Score | 3.92 | 10.00 | 1.41 | 2.75 | 2.27 | 2.46 | 1.60 | 1.07 | 1.00 |

| Rank | 2 | 1 | 7 | 3 | 5 | 4 | 6 | 8 | 9 | |

| 2013 | Score | 3.76 | 10.00 | 1.42 | 2.80 | 2.45 | 2.77 | 1.52 | 1.06 | 1.00 |

| Rank | 2 | 1 | 7 | 3 | 5 | 4 | 6 | 8 | 9 | |

| 2014 | Score | 3.66 | 10.00 | 1.40 | 2.78 | 2.21 | 2.84 | 1.47 | 1.09 | 1.00 |

| Rank | 2 | 1 | 7 | 4 | 5 | 3 | 6 | 8 | 9 | |

| 2015 | Score | 3.59 | 10.00 | 1.42 | 2.69 | 2.19 | 2.80 | 1.46 | 1.13 | 1.00 |

| Rank | 2 | 1 | 7 | 4 | 5 | 3 | 6 | 8 | 9 | |

| 2016 | Score | 3.25 | 10.00 | 1.44 | 2.57 | 2.12 | 3.20 | 1.39 | 1.14 | 1.00 |

| Rank | 2 | 1 | 6 | 4 | 5 | 3 | 7 | 8 | 9 | |

| 2017 | Score | 3.08 | 10.00 | 1.52 | 2.56 | 2.21 | 3.53 | 1.41 | 1.22 | 1.00 |

| Rank | 3 | 1 | 6 | 4 | 5 | 2 | 7 | 8 | 9 | |

| 2018 | Score | 2.97 | 10.00 | 1.52 | 2.51 | 2.08 | 3.62 | 1.33 | 1.24 | 1.00 |

| Rank | 3 | 1 | 6 | 4 | 5 | 2 | 7 | 8 | 9 |

| GZ | SZ | ZH | FS | HZ | DG | ZS | JM | ZQ | |

|---|---|---|---|---|---|---|---|---|---|

| The economic factor | 1 | 2 | 3 | 1 | 3 | 3 | 3 | 3 | 3 |

| The environmental factor | 1 | 2 | 2 | 1 | 3 | 1 | 3 | 2 | 2 |

| The technological factor | 1 | 2 | 3 | 1 | 1 | 1 | 3 | 3 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dou, Z.; Sun, Y.; Wang, T.; Wan, H.; Fan, S. Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area. Int. J. Environ. Res. Public Health 2021, 18, 5800. https://doi.org/10.3390/ijerph18115800

Dou Z, Sun Y, Wang T, Wan H, Fan S. Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area. International Journal of Environmental Research and Public Health. 2021; 18(11):5800. https://doi.org/10.3390/ijerph18115800

Chicago/Turabian StyleDou, Zixin, Yanming Sun, Tao Wang, Huiyin Wan, and Shiqi Fan. 2021. "Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area" International Journal of Environmental Research and Public Health 18, no. 11: 5800. https://doi.org/10.3390/ijerph18115800

APA StyleDou, Z., Sun, Y., Wang, T., Wan, H., & Fan, S. (2021). Exploring Regional Advanced Manufacturing and Its Driving Factors: A Case Study of the Guangdong–Hong Kong–Macao Greater Bay Area. International Journal of Environmental Research and Public Health, 18(11), 5800. https://doi.org/10.3390/ijerph18115800