Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities

Abstract

:1. Introduction

2. Background of Digital Technologies

3. Research Methodology

3.1. Mixed-Systematic Review Method

3.2. Data Collection

3.3. Bibliometric Analysis Tools

4. Results and Discussion

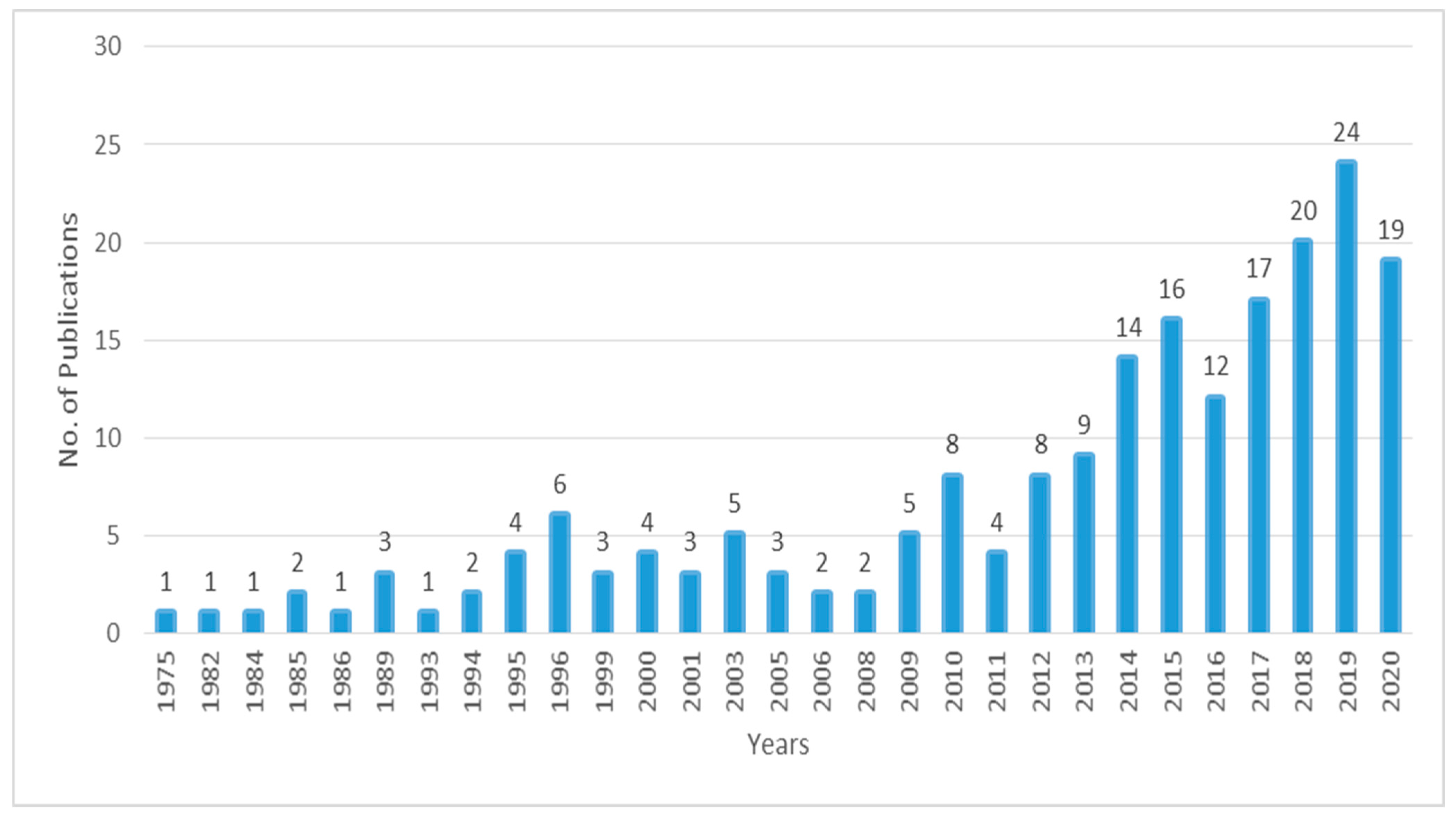

4.1. Annual Publications Trend on DTs in the AEC Industry (20th and 21st Century)

4.2. Journal Contributions on DTs in the AEC Industry

4.3. Bibliometric Analysis

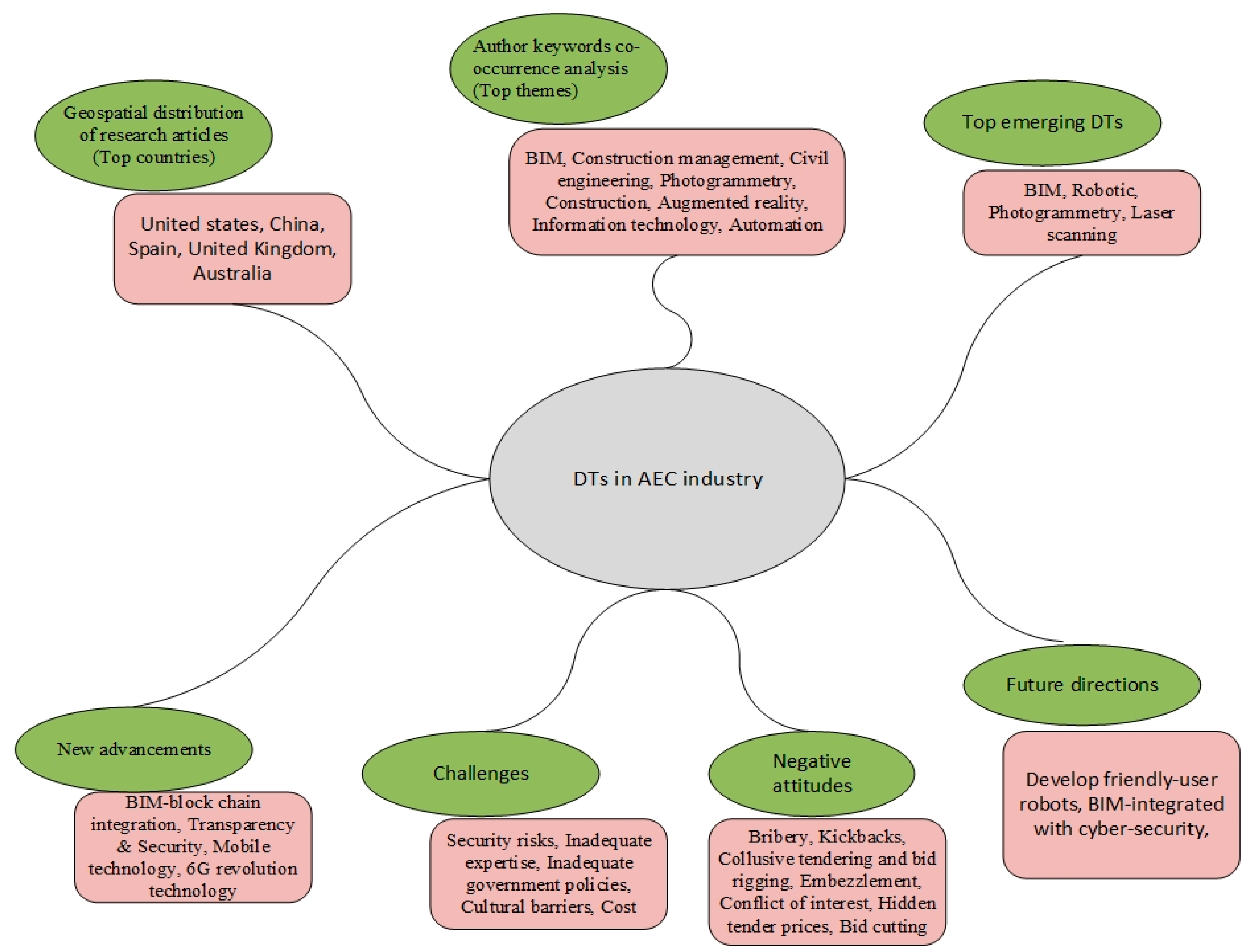

4.3.1. Geospatial Distribution of Research Articles on DTs in the AEC Industry

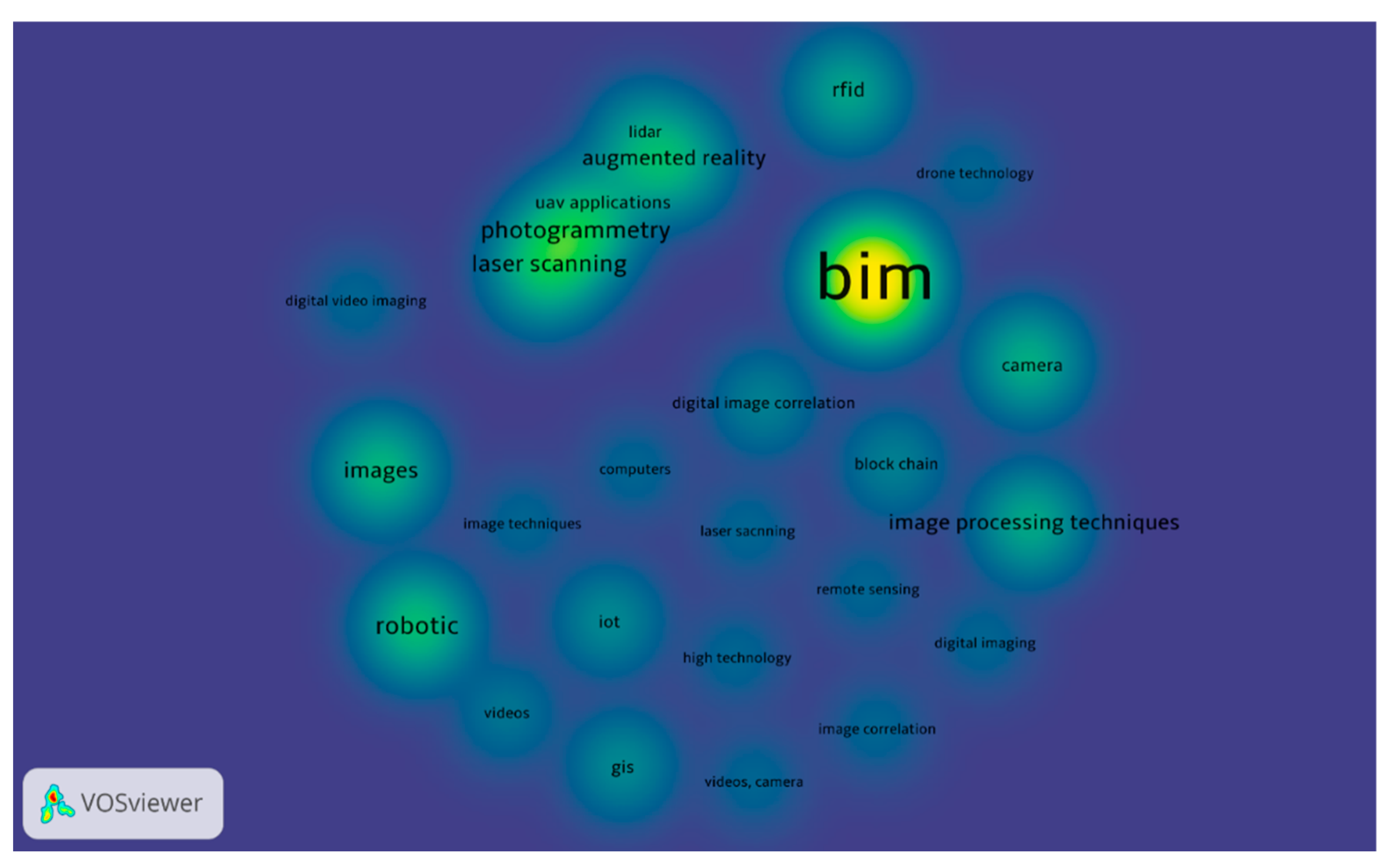

4.3.2. Author Keywords Co-Occurrence Analysis

- (i)

- BIM Integrating Cluster (Green Color)

- (ii)

- Automation Integrating Cluster (Yellow Color)

- (iii)

- Photogrammetry Integrating Cluster (Pink Color)

- (iv)

- Civil Engineering Integrating Cluster (Blue Color)

- (v)

- Augmented Reality (AR) and Computer Applications Integrating Cluster (Light Blue Color–Orange Color)

- (vi)

- Construction Management Integrating Cluster (Purple Color)

4.4. Digital Technologies in the AEC Industry

4.5. Systematic Analysis

4.5.1. New Advancements towards DTs in the AEC Industry

4.5.2. Challenges towards DTs in the AEC Industry

4.5.3. Negative Attitudes towards DTs in the AEC Industry

4.5.4. Future Directions towards DTs in the AEC Industry

5. Summary of Findings

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A Systematic Review of Digital Technology Adoption in Off-Site Construction: Current Status and Future Direction towards Industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Patel, S.; Patt, Y. Introduction to Computing Systems: From Bits & Gates to C & Beyond; McGraw-Hill Professional: New York, NY, USA, 2019. [Google Scholar]

- Xue, X.; Shen, Q.; Ren, Z. Critical Review of Collaborative Working in Construction Projects: Business Environment and Human Behaviors. J. Manag. Eng. 2010, 26, 196–208. [Google Scholar] [CrossRef]

- Alaloul, W.S.; Liew, M.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Maresova, P.; Krejcar, O.; David, O.O. Industry 4.0 for the construction industry: Review of man-agement perspective. Economies 2019, 7, 68. [Google Scholar] [CrossRef] [Green Version]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Ozturk, G.B. Interoperability in building information modeling for AECO/FM industry. Autom. Constr. 2020, 113, 103122. [Google Scholar] [CrossRef]

- Kim, K.; Kim, H.; Kim, H. Image-based construction hazard avoidance system using augmented reality in wearable device. Autom. Constr. 2017, 83, 390–403. [Google Scholar] [CrossRef]

- Sacks, R.; Perlman, A.; Barak, R. Construction safety training using immersive virtual reality. Constr. Manag. Econ. 2013, 31, 1005–1017. [Google Scholar] [CrossRef]

- Rizo-Maestre, C.; González-Avilés, Á.; Galiano-Garrigós, A.; Andújar-Montoya, M.D.; Puchol-García, J.A. UAV BIM: Incor-poration of Photogrammetric Techniques in Architectural Projects with Building Information Modeling versus Classical Work Processes+. Remote Sens. 2020, 12, 2329. [Google Scholar] [CrossRef]

- Martínez-Rojas, M.; Marín, N.; Vila, M.A. The Role of Information Technologies to Address Data Handling in Construction Project Management. J. Comput. Civ. Eng. 2016, 30, 04015064. [Google Scholar] [CrossRef]

- Song, Y.; Wang, X.; Tan, Y.; Wu, P.; Sutrisna, M.; Cheng, J.C.P.; Hampson, K. Trends and Opportunities of BIM-GIS Integration in the Architecture, Engineering and Construction Industry: A Review from a Spatio-Temporal Statistical Perspective. ISPRS Int. J. Geo-Inf. 2017, 6, 397. [Google Scholar] [CrossRef] [Green Version]

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identi-fication technology and GPS. Autom. Constr. 2007, 16, 354–367. [Google Scholar] [CrossRef]

- Mneymneh, B.E.; Abbas, M.; Khoury, H. Vision-based framework for intelligent monitoring of hardhat wearing on con-struction sites. J. Comput. Civ. Eng. 2019, 33, 4018066. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. From BIM to extended reality in AEC industry. Autom. Constr. 2020, 116, 103254. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.; Adabre, M.A.; Edwards, D.J.; Hosseini, M.R.; Ameyaw, E.E. Artificial intelligence in the AEC industry: Scientometric analysis and visualization of research activities. Autom. Constr. 2020, 112, 103081. [Google Scholar] [CrossRef]

- Davtalab, O.; Kazemian, A.; Khoshnevis, B. Perspectives on a BIM-integrated software platform for robotic construction through Contour Crafting. Autom. Constr. 2018, 89, 13–23. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S.; Hosseini, M.R. Integrated project delivery with blockchain: An automated financial system. Autom. Constr. 2020, 114, 103182. [Google Scholar] [CrossRef]

- Zaher, M.; Greenwood, D.; Marzouk, M. Mobile augmented reality applications for construction projects. Constr. Innov. 2018, 18, 152–166. [Google Scholar] [CrossRef] [Green Version]

- Dinis, F.M.; Sanhudo, L.; Martins, J.P.; Ramos, N.M.M. Improving project communication in the architecture, engineering and construction industry: Coupling virtual reality and laser scanning. J. Build. Eng. 2020, 30, 101287. [Google Scholar] [CrossRef]

- Noghabaei, M.; Heydarian, A.; Balali, V.; Han, K. Trend Analysis on Adoption of Virtual and Augmented Reality in the Architecture, Engineering, and Construction Industry. Data 2020, 5, 26. [Google Scholar] [CrossRef] [Green Version]

- Maffei, L.; Masullo, M.; Pascale, A.; Ruggiero, G.; Romero, V.P. Immersive virtual reality in community planning: Acoustic and visual congruence of simulated vs real world. Sustain. Cities Soc. 2016, 27, 338–345. [Google Scholar] [CrossRef]

- Iachini, T.; Maffei, L.; Ruotolo, F.; Senese, V.P.; Ruggiero, G.; Masullo, M.; Alekseeva, N. Multisensory Assessment of Acoustic Comfort Aboard Metros: A Virtual Reality Study. Appl. Cogn. Psychol. 2012, 26, 757–767. [Google Scholar] [CrossRef]

- Vincke, S.; Hernandez, R.D.L.; Bassier, M.; Vergauwen, M. Immersive Visualisation of Construction Site Point Cloud Data, Meshes and BIM Models in a VR Environment using a Gaming Engine. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, XLII-5/W2, 77–83. [Google Scholar] [CrossRef] [Green Version]

- Azhar, S. Role of Visualization Technologies in Safety Planning and Management at Construction Jobsites. Procedia Eng. 2017, 171, 215–226. [Google Scholar] [CrossRef]

- Jensen, C.G. Collaboration and dialogue in Virtual reality. J. Probl. Based Learn. High. Educ. 2017, 5. [Google Scholar] [CrossRef]

- Pauwels, P.; Zhang, S.; Lee, Y.-C. Semantic web technologies in AEC industry: A literature overview. Autom. Constr. 2017, 73, 145–165. [Google Scholar] [CrossRef]

- Irizarry, J.; Karan, E.P.; Jalaei, F. Integrating BIM and GIS to improve the visual monitoring of construction supply chain management. Autom. Constr. 2013, 31, 241–254. [Google Scholar] [CrossRef]

- De Soto, B.G.; Agustí-Juan, I.; Joss, S.; Hunhevicz, J. Implications of Construction 4.0 to the workforce and organizational structures. Int. J. Constr. Manag. 2019, 1–13. [Google Scholar] [CrossRef]

- Zaki, T.; Khalil, C. QR-coded clash-free drawings: An integrated system of BIM and Augmented reality to improve con-struction project visualization. In Proceedings of the ICSC15—The Canadian Society for Civil Engineering’s 5th International/11th Construction Specialty Conference, Vancouver, BC, Canada, 7–10 June 2015. [Google Scholar]

- Patrício, D.I.; Rieder, R. Computer vision and artificial intelligence in precision agriculture for grain crops: A systematic review. Comput. Electron. Agric. 2018, 153, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Mellit, A.; Kalogirou, S.A. Artificial intelligence techniques for photovoltaic applications: A review. Prog. Energy Combust. Sci. 2008, 34, 574–632. [Google Scholar] [CrossRef]

- Araszkiewicz, K. Digital Technologies in Facility Management—The state of Practice and Research Challenges. Procedia Eng. 2017, 196, 1034–1042. [Google Scholar] [CrossRef]

- Guo, B.H.; Scheepbouwer, E.; Yiu, T.W.; Gonzalez, V. Overview and Analysis of Digital Technologies Designed for Construction Safety Management. In Proceedings of the AUBEA 2017: Australasian Universities Building Education Association Conference, Melbourne, Australia, 3–5 July 2017. [Google Scholar]

- Ibem, E.O.; Laryea, S. Survey of digital technologies in procurement of construction projects. Autom. Constr. 2014, 46, 11–21. [Google Scholar] [CrossRef]

- Markoulli, M.; Lee, C.; Byington, E.; Felps, W.A. Mapping Human Resource Management: Reviewing the field and charting future directions. Hum. Resour. Manag. Rev. 2017, 27, 367–396. [Google Scholar] [CrossRef]

- Hamelink, C.J. New Information and Communication Technologies, Social Development and Cultural Change; United Nations Research Institute for Social Development Geneva: Geneva, Switzerland, 1997. [Google Scholar]

- Wu, L.X.; Yin, Z.R.; Zhong, Y.P. Restudy on digital mine: Characteristics, framework and key technologies. J. China Coal Soc. 2003, 28, 1–7. [Google Scholar]

- Saad, I.M.H.; Hancher, D.E. Multimedia for Construction Project Management: Project Navigator. J. Constr. Eng. Manag. 1998, 124, 82–89. [Google Scholar] [CrossRef]

- Matt, C.; Hess, T.; Benlian, A. Digital Transformation Strategies. Bus. Inf. Syst. Eng. 2015, 57, 339–343. [Google Scholar] [CrossRef]

- Taipale, S. Synchronicity matters: Defining the characteristics of digital generations. Inf. Commun. Soc. 2016, 19, 80–94. [Google Scholar] [CrossRef] [Green Version]

- Yoo, Y.; Lyytinen, K. Distributed Innovation in Classes of Networks. In Proceedings of the 41st Annual Hawaii International Conference on System Sciences (HICSS 2008), Waikoloa, HI, USA, 7–10 January 2008; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2008; p. 58. [Google Scholar]

- Lavikka, R.; Kallio, J.; Casey, T.; Airaksinen, M. Digital disruption of the AEC industry: Technology-oriented scenarios for possible future development paths. Constr. Manag. Econ. 2018, 36, 635–650. [Google Scholar] [CrossRef] [Green Version]

- Johnson, R.B.; Onwuegbuzie, A.J. Mixed Methods Research: A Research Paradigm Whose Time Has Come. Educ. Res. 2004, 33, 14–26. [Google Scholar] [CrossRef] [Green Version]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review; SAGE: New York, NY, USA, 2016. [Google Scholar]

- Zhao, X.; Zuo, J.; Wu, G.; Huang, C. A bibliometric review of green building research 2000–2016. Arch. Sci. Rev. 2018, 62, 74–88. [Google Scholar] [CrossRef]

- Meho, L.I.; Rogers, Y. Citation counting, citation ranking, and h-index of human-computer interaction researchers: A com-parison of Scopus and Web of Science. J. Am. Soc. Inf. Sci. Technol. 2008, 59, 1711–1726. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Liu, H.; Chen, Y.; Al-Hussein, M. Building information modelling for off-site construction: Review and future direc-tions. Autom. Constr. 2019, 101, 72–91. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 2017, 111, 1053–1070. [Google Scholar] [CrossRef] [Green Version]

- Vilutiene, T.; Kalibatiene, D.; Hosseini, M.R.; Pellicer, E.; Zavadskas, E.K. Building Information Modeling (BIM) for Structural Engineering: A Bibliometric Analysis of the Literature. Adv. Civ. Eng. 2019, 2019, 1–19. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A.A.; Grilo, A. Bibliometric analysis and review of Building Information Modelling literature published between 2005 and 2015. Autom. Constr. 2017, 80, 118–136. [Google Scholar] [CrossRef]

- Babalola, A.; Musa, S.; Akinlolu, M.T.; Haupt, T.C. A bibliometric review of advances in building information modeling (BIM) research. J. Eng. Des. Technol. 2021. [Google Scholar] [CrossRef]

- Robin, B.R. Digital Storytelling: A Powerful Technology Tool for the 21st Century Classroom. Theory Pract. 2008, 47, 220–228. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Council, N.R. Funding a Revolution: Government Support for Computing Research; National Academies Press: Washington, DC, USA, 1999. [Google Scholar]

- Gu, N.; London, K. Understanding and facilitating BIM adoption in the AEC industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

- Serenko, A. The development of an AI journal ranking based on the revealed preference approach. J. Inf. 2010, 4, 447–459. [Google Scholar] [CrossRef]

- Perianes-Rodriguez, A.; Waltman, L.; van Eck, N.J. Constructing bibliometric networks: A comparison between full and fractional counting. J. Inf. 2016, 10, 1178–1195. [Google Scholar] [CrossRef] [Green Version]

- Ganbat, T.; Chong, H.-Y.; Liao, P.-C.; Wu, Y.-D. A Bibliometric Review on Risk Management and Building Information Modeling for International Construction. Adv. Civ. Eng. 2018, 2018, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Chihib, M.; Salmerón-Manzano, E.; Novas, N.; Manzano-Agugliaro, F. Bibliometric Maps of BIM and BIM in Universities: A Comparative Analysis. Sustainability 2019, 11, 4398. [Google Scholar] [CrossRef] [Green Version]

- Saka, A.B.; Chan, D.W.M. A Scientometric Review and Metasynthesis of Building Information Modelling (BIM) Research in Africa. Buildings 2019, 9, 85. [Google Scholar] [CrossRef] [Green Version]

- van Eck, N.J.; Waltman, L. CitNetExplorer: A new software tool for analyzing and visualizing citation networks. J. Inf. 2014, 8, 802–823. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Pan, Y.; Luo, X. Integration of BIM and GIS in sustainable built environment: A review and bibliometric analysis. Autom. Constr. 2019, 103, 41–52. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M.; Wong, J.K.W. Evolution in the intellectual structure of BIM research: A bibliometric analysis. J. Civ. Eng. Manag. 2017, 23, 1060–1081. [Google Scholar] [CrossRef]

- Li, X.; Wu, P.; Shen, Q.; Wang, X.; Teng, Y. Mapping the knowledge domains of Building Information Modeling (BIM): A bibliometric approach. Autom. Constr. 2017, 84, 195–206. [Google Scholar] [CrossRef]

- Zheng, L.; Chen, K.; Lu, W. Bibliometric Analysis of Construction Education Research from 1982 to 2017. J. Prof. Issues Eng. Educ. Pract. 2019, 145, 04019005. [Google Scholar] [CrossRef]

- Jin, R.; Zou, Y.; Gidado, K.; Ashton, P.; Painting, N. Scientometric analysis of BIM-based research in construction engineering and management. Eng. Constr. Arch. Manag. 2019, 26, 1750–1776. [Google Scholar] [CrossRef] [Green Version]

- Manzoor, B.; Othman, I. Safety Management Model During Construction Focusing on Building Information Modeling (BIM). In Advances in Civil Engineering Materials: Selected Articles from the International Conference on Architecture and Civil Engineering (ICACE2020); Springer Nature: Singapore, 2021; p. 31. [Google Scholar] [CrossRef]

- Jin, R.; Zhong, B.; Ma, L.; Hashemi, A.; Ding, L. Integrating BIM with building performance analysis in project life-cycle. Autom. Constr. 2019, 106, 102861. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual; Univeristeit Leiden: Leiden, The Netherlands, 2013. [Google Scholar]

- Liu, H.; Singh, G.; Lu, M.; Bouferguene, A.; Al-Hussein, M. BIM-based automated design and planning for boarding of light-frame residential buildings. Autom. Constr. 2018, 89, 235–249. [Google Scholar] [CrossRef]

- Choo, S.; Park, H.; Kim, T.; Seo, J. Analysis of Trends in Korean BIM Research and Technologies Using Text Mining. Appl. Sci. 2019, 9, 4424. [Google Scholar] [CrossRef] [Green Version]

- Cheng, J.C.P.; Deng, Y.; Anumba, C. Mapping BIM schema and 3D GIS schema semi-automatically utilizing linguistic and text mining techniques. J. Inf. Technol. Constr. 2015, 20, 193–212. [Google Scholar]

- Yarmohammadi, S.; Pourabolghasem, R.; Castro-Lacouture, D. Mining implicit 3D modeling patterns from unstructured temporal BIM log text data. Autom. Constr. 2017, 81, 17–24. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. BIM log mining: Learning and predicting design commands. Autom. Constr. 2020, 112, 103107. [Google Scholar] [CrossRef]

- Suwal, S.; Jäväjä, P.; Salin, J. BIM Education: Implementing and Reviewing “OpeBIM”—BIM for Teachers. In Computing in Civil and Building Engineering; ASCE: Reston, VA, USA, 2014; pp. 2151–2158. [Google Scholar]

- Bozoglu, J. Collaboration and coordination learning modules for BIM education. J. Inf. Technol. Constr. 2016, 21, 152–163. [Google Scholar]

- Abdirad, H.; Dossick, C.S. BIM curriculum design in architecture, engineering, and construction education: A systematic review. J. Inf. Technol. Constr. 2016, 21, 250–271. [Google Scholar]

- Abbas, A.; Din, Z.U.; Farooqui, R. Integration of BIM in Construction Management Education: An Overview of Pakistani Engineering Universities. Procedia Eng. 2016, 145, 151–157. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Issa, R.R.A. BIM education and recruiting: Survey-based comparative analysis of issues, perceptions, and collabo-ration opportunities. J. Prof. Issues Eng. Educ. Pract. 2014, 140, 4013014. [Google Scholar] [CrossRef]

- Qureshi, A.H.; Alaloul, W.S.; Manzoor, B.; Musarat, M.A.; Saad, S. Implications of Machine Learning Integrated Technologies for Construction Progress Detection Under Industry 4.0 (IR 4.0). In Proceedings of the 2020 Second International Sustainability and Resilience Conference, Sakheer, Bahrain, 11–12 November 2020; pp. 1–6. [Google Scholar]

- Wang, W.; Siau, K. Artificial intelligence, machine learning, automation, robotics, future of work and future of humanity: A review and research agenda. J. Database Manag. 2019, 30, 61–79. [Google Scholar] [CrossRef]

- Shekhar, S.S. Artificial Intelligence in Automation. Artif. Intell. 2019, 3085, 14–17. [Google Scholar]

- Donepudi, P.K. Application of Artificial Intelligence in Automation Industry. Asian J. Appl. Sci. Eng. 2018, 7, 7–20. [Google Scholar]

- Bock, T. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Autom. Constr. 2015, 59, 113–121. [Google Scholar] [CrossRef]

- Skibniewski, M.J.; Russell, J.S. Construction Robot Fleet Management System Prototype. J. Comput. Civ. Eng. 1991, 5, 444–463. [Google Scholar] [CrossRef]

- Keating, S.; Oxman, N. Compound fabrication: A multi-functional robotic platform for digital design and fabrication. Robot. Comput. Manuf. 2013, 29, 439–448. [Google Scholar] [CrossRef]

- Willmann, J.; Knauss, M.; Bonwetsch, T.; Apolinarska, A.A.; Gramazio, F.; Kohler, M. Robotic timber construction—Expanding additive fabrication to new dimensions. Autom. Constr. 2016, 61, 16–23. [Google Scholar] [CrossRef]

- Chen, Q.; de Soto, B.G.; Adey, B.T. Construction automation: Research areas, industry concerns and suggestions for ad-vancement. Autom. Constr. 2018, 94, 22–38. [Google Scholar] [CrossRef]

- Mao, B.; Ban, Y.; Harrie, L. A multiple representation data structure for dynamic visualisation of generalised 3D city models. ISPRS J. Photogramm. Remote Sens. 2011, 66, 198–208. [Google Scholar] [CrossRef]

- Julin, A.; Jaalama, K.; Virtanen, J.-P.; Pouke, M.; Ylipulli, J.; Vaaja, M.; Hyyppä, J.; Hyyppä, H. Characterizing 3D City Modeling Projects: Towards a Harmonized Interoperable System. ISPRS Int. J. Geo-Inf. 2018, 7, 55. [Google Scholar] [CrossRef] [Green Version]

- Cho, H.-B.; Cho, W.-S.; Park, J.-K.; Song, N.-H. 3D building modeling using aerial LiDAR data, Korean. J. Remote Sens. 2008, 24, 141–152. [Google Scholar]

- Zhang, Y.; Zhang, Z.; Zhang, J.; Wu, J. 3D Building Modelling with Digital Map, Lidar Data and Video Image Sequences. Photogramm. Rec. 2005, 20, 285–302. [Google Scholar] [CrossRef]

- Kersten, T.P.; Büyüksalİh, G.; Baz, İ.; Jacobsen, K. Documentation of Istanbul historic peninsula by kinematic terrestrial laser scanning. Photogramm. Rec. 2009, 24, 122–138. [Google Scholar] [CrossRef]

- Yang, L.; Cheng, J.C.; Wang, Q. Semi-automated generation of parametric BIM for steel structures based on terrestrial laser scanning data. Autom. Constr. 2020, 112, 103037. [Google Scholar] [CrossRef]

- Stajano, F.; Hoult, N.; Wassell, I.; Bennett, P.; Middleton, C.; Soga, K. Smart bridges, smart tunnels: Transforming wireless sensor networks from research prototypes into robust engineering infrastructure. Ad Hoc Netw. 2010, 8, 872–888. [Google Scholar] [CrossRef] [Green Version]

- Pour Rahimian, F.; Seyedzadeh, S.; Oliver, S.; Rodriguez, S.; Dawood, N. On-demand monitoring of construction projects through a game-like hybrid application of BIM and machine learning. Autom. Constr. 2020, 110, 103012. [Google Scholar] [CrossRef]

- Ko, J.; Ni, Y. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Ostachowicz, W.; Güemes, A. New Trends in Structural Health Monitoring; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Aggelis, D.; Verbruggen, S.; Tsangouri, E.; Tysmans, T.; Van Hemelrijck, D. Characterization of mechanical performance of concrete beams with external reinforcement by acoustic emission and digital image correlation. Constr. Build. Mater. 2013, 47, 1037–1045. [Google Scholar] [CrossRef]

- Siebert, S.; Teizer, J. Mobile 3D mapping for surveying earthwork projects using an Unmanned Aerial Vehicle (UAV) system. Autom. Constr. 2014, 41, 1–14. [Google Scholar] [CrossRef]

- Wen, M.-C.; Kang, S.-C. Augmented Reality and Unmanned Aerial Vehicle Assist in Construction Management. Comput. Civil Build. Eng. 2014, 1570–1577. [Google Scholar] [CrossRef] [Green Version]

- Khuc, T.; Nguyen, T.A.; Dao, H.; Catbas, F.N. Swaying Displacement Measurement for Structural Monitoring Using Computer Vision and an Unmanned Aerial Vehicle. Measurement 2020, 159, 107769. [Google Scholar] [CrossRef]

- Li, X.; Yi, W.; Chi, H.-L.; Wang, X.; Chan, A.P. A critical review of virtual and augmented reality (VR/AR) applications in construction safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Lin, K.-Y.; Son, J.W.; Rojas, E.M. A pilot study of a 3D game environment for construction safety education. J. Inf. Technol. Constr. 2011, 16, 69–84. [Google Scholar]

- Chen, Y.; Kamara, J.M. A framework for using mobile computing for information management on construction sites. Autom. Constr. 2011, 20, 776–788. [Google Scholar] [CrossRef]

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101212. [Google Scholar] [CrossRef]

- Delgado, J.M.D.; Oyedele, L.; Beach, T.; Demian, P. Augmented and Virtual Reality in Construction: Drivers and Limitations for Industry Adoption. J. Constr. Eng. Manag. 2020, 146, 04020079. [Google Scholar] [CrossRef]

- Noghabaei, M.; Asadi, K.; Han, K. Virtual Manipulation in an Immersive Virtual Environment: Simulation of Virtual Assembly. Comput. Civ. Eng. 2019, 2019, 95–102. [Google Scholar] [CrossRef]

- Sardroud, J.M. Influence of RFID technology on automated management of construction materials and components. Sci. Iran. 2012, 19, 381–392. [Google Scholar] [CrossRef] [Green Version]

- Lu, W.; Huang, G.Q.; Li, H. Scenarios for applying RFID technology in construction project management. Autom. Constr. 2011, 20, 101–106. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Cho, Y.K.; Zhang, S.; Perez, E. Case study of BIM and cloud–enabled real-time RFID indoor localization for con-struction management applications. J. Constr. Eng. Manag. 2016, 142, 5016003. [Google Scholar] [CrossRef]

- Ikonen, J.; Knutas, A.; Hämäläinen, H.; Ihonen, M.; Porras, J.; Kallonen, T. Use of embedded RFID tags in concrete element supply chains. J. Inf. Technol. Constr. 2013, 18, 119–147. [Google Scholar]

- Costin, A.M.; Teizer, J.; Schoner, B. RFID and BIM-enabled worker location tracking to support real-time building protocol and data visualization. J. Inf. Technol. Constr. 2015, 20, 495–517. [Google Scholar]

- Manzoor, B.; Othman, I.; Manzoor, M. Evaluating the critical safety factors causing accidents in high-rise building projects. Ain Shams Eng. J. 2021. [Google Scholar] [CrossRef]

- Gökçe, K.U.; Gökçe, H.U.; Katranuschkov, P. IFC-Based Product Catalog Formalization for Software Interoperability in the Construction Management Domain. J. Comput. Civ. Eng. 2013, 27, 36–50. [Google Scholar] [CrossRef]

- Ciribini, A.; Ventura, S.M.; Paneroni, M. Implementation of an interoperable process to optimise design and construction phases of a residential building: A BIM Pilot Project. Autom. Constr. 2016, 71, 62–73. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Hadavi, A.; Huang, J.C. Assessment of AEC Students’ Performance Using BIM-into-VR. Appl. Sci. 2021, 11, 3225. [Google Scholar] [CrossRef]

- Lee, S.-K.; Kim, K.; Yu, J. BIM and ontology-based approach for building cost estimation. Autom. Constr. 2014, 41, 96–105. [Google Scholar] [CrossRef]

- Nepal, M.; Staub-French, S. Supporting knowledge-intensive construction management tasks in BIM. J. Inf. Technol. Constr. 2016, 21, 13–38. [Google Scholar]

- Xie, H.; Shi, W.; Issa, R.R.A. Using rfid and real-time virtual reality simulation for optimization in steel construction. J. Inf. Technol. Constr. 2011, 16, 291–308. [Google Scholar]

- Meadati, P.; Irizarry, J.; Akhnoukh, A.K. BIM and RFID integration: A pilot study. Adv. Integr. Constr. Educ. Res. Pract. 2010, 5, 570–578. [Google Scholar]

- Li, C.Z.; Zhong, R.Y.; Xue, F.; Xu, G.; Chen, K.; Huang, G.G.; Shen, Q. Integrating RFID and BIM technologies for mitigating risks and improving schedule performance of prefabricated house construction. J. Clean. Prod. 2017, 165, 1048–1062. [Google Scholar] [CrossRef]

- Costin, A.M.; Teizer, J. Fusing passive RFID and BIM for increased accuracy in indoor localization. Vis. Eng. 2015, 3, 17. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.; Chen, W.; Cheng, J.C.P.; Wang, Q. Developing Efficient Mechanisms for BIM-to-AR/VR Data Transfer. J. Comput. Civ. Eng. 2020, 34, 04020037. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Chen, Y.-P.; Yien, H.-W.; Huang, C.-Y.; Su, Y.-C. Integrated BIM, game engine and VR technologies for healthcare design: A case study in cancer hospital. Adv. Eng. Inform. 2018, 36, 130–145. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Li, C.Z.; Xue, F.; Li, X.; Hong, J.; Shen, G.Q. An Internet of Things-enabled BIM platform for on-site assembly services in prefabricated construction. Autom. Constr. 2018, 89, 146–161. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, K.; Zhou, J.X.; Cao, J.; Lyu, Z.; Jin, X.; Shen, G.Q.; Lu, W.; Huang, G.Q. An Internet of Things-enabled BIM platform for modular integrated construction: A case study in Hong Kong. Adv. Eng. Inform. 2019, 42, 100997. [Google Scholar] [CrossRef]

- Dave, B.; Buda, A.; Nurminen, A.; Främling, K. A framework for integrating BIM and IoT through open standards. Autom. Constr. 2018, 95, 35–45. [Google Scholar] [CrossRef]

- Sani, M.J.; Rahman, A.A. GIS and BIM integration at data level: A review. ISPRS—Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2018, XLII-4/W9, 299–306. [Google Scholar] [CrossRef] [Green Version]

- Sanhudo, L.; Ramos, N.M.M.; Martins, J.P.; Almeida, R.; Barreira, E.; Simões, M.L.; Cardoso, V.E.M. A framework for in-situ geometric data acquisition using laser scanning for BIM modelling. J. Build. Eng. 2020, 28, 101073. [Google Scholar] [CrossRef]

- Ham, N.; Lee, S.-H. Empirical Study on Structural Safety Diagnosis of Large-Scale Civil Infrastructure Using Laser Scanning and BIM. Sustainability 2018, 10, 4024. [Google Scholar] [CrossRef] [Green Version]

- Mill, T.; Alt, A.; Liias, R. Combined 3D building surveying techniques–terrestrial laser scanning (TLS) and total station sur-veying for BIM data management purposes. J. Civ. Eng. Manag. 2013, 19, S23–S32. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I.; Celik, T.; Arditi, D. The effectiveness of an integrated BIM/UAV model in managing safety on construction sites. Int. J. Occup. Saf. Ergon. 2020, 26, 829–844. [Google Scholar] [CrossRef]

- Castro-Lacouture, D. Construction Automation; Springer: Berlin/Heidelberg, Germany, 2009; pp. 1063–1078. [Google Scholar]

- Kim, M.J.; Chi, H.-L.; Wang, X.; Ding, L. Automation and Robotics in Construction and Civil Engineering. J. Intell. Robot. Syst. 2015, 79, 347–350. [Google Scholar] [CrossRef] [Green Version]

- Mahbub, R. An Investigation into the Barriers to the Implementation of Automation and Robotics Technologies in the Construction Industry. Ph.D. Thesis, Queensland University of Technology, Brisbane City, QLD, Australia, 2008. [Google Scholar]

- Delgado, J.M.D.; Oyedele, L.; Ajayi, A.; Akanbi, L.; Akinade, O.; Bilal, M.; Owolabi, H. Robotics and automated systems in construction: Understanding industry-specific challenges for adoption. J. Build. Eng. 2019, 26, 100868. [Google Scholar] [CrossRef]

- Hosmer, G.L. Report of progress on accelerometer for recording earthquake-shocks. Trans. Am. Geophys. Union 1931, 12, 70–71. [Google Scholar] [CrossRef]

- Brynjolfsson, E.; McAfee, A. Race Against the Machine: How the Digital Revolution is Accelerating Innovation, Driving Productivity, and Irreversibly Transforming Employment and the Economy; Digital Frontier Press: USA, 2011. [Google Scholar]

- Kensek, K.; Noble, D. Building Information Modeling: BIM in Current and Future Practice; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Li, J.; Afsari, K.; Li, N.; Peng, J.; Wu, Z.; Cui, H. A review for presenting building information modeling education and research in China. J. Clean. Prod. 2020, 259, 120885. [Google Scholar] [CrossRef]

- Saini, V.; Mhaske, S. BIM an emerging technology in AEC industry for time optimization. Int. J. Struct. Civ. Eng. Res. 2013, 2, 196–200. [Google Scholar]

- Succar, B. Building information modelling framework: A research and delivery foundation for industry stakeholders. Autom. Constr. 2009, 18, 357–375. [Google Scholar] [CrossRef]

- Barazzetti, L.; Banfi, F. BIM and GIS: When parametric modeling meets geospatial data. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, IV-5/W1, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, J.; Rossetti, R.J.F.; Silva, D.C.; Oliveira, E.C. BIM, GIS, IoT, and AR/VR Integration for Smart Maintenance and Management of Road Networks: A Review. In 2018 IEEE International Smart Cities Conference (ISC2); Institute of Electrical and Electronics Engineers: New York, NY, USA, 2018; pp. 1–7. [Google Scholar]

- Yang, S.; Cui, G.; Lu, S. Ambidextrous learning of engineering project team: Relying on control or BIM AI VR AR MR? Int. J. Eng. Bus. Manag. 2020, 12, 1847979020948749. [Google Scholar] [CrossRef]

- Lee, S.H.; Woo, S.H.; Ryu, J.R.; Choo, S.Y. Automated building occupancy authorization using BIM and UAV-based spatial information: Photogrammetric reverse engineering. J. Asian Arch. Build. Eng. 2019, 18, 151–158. [Google Scholar] [CrossRef]

- Lee, G.; Sacks, R.; Eastman, C.M. Specifying parametric building object behavior (BOB) for a building information modeling system. Autom. Constr. 2006, 15, 758–776. [Google Scholar] [CrossRef]

- Abdellatif, M.; Al-Shamma’A, A. Review of sustainability in buildings. Sustain. Cities Soc. 2015, 14, 171–177. [Google Scholar] [CrossRef]

- Weerasinghe, A.S.; Ramachandra, T. Economic sustainability of green buildings: A comparative analysis of green vs non-green. Built Environ. Proj. Asset Manag. 2018, 8, 528–543. [Google Scholar] [CrossRef]

- Worzala, E.; Bond, S. Barriers and drivers to green buildings in Australia and New Zealand. J. Prop. Invest. Financ. 2011, 29, 494–509. [Google Scholar]

- Sharma, M. Development of a ‘Green building sustainability model’for Green buildings in India. J. Clean. Prod. 2018, 190, 538–551. [Google Scholar] [CrossRef]

- Smith, C.; Levermore, G. Designing urban spaces and buildings to improve sustainability and quality of life in a warmer world. Energy Policy 2008, 36, 4558–4562. [Google Scholar] [CrossRef]

- Asif, M. Growth and sustainability trends in the buildings sector in the GCC region with particular reference to the KSA and UAE. Renew. Sustain. Energy Rev. 2016, 55, 1267–1273. [Google Scholar] [CrossRef]

- Naji, H.I.; Mahmood, M.S.; Mohammad, H.E. Using BIM to propose building alternatives towards lower consumption of electric power in Iraq. Asian J. Civ. Eng. 2019, 20, 669–679. [Google Scholar] [CrossRef]

- Wang, Q.; Su, M. Drivers of decoupling economic growth from carbon emission–an empirical analysis of 192 countries using decoupling model and decomposition method. Environ. Impact Assess. Rev. 2020, 81, 106356. [Google Scholar] [CrossRef]

- Nawari, N.O.; Ravindran, S. Blockchain and Building Information Modeling (BIM): Review and Applications in Post-Disaster Recovery. Buildings 2019, 9, 149. [Google Scholar] [CrossRef] [Green Version]

- Puthal, D.; Malik, N.; Mohanty, S.P.; Kougianos, E.; Yang, C. The Blockchain as a Decentralized Security Framework [Future Directions]. IEEE Consum. Electron. Mag. 2018, 7, 18–21. [Google Scholar] [CrossRef]

- Llewellyn, J.; Leonard, G.; Jackson, R. Meeting New Zealand’s Peace and Security Challenges Through Disarmament and Nonviolence; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2019; pp. 345–361. [Google Scholar]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef] [Green Version]

- Becerik-Gerber, B.; Jazizadeh, F.; Li, N.; Calis, G. Application areas and data requirements for BIM-enabled facilities man-agement. J. Constr. Eng. Manag. 2012, 138, 431–442. [Google Scholar] [CrossRef]

- Akcamete, A.; Akinci, B.; Garrett, J.H. Potential utilization of building information models for planning maintenance activi-ties. In Proceedings of the International Conference on Computing in Civil and Building Engineering, Nottingham, UK, 30 June–2 July 2010; pp. 151–157. [Google Scholar]

- Kiviniemi, M.; Sulankivi, K.; Kähkönen, K.; Mäkelä, T.; Merivirta, M.-L. BIM-Based Safety Management and Communication for Building Construction; VTT: Espoo, Finland, 2011. [Google Scholar]

- Deng, L.; Zhong, M.; Liao, L.; Peng, L.; Lai, S. Research on Safety Management Application of Dangerous Sources in Engi-neering Construction Based on BIM Technology. Adv. Civ. Eng. 2019. [Google Scholar] [CrossRef] [Green Version]

- Gong, X.; Michel, P.; Cantin, R. Multiple-criteria decision analysis of BIM influences in building energy management. Build. Simul. 2019, 12, 641–652. [Google Scholar] [CrossRef]

- Aram, S.; Eastman, C.; Sacks, R. Requirements for BIM platforms in the concrete reinforcement supply chain. Autom. Constr. 2013, 35, 1–17. [Google Scholar] [CrossRef]

- Chen, P.-H.; Nguyen, T.C. A BIM-WMS integrated decision support tool for supply chain management in construction. Autom. Constr. 2019, 98, 289–301. [Google Scholar] [CrossRef]

- Boukamp, F.; Akinci, B. Automated processing of construction specifications to support inspection and quality control. Autom. Constr. 2007, 17, 90–106. [Google Scholar] [CrossRef]

- Arayici, Y. Towards building information modelling for existing structures. Struct. Surv. 2008, 26, 210–222. [Google Scholar] [CrossRef] [Green Version]

- Tashakkori, H.; Rajabifard, A.; Kalantari, M. A new 3D indoor/outdoor spatial model for indoor emergency response facilitation. Build. Environ. 2015, 89, 170–182. [Google Scholar] [CrossRef]

- Li, N.; Becerik-Gerber, B.; Krishnamachari, B.; Soibelman, L. A BIM centered indoor localization algorithm to support building fire emergency response operations. Autom. Constr. 2014, 42, 78–89. [Google Scholar] [CrossRef]

- Woo, J.-H.; Menassa, C. Virtual Retrofit Model for aging commercial buildings in a smart grid environment. Energy Build. 2014, 80, 424–435. [Google Scholar] [CrossRef]

- Turk, Ž.; Klinc, R. Potentials of Blockchain Technology for Construction Management. Procedia Eng. 2017, 196, 638–645. [Google Scholar] [CrossRef]

- Mousa, M.; Luo, X.; McCabe, B. Utilizing BIM and Carbon Estimating Methods for Meaningful Data Representation. Procedia Eng. 2016, 145, 1242–1249. [Google Scholar] [CrossRef] [Green Version]

- Gan, V.J.; Deng, M.; Tse, K.; Chan, C.; Lo, I.M.; Cheng, J.C. Holistic BIM framework for sustainable low carbon design of high-rise buildings. J. Clean. Prod. 2018, 195, 1091–1104. [Google Scholar] [CrossRef]

- Eastman, C.M.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Guo, H.; Yu, R.; Fang, Y. Analysis of negative impacts of BIM-enabled information transparency on contractors’ interests. Autom. Constr. 2019, 103, 67–79. [Google Scholar] [CrossRef]

- Babič, N. Čuš; Rebolj, D.; Nekrep-Perc, M.; Podbreznik, P. Supply-chain transparency within industrialized construction projects. Comput. Ind. 2014, 65, 345–353. [Google Scholar] [CrossRef]

- Chen, S.; Liang, Y.-C.; Sun, S.; Kang, S.; Cheng, W.; Peng, M. Vision, Requirements, and Technology Trend of 6G: How to Tackle the Challenges of System Coverage, Capacity, User Data-Rate and Movement Speed. IEEE Wirel. Commun. 2020, 27, 218–228. [Google Scholar] [CrossRef] [Green Version]

- Collins, R.; Zhang, S.; Kim, K.; Teizer, J. Integration of Safety Risk Factors in BIM for Scaffolding Construction. Comput. Civ. Build. Eng. 2014, 307–314. [Google Scholar] [CrossRef] [Green Version]

- Swallow, M.; Zulu, S. Students’ awareness and perception of the value of BIM and 4D for site health and safety management. J. Eng. Des. Technol. 2019, 18, 414–430. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W. Development of a benchmarking model for BIM implementation in developing countries. Benchmarking Int. J. 2019, 26, 1210–1232. [Google Scholar] [CrossRef]

- Rao, S.K.; Prasad, R. Impact of 5G Technologies on Industry 4.0. Wirel. Pers. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Chew, M.; Teo, E.; Shah, K.; Kumar, V.; Hussein, G. Evaluating the Roadmap of 5G Technology Implementation for Smart Building and Facilities Management in Singapore. Sustainability 2020, 12, 10259. [Google Scholar] [CrossRef]

- Huang, T.; Yang, W.; Wu, J.; Ma, J.; Zhang, X.; Zhang, D. A Survey on Green 6G Network: Architecture and Technologies. IEEE Access 2019, 7, 175758–175768. [Google Scholar] [CrossRef]

- Chan, A.P.C.; Darko, A.; Olanipekun, A.O.; Ameyaw, E.E. Critical barriers to green building technologies adoption in de-veloping countries: The case of Ghana. J. Clean. Prod. 2018, 172, 1067–1079. [Google Scholar] [CrossRef]

- Okpala, I.; Nnaji, C.; Karakhan, A.A. Utilizing Emerging Technologies for Construction Safety Risk Mitigation. Pract. Period. Struct. Des. Constr. 2020, 25, 04020002. [Google Scholar] [CrossRef]

- Perry, P.; Kent, A.; Bonetti, F. The Use of Mobile Technologies in Physical Stores: The Case of Fashion Retailing; Springer: Berlin/Heidelberg, Germany, 2018; pp. 169–195. [Google Scholar]

- Olawumi, T.O.; Chan, D.W.; Wong, J.K.; Chan, A.P. Barriers to the integration of BIM and sustainability practices in construction projects: A Delphi survey of international experts. J. Build. Eng. 2018, 20, 60–71. [Google Scholar] [CrossRef]

- Marefat, A.; Toosi, H.; Hasankhanlo, R.M. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Arch. Manag. 2019, 26, 1855–1877. [Google Scholar] [CrossRef]

- Babatunde, S.O.; Udeaja, C.; Adekunle, A.O. Barriers to BIM implementation and ways forward to improve its adoption in the Nigerian AEC firms. Int. J. Build. Pathol. Adapt. 2020, 39, 48–71. [Google Scholar] [CrossRef] [Green Version]

- Maina, J.J. Barriers to effective use of CAD and BIM in architecture education in Nigeria. Int. J. Built Environ. Sustain. 2018, 5. [Google Scholar] [CrossRef]

- Zhao, X.; Wu, P.; Wang, X. Risk paths in BIM adoption: Empirical study of China. Eng. Constr. Arch. Manag. 2018, 25, 1170–1187. [Google Scholar] [CrossRef]

- Liu, S.; Xie, B.; Tivendale, L.; Liu, C. Critical Barriers to BIM Implementation in the AEC Industry. Int. J. Mark. Stud. 2015, 7, 162. [Google Scholar] [CrossRef]

- Al-Yami, A.; Sanni-Anibire, M.O. BIM in the Saudi Arabian construction industry: State of the art, benefit and barriers. Int. J. Build. Pathol. Adapt. 2019, 39, 33–47. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Edwards, D.J.; Li, H.; Papadonikolaki, E.; Cao, D. Collaboration barriers in BIM-based construction networks: A conceptual model. Int. J. Proj. Manag. 2019, 37, 839–854. [Google Scholar] [CrossRef]

- Farooq, U.; Rehman, S.K.U.; Javed, M.F.; Jameel, M.; Aslam, F.; Alyousef, R. Investigating BIM Implementation Barriers and Issues in Pakistan Using ISM Approach. Appl. Sci. 2020, 10, 7250. [Google Scholar] [CrossRef]

- Kassem, M.; Brogden, T.; Dawood, N. BIM and 4D planning: A holistic study of the barriers and drivers to widespread adoption. J. Constr. Eng. Proj. Manag. 2012, 2, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Georgiadou, M.C. An overview of benefits and challenges of building information modelling (BIM) adoption in UK residential projects. Constr. Innov. 2019, 19, 298–320. [Google Scholar] [CrossRef]

- Chan, D.W.; Olawumi, T.O.; Ho, A.M. Perceived benefits of and barriers to Building Information Modelling (BIM) implementation in construction: The case of Hong Kong. J. Build. Eng. 2019, 25, 100764. [Google Scholar] [CrossRef]

- Babatunde, S.O.; Ekundayo, D. Barriers to the incorporation of BIM into quantity surveying undergraduate curriculum in the Nigerian universities. J. Eng. Des. Technol. 2019, 17, 629–648. [Google Scholar] [CrossRef]

- Lindblad, H. Black boxing BIM: The public client’s strategy in BIM implementation. Constr. Manag. Econ. 2018, 37, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Vass, S.; Gustavsson, T.K. Challenges when implementing BIM for industry change. Constr. Manag. Econ. 2017, 35, 597–610. [Google Scholar] [CrossRef]

- Enshassi, A.; Abu Hamra, L.A. Challenges to the Utilization of BIM in the Palestinian Construction Industry. In Proceedings of the International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar]

- Jalaei, F.; Jrade, A.; Nassiri, M. Integrating decision support system (DSS) and building information modeling (BIM) to optimize the selection of sustainable building components. J. Inf. Technol. Constr. 2015, 20, 399–420. [Google Scholar]

- Kim, K.; Cho, Y.; Kim, K. BIM-driven automated decision support system for safety planning of temporary structures. J. Constr. Eng. Manag. 2018, 144, 4018072. [Google Scholar] [CrossRef]

- Al-Kasasbeh, M.; Abudayyeh, O.; Liu, H. An integrated decision support system for building asset management based on BIM and Work Breakdown Structure. J. Build. Eng. 2021, 34, 101959. [Google Scholar] [CrossRef]

- Love, P.E.; Matthews, J.; Lockley, S. BIM for Built Asset Management. Built Environ. Proj. Asset Manag. 2015, 5. [Google Scholar] [CrossRef]

- Khosrowshahi, F.; Arayici, Y. Roadmap for implementation of BIM in the UK construction industry. Eng. Constr. Arch. Manag. 2012, 19, 610–635. [Google Scholar] [CrossRef] [Green Version]

- Kaufmann, D.; Vicente, P.C. Legal corruption. Econ. Polit. 2011, 23, 195–219. [Google Scholar] [CrossRef] [Green Version]

- De Jong, M.; Henry, W.P.; Stansbury, N. Eliminating Corruption in Our Engineering/Construction Industry. Leadersh. Manag. Eng. 2009, 9, 105–111. [Google Scholar] [CrossRef]

- Ameyaw, E.E.; Pärn, E.; Chan, A.P.; Manu, D.-G.O.; Edwards, D.J.; Darko, A. Corrupt Practices in the Construction Industry: Survey of Ghanaian Experience. J. Manag. Eng. 2017, 33, 05017006. [Google Scholar] [CrossRef]

- May, D.; Wilson, O.; Skitmore, M. Bid cutting: An empirical study of practice in South-East Queensland. Eng. Constr. Archit. Manag. 2001, 8, 250–256. [Google Scholar]

- Tabish, S.; Jha, K.N. Analyses and evaluation of irregularities in public procurement in India. Constr. Manag. Econ. 2011, 29, 261–274. [Google Scholar] [CrossRef]

- Osei-Tutu, E.; Badu, E.; Owusu-Manu, D. Exploring corruption practices in public procurement of infrastructural projects in Ghana. Int. J. Manag. Proj. Bus. 2010, 3, 236–256. [Google Scholar] [CrossRef]

- Alutu, O.E. Unethical Practices in Nigerian Construction Industry: Prospective Engineers’ Viewpoint. J. Prof. Issues Eng. Educ. Pract. 2007, 133, 84–88. [Google Scholar] [CrossRef]

- Chotibhongs, R.; Arditi, D. Detection of Collusive Behavior. J. Constr. Eng. Manag. 2012, 138, 1251–1258. [Google Scholar] [CrossRef]

- Doree, A.G. Collusion in the Dutch construction industry: An industrial organization perspective. Build. Res. Inf. 2004, 32, 146–156. [Google Scholar] [CrossRef]

- Hartley, R. Fighting Corruption in the Australian Construction Industry: The National Code of Practice. Leadersh. Manag. Eng. 2009, 9, 131–135. [Google Scholar] [CrossRef]

- Brown, J.S.; Loosemore, M. Behavioural factors influencing corrupt action in the Australian construction industry. Eng. Constr. Arch. Manag. 2015, 22, 372–389. [Google Scholar] [CrossRef]

- Bowen, P.; Pearl, R.; Akintoye, A. Professional ethics in the South African construction industry. Build. Res. Inf. 2007, 35, 189–205. [Google Scholar] [CrossRef]

- Zarkada-Fraser, A.; Skitmore, M. Decisions with moral content: Collusion. Constr. Manag. Econ. 2000, 18, 101–111. [Google Scholar] [CrossRef] [Green Version]

- Bowen, P.; Akintoye, A.; Pearl, R.; Edwards, P.J. Ethical behaviour in the South African construction industry. Constr. Manag. Econ. 2007, 25, 631–648. [Google Scholar] [CrossRef]

- Ardiny, H.; Witwicki, S.; Mondada, F. Are autonomous mobile robots able to take over construction? A review. Int. J. Robot. 2015, 4, 10–21. [Google Scholar]

| Topic | Keywords | Results |

|---|---|---|

| the AEC industry | “Digital” OR “technology” OR “technologies” AND “Architectural engineering” OR “Construction engineering” OR “Civil engineering” | 11,047 |

| Digital technologies | “BIM” OR “Building information modeling” OR “Building information modelling” OR “AR” OR “VR” OR “RFID” OR “Photogrammetry” OR “Images” OR “Videos” OR “Cameras” OR “laser scanning” OR “3D scanning” OR “Robotics” OR “Block chain” | 1956 |

| Digital technologies | “Digital” OR “technology” OR “technologies” AND “Architectural engineering” OR “Construction engineering” OR “Civil engineering” AND “BIM” OR “Building information modeling” OR “Building information modelling” OR “AR” OR “VR” OR “RFID” OR “Photogrammetry” OR “Images” OR “Videos” OR “Cameras” OR “laser scanning” OR “3D scanning” OR “Robotics” OR “Block chain” | 1778 |

| Digital technologies and the AEC industry | Screening on the basis of engineering fields, journal papers, unrelated topics, non-English publications | 200 |

| Countries | Research Articles | Average Publication Year |

|---|---|---|

| United States | 60 | 2010 |

| China | 33 | 2017 |

| Spain | 18 | 2016 |

| United Kingdom | 18 | 2016 |

| Australia | 16 | 2017 |

| South Korea | 13 | 2014 |

| Hong Kong | 9 | 2015 |

| Canada | 8 | 2012 |

| Germany | 6 | 2016 |

| Taiwan | 6 | 2014 |

| Israel | 5 | 2007 |

| Poland | 4 | 2015 |

| Brazil | 3 | 2018 |

| Greece | 3 | 2009 |

| Iran | 3 | 2018 |

| New Zealand | 3 | 2019 |

| Austria | 2 | 2002 |

| Finland | 2 | 2013 |

| Hungary | 2 | 2015 |

| India | 2 | 2020 |

| Italy | 2 | 2020 |

| Singapore | 2 | 2016 |

| Switzerland | 2 | 2007 |

| Keywords | Occurrences | Average Publication Year | Links | Total Links Strength |

|---|---|---|---|---|

| BIM | 60 | 2017 | 19 | 46 |

| Construction management | 11 | 2013 | 11 | 16 |

| Civil engineering | 9 | 2017 | 7 | 10 |

| Photogrammetry | 9 | 2016 | 6 | 6 |

| Construction | 8 | 2010 | 9 | 13 |

| Augmented reality | 8 | 2014 | 7 | 12 |

| Information technology | 6 | 2015 | 8 | 10 |

| Automation | 6 | 2007 | 7 | 9 |

| Computer vision | 6 | 2016 | 6 | 7 |

| Inspection | 4 | 2015 | 6 | 6 |

| Curriculum | 4 | 2011 | 5 | 9 |

| Tracking | 4 | 2012 | 5 | 5 |

| Visualization | 4 | 2013 | 4 | 6 |

| Mobile computing | 4 | 2013 | 4 | 6 |

| Construction site | 4 | 2013 | 3 | 3 |

| Artificial intelligence | 4 | 2013 | 3 | 3 |

| Unmanned aerial vehicle | 4 | 2017 | 3 | 4 |

| Architectural engineering | 4 | 2019 | 2 | 4 |

| Case study | 4 | 2017 | 2 | 4 |

| Construction education | 4 | 2015 | 2 | 6 |

| Digital image correlation | 4 | 2018 | 2 | 2 |

| Terrestrial laser scanning | 4 | 2016 | 2 | 2 |

| Computer applications | 3 | 2014 | 7 | 7 |

| Buildings | 3 | 2016 | 5 | 5 |

| Displacement measurement | 3 | 2016 | 4 | 5 |

| Education | 3 | 2016 | 4 | 7 |

| Damage | 3 | 2015 | 3 | 3 |

| LiDAR | 3 | 2017 | 3 | 3 |

| Mapping | 3 | 2006 | 2 | 2 |

| Construction technology | 3 | 2019 | 2 | 4 |

| Structural health monitoring | 3 | 2017 | 2 | 3 |

| Point cloud | 3 | 2015 | 1 | 1 |

| Rfid | 3 | 2012 | 1 | 1 |

| Text mining | 3 | 2019 | 1 | 2 |

| New Advancements | References |

|---|---|

| Facility management activities | [164,165,166] |

| Safety Management | [167,168] |

| Energy management | [169] |

| Supply chain management | [170,171] |

| Quality control | [172] |

| Emergency management | [173,174,175] |

| Retrofit planning | [136,176] |

| BIM–block chain integration | [177] |

| Carbon emissions | [178,179] |

| Monitoring and Tracking assessment | [165,173,180] |

| Transparency and Security | [181,182] |

| Mobile technology | [183] |

| Challenges | References |

|---|---|

| Inadequate expertise | [193,194] |

| Inadequate government policies | [195,196] |

| Cultural barriers | [197] |

| Cost | [198,199] |

| Inadequate demand from clients | [200] |

| Resistance to change | [201,202] |

| Security risks | [198,202,203] |

| Inadequate staff | [204,205] |

| Competing initiatives | [206,207] |

| Lack of industry standards | [194,208] |

| Lack of decision support tools | [209,210,211] |

| Liability concerns | [212,213] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manzoor, B.; Othman, I.; Pomares, J.C. Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities. Int. J. Environ. Res. Public Health 2021, 18, 6135. https://doi.org/10.3390/ijerph18116135

Manzoor B, Othman I, Pomares JC. Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities. International Journal of Environmental Research and Public Health. 2021; 18(11):6135. https://doi.org/10.3390/ijerph18116135

Chicago/Turabian StyleManzoor, Bilal, Idris Othman, and Juan Carlos Pomares. 2021. "Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities" International Journal of Environmental Research and Public Health 18, no. 11: 6135. https://doi.org/10.3390/ijerph18116135

APA StyleManzoor, B., Othman, I., & Pomares, J. C. (2021). Digital Technologies in the Architecture, Engineering and Construction (AEC) Industry—A Bibliometric—Qualitative Literature Review of Research Activities. International Journal of Environmental Research and Public Health, 18(11), 6135. https://doi.org/10.3390/ijerph18116135