Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Reagents and Winery Wastewater Sampling

2.2. Analytical Techniques

2.3. Phenolic and Chromatic (CIELab) Characterization

2.4. Coagulants Characterization

2.5. Coagulation–Flocculatuion–Decantation Experiments

- Application of bentonite, potassium caseinate and PVPP with a lower and upper dosage of 0 and 1.0 g/L, respectively;

- Application of maximum mixture dosage of 1.0 g/L.

2.6. Ozonation Experiments

- Performance of different pH conditions (4.0, 7.0, 9.0 and 11.0) under the following operational conditions: [Fe2+] = 1.0 mM, ozone flow rate 5 mg/min, air flow 1.0 L/min, agitation 350 rpm and UV-C mercury lamp (254 nm);

- Performance of different Fe2+ concentrations (0.0, 0.5, 1.0 and 2.0) at pH 4.0, ozone flow rate 5 mg/min, air flow 1.0 L/min, agitation 350 rpm and a UV-C mercury lamp (254 nm).

3. Results and Discussion

3.1. Coagulation–Flocculation–Decantation Experiments

3.1.1. Simplex Lattice Design—Model Establishment

3.1.2. Simplex Lattice Design—Model Optimization

3.2. Ozonation Experiments

3.2.1. Effect of pH

3.2.2. Effect of Fe2+ Concentration

3.2.3. Evaluation of Ozone Consumption

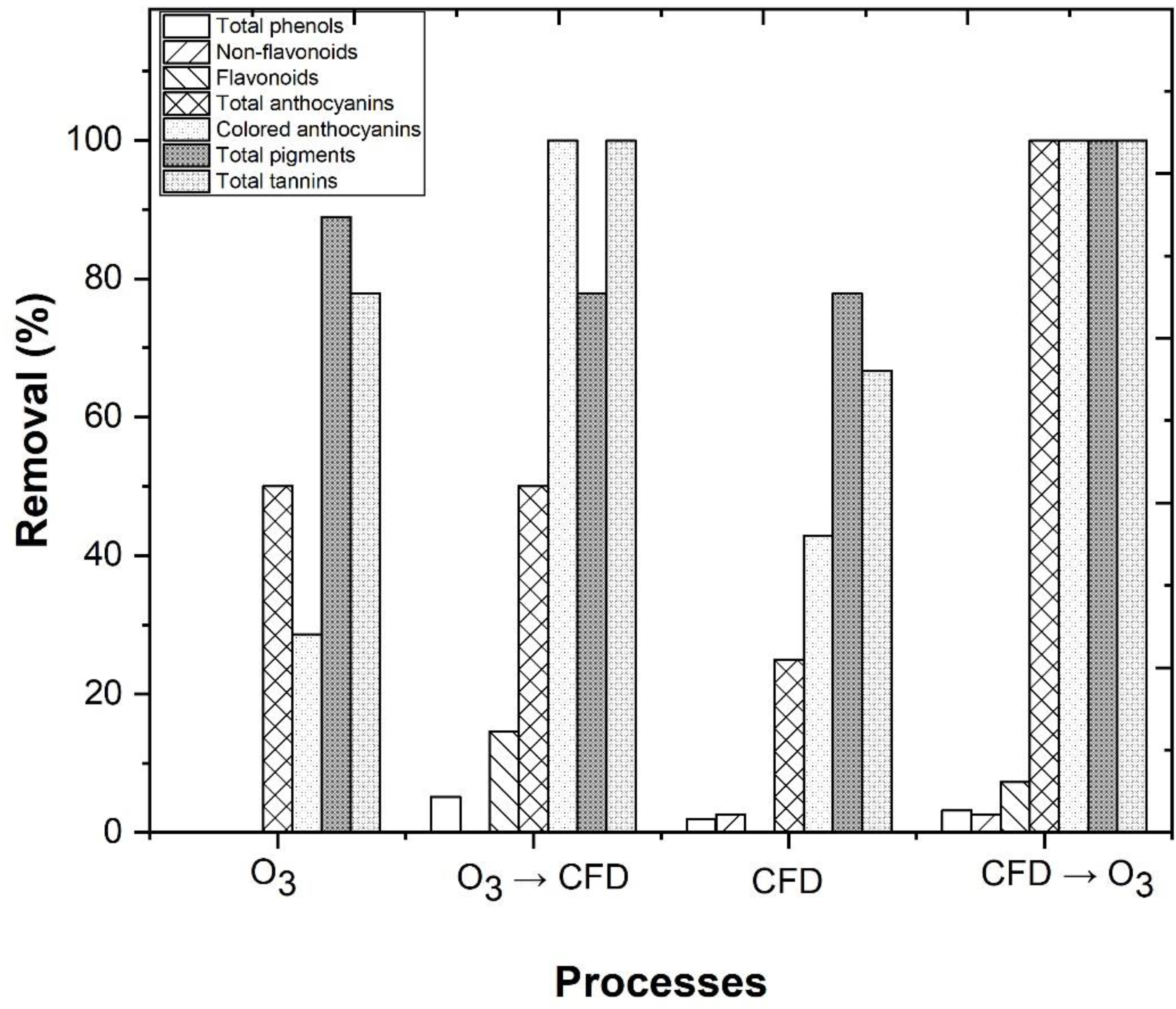

3.3. Combination of Coagulation–Flocculation–Decantation with Ozonation Processes

3.4. Effect of the Treatments in Phytotoxicity of Different Plants

4. Conclusions

- The performance of a CFD process, by application of an SLD statistical design, allows a high removal of turbidity, TSS, TOC, and COD (98.3, 97.6, 44.6, and 48.0%);

- The application of an ozonation process, under the best operational conditions—pH = 4.0, [Fe2+] = 1.0 mM, ozone flow rate 5 mg/min, air flow 1.0 L/min, agitation 350 rpm, time 600 min, and radiation UV-C mercury lamp (254 nm)—achieves a TOC removal of 63.2%;

- The O3/1.0 mM Fe2+/UV-C system is concluded to be very efficient in terms of energy consumption, with an = 1843 kWh m−3 order−1;

- The combined processes O3/CFD and CFD/O3 achieved high TOC removal (66.1 and 65.5%, respectively). It is also concluded that the performance of the CFD/O3 process achieves higher biodegradability (0.40);

- It is concluded that the combined processes O3/CFD and CFD/O3 have lower phytotoxicity effects in the germination of plant seeds;

- The combined process O3/CFD and CFD/O3 have the capacity to completely decolor the WW (L* = 100%), through the high removal of phenolic compounds;

- The combined process O3/CFD and CFD/O3 is concluded to decrease the risk of public and environmental health problems.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OIV-International Organisation of Vine and Wine. State of the World Vitiviniculture Sector in 2020; OIV: Paris, France, 2021; pp. 1–19. [Google Scholar]

- Ioannou, L.A.; Puma, G.L.; Fatta-Kassinos, D. Treatment of Winery Wastewater by Physicochemical, Biological and Advanced Processes: A Review. J. Hazard. Mater. 2015, 286, 343–368. [Google Scholar] [CrossRef] [PubMed]

- Vlyssides, A.G.; Barampouti, E.M.; Mai, S. Wastewater Characteristics from Greek Wineries and Distilleries. Water Sci. Technol. 2005, 51, 53–60. [Google Scholar] [CrossRef]

- Mosteo, R.; Sarasa, J.; Ormad, M.P.; Ovelleiro, J.L. Sequential Solar Photo-Fenton-Biological System for the Treatment of Winery Wastewaters. J. Agric. Food Chem. 2008, 56, 7333–7338. [Google Scholar] [CrossRef] [PubMed]

- Chatzilazarou, A.; Katsoyannos, E.; Gortzi, O.; Lalas, S.; Paraskevopoulos, Y.; Dourtoglou, E.; Tsaknis, J. Removal of Polyphenols from Wine Sludge Using Cloud Point Extraction. J. Air Waste Manag. Assoc. 2010, 60, 454–459. [Google Scholar] [CrossRef] [PubMed]

- Bolzonella, D.; Zanette, M.; Battistoni, P.; Cecchi, F. Treatment of Winery Wastewater in a Conventional Municipal Activated Sludge Process: Five Years of Experience. Water Sci. Technol. 2007, 56, 79–87. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Ferreira, R.; Gomes, J.; Martins, R.C.; Costa, R.; Quinta-ferreira, R.M. Winery Wastewater Treatment by Integrating Fenton’s Process with Biofiltration by Corbicula Fluminea. J. Chem. Technol. Biotechnol. 2018, 93, 333–339. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, J.; Yan, Y.; Yang, L.; Xing, G.; Li, H.; Wu, P.; Wang, M.; Zheng, H. Application of Coagulation/Flocculation in Oily Wastewater Treatment: A Review. Sci. Total Environ. 2021, 765, 142795. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Li, H.; Huang, M.; Yang, H.; Li, A. A Review on Chitosan-Based Flocculants and Their Applications in Water Treatment. Water Res. 2016, 95, 59–89. [Google Scholar] [CrossRef]

- Braz, R.; Pirra, A.; Lucas, M.S.; Peres, J.A. Combination of Long Term Aerated Storage and Chemical Coagulation/Flocculation to Winery Wastewater Treatment. Desalination 2010, 263, 226–232. [Google Scholar] [CrossRef]

- Amor, C.; De Torres-Socías, E.; Peres, J.; Maldonado, M.I.; Oller, I.; Malato, S.; Lucas, M.S. Mature Landfill Leachate Treatment by Coagulation/Flocculation Combined with Fenton and Solar Photo-Fenton Processes. J. Hazard. Mater. 2015, 286, 261–268. [Google Scholar] [CrossRef]

- Peres, J.A.; De Heredia, J.B.; Dominguez, J.R. Integrated Fenton’s Reagent—Coagulation/Flocculation Process for the Treatment of Cork Processing Wastewaters. J. Hazard. Mater. 2004, 107, 115–121. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Robinson, J.; Chong, M.F. A Review on Application of Flocculants in Wastewater Treatment. Process Saf. Environ. Prot. 2014, 92, 489–508. [Google Scholar] [CrossRef]

- Funai, D.H.; Didier, F.; Giménez, J.; Esplugas, S.; Marco, P.; Machulek, A. Photo-Fenton Treatment of Valproate under UVC, UVA and Simulated Solar Radiation. J. Hazard. Mater. 2017, 323, 537–549. [Google Scholar] [CrossRef] [PubMed]

- Zimbron, J.A.; Reardon, K.F. Fenton’s Oxidation of Pentachlorophenol. Water Res. 2009, 43, 1831–1840. [Google Scholar] [CrossRef] [PubMed]

- Lucas, M.S.; Mouta, M.; Pirra, A.; Peres, J.A. Winery Wastewater Treatment by a Combined Process: Long Term Aerated Storage and Fenton’s Reagent. Water Sci. Technol. 2009, 60, 1089–1095. [Google Scholar] [CrossRef] [PubMed]

- Lucas, M.S.; Mosteo, R.; Maldonado, M.I.; Malato, S.; Peres, J.A. Solar Photochemical Treatment of Winery Wastewater in a CPC Reactor. J. Agric. Food Chem. 2009, 57, 11242–11248. [Google Scholar] [CrossRef] [PubMed]

- Lucas, M.S.; Dias, A.A.; Bezerra, R.M.; Peres, J.A. Gallic Acid Photochemical Oxidation as a Model Compound of Winery Wastewaters. J. Environ. Sci. Health Part A 2008, 43, 1288–1295. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Amor, C.; Silva, T.; Dionysiou, D.D.; Li Puma, G.; Lucas, M.S.; Peres, J.A. Treatment of Winery Wastewater by Sulphate Radicals: HSO5-/Transition Metal/UV-A LEDs. Chem. Eng. J. 2017, 310, 473–483. [Google Scholar] [CrossRef]

- Rodríguez-Chueca, J.; Amor, C.; Mota, J.; Lucas, M.S.; Peres, J.A. Oxidation of Winery Wastewater by Sulphate Radicals: Catalytic and Solar Photocatalytic Activations. Environ. Sci. Pollut. Res. 2017, 24, 22414–22426. [Google Scholar] [CrossRef]

- Jorge, N.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Combination of Adsorption in Natural Clays and Photo-Catalytic Processes for Winery Wastewater Treatment. In Advances in Geoethics and Groundwater Management: Theory and Practice for a Sustainable Development; Abrunhosa, M., Chambel, A., Peppoloni, S., Chaminé, H.I., Eds.; Springer: Cham, Switzerland, 2021; pp. 291–294. ISBN 978-3-030-59320-9. [Google Scholar]

- Guimarães, V.; Teixeira, A.R.; Lucas, M.S.; Peres, J.A. Effect of Zr Impregnation on Clay-Based Materials for H2O2-Assisted Photocatalytic Wet Oxidation of Winery Wastewater. Water 2020, 12, 3387. [Google Scholar] [CrossRef]

- Lucas, M.S.; Peres, J.A.; Li Puma, G. Treatment of Winery Wastewater by Ozone-Based Advanced Oxidation Processes (O3, O3/UV and O3/UV/H2O2) in a Pilot-Scale Bubble Column Reactor and Process Economics. Sep. Purif. Technol. 2010, 72, 235–241. [Google Scholar] [CrossRef]

- Wang, J.; Chen, H. Catalytic Ozonation for Water and Wastewater Treatment: Recent Advances and Perspective. Sci. Total Environ. 2020, 704, 135249. [Google Scholar] [CrossRef]

- Liu, Z.; Demeestere, K.; Hulle, S. Van Comparison and Performance Assessment of Ozone-Based AOPs in View of Trace Organic Contaminants Abatement in Water and Wastewater: A Review. J. Environ. Chem. Eng. 2021, 9, 105599. [Google Scholar] [CrossRef]

- Yao, W.; Waqi, S.; Rehman, U.; Wang, H.; Yang, H.; Yu, G.; Wang, Y. Pilot-Scale Evaluation of Micropollutant Abatements by Conventional Ozonation, UV/O3, and an Electro-Peroxone Process. Water Res. 2018, 138, 106–117. [Google Scholar] [CrossRef]

- Lan, B.Y.; Nigmatullin, R.; Li Puma, G. Ozonation Kinetics of Cork-Processing Water in a Bubble Column Reactor. Water Res. 2008, 42, 2473–2482. [Google Scholar] [CrossRef]

- Monteagudo, J.M.; Carmona, M.; Dura, A. Photo-Fenton-Assisted Ozonation of p-Coumaric Acid in Aqueous Solution. Chemosphere 2005, 60, 1103–1110. [Google Scholar] [CrossRef] [PubMed]

- Benitez, F.J.; Real, F.J.; Acero, J.L.; Garcia, J.; Sanchez, M. Kinetics of the Ozonation and Aerobic Biodegradation of Wine Vinasses in Discontinuous and Continuous Processes. J. Hazard. Mater. 2003, 101, 203–218. [Google Scholar] [CrossRef]

- Standard Methods for the Examination of Water and Wastewater, 20th ed; American Public Health Association, American Water Works Association; Water Environment Federation: Washington, DC, USA, 1999.

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar]

- OECD. OECD Guidelines for the Testing of Chemicals; Terrestrial Plant Test: Paris, France, 2004; Volume 208. [Google Scholar]

- Varnero, M.T.; Rojas, C.; Orellana, R. Índices de Fitotoxicidad En Residuos Orgánicos Durante El Compostaje. Rev. Cienc. Suelo Y Nutr. Veg. 2007, 7, 28–37. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y. Elimination of Phytotoxicity during Co-Composting of Spent Pig-Manure Sawdust Litter and Pig Sludge. Bioresour. Technol. 1998, 65, 43–49. [Google Scholar] [CrossRef]

- OIV. Compendium of International Methods of Wine and Must Analysis—Volume I, 2017th ed.; OIV: Paris, France, 2017; ISBN 979-10-91799-64-5. [Google Scholar]

- Curvelo-Garcia, A. Controlo de qualidade dos vinhos. In Química Enológica e Métodos Analíticos. Avanços Recentes no Controlo da Qualidade de Vinhos e de Outros Produtos Vitivinícolas; António Sérgio Curvelo Garcia e Paulo Barros, Ed.; Engebook/Publindustria; Edições Técnicas, Lda: Porto, Portugal, 1988; ISBN 978-989-723-118-6. [Google Scholar]

- Kramling, T.E.; Singleton, V.L. An Estimate of the Nonflavonoid Phenols in Wines. Am. J. Enol. Vitic. 1969, 20, 86–92. [Google Scholar]

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology Volume 2 The Chemistry of Wine Stabilization and Treatments, 2nd ed.; John Wiley & Sons Inc.: Chichester, UK, 2006; Volume 2, ISBN 9780470010396. [Google Scholar]

- Somers, T.C.; Evans, M.E. Spectral Evaluation of Young Red Wines: Anthocyanin Equilibria, Total Phenolics, Free and Molecular SO2, “Chemical Age”. J. Sci. Food Agric. 1977, 28, 279–287. [Google Scholar] [CrossRef]

- Ribéreau-Gayon, P.; Stonestreet, E. Dosage Des Tanins Du Vin Rouge et Détermination de Leur Structure. Chim. Anal. 1966, 48, 188. [Google Scholar]

- Spagna, G.; Pifferi, G.; Rangoni, C.; Mattivi, F.; Nicolinib, G.; Palmonari, R. The Stabilization of White Wines by Adsorption of Phenolic Compounds on Chitin and Chitosan. Food Res. Int. 1996, 29, 241–248. [Google Scholar] [CrossRef]

- Schanda, J. Colorimetry: Understanding the CIE System; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; ISBN 978-0-470-04904-4. [Google Scholar]

- Xue, J.; Wang, T.; Hu, Q.; Zhou, M.; Luo, Y. A Novel and Organic Solvent-Free Preparation of Solid Lipid Nanoparticles Using Natural Biopolymers as Emulsi Fi Er and Stabilizer. Int. J. Pharm. 2017, 531, 59–66. [Google Scholar] [CrossRef]

- Ren, J.; Hou, Y.; Fan, G.; Zhang, L.; Li, X.; Yin, K.; Pan, S. Extraction of Orange Pectin Based on the Interaction between Sodium Caseinate and Pectin. Food Chem. 2019, 283, 265–274. [Google Scholar] [CrossRef] [PubMed]

- Borodko, Y.; Habas, S.E.; Koebel, M.; Yang, P.; Frei, H.; Somorjai, G.A. Probing the Interaction of Poly (Vinylpyrrolidone) with Platinum Nanocrystals by UV—Raman and FTIR. J. Phys. Chem. B 2006, 110, 23052–23059. [Google Scholar] [CrossRef]

- Abdelghany, A.M.; Mekhail, M.S.; Abdelrazek, E.M.; Aboud, M.M. Combined DFT/FTIR Structural Studies of Monodispersed PVP/Gold and Silver Nano Particles. J. Alloys Compd. 2015, 646, 326–332. [Google Scholar] [CrossRef]

- Laot, C.M.; Marand, E.; Oyama, H.T. Spectroscopic Characterization of Molecular Interdiffusion at a Poly (Vinylpyrrolidone)/Vinyl Ester Interface. Polymer 1999, 40, 1095–1108. [Google Scholar] [CrossRef]

- Lewandowska, K. The Miscibility of Poly (Vinyl Alcohol)/Poly (N-Vinylpyrrolidone) Blends Investigated in Dilute Solutions and Solids. Eur. Polym. J. 2005, 41, 55–64. [Google Scholar] [CrossRef]

- Abdelaziz, M.; Abdelrazek, E.M. Effect of Dopant Mixture on Structural, Optical and Electron Spin Resonance Properties of Polyvinyl Alcohol. Phys. B Condens. Matter 2007, 390, 1–9. [Google Scholar] [CrossRef]

- Abdelrazek, E.M.; Elashmawi, I.S.; El-khodary, A.; Yassin, A. Structural, Optical, Thermal and Electrical Studies on PVA/PVP Blends Filled with Lithium Bromide. Curr. Appl. Phys. 2010, 10, 607–613. [Google Scholar] [CrossRef]

- Tawansi, A.; El-Khodary, A.; Abdelnaby, M.M. A Study of the Physical Properties of FeCl3 Filled PVA. Curr. Appl. Phys. 2005, 5, 572–578. [Google Scholar] [CrossRef]

- Schuttlefield, J.D.; Cox, D.; Grassian, V.H. An Investigation of Water Uptake on Clays Minerals Using ATR-FTIR Spectroscopy Coupled with Quartz Crystal Microbalance Measurements. J. Geophys. Res. Atmos. 2007, 112, D21. [Google Scholar] [CrossRef]

- Sevim, A.M.; Hojiyev, R.; Gül, A.; Celik, M.S. Preparation of Novel Heterogeneous Catalysts by Adsorption of a Cationic Tetrapyrrole on to Bentonite: Equilibrium, Kinetics, and Thermodynamics. Mon. Für Chem. Chem. Mon. 2012, 143, 385–400. [Google Scholar] [CrossRef]

- Żymankowska-kumon, S.; Holtzer, M.; Olejnik, E.; Bobrowski, A. Influence of the Changes of the Structure of Foundry Bentonites on Their Binding Properties. Mater. Sci. 2012, 18, 57–61. [Google Scholar] [CrossRef]

- Hojiyev, R.; Ulcay, Y.; Çelik, M.S. Development of a Clay-Polymer Compatibility Approach for Nanocomposite Applications. Appl. Clay Sci. 2017, 146, 548–556. [Google Scholar] [CrossRef]

- Guimarães, V.; Teixeira, A.R.; Lucas, M.S.; Silva, A.M.T.; Peres, J.A. Pillared Interlayered Natural Clays as Heterogeneous Photocatalysts for H2O2-Assisted Treatment of a Winery Wastewater. Sep. Purif. Technol. 2019, 228, 115768. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Anderson, M.J. A New Method for Non-Parametric Multivariate Analysis of Variance. Austral Ecol. 2001, 26, 32–46. [Google Scholar] [CrossRef]

- Bahadir, K.K.; Rauf, M.A. Application of Response Surface Analysis to the Photolytic Degradation of Basic Red 2 Dye. Chem. Eng. J. 2008, 138, 166–171. [Google Scholar] [CrossRef]

- Joglekar, A.M.; May, A.T. Product Excellence through Design of Experiments. Cereal Foods World 1987, 32, 857–868. [Google Scholar]

- Muhamad, M.H.; Mohamad, S.R.S.A.A.B.; Rahman, R.A.; Kadhum, A.A.H. Application of Response Surface Methodology (RSM) for Optimisation of COD, NH3 e N and 2, 4-DCP Removal from Recycled Paper Wastewater in a Pilot-Scale Granular Activated Carbon Sequencing Batch Bio Fi Lm Reactor (GAC-SBBR). J. Environ. Manag. 2013, 121, 179–190. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.L.; Wong, S.S.; Teng, T.T.; Zuhairi, A. Optimization of Coagulation—Flocculation Process for Pulp and Paper Mill Effluent by Response Surface Methodological Analysis. J. Hazard. Mater. 2007, 145, 162–168. [Google Scholar] [CrossRef]

- Chantarangsi, W.; Liu, W.; Bretz, F.; Kiatsupaibul, S.; Hayter, A.J. Computation Normal Probability Plots with Confidence for the Residuals in Linear Regression. Commun. Stat. Comput. 2018, 47, 367–379. [Google Scholar] [CrossRef]

- Harbi, B.; Chaieb, K.; Mahdouani, K.; Bakhrouf, A. PCR Detection of Nitrite Reductase Genes (NirK and NirS) and Use of Active Consortia of Constructed Ternary Adherent Staphylococcal Cultures via Mixture Design for a Denitrification Process. World J. Microbiol. Biotechnol. 2010, 26, 473–480. [Google Scholar] [CrossRef]

- Cosme, F.; Ricardo-da-Silva, J.M.; Laureano, O. Interactions between Protein Fining Agents and Proanthocyanidins in White Wine. Food Chem. 2008, 106, 536–544. [Google Scholar] [CrossRef]

- Cosme, F.; Capão, I.; Filipe-Ribeiro, L.; Bennett, R.N.; Mendes-Faia, A. Evaluating Potential Alternatives to Potassium Caseinate for White Wine Fining: Effects on Physicochemical and Sensory Characteristics. Food Sci. Technol. 2012, 46, 382–387. [Google Scholar] [CrossRef]

- Cosme, F.; Ricardo-Da-Silva, J.M.; Laureano, O. Protein Fining Agents: Characterization and Red Wine Fining Assays. Ital. J. Food Sci. 2007, 19, 39–56. [Google Scholar]

- Benna, M.; Magnin, A.; Bergaya, F. Effect of PH on Rheological Properties of Purified Sodium Bentonite Suspensions. J. Colloid Interface Sci. 1999, 218, 442–455. [Google Scholar] [CrossRef]

- Guimarães, V.; Lucas, M.S.; Peres, J.A. Combination of Adsorption and Heterogeneous Photo-Fenton Processes for the Treatment of Winery Wastewater. Environ. Sci. Pollut. Res. 2019, 26, 31000–31013. [Google Scholar] [CrossRef]

- Guimarães, V.; Rodríguez-castellón, E.; Algarra, M.; Rocha, F.; Bobos, I. Influence of PH, Layer Charge Location and Crystal Thickness Distribution on U(VI) Sorption onto Heterogeneous Dioctahedral Smectite. J. Hazard. Mater. 2016, 317, 246–258. [Google Scholar] [CrossRef]

- Laborde, B.; Moine-Ledoux, V.; Richard, T.; Saucier, C.; Dubourdieu, D.; Monti, J.-P. PVPP−Polyphenol Complexes: A Molecular Approach. J. Agric. Food Chem. 2006, 54, 4383–4389. [Google Scholar] [CrossRef]

- Pierpoint, W.S. The Extraction of Enzymes from Plant Tissues Rich in Phenolic Compounds. Protein Purif. Protoc. 1996, 59, 69–80. [Google Scholar] [CrossRef]

- Howe, K.J.; Hand, D.W.; Crittenden, J.C.; Trussell, R.R.; Tchobanoglous, G. Principles of Water Treatment; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; ISBN 9780470405383. [Google Scholar]

- Braga, A.; Cosme, F.; Ricardo-da-Silva, J.M.; Laureano, O. Gelatine, Casein and Potassium Caseinate as Distinct Wine Fining Agents: Different Effects on Colour, Phenolic Compounds and Sensory Characteristics. OENO One 2007, 41, 203–214. [Google Scholar] [CrossRef]

- Hunter, R.J. Foundations of Colloid Science, 2nd ed.; Oxford University Press: Oxford, UK, 2001; ISBN 978-0-19-850502-0. [Google Scholar]

- Huang, Y.; Jiang, J.; Ma, L.; Wang, Y.; Liang, M.; Zhang, Z.; Li, L. Iron Foam Combined Ozonation for Enhanced Treatment of Pharmaceutical Wastewater. Environ. Res. 2020, 183, 109205. [Google Scholar] [CrossRef] [PubMed]

- Hassanshahi, N.; Karimi-jashni, A. Comparison of Photo-Fenton, O3/H2O2/UV and Photocatalytic Processes for the Treatment of Gray Water. Ecotoxicol. Environ. Saf. 2018, 161, 683–690. [Google Scholar] [CrossRef] [PubMed]

- Hoigne, J.; Bader, H. The Role of Hydroxyl Radical Reactions in Ozonation Processes in Aqueous Solutions. Water Res. 1976, 10, 377–386. [Google Scholar] [CrossRef]

- Agustina, T.E.; Ang, H.M.; Vareek, V.K. A Review of Synergistic Effect of Photocatalysis and Ozonation on Wastewater Treatment. J. Photochem. Photobiol. C Photochem. Rev. 2005, 6, 264–273. [Google Scholar] [CrossRef]

- Hodges, J.T.; Viallon, J.; Brewer, P.J.; Drouin, B.J.; Gorshelev, V.; Janssen, C.; Lee, S.; Possolo, A.; Smith, M.A.H.; Walden, J.; et al. Recommendation of a Consensus Value of the Ozone Absorption Cross-Section at 253.65 Nm Based on a Literature Review. Metrologia 2019, 56, 034001. [Google Scholar] [CrossRef]

- Jodpimai, S.; Boonduang, S.; Limsuwan, P. Sensors and Actuators B: Chemical Inline Ozone Concentration Measurement by a Visible Absorption Method at Wavelength 605 Nm. Sens. Actuators B. Chem. 2016, 222, 8–14. [Google Scholar] [CrossRef]

- Piera, E.; Calpe, J.C.; Brillas, E.; Domènech, X.; Peral, J. 2,4-Dichlorophenoxyacetic Acid Degradation by Catalyzed Ozonation: TiO2/UVA/O3 and Fe (II)/UVA/O3 Systems. Appl. Catal. B Environ. 2000, 27, 169–177. [Google Scholar] [CrossRef]

- Adar, E. Optimization of Triple Dye Mixture Removal by Oxidation with Fenton. Int. J. Environ. Sci. Technol. 2020, 17, 4431–4440. [Google Scholar] [CrossRef]

- Chaturvedi, N.K.; Katoch, S.S. O-Anisidine Degradation by Fenton’s Reagent and Reaction Time Estimation. Pollution 2020, 6, 127–134. [Google Scholar] [CrossRef]

- Clarizia, L.; Russo, D.; Di Somma, I.; Marotta, R.; Andreozzi, R. Homogeneous Photo-Fenton Processes at near Neutral PH: A Review. Appl. Catal. B Environ. 2017, 209, 358–371. [Google Scholar] [CrossRef]

- Dowd, K.O.; Pillai, S.C. Photo-Fenton Disinfection at near Neutral PH: Process, Parameter Optimization and Recent Advances. J. Environ. Chem. Eng. 2020, 8, 104063. [Google Scholar] [CrossRef]

- Chang, R. CHEMISTRY, 10th ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2010; ISBN 978–0–07–351109–2. [Google Scholar]

- Ebrahiem, E.E.; Al-Maghrabi, M.N.; Mobarki, A.R. Removal of Organic Pollutants from Industrial Wastewater by Applying Photo-Fenton Oxidation Technology. Arab. J. Chem. 2017, 10, S1674–S1679. [Google Scholar] [CrossRef]

- Quiroz, A.C.; Barrera-díaz, C.; Roa-morales, G.; Hern, P.B.; Romero, R.; Natividad, R. Wastewater Ozonation Catalyzed by Iron. Ind. Eng. Chem. Res. 2011, 50, 2488–2494. [Google Scholar] [CrossRef]

- Bolton, J.R.; Bircher, K.G.; Tumas, W.; Tolman, C.A. Figures-of-Merit for the Technical Development and Application of Advanced Oxidation Technologies for Both Electric-and Solar-Driven Systems (IUPAC Technical Report). Pure Appl. Chem. 2001, 73, 627–637. [Google Scholar] [CrossRef]

- Bessegato, G.G.; De Souza, J.C.; Cardoso, J.C.; Zanoni, M.V.B. Assessment of Several Advanced Oxidation Processes Applied in the Treatment of Environmental Concern Constituents from a Real Hair Dye Wastewater. J. Environ. Chem. Eng. 2018, 6, 2794–2802. [Google Scholar] [CrossRef]

- Cardoso, J.C.; Bessegato, G.G.; Zanoni, M.V.B. Efficiency Comparison of Ozonation, Photolysis, Photocatalysis and Photoelectrocatalysis Methods in Real Textile Wastewater Decolorization. Water Res. 2016, 98, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Kang, W.; Chen, S.; Yu, H.; Xu, T.; Wu, S.; Wang, X.; Lu, N.; Quan, X.; Liang, H. Photocatalytic Ozonation of Organic Pollutants in Wastewater Using a Flowing through Reactor. J. Hazard. Mater. 2021, 405, 124277. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Wang, Q.; Zhai, X.; Huang, Q.; Huang, P. Improved Pretreatment (Coagulation-Floatation and Ozonation) of Younger Landfill Leachate by Microbubbles. Water Environ. Res. 2010, 82, 657–665. [Google Scholar] [CrossRef] [PubMed]

- Bu, F.; Gao, B.; Shen, X.; Wang, W.; Yue, Q. The Combination of Coagulation and Ozonation as a Pre-Treatment of Ultrafiltration in Water Treatment. Chemosphere 2019, 231, 349–356. [Google Scholar] [CrossRef] [PubMed]

- Casa, R.; D’Annibale, A.; Pieruccetti, F.; Stazi, S.; Sermanni, G.G.; Cascio, B.L. Reduction of the Phenolic Components in Olive-Mill Wastewater by an Enzymatic Treatment and Its Impact on Durum Wheat (Triticum Durum Desf.) Germinability. Chemosphere 2003, 50, 959–966. [Google Scholar] [CrossRef]

- Komilis, D.P.; Karatzas, E.; Halvadakis, C.P. The Effect of Olive Mill Wastewater on Seed Germination after Various Pretreatment Techniques. J. Environ. Manag. 2005, 74, 339–348. [Google Scholar] [CrossRef]

- Saadi, I.; Laor, Y.; Raviv, M.; Medina, S. Land Spreading of Olive Mill Wastewater: Effects on Soil Microbial Activity and Potential Phytotoxicity. Chemosphere 2007, 66, 75–83. [Google Scholar] [CrossRef]

- Mosse, K.P.M.; Patti, A.F.; Christen, E.W.; Cavagnaro, T.R. Winery Wastewater Inhibits Seed Germination and Vegetative Growth of Common Crop Species. J. Hazard. Mater. 2010, 180, 63–70. [Google Scholar] [CrossRef]

- Milheiro, J.; Filipe-Ribeiro, L.; Cosme, F.; Nunes, F.M. A Simple, Cheap and Reliable Method for Control of 4-Ethylphenol and 4-Ethylguaiacol in Red Wines. Screening of Fining Agents for Reducing Volatile Phenols Levels in Red Wines. J. Chromatogr. B 2017, 1041–1042, 183–190. [Google Scholar] [CrossRef]

- Filipe-Ribeiro, L.; Milheiro, J.; Matos, C.C.; Cosme, F.; Nunes, F.M. Data on Changes in Red Wine Phenolic Compounds, Headspace Aroma Compounds and Sensory Profile after Treatment of Red Wines with Activated Carbons with Different Physicochemical Characteristics. Data Br. 2017, 12, 188–202. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| pH | 4.0 |

| Conductivity (µS/cm) | 475 |

| Turbidity (NTU) | 1040 |

| Total suspended solids (mg/L) | 2430 |

| Chemical oxygen demand (mg O2/L) | 9432 |

| Biochemical oxygen demand (mg O2/L) | 2611 |

| Total organic carbon (mg C/L) | 1962 |

| Total polyphenols (mg gallic acid/L) | 123 |

| Ferrous iron (mg Fe/L) | 0.05 |

| Biodegradability index—BOD5/COD | 0.28 |

| Formulas | Parameters | References |

|---|---|---|

| Color intensity (CI) | A420—absorbance at 420 nm | OIV, [35] |

| CI = A420 + A520 + A620 | A520—absorbance at 520 nm | |

| Hue | A620—absorbance at 620 nm | OIV, [35] |

| A280—absorbance at 280 nm | ||

| Total polyphenol index (TPI) | DF—dilution factor | Curvelo-Garcia, [36] |

| TPI = A280*DF | ||

| Total phenols | Kramling and Singleton, [37] | |

| Non-flavonoids | Kramling and Singleton, [37] | |

| Flavonoids | Kramling and Singleton, [37] | |

| Flavonoids (mg gallic acid/L) = total phenols–non-flavonoids | ||

| Total anthocyanins (C) | Ribéreau-Gayon et al. [38] | |

| C (mg/L) = 875*(A1–A2) | A1/A2—absorbance at 520 nm | |

| Colored anthocyanins (CA) | Somers and Evans [39] | |

| *10) | ||

| Total pigments (TP) | Somers and Evans [39] | |

| *10 | ||

| Polymeric pigments (PP) | Somers and Evans [39] | |

| *10 | ||

| Total tannins (L.A.) | Ribéreau-Gayon and Stonestreet [40] | |

| L.A. (g/L) = 19.33*(D2–D1) | D1/D2—absorbance at 520 nm | |

| CIELab | L—lightness | Schanda [42] |

| ∆L = − | a—redness | |

| ∆a = − | b—yellowness | |

| ∆b = − | ||

| ∆Eab = [( + ( + (] |

| Element | Mass Concentration (wt %) |

|---|---|

| Si | 69.49 |

| Al | 17.67 |

| Fe | 2.95 |

| Mg | 2.73 |

| Ca | 2.00 |

| Na | 2.76 |

| K | 1.37 |

| S | 1.03 |

| Coagulants | SBET (m2/g) | Vtotal pore (cm3/g) | Particle Size (nm) |

|---|---|---|---|

| Activated sodium bentonite | 8.8 | 0.045 | 4.0 |

| Potassium caseinate | 1.0 | n.q. | n.q. |

| PVPP | n.q. | n.q. | n.q. |

| Experiments | Samples | Y1: Turbidity | Y2: TSS | Y3: COD | Y4: TOC | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | Observed | Predicted | Observed | Predicted | Observed | Predicted | Observed | Predicted | |

| CFD1 | 0.00 | 1.00 | 0.00 | 99.6 | 99.6 | 98.3 | 98.3 | 54.3 | 54.4 | 28.4 | 28.4 |

| CFD2 | 0.67 | 0.17 | 0.17 | 99.5 | 99.5 | 98.0 | 98.0 | 52.9 | 52.5 | 32.5 | 32.4 |

| CFD3 | 1.00 | 0.00 | 0.00 | 99.5 | 99.5 | 97.9 | 97.9 | 48.5 | 48.6 | 31.6 | 31.6 |

| CFD4 | 0.17 | 0.17 | 0.67 | 99.3 | 99.3 | 97.9 | 97.9 | 52.1 | 51.7 | 29.6 | 29.5 |

| CFD5 | 0.00 | 0.00 | 1.00 | 98.9 | 98.9 | 97.5 | 97.5 | 56.2 | 56.3 | 37.0 | 37.0 |

| CFD6 | 0.33 | 0.33 | 0.33 | 99.5 | 99.5 | 98.0 | 98.1 | 50.7 | 51.7 | 31.6 | 31.9 |

| CFD7 | 0.17 | 0.67 | 0.17 | 99.7 | 99.7 | 98.3 | 98.3 | 52.5 | 52.1 | 34.4 | 34.3 |

| [Fe2+] | k | ||

|---|---|---|---|

| mM | (min−1) | (min) | (kWh∙m−3∙order−1) |

| UV-C | 7.17 × 10−4 | 966.5 | 1720 |

| O3/UV-C | 1.31 × 10−3 | 529.0 | 2153 |

| O3 | 6.86 × 10−4 | 1009.9 | 2996 |

| O3/0.5 mM Fe2+/UV-C | 1.34 × 10−3 | 517.2 | 2065 |

| O3/1.0 mM Fe2+/UV-C | 1.67 × 10−3 | 414.9 | 1843 |

| O3/2.0 mM Fe2+/UV-C | 1.72 × 10−3 | 402.9 | 1677 |

| Wastewater Type | AOP Process | Observations | References | |

|---|---|---|---|---|

| Winery wastewater | UV-C (254 nm)/PMS/Co(II) | [PMS] = 2.5 mM [Co(II)] = 1.0 mM t = 90 min = 143 mg C/L | 173 | [19] |

| Active pharmaceutical ingredients (APIs) | UV-C/O3 | Gas flow = 3.2 L/min t = 30 min = 21.5 mg C/L | 1.50 | [91] |

| Real textile wastewater | Direct ozonation | Gas flow = 1.4 L/min t = 9 min = 169 mg C/L | 2.43 | [92] |

| Organic pollutants | UV-C (254 nm)/O3 | Gas flow = 0.4 L/min t = 15 min TOCi = 79 mg C/L | 29.10 | [93] |

| UV-C (254 nm)/TiO2/O3 | Gas flow = 0.4 L/min t = 20 h TOCi = 79 mg C/L | 10.23 | ||

| Winery wastewater | Fe2+/O3/Fe2+/UV-C (254 nm) | Gas flow = 1.0 L/min [Fe2+] = 1.0 mM t = 10 h TOCi = 1962 mg C/L | 1843 | Present results |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jorge, N.; Teixeira, A.R.; Matos, C.C.; Lucas, M.S.; Peres, J.A. Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment. Int. J. Environ. Res. Public Health 2021, 18, 8882. https://doi.org/10.3390/ijerph18168882

Jorge N, Teixeira AR, Matos CC, Lucas MS, Peres JA. Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment. International Journal of Environmental Research and Public Health. 2021; 18(16):8882. https://doi.org/10.3390/ijerph18168882

Chicago/Turabian StyleJorge, Nuno, Ana R. Teixeira, Carlos C. Matos, Marco S. Lucas, and José A. Peres. 2021. "Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment" International Journal of Environmental Research and Public Health 18, no. 16: 8882. https://doi.org/10.3390/ijerph18168882

APA StyleJorge, N., Teixeira, A. R., Matos, C. C., Lucas, M. S., & Peres, J. A. (2021). Combination of Coagulation–Flocculation–Decantation and Ozonation Processes for Winery Wastewater Treatment. International Journal of Environmental Research and Public Health, 18(16), 8882. https://doi.org/10.3390/ijerph18168882