Flow. A Socially Responsible 3D Printed One-Handed Recorder

Abstract

:1. Introduction

“Some of the most successful one-handed instrument adaptations have been wind instruments. This has largely to do with the fact that both hands tend to play a similar role, i.e., pressing different combinations of buttons to open and close valves, while sound activation is achieved using the mouth. This playing method lends itself to a conceptually straightforward (albeit mechanically challenging) adaptation for one hand, whereby the mapping between valve closure and the buttons is reconfigured for a single hand.”[10]

“Examples of successful one-handed wind instrument adaptations can be found on the One-Handed Musical Instrument (OHMI). Ref. [16] also summarises several earlier wind instrument adaptations for one hand or otherwise. For many wind instruments, successful one-handed adaptations have been achieved.”[10]

2. Materials and Methods

2.1. Design Process

- The inspirational stage: The designer immerses himself/herself in the user’s life while establishing a close relationship based on trust and reciprocity, which favours a better understanding of the user’s needs.In this stage, with the aim of gathering some information from potential users about some areas of interest, such as the teaching of music or the use of the recorder in the classroom, several interviews and surveys are conducted with children (and their families) as well as with some associations interested in the implementation of the project. Some of these associations are Child Hemiparesis (Hemiweb), Spanish Association of Professional Musicians (Ampemusicos) and the National Spanish Confederation of Associations of Musical Education (COAEM).

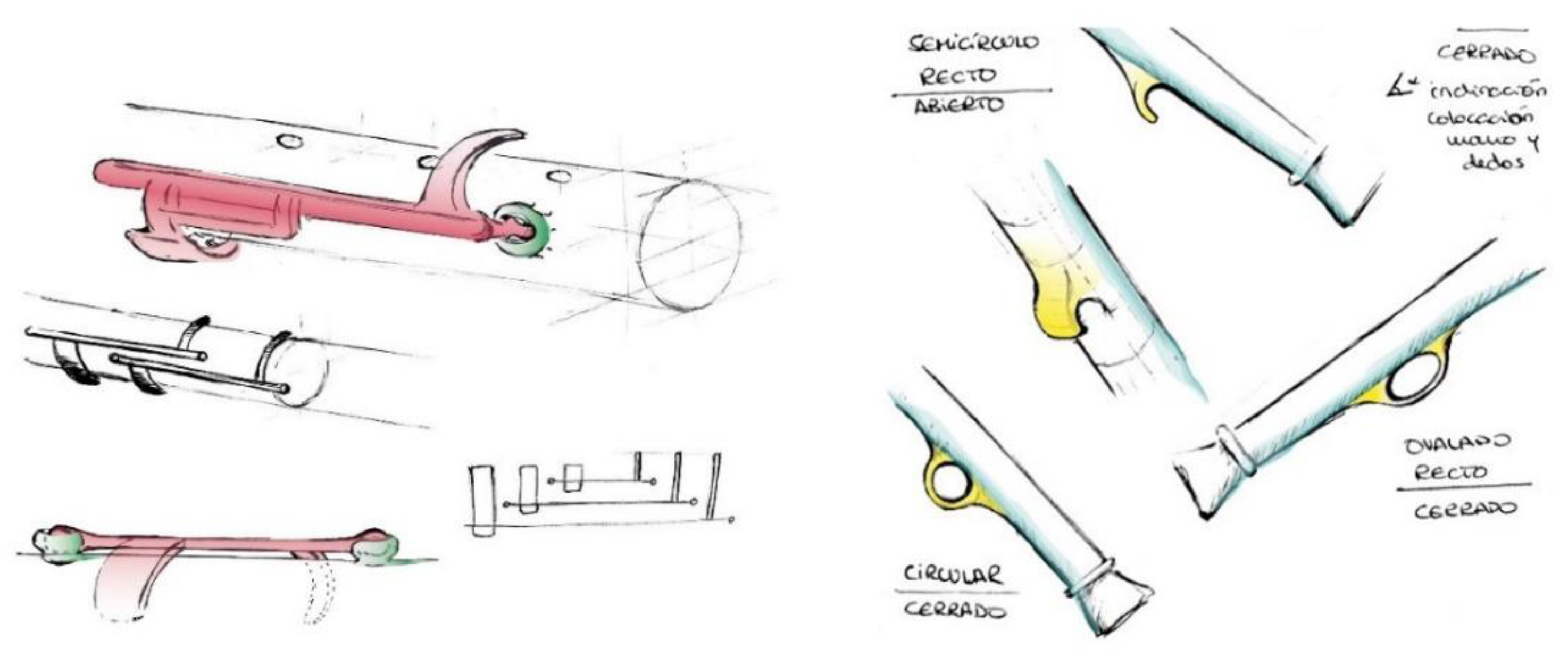

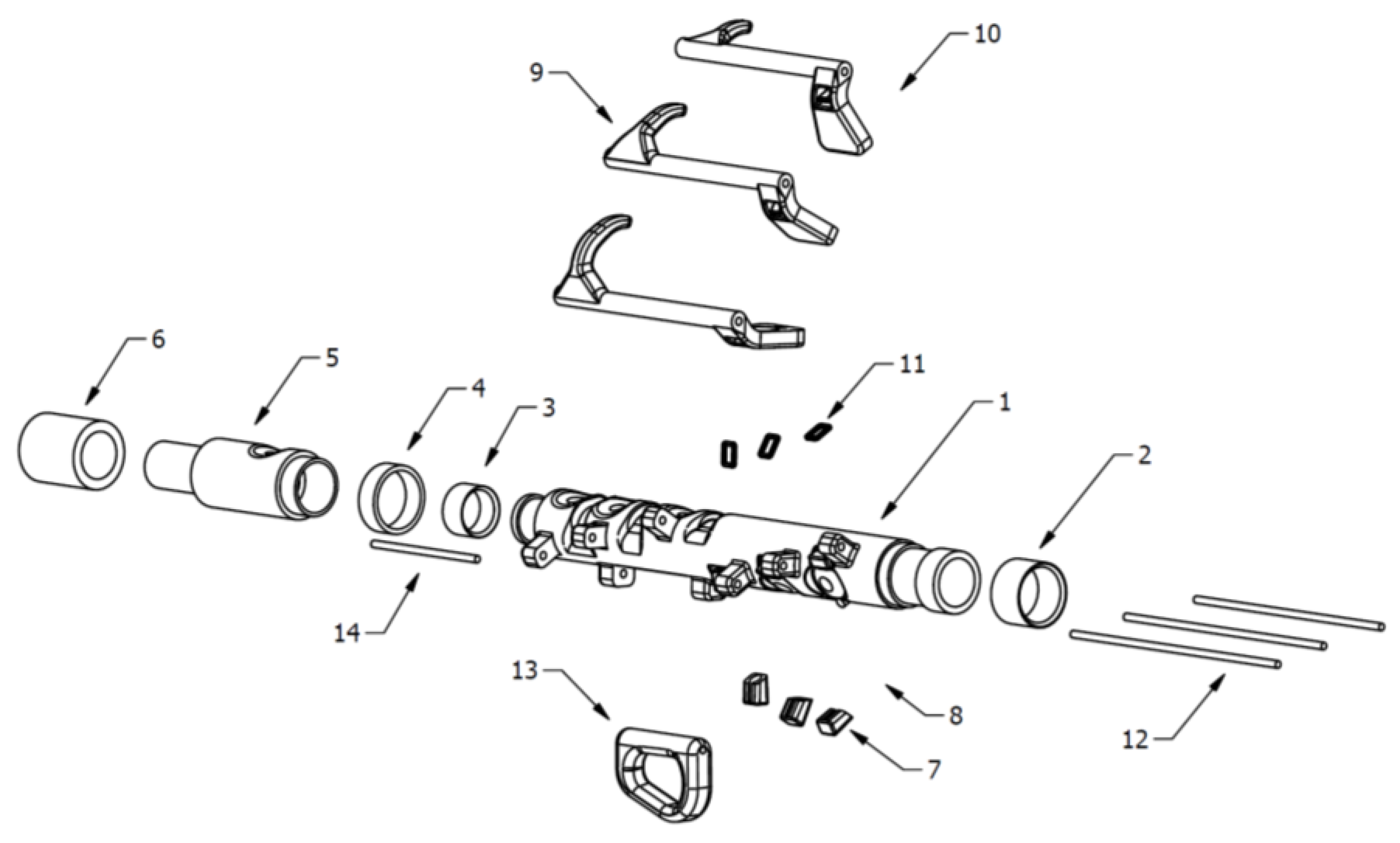

- The conceptualization stage: Design requirements are identified, and a prototype is developed. Section 2.2 and Section 3.1 shows the methodology and results of this stage, respectively.

- The implementation stage: The proposed solution is assessed and once it has been approved it is offered to the user [28,29,30,31]. The assessment of the psychosocial impact of assistive technologies is performed using the PIADS [23]. Section 2.3, Section 2.4 and Section 3.2 shows the methodology and results of this stage, respectively.

2.2. Product Development

2.2.1. Software. 3D Modelling and Lamination for Additive Manufacturing

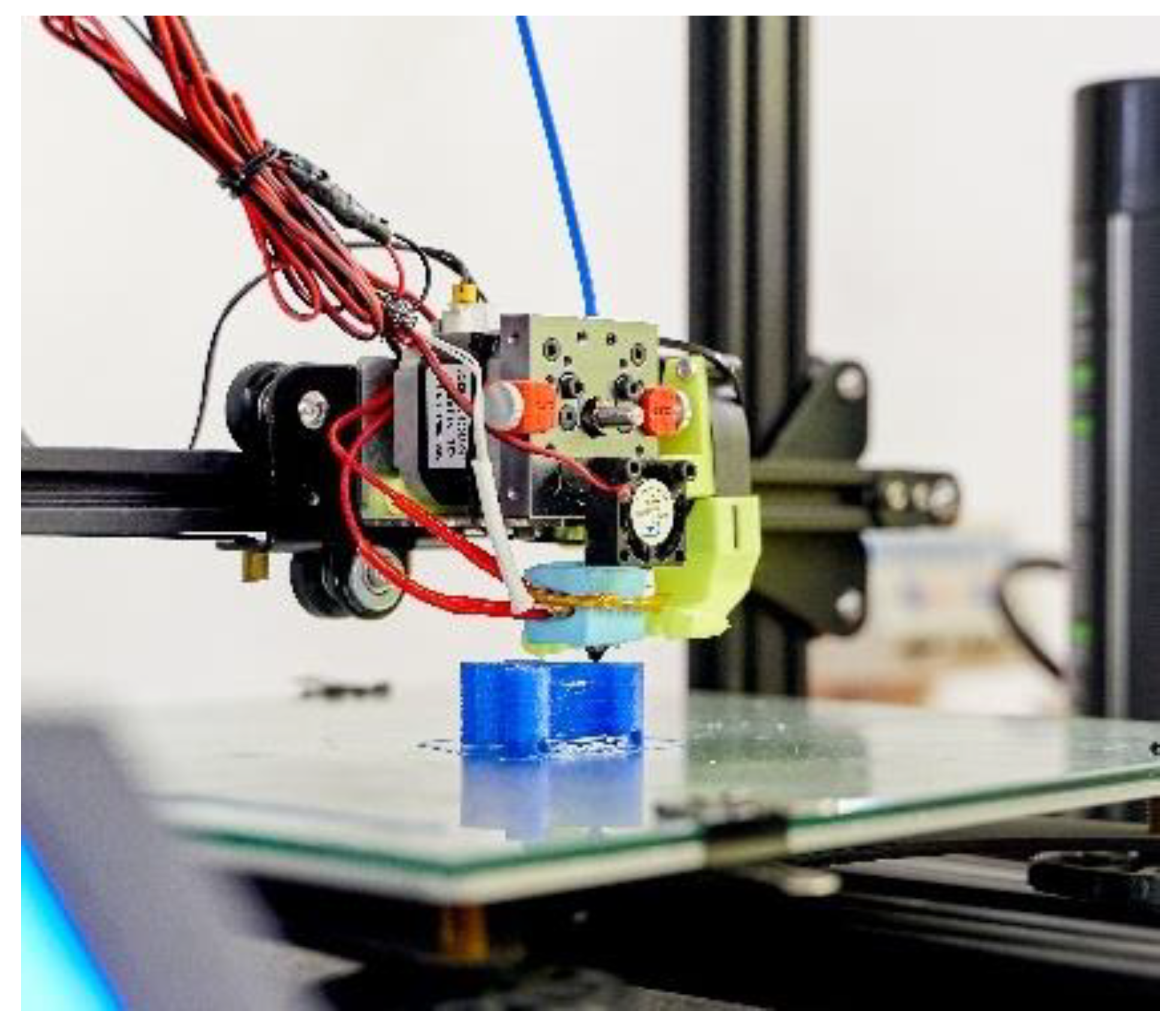

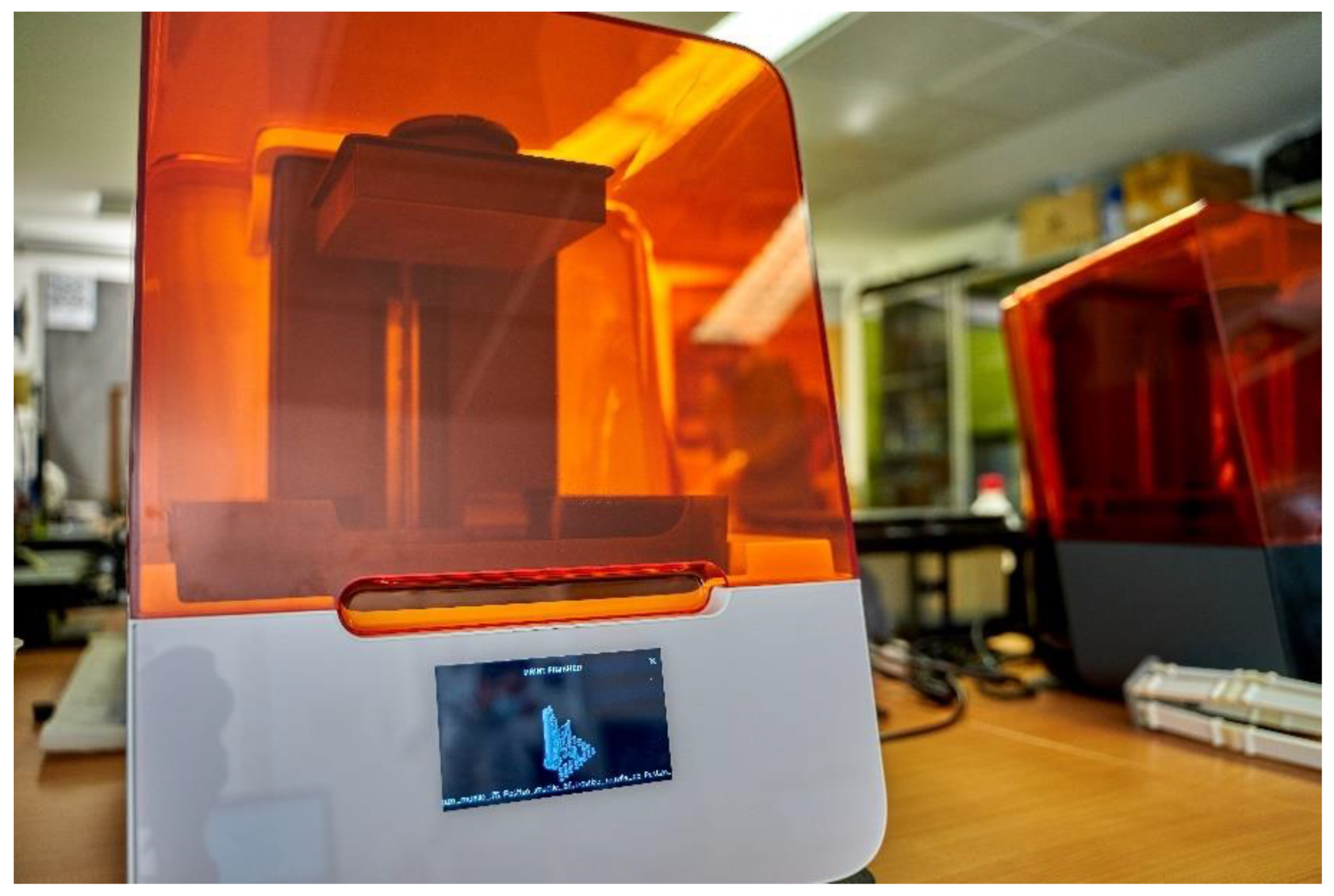

2.2.2. Hardware. Additive Manufacturing and Materials

2.2.3. Acoustic/Musical Properties

2.3. Instruments and Variables

2.4. Sample

2.5. Ethical Consideration

- To promote in all relevant disciplines socially responsive and responsible research, the investigation of existing barriers preventing full inclusion of all in society as well as developing strategies and solutions—many of which may be technology-related—to enable participation.

- To assure that technological innovation takes into account the greatest possible number of potential beneficiaries following a universal design approach, and make sure that it does not contribute to further exclusion by widening the gap between the haves and have-nots.

- To foster assistive technology provision systems that are person-centered, independent from commercial interests, and able to provide, in a timely and affordable manner, personalised forward-looking solutions that are suitable for the environment of use and based on the abilities, preferences and expectations of the final user.

- To pursue and assure the quality of assistive technology solutions for the equitable and global provision of assistive technology systems.

- To promote positive images, designs and initiatives, which counteract the stigma that sometimes is associated with impairment and the use of assistive technology.

3. Results

3.1. Design and Development Results

3.1.1. Design Results

3.1.2. Acoustic Results

3.1.3. Views from Experts in Musical Education at Schools

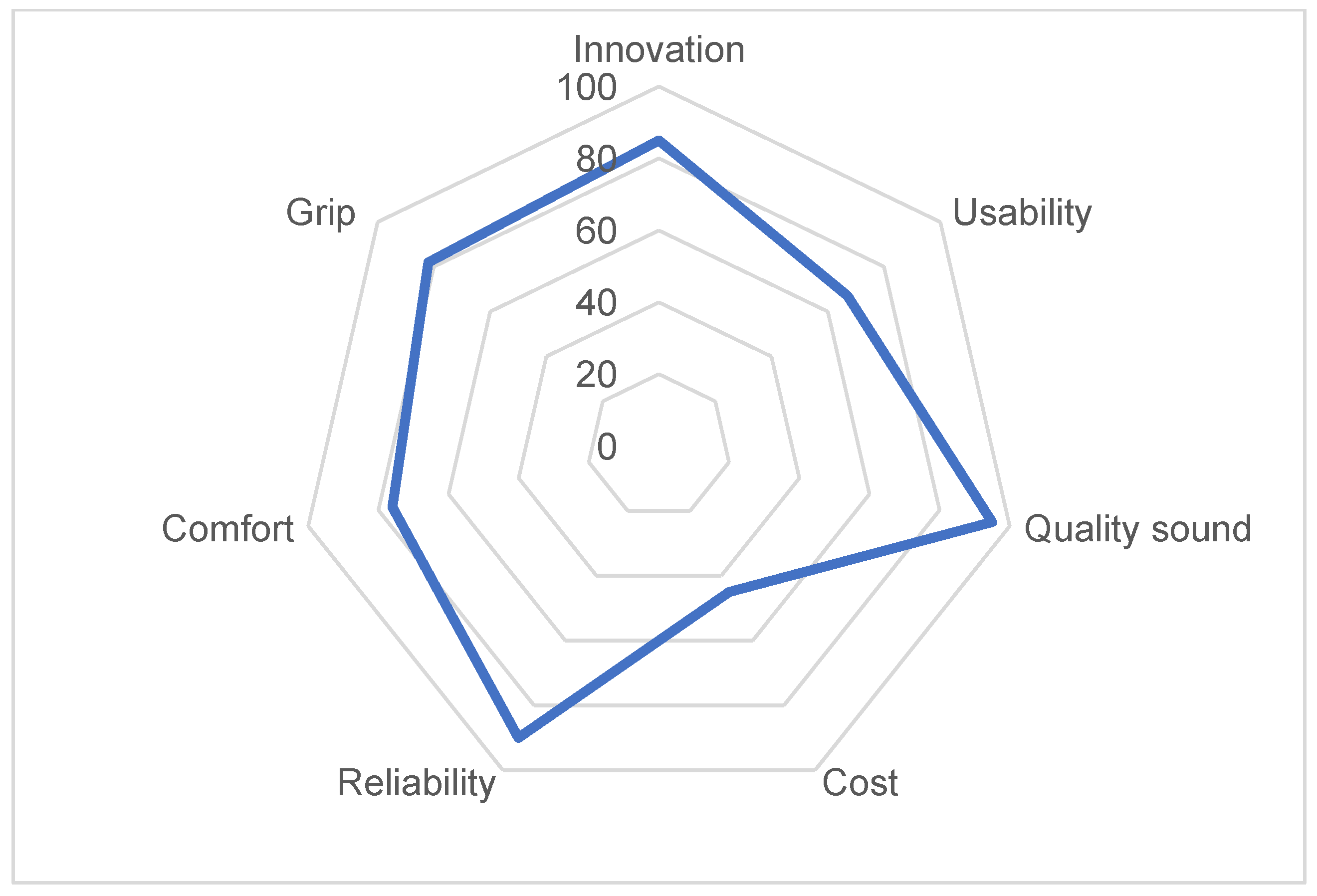

3.2. User’s Perspective

4. Discussion

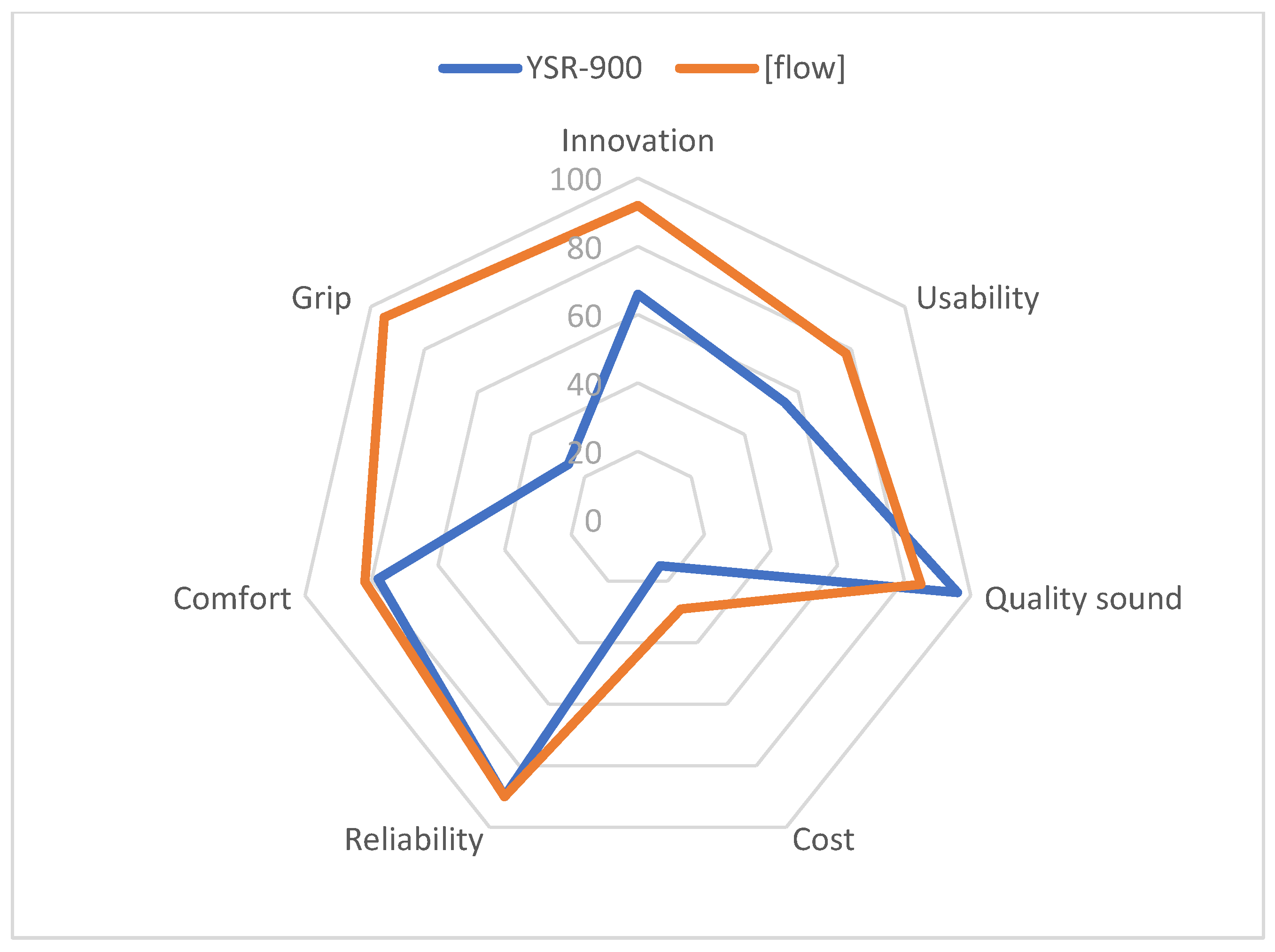

- Adaptability: Both users and music teachers show a medium-high degree of satisfaction with features related to the adaptability of the product (usability, comfort, and grip; Figure 7 and Figure 9). This is most probably due to the methodology used, which is user-centered [29,30], thus allowing to achieve the biggest challenge of this project, namely, to design a recorder that can be played with one hand.

- User-friendly: Both users and music teachers show a medium-high degree of satisfaction in terms of how user friendly the recorder is (reliability, grip, usability, and comfort; Figure 7 and Figure 9). This user friendliness has been possible due to the simple design of the key system [47,48], and the exclusion of the thumbhole, which is not necessary at the school level for which the recorder is designed.

- Good acoustics and tuning: the acoustic tests (Table 3) and the assessment provided by music teachers (Figure 7) show the good quality of the recorder’s acoustics. This might be linked to the specific benefits of resin, and its special acoustic features, which have been discussed in other articles [18].

- Durable: It was important to propose a design that will consider and respond to children’s activity. Therefore, it was decided to use an impact-resistant material. As shown in the assessment, both users and music teachers show a high degree of satisfaction in this regard (reliability and comfort; Figure 7 and Figure 9).

- Lightweight: The simple design and the properties of the material (resin Tough 2000) have allowed the design of a lightweight and slim device. This feature prevents overload while using or carrying the recorder.

- Fair cost: Additive manufacturing allows for the production of a tailored-made and customized device, which can be produced in a short period [36,47]. In addition to this, the device does not require a great initial investment in technology, manufacturing, or storage. Accordingly, the user is offered a high quality instrument for an estimated price of EUR 140 (as opposed to the initial EUR 400). Such price would cover the production cost (without being overly costly).

- Psychosocial aspects: As analysis of results show in Table 5, learning and playing with this recorder have clear psychological benefits for one-handed children. Users and families point out the clear benefits of playing this recorder at a social level, as well as with classmates and friends, thus promoting one of the most important goals of this research, namely, inclusion at schools [20,21,49,50].

Further Research

5. Conclusions

6. Patents

- Esclapés Jover, J., and Gomez Hernansanz, A. (2021). Patente n° U202131434. España.

- Esclapés Jover, J., Gómez Hernansanz, A., and Cabrera Madrigal, L. (2019). Patente n° PCT201932022. España.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Global perspectives on assistive technology. In Proceedings of the GReAT Consultation 2019, World Health Organization, Geneva, Switzerland, 22–23 August 2019; Volume 1. [Google Scholar]

- I.E.D.E. Encuesta Sobre Discapacidades Autonomía Personal y Situaciones de Dependencia 2008. Instituto Nacional de Estadística. 2008. Available online: https://www.ine.es/dyngs/INEbase/es/operacion.htm?c=Estadistica_C&cid=1254736176782&menu=resultados&idp=1254735573175 (accessed on 10 November 2021).

- MacKay, D. The United Nations Convention on the Rights of Persons with Disabilities Symposium: The United Nations Convention on the Rights of Persons with Disabilities. Syracuse J. Int.’l L. Com. 2007, 34, 323–332. [Google Scholar]

- Zoran, A. The 3D Printed Flute: Digital Fabrication and Design of Musical Instruments. J. New Music Res. 2011, 40, 379–387. [Google Scholar] [CrossRef]

- Hopkinson, N.; Hague, R.; Dickens, P. Rapid Manufacturing: An Industrial Revolution for the Digital Age; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Artefactos, Diseño y Fabricación Social. Available online: https://www.artefactos.org/ (accessed on 30 July 2021).

- de España, G. Ley Orgánica 2/2006, de 3 de mayo, de Educación. Boletín Oficial Estado 2006, 106, 17158–17207. [Google Scholar]

- Ministerio de Educación y Formación Profesional de España. Las Cifras de la Educación en España Estadísticas e Indicadores. Edición 2020. Available online: https://sede.educacion.gob.es/publiventa/las-cifras-de-la-educacion-estadisticas-e-indicadores-estadisticas-2020/organizacion-y-gestion-educativa/23984 (accessed on 10 November 2021).

- Hemiparesia y Entorno Escolar. Available online: https://www.hemiweb.org/guias (accessed on 30 July 2021).

- Harrison, J.; McPherson, A.P. Adapting the Bass Guitar for One-Handed Playing. J. New Music Res. 2017, 46, 270–285. [Google Scholar] [CrossRef]

- Woldendorp, K.H.; van Gils, W. One-handed musicians—More than a gimmick. Med. Probl. Perform. Artist. 2012, 27, 231–237. [Google Scholar] [CrossRef]

- Cassels, J. Is this a Recorde? Math. Gaz. 1976, 60, 59–61. [Google Scholar] [CrossRef]

- Dickeson, B. The one-handed recorder. Rec. Mag. 2004, 24, 82–86. [Google Scholar]

- Nabb, D.; Balcetis, E. Access to music education: Nebraska band directors’ experiences and attitudes regarding students with physical disabilities. J. Res. Music Educ. 2010, 57, 308–319. [Google Scholar] [CrossRef]

- Cohen, P. The one handed saxophone. Saxophone J. 1987, 11, 4–8. [Google Scholar]

- Snedeker, J.P. Adaptive engineering for musical instruments. Med Probl. Perform. Artist. 2005, 20, 89. Available online: https://link.gale.com/apps/doc/A173230617/HRCA?u=anon~df9e375b&sid=googleScholar&xid=a49bfd82 (accessed on 10 November 2021). [CrossRef]

- Dabin, M.; Narushima, T.; Beirne, S.T.; Ritz, C.H.; Grady, K. 3d modelling and printing of microtonal flutes. In Proceedings of the 16th International Conference on New Interfaces for Musical Expression (NIME 2016), Brisbane, Australia, 11–15 July 2016. [Google Scholar]

- Kolomiets, A.; Grobman, Y.J.; Popov, V.V.; Strokin, E.; Senchikhin, G.; Tarazi, E. The titanium 3D-printed flute: New prospects of additive manufacturing for musical wind instruments design. J. New Music Res. 2021, 50, 1–17. [Google Scholar] [CrossRef]

- Huang, J.; Qin, Q.; Wang, J. A review of stereolithography: Processes and systems. Processes 2020, 8, 1138. [Google Scholar] [CrossRef]

- Samuels, K. The Meanings in Making: Openness, Technology and Inclusive Music Practices for People with Disabilities. Leonardo Music J. 2015, 25, 25–29. [Google Scholar] [CrossRef]

- Samuels, K. The Drake music project Northern Ireland: Providing access to music technology for individuals with unique abilities. Soc. Incl. 2019, 7, 152–163. [Google Scholar] [CrossRef]

- United Nations Educational Scientific and Cultural Organization. SDG 4 Data Book: Global Education Indicators 2019; UNESCO Institute for Statistics: Montreal, QC, Canada, 2019. [Google Scholar]

- Jutai, J.; Day, H. Psychosocial Impact of Assistive Devices Scale (PIADS). Technol. Disabil. 2002, 14, 107–111. [Google Scholar] [CrossRef]

- Martinez de Carrasquero, C.; Mavarez, R.J.; Rojas, P.; Ligibther, A.; Carvallo, B. La responsabilidad social universitaria como estrategia de vinculacion con su entorno social. Fronesis 2008, 15, 81–103. [Google Scholar]

- Brown, T.; Wyatt, J. Design Thinking for Social Innovation. Dev. Outreach 2010, 12, 29–43. [Google Scholar] [CrossRef]

- Brown, T.; Katz, B. Change by Design. J. Prod. Innov. Manag. 2011, 28, 381–383. [Google Scholar] [CrossRef]

- Ku, B.; Lupton, E. Health Design Thinking: Creating Products and Services for Better Health; MIT Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Hofmann, M.L. Human Centered Design; Wilhelm Fink: Paderborn, Germany, 2017. [Google Scholar]

- Santos, A.V.F.; Silveira, Z.C. AT-design: Methodology to support development of assistive devices focused on user-centered design and 3D technologies. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 260. [Google Scholar] [CrossRef]

- IDEO.org. The Field Guide to Human-Centered Design; IDEO: San Francisco, CA, USA, 2015. [Google Scholar]

- García, T.P.; Garabal-Barbeira, J.; Trillo, P.P.; Figueira, O.V.; Díaz, C.N.; Loureiro, J.P. A Framework for a New Approach to Empower Users through Low-Cost and Do-It-Yourself Assistive Technology. Int. J. Environ. Res. Public Health 2021, 18, 3039. [Google Scholar] [CrossRef]

- Autodesk Inventor. Available online: https://www.autodesk.es/products/inventor/overview (accessed on 30 July 2021).

- FreeCAD. Available online: https://www.freecadweb.org/ (accessed on 30 July 2021).

- Ultimaker Cura. Available online: https://ultimaker.com/es/software/ultimaker-cura (accessed on 30 July 2021).

- Preform Formlabs. Available online: https://formlabs.com/es/software/ (accessed on 30 July 2021).

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Bogue, R. 3D printing: The dawn of a new era in manufacturing? Assem. Autom. 2013, 33, 307–311. [Google Scholar] [CrossRef]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A review on stereolithography and its applications in biomedical engineering. Biomaterials 2010, 31, 6121–6130. Available online: https://www.sciencedirect.com/science/article/pii/S0142961210005661 (accessed on 10 November 2021). [CrossRef] [Green Version]

- Demers, L.; Monette, M.; Descent, M.; Jutai, J.; Wolfson, C. The Psychosocial Impact of Assistive Devices Scale (PIADS): Translation and preliminary psychometric evaluation of a Canadian–French version. Qual. Life Res. 2002, 11, 583–592. [Google Scholar] [CrossRef] [PubMed]

- Harada, N.; Fong, S.; Heiney, C.; Yentes, J.M.; Perell-Gerson, K.L.; Fang, M.A. Evaluation of two cane instruments in older adults with knee osteoarthritis. J. Rehabil. Res. Dev. 2014, 51, 275–283. [Google Scholar] [CrossRef] [PubMed]

- Barua, A. Methods for decision-making in survey questionnaires based on Likert scale. J. Asian Sci. Res. 2013, 3, 35–38. [Google Scholar]

- Bolonia Declaration. Available online: https://aaate.net/the-bologna-declaration/ (accessed on 10 November 2021).

- Frid, E. Accessible Digital Musical Instruments—A Review of Musical Interfaces in Inclusive Music Practice. Multimodal Technol. Interact. 2019, 3, 57. [Google Scholar] [CrossRef] [Green Version]

- Lucas, A.; Ortiz, M.; Schroeder, F. Bespoke Design for Inclusive Music: The Challenges of Evaluation, NIME2019. In Proceedings of the New Interfaces for Musical Expression 2019, Porto Alegre, Brazil, 3–6 June 2019; pp. 1–6. [Google Scholar]

- Gherardini, F.; Mascia, M.T.; Bettelli, V.; Leali, F. A Co-Design Method for the Additive Manufacturing of Customised Assistive Devices for Hand Pathologies. J. Integr. Des. Process Sci. 2018, 22, 21–37. [Google Scholar] [CrossRef]

- Challis, B. Octonic: An accessible electronic musical instrument. Digit. Creat. 2011, 22, 1–12. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Celentano, F.; DiPasquale, R.; Simoneau, E.; May, N.; Shahbazi, Z.; Shahbazmohamadi, S. Reverse Engineering and Geometric Optimization for Resurrecting Antique Saxophone Sound Using Micro-Computed Tomography and Additive Manufacturing. J. Comput. Inf. Sci. Eng. 2017, 17, 034501. [Google Scholar] [CrossRef]

- Hahna, N.D.; Hadley, S.; Miller, V.H.; Bonaventura, M. Music technology usage in music therapy: A survey of practice. Arts Psychother. 2012, 39, 456–464. [Google Scholar] [CrossRef]

- Zimmermann, S. Exceptional Music Pedagogy for Children with Exceptionalities; Blair, D.V., McCord, K.A., Eds.; Oxford University Press: New York, NY, USA, 2016; 305p, ISBN 978-0-19-023457-7. [Google Scholar]

| Diagnosis | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Hemiplegia | Agenesis | OBPI | Total | ||||||

| No. | % | No. | % | No. | % | No. | % | ||

| Genre | Male | 2 | 40 | 5 | 62.5 | 6 | 85.7 | 13 | 65 |

| Female | 3 | 60 | 3 | 37.5 | 1 | 14.3 | 7 | 35 | |

| Type of AT | Recorder Right | 3 | 60 | 5 | 62.5 | 1 | 14.3 | 9 | 45 |

| Recorder Left | 2 | 40 | 3 | 37.5 | 6 | 85.7 | 11 | 55 | |

| Yamaha YRS900 | Flow Concept | |

|---|---|---|

| No. of parts (Without mouthpiece) | 24 units. | 20 units. |

| Weight (gr.) (Without mouthpiece) | 114 gr. | 70 gr. |

| No. of keys | 7 | 3 |

| Manufacturing process | Casting and machining | SLA and FDM |

| Material | Wood and brass | Tough resin and TPE |

| Use | All keys can be played using five fingers | All keys can be played with four fingers |

| Grip | Not adapted. It requires extra support for one-handed people. | Thumb ring and non-slip foot of the body. It can be played with one hand. |

| Affordances |

|

|

| Limitations |

|

|

| Standard | Yamaha YRS-900 | Flow Concept | ||||

|---|---|---|---|---|---|---|

| Scientific Notation | Musical Notation | Frequency (Hz) | Frequency (Hz) | Deviation (cents) | Frequency (Hz) | Deviation (cents) |

| C5 | C | 523.2 | 524 | 2.6 | 538.2 | 48.9 |

| D5 | D | 587.3 | 585.4 | −5.6 | 592.5 | 15.3 |

| E5 | E | 659.3 | 648.7 | −28.1 | 652.7 | −17.4 |

| F5 | F | 698.5 | 711.3 | 31.4 | 693.4 | −12.7 |

| G5 | G | 784 | 769.8 | −31.6 | 785.0 | 2.2 |

| A5 | A | 880 | 871.1 | −17.6 | 873.9 | −12 |

| B5 | B | 987.8 | 979.5 | −14.6 | 973.3 | −25.6 |

| C6 | C′ | 1046.5 | 1036.4 | −16.8 | 1036.2 | −17.1 |

| ID | Age | Genre | What Is Your Connection to the Recorder? | How Many Hours Do You Teach in Primary School? | How Many Hours Do You Teach in Secondary School? |

|---|---|---|---|---|---|

| 1 | 48 | Female | Music teacher in secondary school | 1 | 2 |

| 2 | 44 | Female | Music teacher in primary school | 2 | 3 |

| 3 | 49 | Female | Music teacher | 3 | |

| 4 | 38 | Female | Teacher | 1 | |

| 5 | 43 | Male | Teacher | 1 | 1 |

| 6 | 46 | Male | Music teacher in secondary school | 5 | |

| 7 | 57 | Male | Music teacher | 2 | 2 |

| 8 | 28 | Female | Teacher | 1 | 2 |

| 9 | 28 | Female | Teacher | 1 | 2 |

| 10 | 23 | Male | Music teacher, Teacher of education, therapeutics, hearing and language | 2 | 1 |

| 11 | 38 | Male | Music teacher | 5 | |

| 12 | 33 | Female | Teacher | 1 | 2 |

| 13 | 42 | Male | Music teacher | 1 | 2 |

| 14 | 42 | Male | Music teacher in secondary school | 2 | |

| 15 | 43 | Male | Music teacher | 1 | 2 |

| User | Type Flow | Diagnostic | Competence | Adaptability | Self-Esteem |

|---|---|---|---|---|---|

| 1 | Left | Hemiparesis | 1.25 | 2.00 | 0.88 |

| 2 | Right | Agenesis | 1.25 | 1.00 | 1.38 |

| 3 | Left | Agenesis | 1.17 | 1.67 | 0.75 |

| 4 | Left | OBPI | 0.50 | 0.83 | 0.50 |

| 5 | Left | OBPI | 0.58 | 0.17 | 0.75 |

| 6 | Left | OBPI | 1.08 | 0.67 | 0.88 |

| 7 | Right | Agenesis | 0.83 | 1.17 | 0.50 |

| 8 | Left | OBPI | 0.83 | 1.33 | 1.00 |

| 9 | Left | OBPI | 0.58 | 0.17 | 0.50 |

| 10 | Left | OBPI | 0.33 | 0.33 | 0.50 |

| 11 | Left | Agenesis | 0.92 | 0.83 | 0.38 |

| 12 | Right | Agenesis | 0.25 | 0.33 | 0.38 |

| 13 | Right | Hemiparesis | 0.83 | 0.50 | 0.63 |

| 14 | Left | Hemiparesis | 1.00 | 0.83 | 1.00 |

| 15 | Right | Hemiparesis | 0.75 | 1.00 | 0.50 |

| 16 | Right | Hemiparesis | 1.17 | 0.50 | 0.63 |

| 17 | Left | Agenesis | 1.33 | 0.50 | 0.50 |

| 18 | Right | Agenesis | 1.17 | 0.83 | 0.88 |

| 19 | Right | Agenesis | 1.58 | 2.00 | 1.00 |

| 20 | Right | OBPI | 1.58 | 1.00 | 1.00 |

| Mean (SD) | 0.95 (0.38) | 0.88 (0.54) | 0.73 (0.27) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Esclapés, J.; Gómez, A.; Ibañez, A. Flow. A Socially Responsible 3D Printed One-Handed Recorder. Int. J. Environ. Res. Public Health 2021, 18, 12200. https://doi.org/10.3390/ijerph182212200

Esclapés J, Gómez A, Ibañez A. Flow. A Socially Responsible 3D Printed One-Handed Recorder. International Journal of Environmental Research and Public Health. 2021; 18(22):12200. https://doi.org/10.3390/ijerph182212200

Chicago/Turabian StyleEsclapés, Javier, Almudena Gómez, and Ana Ibañez. 2021. "Flow. A Socially Responsible 3D Printed One-Handed Recorder" International Journal of Environmental Research and Public Health 18, no. 22: 12200. https://doi.org/10.3390/ijerph182212200

APA StyleEsclapés, J., Gómez, A., & Ibañez, A. (2021). Flow. A Socially Responsible 3D Printed One-Handed Recorder. International Journal of Environmental Research and Public Health, 18(22), 12200. https://doi.org/10.3390/ijerph182212200