Numerical Analysis on the Thermal Performance in an Excavating Roadway with Auxiliary Ventilation System

Abstract

1. Introduction

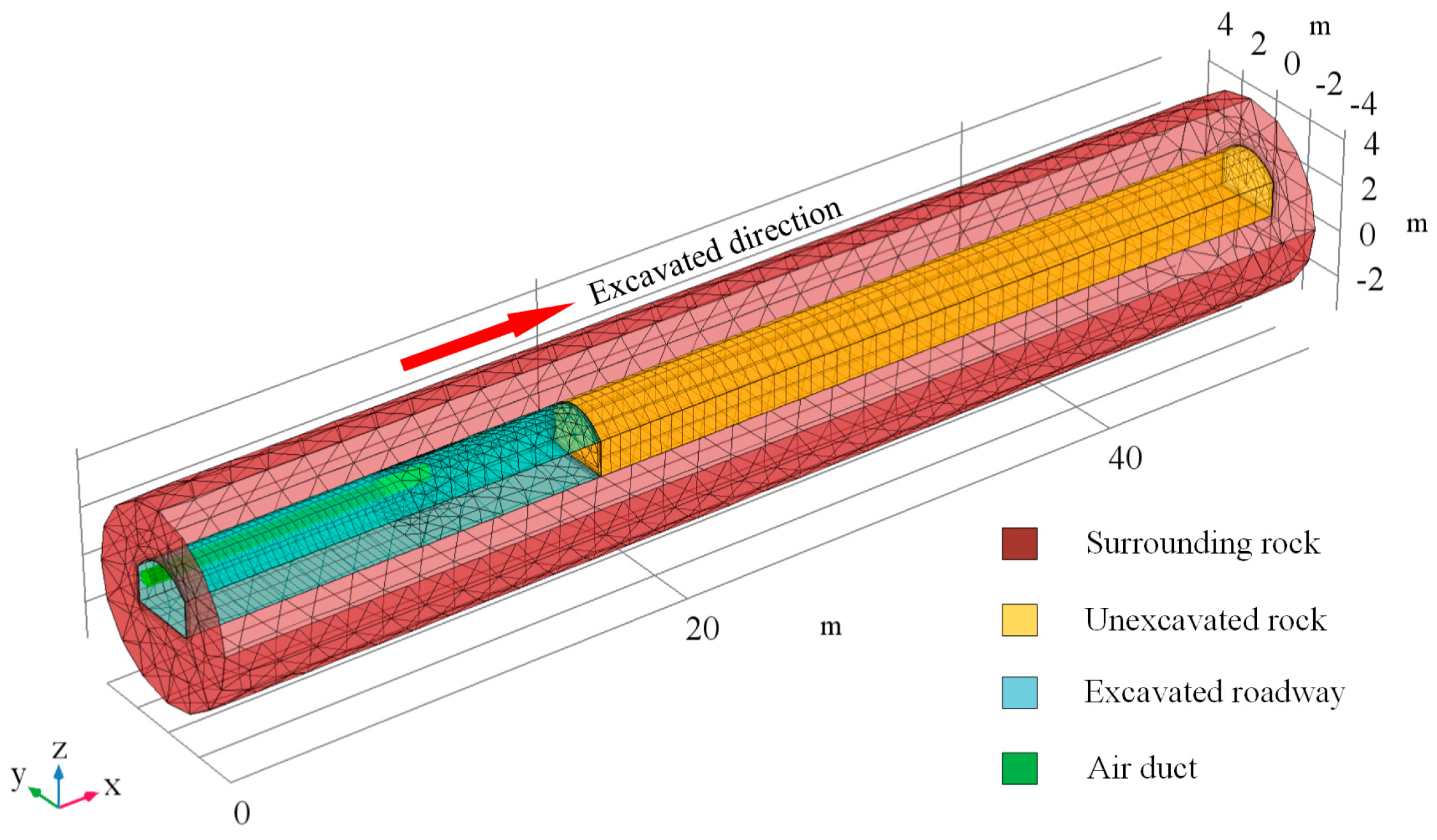

2. Numerical Methods

3. Numerical Results

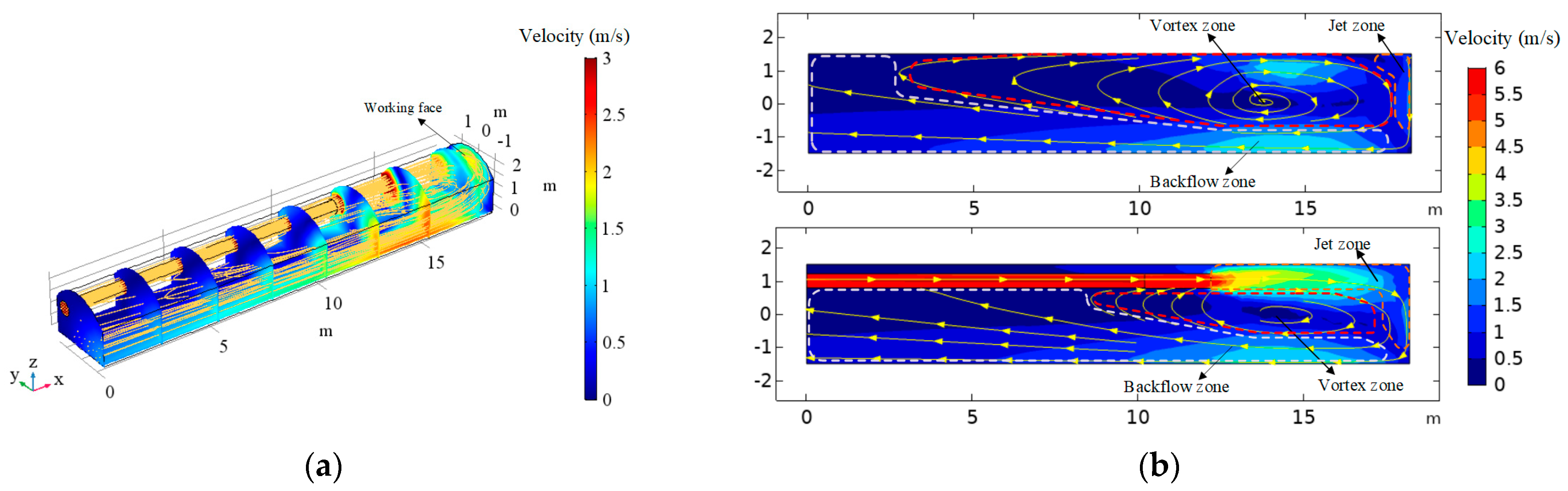

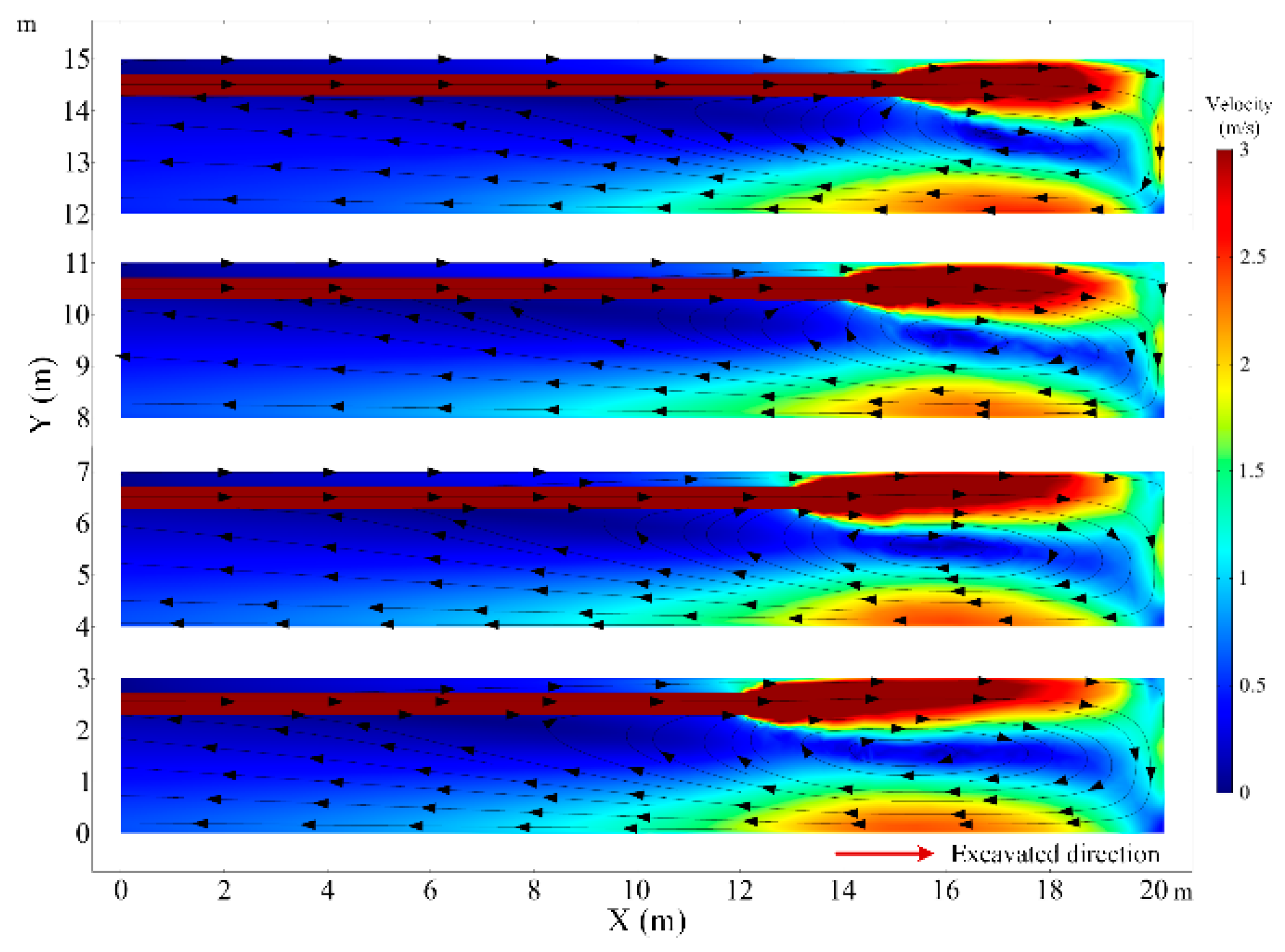

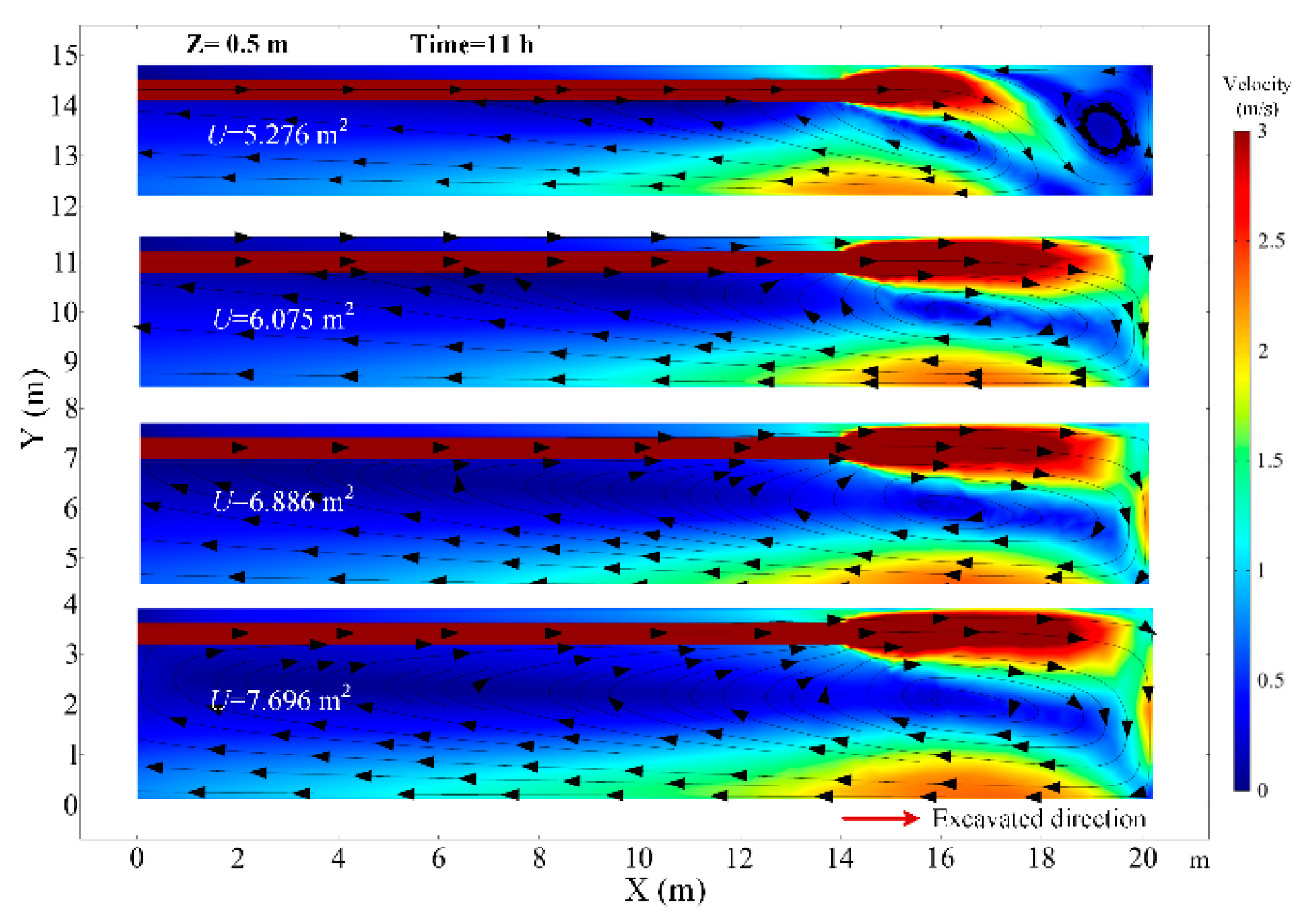

3.1. Numerical Simulation of the Airflow Field

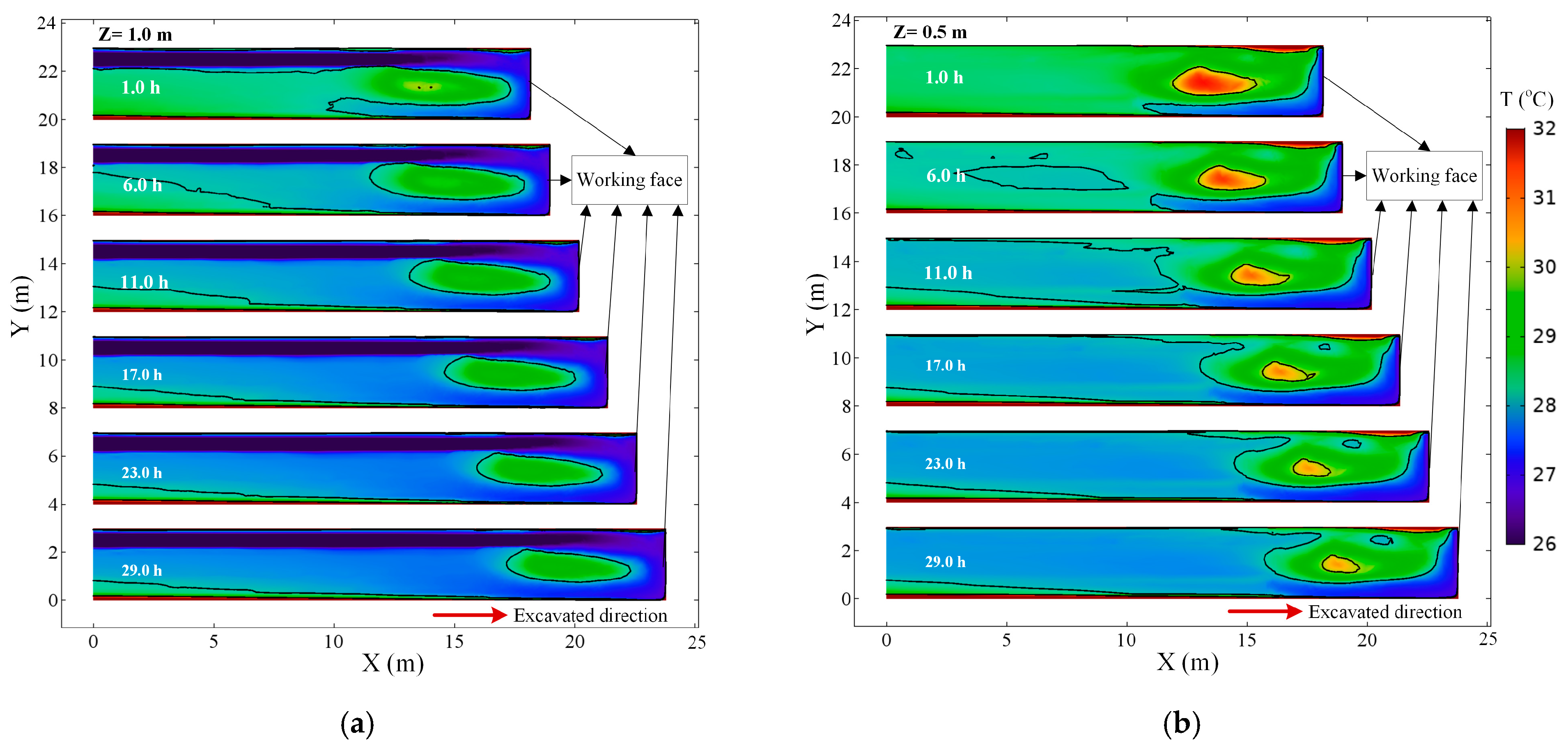

3.2. Numerical Simulation of the Temperature Field

4. Sensitivity Analysis for Single Factor

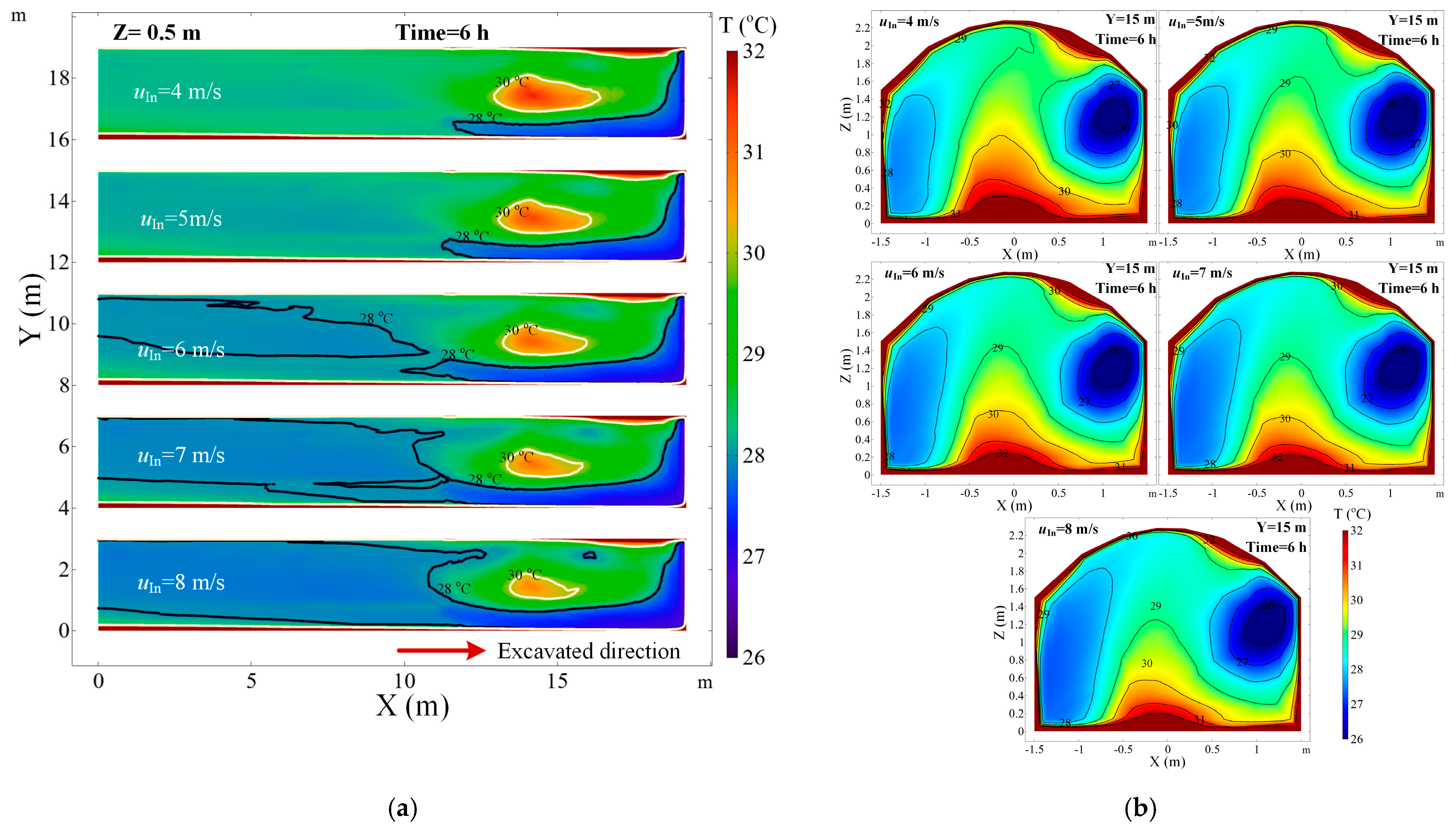

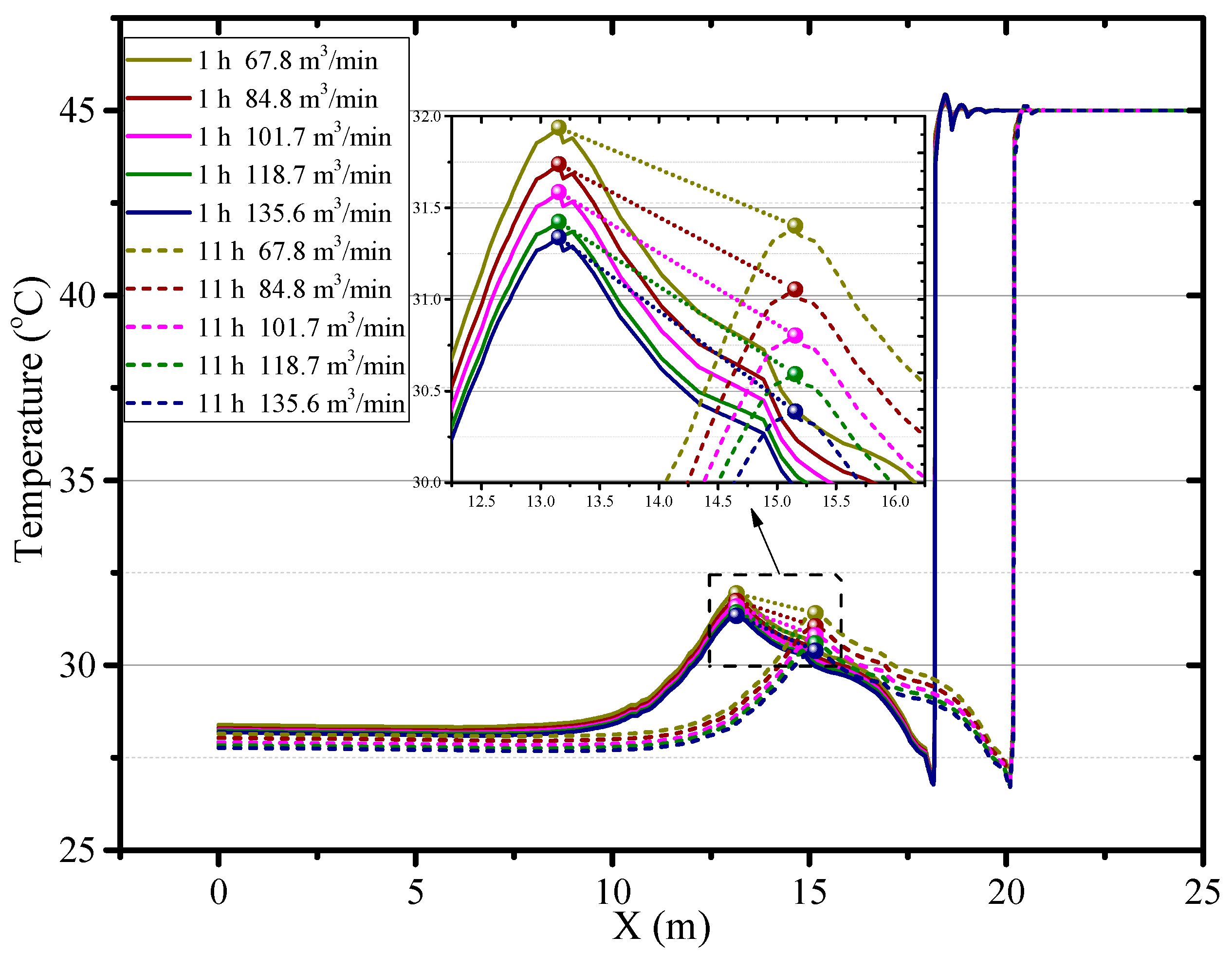

4.1. The Effect of Ventilation Volume

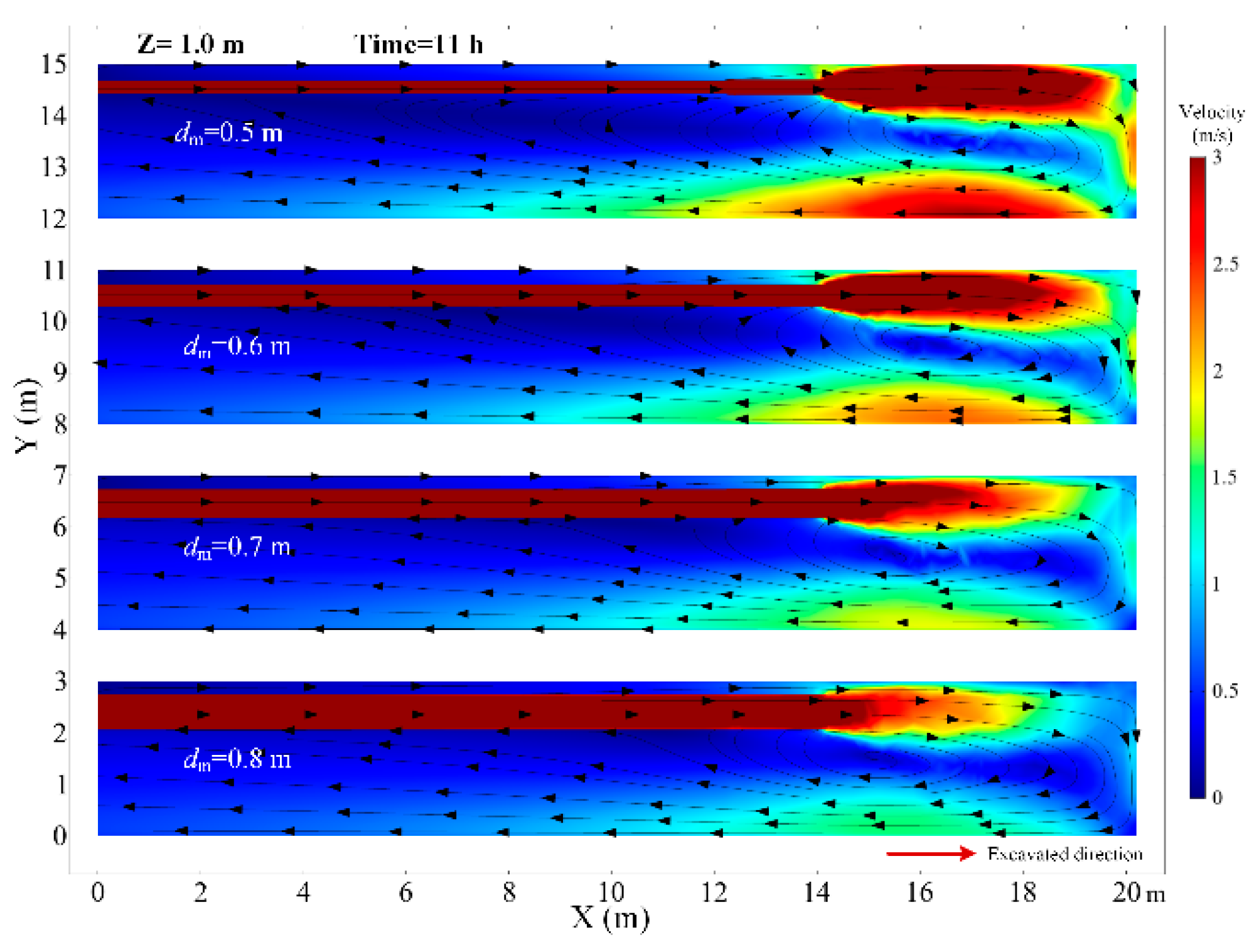

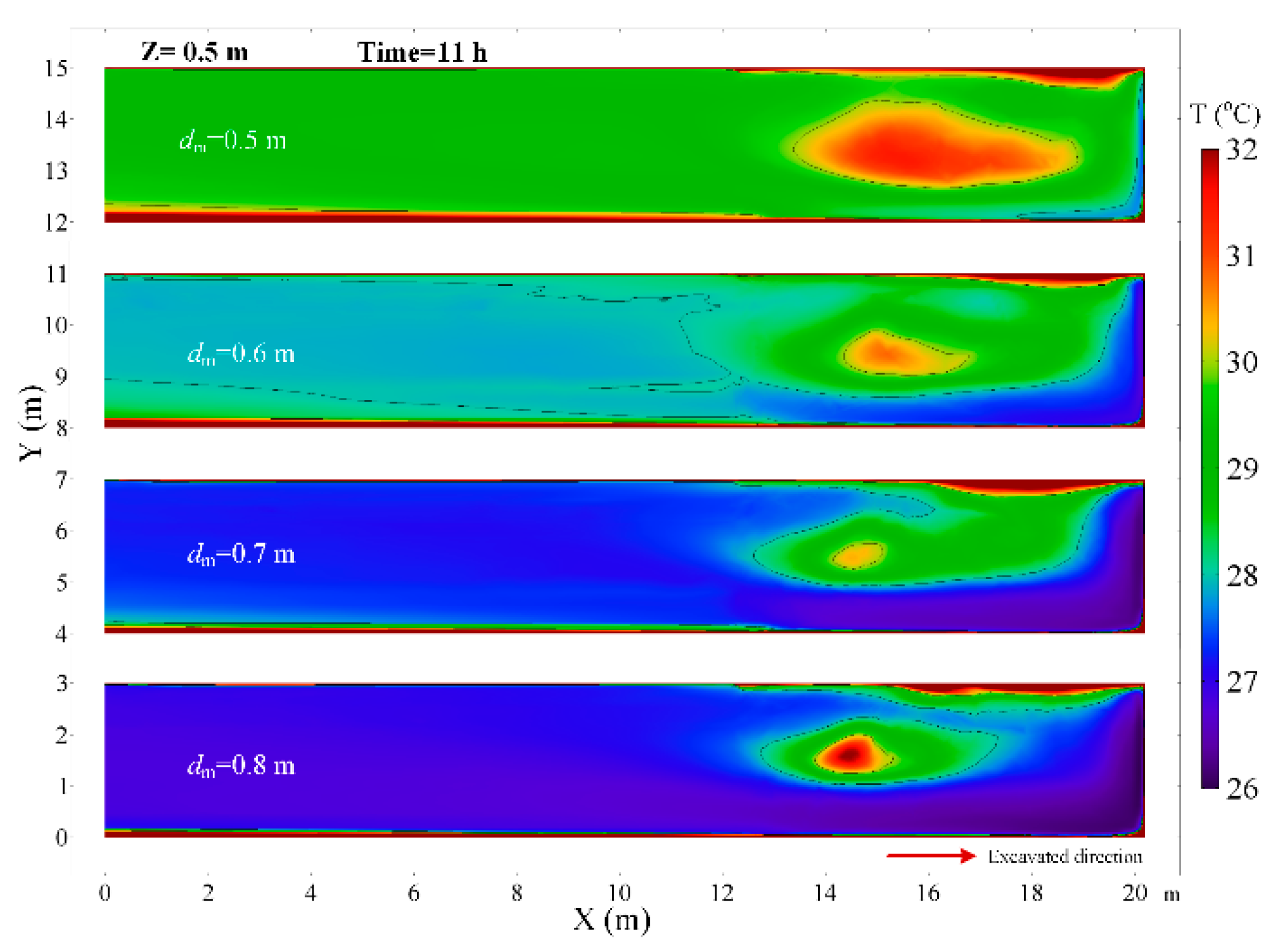

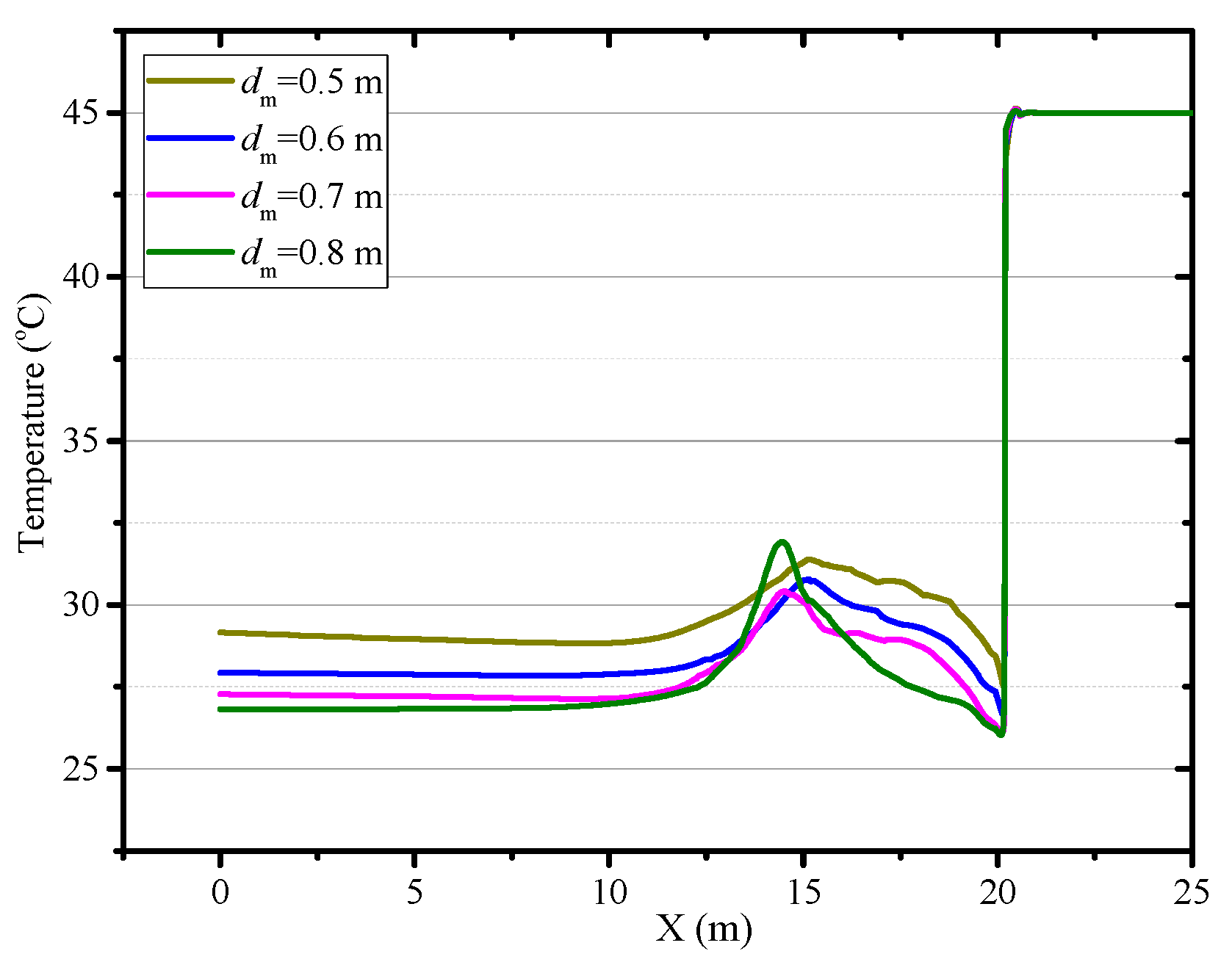

4.2. The Effects of the Diameter of Air Duct

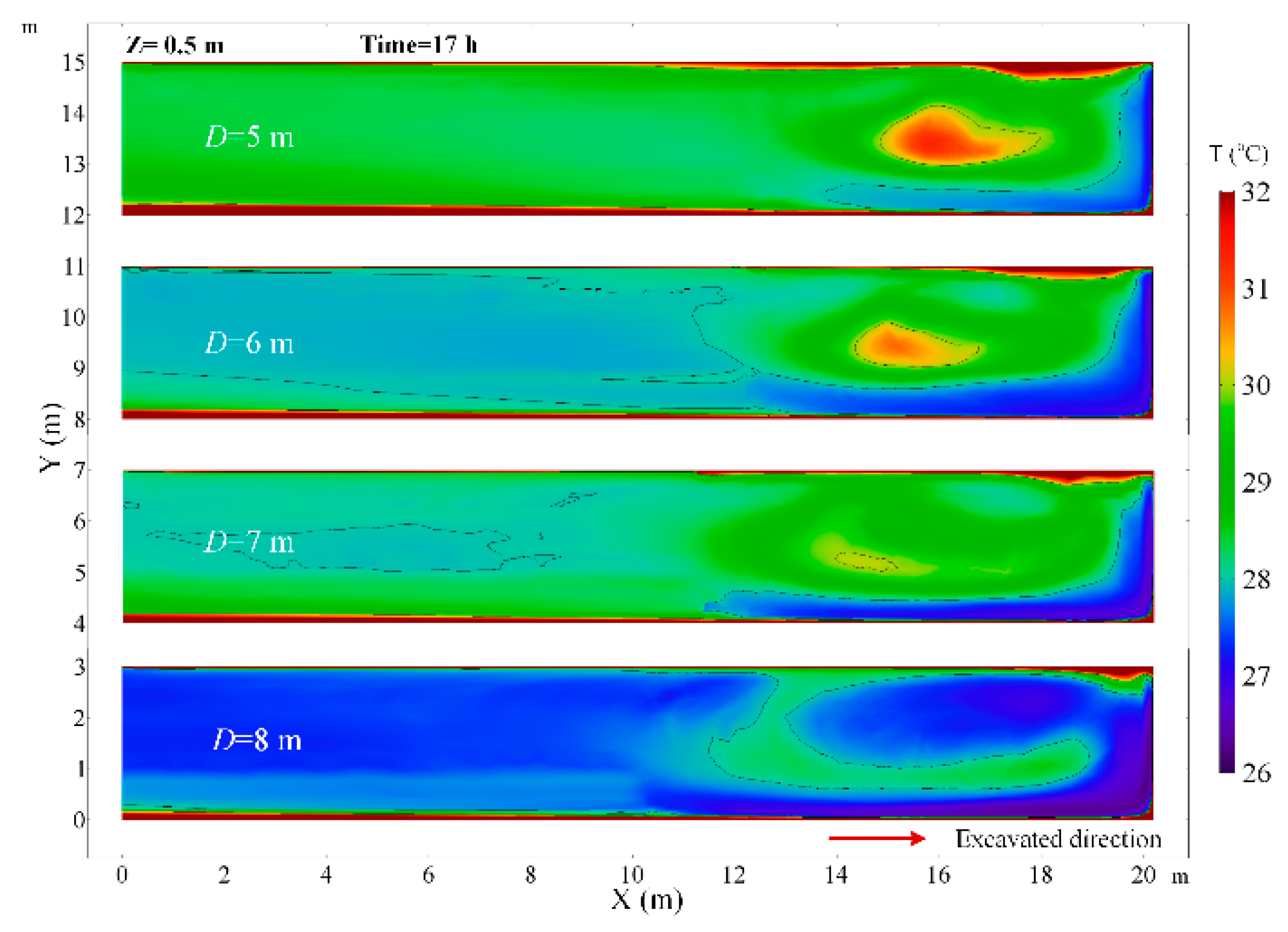

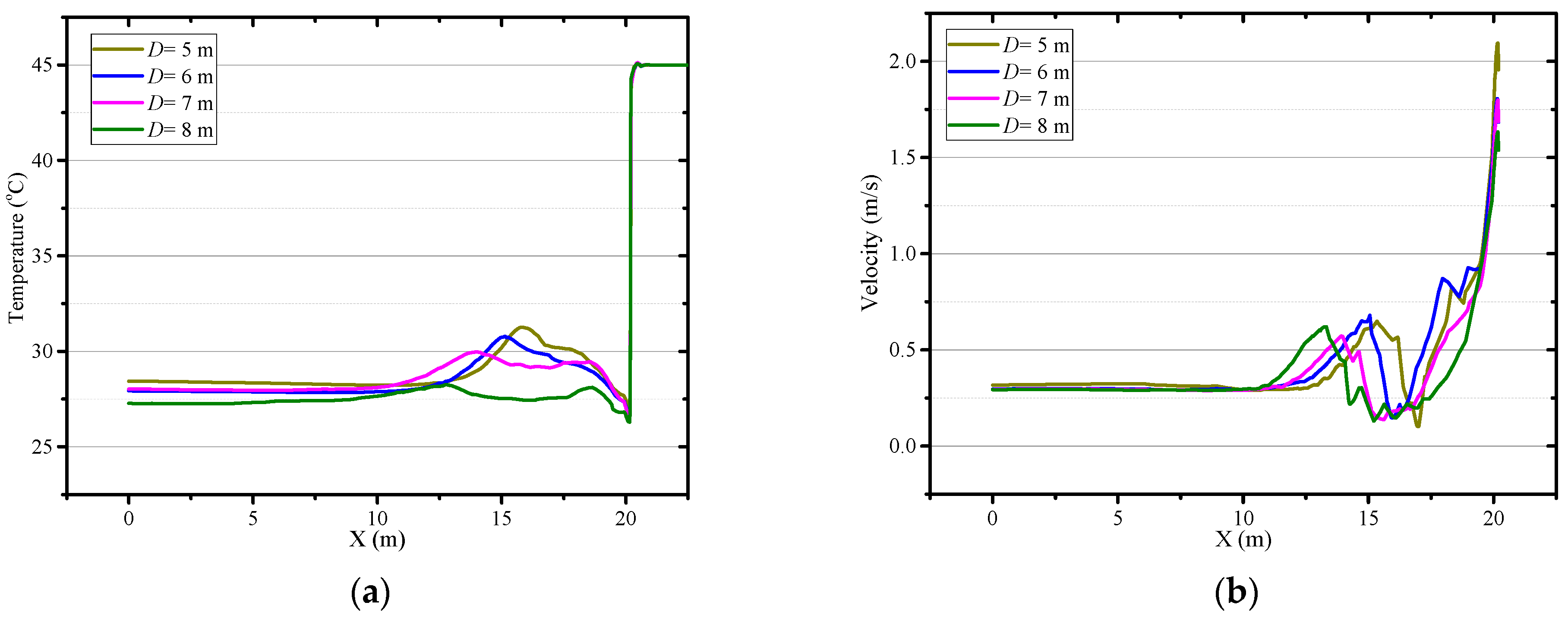

4.3. The Effect of the Distance between Duct Outlet and Working Face

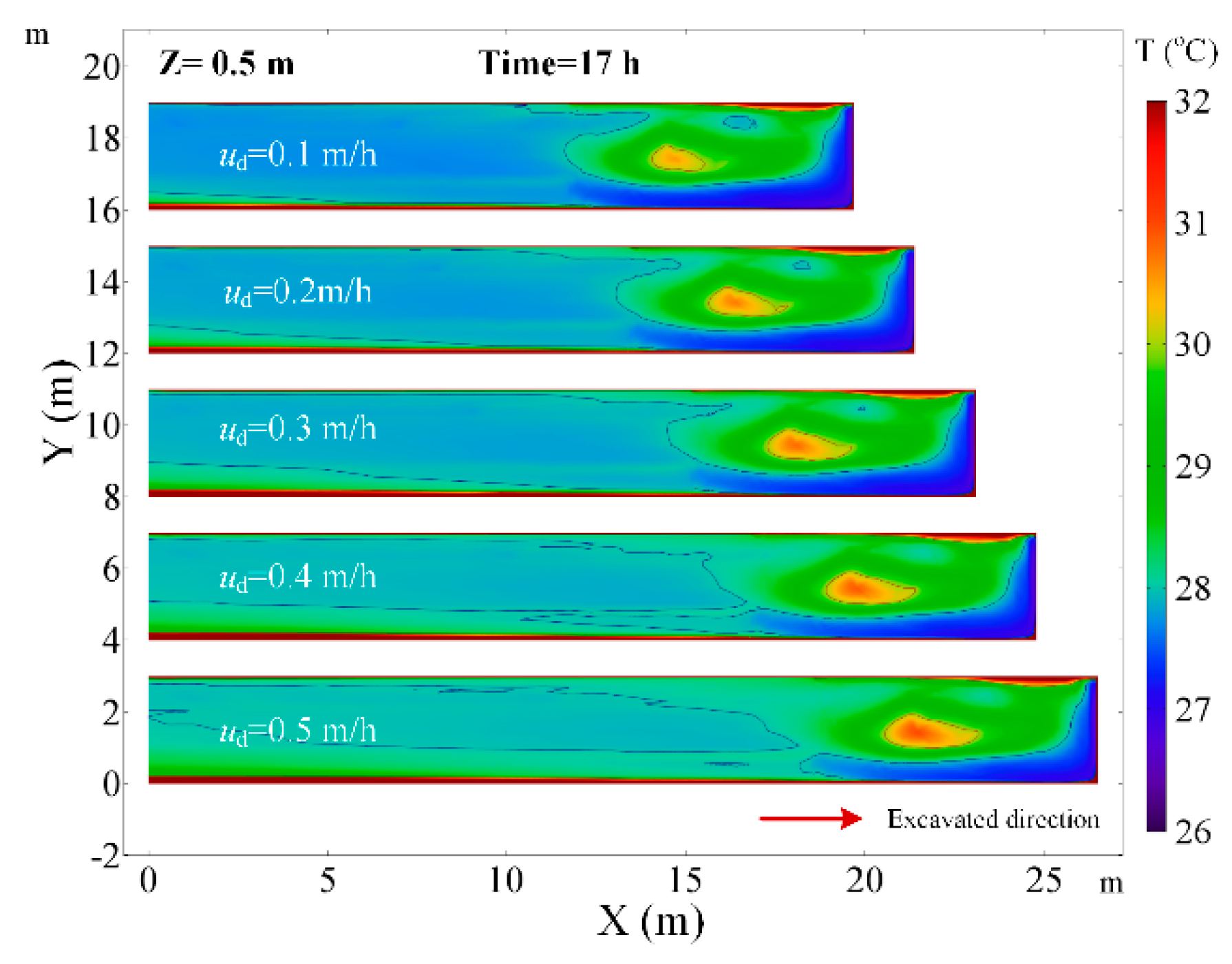

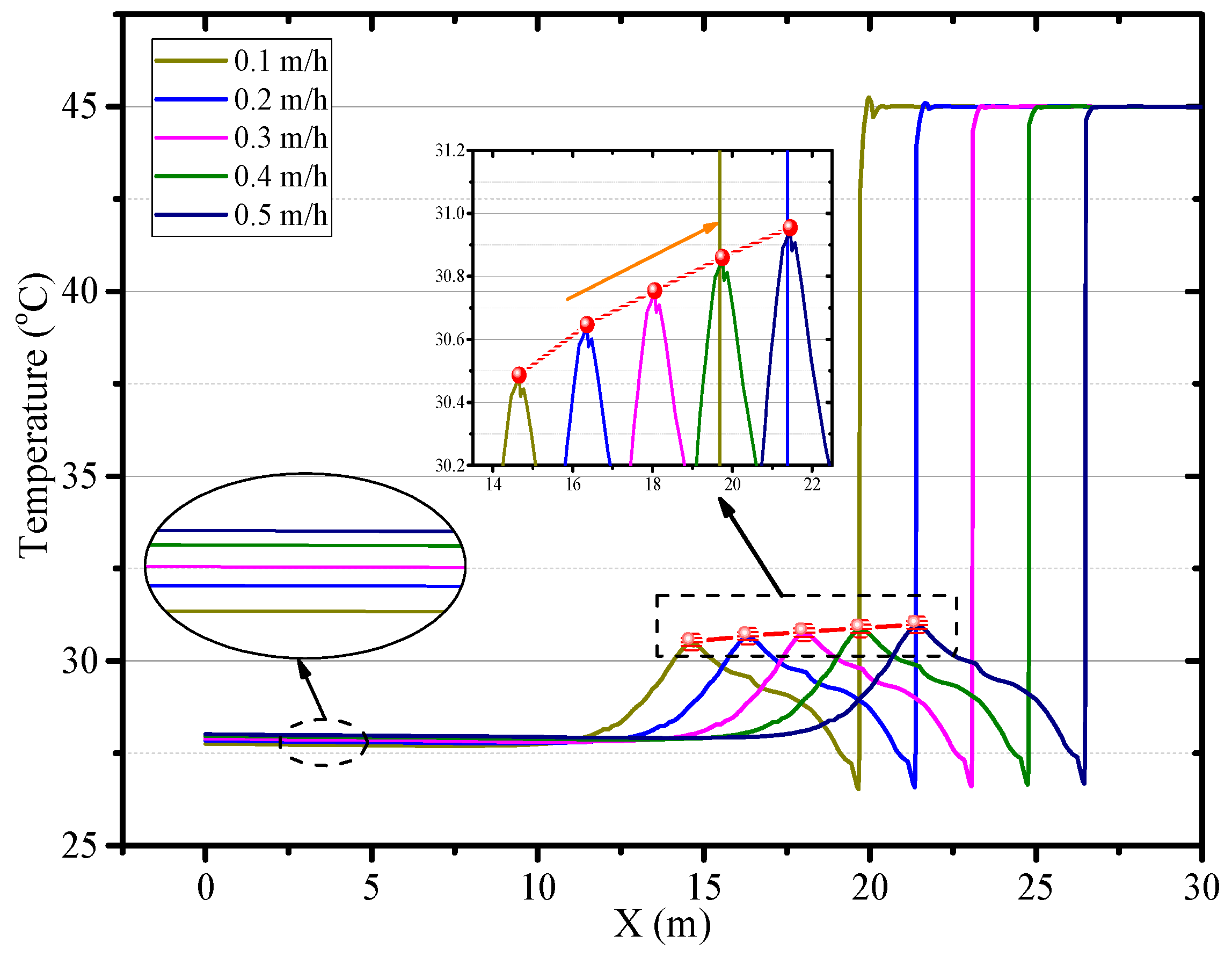

4.4. The Effects of the Advance Rate of the Working Face

4.5. The Effects of the Roadway Section Size

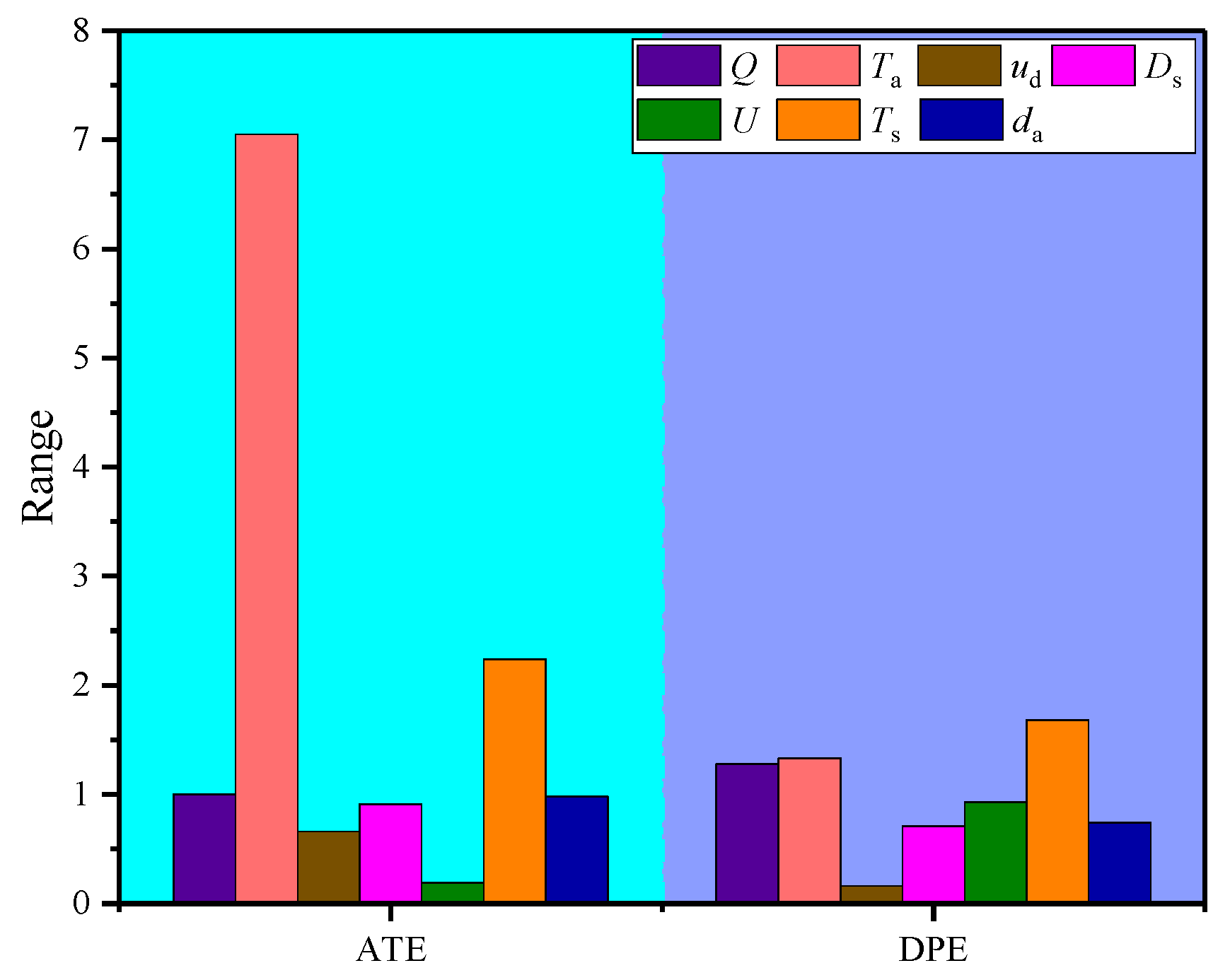

5. Orthogonal Test

6. Conclusions

- (1)

- The airflow field is distinguished into three parts: Jet zone, Backflow zone, and Vortex zone. The triangular swirling vortex exists in the middle of the roadway and 4–5 m away from the working face where the heat is easily accumulated and the air temperature is high.

- (2)

- Under the condition of continuous ventilation and excavation of roadway, the air temperature in the roadway decreases first and then go stabilized. The local high-temperature zone in the roadway moves forward with the advance of the working face.

- (3)

- Increasing the ventilation volume can promote the thermal environment in the roadway, but there is a limit to adjust air temperature. Reducing the diameter of air duct or distance between the duct outlet and the working face will increase the airflow velocity near the working face and enhance the convective heat in the working face, which leads to an increase in air temperature in the roadway.

- (4)

- The temperature of surrounding rock, the initial temperature of ventilation airflow and ventilation volume have a significant influence on the air temperature and local heat accumulation in the roadway, and decreasing the initial temperature of ventilation airflow and the temperature of surrounding rock is the key to control the heat hazard in an excavating roadway. The priority of control measures for heat hazard can be determined by referring to the sensitivity degree of factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ranjith, P.G.; Zhao, J.; Ju, M.; De Silva, R.V.; Rathnaweera, T.D.; Bandara, A.K. Opportunities and challenges in deep mining: A brief review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Xie, H. Research framework and anticipated results of deep rock mechanics and mining theory. Adv. Eng. Sci. 2017, 49, 1–6. [Google Scholar]

- Yang, S.; Lang, X.; Wang, Y.; Wen, Y.; Fan, S. Numerical simulation of Class 3 hydrate reservoirs exploiting using horizontal well by depressurization and thermal co-stimulation. Energy Convers. Manag. 2014, 77, 298–305. [Google Scholar] [CrossRef]

- Hao, X.; Guo, C.; Lin, Y.; Wang, H.; Liu, H. Analysis of heat stress and the indoor climate control requirements for movable refuge chambers. Int. J. Environ. Res. Public Health 2016, 13, 518. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Fu, H. Development of an efficient cooling strategy in the heading face of underground mines. Energies 2020, 13, 1116. [Google Scholar] [CrossRef]

- Zhai, X.; Xu, Y.; Yu, Z. Numerical analysis on the evolution of CO concentration in return corner: A case study of steady U-type ventilation working face. Numer. Heat Transf. Part. A Appl. 2018, 74, 1732–1746. [Google Scholar] [CrossRef]

- Wagoner, R.; López-Gálvez, N.; De Zapien, J.; Griffin, S.C.; Canales, R.A.; Beamer, P.I. An occupational heat stress and hydration assessment of agricultural workers in North Mexico. Indoor Built Environ. 2020, 17, 2102. [Google Scholar] [CrossRef]

- Zeng, Y.; Tao, L.; Ye, X.; Zhou, X.; Fang, Y.; Fan, L.; Liu, X.; Yang, Z. Temperature reduction for extra-long railway tunnel with high geotemperature by longitudinal ventilation. Tunn. Undergr. Space Technol. 2020, 99, 103381. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Liu, H.; Lin, L. Unsteady model and numerical calculation on airflow temperature distribution in roadway with heat source. J. Saf. Sci. Techn. 2018, 14, 93–98. [Google Scholar]

- Li, Z.; Li, R.; Xu, Y.; Xu, Y. Study on the oxygen enrichment effect of individual oxygen-supply device in a tunnel of plateau mine. Int. J. Environ. Res. Public Health 2020, 17, 5934. [Google Scholar] [CrossRef]

- Parra, M.; Villafruela, J.; Castro, F.; Méndez, C. Numerical and experimental analysis of different ventilation systems in deep mines. Build. Environ. 2006, 41, 87–93. [Google Scholar] [CrossRef]

- Hasheminasab, F.; Bagherpour, R.; Aminossadati, S.M. Numerical simulation of methane distribution in development zones of underground coal mines equipped with auxiliary ventilation. Tunn. Undergr. Space Technol. 2019, 89, 68–77. [Google Scholar] [CrossRef]

- Chang, X.; Chai, J.; Luo, J.; Qin, Y.; Xu, Z.; Cao, J. Tunnel ventilation during construction and diffusion of hazardous gases studied by numerical simulations. Build. Environ. 2020, 177, 106902. [Google Scholar] [CrossRef]

- Huang, R.; Shen, X.; Wang, B.; Liao, X. Migration characteristics of CO under forced ventilation after excavation roadway blasting: A case study in a plateau mine. J. Clean. Prod. 2020, 267, 122094. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Z.; Zhou, Z.-Y.; Chen, H. Numerical simulation of TBM construction ventilation in a long diversion tunnel. Tunn. Undergr. Space Technol. 2011, 26, 560–572. [Google Scholar] [CrossRef]

- Zhang, G.; Li, L.; Ji, H.; Xiao, K.; Yin, G.; Li, S. In situ investigation of gaseous pollution in the ramp of an underground gold mine. Indoor Built Environ. 2013, 23, 293–298. [Google Scholar] [CrossRef]

- Guo, L.; Nie, W.; Yin, S.; Liu, Q.; Hua, Y.; Cheng, L.; Cai, X.; Xiu, Z.; Du, T. The dust diffusion modeling and determination of optimal airflow rate for removing the dust generated during mine tunneling. Build. Environ. 2020, 178, 106846. [Google Scholar] [CrossRef]

- Liu, X.; Nie, W.; Zhou, W.; Liu, C.; Liu, Q.; Wei, C. The optimization of a dust suppression and clean production scheme in a TBM-constructed tunnel based on an orthogonal experiment. Process. Saf. Environ. Prot. 2020, 136, 353–370. [Google Scholar] [CrossRef]

- Tan, X.; Chen, W.; Yang, D.; Dai, Y.; Wu, G.; Yang, J.; Yu, H.; Tian, H.M.; Zhao, W. Study on the influence of airflow on the temperature of the surrounding rock in a cold region tunnel and its application to insulation layer design. Appl. Therm. Eng. 2014, 67, 320–334. [Google Scholar] [CrossRef]

- Huang, R.; Shen, X.; Wu, E.; Li, Z. Study on the influence law of ventilation conditions on heat loss in a roadway of high altitude mine. Numer. Heat Transf. Part. A Appl. 2019, 77, 69–79. [Google Scholar] [CrossRef]

- Peltier, M.; Laloui, L.; Lepage, L.; Garin, E.; Laloui, L. Numerical investigation of the convection heat transfer driven by airflows in underground tunnels. Appl. Therm. Eng. 2019, 159, 113844. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X. Response-surface-model based on influencing factor analysis of subway tunnel temperature. Build. Environ. 2019, 160, 1041–1049. [Google Scholar] [CrossRef]

- He, X.; Li, A.; Ning, Y. Optimization of outdoor design temperature for summer ventilation for undersea road tunnel using field measurement and statistics. Build. Environ. 2020, 167, 106457. [Google Scholar] [CrossRef]

- Toraño, J.; Torno, S.; Menendez, M.; Gent, M.R.; Velasco, J. Models of methane behaviour in auxiliary ventilation of underground coal mining. Int. J. Coal Geol. 2009, 80, 35–43. [Google Scholar] [CrossRef]

- Wei, D.; Du, C.; Xu, H.; Zhang, L. Influencing factors and correlation analysis of ventilation and cooling in deep excavation roadway. Case Stud. Therm. Eng. 2019, 14, 100483. [Google Scholar]

- Schafrik, S.; Millar, D. Verification of a CFD code use for air flow simulations of fractured and broken rock. Appl. Therm. Eng. 2015, 90, 1131–1143. [Google Scholar] [CrossRef]

- Chen, W.; Liang, S.; Liu, J. Proposed split-type vapor compression refrigerator for heat hazard control in deep mines. Appl. Therm. Eng. 2016, 105, 425–435. [Google Scholar] [CrossRef]

- Guo, P.; He, M.; Zheng, L.; Zhang, N. A geothermal recycling system for cooling and heating in deep mines. Appl. Therm. Eng. 2017, 116, 833–839. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, Y.; Li, K.; Zou, S. Computational evaluation of cooling system under deep hot and humid coal mine in China: A thermal comfort study. Tunn. Undergr. Sp. Tech. 2019, 90, 394–403. [Google Scholar]

- Zhai, X.; Xu, Y.; Yu, Z. Design and performance simulation of a novel liquid CO2 cycle refrigeration system for heat hazard control in coal mines. J. Therm. Sci. 2019, 28, 585–595. [Google Scholar] [CrossRef]

- Chatterjee, A.; Zhang, L.; Xia, X. Optimization of mine ventilation fan speeds according to ventilation on demand and time of use tariff. Appl. Energy 2015, 146, 65–73. [Google Scholar] [CrossRef]

- Du, C.; Bian, M. Numerical simulation of fluid solid coupling heat transfer in tunnel. Case Stud. Therm. Eng. 2018, 12, 117–125. [Google Scholar]

- Zhang, Y.; Wan, Z.-J.; Gu, B.; Zhou, C.-B.; Cheng, J.-Y. Unsteady temperature field of surrounding rock mass in high geothermal roadway during mechanical ventilation. J. Cent. South Univ. 2017, 24, 374–381. [Google Scholar] [CrossRef]

- Wang, F.; Luo, F.; Xu, H.; Wang, Y. Calculation method of air temperature in tunneling section of open-type TBM construction. China Railw. Sci. 2019, 40, 64–70. [Google Scholar]

- Wang, X.; Wang, Z.; Deng, X.; Sun, B.; Zhao, Y.; Fu, W. Coupled thermal model of wellbore and permafrost in Arctic regions. Appl. Therm. Eng. 2017, 123, 1291–1299. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Cheng, Z.; Sun, R.; Zhang, A. Simulation of construction ventilation in deep diversion tunnels using Euler–Lagrange method. Comput. Fluids 2014, 105, 28–38. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, H.; Guo, K.; Xue, P.; Wang, J.; Wu, J. Simulation of finite volume method and experimental analysis for temperature field of roadway surrouding rock. J. China Coal Soc. 2017, 42, 3166–3175. [Google Scholar]

- Habibi, A.; Kramer, R.; Gillies, A. Investigating the effects of heat changes in an underground mine. Appl. Therm. Eng. 2015, 90, 1164–1171. [Google Scholar] [CrossRef]

- Ji, J.; Liao, Q.; Hu, Q.; Chu, Z.; Zhang, X. Characteristics of jet flow heat transfer in heading face. J. China Coal Soc. 2013, 38, 554–560. [Google Scholar]

- Zhang, Z.; Wu, H.; Wang, K.; Day, R.; Yuan, Y. Thermal performance of a mine refuge chamber with human body heat sources under ventilation. Appl. Therm. Eng. 2019, 162, 114243. [Google Scholar] [CrossRef]

- Park, D.W.; Lee, S.B. The sensitivity of ship resistance to wall-adjacent grids and near-wall treatments. Int. J. Nav. Arch. Ocean. Eng. 2018, 10, 683–691. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Liu, H.; Zhai, X.; Li, R.; Song, P.; Jia, M. A model for assessing the compound risk represented by spontaneous coal combustion and methane emission in a gob. J. Clean. Prod. 2020, 273, 122925. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Zhang, Y.; Han, F.; Ji, C.; Zhang, J. Study on coupled heat transfer and seepage in large sparsely fractured surrounding rocks in deep underground spaces. Appl. Therm. Eng. 2019, 162, 114277. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Density of rock, ρs (kg·m−3) | 2600 |

| Specific heat capacity of rock, Cps (J·(kg·K)−1) | 1300 |

| Heat conduction coefficient of rock, Kps (W·(m·K)−1) | 3.5 |

| Density of gas, ρg (kg·m−3) | 1.213 |

| Gas dynamic viscosity, μg (Pa·s) | 1.84 × 10−5 |

| Heat conduction coefficient of gas, Kpg (W·(m·K)−1) | 0.259 |

| Specific heat capacity of gas, Cpg (J·(kg·K)−1) | 1012 |

| The working face advance rate, Ra (m/h) | 0.2 |

| The diameter of air duct, da (m) | 0.6 |

| The distance between duct outlet and working face, Ds (m) | 6 |

| The initial rock temperature, Tr (°C) | 45 |

| The initial temperature of ventilation airflow, Ta (°C) | 25 |

| Test Number | Factors | ||||||

|---|---|---|---|---|---|---|---|

| Ventilation Volume Q (m3/min) | Initial Temperature of Ventilation Airflow Ta (°C) | Advance Rate ud (m/h) | Distance between Duct Outlet and Working Face Ds (m) | Roadway Section Size U (m2) | Temperature of Surrounding Rock Ts (°C) | Diameter of Air Duct da (m) | |

| 1 | 1 (85) | 1 (20) | 1 (0.15) | 1 (6) | 1 (6.075) | 1 (40) | 1 (0.25) |

| 2 | 1 (85) | 2 (25) | 2 (0.2) | 2 (7) | 2 (6.886) | 2 (45) | 2 (0.30) |

| 3 | 1 (85) | 3 (30) | 3 (0.25) | 3 (8) | 3 (7.696) | 3 (50) | 3 (0.35) |

| 4 | 2 (102) | 1 (20) | 1 (0.15) | 2 (7) | 2 (6.886) | 3 (50) | 3 (0.35) |

| 5 | 2 (102) | 2 (25) | 2 (0.2) | 3 (8) | 3 (7.696) | 1 (40) | 1 (0.25) |

| 6 | 2 (102) | 3 (30) | 3 (0.25) | 1 (6) | 1(6.075) | 2 (45) | 2 (0.30) |

| 7 | 3 (119) | 1 (20) | 2 (0.2) | 1 (6) | 3 (7.696) | 2 (45) | 3 (0.35) |

| 8 | 3 (119) | 2 (25) | 3 (0.25) | 2 (7) | 1(6.075) | 3 (50) | 1 (0.25) |

| 9 | 3 (119) | 3 (30) | 1 (0.15) | 3 (8) | 2 (6.886) | 1 (40) | 2 (0.30) |

| 10 | 1 (85) | 1 (20) | 3 (0.25) | 3 (8) | 2 (6.886) | 2 (45) | 1 (0.25) |

| 11 | 1 (85) | 2 (25) | 1 (0.15) | 1 (6) | 3(7.696) | 3 (50) | 2 (0.30) |

| 12 | 1 (85) | 3 (30) | 2 (0.2) | 2 (7) | 1(6.075) | 1 (40) | 3 (0.35) |

| 13 | 2 (102) | 1 (20) | 2 (0.2) | 3 (8) | 1 (6.075) | 3 (50) | 2 (0.30) |

| 14 | 2 (102) | 2 (25) | 3 (0.25) | 1 (6) | 2 (6.886) | 1 (40) | 3 (0.35) |

| 15 | 2 (102) | 3 (30) | 1 (0.15) | 2 (7) | 3 (7.696) | 2 (45) | 1 (0.25) |

| 16 | 3 (119) | 1 (20) | 3 (0.25) | 2 (7) | 3(7.696) | 1 (40) | 2 (0.30) |

| 17 | 3 (119) | 2 (25) | 1 (0.15) | 3 (8) | 1(6.075) | 2 (45) | 3 (0.35) |

| 18 | 3 (119) | 3 (30) | 2 (0.2) | 1 (6) | 2 (6.886) | 3 (50) | 1 (0.25) |

| Factors | Ventilation Volume | Initial Temperature of Ventilation Airflow | Advance Rate | Distance between Duct Outlet and Working Face | Roadway Section Size | Temperature of Surrounding Rock | Diameter of Air Duct | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Index | ATE | DPE | ATE | DPE | ATE | DPE | ATE | DPE | ATE | DPE | ATE | DPE | ATE | DPE |

| Level 1 | 30.78 | 2.18 | 26.65 | 3.10 | 30.01 | 2.38 | 30.83 | 1.87 | 30.25 | 2.73 | 29.40 | 1.60 | 30.69 | 1.88 |

| Level 2 | 29.78 | 3.00 | 30.65 | 2.03 | 30.67 | 2.30 | 29.92 | 2.45 | 30.30 | 2.37 | 29.95 | 2.02 | 30.58 | 2.40 |

| Level 3 | 30.43 | 1.72 | 33.70 | 1.77 | 30.31 | 2.22 | 30.25 | 2.58 | 30.44 | 1.80 | 31.64 | 3.28 | 29.71 | 2.62 |

| Range | 1.00 | 1.28 | 7.05 | 1.33 | 0.66 | 0.16 | 0.91 | 0.71 | 0.19 | 0.93 | 2.24 | 1.68 | 0.98 | 0.74 |

| Rank | 3 | 3 | 1 | 2 | 6 | 7 | 5 | 6 | 7 | 4 | 2 | 1 | 4 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Liu, H.; Xu, Y.; Li, R.; Jia, M.; Zhang, M. Numerical Analysis on the Thermal Performance in an Excavating Roadway with Auxiliary Ventilation System. Int. J. Environ. Res. Public Health 2021, 18, 1184. https://doi.org/10.3390/ijerph18031184

Li Z, Liu H, Xu Y, Li R, Jia M, Zhang M. Numerical Analysis on the Thermal Performance in an Excavating Roadway with Auxiliary Ventilation System. International Journal of Environmental Research and Public Health. 2021; 18(3):1184. https://doi.org/10.3390/ijerph18031184

Chicago/Turabian StyleLi, Zijun, Huasen Liu, Yu Xu, Rongrong Li, Mintao Jia, and Mengsheng Zhang. 2021. "Numerical Analysis on the Thermal Performance in an Excavating Roadway with Auxiliary Ventilation System" International Journal of Environmental Research and Public Health 18, no. 3: 1184. https://doi.org/10.3390/ijerph18031184

APA StyleLi, Z., Liu, H., Xu, Y., Li, R., Jia, M., & Zhang, M. (2021). Numerical Analysis on the Thermal Performance in an Excavating Roadway with Auxiliary Ventilation System. International Journal of Environmental Research and Public Health, 18(3), 1184. https://doi.org/10.3390/ijerph18031184