1. Introduction

The high level of competition in the global market has compelled companies to implement new technologies, change organizational structure, and introduce novel workplace improvement programs. For example, ergonomics programs with a strong focus on preventing work-related injuries and human error accidents have been employed in various industries [

1,

2]. Ergonomics is a system-oriented approach focused on both human interactions with work and the design of work processes. Generally, organizations implement ergonomic programs to reduce injury costs, decrease waste, and reduce the rate of absenteeism. Ergonomic programs can also increase employee motivation and productivity while improving the quality of the products and services [

3,

4,

5,

6]. Measurements of an organizations ergonomics climate are utilized to quantify the value that an organization places on integrating ergonomics principles to maximize operational performance and well-being outcomes [

7]. This measure was first introduced in a study by Hoffmeister et al. [

7] at a large manufacturing facility in the United States.

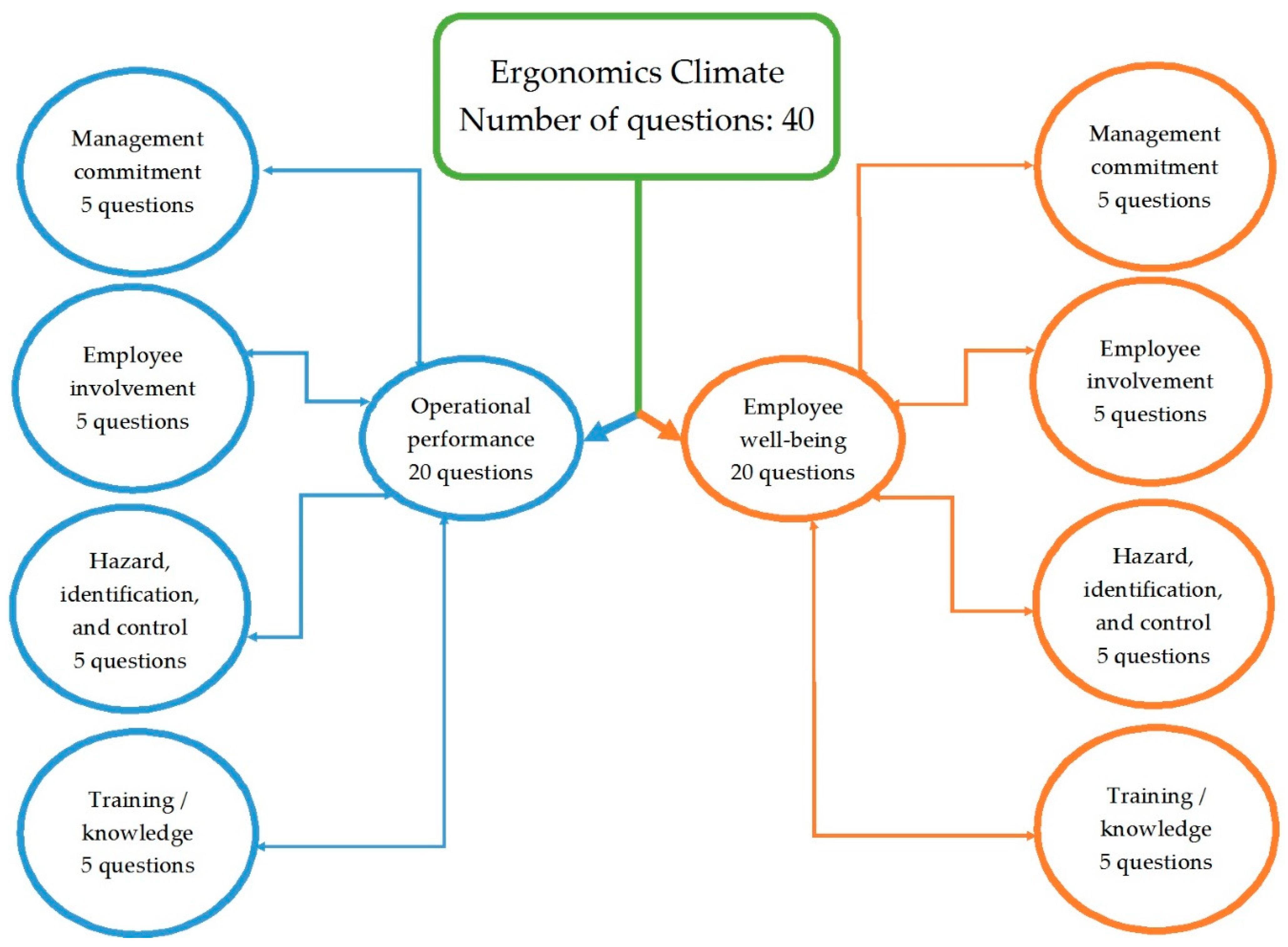

Ergonomics climate was defined as “employee perceptions of the extent to which the organization emphasizes and supports the design and modification of work such that both operational performance and employee well-being are maximized” [

7,

8]. Climate reflects the employees’ perception and knowledge of the organization’s field of activities and represents the atmosphere and space in which the employees work [

9,

10]. In the definition of ergonomics climate, operational performance refers to the economic aspects of an organization’s functions. These include productivity, efficiency, quality, sustainability, competitive advantage, and the ability to perform the organization’s task to stay successful [

11]. Operational performance is a broad concept that shows the state or quality of performance for different activities and their associated outcomes [

12]. Managers often consider these activities a high priority because they directly impact their organization’s productivity and effectiveness [

13,

14]. As an organization’s human resources, employees play a significant role in improving productivity and effectiveness, which can promote overall organizational performance [

15]. Employee well-being refers to the organization’s focus on maintaining a high level of health and safety in the workforce. Some of the variables considered in employee well-being include injury and illness rates, job satisfaction, stress, absenteeism, and work-life balance [

16,

17,

18].

According to the definition of ergonomics climate, the workplace’s design and modification can improve employee well-being while improving operational performance [

8]. This approach has long been considered one of the most comprehensive methods for improving the work environment [

19,

20].

Organizations should strive for a climate that supports both operational performance and employee well-being to maximize their overall success as a company. Organizations that value performance improvement more than health and safety report higher work-related musculoskeletal pain levels among their workforce [

21]. Organizations that value employee well-being more than performance may still report higher levels of work-related pain among their employees because of a decline in productivity, increasing pressure to compensate for this lack of productivity in the future. Organizations that equally value performance and employee well-being and act by a system-oriented approach can expect the highest amount of growth and success [

7,

22]. Although many studies have explored the safety climate [

23,

24,

25] and performance climate [

26,

27,

28], there is only one published study on ergonomics climate in the workplace [

7]. Safety climate focuses on employee safety but does not reflect employee work performance, represented by ergonomics climate [

29]. Ergonomics climate assesses deeper and more diverse values within an organization than other climate measures. However, like safety climate measures, ergonomic climate measures are also leading, rather than lagging, indicators of work performance outcomes. The purpose of this study was to evaluate ergonomics climate and its association with employee well-being and organizational performance at two Iranian power plants.

4. Discussion

This study utilized previously developed measures but is the first to assess the ergonomics climate to investigate its association with employee well-being and organizational performance. In the ergonomics climate subscales, the mean operational performance score was higher than the mean employee well-being score at both facilities.

There was a significant difference between the overall ergonomics climate score and each subscale score at two Rey and Besat power plants. Holding an ergonomics awareness training session for management and employees at Rey power plant may be a primary source for the difference between ergonomics climate scores at the two power plants. In both operational performance and employee well-being, management commitment had the highest mean value at the Rey facility. The difference was significant betweenthe overall ergonomics climate scores and each subscale scores at two power plants. The employee’s perception of management commitment was reported higher at the Rey facility due to various practices. These practices include more collaborative relationships between management and employees, employee involvement in the decision-making to address ergonomics and safety issues, and employees participantion in ergonomics training awareness. Previous studies have introduced management commitment as a factor that can influence the other dimensions of safety [

39,

40,

41].

Further studies indicated the critical role of management commitment in implementing the ergonomic principle and its influence on employee buy-in and commitment to the organization [

42,

43]. Management commitment to operational performance usually manifests itself in employee training and job enrichment which can ultimately improve employee perceptions regarding the quality of goods and services [

44]. Management support and psychosocial attitudes are the most important predictors of an ergonomics program’s success or failure [

45].

The ergonomics climate measure included another subscale, employee involvement, which can be positively influenced by management support of employee participation in providing solutions for controlling the workplace hazards. The employee involvment subscale was significantly higher at the Rey plant when compared to the Besat plant. The high level of employee involvement likely influenced the level of perceived ergonomics climate at the Rey facility. Previous studies have found that the employee perception of an organization’s climate directly affects the employee perception of involvement [

46,

47]. The climate of an organization should be considered an essential factor in promoting employee involvement. Ultimately, a climate of management support and commitment encourages employee involvement, directly influencing climate perception [

48,

49].

Training and knowledge also promoted a higher perception of the ergonomics climate at the Rey plant. Training employees leads to self-protection practices, resulting in several beneficial outcomes for the organization [

50]. Similar to our research finding, Mazzetti et al. (2020) demonstrated that the perception of a safety climate among construction workers is inversely associated with the higher perception of risk and safety knowledge [

51]. Training can reduce the rate of absenteeism and accidents, lower healthcare costs, and increase productivity [

52]. Ergonomics training can improve employee knowledge of how they interact with the work environment as individuals and teams. This knowledge and the ability to apply it can decrease health-related issues and increase organizational performance. Several studies have shown that training significantly impacts overall job satisfaction and identifies work-related hazards [

53,

54]. Ergonomics training has previously been considered a key element in improving employee’s safety, well-being, and productivity [

55,

56]. All subscales of the ergonomics climate are essential, and it is beneficial to consider how they influence each other. Based on this study and previous studies, management commitment directly influences employee involvement, affecting the effectiveness of training and workers’ ability to identify and control hazards.

The mean ergonomics climate score was reported as significantly higher by employees who did not self-report pain than those who reported musculoskeletal pain. Hence, a higher perceived ergonomics climate is likely associated with lower musculoskeletal pain levels [

57]. An ergonomics program that focuses on the design and modification of the workplace to improve overall health and operational performance can significantly impact employee perceptions regarding the ergonomics climate [

8]. Implementing an effective ergonomics program can help reduce the prevalence of musculoskeletal disorders while also improving the efficiency and productivity of the employees [

5,

58,

59]. A similar study also showed an association between psychosocial working conditions including low autonomy, low quality of leadership, and increased risk of reporting higher physical exertion [

6].

A positive association was observed between the overall ergonomics climate and each of its subscales and organizational performance. Other studies have also observed a similar relationship. A positive correlation between applying ergonomics principles to reduce workplace-related problems and enhanced quality has been observed [

60]. Additionally, the implementation of ergonomic and safety regulations to improve productivity and worker well-being can produce a more efficient production system [

61,

62]. Another study showed that enhancing efficiency and quality of work will reduce absenteeism and work-related injuries and diseases [

63]. The implementation of ergonomics principles in designing a training program can be highly effective in individual’s learning performance [

63]. Organizations that aim to improve their organizational performance should evaluate their ergonomics climate to develop targeted interventions [

14].

Furthermore, the mean overall ergonomics climate score of employees with the absence of a disorder was significantly higher than the employees with the presence of disorder regarding their general health. The mean of each subscale score of ergonomics climate was higher in the employees with the absence of disorder than the group with the risk of developing the disorder. However, this difference was only significant in the management commitment and employee involvement subscales for operational performance and management commitment for employee well-being. Overall, higher levels of general health were reported when the organization had a higher ergonomics climate. It has been suggested that social supports of coworkers and supervisors in the workplace, as one of the characteristics of an ergonomics approach, can reduce the incidence rate of diseases in employees [

64,

65]. Similar to the significant relationship between each of the ergonomics climate subscales, including management commitment and employee involvement, was observed in this study, Vosoughi et al. [

66] demonstrated that an organization’s climate and the relationships between employees and management had an impact on work-related stress. This stress had a positive correlation with the physical and mental well-being of employees [

67]. Finally, other studies indicated that the organizational climate and management style could affect the mental well-being of employees [

7,

68,

69]. Assessing the organization’s ergonomics climate and creating interventions based on the results could be an effective way to improve employees’ general health.

The present study was based on cross-sectional and self-reported data collected through three separate questionnaires. This type of study design and data have several limitations, such as the inability to determine a causal relationship and analyze data over time. The relationships between the ergonomics climate score and the outcomes are associations at the time of the questionnaire administration, and do not suggest causal inferences. Because the ergonomics climate measure is relatively new, and little research has been conducted using this measure, various outcomes were measured to investigate their possible association with the ergonomics climate scores. With many comparisons, this increases the possibility of getting a significant result simply by chance (type I error). Since this was the first study ever to use ergonomics climate to compare two occupational settings from the same industry the results should guide the path for future studies. Future studies should be conducted in various industries and workplaces, multilevel designs, and a large number of employees. Prospective cohort studies encompassing ergonomics climate measures would be beneficial in demonstrating possible causal pathways.

5. Conclusions

The translated (English to Persian) version of the Ergonomics Climate Assessment was an appropriate and beneficial tool for assessing the ergonomics climate’s status at two Iranian power plants. The ergonomics climate assessment can assist in prioritizing resources devoted to safety and production improvements within occupational settings, such as the power plants described in the present study. Furthermore, climate subscales can provide valuable and specific information to assist with targeted interventions for improving both worker well-being and operational metrics. The present study has demonstrated the cross-cultural use of the ergonomics climate assessment tool. A longitudinal study employing the ergonomics climate assessment tool to assess the effectiveness of systematic ergonomic interventions in a variety of occupational settings is needed.

This study confirms the findings of previously published work that implementing ergonomics’ principles focusing on improving both employee well-being and operational performance is beneficial for both the organization and employees. We believe that our findings have important policy implications. Future work policies should focus on leading indicators rather than lagging indicators to improve worker and organizational health and well-being [

7]. Leading indicators allow organizations to be proactive rather than reactive in their safety and operational performance.

In the present study, higher ergonomics climate scores were associated with less self- reported musculoskeletal pain among the workers and higher operational performance for the company. Thus, businesses that focus their climate messages on the goals that include a system approach to workplace ergonomics will tend to have a healthier and more productive workforce.