Enhanced Dewatering of Activated Sludge by Skeleton-Assisted Flocculation Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sludge Conditioning and Dehydration Experiments

2.3. Sludge Index Analysis Method

3. Results

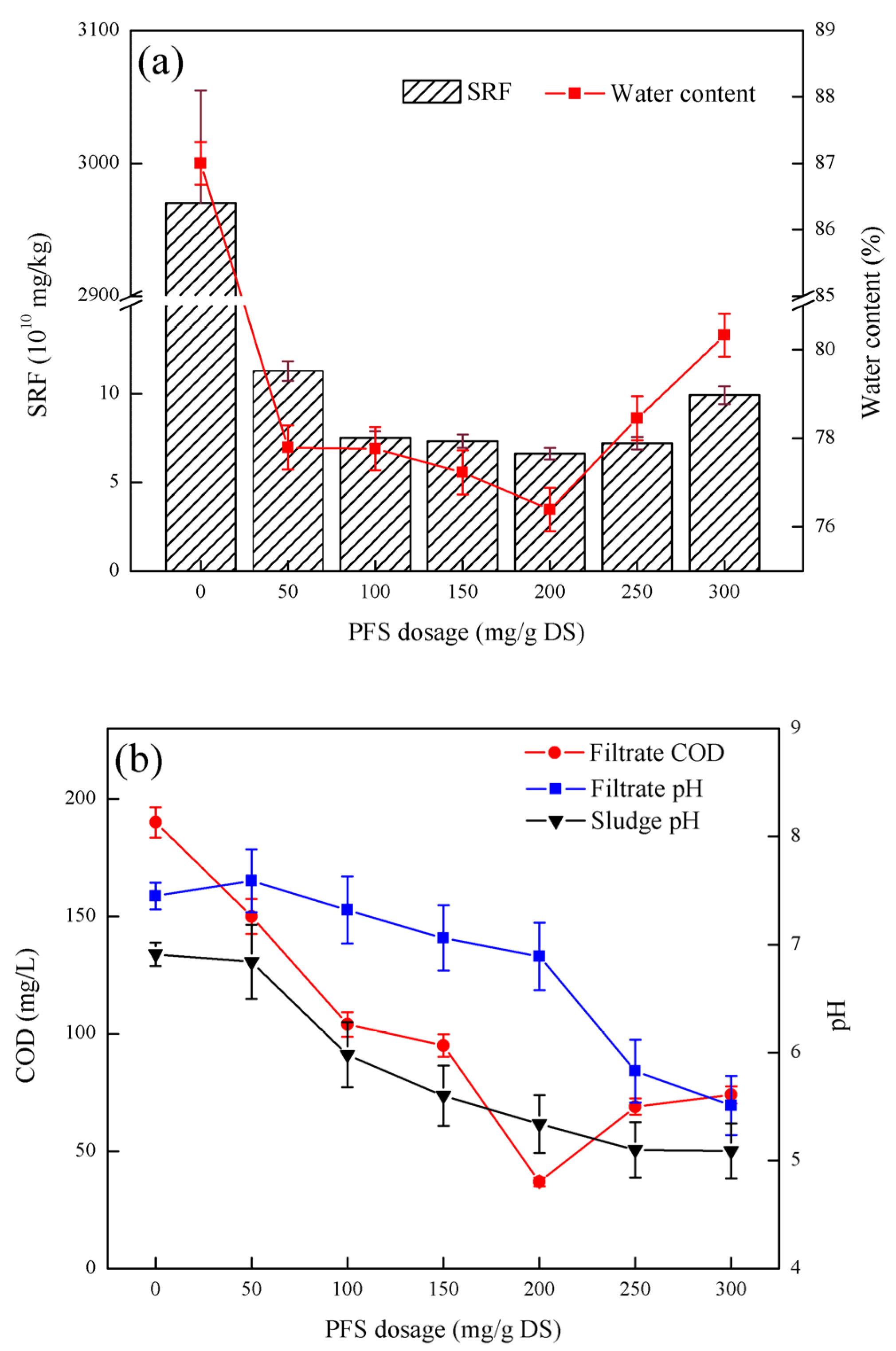

3.1. Effect of PFS Dosage on Sludge Dewatering Performance

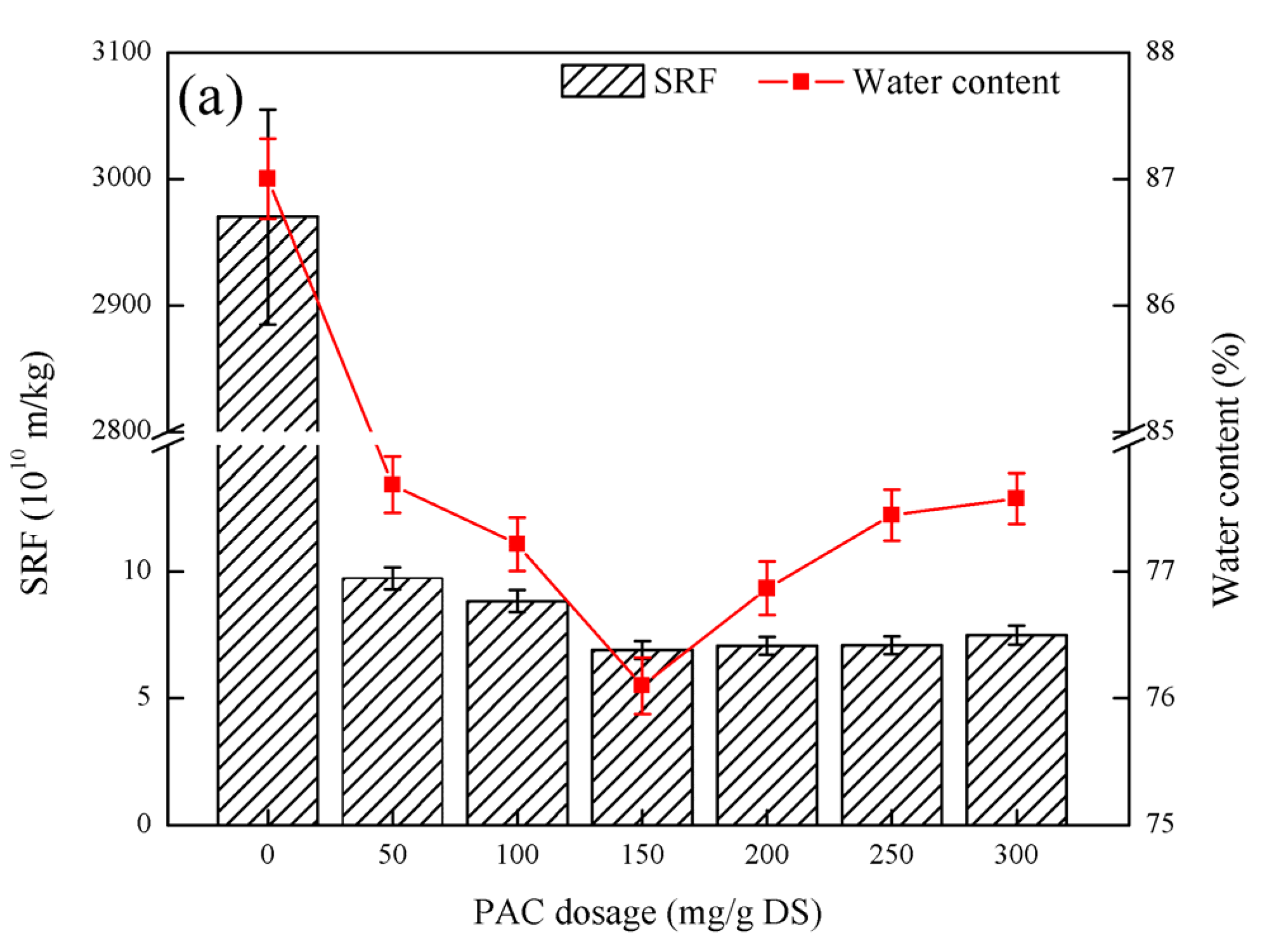

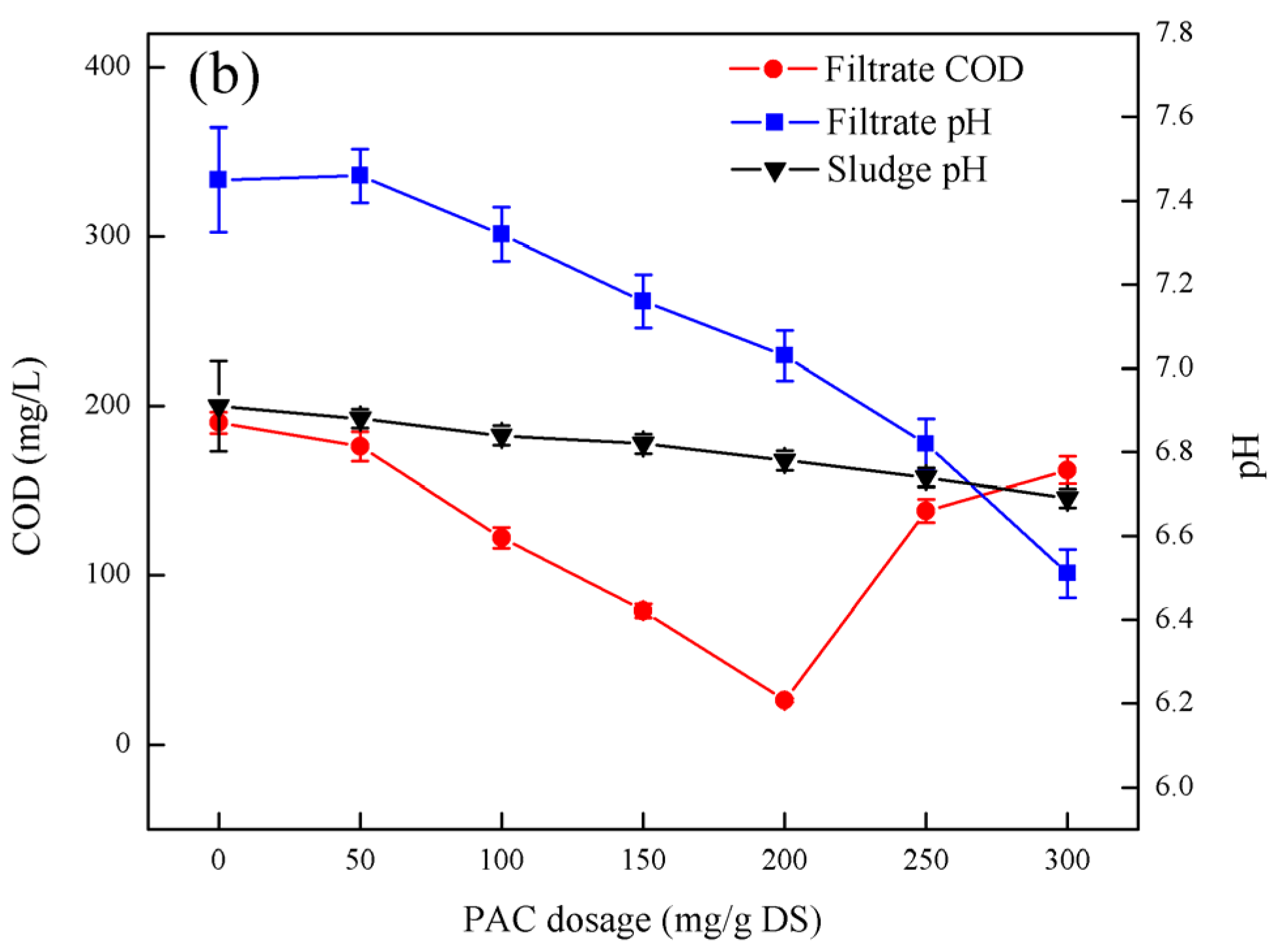

3.2. Effect of PAC Dosage on Sludge Dewatering Performance

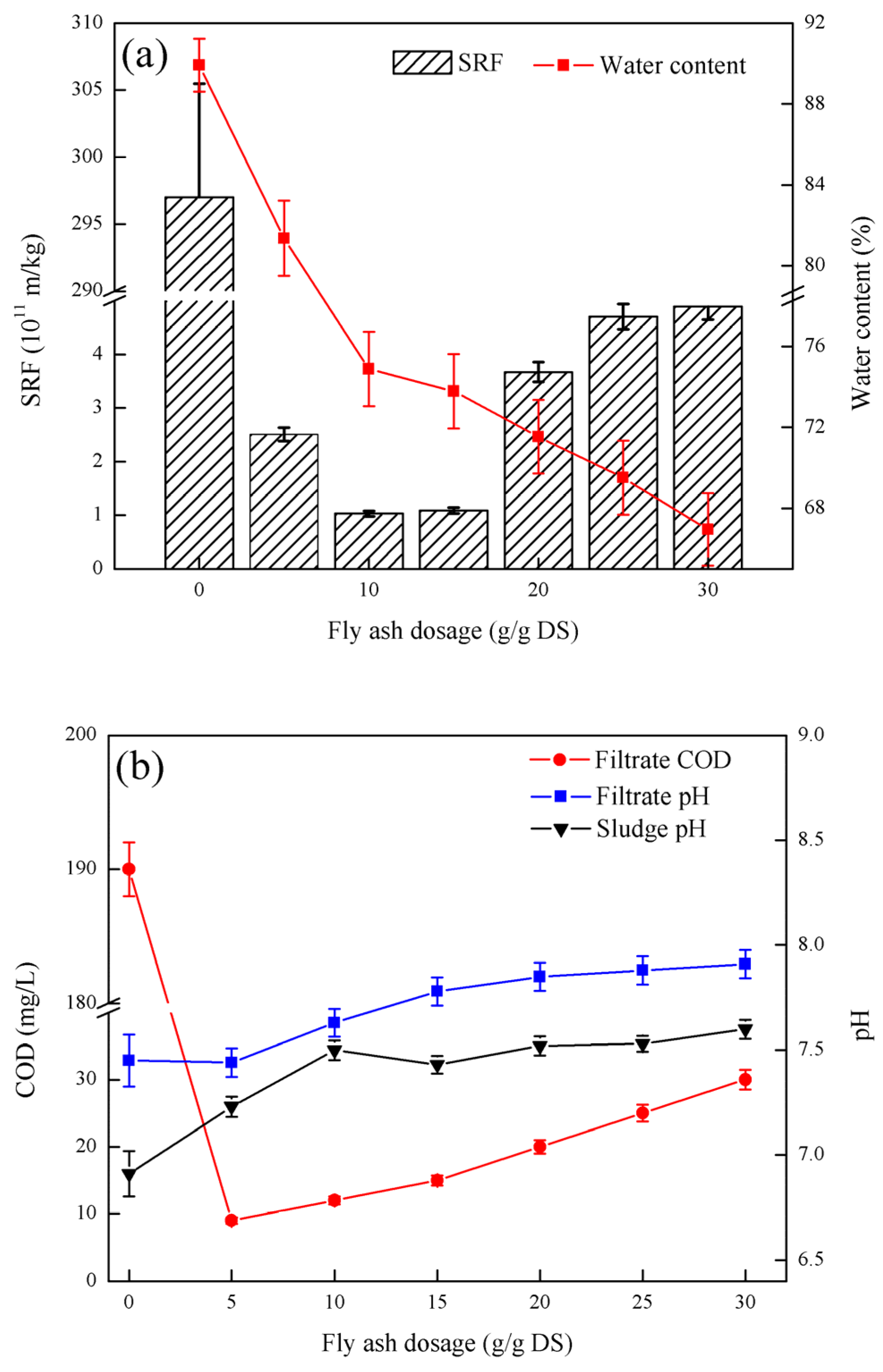

3.3. Effect of Fly Ash Dosage on Sludge Dewatering Performance

3.4. Effect of Fly Ash Coupled with PFS on Sludge Dewatering Performance

3.5. Effect of FA-Coupled PAC on Sludge Dewatering Performance

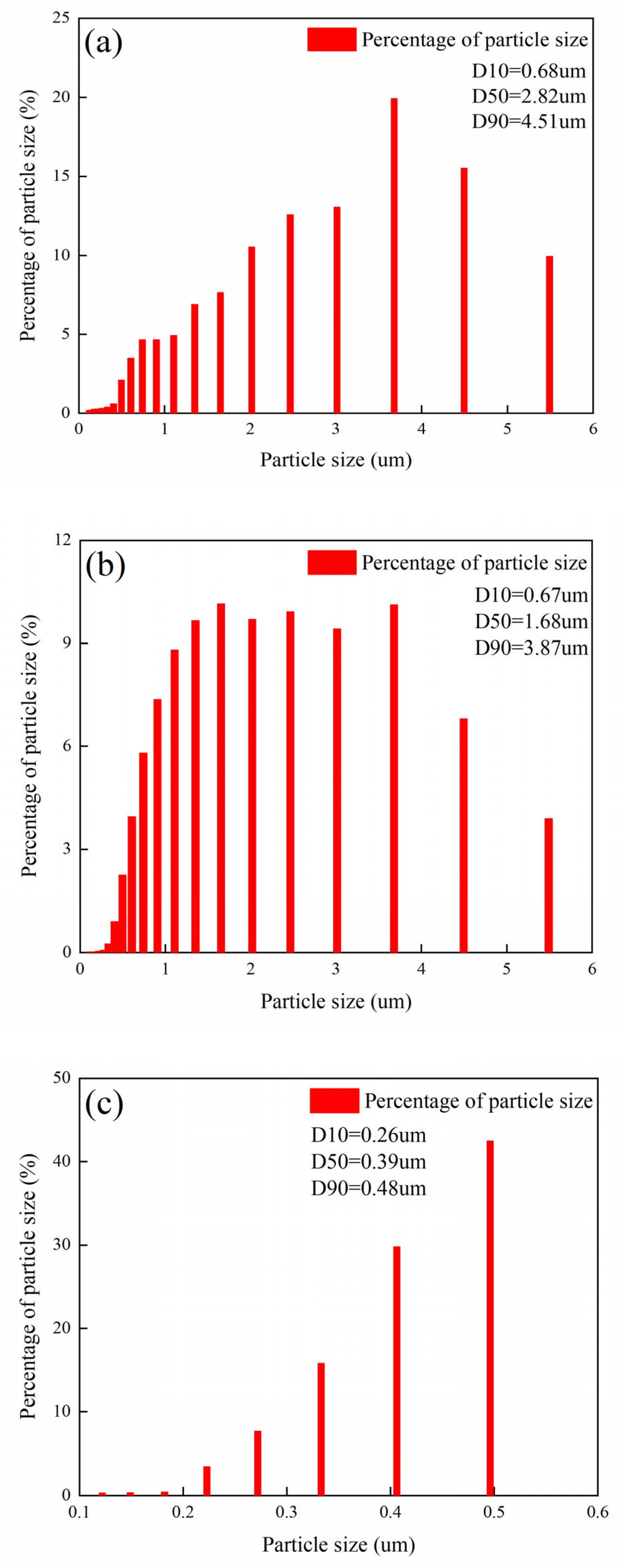

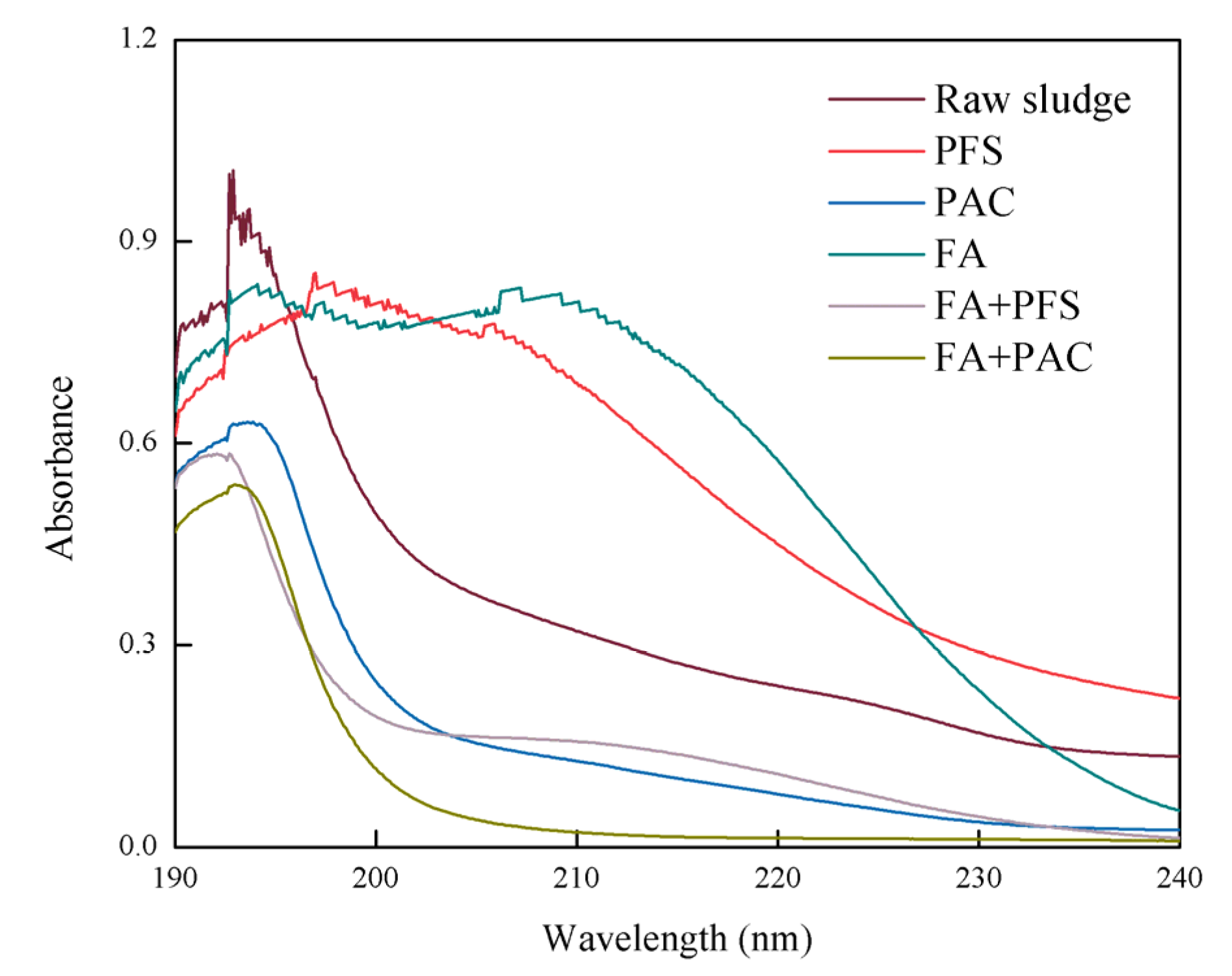

3.6. Floc Structure after Sludge Conditioning

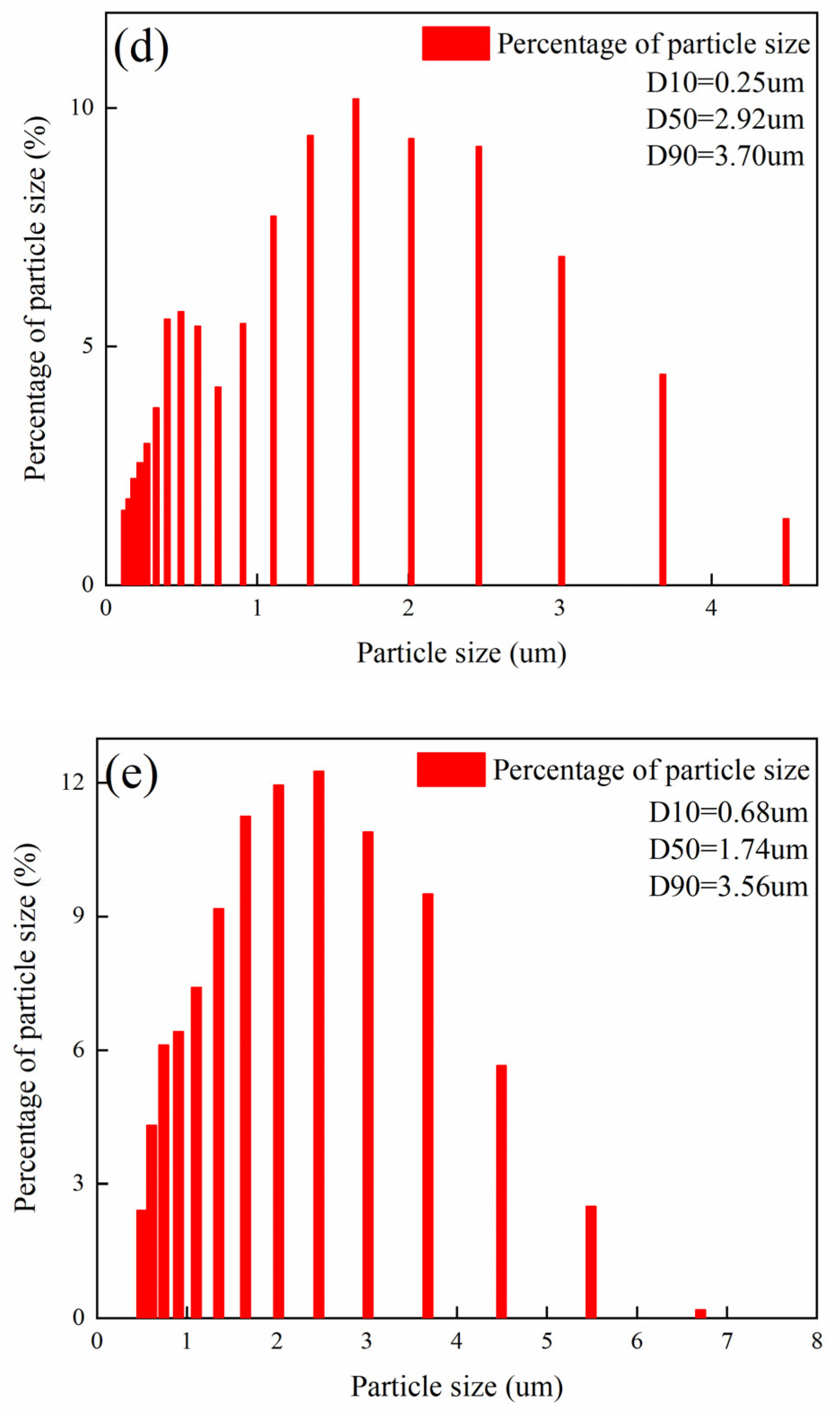

3.7. Effects of Different Conditioners on UV of Filtrate

3.8. Effect of Conditioner on Fractal Dimension of Sludge Floc

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, G.; Zhang, G.; Wang, H. Current state of sludge production, management, treatment and disposal in China. Water Res. 2015, 78, 60–73. [Google Scholar] [CrossRef] [PubMed]

- Christensen, M.L.; Keiding, K.; Nielsen, P.H.; Jørgensen, M.K. Dewatering in biological wastewater treatment: A review. Water Res. 2015, 82, 14–24. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Zhang, M.; Wang, F.; Meng, F.; Liao, B.; Hong, H.; Chen, J.; Gao, W. A critical review of extracellular polymeric substances (EPSs) in membrane bioreactors: Characteristics, roles in membrane fouling and control strategies. J. Membr. Sci. 2014, 460, 110–125. [Google Scholar] [CrossRef]

- Zhao, P.; Shen, Y.; Ge, S.; Yoshikawa, K. Energy recycling from sewage sludge by producing solid biofuel with hydrothermal carbonization. Energ. Convers. Manag. 2014, 78, 815–821. [Google Scholar] [CrossRef] [Green Version]

- Mowla, D.; Tran, H.N.; Allen, D.G. A review of the properties of biosludge and its relevance to enhanced dewatering processes. Biomass Bioenergy 2013, 58, 365–378. [Google Scholar] [CrossRef]

- Chen, R.; Sheng, Q.; Chen, S.; Dai, X.; Dong, B. The three-stage effect of hydrothermal treatment on sludge physical-chemical properties: Evolution of polymeric substances and their interaction with physicochemical properties. Water Res. 2022, 211, 118043. [Google Scholar] [CrossRef]

- Zheng, H.; Sun, Y.; Zhu, C.; Guo, J.; Zhao, C.; Liao, Y.; Guan, Q. UV-initiated polymerization of hydrophobically associating cationic flocculants: Synthesis, characterization, and dewatering properties. Chem. Eng. J. 2013, 234, 318–326. [Google Scholar] [CrossRef]

- Geng, N.; Wang, Y.; Zhang, D.; Fan, X.; Li, E.; Han, Z.; Zhao, X. An electro-peroxone oxidation-Fe(III) coagulation sequential conditioning process for the enhanced waste activated sludge dewatering: Bound water release and organics multivariate change. Sci. Total Environ. 2022, 833, 155272. [Google Scholar] [CrossRef]

- Zheng, H.; Sun, Y.; Guo, J.; Li, F.; Fan, W.; Liao, Y.; Guan, Q. Characterization and evaluation of dewatering properties of PADB, a highly efficient cationic flocculant. Ind. Eng. Chem. Res. 2014, 53, 2572–2582. [Google Scholar] [CrossRef]

- Li, Y.; Yuan, X.; Wu, Z.; Wang, H.; Xiao, Z.; Wu, Y.; Chen, X.; Zeng, G. Enhancing the sludge dewaterability by electrolysis/electrocoagulation combined with zero-valent iron activated persulfate process. Chem. Eng. J. 2016, 303, 636–645. [Google Scholar] [CrossRef]

- Zhou, L.; Ying, G.; Liu, S.; Zhao, J.; Yang, B.; Chen, Z.; Lai, H. Occurrence and fate of eleven classes of antibiotics in two typical wastewater treatment plants in South China. Sci. Total Environ. 2013, 452–453, 365–376. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.S.; Lee, K.; Kim, H.; Lee, H.; Lee, C.; Lee, C. Disintegration of waste activated sludge by Thermally-Activated persulfates for enhanced dewaterability. Environ. Sci. Technol. 2016, 50, 7106–7115. [Google Scholar] [CrossRef] [PubMed]

- Jia, A.; Wan, Y.; Xiao, Y.; Hu, J. Occurrence and fate of quinolone and fluoroquinolone antibiotics in a municipal sewage treatment plant. Water Res. 2012, 46, 387–394. [Google Scholar] [CrossRef] [PubMed]

- Hyrycz, M.; Ochowiak, M.; Krupińska, A.; Włodarczak, S.; Matuszak, M. A review of flocculants as an efficient method for increasing the efficiency of municipal sludge dewatering: Mechanisms, performances, influencing factors and perspectives. Sci. Total Environ. 2022, 820, 153328. [Google Scholar] [CrossRef]

- Rao, B.; Su, J.; Xu, J.; Xu, S.; Pang, H.; Zhang, Y.; Xu, P.; Wu, B.; Lian, J.; Deng, L. Coupling mechanism and parameter optimization of sewage sludge dewatering jointly assisted by electric field and mechanical pressure. Sci. Total Environ. 2022, 817, 152939. [Google Scholar] [CrossRef]

- Cai, M.; Qian, Z.; Xiong, X.; Dong, C.; Song, Z.; Shi, Y.; Wei, Z.; Jin, M. Cationic polyacrylamide (CPAM) enhanced pressurized vertical electro-osmotic dewatering of activated sludge. Sci. Total Environ. 2022, 818, 151787. [Google Scholar] [CrossRef]

- Sun, Y.; Zheng, H.; Zhai, J.; Teng, H.; Zhao, C.; Zhao, C.; Liao, Y. Effects of surfactants on the improvement of sludge dewaterability using cationic flocculants. PLoS ONE 2014, 9, e111036. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Fan, W.; Zheng, H.; Zhang, Y.; Li, F.; Chen, W. Evaluation of dewatering performance and fractal characteristics of alum sludge. PLoS ONE 2015, 10, e130683. [Google Scholar] [CrossRef] [Green Version]

- Guan, Q.Q.; Zheng, H.L.; Zhai, J.; Zhao, C.; Zheng, X.K.; Tang, X.M.; Chen, W.; Sun, Y.J. Effect of template on structure and properties of cationic polyacrylamide: Characterization and mechanism. Ind. Eng. Chem. Res. 2014, 53, 5624–5635. [Google Scholar] [CrossRef]

- Liao, Y.; Zheng, H.L.; Qian, L.; Sun, Y.J.; Dai, L.; Xue, W.W. UV-Initiated polymerization of hydrophobically associating cationic polyacrylamide modified by a Surface-Active monomer: A comparative study of synthesis, characterization, and sludge dewatering performance. Ind. Eng. Chem. Res. 2014, 53, 11193–11203. [Google Scholar] [CrossRef]

- Zhu, J.; Zheng, H.; Jiang, Z.; Zhang, Z.; Liu, L.; Sun, Y.; Tshukudu, T. Synthesis and characterization of a dewatering reagent: Cationic polyacrylamide (P(AM-DMC-DAC)) for activated sludge dewatering treatment. Desalin. Water Treat. 2013, 51, 2791–2801. [Google Scholar] [CrossRef]

- Zhen, G.; Lu, X.; Wang, B.; Zhao, Y.; Chai, X.; Niu, D.; Zhao, A.; Li, Y.; Song, Y.; Cao, X. Synergetic pretreatment of waste activated sludge by Fe(II)–activated persulfate oxidation under mild temperature for enhanced dewaterability. Bioresour. Technol. 2012, 124, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Guan, Q.; Zheng, H.; Zhai, J.; Liu, B.; Sun, Y.; Wang, Y.; Xu, Z.; Zhao, C. Preparation, characterization, and flocculation performance of P(acrylamide-co-diallyldimethylammonium chloride) by UV-initiated template polymerization. J. Appl. Polym. Sci. 2015, 132, 41747. [Google Scholar] [CrossRef]

- Sun, Y.; Ren, M.; Zhu, C.; Xu, Y.; Zheng, H.; Xiao, X.; Wu, H.; Xia, T.; You, Z. UV-Initiated graft copolymerization of cationic Chitosan-Based flocculants for treatment of zinc Phosphate-Contaminated wastewater. Ind. Eng. Chem. Res. 2016, 55, 10025–10035. [Google Scholar] [CrossRef]

- Yan, C.; Zhan, M.; Xv, K.; Zhang, S.; Liang, T.; Yu, R. Sludge dewaterability enhancement under low temperature condition with cold-tolerant Bdellovibrio sp. CLL13. Sci. Total Environ. 2022, 820, 153269. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhu, C.; Zheng, H.; Sun, W.; Xu, Y.; Xiao, X.; You, Z.; Liu, C. Characterization and coagulation behavior of polymeric aluminum ferric silicate for high-concentration oily wastewater treatment. Chem. Eng. Res. Des. 2017, 119, 23–32. [Google Scholar] [CrossRef]

- Sun, W.; Tang, M.; Sun, Y.; Xu, Y.; Zheng, H. Effective sludge dewatering technique using the combination of Fenton’s reagent and CPAM. Can. J. Chem. Eng. 2018, 96, 1256–1263. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, H.; Jin, M.; Deng, H.; Wang, J.; Yao, H. Process control for improving dewatering performance of sewage sludge based on carbonaceous skeleton-assisted thermal hydrolysis. Chemosphere 2022, 296, 134006. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, H.; Sun, Y.; Chiang, P.; Sun, W.; Xu, Y.; Zheng, H.; Shah, K.J. Characterization and sludge dewatering performance evaluation of the photo-initiated cationic flocculant PDD. J. Taiwan Inst. Chem. E. 2018, 93, 253–262. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Wang, D.; Yuan, L.; Liu, X.; Pan, C.; Zhang, X. Insights into cetyl trimethyl ammonium bromide improving dewaterability of anaerobically fermented sludge. Chem. Eng. J. 2022, 435, 134968. [Google Scholar] [CrossRef]

- Lu, X.; Xu, Y.; Sun, W.; Sun, Y.; Zheng, H. UV-initiated synthesis of a novel chitosan-based flocculant with high flocculation efficiency for algal removal. Sci. Total Environ. 2017, 609, 410–418. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Chen, A.; Pan, S.; Sun, W.; Zhu, C.; Shah, K.J.; Zheng, H. Novel chitosan-based flocculants for chromium and nickle removal in wastewater via integrated chelation and flocculation. J. Environ. Manag. 2019, 248, 109241. [Google Scholar] [CrossRef] [PubMed]

- Ding, A.; Lin, W.; Chen, R.; Ngo, H.H.; Zhang, R.; He, X.; Nan, J.; Li, G.; Ma, J. Improvement of sludge dewaterability by energy uncoupling combined with chemical re-flocculation: Reconstruction of floc, distribution of extracellular polymeric substances, and structure change of proteins. Sci. Total Environ. 2022, 816, 151646. [Google Scholar] [CrossRef] [PubMed]

- Zeng, R.; Li, Y.; Sha, L.; Liu, X.; Zhang, S. Electro-dewatering of steel industrial sludge: Performance and metal speciation. J. Water Process Eng. 2022, 46, 102600. [Google Scholar] [CrossRef]

- Deng, H.; Liu, H.; Jin, M.; Xiao, H.; Yao, H. Phosphorus transformation during the carbonaceous skeleton assisted thermal hydrolysis of sludge. Sci. Total Environ. 2022, 827, 154252. [Google Scholar] [CrossRef] [PubMed]

- Raynaud, M.; Vaxelaire, J.; Olivier, J.; Dieudé-Fauvel, E.; Baudez, J. Compression dewatering of municipal activated sludge: Effects of salt and pH. Water Res. 2012, 46, 4448–4456. [Google Scholar] [CrossRef] [PubMed]

| Sludge Index | Moisture Content of Raw Slduge (%) | Organic Matter Content (%) | SRF (m/kg) | pH Value |

|---|---|---|---|---|

| Numerical value | 98.90 | 46.30 | 2.97 × 1012 | 7.51 |

| Conditioner | PFS | PAC | Fly Ash | Fly Ash +PFS | Fly Ash + PAC |

|---|---|---|---|---|---|

| Fractal dimension | 2.03 | 1.99 | 1.96 | 1.91 | 1.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, J.; Rao, T.; Ji, J.; He, B.; Liu, A.; Sun, Y. Enhanced Dewatering of Activated Sludge by Skeleton-Assisted Flocculation Process. Int. J. Environ. Res. Public Health 2022, 19, 6540. https://doi.org/10.3390/ijerph19116540

Xia J, Rao T, Ji J, He B, Liu A, Sun Y. Enhanced Dewatering of Activated Sludge by Skeleton-Assisted Flocculation Process. International Journal of Environmental Research and Public Health. 2022; 19(11):6540. https://doi.org/10.3390/ijerph19116540

Chicago/Turabian StyleXia, Jiahua, Ting Rao, Juan Ji, Bijuan He, Ankang Liu, and Yongjun Sun. 2022. "Enhanced Dewatering of Activated Sludge by Skeleton-Assisted Flocculation Process" International Journal of Environmental Research and Public Health 19, no. 11: 6540. https://doi.org/10.3390/ijerph19116540

APA StyleXia, J., Rao, T., Ji, J., He, B., Liu, A., & Sun, Y. (2022). Enhanced Dewatering of Activated Sludge by Skeleton-Assisted Flocculation Process. International Journal of Environmental Research and Public Health, 19(11), 6540. https://doi.org/10.3390/ijerph19116540