A Tester to Evaluate the Correct Placement of Earplugs

Abstract

1. Introduction

2. Material and Methods

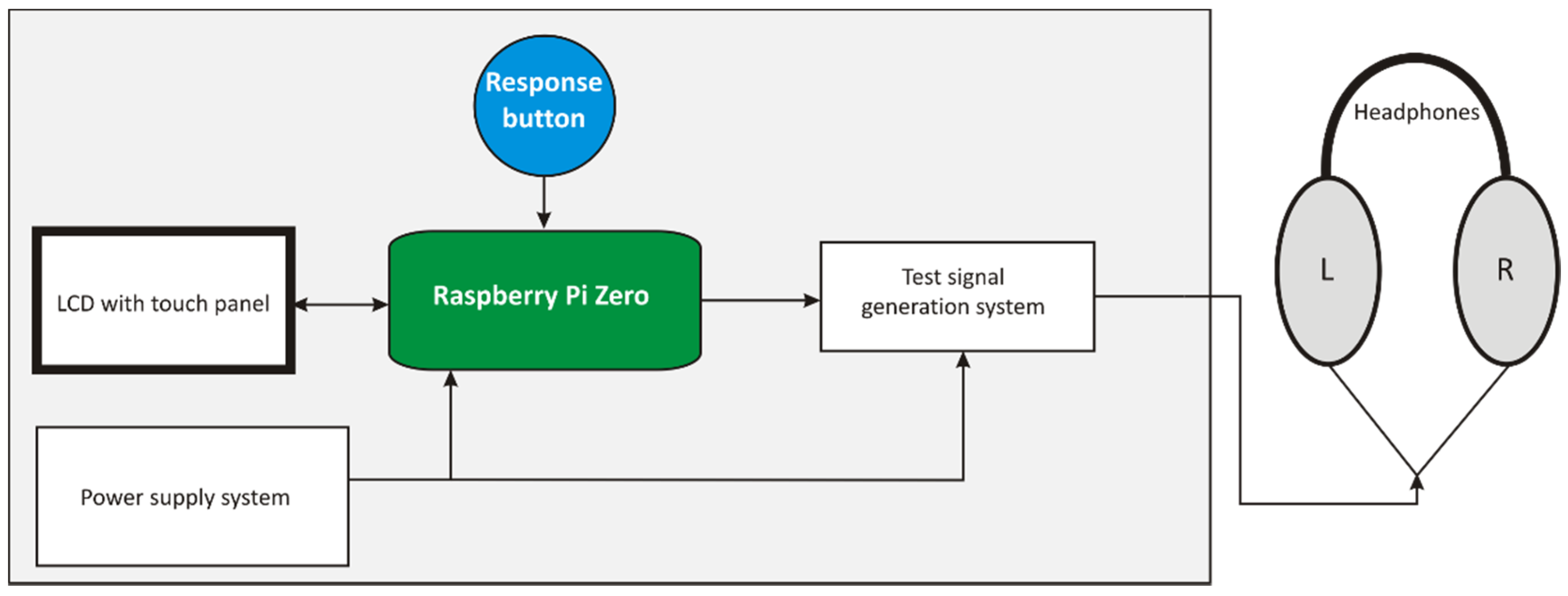

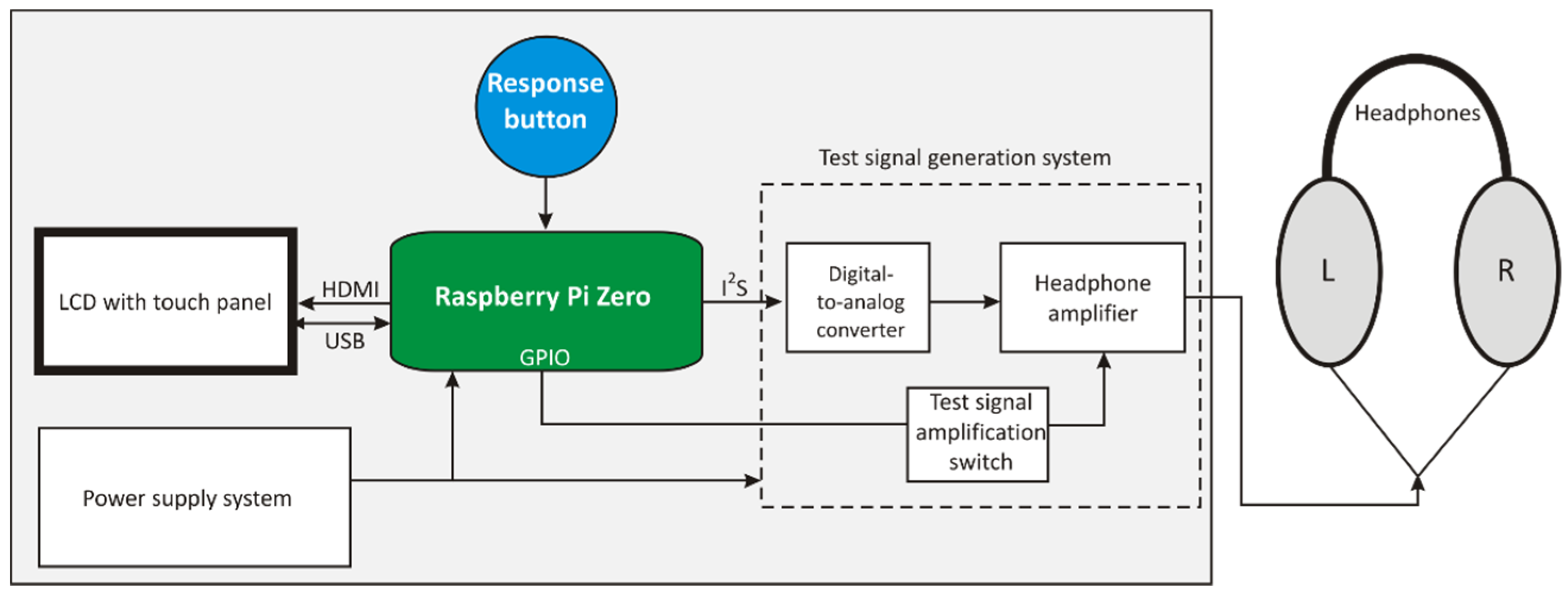

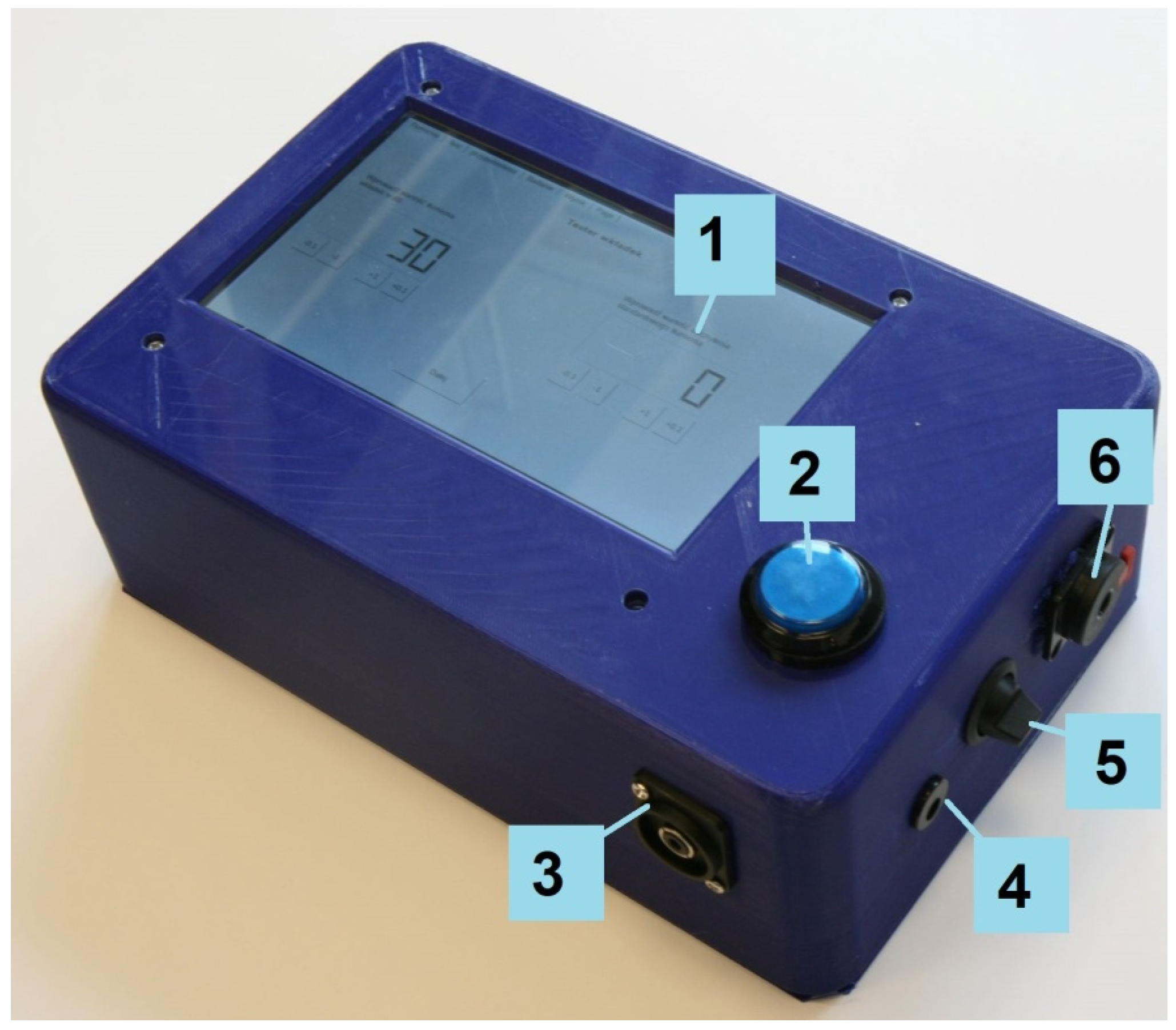

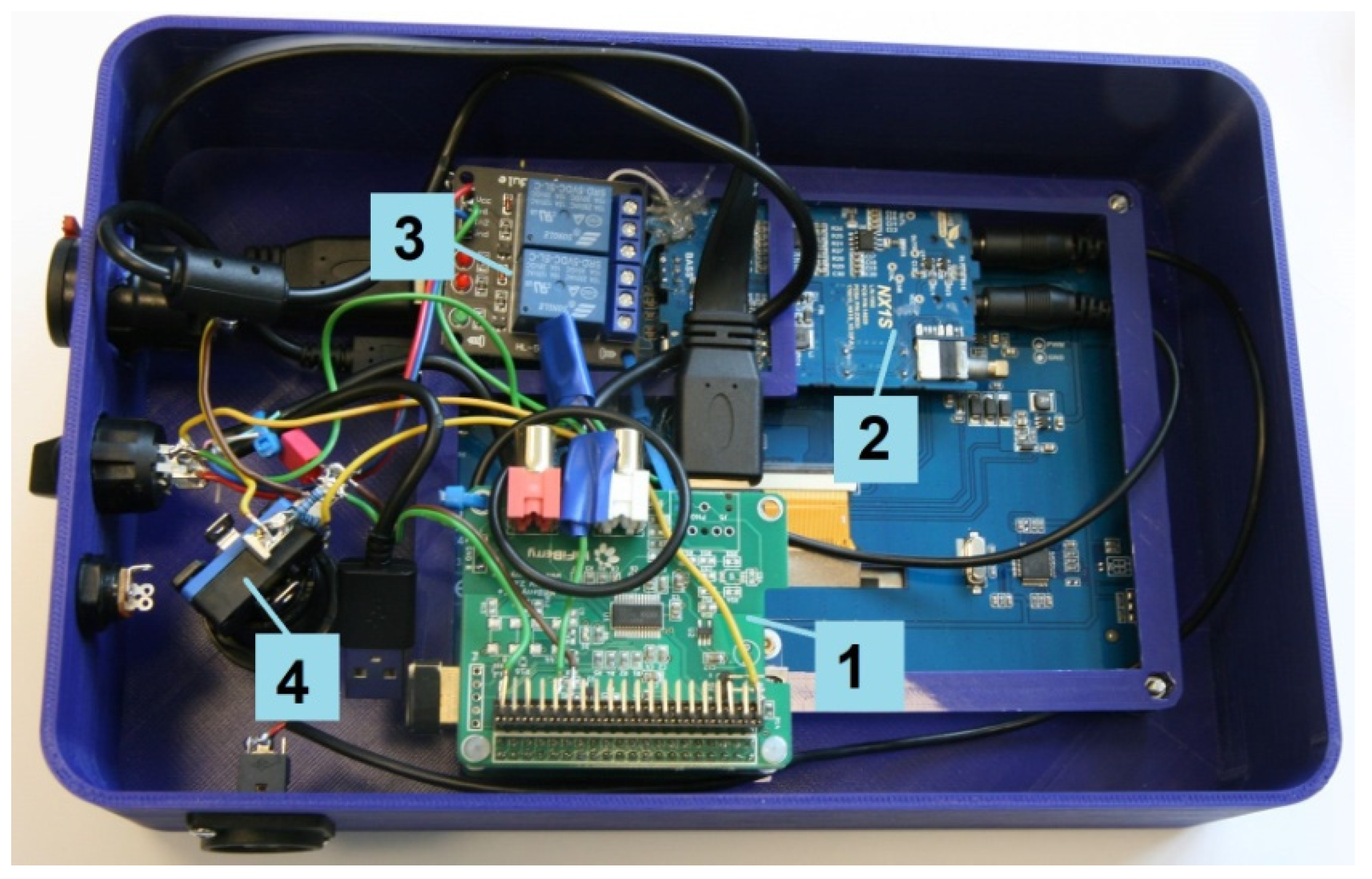

2.1. Concept and Design of the Tester

- Raspberry Pi Zero v.1.3 single-board computer;

- Liquid-crystal display (LCD) with a capacitive touch panel;

- Test signal generation system;

- Headphones;

- Response button;

- Power supply system.

Test Signal Generation System

2.2. Tester’s Operating Principles

2.3. Statistical Analysis

2.4. Ethics and Bioethics Commission

3. Results

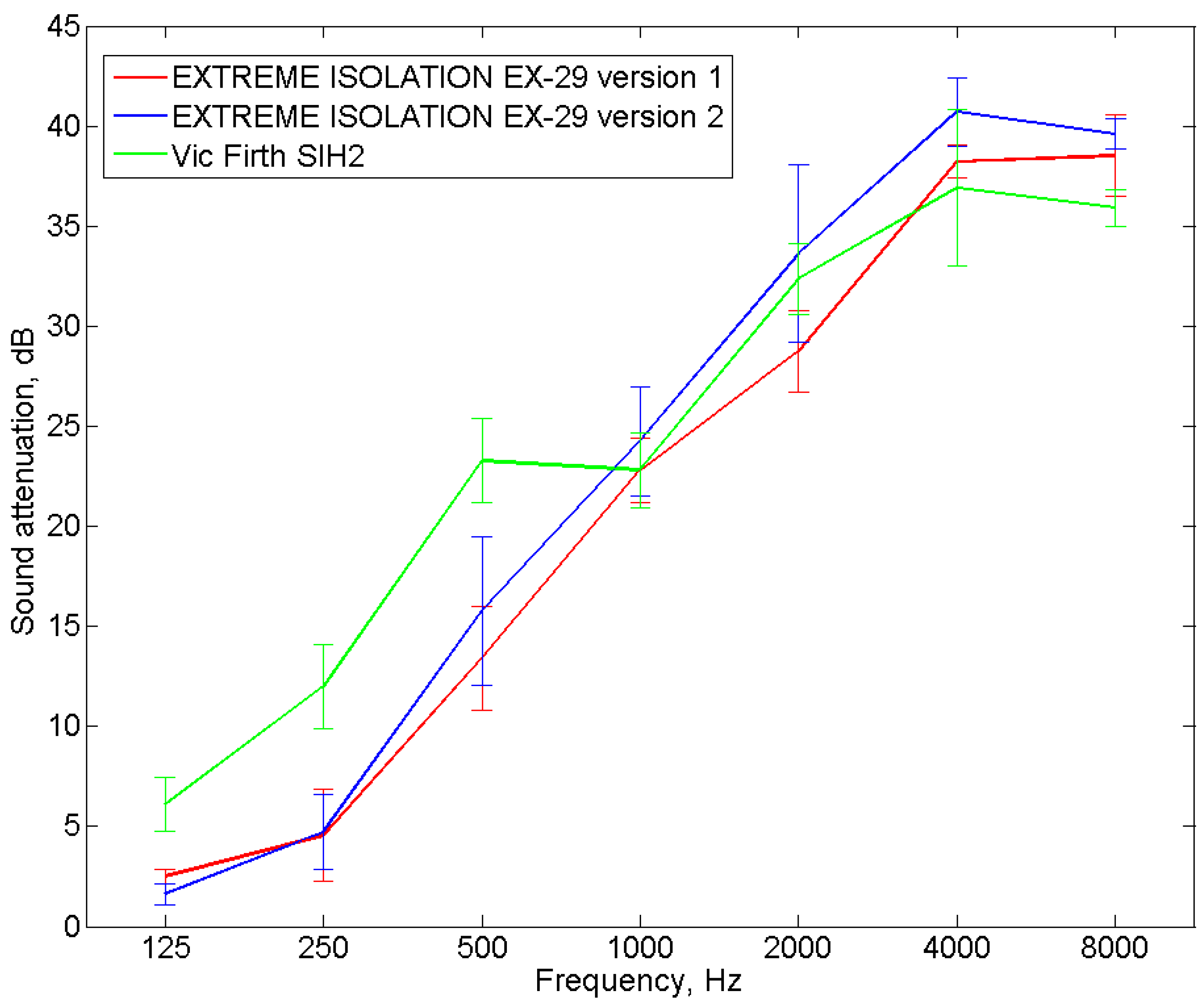

3.1. Headphone Selection

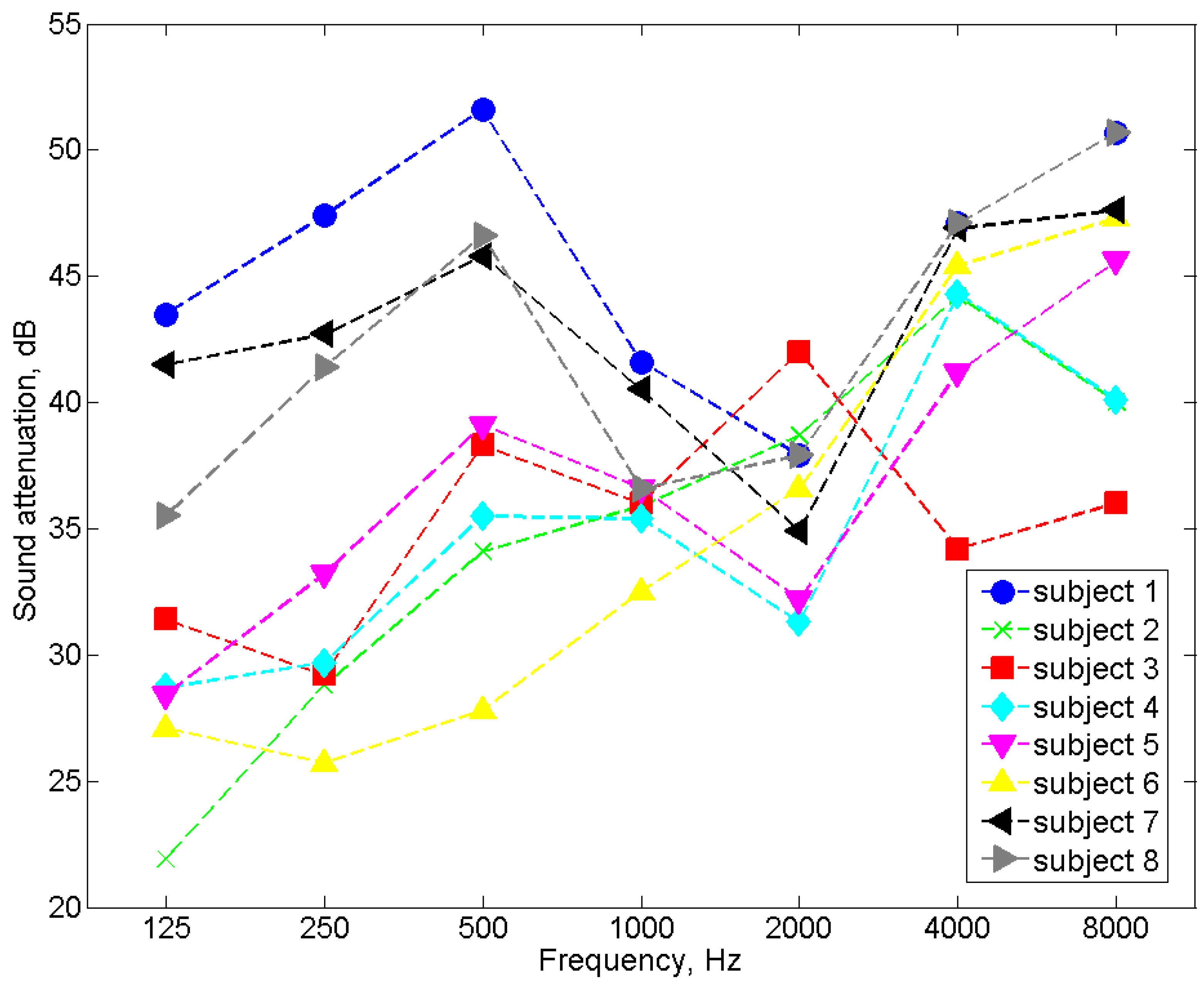

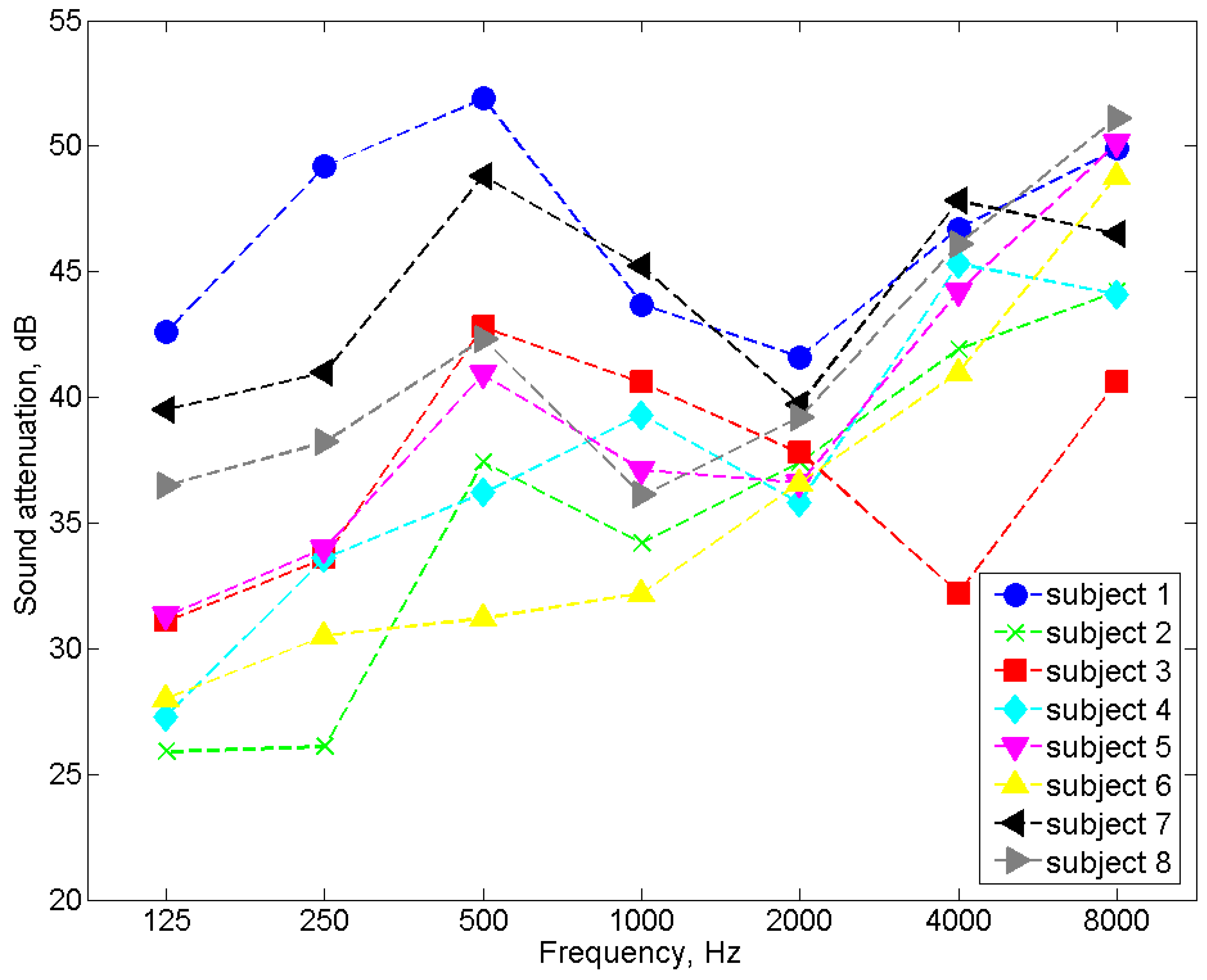

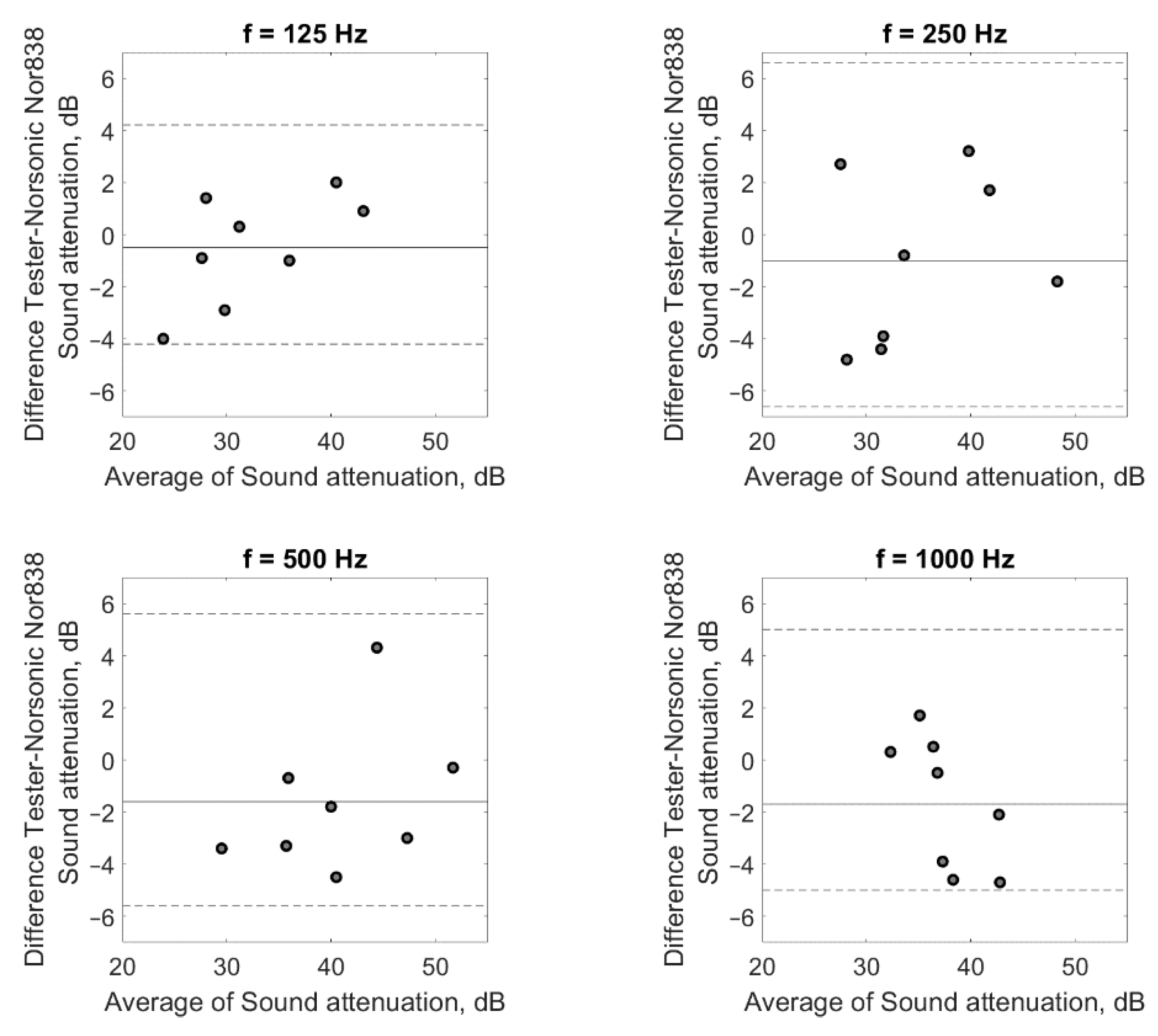

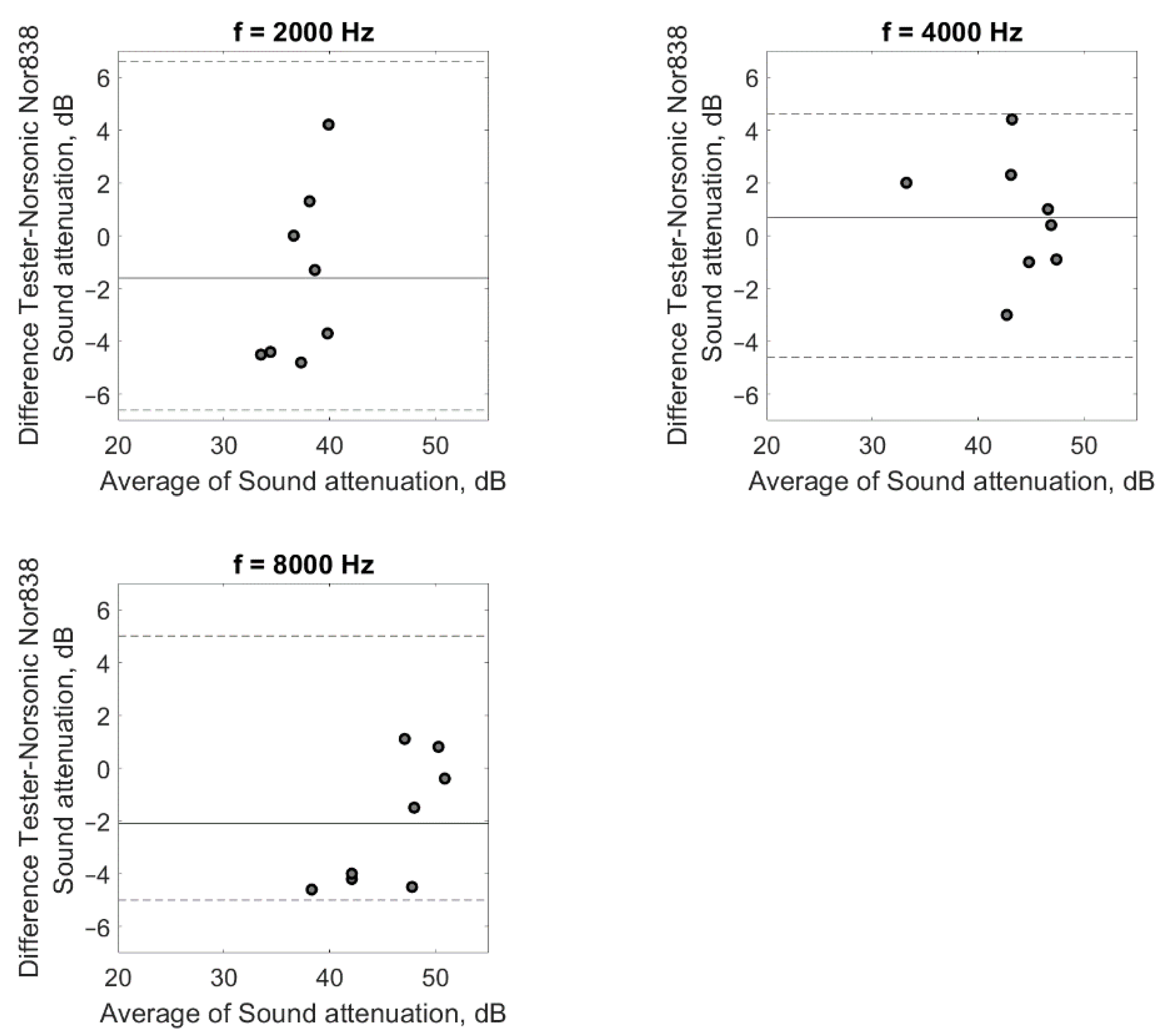

3.2. Measurements of Sound Attenuation Performed with the Use of the Tester

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nelson, D.I.; Nelson, R.Y.; Concha-Barrientos, M.; Fingerhut, M. The global burden of occupational noise-induced hearing loss. Am. J. Ind. Med. 2005, 48, 446–458. [Google Scholar] [CrossRef] [PubMed]

- Themann, C.; Suter, A.H.; Stephenson, M.R. National research agenda for the prevention of occupational hearing loss—Part 2. Semin. Hear. 2013, 34, 208–252. [Google Scholar] [CrossRef]

- EN ISO 4869-1 2018; Acoustics—Hearing Protectors—Part 1: Subjective Method for the Measurement of Sound Attenuation; International Organization for Standardization: Geneva, Switzerland, 2018.

- Kotarbinska, E. The influence of aging on the noise attenuation of ear-muffs. Noise Health 2005, 7, 39–45. [Google Scholar] [CrossRef] [PubMed]

- Rawlinson, R.D.; Wheeler, P.D. The effects of industrial use on the acoustical performance of some earmuffs. Ann. Occup. Hyg. 1987, 31, 291–298. [Google Scholar]

- Carletti, E.; Pedrielli, F. The ageing effect on the acoustic performance of earmuffs: An investigation involving the forestry compartment. In Proceedings of the 10th International Congress on Sound and Vibration 2003, Stockholm, Sweden, 7–10 July 2003. [Google Scholar]

- Abel, S.M.; Sass-Kortsak, A.; Kielar, A. The effect on earmuff attenuation of other safety gear worn in combination. Noise Health 2002, 5, 1–13. [Google Scholar]

- Chung, D.Y.; Hardie, R.; Gannon, R.P. The effect of hair, glasses, or cap on the performance of one pair of Bilsom Viking circumaural hearing protectors. Can. Acoust. 1983, 11, 45–49. [Google Scholar]

- Lemstad, F.; Kluge, R. Real-world attenuation of muff-type hearing protectors: The effect of spectacles. In Proceedings of the Joint Baltic-Nordic Acoustics Meeting 2004, Mariehamn, Aland, Finland, 8–10 June 2004. [Google Scholar]

- Nélisse, H.; Gaudreau, M.A.; Boutin, J.; Voix, J.; Laville, F. Measurement of hearing protection devices performance in the workplace during full-shift working operations. Ann. Occup. Hyg. 2012, 56, 221–232. [Google Scholar]

- Kozlowski, E.; Mlynski, R. Attenuation of earmuffs used simultaneously with respiratory protective devices. Med. Pr. 2017, 68, 349–361. (In Polish) [Google Scholar] [CrossRef]

- Kozlowski, E.; Mlynski, R. Selection of earmuffs and other personal protective equipment used in combination. Int. J. Environ. Res. Public Health 2019, 16, 1477. [Google Scholar] [CrossRef]

- Biabani, A.; Aliabadi, M.; Golmohammadi, R.; Farhadian, M. Individual fit testing of hearing protection devices based on microphone in real ear. Saf. Health Work 2017, 8, 364–370. [Google Scholar] [CrossRef]

- Neitzel, R.; Seixas, N. The effectiveness of hearing protection among construction workers. J. Occup. Environ. Hyg. 2005, 2, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Morata, T.C.; Fiorini, A.C.; Fischer, F.M.; Krieg, E.F.; Gozzoli, L.; Colacioppo, S. Factors affecting the use of hearing protectors in a population of printing workers. Noise Health 2001, 4, 21–28. [Google Scholar]

- Landen, D.; Wilkins, S.; Stephenson, M.; McWilliams, L. Noise exposure and hearing loss among sand and gravel miners. J. Occup. Environ. Med. 2004, 1, 532–541. [Google Scholar] [CrossRef] [PubMed]

- Hansia, M.R.; Dickinson, D. Hearing protection device usage at a South African gold mine. Occup. Med. 2010, 60, 72–74. [Google Scholar] [CrossRef]

- Tak, S.; Davis, R.R.; Calvert, G.M. Exposure to hazardous workplace noise and use of hearing protection devices among US workers—NHANES, 1999–2004. Am. J. Indus. Med. 2009, 52, 358–371. [Google Scholar] [CrossRef]

- EN 458:2016; Hearing Protectors—Recommendations for Selection, Use, Care and Maintenance—Guidance Document; European Committee for Standardization: Brussels, Belgium, 2016.

- Stephenson, M.R. Hearing protection in the 21st century: They’re not your father’s earplugs anymore. Semin. Hear. 2009, 30, 56–64. [Google Scholar] [CrossRef]

- Schultz, T. Individual fit-testing of earplugs: A review of uses. Noise Health 2011, 13, 152–162. [Google Scholar] [CrossRef]

- Joseph, A.; Punch, J.; Stephenson, M.; Paneth, N.; Wolfe, E.; Murphy, W. The effects of training format on earplug performance. Int. J. Audiol. 2007, 46, 609–618. [Google Scholar] [CrossRef]

- Takahashi, K.; Kawanami, S.; Inoue, J.; Horie, S. Improvements in sound attenuation performance with earplugs following checklist-based self-practice. J. UOEH 2011, 33, 271–282. [Google Scholar] [CrossRef][Green Version]

- Toivonen, M.; Pääkkönen, R.; Savolainen, S.; Lehtomäki, K. Noise attenuation and proper insertion of earplugs into ear canals. Ann. Occup. Hyg. 2002, 46, 527–530. [Google Scholar]

- Tsukada, T.; Sakakibara, H. A trail of individual education for hearing protection with an instrument that measures the noise attenuation effect of wearing earplugs. Ind. Health 2008, 46, 393–396. [Google Scholar] [CrossRef] [PubMed]

- Murphy, W.; Stephenson, M.; Byrne, D.; Witt, B.; Duran, J. Effects of training on hearing protector attenuation. Noise Health 2011, 13, 132–141. [Google Scholar] [CrossRef] [PubMed]

- FitCheck Solo™. Available online: https://michaelassociates.com/products/fitcheck-solo-tm/ (accessed on 25 May 2022).

- Introducing INTEGRAfit® for Apple® iPad®. Available online: https://www.workplaceintegra.com/integrafit/integrafit-ipad.php (accessed on 25 May 2022).

- QuickFit Earplug Test Device. Dept. of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, Pittsburgh, PA, USA. 2008. Available online: https://www.cdc.gov/niosh/mining/UserFiles/works/pdfs/2009-112.pdf (accessed on 25 May 2022).

- Honeywell Howard Leight™ VeriPRO® 4.0. Available online: https://www.honeywellsafety.com/Products/Hearing/Hearing_Protection/VeriPRO_Earplug_Fit_Testing.aspx?site=/au (accessed on 25 May 2022).

- 3M Hearing Protection Fit Testing. Available online: https://www.https://www.3m.com/3M/en_US/p/c/ppe/hearing-protection/fit-testing/ (accessed on 25 May 2022).

- Serenity SafetyMeter. Available online: https://www.phonak-communications.com/en/products/serenity/safetymeter (accessed on 25 May 2022).

- Chiu, C.-C.; Wan, T.-J. Individual fit testing of hearing-protection devices based on microphones in real ears among workers in industries with high-noise-level manufacturing. Int. J. Environ. Res. Public Health 2020, 17, 3242. [Google Scholar] [CrossRef] [PubMed]

- JASP. A Fresh Way to Do Statistics. Available online: https://jasp-stats.org/ (accessed on 4 July 2022).

- ASA S12.6-2016; Methods for Measuring the Real Ear Attenuation of Hearing Protectors; Acoustical Society of America: New York, NY, USA, 2016.

- Suter, A.H.; Lempert, B.L.; Franks, J.R. Real-ear attenuation of earmuffs in normal-hearing and hearing-impaired individuals. J. Acoust. Soc. Am. 1990, 87, 2114–2117. [Google Scholar] [CrossRef] [PubMed]

| Frequency, Hz | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 | |

|---|---|---|---|---|---|---|---|---|

| Sound attenuation difference, dB | Subject 1 | 0.9 | −1.8 | −0.3 | −2.1 | −3.7 | 0.4 | 0.8 |

| Subject 2 | −4.0 | 2.7 | −3.3 | 1.7 | 1.3 | 2.3 | −4.2 | |

| Subject 3 | 0.3 | −4.4 | −4.5 | −4.6 | 4.2 | 2.0 | −4.6 | |

| Subject 4 | 1.4 | −3.9 | −0.7 | −3.9 | −4.5 | −1.0 | −4.0 | |

| Subject 5 | −2.9 | −0.8 | −1.8 | −0.5 | −4.4 | −3.0 | −4.5 | |

| Subject 6 | −0.9 | −4.8 | −3.4 | 0.3 | 0.0 | 4.4 | −1.5 | |

| Subject 7 | 2.0 | 1.7 | −3.0 | −4.7 | −4.8 | −0.9 | 1.1 | |

| Subject 8 | −1.0 | 3.2 | 4.3 | 0.5 | −1.3 | 1.0 | −0.4 | |

| Frequency, Hz | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

|---|---|---|---|---|---|---|---|

| p-value | 0.8798 | 0.7926 | 0.6644 | 0.3047 | 0.2713 | 0.7820 | 0.3723 |

| Frequency, Hz | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 |

|---|---|---|---|---|---|---|---|

| BF10 | 0.4311 | 0.4384 | 0.4565 | 0.5533 | 0.6667 | 0.439 | 0.5714 |

| Device | Measurement Method | Control | Measured Frequencies | Application |

|---|---|---|---|---|

| Tester presented in this study | Audiometry-based | Complete instrument | 125, 250, 500, 1000, 2000, 4000, 8000 | All earplugs. |

| FitCheck Solo | Audiometry-based | PC-based | 125, 250, 500, 1000, 2000, 4000, 8000 | All earplugs. |

| INTEGRAfit | Audiometry-based | iPad-based | 500, 1000, 2000 | All earplugs. |

| QuickFit | Audiometry-based | Complete instrument | 1000 | All earplugs. |

| VeriPRO | Loudness balancing | PC-based | 125, 250, 500, 1000, 2000, 4000 | All earplugs. |

| E-A-Rfit | MIRE * | PC-based | 125, 250, 500, 1000, 2000, 4000, 8000 | Only for earplugs from the device manufacturer |

| SafetyMeter | MIRE | PC-based | 125, 250, 500, 1000, 2000, 4000, 8000 | Only for earplugs from the device manufacturer |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlowski, E.; Mlynski, R.; Morzynski, L.; Swidzinski, A. A Tester to Evaluate the Correct Placement of Earplugs. Int. J. Environ. Res. Public Health 2022, 19, 8482. https://doi.org/10.3390/ijerph19148482

Kozlowski E, Mlynski R, Morzynski L, Swidzinski A. A Tester to Evaluate the Correct Placement of Earplugs. International Journal of Environmental Research and Public Health. 2022; 19(14):8482. https://doi.org/10.3390/ijerph19148482

Chicago/Turabian StyleKozlowski, Emil, Rafal Mlynski, Leszek Morzynski, and Adam Swidzinski. 2022. "A Tester to Evaluate the Correct Placement of Earplugs" International Journal of Environmental Research and Public Health 19, no. 14: 8482. https://doi.org/10.3390/ijerph19148482

APA StyleKozlowski, E., Mlynski, R., Morzynski, L., & Swidzinski, A. (2022). A Tester to Evaluate the Correct Placement of Earplugs. International Journal of Environmental Research and Public Health, 19(14), 8482. https://doi.org/10.3390/ijerph19148482