Removal of Arsenic from Wastewater by Using Nano Fe3O4/Zinc Organic Frameworks

Abstract

:1. Introduction

2. Experimental Section

2.1. Chemicals

2.2. Synthesis of Adsorbents

2.2.1. Synthesis of Magnetic Fe3O4 Nanoparticles

2.2.2. Synthesis of Fe3O4@ZIF-8

3. Results and Discussion

3.1. Adsorption Experiments

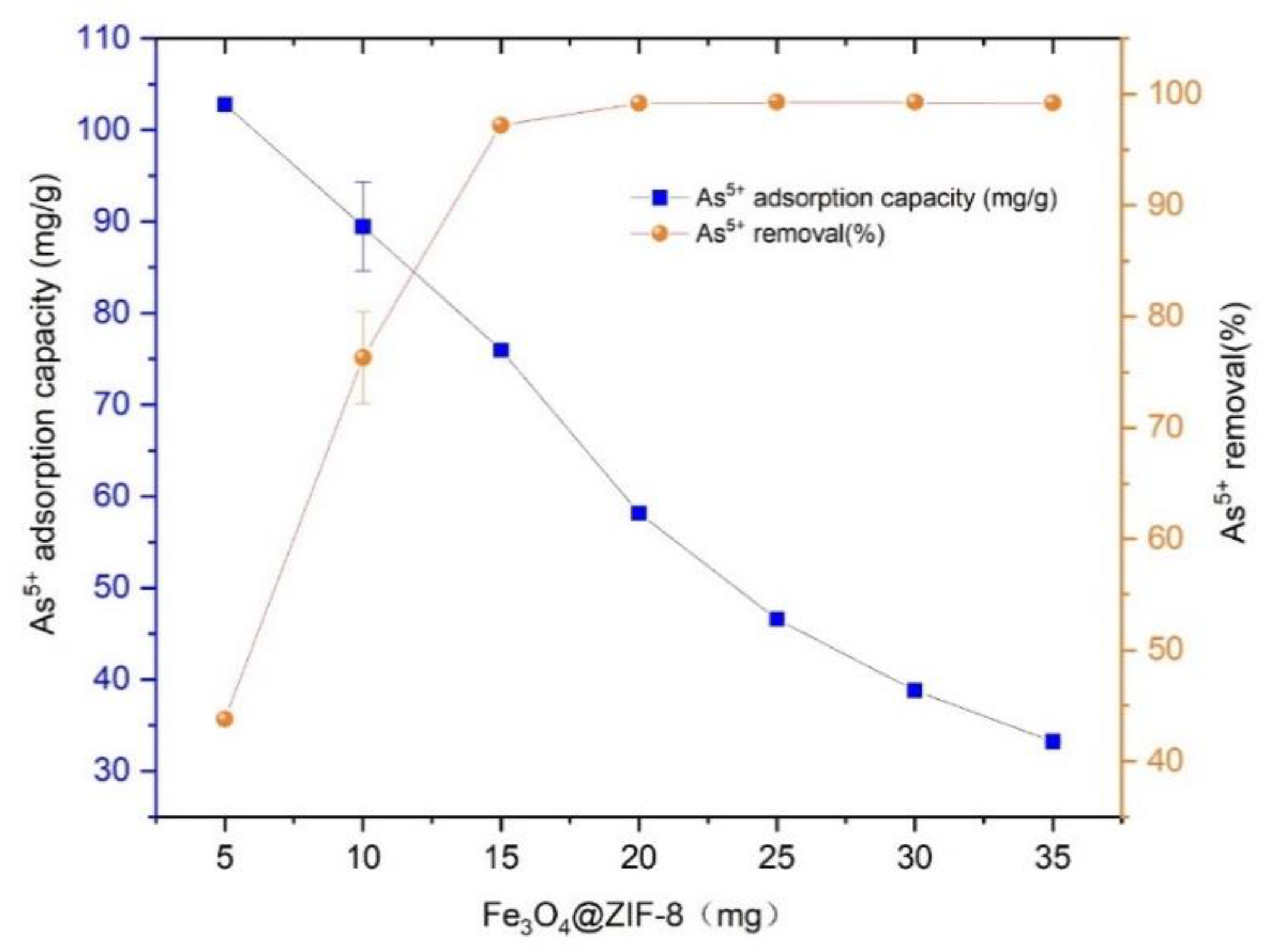

3.1.1. Effect of Adsorbent Dosage

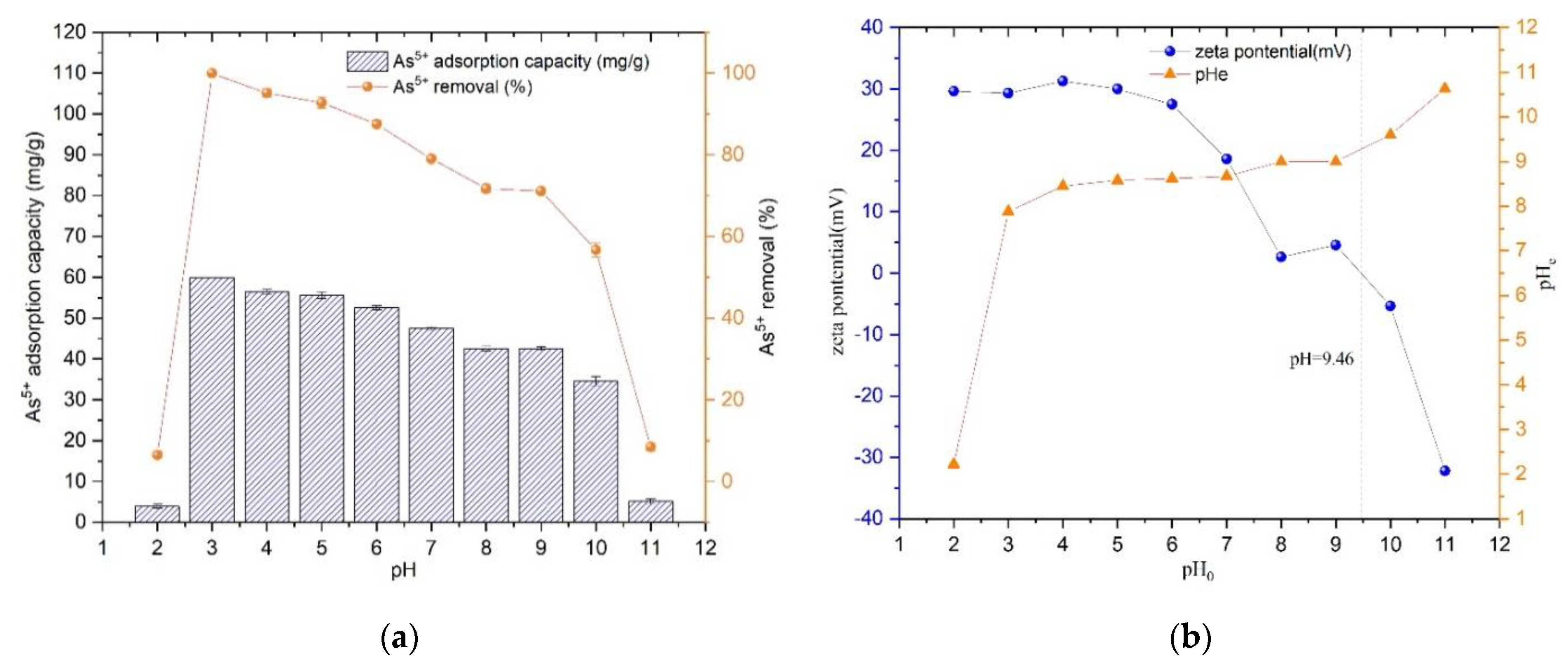

3.1.2. Effect of pH

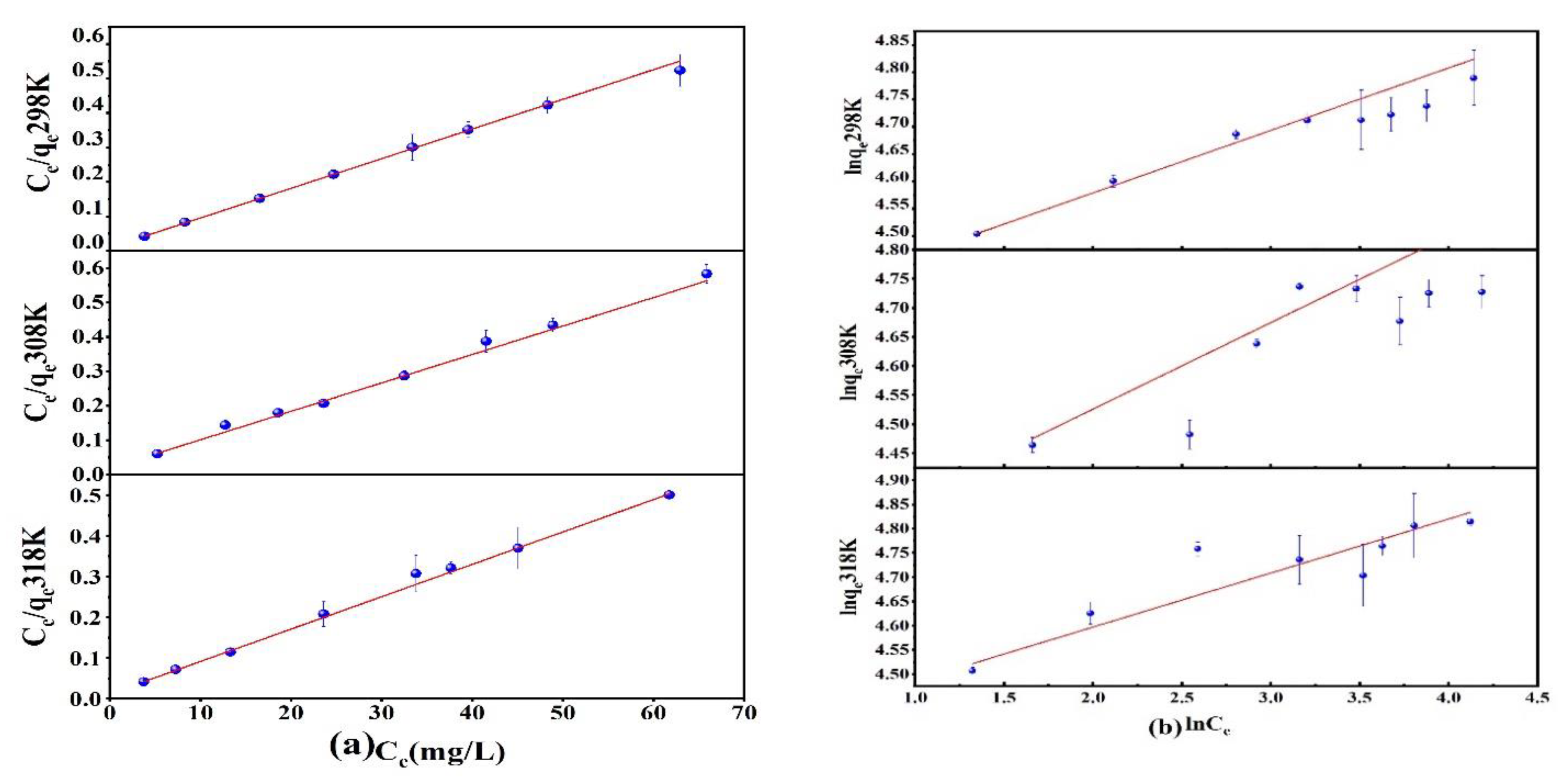

3.1.3. Adsorption Isotherm

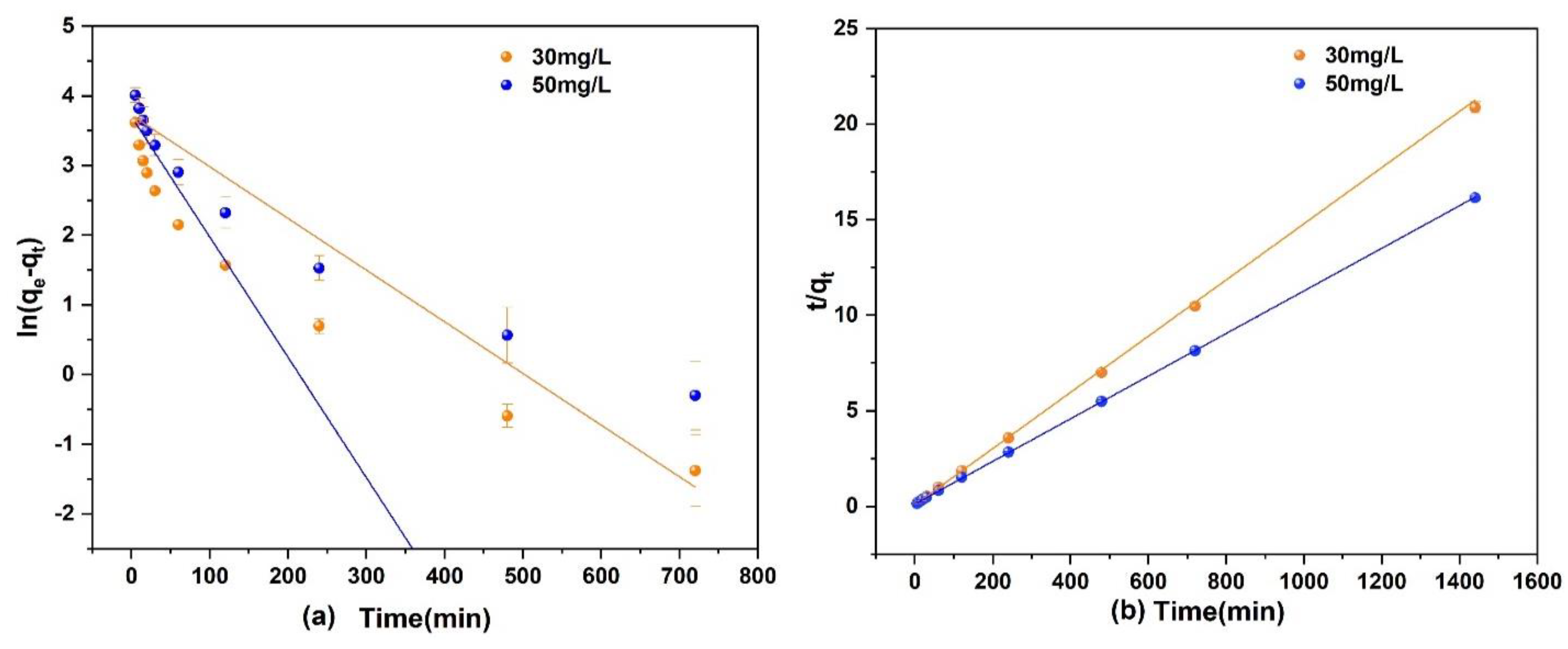

3.1.4. Kinetic Study

3.1.5. Thermodynamic Studies

3.2. Characterization

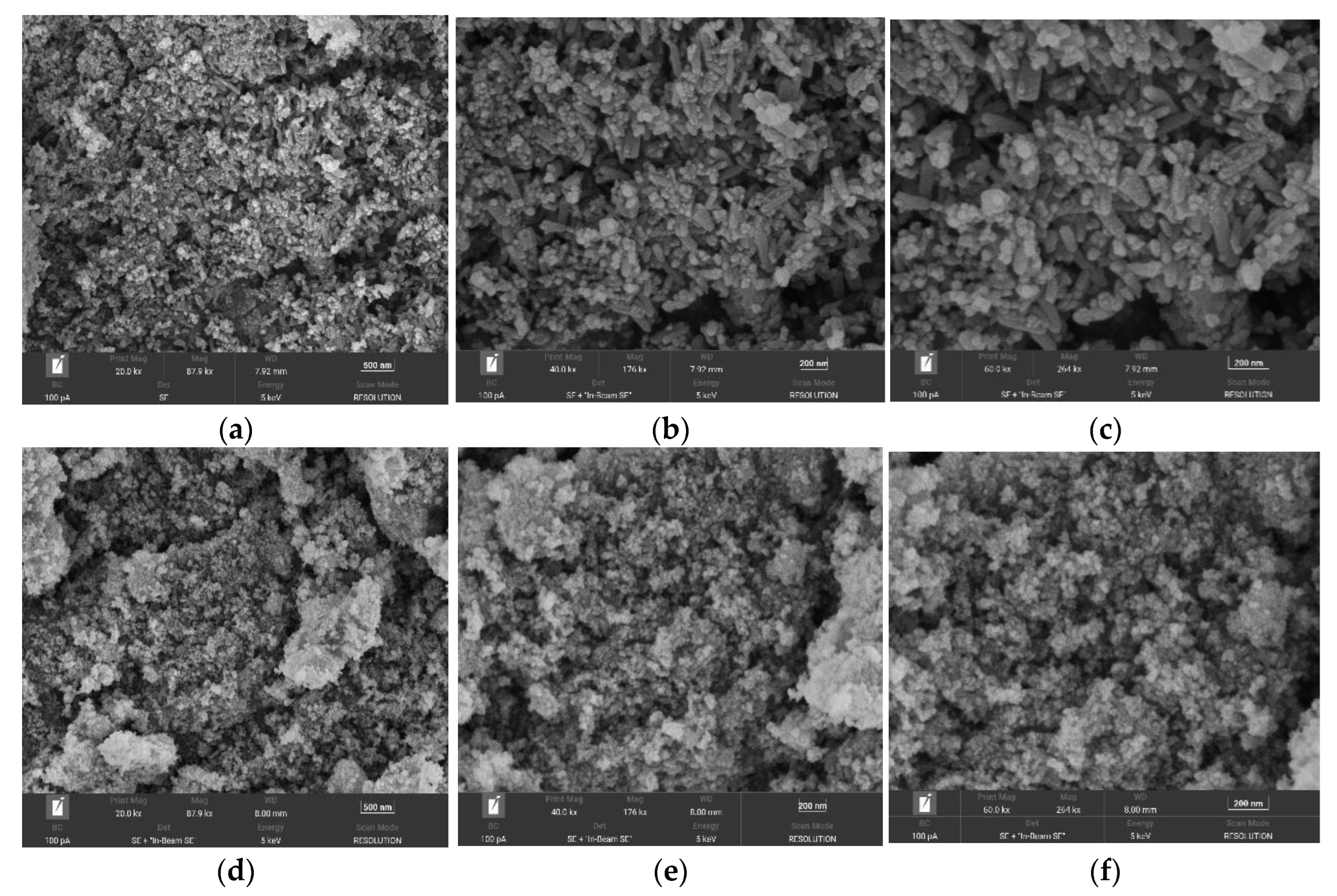

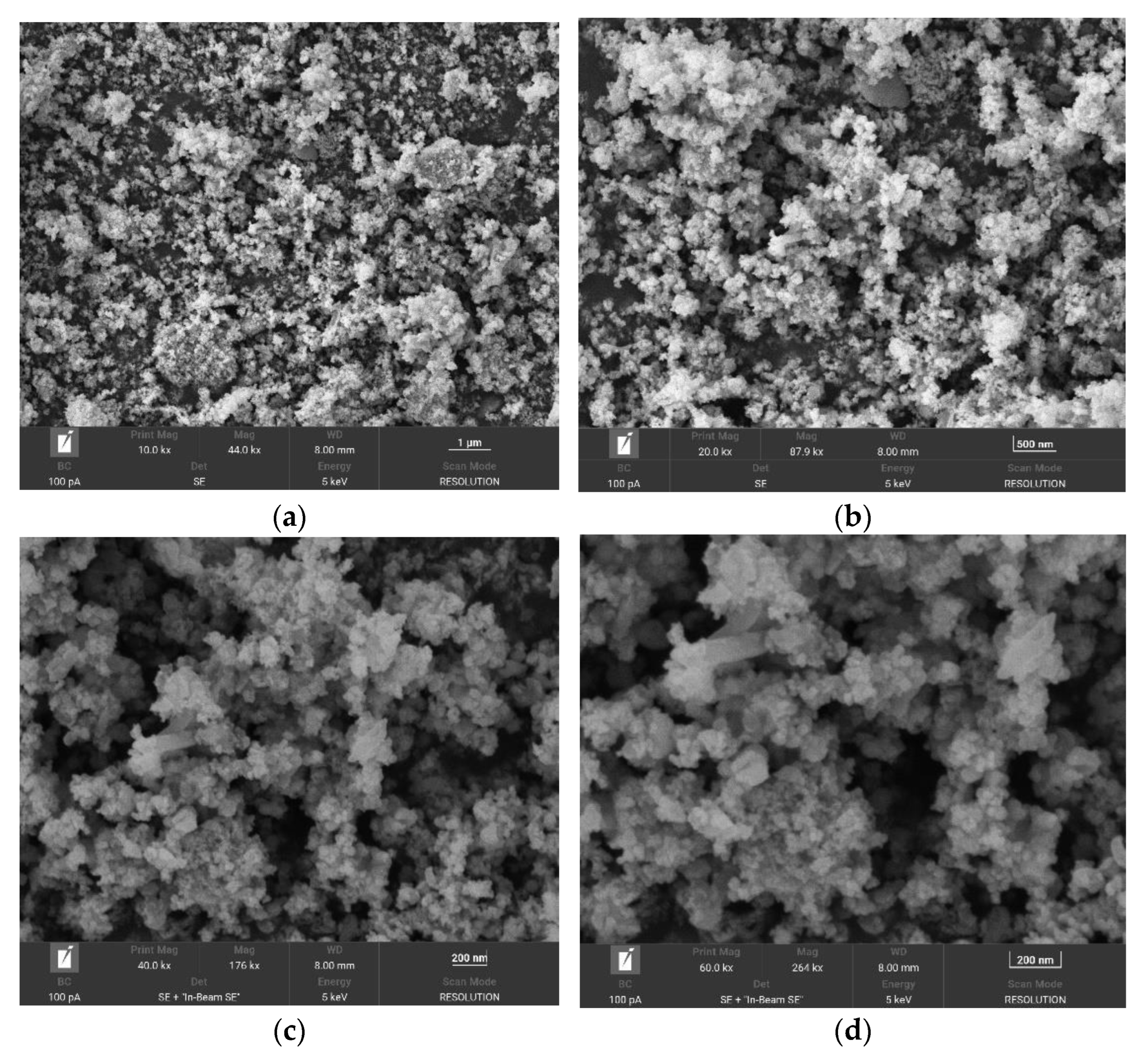

3.2.1. Scanning Electron Microscopy (SEM)

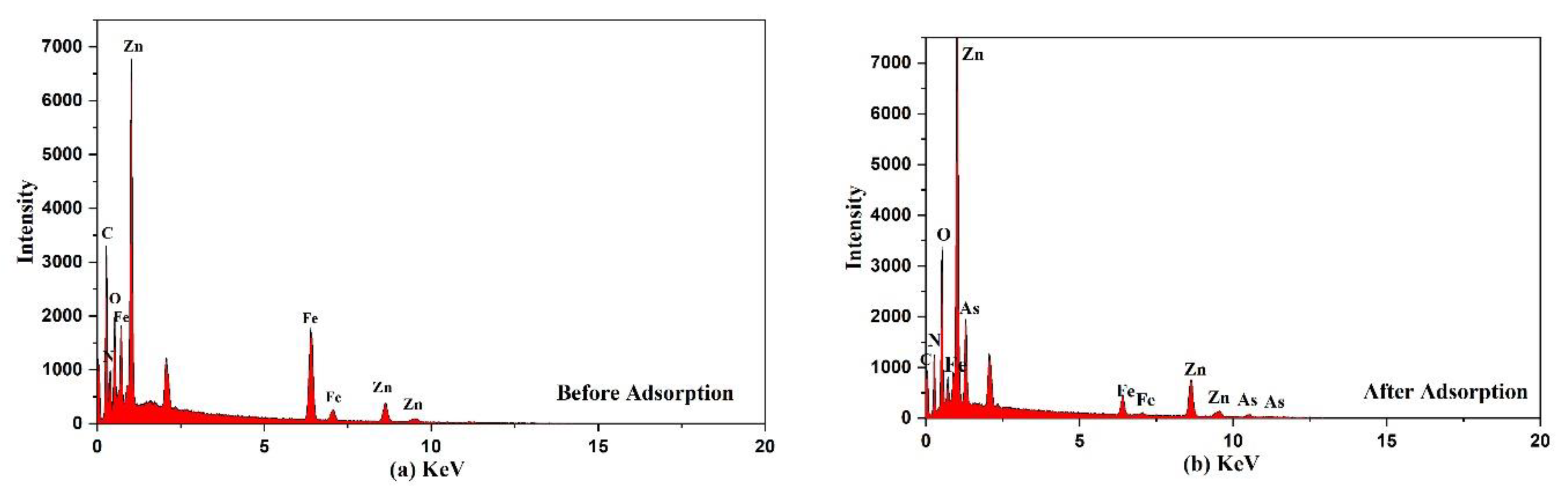

3.2.2. EDS Analysis

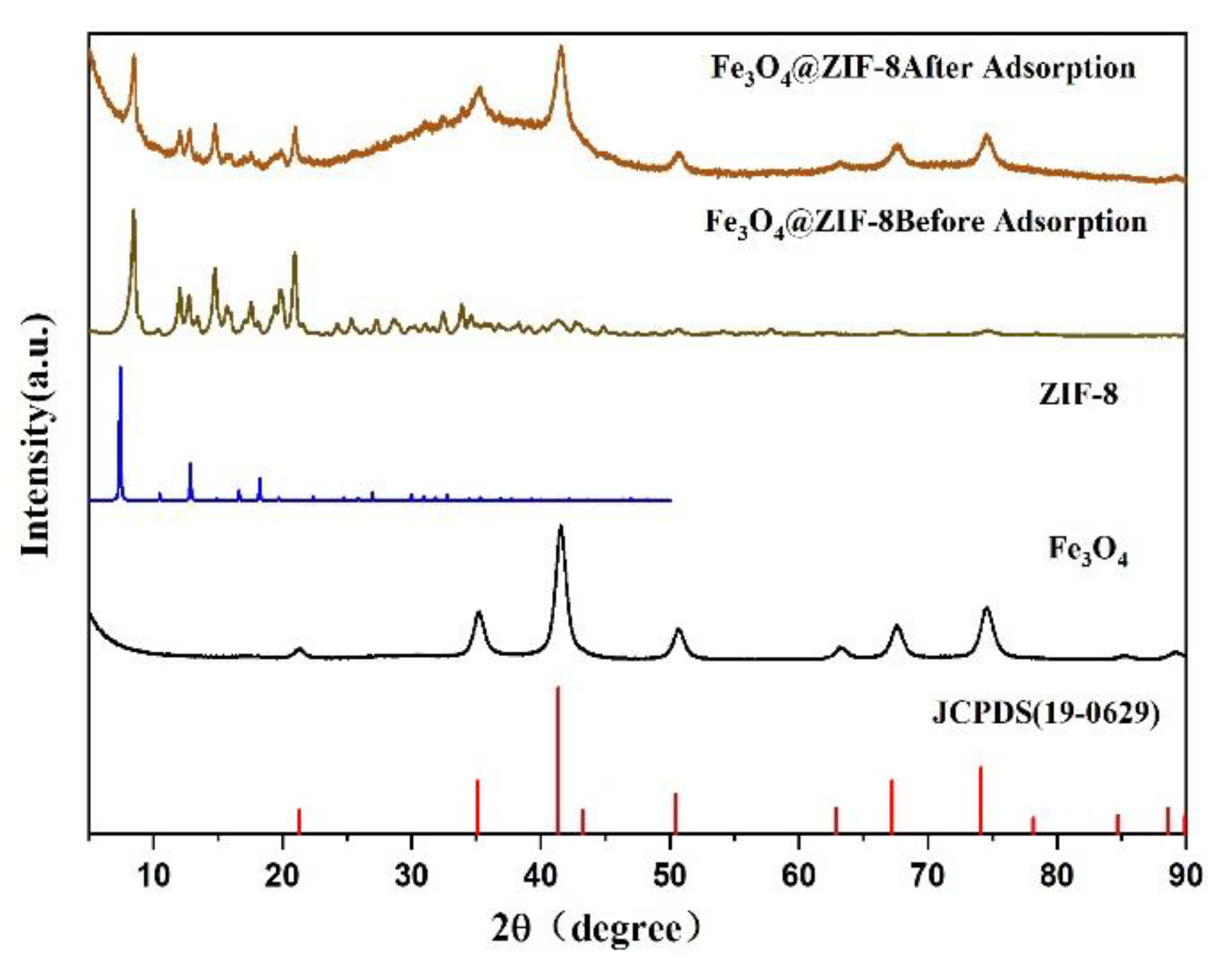

3.2.3. XRD Analysis

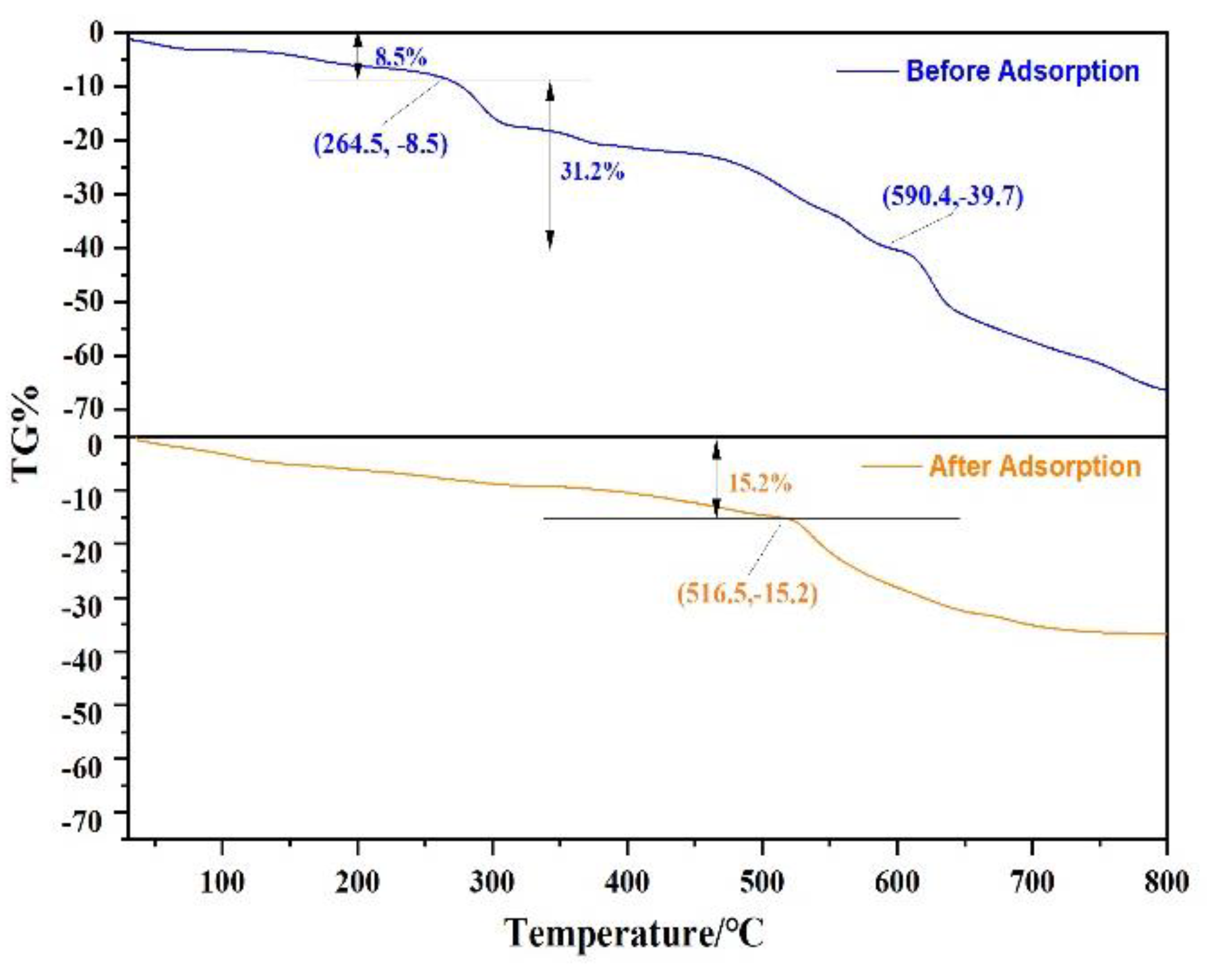

3.2.4. Thermogravimetric Analysis (TG)

3.2.5. FTIR Analysis

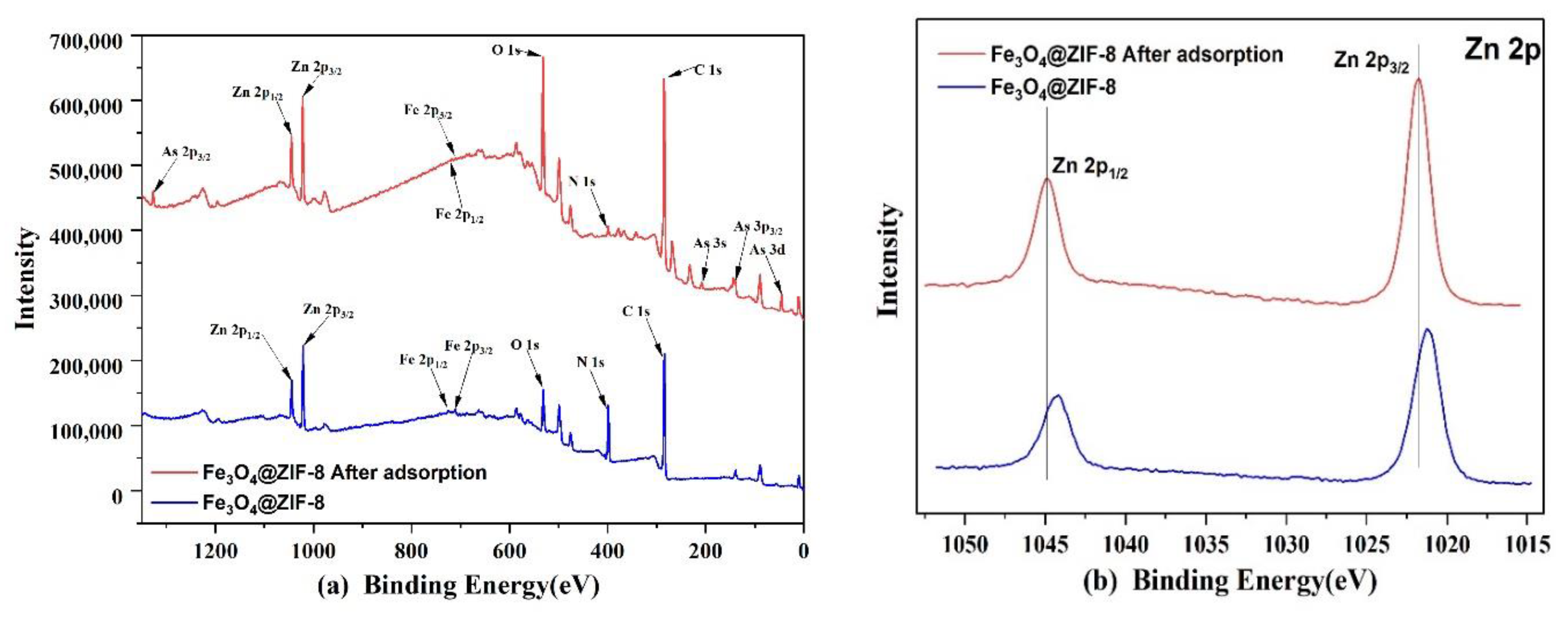

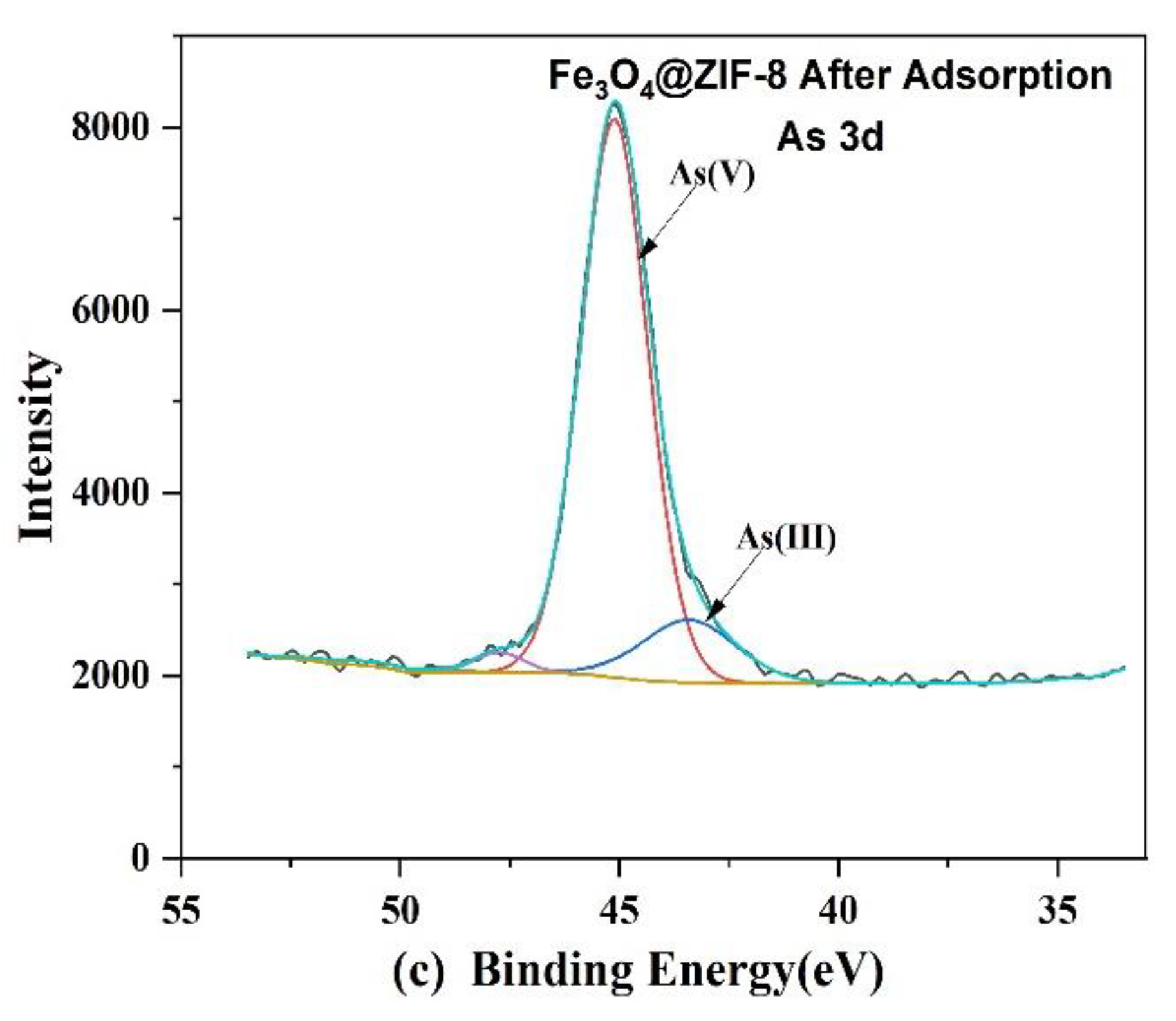

3.2.6. XPS Analysis

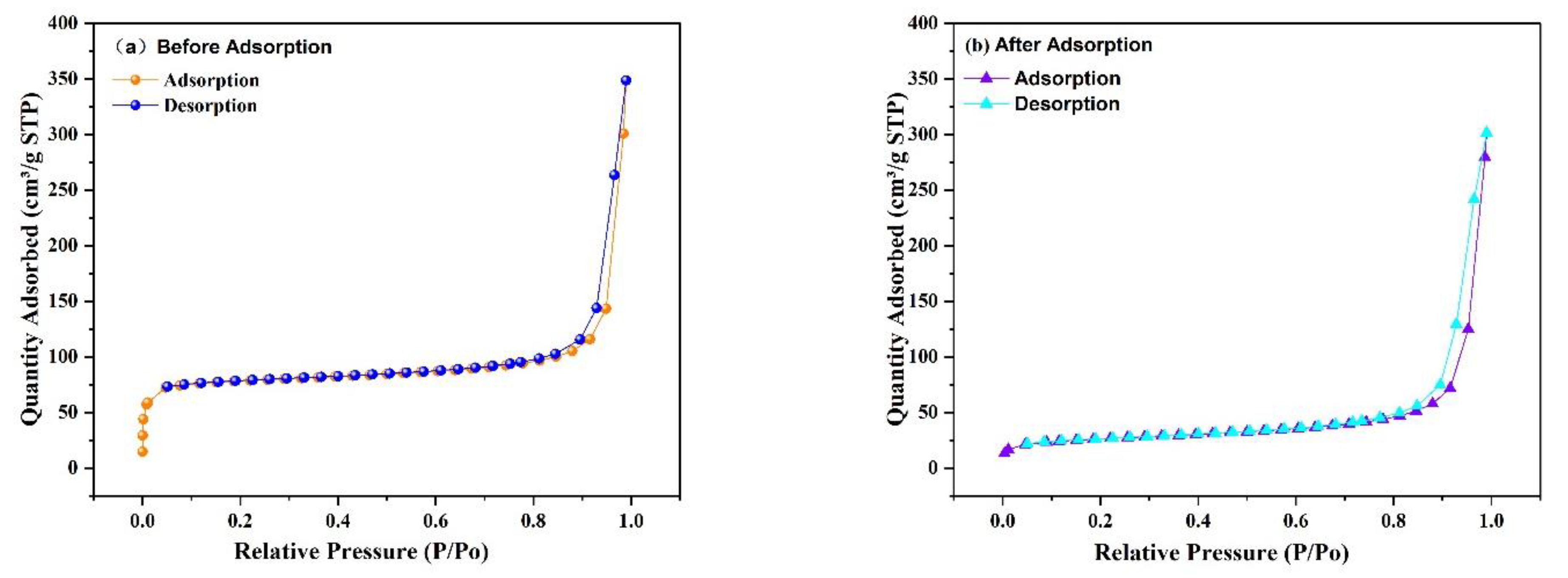

3.2.7. Surface Area Analysis (BET)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sikdar, S.; Kundu, M. A Review on Detection and Abatement of Heavy Metals. ChemBioEng Rev. 2018, 5, 18–29. [Google Scholar] [CrossRef]

- Senila, M.; Levei, E.; Cadar, O.; Senila, L.R.; Roman, M.; Puskas, F.; Sima, M. Assessment of Availability and Human Health Risk Posed by Arsenic Contaminated Well Waters from Timis-Bega Area, Romania. J. Anal. Methods Chem. 2017, 2017, 3037651. [Google Scholar] [CrossRef] [PubMed]

- Alkurdi, S.S.A.; Herath, I.; Bundschuh, J.; Al-Juboori, R.A.; Vithanage, M.; Mohan, D. Biochar versus bone char for a sustainable inorganic arsenic mitigation in water: What needs to be done in future research? Environ. Int. 2019, 127, 52–69. [Google Scholar] [CrossRef]

- Ravi, R.; Mishra, A. Preparation of Iron Nanoparticles and Composites for Arsenic Removal: An Updated Review. Biosci. Biotechnol. Res. Commun. 2021, 14, 83–89. [Google Scholar] [CrossRef]

- Palma-Lara, I.; Martinez-Castillo, M.; Quintana-Perez, J.C.; Arellano-Mendoza, M.G.; Tamay-Cach, F.; Valenzuela-Limon, O.L.; Garcia-Montalvo, E.A.; Hernandez-Zavala, A. Arsenic exposure: A public health problem leading to several cancers. Regul. Toxicol. Pharmacol. 2020, 110, 104539. [Google Scholar] [CrossRef] [PubMed]

- Ricci Nicomel, N.; Leus, K.; Folens, K.; Van der Voort, P.; Du Laing, G. Technologies for Arsenic Removal from Water: Current Status and Future Perspectives. Int. J. Environ. Res. Public Health 2016, 13, 62. [Google Scholar] [CrossRef] [PubMed]

- Asere, T.G.; Stevens, C.V.; Du Laing, G. Use of (modified) natural adsorbents for arsenic remediation: A review. Sci. Total Environ. 2019, 676, 706–720. [Google Scholar] [CrossRef]

- Martinez-Castillo, M.; Garcia-Montalvo, E.A.; Arellano-Mendoza, M.G.; Sanchez-Pena, L.d.C.; Soria Jasso, L.E.; Izquierdo-Vega, J.A.; Valenzuela, O.L.; Hernandez-Zavala, A. Arsenic exposure and non-carcinogenic health effects. Hum. Exp. Toxicol. 2021, 40, S826–S850. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Parihar, P.; Singh, V.P.; Prasad, S.M. Arsenic contamination, consequences and remediation techniques: A review. Ecotoxicol. Environ. Saf. 2015, 112, 247–270. [Google Scholar] [CrossRef]

- Sanjrani, M.A.; Zhou, B.; Zhao, H.; Bhutto, S.A.; Muneer, A.S.; Xia, S.B. Arsenic Contaminated Groundwater in China and its Treatment Options, a Review. Appl. Ecol. Environ. Res. 2019, 17, 1655–1683. [Google Scholar] [CrossRef]

- Tokoro, C.; Yatsugi, Y.; Koga, H.; Owada, S. Sorption Mechanisms of Arsenate during Coprecipitation with Ferrihydrite in Aqueous Solution. Environ. Sci. Technol. 2010, 44, 638–643. [Google Scholar] [CrossRef]

- Rashid, R.; Shafiq, I.; Akhter, P.; Iqbal, M.J.; Hussain, M. A state-of-the-art review on wastewater treatment techniques: The effectiveness of adsorption method. Environ. Sci. Pollut. Res. 2021, 28, 9050–9066. [Google Scholar] [CrossRef]

- Anil, I.; Gunday, S.T.; Bozkurt, A.; Alagha, O. Design of Crosslinked Hydrogels Comprising Poly(Vinylphosphonic Acid) and Bis 2-(Methacryloyloxy)Ethyl Phosphate as an Efficient Adsorbent for Wastewater Dye Removal. Nanomaterials 2020, 10, 131. [Google Scholar] [CrossRef]

- Mueller-Buschbaum, K.; Beuerle, F.; Feldmann, C. MOF based luminescence tuning and chemical/physical sensing. Microporous Mesoporous Mater. 2015, 216, 171–199. [Google Scholar] [CrossRef]

- Liu, Q.; Zhou, Y.; Lu, J.; Zhou, Y. Novel cyclodextrin-based adsorbents for removing pollutants from wastewater: A critical review. Chemosphere 2020, 241, 125043. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.; Yuan, X.; Zhang, J.; Chew, J.W. Metal-organic framework membranes for wastewater treatment and water regeneration. Coord. Chem. Rev. 2020, 404, 213116. [Google Scholar] [CrossRef]

- Rezk, A.; Al-Dadah, R.; Mahmoud, S.; Elsayed, A. Characterisation of metal organic frameworks for adsorption cooling. Int. J. Heat Mass Transf. 2012, 55, 7366–7374. [Google Scholar] [CrossRef]

- Ma, X.; Chai, Y.; Li, P.; Wang, B. Metal-Organic Framework Films and Their Potential Applications in Environmental Pollution Control. Acc. Chem. Res. 2019, 52, 1461–1470. [Google Scholar] [CrossRef]

- Zhu, B.-J.; Yu, X.-Y.; Jia, Y.; Peng, F.-M.; Sun, B.; Zhang, M.-Y.; Luo, T.; Liu, J.-H.; Huang, X.-J. Iron and 1,3,5-Benzenetricarboxylic Metal-Organic Coordination Polymers Prepared by Solvothermal Method and Their Application in Efficient As(V) Removal from Aqueous Solutions. J. Phys. Chem. C 2012, 116, 8601–8607. [Google Scholar] [CrossRef]

- Wang, C.; Luan, J.; Wu, C. Metal-organic frameworks for aquatic arsenic removal. Water Res. 2019, 158, 370–382. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, M.; Hao, Y. Study on the adsorption of Cu(II) by EDTA functionalized Fe3O4 magnetic nano-particles. Chem. Eng. J. 2013, 218, 46–54. [Google Scholar] [CrossRef]

- Yang, H.; Hu, S.; Zhao, H.; Luo, X.; Liu, Y.; Deng, C.; Yu, Y.; Hu, T.; Shan, S.; Zhi, Y.; et al. High-performance Fe-doped ZIF-8 adsorbent for capturing tetracycline from aqueous solution. J. Hazard. Mater. 2021, 416, 126046. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.S.; Itoh, H. Iron oxide-loaded slag for arsenic removal from aqueous system. Chemosphere 2005, 60, 319–325. [Google Scholar] [CrossRef] [PubMed]

- Burton, E.D.; Bush, R.T.; Johnston, S.G.; Watling, K.M.; Hocking, R.K.; Sullivan, L.A.; Parker, G.K. Sorption of Arsenic(V) and Arsenic(III) to Schwertmannite. Environ. Sci. Technol. 2009, 43, 9202–9207. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Fang, D.; Ye, X.; Liu, H.; Tan, X.; Li, Q.; Li, J.; Wu, Z. Ammonium molybdophosphate/metal-organic framework composite as an effective adsorbent for capture of Rb+ and Cs+ from aqueous solution. J. Solid State Chem. 2022, 306, 122767. [Google Scholar] [CrossRef]

- Morris, W.; Stevens, C.J.; Taylor, R.E.; Dybowski, C.; Yaghi, O.M.; Garcia-Garibay, M.A. NMR and X-ray Study Revealing the Rigidity of Zeolitic Imidazolate Frameworks. J. Phys. Chem. C 2012, 116, 13307–13312. [Google Scholar] [CrossRef]

- Max, J.J.; Chapados, C. Infrared spectroscopy of aqueous carboxylic acids: Comparison between different acids and their salts. J. Phys. Chem. A 2004, 108, 3324–3337. [Google Scholar] [CrossRef]

- Kim, C.; Ahn, J.-Y.; Kim, T.Y.; Shin, W.S.; Hwang, I. Activation of Persulfate by Nanosized Zero-Valent Iron (NZVI): Mechanisms and Transformation Products of NZVI. Environ. Sci. Technol. 2018, 52, 3625–3633. [Google Scholar] [CrossRef]

- Miao, D.; Zhao, S.; Zhu, K.; Zhang, P.; Wang, T.; Jia, H.; Sun, H. Activation of persulfate and removal of ethyl-parathion from soil: Effect of microwave irradiation. Chemosphere 2020, 253, 126679. [Google Scholar] [CrossRef]

- Kim, E.J.; Batchelor, B. X-Ray Photoelectron Spectroscopic Investigation of Interactions of Arsenic with Microwave Synthesized Pyrite as a Function of pH. Environ. Eng. Sci. 2009, 26, 1785–1793. [Google Scholar] [CrossRef]

- Wang, S.; Liu, Y.; Wang, J. Iron and sulfur co-doped graphite carbon nitride (FeOy/S-g-C3N4) for activating peroxymonosulfate to enhance sulfamethoxazole degradation. Chem. Eng. J. 2020, 382, 122836. [Google Scholar] [CrossRef]

- Du, J.; Bao, J.; Liu, Y.; Kim, S.H.; Dionysiou, D.D. Facile preparation of porous Mn/Fe3O4 cubes as peroxymonosulfate activating catalyst for effective bisphenol A degradation. Chem. Eng. J. 2019, 376, 119193. [Google Scholar] [CrossRef]

- Sahar, S.; Zeb, A.; Liu, Y.; Ullah, N.; Xu, A. Enhanced Fenton, photo-Fenton and peroxidase-like activity and stability over Fe3O4/g-C3N4 nanocomposites. Chin. J. Catal. 2017, 38, 2110–2119. [Google Scholar] [CrossRef]

- Biesinger, M.C.; Payne, B.P.; Lau, L.W.M.; Gerson, A.; Smart, R.S.C. X-ray photoelectron spectroscopic chemical state quantification of mixed nickel metal, oxide and hydroxide systems. Surf. Interface Anal. 2009, 41, 324–332. [Google Scholar] [CrossRef]

- Wang, M.; Cui, S.; Yang, X.; Bi, W. Synthesis of g-C3N4/Fe3O4 nanocomposites and application as a new sorbent for solid phase extraction of polycyclic aromatic hydrocarbons in water samples. Talanta 2015, 132, 922–928. [Google Scholar] [CrossRef]

- Ding, Y.; Pan, C.; Peng, X.; Mao, Q.; Xiao, Y.; Fu, L.; Huang, J. Deep mineralization of bisphenol A by catalytic peroxymonosulfate activation with nano CuO/Fe3O4 with strong Cu-Fe interaction. Chem. Eng. J. 2020, 384, 123378. [Google Scholar] [CrossRef]

- Dong, L.; Li, Y.; Chen, D.; Chen, X.; Zhang, D. Facilitated Activation of Peroxymonosulfate by Loading ZIF-8 on Fe3O4-MnO2 for Deep Mineralization of Bisphenol A. ACS EST Water 2021, 1, 417–429. [Google Scholar] [CrossRef]

- Huo, J.-B.; Xu, L.; Yang, J.-C.E.; Cui, H.-J.; Yuan, B.; Fu, M.-L. Magnetic responsive Fe3O4-ZIF-8 core-shell composites for efficient removal of As(III) from water. Colloids Surf. A-Physicochem. Eng. Asp. 2018, 539, 59–68. [Google Scholar] [CrossRef]

- Yang, D.-H.; Zhao, B.-J.; Chen, B.-J.; Zhu, S.-F.; He, Z.-Y.; Zhao, Z.-R.; Liu, M.-D. Study on impurities of ZnGeP2 single crystal and its effect on infrared optical property. Mater. Res. Express 2017, 4, 075906. [Google Scholar] [CrossRef]

- Yang, D.; Zhao, B.; Chen, B.; Zhu, S.; He, Z.; Huang, W.; Zhao, Z.; Liu, M. Impurity phases analysis of ZnGeP2 single method crystal grown by Bridgman. J. Alloys Compd. 2017, 709, 125–128. [Google Scholar] [CrossRef]

- Yang, D.-H.; Cao, X.-L. Effect of weak Mn doping on optical properties of ZnGeP2 single crystal grown by vertical gradient freezing method. Mater. Res. Express 2020, 7, 105905. [Google Scholar] [CrossRef]

- Chowdhury, S.R.; Yanful, E.K. Arsenic removal from aqueous solutions by adsorption on magnetite nanoparticles. Water Environ. J. 2011, 25, 429–437. [Google Scholar] [CrossRef]

- Luo, X.; Wang, C.; Luo, S.; Dong, R.; Tu, X.; Zeng, G. Adsorption of As (III) and As (V) from water using magnetite Fe3O4-reduced graphite oxide-MnO2 nanocomposites. Chem. Eng. J. 2012, 187, 45–52. [Google Scholar] [CrossRef]

- Jian, M.; Liu, B.; Zhang, G.; Liu, R.; Zhang, X. Adsorptive removal of arsenic from aqueous solution by zeolitic imidazolate framework-8 (ZIF-8) nanoparticles. Colloids Surf. A-Physicochem. Eng. Asp. 2015, 465, 67–76. [Google Scholar] [CrossRef]

- Vu, T.A.; Le, G.H.; Dao, C.D.; Dang, L.Q.; Nguyen, K.T.; Nguyen, Q.K.; Dang, P.T.; Tran, H.T.K.; Duong, Q.T.; Nguyen, T.V.; et al. Arsenic removal from aqueous solutions by adsorption using novel MIL-53(Fe) as a highly efficient adsorbent. RSC Adv. 2015, 5, 5261–5268. [Google Scholar] [CrossRef]

| Temperature | Langmuir Equation | Freundlich Equation | |||||

|---|---|---|---|---|---|---|---|

| (K) | qmax (mg/g) | KL (L/mg) | R2 | RL | Kf (L/mg) | n | R2 |

| 298 | 116.114 | 0.907 | 0.9996 | 0.009 | 77.493 | 8.740 | 0.9846 |

| 308 | 120.919 | 0.445 | 0.9876 | 0.018 | 68.601 | 6.722 | 0.7088 |

| 318 | 125.628 | 0.690 | 0.9995 | 0.012 | 79.365 | 8.976 | 0.9158 |

| C0 | qe | Quasi-First-Order Dynamics Equation | Quasi-Second-Order Dynamics Equation | ||||

|---|---|---|---|---|---|---|---|

| (mg/L) | (mg/g) | qe | K1 | R2 | qe | K2·10−3 | R2 |

| 30 | 69.010 | 40.600 | 0.0173 | 0.9138 | 68.027 | 2.272 | 0.9992 |

| 50 | 89.186 | 41.558 | 0.0074 | 0.8584 | 89.686 | 0.919 | 0.9999 |

| Temperature (K) | ΔG0 (kJ/moL) | ΔH0 (kJ/moL) | ΔS0 (kJ/moL) |

|---|---|---|---|

| 298 | −3.73 | 40.41 | 0.318 |

| 308 | −4.03 | 40.41 | 0.318 |

| 318 | −4.16 | 40.41 | 0.318 |

| Element | Wt (%) | At (%) | ||

|---|---|---|---|---|

| Before | After | Before | After | |

| C K | 41.65 | 24.61 | 61.58 | 50.33 |

| N K | 19.39 | 0.75 | 24.58 | 1.32 |

| O K | 3.51 | 17.60 | 3.90 | 27.02 |

| Fe K | 6.58 | 6.38 | 2.09 | 2.81 |

| Zn K | 28.88 | 40.25 | 7.85 | 15.12 |

| As K | 0 | 10.39 | 0 | 3.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, X.; Liu, Y.; Wang, X.; Zeng, L.; Xiao, T.; Luo, D.; Jiang, J.; Zhang, H.; Huang, Y.; Ye, M.; et al. Removal of Arsenic from Wastewater by Using Nano Fe3O4/Zinc Organic Frameworks. Int. J. Environ. Res. Public Health 2022, 19, 10897. https://doi.org/10.3390/ijerph191710897

Huang X, Liu Y, Wang X, Zeng L, Xiao T, Luo D, Jiang J, Zhang H, Huang Y, Ye M, et al. Removal of Arsenic from Wastewater by Using Nano Fe3O4/Zinc Organic Frameworks. International Journal of Environmental Research and Public Health. 2022; 19(17):10897. https://doi.org/10.3390/ijerph191710897

Chicago/Turabian StyleHuang, Xuexia, Yun Liu, Xinyi Wang, Linwei Zeng, Tangfu Xiao, Dinggui Luo, Jia Jiang, Hongguo Zhang, Yuhui Huang, Mingzhen Ye, and et al. 2022. "Removal of Arsenic from Wastewater by Using Nano Fe3O4/Zinc Organic Frameworks" International Journal of Environmental Research and Public Health 19, no. 17: 10897. https://doi.org/10.3390/ijerph191710897